Cationic surfactant and preparation method thereof

A surfactant and cationic technology, applied in the field of 3--2-hydroxypropyltrimethylammonium halide and its manufacture, can solve the problems of low output and low proportion, and achieve simple and convenient method, good water solubility and Effect of foaming and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

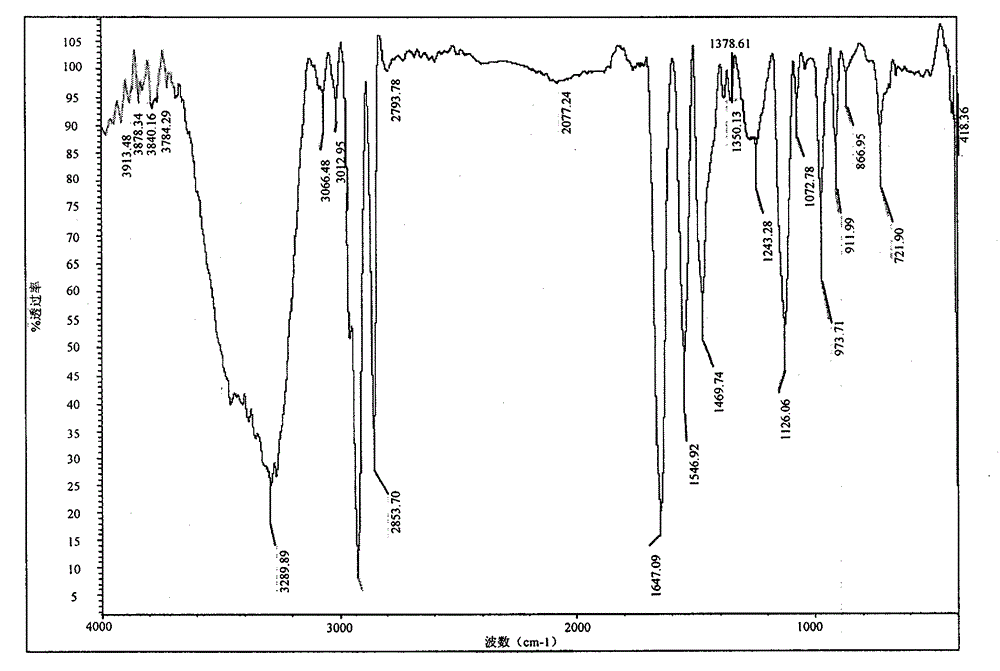

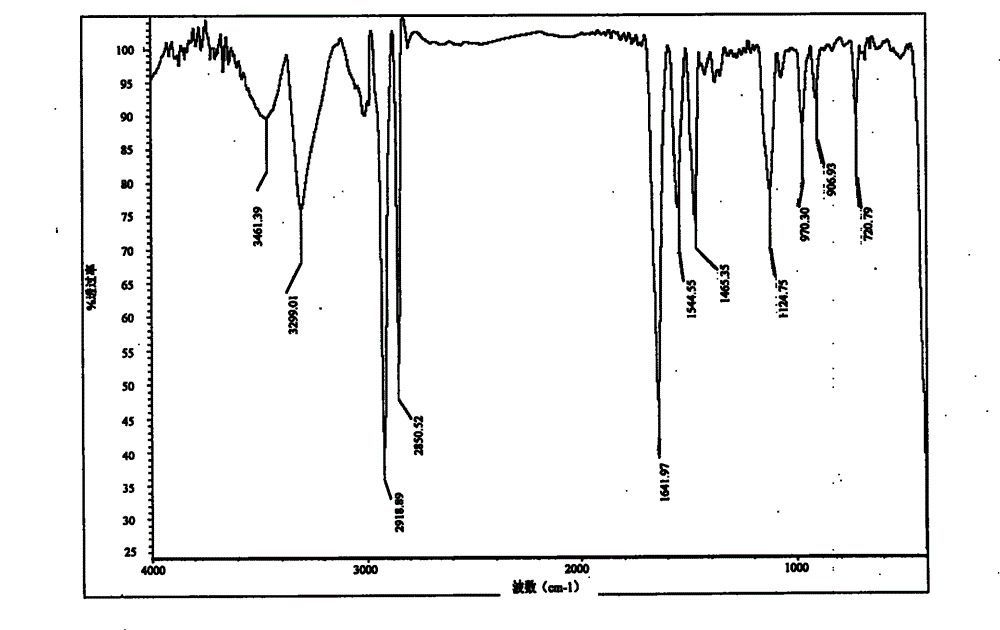

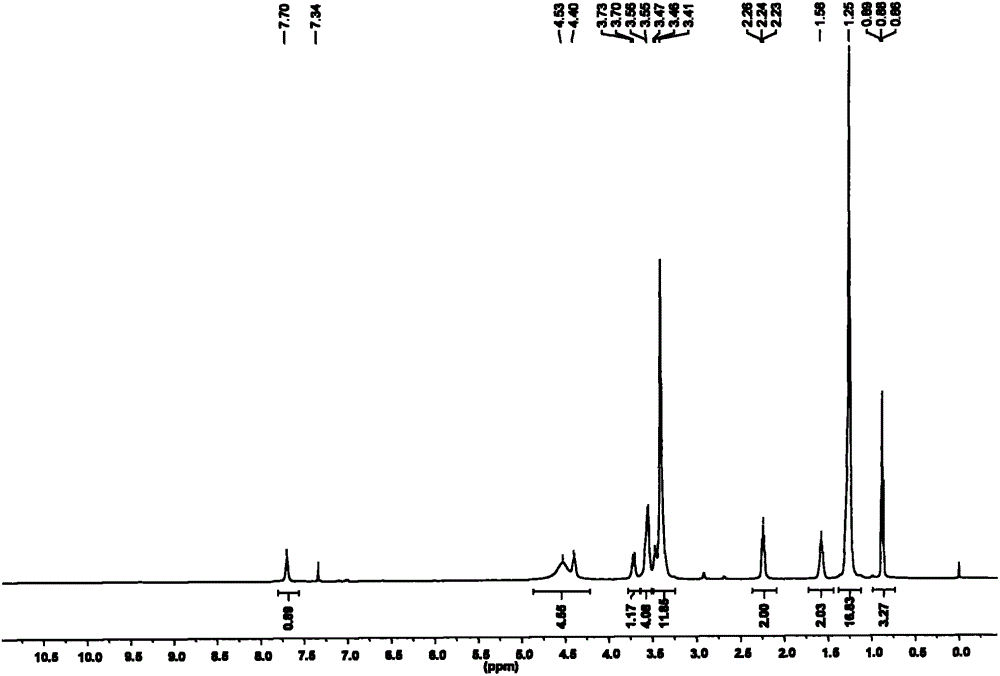

Image

Examples

Embodiment 1

[0023] Embodiment 1: 24.3g (0.1mol) lauric acid monoethanolamide, mass percent concentration are 60% sodium hydroxide solution 20g (0.3mol) and 700mL benzene drop into to be equipped with agitator, reflux condenser and constant pressure drop Add 2.6g (0.008mol) tetrabutylammonium bromide to the three-necked flask with liquid funnel and heat to dissolve. After stirring for a period of time, add 63mL (0.8mol) epichlorohydrin dropwise for 1 hour. After 10 hours of reaction, , transferred to a separatory funnel, washed each time with 300mL of warm water at 60-70°C until neutral, the water phase was extracted three times with 100mL of benzene, the organic phase was combined, and the solvent and unreacted epichlorohydrin were removed to obtain a light yellow wax Solid, the obtained solid and 10.5g (0.11mol) of trimethylamine hydrochloride were dissolved in 75mL of 95% (V / V) ethanol, after reacting at 30°C for 2 hours, the solvent was removed, and acetone recrystallized three times to...

Embodiment 2

[0024] Embodiment 2: 24.3g (0.1mol) lauric acid monoethanolamide, concentration are 60% sodium hydroxide solution 20g (0.3mol) and 700mL benzene drop into agitator, reflux condenser and constant pressure dropping funnel In a three-necked flask, add 2.6g (0.008mol) tetrabutylammonium bromide and heat to dissolve. After stirring for a period of time, 63mL (0.8mol) epichlorohydrin is added dropwise for 1 hour. After 10 hours of reaction, transfer to a separatory funnel, wash with 300mL hot water at 60-70°C each time until neutral, extract the aqueous phase with 100mL benzene three times, combine the organic phases, remove the solvent and unreacted epichlorohydrin to obtain a light yellow waxy solid , the gained solid and 15.1g (0.11mol) triethylamine hydrochloride were dissolved in 75mL95% ethanol, after reacting for 3 hours at 40°C, the solvent was removed, acetone recrystallized three times to obtain 33.6g cationic surfactant 3-( 2-dodecylaminoethoxy)-2-hydroxypropyltriethylamm...

Embodiment 3

[0025] Embodiment 3: 30.0g (0.1mol) palmitic acid monoethanolamide, concentration are 60% potassium hydroxide solution 28g (0.3mol) and 700mL benzene are dropped into and are equipped with agitator, reflux condenser and constant pressure dripping In the three-necked flask with a funnel, add 1.8g (0.008mol) tetrabutylammonium bromide and heat to dissolve. After stirring for a period of time, 78.4mL (1mol) epichlorohydrin is added dropwise for 1 hour. After 12 hours of reaction, Transfer to a separatory funnel, wash with 300mL of warm water at 60-70°C each time until neutral, extract the aqueous phase with 100mL of benzene three times, combine the organic phases, remove the solvent and unreacted epichlorohydrin to obtain a light yellow waxy solid , the obtained solid and 10.5g (0.11mol) trimethylamine hydrochloride were dissolved in 75mL95% ethanol, after reacting at 30°C for 2 hours, the solvent was removed, and acetone recrystallized three times to obtain 35.2g cationic surfact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com