Driving belt and manufacturing method thereof

A manufacturing method and transmission belt technology, applied to transmission belts, belts, and other household appliances, can solve the problems of poor flexibility, short service life, and complicated manufacturing process of transmission belts, and achieve full tooth shape, long service life, and transmission smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

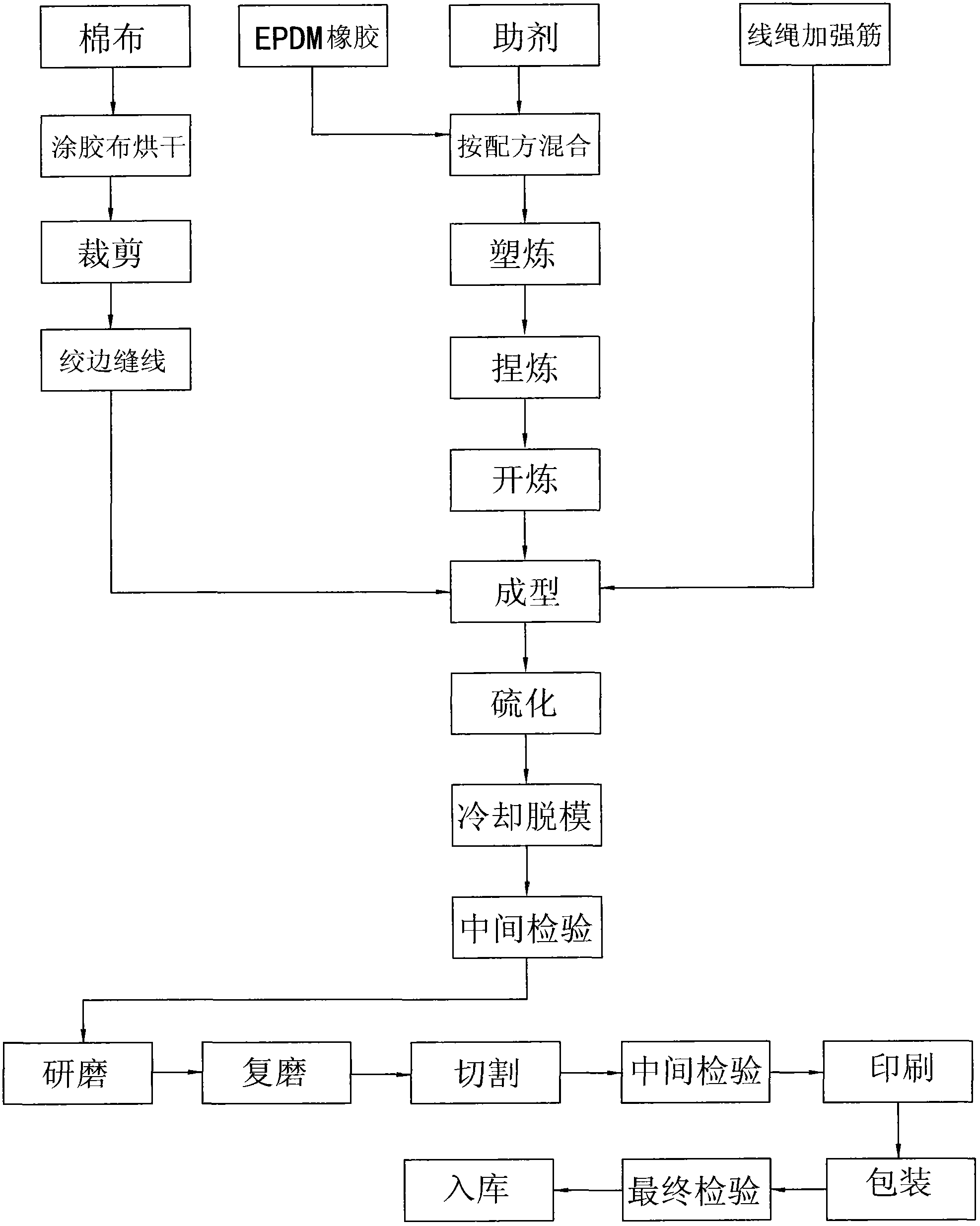

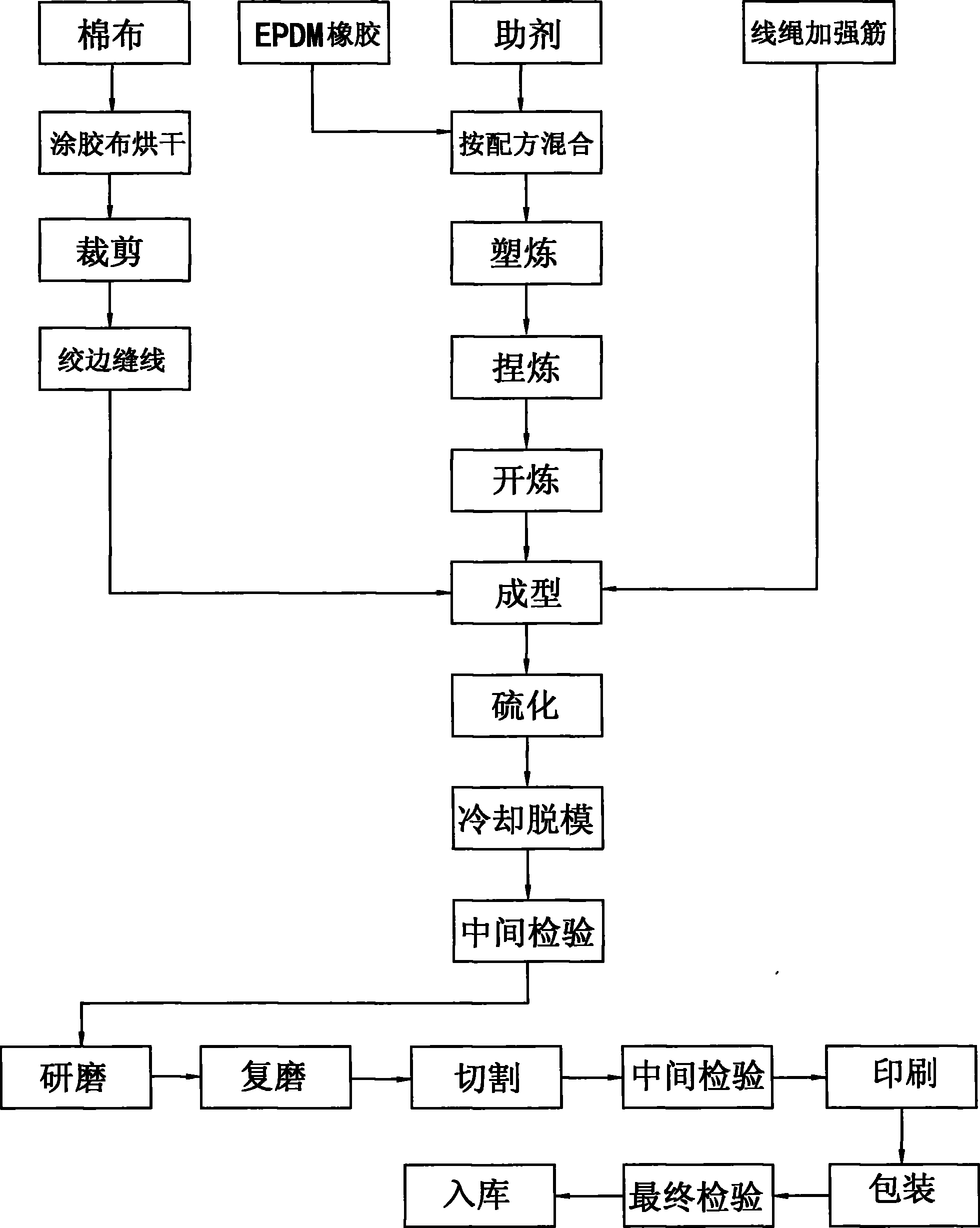

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] Implement one, such as figure 1 As shown, the basic composition of the transmission belt of this embodiment is as follows: in every 100 parts of EPDM rubber, add 1.5 parts of anti-aging agent, 1.5 parts of polyethylene glycol, 5 parts of phenolic resin, and 4 parts of resorcinol , 50 parts of paraffin oil, 20 parts of carbon black, 5 parts of reinforcing ribs made of aramid fiber, 30 parts of reinforcing agent 6851, 25 parts of industrial cloth, and the above are parts by weight. The anti-aging agent is: 2,2,4-trimethyl-1,2-dihydroquinoline polymer or 2,2,4-trimethyl-1,2-dihydroquinoline polymer or 1, A homopolymer of 2-dihydro-2,2,4-trimethylquinoline or 2,2,4-trimethyl-1,2-dihydroquinoline. The formula includes 1.5-2.5 parts of dispersant WB222, and the above are parts by weight.

[0027] According to above-mentioned formula, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com