Nanometer silver transparent electrode material and preparation method thereof

A technology of transparent electrodes and nano-silver, which is used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of poor adhesion of substrate materials, easy damage to transparent electrodes, and low surface flatness of transparent electrodes. Achieve the effect of low cost, good conductivity and excellent light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

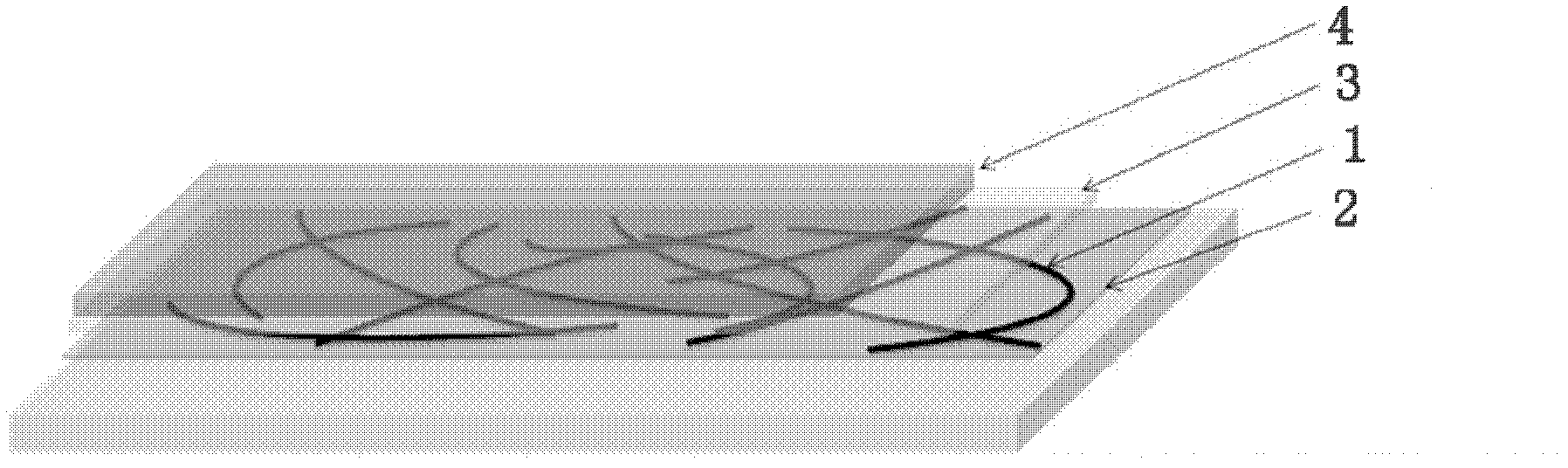

[0046] Embodiment 1, with reference to figure 1 , 3 , 4.

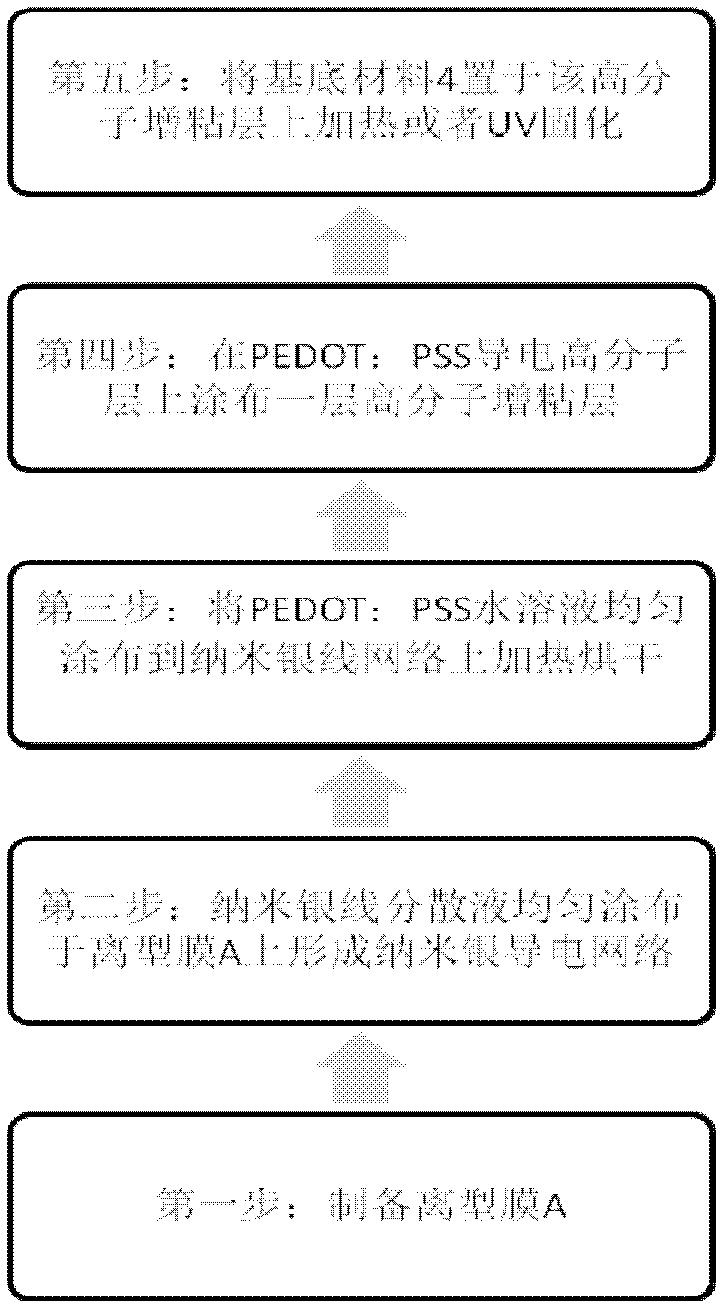

[0047] 1. Coating silicone release agent on PET film to make release film;

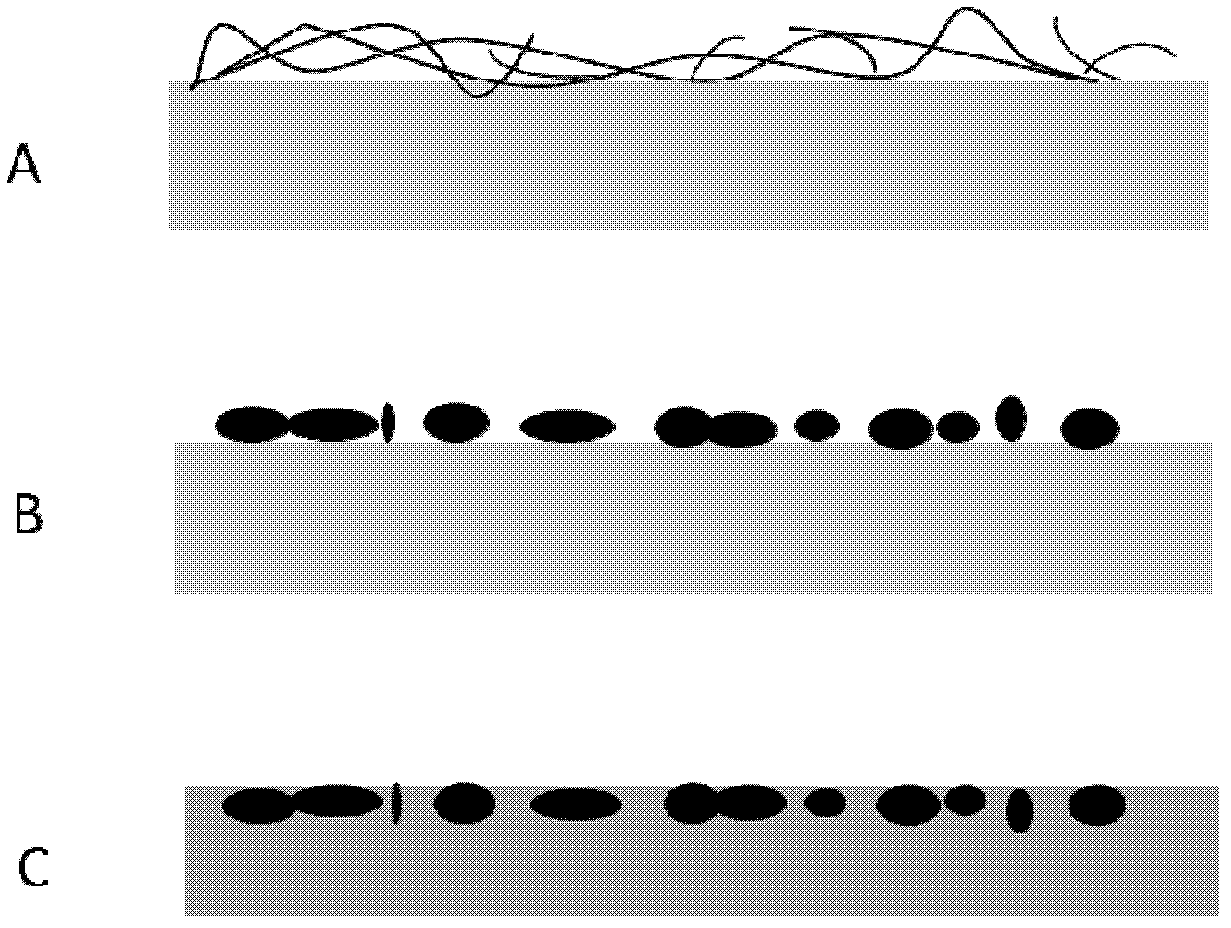

[0048] 2. Evenly coat the 2.5% dispersion (mass concentration) of nano-silver wires with a diameter of 55nm±11 and a length of 15±12μm on the release film A, and bake at 100°C for 30min. Form a layer of uniform nano-silver wire network 1;

[0049] 3. Apply 2% mass concentration of PEDOT:PSS aqueous solution evenly on the silver nano wire network formed in step 2, and heat to 130°C and bake for 30-60min to form a certain thickness of PEDOT:PSS conductive polymer layer 2;

[0050] 4. Prepare PEDOT:PSS conductive polymer layer 2 in step 3 and coat a mixture of polyurethane and polyurethane curing agent, then place polyolefin base material 4 on top of the mixture, heat to 150°C and bake for 30 minutes , the polyurethane is fully cured to form an adhesion-promoting layer 3 with good binding force; thus, a transparent conductive film is formed,...

Embodiment 2

[0052] Embodiment 2, with reference to figure 1 , 3 , 5.

[0053] 1. Coating silicone release agent on PI film to make release film;

[0054] 2. Evenly coat the 5% dispersion (mass concentration) of nano-silver wires with a diameter of 85nm±17 and a length of 25±20μm on the release film A, and bake at 120°C for 60min. Form a layer of uniform nano-silver wire network 1;

[0055] 3. Apply 3% mass concentration of PEDOT:PSS aqueous solution evenly on the silver nanowire network formed in step 2, and heat to 150°C and bake for 30-60min to form a certain thickness of PEDOT:PSS conductive polymer layer 2;

[0056] 4. Prepare a layer of thermoplastic polyester resin solution on the PEDOT:PSS conductive polymer layer 2 prepared in step 3, then place the PI base material 4 on top of the mixture, heat and pressurize to 170°C and bake for 30 minutes, The thermoplastic polyester resin is fully cured to form an adhesion-promoting layer 3 with good bonding force; thus, a transparent co...

Embodiment 3

[0058] Embodiment 3, with reference to figure 1 , 3 6.

[0059] 1. Coating silicone release agent on PE film to make release film;

[0060] 2. Evenly coat the 4.5% dispersion (mass concentration) of nano-silver wires with a diameter of 120nm±20 and a length of 32±28μm on the release film A, and bake at 100°C for 30min, and then put it on the release film A Form a layer of uniform nano-silver wire network 1;

[0061] 3. Apply 1% PEDOT:PSS aqueous solution evenly to the silver nanowire network formed in step 2, and heat to 130°C and bake for 30-60min to form a certain thickness of PEDOT:PSS conductive polymer layer 2;

[0062] 4. Prepare PEDOT in step 3: the PSS conductive polymer layer is coated with a mixture of thermosetting epoxy resin and curing agent with good bendability, and then the PET base material 4 is placed on the mixture and heated to Bake at 120°C for 30 minutes to fully cure the thermosetting epoxy resin to form an adhesion-promoting layer 4 with good adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com