A kind of anti-high temperature oxidation film sensor and its production method

A thin film sensor, high temperature oxidation resistance technology, applied in metal material coating process, coating, superimposed layer plating and other directions, can solve the problem of ITO thin film resistivity increase, affecting performance stability, reliability and measurement accuracy, The problem of carrier concentration decline, etc., achieves excellent anti-oxidation and insulating properties, good blocking of sodium ions, and high chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

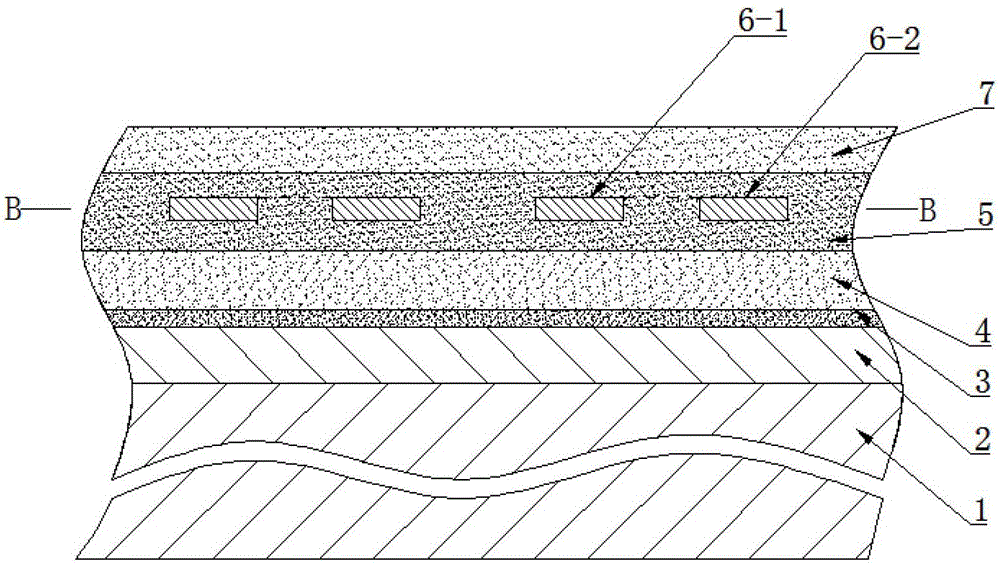

[0033] Example 1: A nickel (Ni)-based alloy plate is used as the alloy substrate to be tested 1. An ITO thermocouple thin film sensor is prepared on it, and silicon nitride is selected as the protective layer material as an example:

[0034] 1) Surface treatment of alloy substrate: use (length×width×thickness) 30×95×5mm nickel (Ni)-based alloy plate as the test alloy substrate 1, and then use acetone and ethanol to perform the surface of the test alloy substrate. After cleaning, dry it under nitrogen atmosphere;

[0035] 2) Depositing NiCrAlY alloy transition layer on the alloy substrate: Put the cleaned Ni-based alloy substrate 1 in a vacuum of 6.0×10 -4 In a Pa vacuum (ie, background vacuum) environment, NiCrAlY alloy is used as the target material, and argon gas with a purity of 99.999% (volume percentage) is input as the sputtering medium. The temperature is 500℃, the power is 300W, and the sputtering pressure (working pressure) ) Under the condition of 0.6 Pa, the NiCrAlY allo...

Embodiment 2

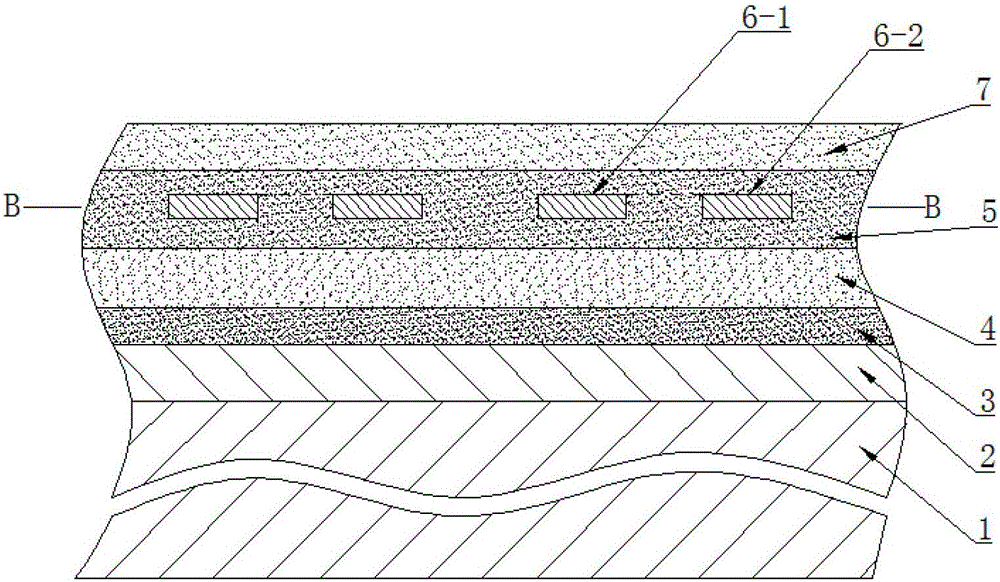

[0042] Embodiment 2: A nickel (Ni)-based alloy plate is used as the alloy substrate to be tested, and a K-type NiCr-NiSi thermocouple thin film sensor is prepared on it:

[0043] This embodiment specifically implements steps 1), 2), 3), 4), 5), and 6) and the process conditions and parameters of A, B, C, D, E, and F in the specific implementation in the disclosure specification of invention patent application CN102212823A Correspond to the same;

[0044] 7) Set up the functional layer of thin film sensor and its Si 3 N 4 Isolation layer: first place the composite substrate prepared in step 6) on the background and the vacuum degree is 6.0×10 -4 SiH is used in Pa CVD processing equipment 4 / NH 3 (The flow ratio is SiH 4 : NH 3 =1: 9) As the gas source, the background vacuum degree is 6.0×10 -4 Pa, working pressure is 60Pa, deposition temperature is 270℃, radio frequency power is 20W, the Si 3 N 4 Deposited on the composite substrate to obtain Si with a thickness of 1μm 3 N 4 The base...

Embodiment 3

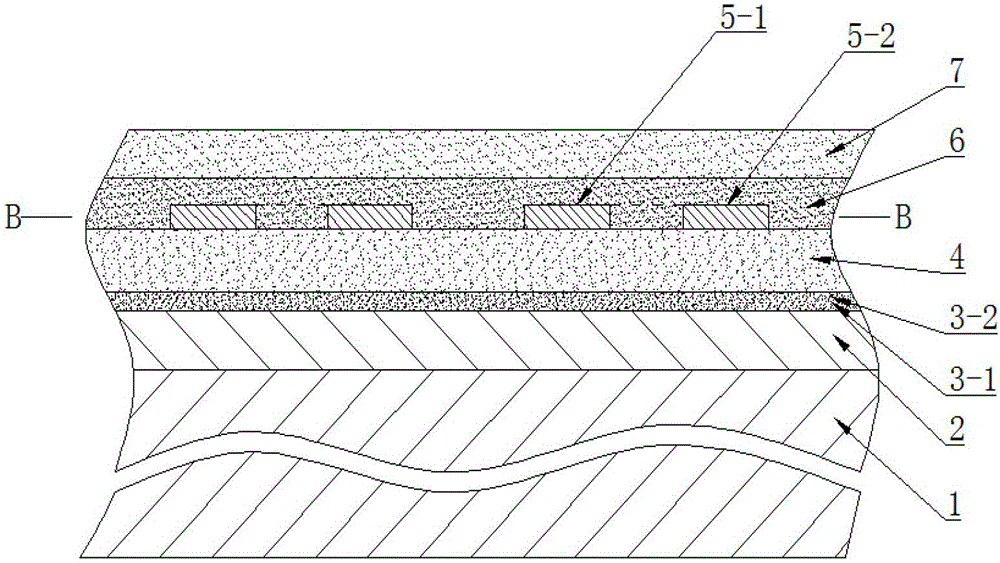

[0046] Example 3: A nickel (Ni)-based alloy plate is used as the alloy substrate to be tested, and a K-type NiCr-NiSi thermocouple thin film sensor is prepared on it:

[0047] This embodiment specifically implements steps 1), 2), 3), 4), and 5) and the specific embodiments disclosed in the disclosure specification CN101894904A of the invention patent application in 1), 2), 3), 4), 5) process conditions and The parameters correspond to the same;

[0048] 6) Set up the functional layer of the thin film sensor and its Si 3 N 4 Isolation layer: First, the vacuum on the background is 6.0×10 -4 Pa, with argon as the reaction medium, Ni90Cr10 and Ni97Si3 as the target materials, under the conditions of room temperature, power of 100W, and working pressure of 0.4Pa, the conventional magnetron sputtering method is used to deposit sequentially on the surface of the AlN ceramic insulating layer 4 Two NiCr-NiSi thermocouples with a thickness of 1μm are used as the (thin film) sensor functional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com