Preparation method of porous tantalum applicable to replacing human dentale tissue

A porous tantalum and dental bone technology is applied in the field of preparation of medical metal implant materials, which can solve the problems affecting the processing and mechanical properties of porous tantalum materials such as ductility, compressive strength, and insufficient bending strength, and improve biocompatibility. and biological safety, good pore size uniformity of finished products, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

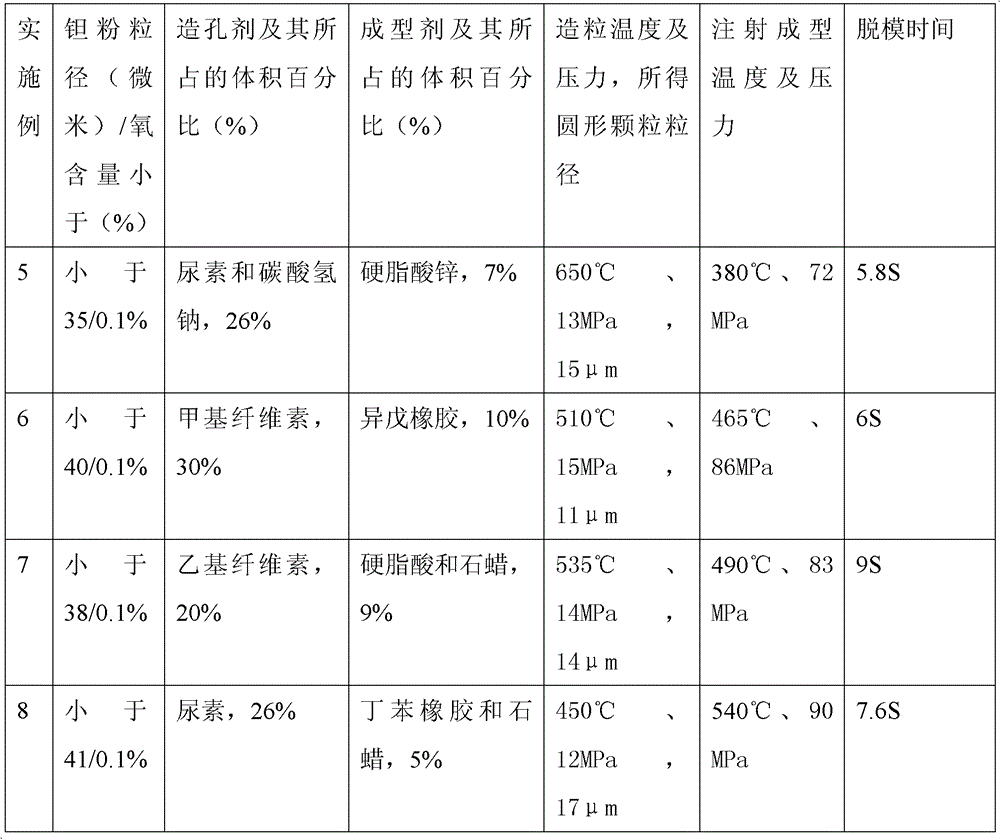

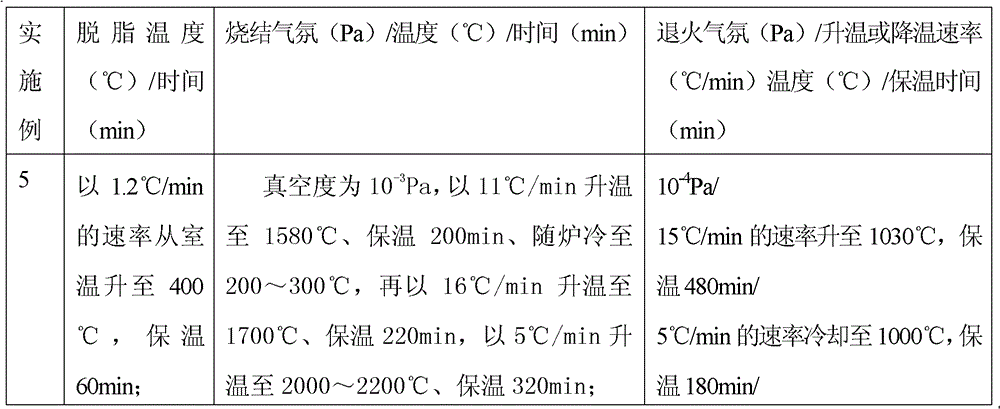

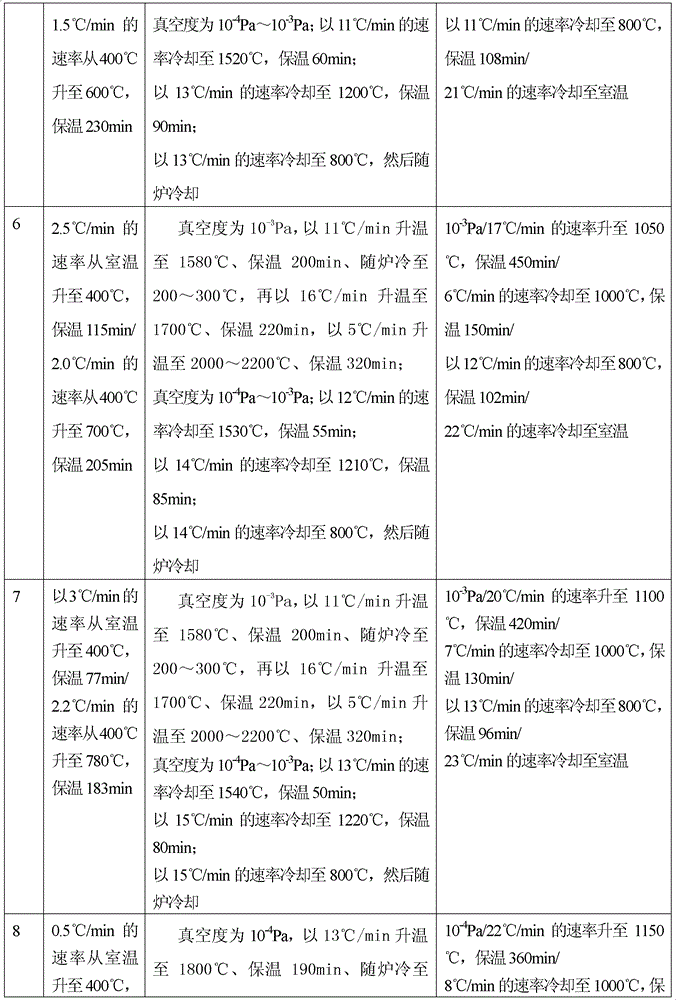

Examples

Embodiment 1

[0021] Embodiment 1: Take paraffin wax, tantalum powder and ethyl cellulose with an average particle size less than 43 microns and an oxygen content of less than 0.1% and mix them uniformly to form a mixed powder, wherein paraffin wax accounts for 8%, ethyl cellulose accounts for 27%, tantalum powder accounts for 65%, all in volume percentage. Granulation: The mixed powder is granulated into round particles with a particle diameter of 10-13 μm at a working temperature of 510-520° C. and a working pressure of 12-13 MPa. Injection molding: the temperature for injecting the round particles into the mold is 465-490° C. and the pressure is 83-85 MPa. Demolding time: 6~7S. Degreasing treatment: vacuum degree 10 -4 Pa, rise from room temperature to 400°C at a rate of 1-3°C / min, hold for 60-120 minutes, rise from 400°C to 600-800°C at a rate of 1.5-2.5°C / min, and hold for 180-240 minutes. Vacuum sintering: vacuum degree is 10 -4 Pa~10 -3 Pa, heat up to 1800°C at 13°C / min, hold fo...

Embodiment 2

[0023] Embodiment 2: Weigh polyvinyl alcohol, tantalum powder with an average particle size less than 43 microns and an oxygen content of less than 0.1%, and sodium bicarbonate and mix them uniformly to form a mixed powder, wherein polyvinyl alcohol accounts for 6%, sodium bicarbonate accounts for 29%, tantalum Powder accounted for 65%, all in volume percentage. Granulation: The mixed powder was granulated into round particles with a particle diameter of 20 μm at a working temperature of 450° C. and a working pressure of 15 MPa. Injection molding: the temperature of injecting the round particles into the mold is 540° C. and the pressure is 90 MPa. Demolding time: 9S. Degreasing treatment: vacuum degree 10 -4 Pa, raise the temperature from room temperature to 400°C at a heating rate of 1°C / min, and hold for 60 minutes; then raise the temperature from 400°C to 800°C at a heating rate of 2.5°C / min, and hold for 180 minutes. Vacuum sintering: the vacuum degree is 10-4Pa, heat u...

Embodiment 3

[0025] Embodiment 3: take by weighing zinc stearate, average particle diameter less than 43 micron oxygen content less than 0.1% tantalum powder and methyl cellulose and mix uniformly into mixed powder, wherein zinc stearate accounts for 10%, methyl cellulose accounts for 10%. 23%, tantalum powder accounted for 67%, both by volume percentage. Granulation: The mixed powder was granulated into circular particles with a particle diameter of 10 μm at a working temperature of 650° C. and a working pressure of 12 MPa. Injection molding: the temperature of injecting the round particles into the mold is 380° C. and the pressure is 72 MPa. Demolding time: 6S. Degreasing treatment: vacuum degree 10 -4 Pa, from room temperature to 400°C at a heating rate of 3°C / min and hold for 120 minutes; then at a heating rate of 1.5°C / min from 400°C to 750°C for 240 minutes. Vacuum sintering: vacuum degree is 10 -3 Pa, heat up to 1800°C at 15°C / min, hold for 200min, cool with the furnace to 200-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com