Antistatic and flame retardant copolyester fiber and preparation method thereof

A copolyester, antistatic technology, applied in the manufacture of fire-retardant and flame-retardant filaments, conductive/antistatic filaments, single-component copolyester rayon, etc., can solve problems that are not conducive to large-scale industrial production, The synthesis process is not well controlled and other problems, to achieve the effects of good biodegradability, easy industrial production and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

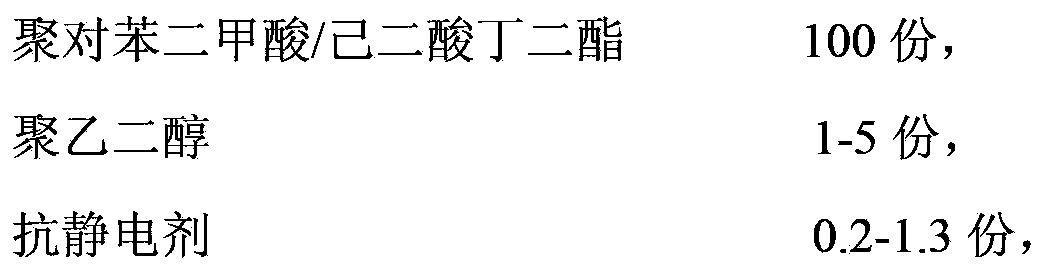

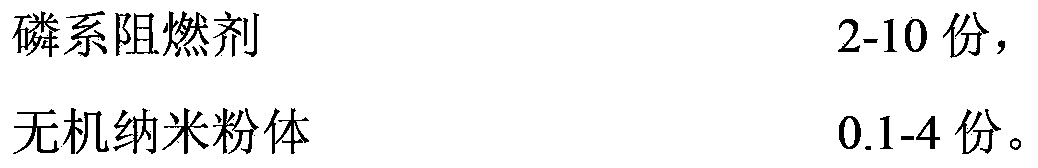

[0046] (1) Vacuum dry polybutylene terephthalate / adipate and polyethylene glycol (molecular weight: 5000) respectively, and the moisture content is less than 200ppm;

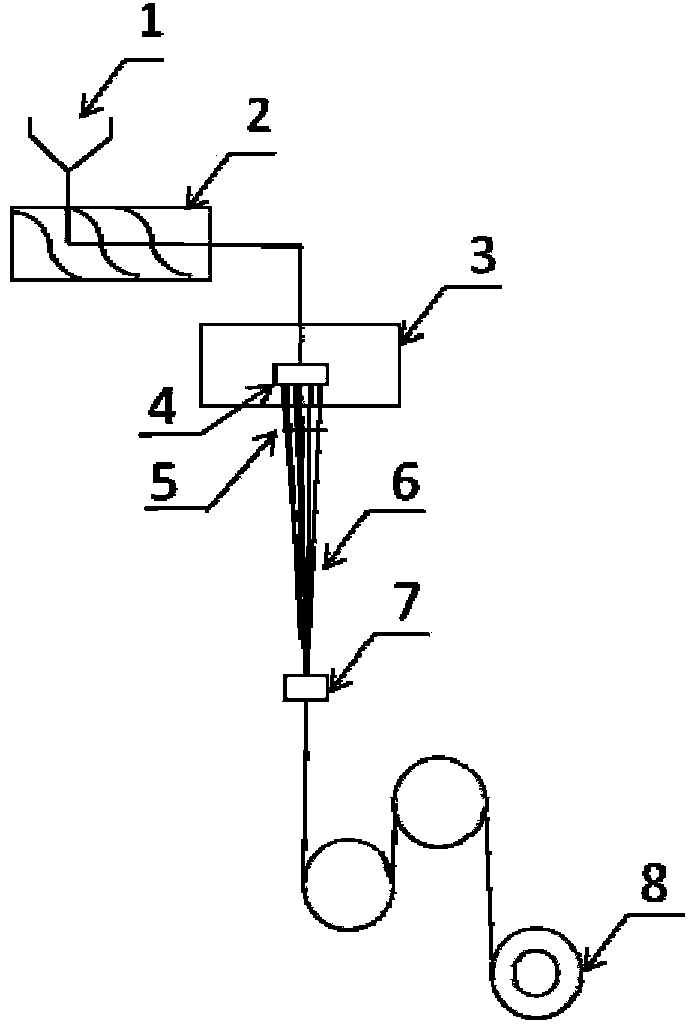

[0047] (2) Dry 100 parts of polybutylene terephthalate / adipate, 1 part of polyethylene glycol, 0.2 parts of sodium dodecylbenzenesulfonate, 2 parts of 2-hydroxy Ethylphenylphosphoric acid and 0.1 part of silicon dioxide are blended for 3 minutes, and then enter the twin-screw extruder through the hopper 1 successively, melt and extrude under the action of the screw 2, enter the casing 3 of the spinning assembly through the melt pipeline, and pass Metering by the metering pump 4, followed by extrusion from the spinneret 5, cooling by the cooling zone 6, oiling by the cluster oiling device 7, pre-drawing and winding by the winding roller 8, to obtain a copolymer with uniform structure and controllable fineness Ester fiber. Among them, the spinning temperature is 250°C, the spinning speed is 800m / min; the fiber st...

Embodiment 2

[0051] (1) Vacuum dry polybutylene terephthalate / adipate and polyethylene glycol (molecular weight: 10,000), and the water content is less than 200ppm;

[0052](2) Dry 100 parts of polybutylene terephthalate / adipate, 2 parts of polyethylene glycol, 0.8 parts of sodium pentadecylsulfonate, 5 parts of 2-hydroxyethylene Methyl phosphate and 1 part of calcium carbonate were blended for 5 minutes, and entered into the twin-screw extruder through the hopper 1 successively, melted and extruded under the action of the screw 2, and then entered the casing 3 of the spinning assembly through the melt pipeline, and passed The metering pump 4 measures, and is extruded by the spinneret 5, cooled by the cooling zone 6, oiled by the cluster oiling device 7, and pre-drawn and wound by the winding roller 8 to obtain a degradable material with uniform structure and controllable fineness. Polyester. Wherein, the spinning temperature is 260° C., and the spinning speed is 1000 m / min. Its fiber st...

Embodiment 3

[0056] (1) Extrude 50 parts of polybutylene terephthalate / adipate, 3 parts of polyethylene glycol (molecular weight 15000), 4 parts of 2-hydroxyethyl methyl phosphoric acid and 2 parts of barium sulfate through twin-screw extrusion Extrude and granulate to obtain polyethylene glycol / polyethylene terephthalic acid / butylene adipate blend, and the processing temperature is 140°C;

[0057] (2) 50 parts of polybutylene terephthalic acid / butylene adipate and the polyethylene glycol / polybutylene terephthalic acid / butylene adipate blend obtained in step (1) were vacuum-dried to remove moisture Less than 200ppm. Take 50 parts of polybutylene terephthalate / adipate and polyethylene glycol / polybutylene terephthalate adipate blend, 1.0 parts of sodium dodecylbenzene sulfonate after drying Blending for 8 minutes, enter the twin-screw extruder through the hopper 1 in turn, melt and extrude under the action of the screw 2, enter the box 3 of the spinning assembly through the melt pipeline, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume specific resistance | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Fiber strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com