Preparation method of polymer optical waveguide with inclined-surface coupling port

A technology of coupling ports and polymers, which is applied in the direction of optical waveguide light guides, pattern surface photolithography, and optomechanical equipment, can solve the problems of high cost of background technology, complex processing technology, and small range of change in the length of the gradient area. Achieve the effect of simple and fast process, low cost, and reduce device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

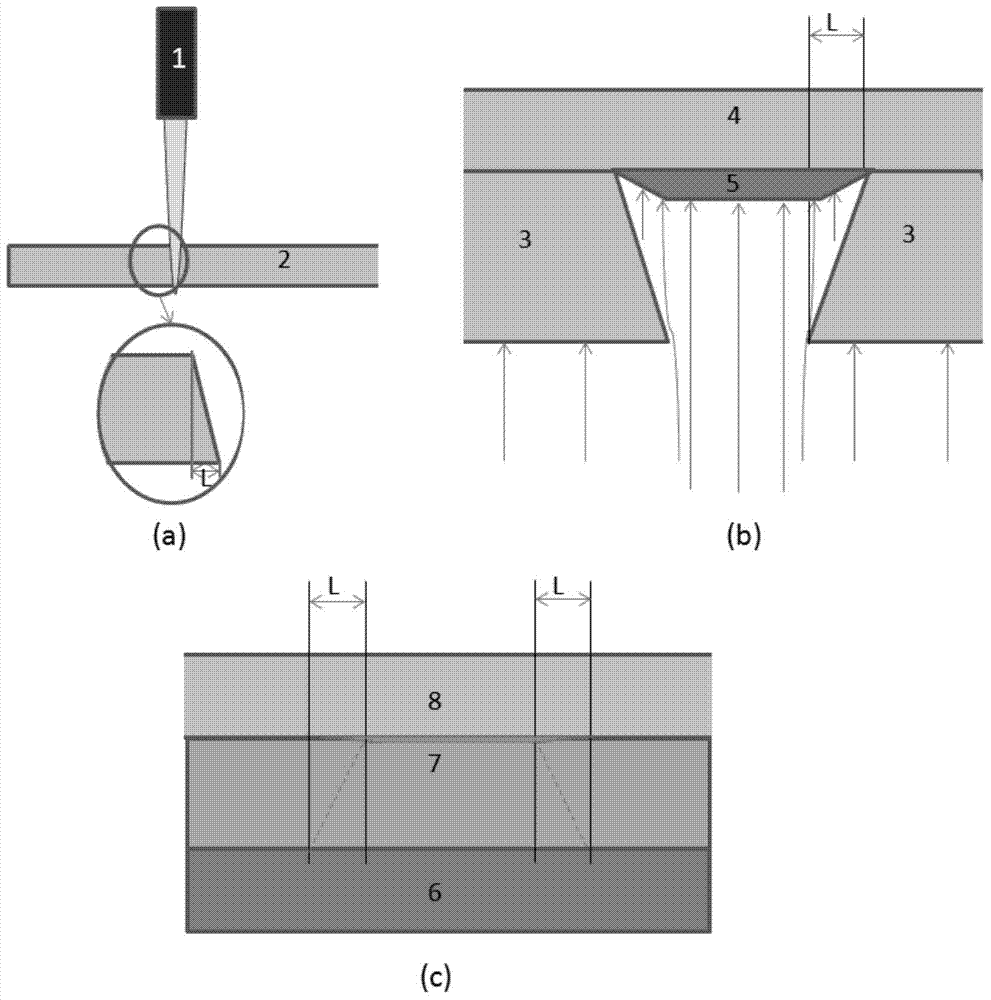

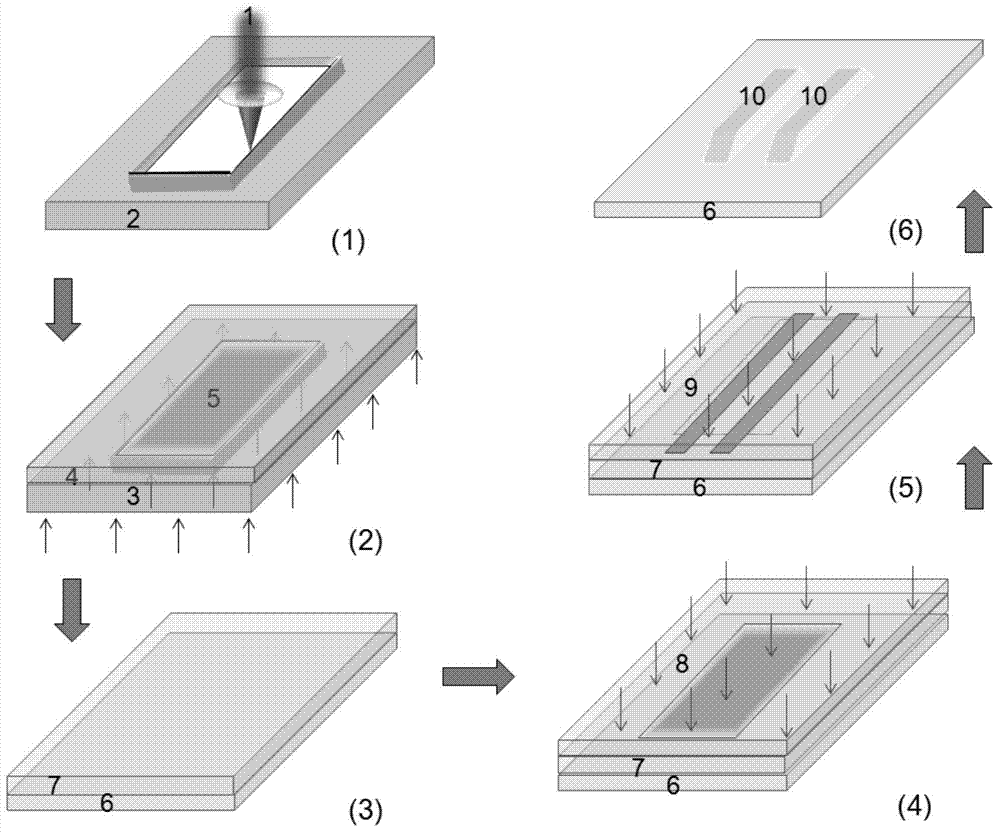

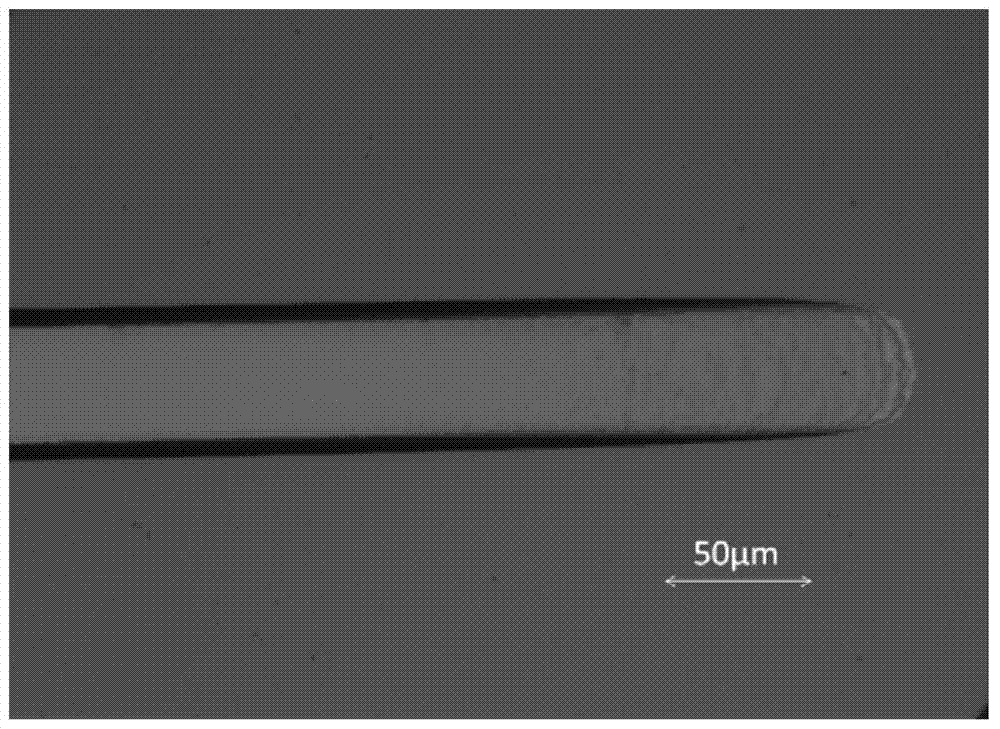

[0045] When the cutting power is 18W, the cutting speed is 10mm / s, the aluminum film thickness is 37nm, the photoresist spin coating revolution is 3000 revolutions, and the gray scale exposure time is 8s, the waveguide embodiment with beveled coupling port

[0046] Mask evaporation mask preparation: select 100.0mm*100.0mm*1.5mm surface-polished methyl methacrylate (PMMA) polymer sheet 2, which is produced by carbon dioxide laser 1 (produced by Shandong Ketai Laser Co., Ltd., maximum power 60W), The cutting speed is 10mm / s, the output power of the carbon dioxide laser is 18W, and the size of the evaporation window is 15mm*10mm (corresponding to the cutting pattern size of the computer corel draw software) to form an evaporation mask 3 with an evaporation window, and then use acetone, ethanol, Wipe the mask with deionized water in turn. The projection length L of the slope on the surface of the sheet is 90 μm.

[0047] A polymer sheet of polymer methyl methacrylate (PMMA) with a siz...

Embodiment 2

[0051] When the cutting power is 21W, the cutting speed is 10mm / s, the aluminum film thickness is 37nm, the photoresist spin coating revolution is 3000 revolutions, and the gray scale exposure time is 8s, the waveguide embodiment with beveled coupling port

[0052] Mask evaporation mask preparation: select 100.0mm*100.0mm*1.5mm surface-polished methyl methacrylate (PMMA) polymer sheet 2, which is produced by carbon dioxide laser 1 (produced by Shandong Ketai Laser Co., Ltd., maximum power 60W), The cutting speed is 10mm / s, and the CO2 laser output power is 21W to cut the evaporation window. The size of the evaporation window is 15mm*10mm (correl draw software corresponds to the cutting pattern size) to form an evaporation mask 3 with an evaporation window, and then use The reticle was wiped with acetone, ethanol, and deionized water in sequence, and the projection length L of the slope on the surface of the sheet was 160 μm. .

[0053] Select the polymer methyl methacrylate (PMMA)...

Embodiment 3

[0057] When the cutting power is 18W, the cutting speed is 10mm / s, the aluminum film thickness is 37nm, the photoresist spin-coating revolution is 3000 revolutions, and the gray scale exposure time is 8.5s, the waveguide embodiment with beveled coupling port

[0058] Mask evaporation mask preparation: select 100.0mm*100.0mm*1.5mm surface-polished methyl methacrylate (PMMA) polymer sheet 2, which is produced by carbon dioxide laser 1 (produced by Shandong Ketai Laser Co., Ltd., maximum power 60W), The cutting speed is 10mm / s, and the CO2 laser output power is 18W to cut the evaporation window. The size of the evaporation window is 15mm*10mm (the size of the computer corel draw software corresponds to the cutting graph size) to form the evaporation mask 3 with the evaporation window, and then use The reticle was wiped with acetone, ethanol, and deionized water in sequence, and the projection length L of the slope on the surface of the sheet was 80 μm. .

[0059] Select the polymer m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Projection length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com