Embedded type combined heat sink as well as preparation method thereof

An embedded, heat sink technology, used in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of increased thermal diffusion distance, large contact thermal resistance, low strength, etc., to reduce thermal expansion coefficient, improve Adhesion strength, effect of reducing interfacial thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Select CuCr (0.8%wt.) alloy as the secondary heat sink (substrate), cut into 20×10×2mm block samples, mechanically polish the surface to be sprinkled with diamond powder, and ultrasonically clean it with anhydrous alcohol for 15 Minutes to remove the remaining polishing paste on the surface, and finally dry it with cold air;

[0036] (2) Put the polished and cleaned sample into a hydrogen protective atmosphere furnace, heat it to 500°C, keep it warm for 20 minutes, and then cool it down to room temperature with the furnace. The hydrogen protection can only be removed by cooling below 80°C, and the bright softening annealed CuCr (0.8%wt.) alloy can be obtained;

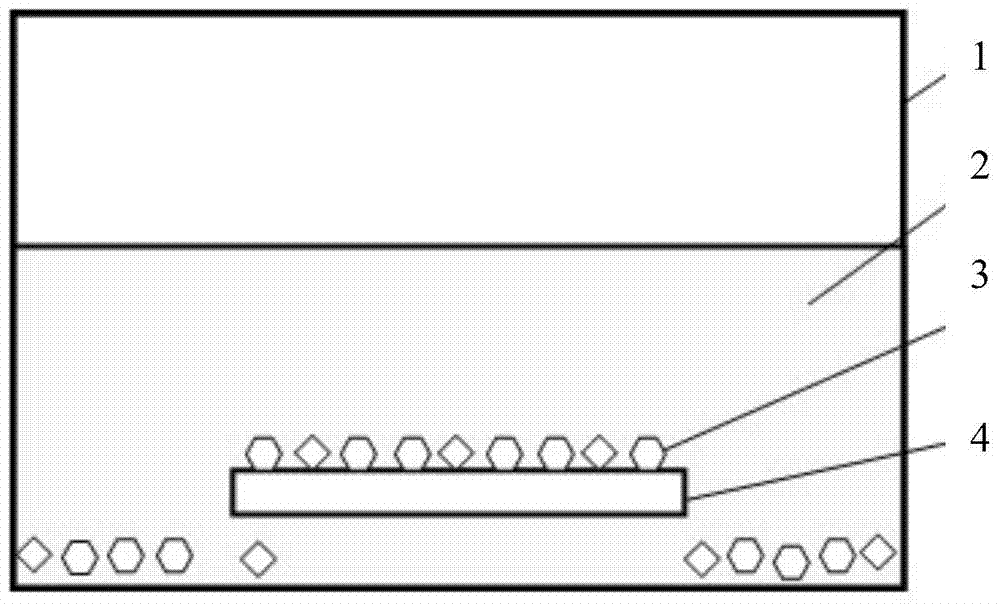

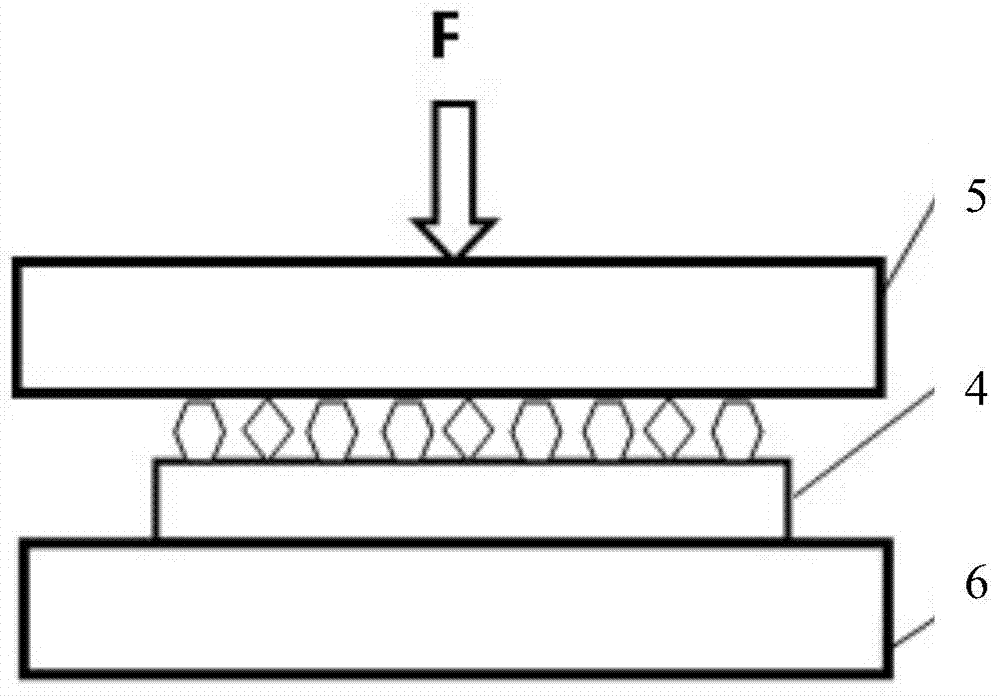

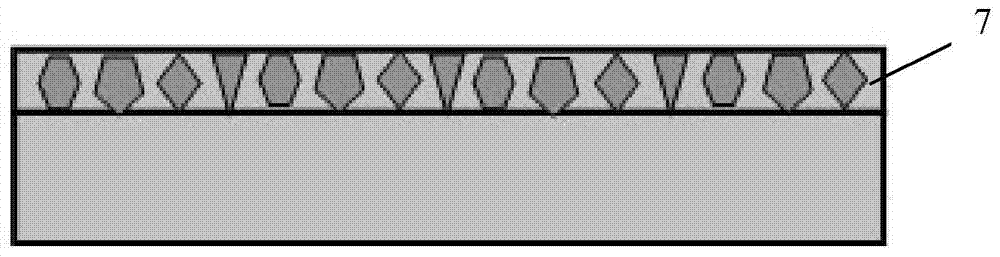

[0037] (3) Use MBD4 grade W10 diamond powder as embedded particles. Use a 50 ml flat-bottomed beaker as a dusting container with an inner diameter of 4.2 cm. The coverage rate of the diamond micropowder to the bottom surface of the container is 60%, and according to the formula 60%3.5Sh, the addition amoun...

Embodiment 2

[0046] (1) Select CuB (0.5%wt.) alloy as the secondary heat sink (substrate), cut into 20×10×2mm block samples, mechanically polish the surface to be sprinkled with diamond powder, and ultrasonically clean it with anhydrous alcohol for 15 Minutes to remove the remaining polishing paste on the surface, and finally dry it with cold air;

[0047] (2) Put the polished and cleaned sample into a hydrogen protective atmosphere furnace, heat it to 500°C, keep it warm for 20 minutes, and then cool it down to room temperature with the furnace. The hydrogen protection can only be removed by cooling below 80°C, and the bright softening annealed CuB (0.5%wt.) alloy can be obtained;

[0048] (3) Use MBD4 grade W30 diamond powder as embedded particles. Use a 50 ml flat-bottomed beaker as a dusting container with an inner diameter of 4.2 cm. The coverage of the diamond micropowder on the bottom surface of the container is 60%. According to the formula 60%3.5Sh, the amount of W30 diamond mic...

Embodiment 3

[0057] (1) Select ZL102 (containing Si10~13wt.%) alloy as the secondary heat sink (substrate), cut into 20×10×4mm block samples, mechanically polish the required diamond powder surface, and use anhydrous alcohol ultrasonic Wash for 15 minutes to remove the residual polishing paste on the surface, and finally dry it with cold air;

[0058] (2) Put the polished and cleaned sample into a low-temperature annealing furnace, heat it to 250-300°C, keep it warm for 60 minutes, and then cool it down to room temperature with the furnace. Place the annealed sample in 5% NaOH solution, and rinse it with distilled water quickly when hydrogen bubbles are seen. The purpose of soaking in NaOH solution is to reduce the thickness of the oxide film formed during annealing;

[0059] (3) Use MBD4 grade W10 diamond powder as embedded particles. Use a 50 ml flat-bottomed beaker as a dusting container with an inner diameter of 4.2 cm. The coverage rate of the diamond micropowder to the bottom surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com