A kind of aqueous wood lacquer aqueous acrylate emulsion and preparation method thereof

A water-based acrylate and water-based wood lacquer technology, applied in the direction of coating, can solve the problems of poor molecular chain mobility, decreased anti-blocking, dry and glossy paint film, etc., achieve uniform molecular weight distribution, reduce film forming temperature, paint film fullness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

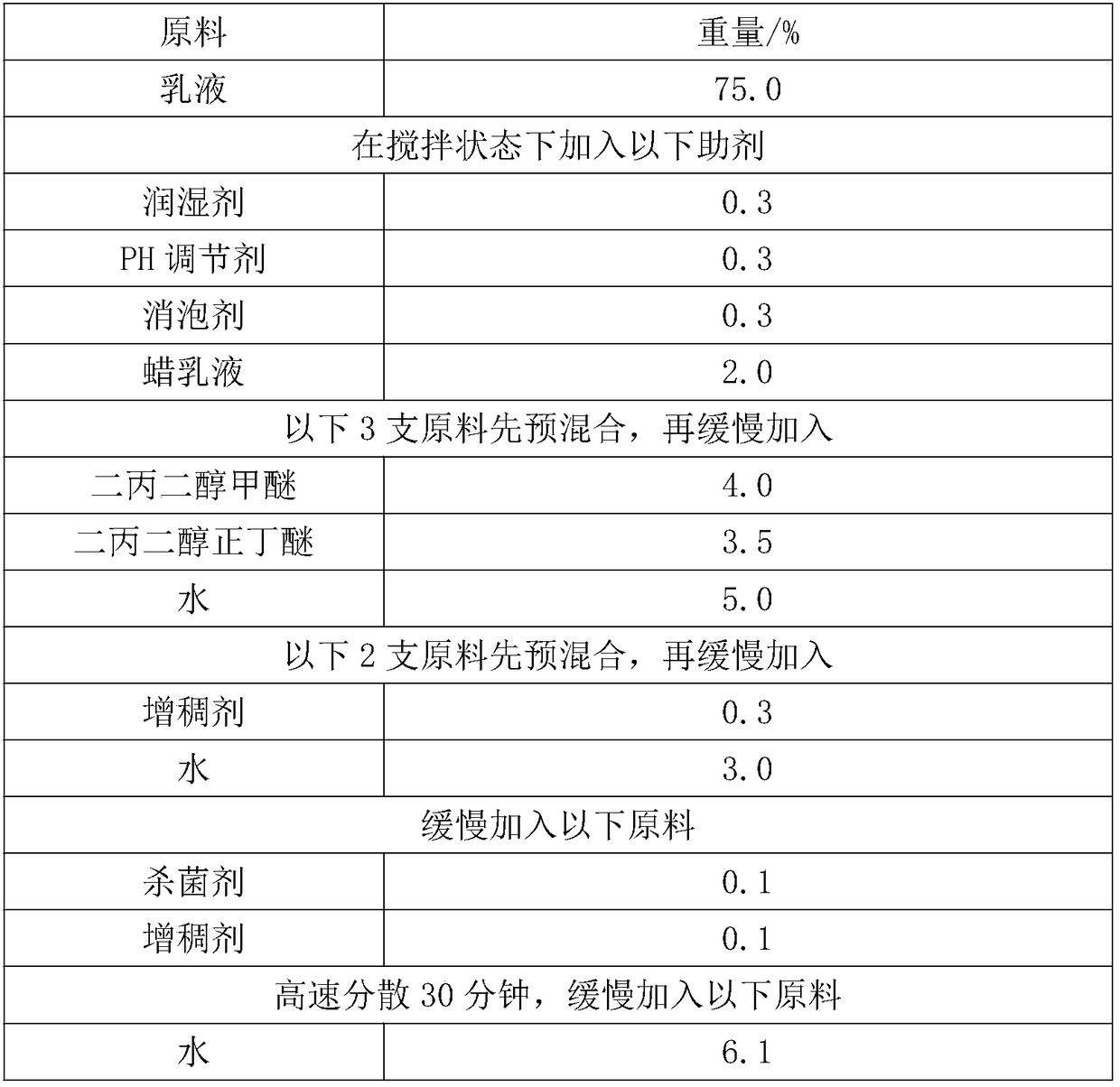

Image

Examples

Embodiment 1

[0030] A water-based acrylate emulsion for water-based wood paint, characterized in that it is prepared from the following raw materials in parts by weight: 0.1 parts of butyl acrylate, 10 parts of methyl methacrylate, 5 parts of isooctyl acrylate, and 3 parts of oligomers , 0.1 part of emulsifier, 0.1 part of crosslinking monomer, 0.05 part of chain transfer agent, 0.1 part of carboxyl monomer, 0.1 part of persulfate, 2 parts of ammonia water, 0.1 part of adipic acid dihydrazide, 43 parts of water.

[0031]Further, the oligomer is BASF Joncryl 678.

[0032] Further, the chain transfer agent is n-dodecyl mercaptan.

[0033] Further, the persulfate is ammonium persulfate.

[0034] The preparation method of above-mentioned water-based wood paint water-based acrylic ester emulsion, comprises the following steps:

[0035] (1) Pre-emulsification: under normal temperature and pressure, mix 0.1 parts of emulsifier and 15 parts of water in an emulsification tank with a high-speed mi...

Embodiment 2

[0041] A water-based acrylate emulsion for water-based wood paint, characterized in that it is prepared from the following raw materials in parts by weight: 5 parts of butyl acrylate, 30 parts of methyl methacrylate, 15 parts of isooctyl acrylate, and 15 parts of oligomers , 3 parts of emulsifier, 5 parts of crosslinking monomer, 0.2 part of chain transfer agent, 5 parts of carboxyl monomer, 0.3 part of persulfate, 3 parts of ammonia water, 5 parts of adipic acid dihydrazide, 67 parts of water.

[0042] Further, the oligomer is BASF Joncryl 682.

[0043] Further, the emulsifier is sodium lauryl polyoxyethylene ether sulfate.

[0044] Further, the crosslinking monomer is acetoacetoxy ethyl methacrylate.

[0045] Further, the chain transfer agent is tertiary dodecyl mercaptan.

[0046] Further, the carboxyl monomer is methacrylic acid.

[0047] Further, the persulfate is potassium persulfate.

[0048] The preparation method of above-mentioned water-based wood paint water-bas...

Embodiment 3

[0055] A water-based acrylate emulsion for water-based wood lacquer, characterized in that it is prepared from the following raw materials in parts by weight: 3 parts of butyl acrylate, 20 parts of methyl methacrylate, 10 parts of isooctyl acrylate, and 8 parts of oligomers , 1.5 parts of emulsifier, 3 parts of cross-linking monomer, 0.15 parts of chain transfer agent, 2.5 parts of carboxyl monomer, 0.2 parts of persulfate, 2 parts of ammonia water, 3 parts of adipic acid dihydrazide, and 55 parts of water.

[0056] Further, the oligomer is a mixture of BASF Joncryl 678 and Joncryl 682 at a mass ratio of 1:1.

[0057] Further, the emulsifier is a mixture of dioctyl sodium sulfosuccinate and sodium lauryl polyoxyethylene ether sulfate in a mass ratio of 1:1.

[0058] Further, the cross-linking monomer is a mixture of diacetone acrylamide and acetoacetoxyethyl methacrylate in a mass ratio of 1:1.

[0059] Further, the chain transfer agent is a mixture of n-dodecyl mercaptan and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com