Ordered double porosity Al203-TiO2 and preparation method thereof and application thereof

An al2o3-tio2, double-porous technology, applied in chemical instruments and methods, treatment of hydrocarbon oil, metal/metal oxide/metal hydroxide catalysts, etc. It is difficult to control the pore size of macropores and mesopores, so as to achieve the effects of easy large-scale industrial production, mitigation of diffusion effects, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The sulfuric acid solution was added to deionized water to prepare 50 ml of an acid solution with a pH of 1. Take 2 grams of a mixture of aluminum sec-butoxide and n-butyl titanate (after ultrasonic pretreatment, the molar ratio of aluminum source and titanium source is 9:1) and add it to the above acid solution, stir and hydrolyze it at room temperature for 3 hours, stir The speed is 500 rpm. The precipitate was washed, centrifuged, dried at 40°C for 12 hours, and then calcined at 200°C for 3 hours to obtain the product.

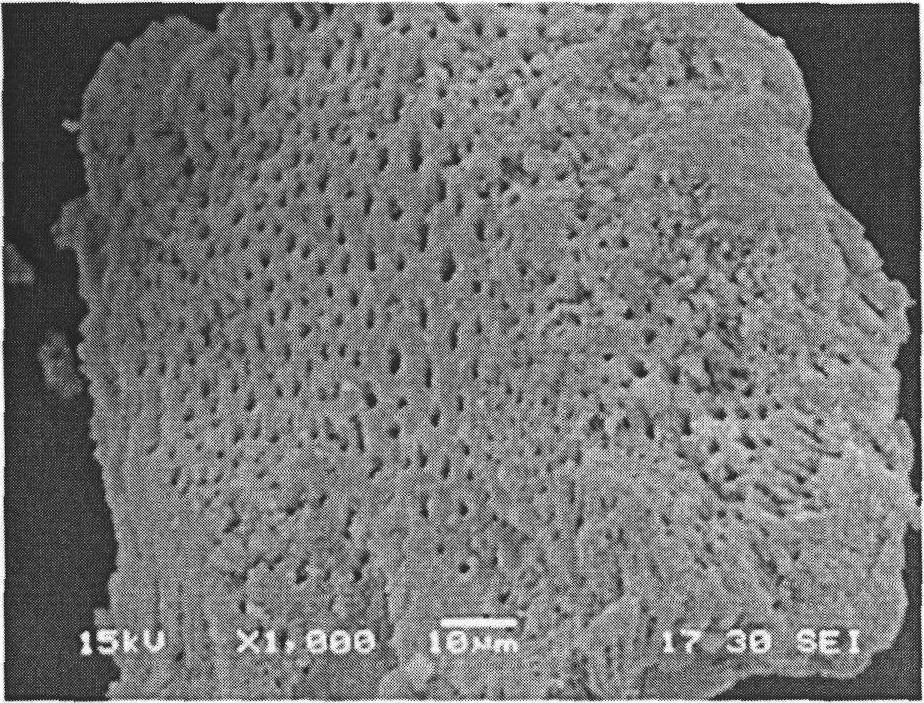

[0042] figure 1 The scanning electron microscope photo of the uncalcined particle morphology is given. All the macropores are parallel to each other and distributed in an orderly manner, while the walls of the macropores are formed by the aggregation of fine particles. The gaps between these particles and the gaps inside the particles constitute the mesoporous channel. figure 2 It is Al calcined at 200°C 2 o 3 -TiO 2 The scanning electron micr...

Embodiment 2

[0044] Mix 35 milliliters of ethanol and 15 milliliters of deionized water to prepare an alcoholic aqueous solution, then add sodium hydroxide solution to the alcoholic aqueous solution to prepare 50 ml of an alkali solution with a pH of about 10. Take 4 grams of a mixture of aluminum isopropoxide and n-propyl titanate (after stirring pretreatment, the molar ratio of aluminum source and titanium source is 7:3) and add it to the above alkaline solution, stir and hydrolyze it at 5°C for 5 hours, The stirring rate was 200 rpm. The precipitate was washed, centrifuged, dried at 20°C for 24 hours, and then calcined at 400°C for 4 hours to obtain the product.

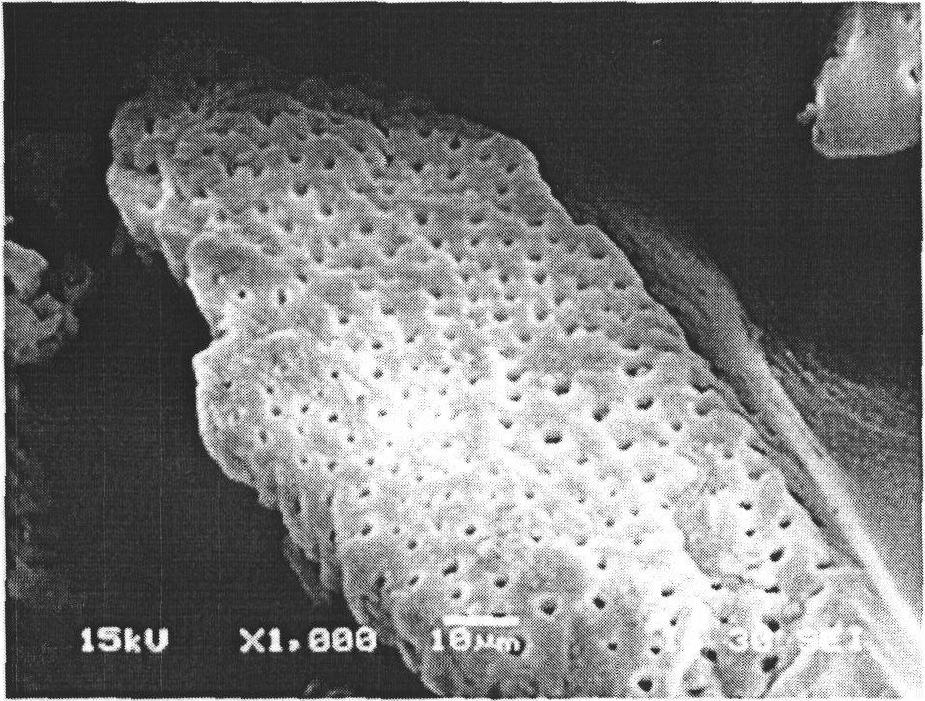

[0045] image 3 Provide the scanning electron micrograph of the particle morphology without roasting treatment, its morphology and the prepared particle morphology of embodiment 1 ( figure 1 )very similar. Figure 4 It is Al calcined at 400°C 2 o 3 -TiO 2 The scanning electron micrograph of the composite oxide particles ...

Embodiment 3

[0047] Mix 10ml of n-butanol and 40ml of deionized water to prepare an alcoholic aqueous solution, then add a certain amount of ammonia solution to the alcoholic aqueous solution to prepare 50ml of an alkaline solution with a pH of about 13, and add 5 grams of Brij56 to the above in solution. After Brij56 is dissolved, add 4 g of a mixture of aluminum isopropoxide and ethyl titanate (after ultrasonic pretreatment, the molar ratio of aluminum source to titanium source is 1:1), stir and hydrolyze at 70°C for 0.5 hours , with a stirring rate of 600 rpm. The precipitate was washed, centrifuged, Soxhlet extracted, dried at 70°C for 8 hours, and roasted at 650°C for 5 hours to obtain the product.

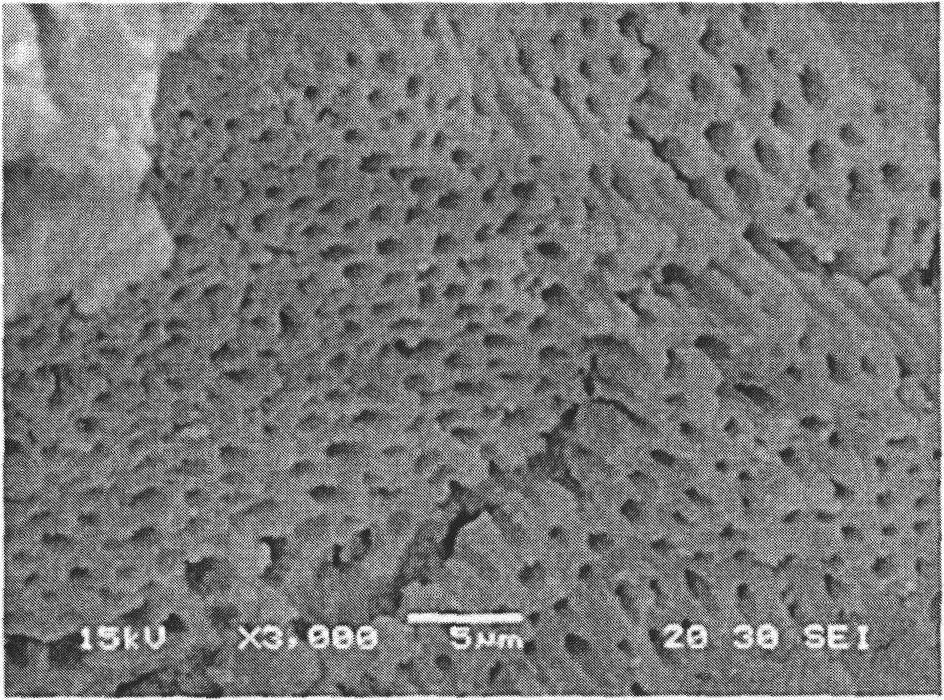

[0048] Figure 5 Provide the scanning electron micrograph of the particle shape that is not processed by roasting, its shape and embodiment 1 ( figure 1 ) and Example 2 ( image 3 ) had similar morphology to the prepared particles. Figure 6 It is Al calcined at 650℃ 2 o 3 -TiO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com