Ternary copolymer polycarbonate foam material

A ternary copolymerized polycarbonate and polycarbonate technology, applied in the field of biodegradable foam materials, can solve the problems of limited industrial application, high foaming temperature, complicated operation, etc., and achieve excellent foaming and degradation properties, excellent foaming Good effect of foam performance, foaming performance and cell stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

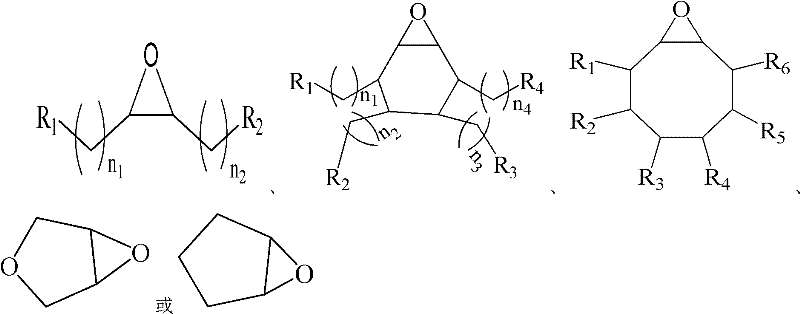

Method used

Image

Examples

Embodiment 1 3

[0037] Example 1 Direct synthesis of ternary copolymer PPCHC foam material:

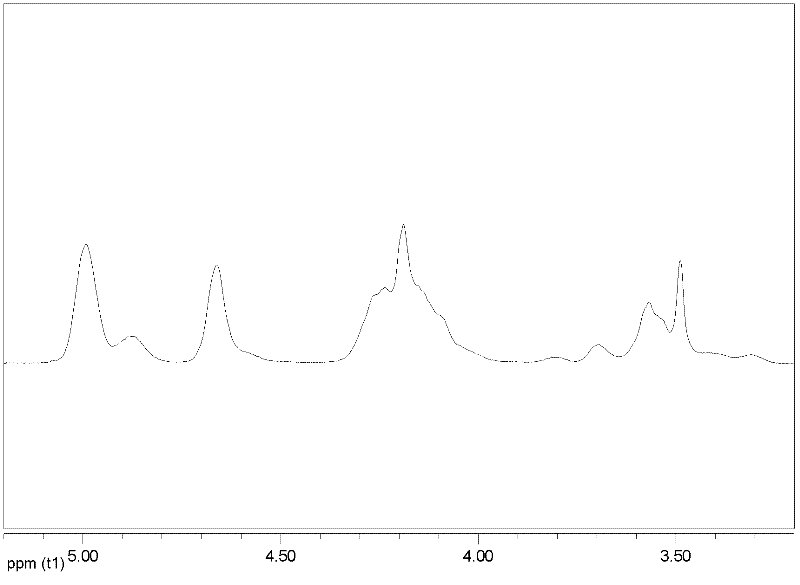

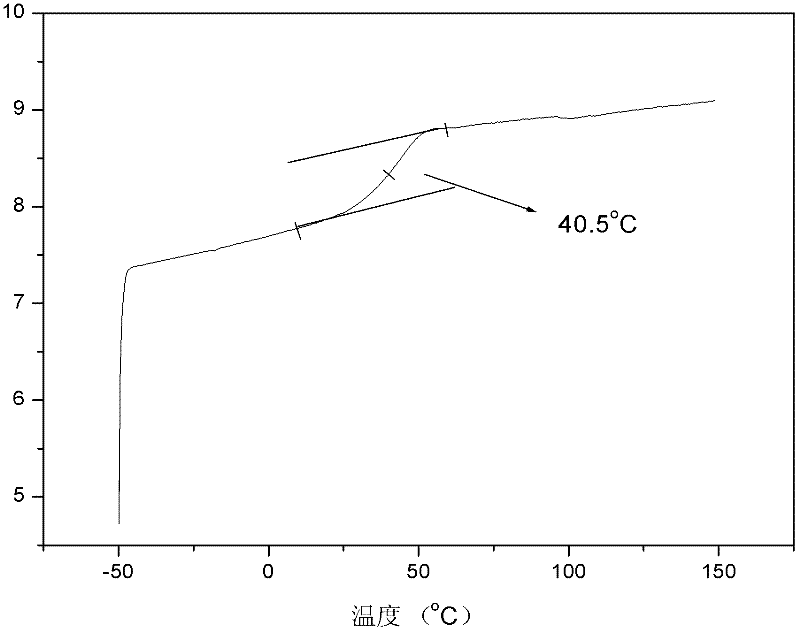

[0038] Add 5mg of zinc-cobalt double metal cyanide complex catalyst (structural formula Zn 3 [Co(CN) 6 ] 2 ·1.3ZnCl 2 ·2.0t-BuOH·0.5H 2 O) Put it in a 250ml autoclave, use a vacuum pump at 90°C for about 2 hours to remove trace moisture and oxygen in the kettle, cool to about 25°C, add 24g propylene oxide and 0.9g cyclohexane oxide, and fill CO 2 And turn on the stirring, place the kettle body in a water bath preheated to 70°C, and start the reaction. When the system temperature reaches and stabilizes at 60°C, the pressure is controlled at 5.5MPa. After 6 hours of reaction, the temperature is quickly cooled to room temperature and the pressure is released. Under normal pressure, 48.1g of foam material is obtained, and its polymerization activity is calculated to be 9.6Kg / g cat, its number average molecular weight is 150,000 and its molecular weight distribution is 3.2 by GPC test; figure 1 It is a terpol...

Embodiment 2 3

[0039] Example 2 Direct synthesis of ternary copolymer PPCHC foam material:

[0040] The other steps are the same as in Example 1. The difference is that the amount of the catalyst is 10mg to obtain 49.4g of foam material. The calculated polymerization activity is 4.9Kg / g cat, the number average molecular weight is 120,000, the molecular weight distribution is 3.5, and the content of carbon dioxide units in the polymer It is 45.3%, the glass transition temperature is 30.1°C, the average cell size is 0.85mm, and the impact rebound rate is 36.2%.

Embodiment 3 3

[0041] Example 3 Direct synthesis of ternary copolymer PPCHC foam material:

[0042] The other steps are the same as in Example 1. The difference is that the amount of the catalyst is 15mg to obtain 42.2g of foam material. The calculated polymerization activity is 8.4Kg / g cat, the number average molecular weight is 130,000, the molecular weight distribution is 3.1, and the content of carbon dioxide units in the polymer It is 45.3%, the glass transition temperature is 37.9°C, the average cell size is 0.81mm, and the impact rebound rate is 36.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Average cell size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com