Method for preparing distillate oil hydrotreatment catalyst

A hydrogenation treatment and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. High, not enough mild reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

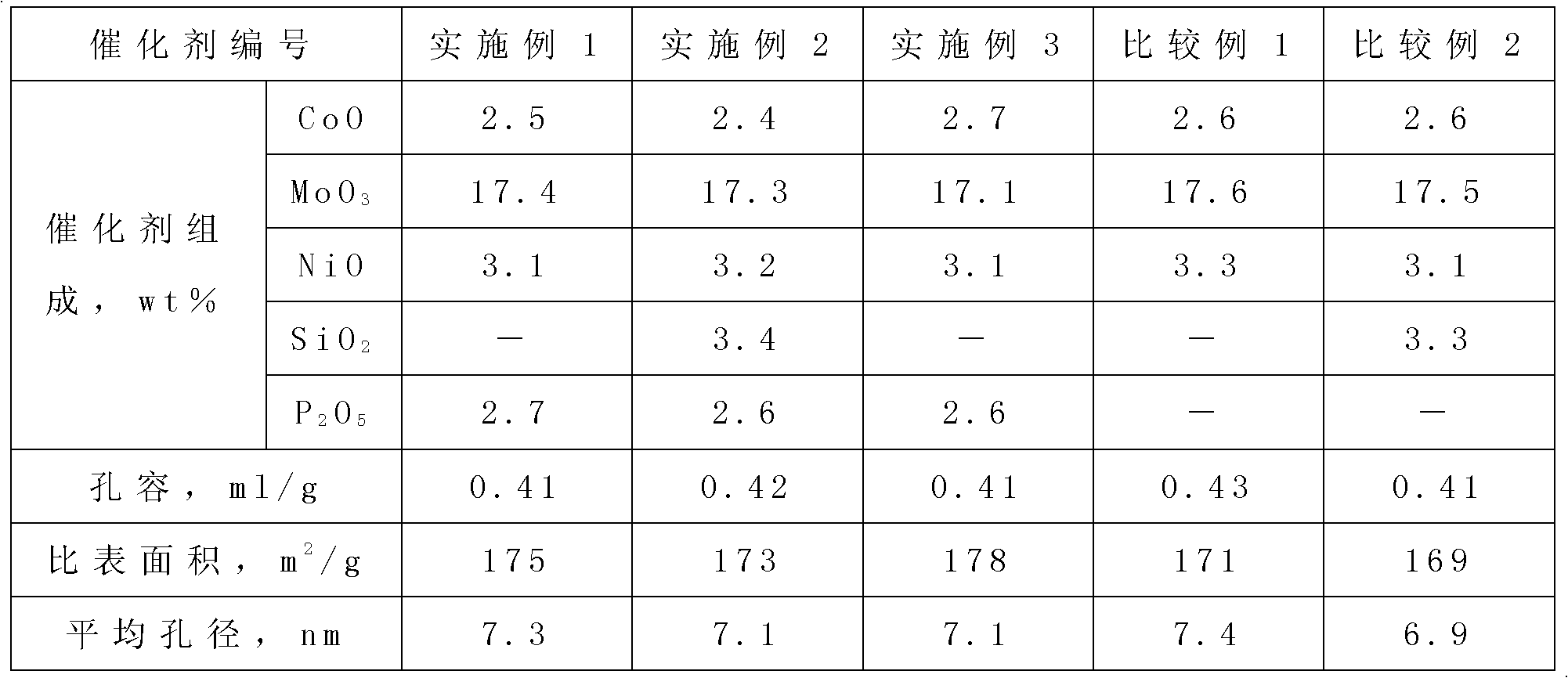

Examples

Embodiment 1

[0020] (1) γ-Al 2 o 3 Preparation of vector

[0021] Weigh 1000g of silicon-free pseudo-boehmite powder, 30g of Tianqing powder, 30g of citric acid, and 700ml of 3-5% dilute nitric acid, mix them evenly, extrude them with an extruder, dry them at 110°C for 10h, and place them at 650°C in an air atmosphere. After calcination at ℃, γ-Al 2 o 3 carrier.

[0022] (2) Ni-P / γ-Al 2 o 3 preparation of

[0023] Prepare 1000ml impregnation solution: weigh 107.6g of tartaric acid and add it to 600ml of deionized water, stir and heat to 50°C, weigh 83.6g of nickel nitrate (industrial grade) and 26.3g of ammonium dihydrogen phosphate (industrial grade) into the solution , boiled for 0.5 hour, and added dilute ammonia to adjust the pH value of the solution to 4.0. After cooling to room temperature, the solution was transferred to a volumetric flask, and water was added to make the volume to 1000ml to obtain an impregnating solution containing nickel and phosphorus.

[0024] Weigh th...

Embodiment 2

[0029] (1) Silicon-containing γ-Al 2 o 3 Preparation of vector

[0030] Weigh 1000g of silicon-containing pseudo-boehmite, 45g of Tianqing powder, 35g of oxalic acid, and 680ml of 3-5% dilute nitric acid, mix them evenly, extrude them with an extruder, dry at 110°C, and dry at 550°C in an air atmosphere After roasting treatment, silicon-containing γ-Al 2 o 3 carrier.

[0031] (2) Ni-P / silicon-containing γ-Al 2 o 3 preparation of

[0032] Prepare 1000ml impregnation solution: weigh 140.0g oxalic acid and add it to 600ml water, stir and heat to 50°C, weigh 45.5g basic nickel nickel carbonate (industrial grade) and 31.3g calcium hydrogen phosphate (industrial grade) and add to the solution , boil for 0.5 hours, cool to room temperature, transfer the solution to a volumetric flask, add water to make the volume 1000ml, and obtain an impregnating solution containing nickel and phosphorus.

[0033] Weigh the silicon-containing γ-Al prepared by 500g step (1) 2 o 3 For the ca...

Embodiment 3

[0038] (1) γ-Al 2 o 3 Preparation of vector

[0039] With embodiment 1 (1).

[0040] (2) Ni-P / γ-Al 2 o 3 preparation of

[0041] The preparation of the dipping solution is the same as in Example 2 (2).

[0042] Weigh 500g γ-Al 2 o 3 As for the carrier, measure 375ml of the prepared impregnation solution containing nickel and phosphorus, impregnate with equal volume for 30 minutes, dry at 110°C for 2 hours, and roast at 460°C to obtain a semi-finished catalyst.

[0043] (3) Co-Mo-Ni-P / γ-Al 2 o 3 Catalyst preparation

[0044] The preparation of the dipping solution is the same as in Example 1 (3).

[0045] Weigh the prepared Ni-P / γ-Al of 500g step (2) 2 o 3 For the catalyst semi-finished product, measure 347ml of the prepared impregnation solution containing cobalt and molybdenum, impregnate with equal volume for 30 minutes, dry at 110°C for 2 hours, and roast at 460°C to obtain the finished catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com