Arc welding-brazing method for pre-coating titanium alloy and aluminum alloy

A technology of aluminum alloy and titanium alloy, which is applied in the direction of arc welding equipment, welding medium, welding equipment, etc., can solve the problems of expensive production cycle of connecting equipment, thick hard and brittle intermetallic compounds, and low bonding strength of joints, and achieve low manufacturing cost , short production cycle, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Clean the surface of the titanium alloy plate and the aluminum alloy plate, and process a 45° groove at the welding position;

[0033] (2) Dissolve the aluminum alloy brazing flux in acetone to form a suspension, and evenly brush it on the front and back of the dipping position of the titanium plate to form a thin brazing flux layer with a thickness of 0.2-0.5mm;

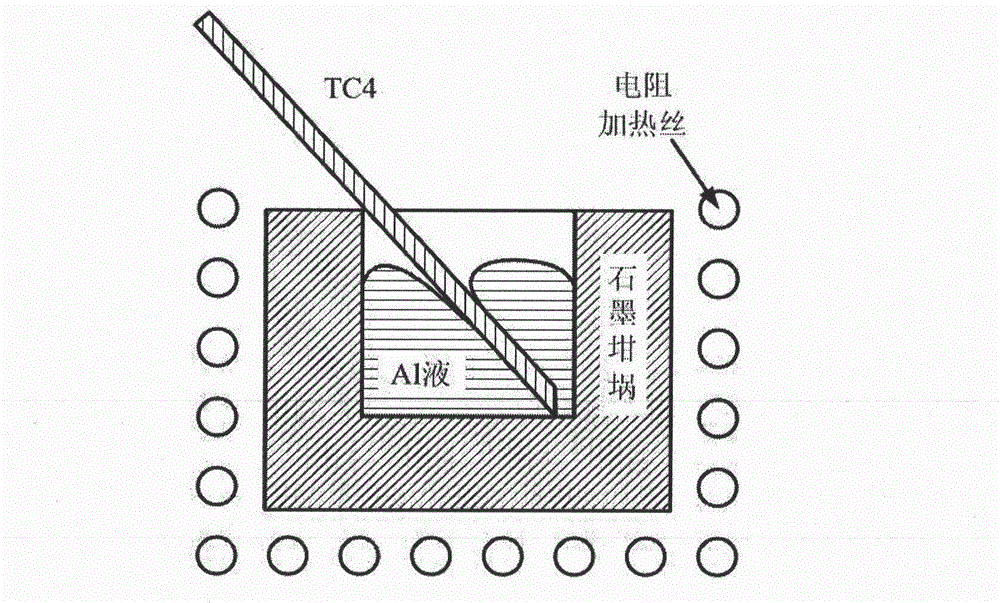

[0034] (3) Immerse the titanium alloy plate coated with flux into pure aluminum in a molten state at a temperature of 750-800°C, keep the temperature constant for 1-3min, and then pull out the titanium plate at a constant speed of 2cm / s to achieve hot dipping plating;

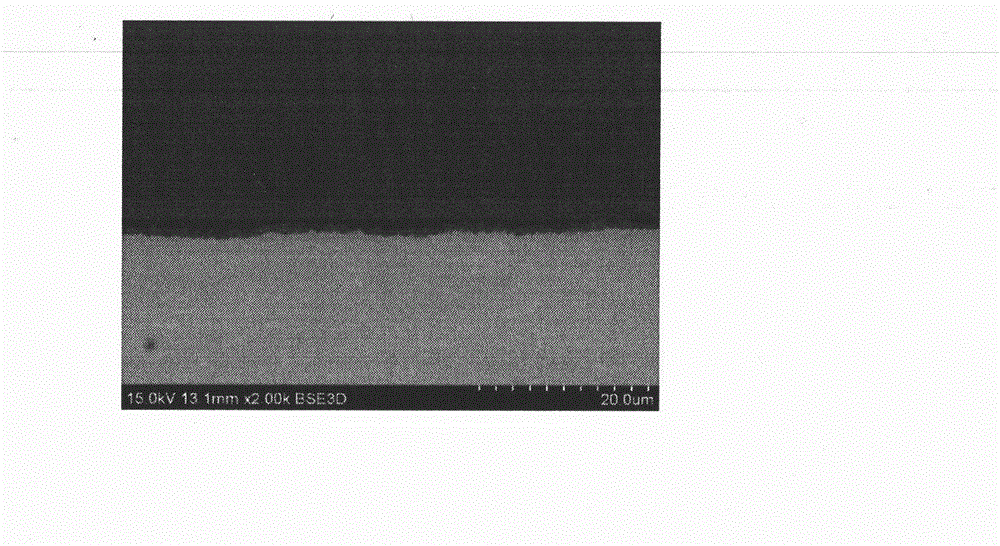

[0035] (4), grinding the aluminum alloy layer dipped on the surface of the titanium alloy plate, the thickness of the aluminum alloy layer after grinding is uniform and smooth, and the thickness is 20-30 μm;

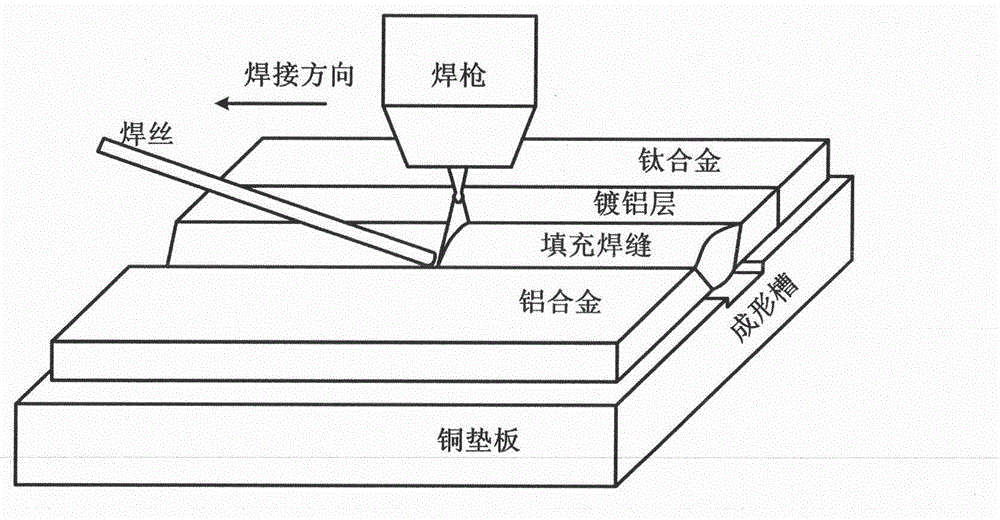

[0036](5) Fix the parts to be welded between the titanium alloy plate and the aluminum alloy plate after immersion plating on the ...

Embodiment 2

[0042] The difference between this embodiment and the first embodiment is that the titanium alloy in the titanium alloy plate in the first step is TA and TB series alloys. Other steps and parameters are the same as in the first embodiment.

Embodiment 3

[0044] The difference between this embodiment and the specific embodiment 1 is: in step 1, the aluminum alloy in the aluminum alloy and its composite material plate is LY, LD series alloy or pure aluminum. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com