High-strength and high-damping Ti3Sn/TiNi memory alloy composite material

A composite material and memory alloy technology, which is applied in the field of high-strength and high-damping Ti3Sn/TiNi memory alloy composite materials and memory alloy composite materials, can solve the problems of limited use and low strength of high-damping materials, and achieve high interface bonding strength, The effect of excellent damping performance, excellent strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Ti provided by the present invention 3 The preparation method of Sn / TiNi memory alloy composite material can comprise the following specific steps:

[0039] (1), press Ti 3 The composition ratio of Sn / TiNi memory alloy composite material is selected from tin with a purity of more than 99wt.% (preferably 99.9wt.%), titanium with a purity of more than 99wt.% (preferably 99.9wt.%), and a purity of 99wt.%. Nickel above (preferably 99.9wt.%);

[0040] (2), put the above-mentioned composite material composition into the smelting furnace, and smelt to obtain Ti 3 Sn / TiNi memory alloy composite material, and casting it into ingot;

[0041] (3) In a vacuum furnace, the ingot is subjected to homogenization annealing at 800-1050°C (preferably 950°C) for 5-60h (preferably 10h);

[0042] (4) Cold-rolling the annealed ingot, and annealing at 800-1050° C. (preferably 950° C.) several times in the middle to obtain a plate.

Embodiment 1

[0043] Example 1Ti 57 Ni 35 sn 8 memory alloy composite

[0044] This embodiment provides a Ti 57 Ni 35 sn 8 Memory alloy composite material, which is prepared through the following steps:

[0045] (1), by Sn content 8at.%, Ti and Ni atomic ratio 57: 35 proportioning selects the tin that purity is 99.9wt.%, the titanium that purity is 99.9wt.% and the nickel that purity is 99.9wt.%, Wherein, the sum of the atomic percentages of Sn, Ti and Ni is 100%;

[0046] (2), put the above alloy components into a vacuum melting furnace, and melt them into ingots under the protection of argon at -0.5MPa;

[0047] (3) In a vacuum furnace, the smelted ingot is subjected to homogenization annealing at 950° C. for 10 hours;

[0048] (4) The annealed ingot is cold-rolled, and annealed at 950°C for multiple times in the middle to obtain a plate, that is, Ti 57 Ni 35 sn 8 Memory alloy composite material.

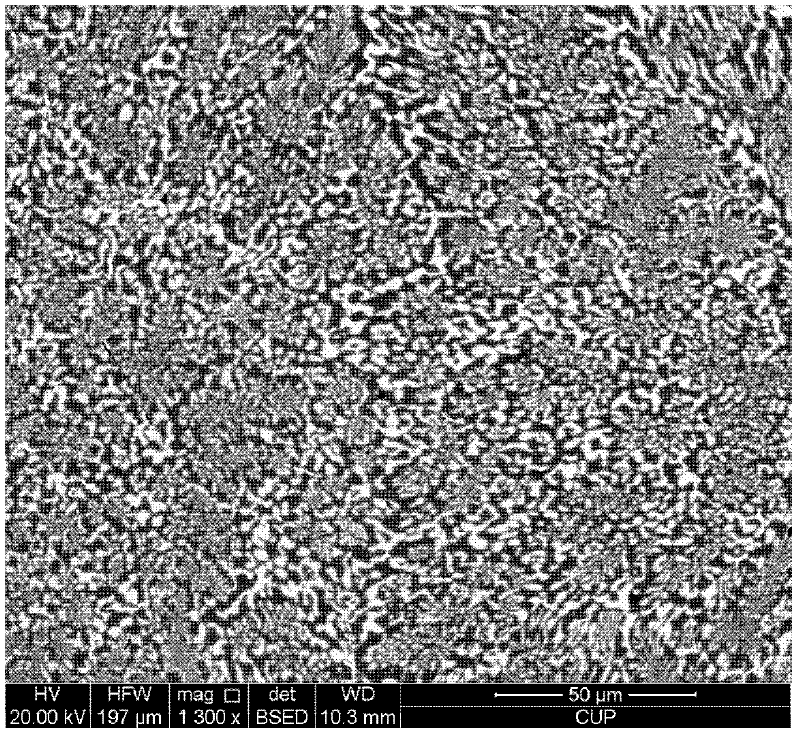

[0049] From the homogenized annealed ingot that obtains in step (3), cut off th...

Embodiment 2

[0055] Example 2Ti 69 Ni 11 sn 20 memory alloy composite

[0056] This embodiment provides a Ti 69 Ni 11 sn 20 Memory alloy composite material, which is prepared through the following steps:

[0057] (1), by Sn content 20at.%, Ti and Ni atomic ratio 69: 11 proportioning selects the tin that purity is 99.9wt.%, the titanium that purity is 99.9wt.% and the nickel that purity is 99.9wt.%, Wherein, the sum of the atomic percentages of Sn, Ti and Ni is 100%;

[0058] (2), put the above alloy components into a smelting furnace, melt and cast them into ingots under the protection of argon at -0.5MPa;

[0059](3) In a vacuum furnace, the ingot is subjected to homogenization annealing at 950°C for 10 hours to obtain Ti 69 Ni 11 sn 20 Memory alloy composite material.

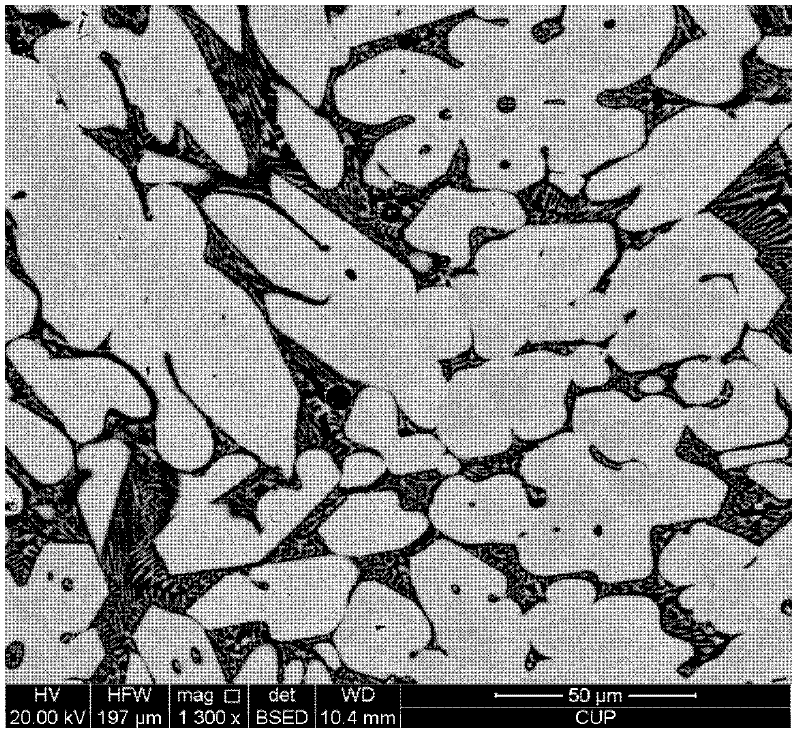

[0060] From the homogenized annealed ingot that obtains in step (3), cut off the sheet of 2mm thick, 20mm long, 10mm wide, observe its microstructure with scanning electron microscope, its microstructure is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com