2-(2,3-dimethyl phenyl) diester malonate, preparation method thereof, and application thereof

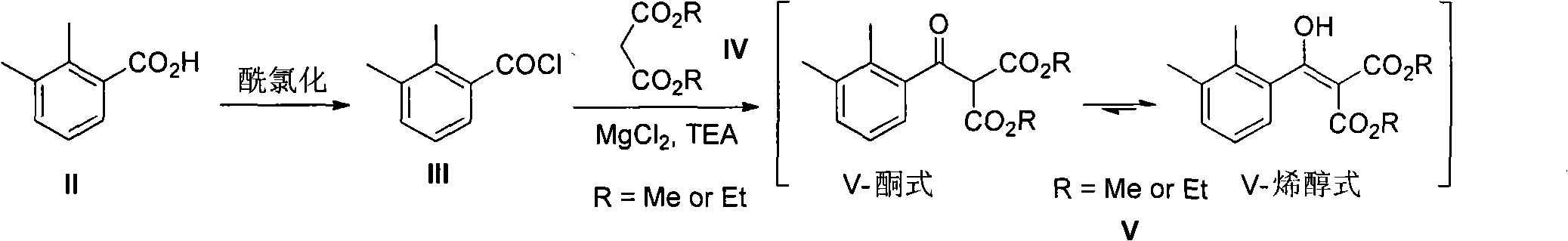

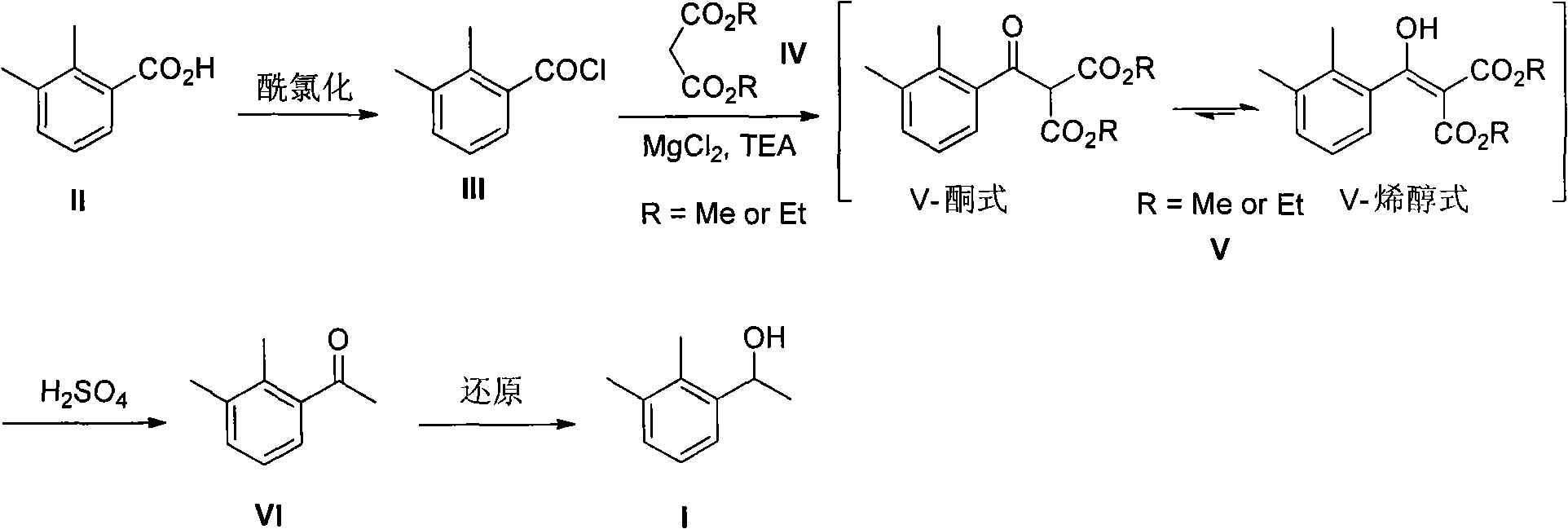

A technology of dimethylphenyl and malonic acid diester is applied in the field of preparation of dexmedetomidine hydrochloride intermediate 1-ethanol, and can solve the problems of harsh reaction conditions, inflammable and explosive, inconvenient operation and the like, and achieves the Mild conditions, easy to scale production, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve II (8.25g) in 80mL of dichloromethane, add 8.90g of thionyl chloride, drop a few drops of DMF to initiate the reaction, stir at room temperature overnight, evaporate the solvent to obtain acid chloride III; 11.71g of diethyl malonate , 14.73g of triethylamine and 3.50g of anhydrous magnesium chloride were put into 70mL of ethyl acetate and stirred at room temperature for 45 minutes. After cooling slightly to 10°C, the above-prepared acid chloride III was slowly added dropwise to the system. Stir for 50 minutes to end the reaction, wash with 10% dilute hydrochloric acid, saturated sodium bicarbonate, and saturated brine successively, dry the organic layer through anhydrous magnesium sulfate, and obtain 18.60 g of the crude product of V after removing the solvent; in order to obtain the analysis of V With the sample, 3.40g of it was purified by silica gel column chromatography (eluent: petroleum ether: ethyl acetate = 20:1) to obtain 2.81g of pure V, which was a c...

Embodiment 2

[0022] Dissolve II (8.25g) in 80mL of dichloromethane, add 10.20g of thionyl chloride, drop a few drops of DMF to initiate the reaction, stir at room temperature overnight, evaporate the solvent to obtain acid chloride III; add 9.64g of dimethyl malonate , 14.73g of triethylamine and 3.50g of anhydrous magnesium chloride were put into 70mL of ethyl acetate and stirred at room temperature for 45 minutes. After cooling slightly to 10°C, the above-prepared acid chloride III was slowly added dropwise to the system. Stir for 50 minutes to end the reaction, wash with 10% dilute hydrochloric acid, saturated sodium bicarbonate, and saturated brine successively, dry the organic layer through anhydrous magnesium sulfate, and obtain 15.46 g of the crude product of V after removing the solvent; in order to obtain the analysis of V With the sample, 3.0 g of it was purified by silica gel column chromatography (eluent: petroleum ether: ethyl acetate = 20: 1) to obtain 2.63 g of pure V, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com