Injection molding formula and injection molding method for ceramic bond superhard material grinding tool

A super-hard material abrasive tool and ceramic bond technology, which is applied in the direction of ceramic molding machines, grinding devices, manufacturing tools, etc., can solve the problems of severe mechanical wear of injection machine screw, low quality stability, poor microstructure uniformity of forming abrasive tools, etc. problems, to achieve the effect of not being able to form in place at one time, high quality stability, and overcoming poor uniformity of axial density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

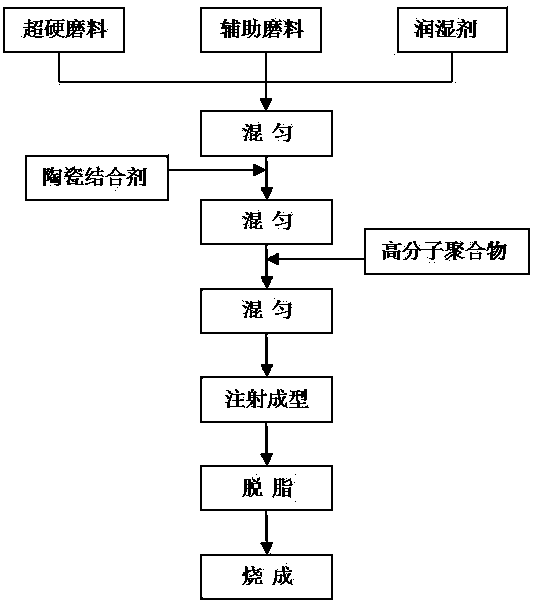

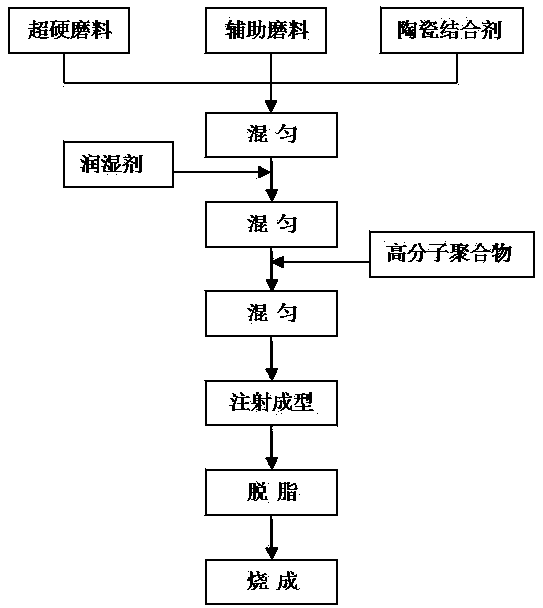

Method used

Image

Examples

Embodiment 1

[0029] Cylindrical vitrified bonded cubic boron nitride grinding wheel, aspect ratio The ratio of wheel height to wall thickness is 15.

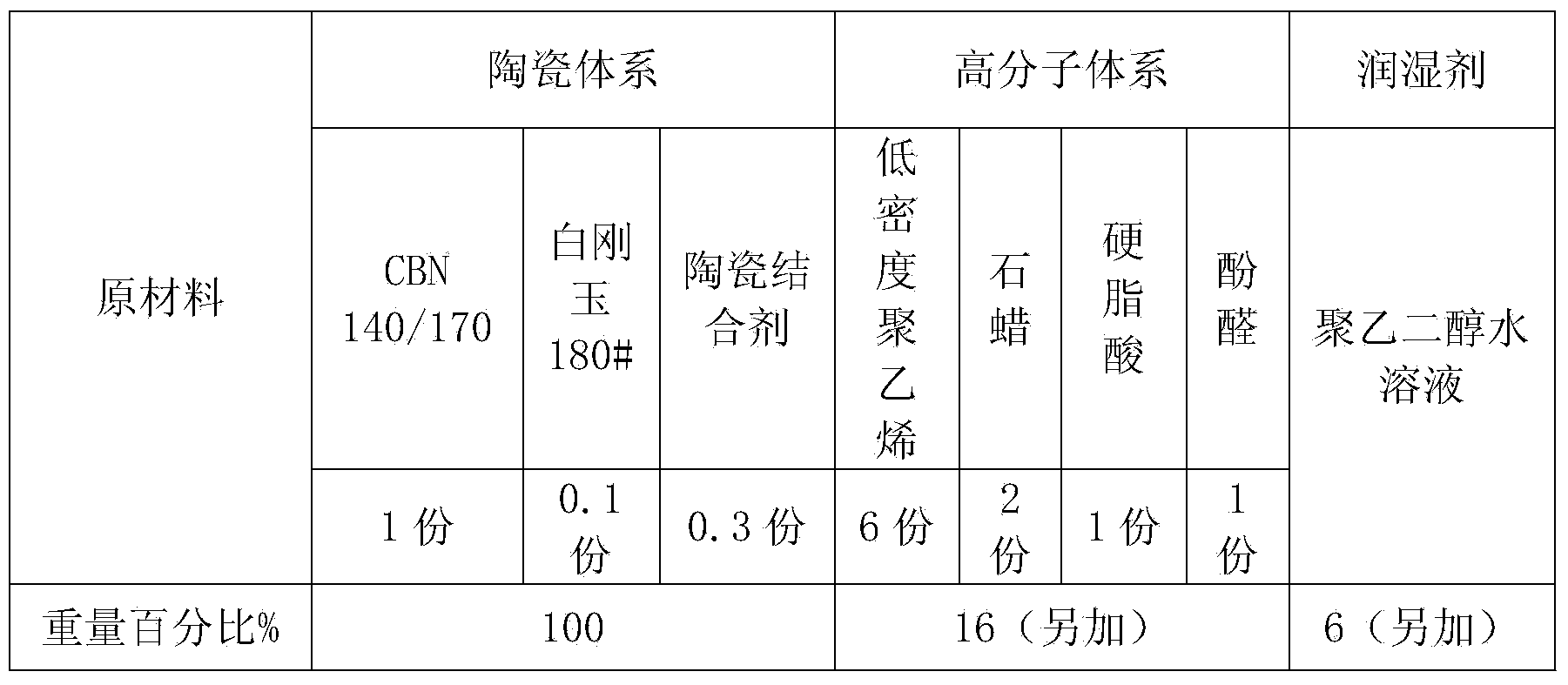

[0030] 1. Formulation design: the design density of this grinding wheel is 2.2g / cm 3 , the design ceramic system is 100wt% of the total amount, the polymer system accounts for 16wt% of the total amount, and the wetting agent is polyethylene glycol aqueous solution with a concentration of 20%, accounting for 6wt% of the ceramic system. In the ceramic system, superabrasive: auxiliary abrasive: vitrified bond = 1:0.1:0.3; in the polymer system, low-density polyethylene: paraffin: stearic acid: phenolic = 6:2:1:1.

[0031] In this formula, the superhard abrasive is cubic boron nitride, the particle size is 60 / 70, and the particle size is 213-271 μm; the auxiliary abrasive is white corundum, the particle size is 80#, and the average particle size is 200 μm.

[0032] It is planned to form 30 grinding wheels, and the raw materials are calculated a...

Embodiment 2

[0041] Manufacture of special-shaped vitrified bonded diamond grinding wheels

[0042] 1. Formulation design: the design density of this grinding wheel is 2.3g / cm 3 , the design ceramic system is 100wt% of the total amount, the polymer system accounts for 12wt% of the total amount, and the wetting agent is an aqueous solution of sodium carboxymethyl cellulose, which accounts for 7wt% of the ceramic system. In the ceramic system, superabrasive: auxiliary abrasive: vitrified bond = 1:0.5:0.5; in the polymer system, high-density polyethylene: polyethylene wax: stearyl alcohol: phenolic resin = 4:5:0.5:0.5 .

[0043] In this formula, the superabrasive is diamond, the particle size is W28, and the particle size is 14-28 μm; the auxiliary abrasive is green silicon carbide, the particle size is W20, and the particle size is 10-20 μm.

[0044] It is planned to form 50 grinding wheels, and the raw materials are calculated according to the following formula table:

[0045] Table 2 is...

Embodiment 3

[0053] Manufacture of Vitrified Bond Superhard Material Grinding Disc Shots

[0054] 1. Formulation design: the design density of this grinding wheel is 2.1g / cm 3 , the design ceramic system is 100wt% of the total amount, the polymer system accounts for 20wt% of the total amount, and the wetting agent is glycerol with a concentration of 50%, accounting for 8wt% of the ceramic system. In the ceramic system, superabrasive: auxiliary abrasive: vitrified bond = 1:0.2:0.5; in the polymer system, polypropylene: microcrystalline wax: palmitic acid: epoxy resin = 3:5:1:1.

[0055] In this formula, the superabrasive is a mixture of diamond and cubic boron nitride. Boron nitride is half of each; the auxiliary abrasive is microcrystalline corundum, the particle size is W10, and the particle size is 5-10 μm.

[0056] It is planned to form 1000 millstone pellets, and the raw materials are calculated according to the following formula table:

[0057] Table 3 is the list of ingredients of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com