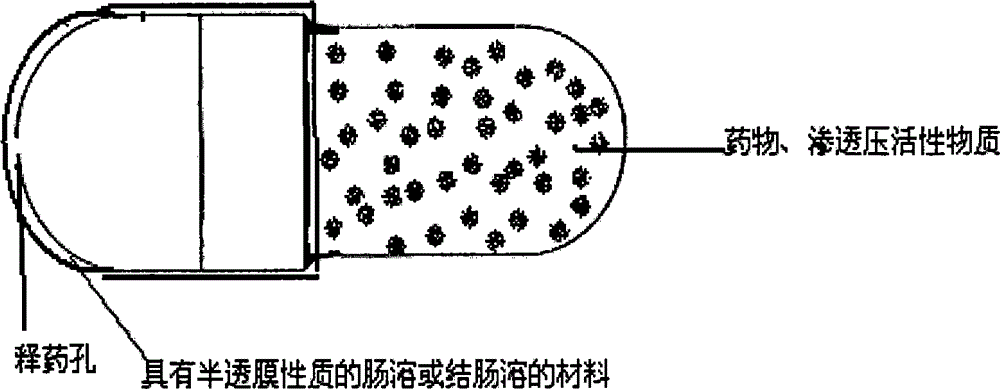

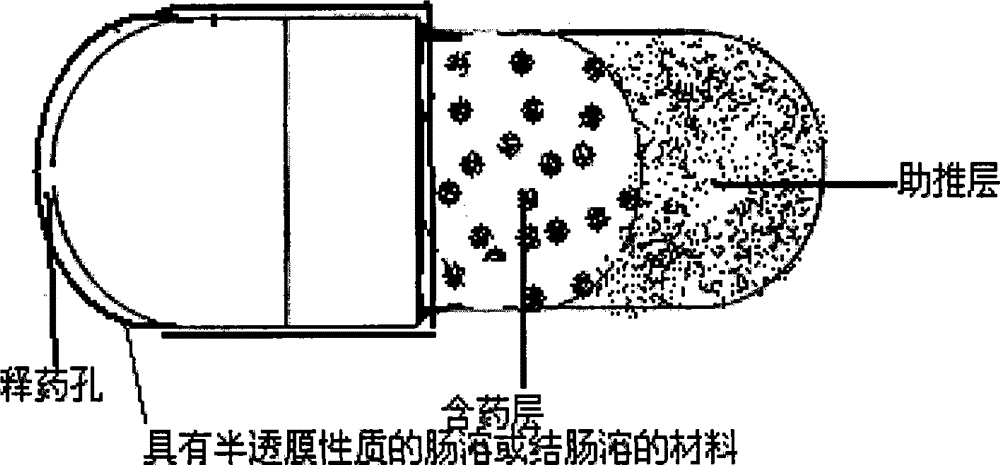

Site-specific osmotic-pump controlled-release capsule shell and preparation method thereof

A technology of osmotic pump controlled release and capsule shell, which is applied in the field of medicine, can solve the problems that it is not suitable for the preparation of osmotic pump tablets, and achieve the effects of stable curative effect, slow drug release, and constant drug release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Capsule Shell Composition:

[0026] 1.5 g of cellulose acetate; 5.0 g of cellulose acetate phthalate; 1.5 g of polyethylene glycol-200; 1.5 g of tributyl citrate; 0.5 g of titanium dioxide;

[0027] Preparation process: first dissolve cellulose acetate and phthalate cellulose acetate in acetone, add polyethylene glycol and tributyl citrate as plasticizers, put the weighed titanium dioxide into it, stir well, Let stand to remove air bubbles. Make a blank by dipping in glue, dry it, prepare a drug release hole with a diameter of 1.0mm on the capsule body by laser or mechanical drilling, seal the enteric-coated or colonic-coated capsule liquid and dry it, pull out the shell, cut, and arrange, that is Position the osmotic pump capsule housing.

Embodiment 2

[0029] Capsule Shell Composition:

[0030] 1.5 g of cellulose acetate; 5.0 g of hydroxypropyl methylcellulose acetate succinate (HPMCAS); 2.0 g of castor oil; 1.0 g of triethyl citrate;

[0031] Preparation process: first dissolve cellulose acetate and hydroxypropyl methylcellulose acetate succinate (HPMCAS) in acetone, add castor oil and triethyl citrate as plasticizers, the preparation process is the same as Example 1, Prepare a drug release hole with a diameter of 0.5mm on the capsule body and capsule cap by laser or mechanical drilling, seal with gelatin solution and dry, pull out the shell, cut, and arrange to obtain the positioning osmotic pump capsule shell.

Embodiment 3

[0033] Capsule Shell Composition:

[0034] Ethyl cellulose 2.5g; cellulose acetate phthalate 10g; polyethylene glycol-400 2.0g; dibutyl phthalate 1.5g; titanium dioxide 0.5g;

[0035] Preparation process: first dissolve ethyl cellulose and cellulose acetate phthalate in 95% ethanol, add polyethylene glycol-400 and dibutyl phthalate as plasticizers, add titanium dioxide and stir well, and prepare The process is the same as in Example 1. A drug release hole with a diameter of 1.0 mm is prepared on the capsule body by laser or mechanical drilling, and the capsule liquid is sealed and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com