Nano Ti/tin gradient film on titanium alloy surface and preparation method thereof

A gradient film and titanium alloy technology, applied in the field of materials, can solve the problems of high friction coefficient of TiN coating, easy cracking, corrosion resistance, etc., and achieve inhibition of crack formation and expansion, improvement of bonding force, high corrosion resistance and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Use Ti6Al4V alloy as the substrate, clean the surface of the substrate and place it in the vacuum chamber of the magnetron sputtering equipment, heat it to 400°C, and keep it warm for 10min under the condition of vacuum degree of 0.001Pa;

[0041] Introduce argon gas into the vacuum chamber and keep it flowing. The pressure of argon gas is 0.3Pa, and then perform ion bombardment on the substrate to clean the surface for 10 minutes;

[0042] Metal Ti is used as the target material, ion bombardment is carried out on the target material, and a Ti adhesion layer is deposited on the substrate for 5 minutes to obtain a substrate with a Ti adhesion layer;

[0043] Introduce nitrogen gas into the vacuum chamber and keep the nitrogen gas flowing, carry out ion bombardment on the target, and deposit TiN on the surface of the substrate with Ti adhesion layer. The process of depositing TiN is divided into 5 stages. During this process, the flow of argon gas remains constant. , the ...

Embodiment 2

[0049] Method is with embodiment 1, and difference is:

[0050] (1) Heat to 350°C, and keep it warm for 15 minutes in a vacuum chamber with a vacuum degree of 0.003Pa;

[0051] (2) The pressure of argon gas is 0.4Pa, and the time for cleaning the surface by ion bombardment is 8 minutes;

[0052] (3) The time for depositing the Ti adhesion layer is 10 minutes;

[0053] (4) The process of depositing TiN is divided into 6 levels. The flow ratios of nitrogen and argon in each level of deposition are 0.07, 0.10, 0.13, 0.16, 0.19 and 0.30, and the deposition times of each level are 4, 5, 6, 8, 17 and 60min; the total deposition time is 100min;

[0054] (5) The voltage during ion bombardment is 420V, and the current is 1.6A;

[0055] (6) The nano-Ti / TiN gradient film on the surface of the titanium alloy is divided into 6 layers, with a total thickness of 3.3 μm; a microhardness of 17GPa, and a bonding force of 80N;

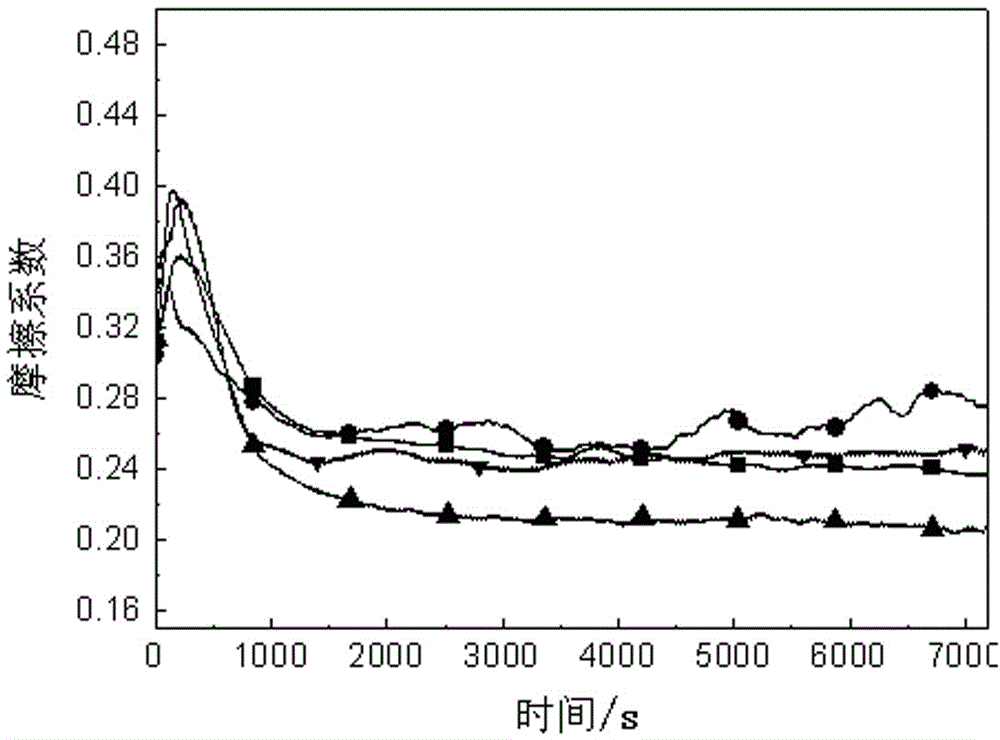

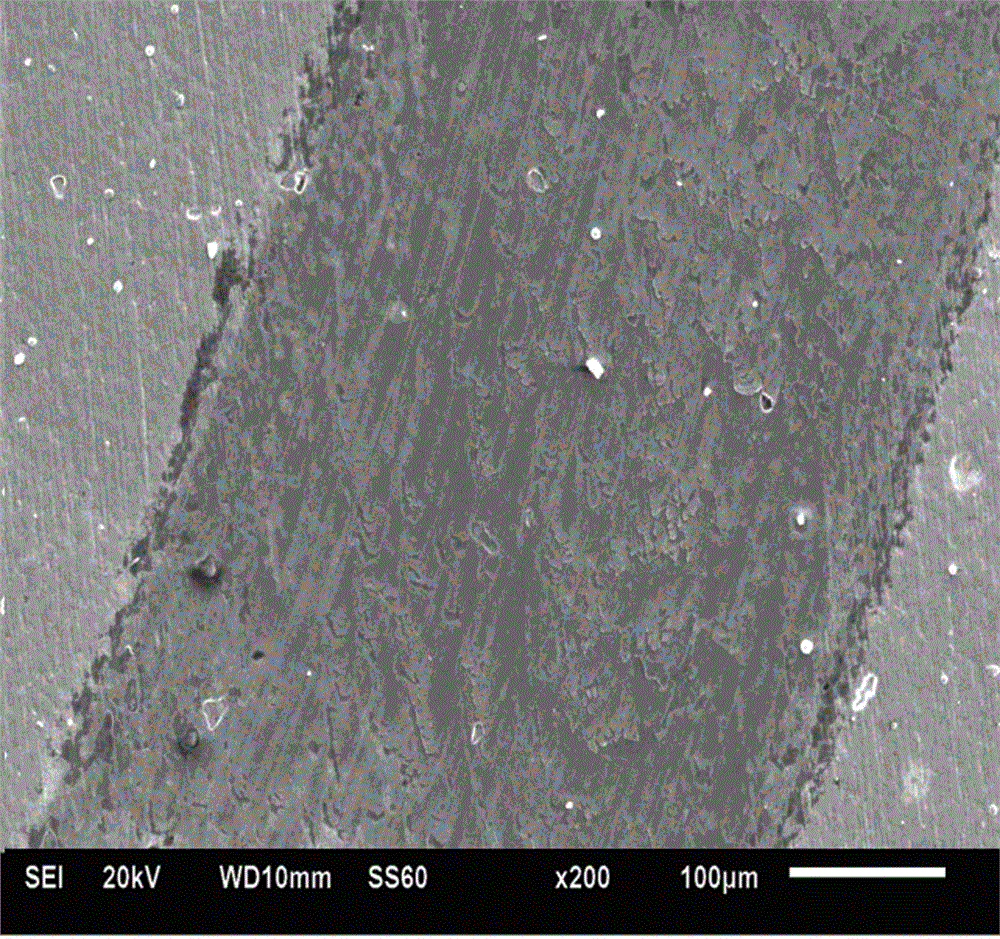

[0056] The friction coefficient-slip time curve of the nano-Ti / ...

Embodiment 3

[0058] Method is with embodiment 1, and difference is:

[0059] (1) Heat to 320°C, and keep it warm for 20 minutes in a vacuum chamber with a vacuum degree of 0.005Pa;

[0060] (2) The pressure of argon gas is 0.5 Pa, and the time for cleaning the surface by ion bombardment is 6 minutes;

[0061] (3) The deposition time of Ti adhesion layer is 15min;

[0062] (4) The process of depositing TiN is divided into 8 levels. The flow ratios of nitrogen and argon in each level of deposition are 0.07, 0.09, 0.12, 0.14, 0.16, 0.18, 0.20 and 0.30, and the deposition times of each level are 3, 5, 7, 10, 15, 20, 30 and 60min; the total deposition time is 150min;

[0063] (5) The voltage during ion bombardment is 390V and the current is 1.4A;

[0064] (6) The nano-Ti / TiN gradient film on the surface of titanium alloy is divided into 8 layers, with a total thickness of 4.8μm; microhardness of 21GPa, and bonding force of 73N;

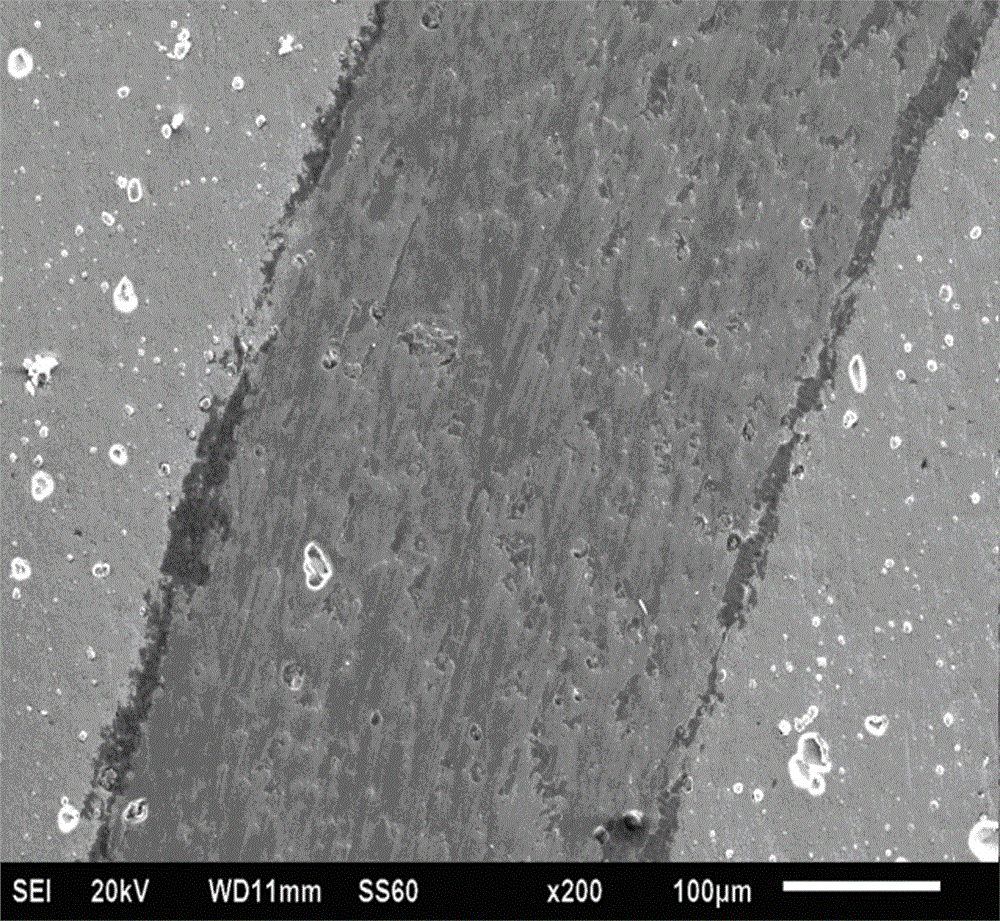

[0065] The friction coefficient-slip time curve of the nano-T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com