Abrasion-resistant coating for automobile spring steel plate and preparation method of abrasion-resistant coating

A technology for automotive springs and wear-resistant coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of slow decomposition speed, small decomposition amount, poor temperature resistance, etc., and achieve enhanced densification and bonding force, Easy to operate and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

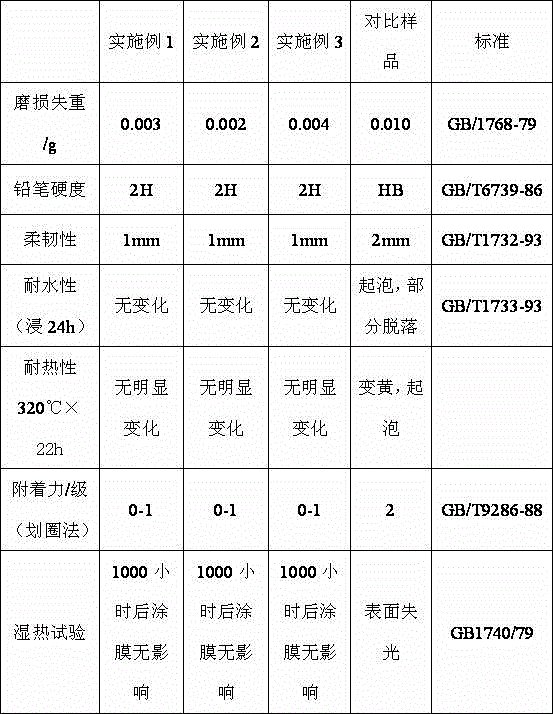

Examples

Embodiment 1

[0051] Embodiment 1: The invention provides a wear-resistant coating for automobile spring steel plates, which consists of the following components in parts by weight:

[0052] Bisphenol A type E44 12 parts;

[0053] Bisphenol A type E51 18 parts;

[0054] 20 parts of polytetrafluoroethylene latex;

[0055] 2 parts of methyl silicone oil;

[0056] 4 parts of polydimethylsiloxane;

[0057] 4 parts of nano silicon dioxide powder;

[0058] 5 parts of nano silicon carbide powder;

[0059] 6 parts of nano molybdenum disulfide;

[0060] 2 parts of 1,4-butanediol;

[0061] 8 parts of absolute ethanol;

[0062] Sodium polyacrylate 2 parts;

[0063] 3 parts sodium polycarboxylate;

[0064] Sodium tripolyphosphate 2 parts;

[0065] 1 part of diethylenetriamine;

[0066] Mannich base 1 part.

[0067] The present invention is used for the preparation of the wear-resisting paint of automobile spring steel plate and coating technology as follows:

[0068] (1) Add 23.5kg of sodi...

Embodiment 2

[0074] Embodiment 2: The invention provides a wear-resistant coating for automobile spring steel plates, which consists of the following components in parts by weight:

[0075] Bisphenol A type E44 15 parts;

[0076] Bisphenol A type E51 20 parts;

[0077] 25 parts of polytetrafluoroethylene latex;

[0078] 3 parts of methyl silicone oil;

[0079] 5 parts of polydimethylsiloxane;

[0080] 5 parts of nano silicon dioxide powder;

[0081] 7 parts of nano silicon carbide powder;

[0082] 6 parts of nano molybdenum disulfide;

[0083] 5 parts of 1,4-butanediol;

[0084] 10 parts of absolute ethanol;

[0085] 3 parts of sodium polyacrylate;

[0086] 4 parts sodium polycarboxylate;

[0087] 3 parts of sodium tripolyphosphate;

[0088] 1 part of diethylenetriamine;

[0089] Mannich base 1 part.

[0090] The present invention is used for the preparation of the wear-resisting paint of automobile spring steel plate and coating technology as follows:

[0091] (1) Add 24.3k...

Embodiment 3

[0097] Example 3: The invention provides a wear-resistant coating for automobile spring steel plates, which consists of the following components in parts by weight:

[0098] Bisphenol A type E44 18 parts;

[0099] Bisphenol A type E51 22 parts;

[0100] 30 parts of polytetrafluoroethylene latex;

[0101] 5 parts of methyl silicone oil;

[0102] 6 parts of polydimethylsiloxane;

[0103] 6 parts of nano silicon dioxide powder;

[0104] 8 parts of nano silicon carbide powder;

[0105] 7 parts of nano molybdenum disulfide;

[0106] 8 parts of 1,4-butanediol;

[0107] 12 parts of absolute ethanol;

[0108] 5 parts of sodium polyacrylate;

[0109] 4 parts sodium polycarboxylate;

[0110] 4 parts of sodium tripolyphosphate;

[0111] 2 parts of diethylenetriamine;

[0112] Mannich base 2 parts.

[0113] The present invention is used for the preparation of the wear-resisting paint of automobile spring steel plate and coating technology as follows:

[0114] (1) Add 26.4kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com