Olefin-based polymer

A technology of polymers and olefins, applied in the field of low-density olefin-based polymers, can solve the problems of complex process, low miscibility, poor viscosity balance of grafted polymers and polar resins, etc., and achieve the goal of improving anti-adhesive properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

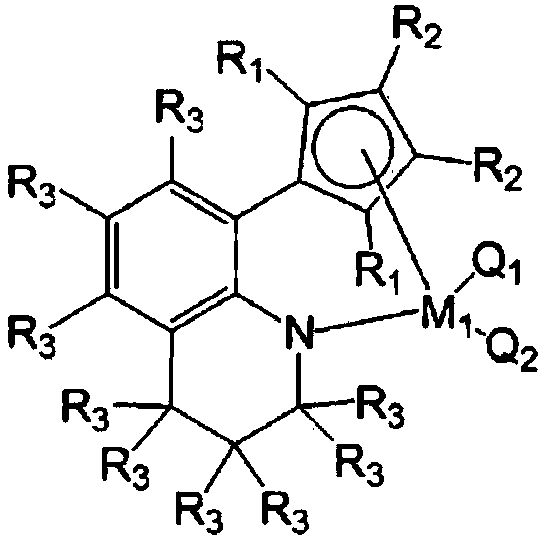

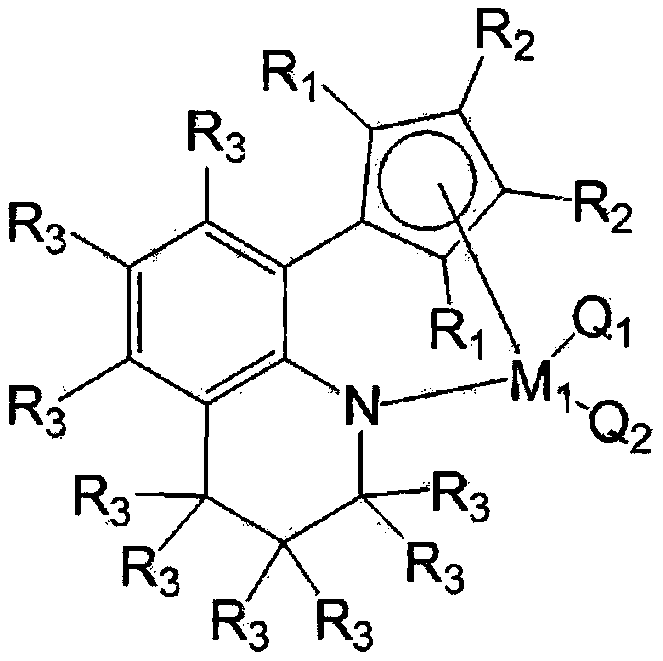

[0118]In the first method in the preparation method of the above-mentioned catalyst composition, the molar ratio of the transition metal compound represented by formula 1 and the transition metal compound represented by formula 2 / the compound represented by formula 3 or 4 can be 1 / 5,000 to 1 / 2, especially in the range of 1 / 1000 to 1 / 10, more particularly in the range of 1 / 500 to 1 / 20. When the molar ratio of the transition metal compound represented by formula 1 and the transition metal compound represented by formula 2 / compound represented by formula 3 or 4 exceeded 1 / 2, the amount of the alkylating agent was very small, so the alkylation of the metal compound did not fully carried out. When the molar ratio was less than 1 / 5000, the alkylation of the metal compound was carried out, but due to the side reaction between the remaining excess alkylating agent and the activator of the compound of formula 5, the alkylation of the metal compound could not be fully realized activat...

preparation Embodiment 1

[0135] Preparation Example 1: Preparation of Transition Metal Compound 1

[0136] (1) Preparation of 8-(2,3,4,5-tetramethyl-1,3-cyclopentadienyl)-1,2,3,4-tetrahydroquinoline

[0137]

[0138] (i) Preparation of lithium carbamate

[0139] 1,2,3,4-Tetrahydroquinoline (13.08 g, 98.24 mmol) and diethyl ether (150 mL) were added to the Schlenk flask. The above-mentioned Schlenk flask was immersed in a -78°C low-temperature bath formed of dry ice and acetone, and stirred for 30 minutes. Subsequently, n-BuLi (39.3 mL, 2.5 M, 98.24 mmol) was added thereto via a syringe under a nitrogen atmosphere, thereby forming a pale yellow slurry. Then, after the flask was stirred for 2 hours, the temperature of the flask was raised to room temperature while removing generated butane gas. The flask was again immersed in a cryogenic bath at -78 °C to lower the temperature, and then CO was introduced into it 2 gas. When carbon dioxide gas was introduced, the slurry disappeared and the solu...

preparation Embodiment 2

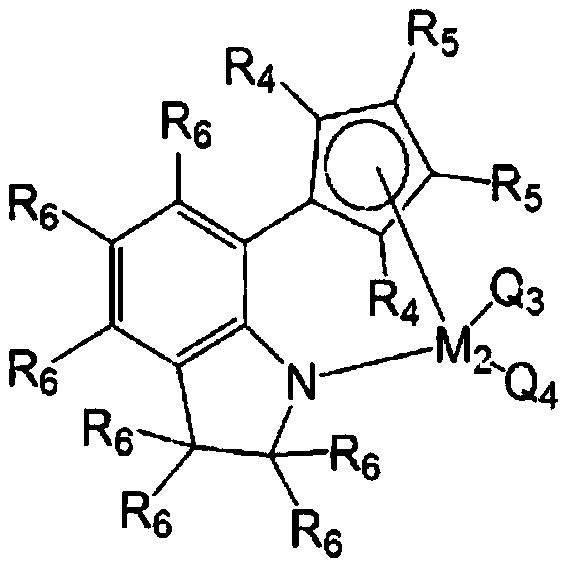

[0154] Preparation Example 2: Preparation of Transition Metal Compound 2

[0155] (1) Preparation of 2-methyl-7-(2,3,4,5-tetramethyl-1,3-cyclopentadienyl)indoline

[0156] Prepare in the same manner as (1) of Preparation Example 1, except that 2-methylindoline is used instead of 1,2,3,4-tetrahydroquinoline in (1) of Preparation Example 1 2-methyl-7-(2,3,4,5-tetramethyl-1,3-cyclopentadienyl)indoline. The yield was 19%.

[0157] 1 H NMR (C 6 D. 6 ): δ6.97(d, J=7.2Hz, 1H, CH), δ6.78(d, J=8Hz, 1H, CH), δ6.67(t, J=7.4Hz, 1H, CH), δ3 .94(m, 1H, quinoline-CH), δ3.51(br s, 1H, NH), δ3.24-3.08(m, 2H, quinoline-CH 2 ,Cp-CH),δ2.65(m,1H,quinoline-CH 2 ),δ1.89(s,3H,Cp-CH 3 ),δ1.84(s,3H,Cp-CH 3 ),δ1.82(s,3H,Cp-CH 3 ), δ1.13(d, J=6Hz, 3H, quinoline-CH 3 ),δ0.93(3H,Cp-CH 3 ) ppm.

[0158] (2) Preparation of [(2-methylindolin-7-yl)tetramethylcyclopentadienyl-η5,κ-N]dimethyltitanium

[0159]

[0160] (i) except that 2-methyl-7-(2,3,4,5-tetramethyl-1,3-cyclopentadienyl)-indo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com