Thermochemistry mechanical polishing method of sapphire substrate material and polishing solution

A sapphire substrate and mechanical polishing technology, which is applied to polishing compositions containing abrasives, grinding machine tools, grinding devices, etc., can solve the problems of low polishing efficiency, complicated polishing process, and reduced processing efficiency, and achieve improved polishing rate, High quality, guaranteed uniform results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The invention discloses a polishing fluid for thermochemical mechanical polishing of sapphire substrate materials, which is composed of composite abrasives, ph composite regulators, surfactants, dispersants and deionized water.

[0046] The configuration of the polishing liquid: take 200g of silica sol with a particle size of 300nm, 5ml of polyethylene glycol ether and 3ml of polyethylene glycol 200, mix them and dilute them to 1000ml with deionized water to form an abrasive suspension, and then take a particle size of 100nm 50g of diamond powder, the diamond powder is slowly added to the above-mentioned abrasive suspension and stirred rapidly until uniform. A mixture of organic strong base tetramethylammonium hydroxide and organic weak base dihydroxyethylethylenediamine is used as the pH regulator (volume ratio 4:1), and the pH value is adjusted to 8.

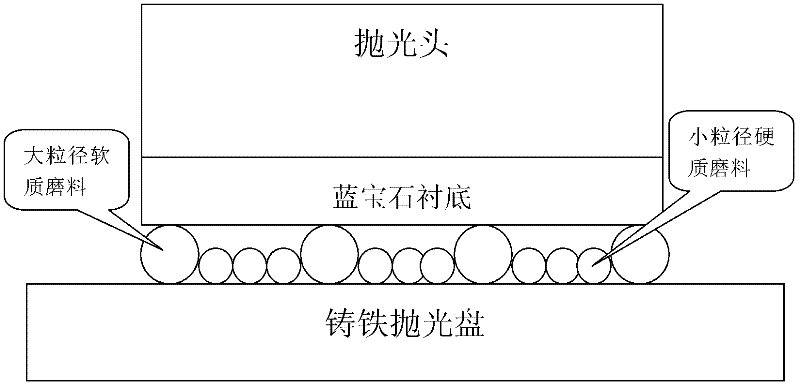

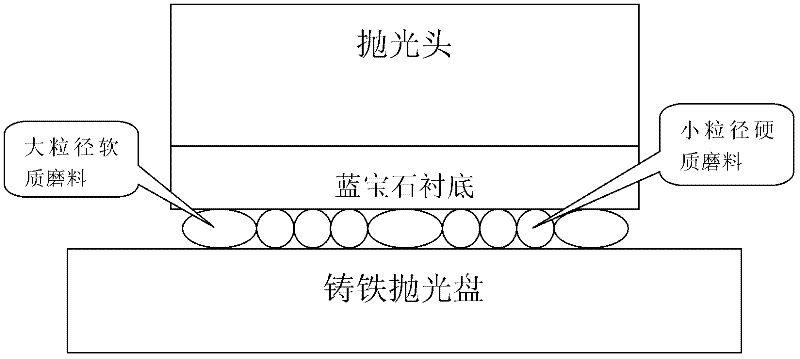

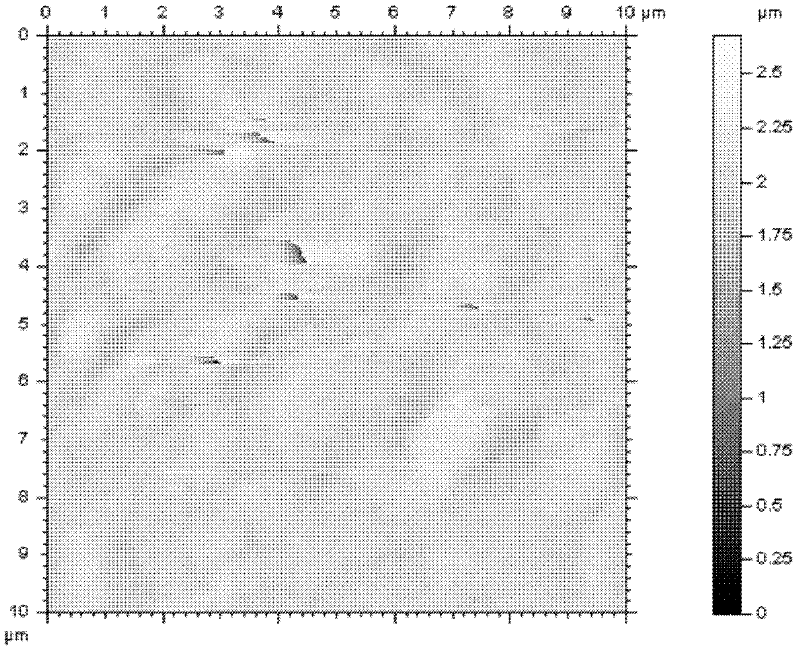

[0047] Realization of polishing process: use UNIPOL-1260-TCMP single-sided polishing machine for polishing, the polis...

Embodiment 2

[0051] The invention discloses a polishing fluid for thermochemical mechanical polishing of sapphire substrate materials, which is composed of composite abrasives, ph composite regulators, surfactants, dispersants and deionized water.

[0052] The configuration of the polishing liquid: take 200g of silica sol with a particle size of 200nm, 3ml of dodecyl glycol ether and 4ml of polyethylene glycol 400, mix them and dilute to 1000ml with deionized water to form an abrasive suspension, and then take 70g of diamond powder with a particle size of 80nm was slowly added to the above-mentioned abrasive suspension and stirred rapidly until uniform. The mixture of strong organic base hydroxylamine and organic weak base dihydroxyethylethylenediamine is selected as the pH value regulator (volume ratio is 4:1), and the pH value is adjusted to 9.

[0053] Realization of polishing process: use UNIPOL-1260-TCMP single-sided polishing machine for polishing, the polishing disc is cast iron dis...

Embodiment 3

[0057] The invention discloses a polishing fluid for thermochemical mechanical polishing of sapphire substrate materials, which is composed of composite abrasives, ph composite regulators, surfactants, dispersants and deionized water.

[0058] The configuration of the polishing liquid: take 200g of cerium oxide and zirconia mixture with a particle size of 200nm, 2ml of silane polyglycol ether and 3ml of polyethylene glycol 200, mix them and dissolve them with deionized water to 1000ml to form an abrasive suspension, and then take Diamond powder and corundum powder with a particle size of 100nm totaled 50g, and the mixture of diamond powder and corundum powder was slowly added to the aforementioned abrasive suspension and stirred rapidly until uniform. A mixture of organic strong base tetramethylammonium hydroxide and organic weak base diethylenetriamine is selected as the pH regulator (volume ratio is 5:1), and the pH value is adjusted to 10.

[0059] Realization of polishing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com