Vibration reduction and sound insulation device

A vibration and sound insulation, steel belt technology, applied in the direction of springs, etc., can solve the problems that the new load affects the safety of the corridor structure and the high cost of closing investment, and achieves the effect of ensuring stable and safe operation, reducing the impact of environmental diffusion, and inhibiting transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0022] In the present invention, in the absence of a contrary statement, the orientation words included in the term, such as "upper, lower, top, bottom", etc., only represent the orientation of the term in the normal use state, or are understood by those skilled in the art colloquial term and should not be construed as a limitation of the term.

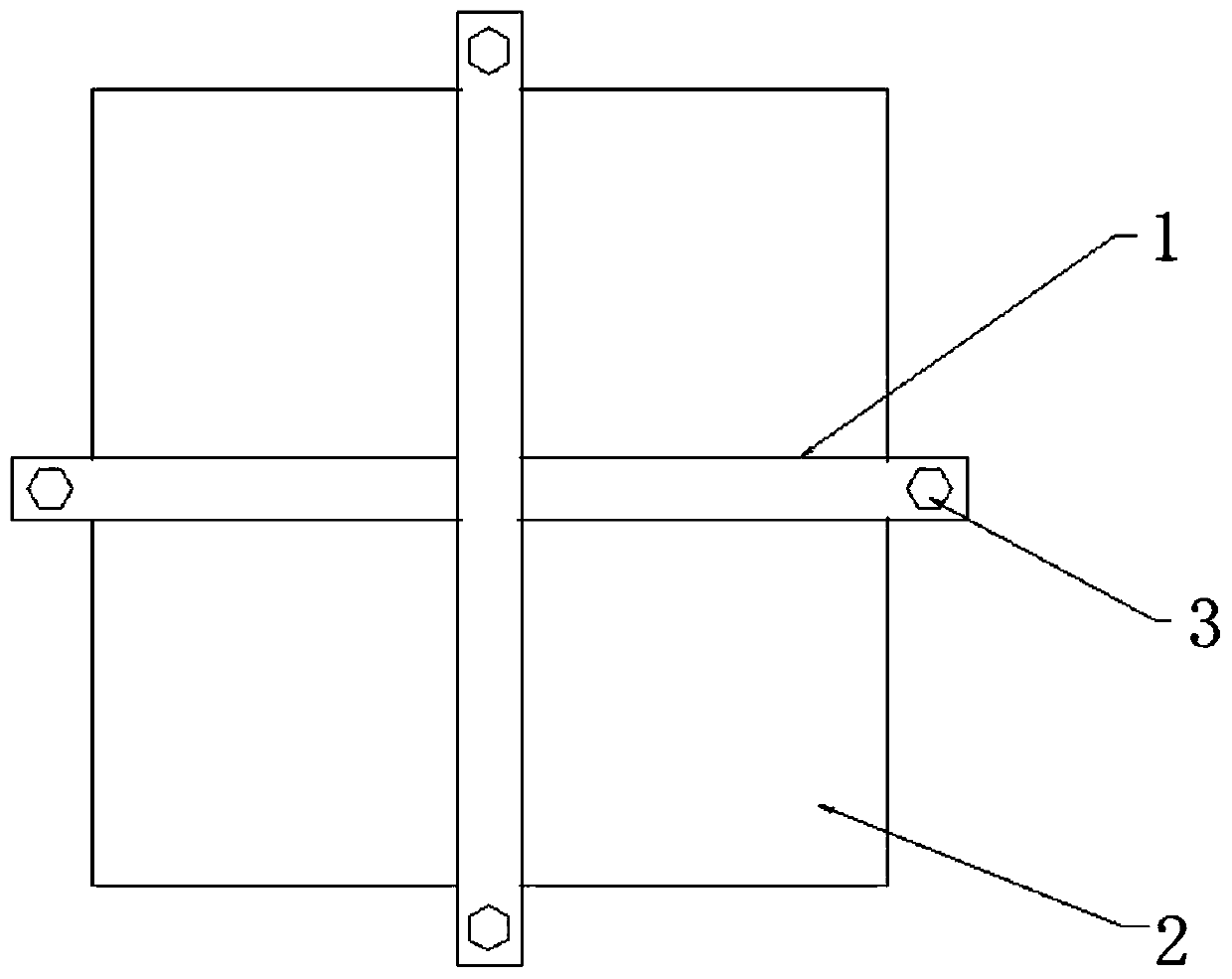

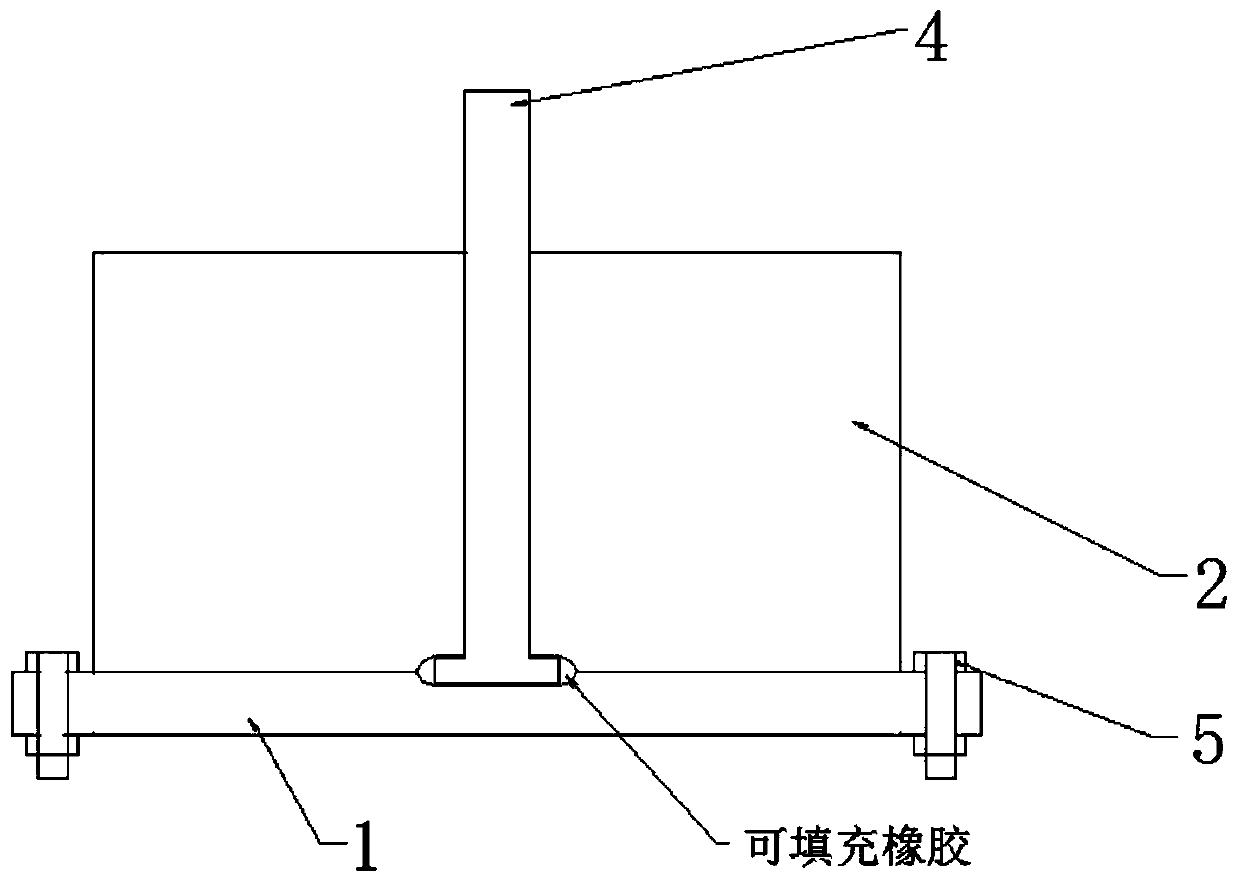

[0023] like figure 1 , figure 2 As shown, the present invention provides a vibration and sound insulation device, including a fixed base, the fixed base at least includes a plurality of horizontal steel belts 1 intersected; rubber blocks 2 arranged above the horizontal steel belts 1, the The rubber block 2 is embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com