Manufacturing method of electroformed diamond geological drill bit with honeycomb structure

A technology of honeycomb structure and manufacturing method, which is applied in the field of manufacturing diamond geological drill bits with electroformed honeycomb structure, which can solve the problems of long cycle time, high manufacturing and use costs, and high consumption of metal nickel, so as to reduce impurities, reduce consumption, and drill rigs Effect of Reduction in Total Diesel Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

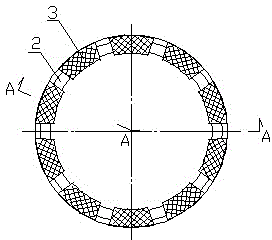

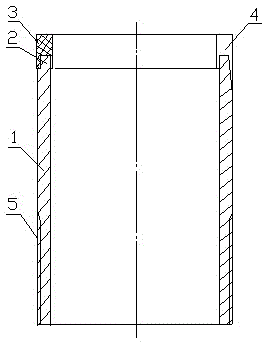

[0023] Such as figure 1 with figure 2 As shown, the electroformed honeycomb structure diamond geological drill bit includes a drill sleeve 1 and a cutter head 3, one end of the drill sleeve is provided with a deposition platform 2 and a relief groove 4, and the other end is provided with a thread 5, and the diamond geological drill bit manufacturing method includes the following Steps: 1. First add nickel sulfate: 220-250g / L, cobalt sulfate: 10-15g / L, manganese sulfate: 5-10g / L, nickel chloride: 30- 45g / L, boric acid: 30-40g / L, saccharin: 0.5-1g / L, sodium lauryl sulfate: 0.05-0.1g / L, ammonium chloride: 5-10g / L, stirring and mixing to form electroforming 2. Add 0.2-0.5 g / L cerium oxide to the above electroforming soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com