An anti-bonding high temperature resistant setter and its preparation method

A technology with high temperature resistance and anti-bonding, which is applied in lighting and heating equipment, furnaces, charging support, etc., can solve the problems of high cost, high firing temperature, complex structure, etc., and achieve long service life and good firing effect Good, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

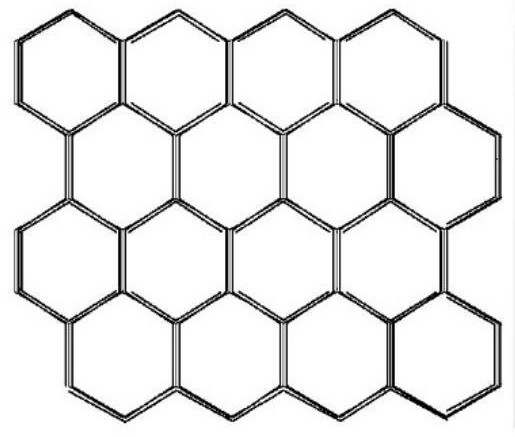

[0034] A method for preparing an anti-bonding and high-temperature resistant setter, which comprises uniformly spraying slurry on the surface of a substrate and sintering to form a coating; wherein, the slurry is obtained by uniformly mixing the following components: 90 g of yttrium oxide, Zirconium oxide 5g, tungsten oxide 3g, binder 15g; figure 1 ) is obtained.

[0035] The process conditions for sintering are: sintering at 1050° C. for 2 hours.

[0036] The thickness of the coating is 30 μm.

[0037] The honeycomb structure is formed by the close arrangement of regular hexagons with a side length of 5cm and a depth of 10cm.

[0038] Yttrium oxide, zirconium oxide and tungsten oxide are subjected to surface modification treatment before preparing the slurry, wherein, yttrium oxide is treated with a rare earth crosslinking agent, and the chemical formula of the rare earth crosslinking agent is (C 3 H 7 O) x Re(OCOR) (purchased from Foshan Shengyi Plastic Chemical Co., L...

Embodiment 2

[0048]A preparation method for an anti-bonding and high-temperature resistant setter, which comprises uniformly spraying slurry on the surface of a substrate and sintering to form a coating; wherein, the slurry is obtained by uniformly mixing the following components: 92 g of yttrium oxide, 3g of zirconia, 5g of tungsten oxide, 8g of binder; the matrix is to process the zirconia into a honeycomb structure ( figure 1 ) is obtained.

[0049] The process conditions for sintering are: sintering at 1050° C. for 2 hours.

[0050] The thickness of the coating is 50 μm.

[0051] The honeycomb structure is closely arranged by regular hexagons with a side length of 1cm and a depth of 3cm.

[0052] Yttrium oxide, zirconium oxide and tungsten oxide are subjected to surface modification treatment before preparing the slurry, wherein, yttrium oxide is treated with a rare earth crosslinking agent, and the chemical formula of the rare earth crosslinking agent is (C 3 H 7 O) x Re (OCOR...

Embodiment 3

[0062] A preparation method for an anti-bonding and high-temperature resistant setter, the slurry is uniformly sprayed on the surface of a substrate, and then sintered to form a coating; wherein, the slurry is obtained by uniformly mixing the following components: 91 g of yttrium oxide, Zirconia 4g, tungsten oxide 4g, binder 10g; figure 1 ) is obtained.

[0063] The process conditions for sintering are: sintering at 1050° C. for 2 hours.

[0064] The thickness of the coating is 40 μm.

[0065] The honeycomb structure is closely arranged by regular hexagons with a side length of 3cm and a depth of 7cm.

[0066] Yttrium oxide, zirconium oxide and tungsten oxide are subjected to surface modification treatment before preparing the slurry, wherein, yttrium oxide is treated with a rare earth crosslinking agent, and the chemical formula of the rare earth crosslinking agent is (C 3 H 7 O) x Re(OCOR) (purchased from Foshan Shengyi Plastic Chemical Co., Ltd.), Re is Ce, R is ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com