Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Solve the problem of small capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

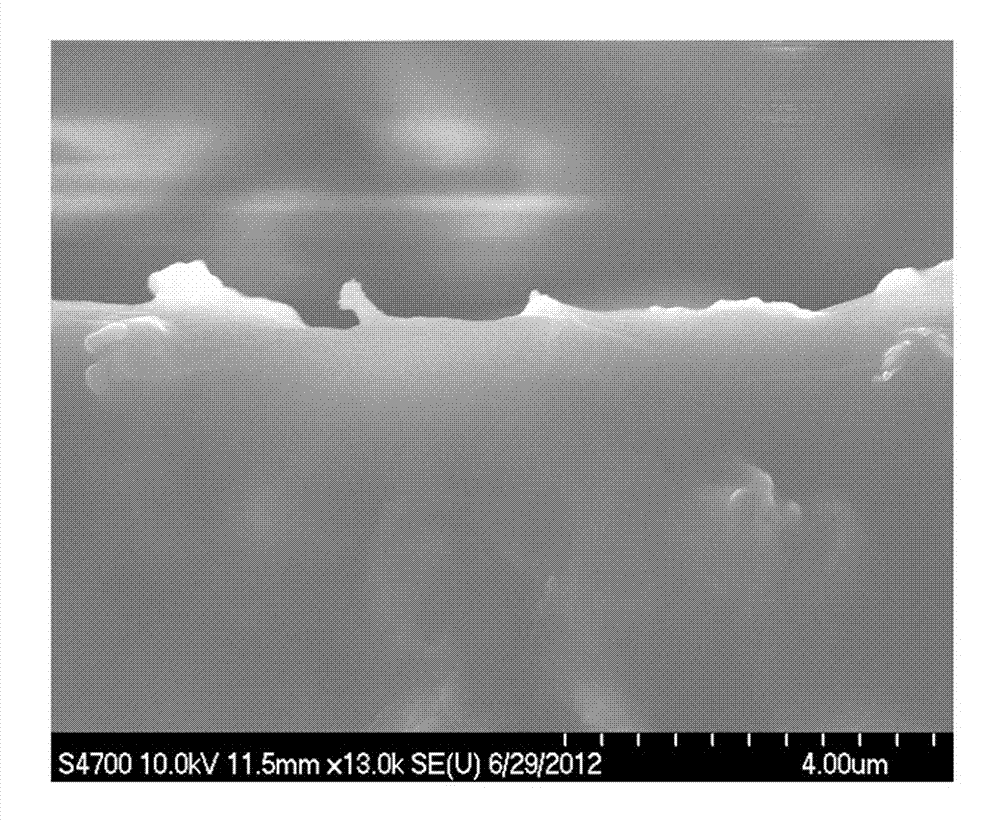

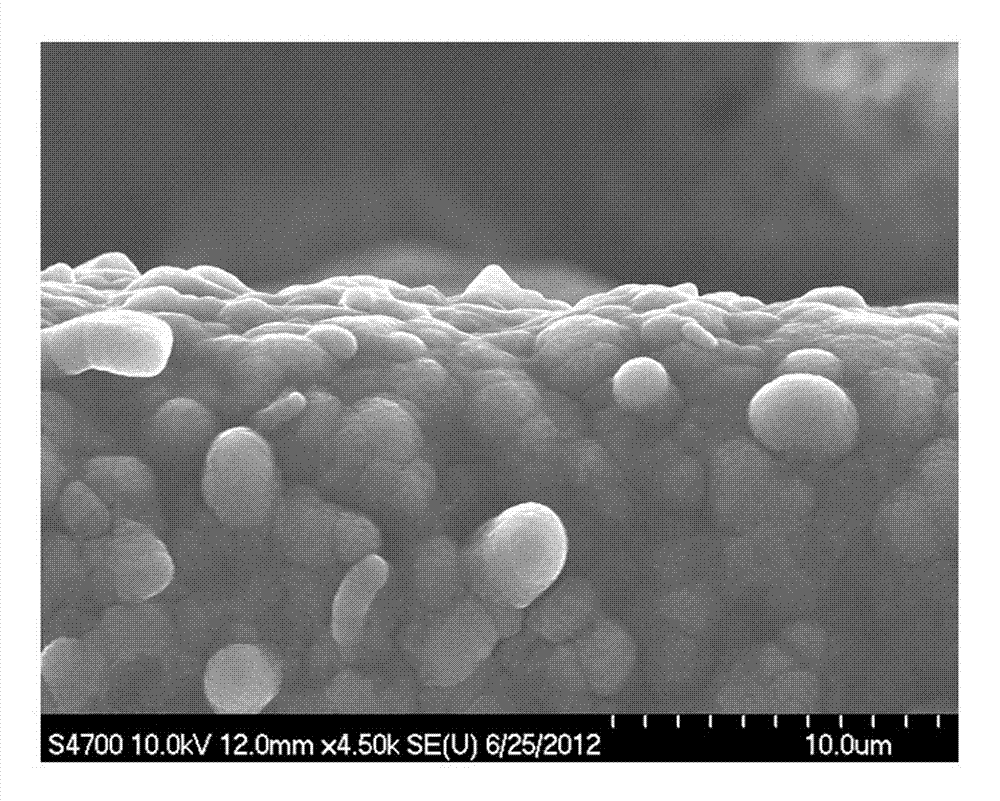

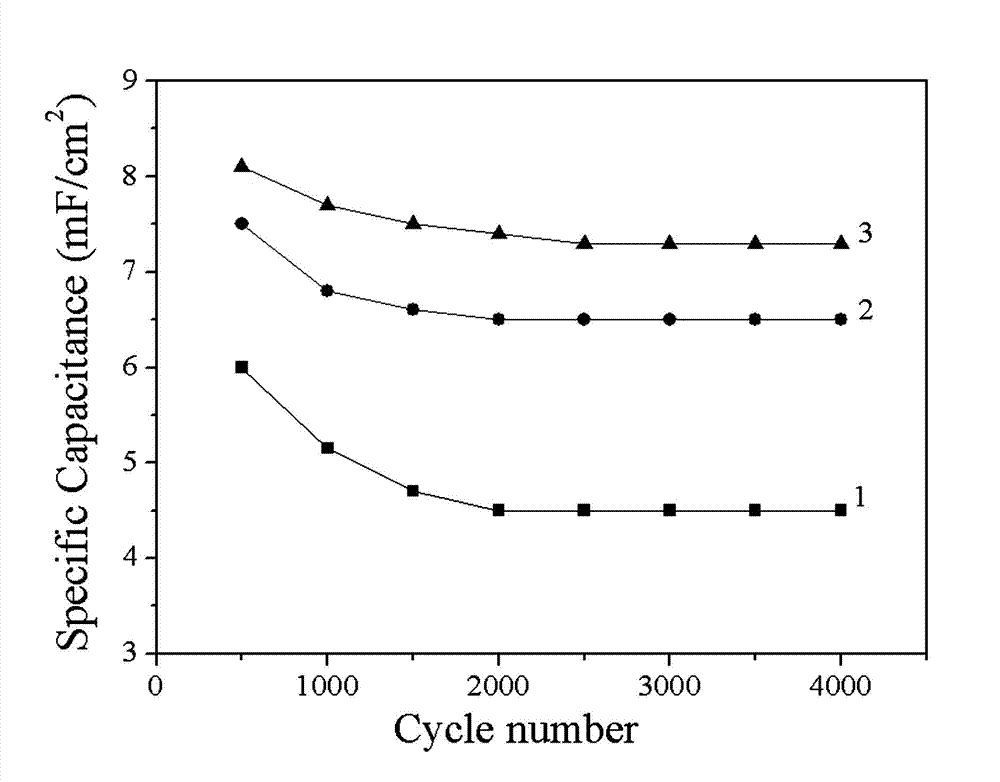

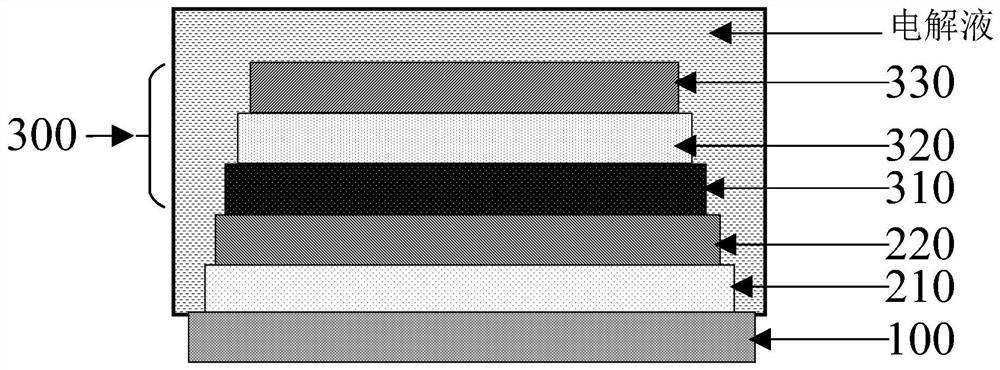

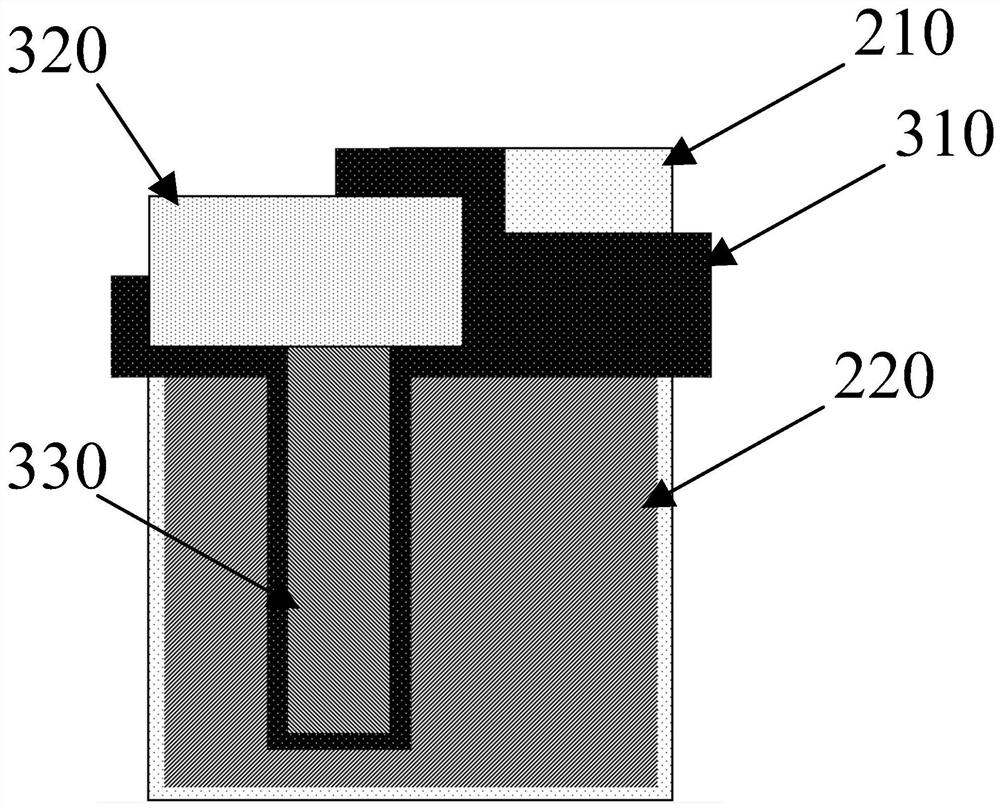

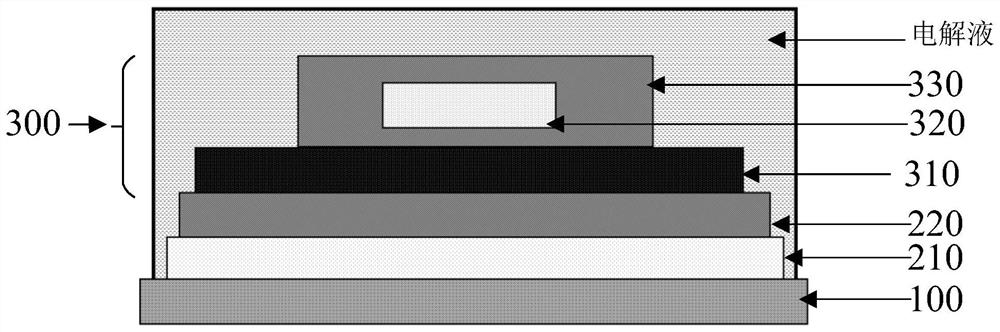

Preparation method of composite membrane electrode materials applied to micro-electromechanical system (MEMS) supercapacitor

InactiveCN103093972ASolve the problem of small capacityFix stability issuesHybrid capacitor electrodesHybrid/EDL manufactureNanotechnologySupercapacitor

The invention relates to the preparation technology of micro-electromechanical system (MEMS) supercapacitors, in particular to a preparation method of composite membrane electrode materials applied to a micro-electromechanical system (MEMS) supercapacitor. The preparation method solves the problems that conducting polymers are small in specific capacity and poor in cycling stability. The method is achieved by the adoption of the following steps that 1) conducting polymer monomers are added to distilled water; then supporting electrolyte is added to the distilled water; and finally electrical conductivity carbon materials are added to the distilled water, so composite solution for electrochemical deposition is manufactured; and 2) a current collector of the MEMS supercapacitor is selected to serve as a working electrode; a platinum sheet is selected to serve as a counter electrode, and a saturated calomel electrode is selected to serve as a reference electrode; and then the working electrode, the counter electrode and the reference electrode are simultaneously placed in the composite solution for the electrochemical deposition to carry out cyclic voltammetry electrochemical polymerization. The preparation method of the composite membrane electrode materials applied to the MEMS supercapacitor is suitable for preparation of the MEMS supercapacitor.

Owner:ZHONGBEI UNIV

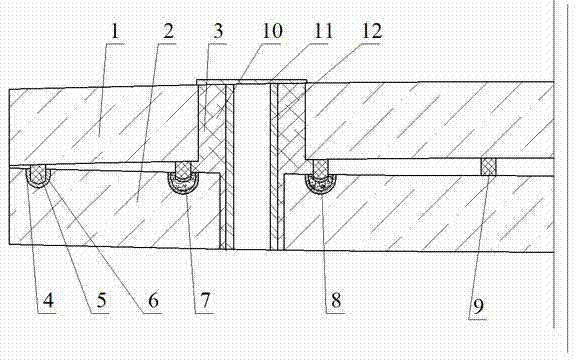

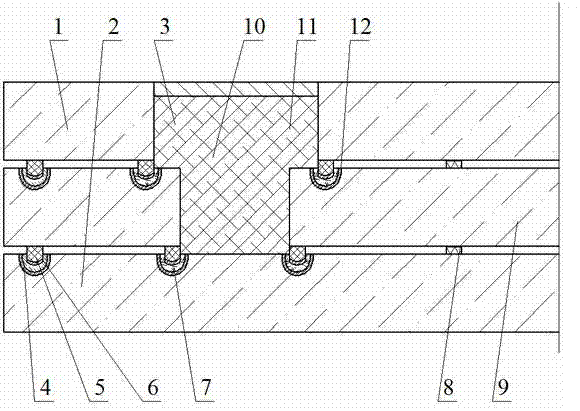

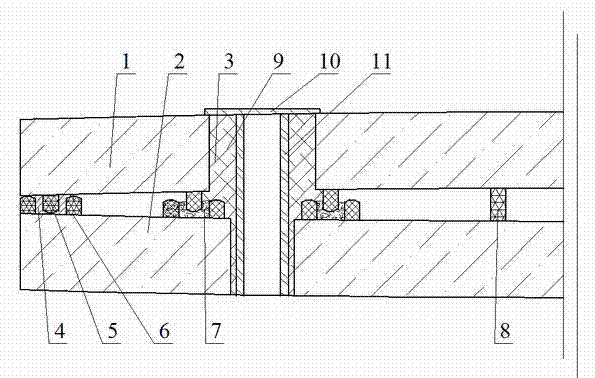

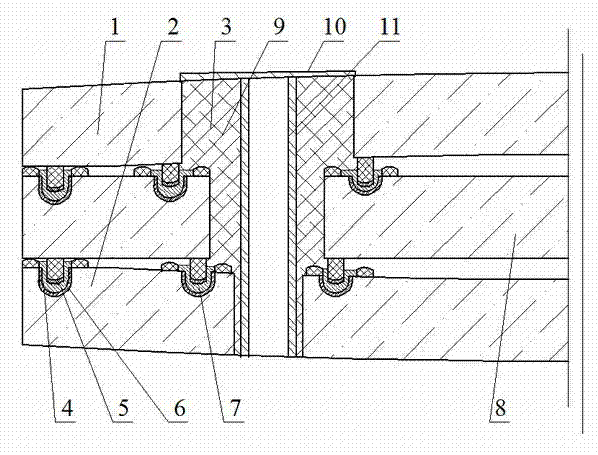

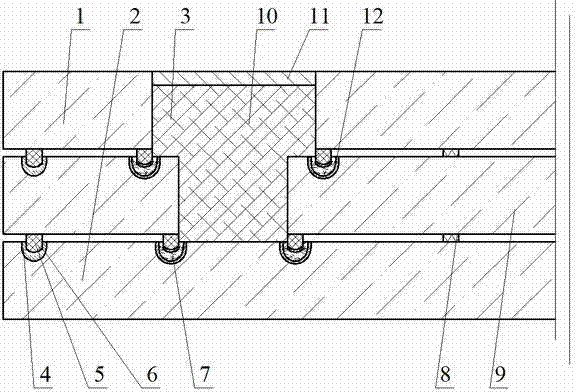

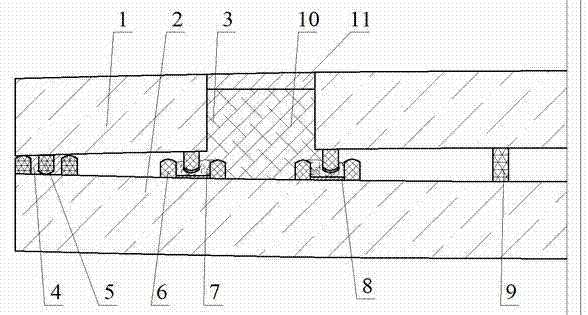

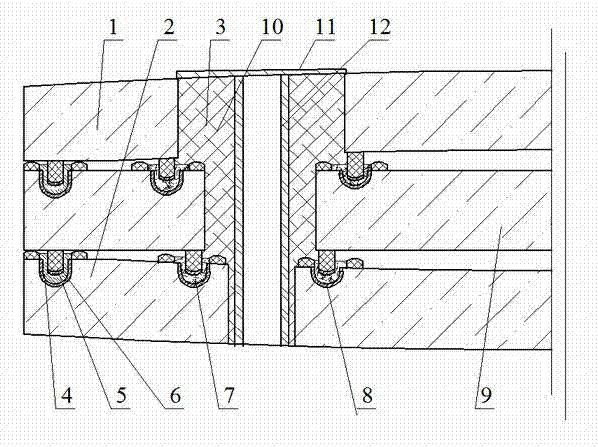

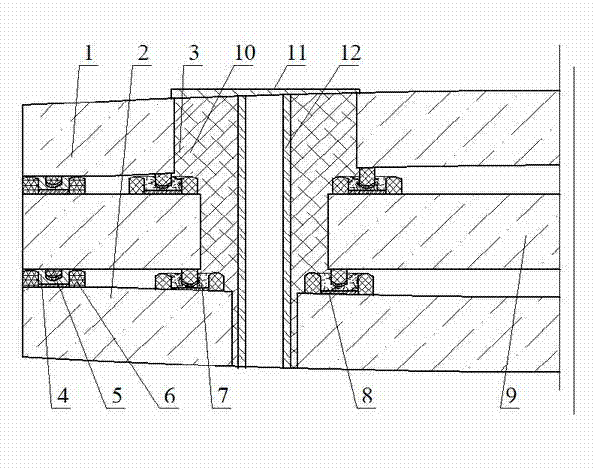

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743825AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

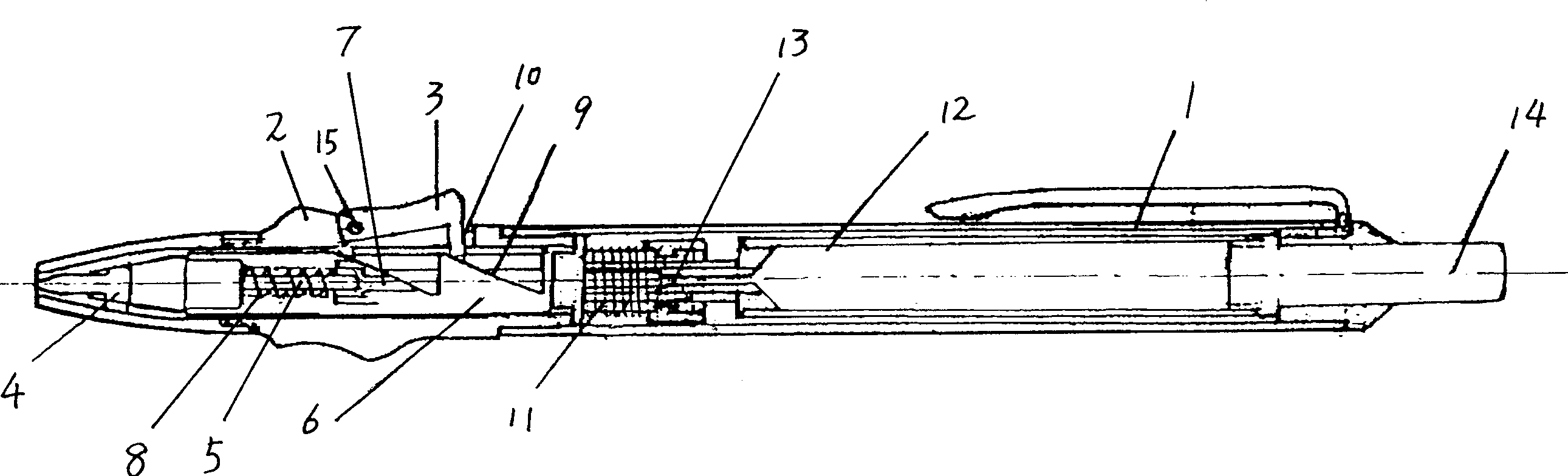

Propelling pencil with multiple pencil leads and posture correcting and positioning function

InactiveCN1693095ASolve the problem of small capacityEasy to use for a long timePropelling pencilsKey pressingEngineering

A propelling pencil with high lead capacity for correcting the error sitting posture of its user is composed of holder with the holding position, locating key, tip end, internal tube behind the tip end, internal guide tube with spring on its rear end, and a lead cavity containing 50 leads.

Owner:宣华牛

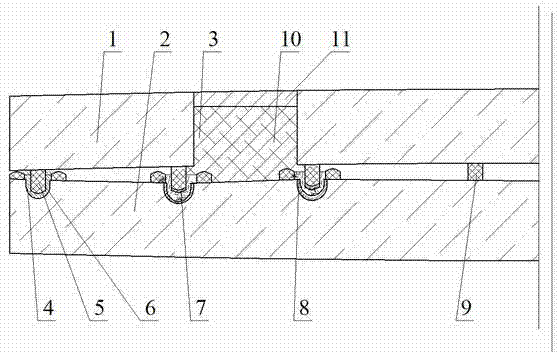

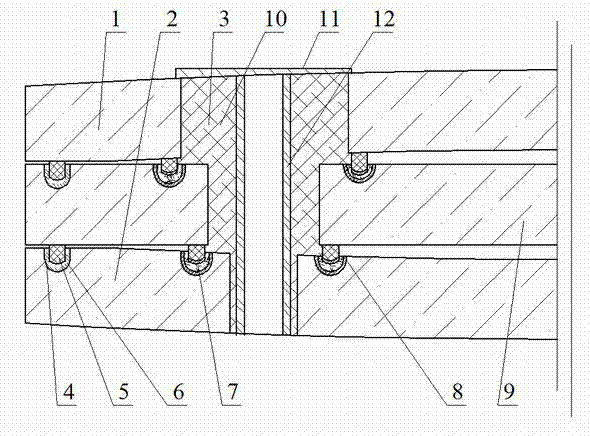

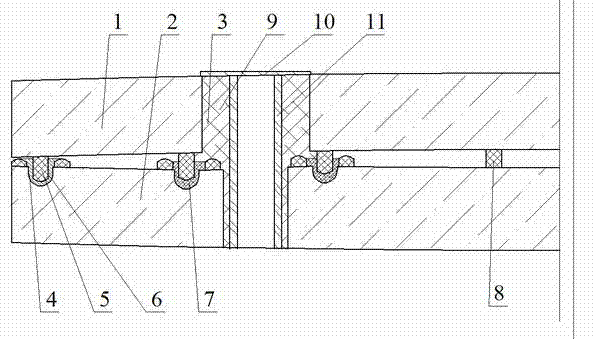

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

InactiveCN104743805AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips. After being heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

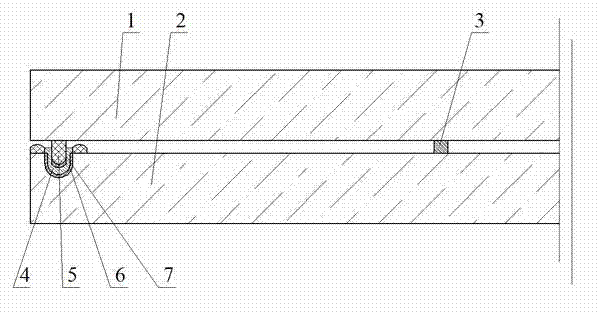

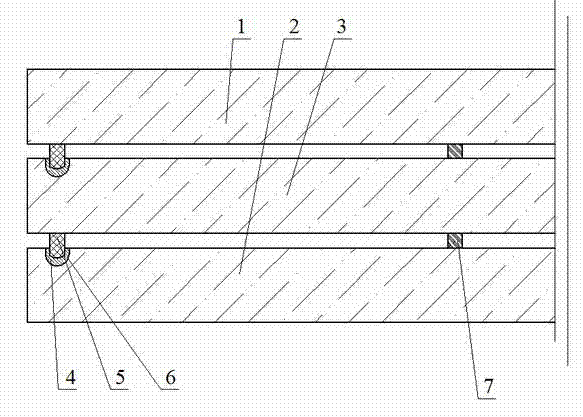

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the periphery of the upper glass is provided with sealing strips; corresponding positions of the periphery of the lower glass are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

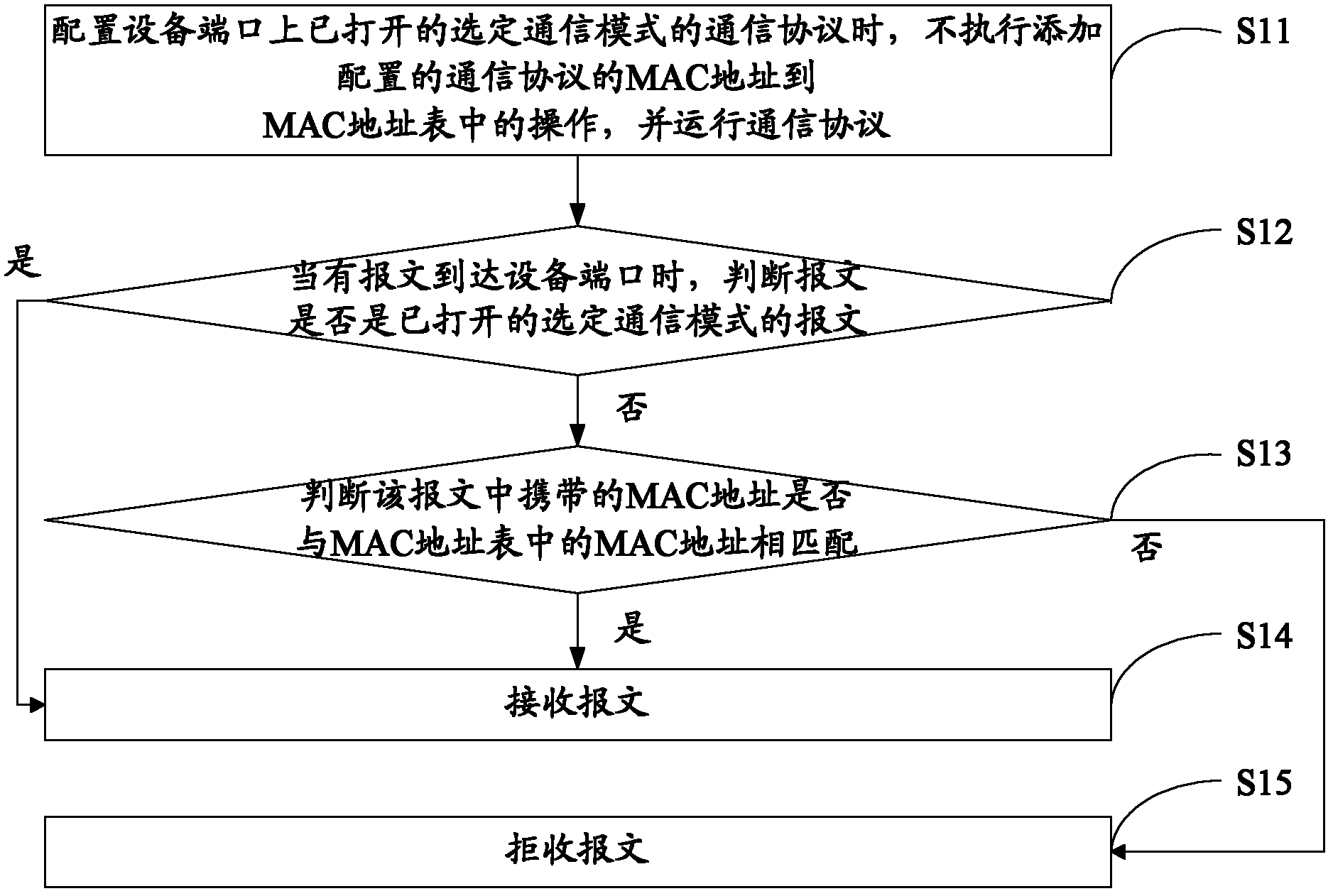

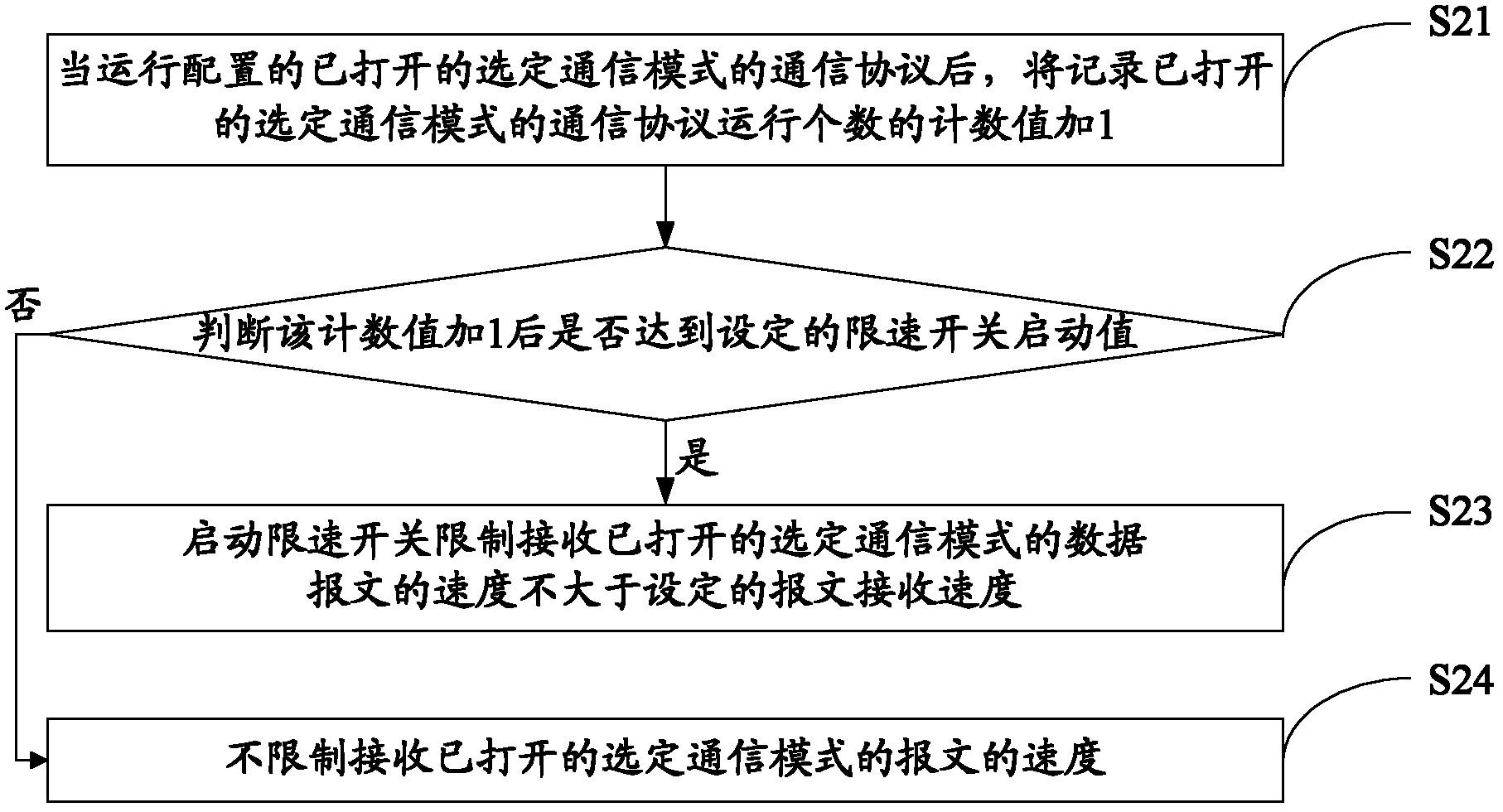

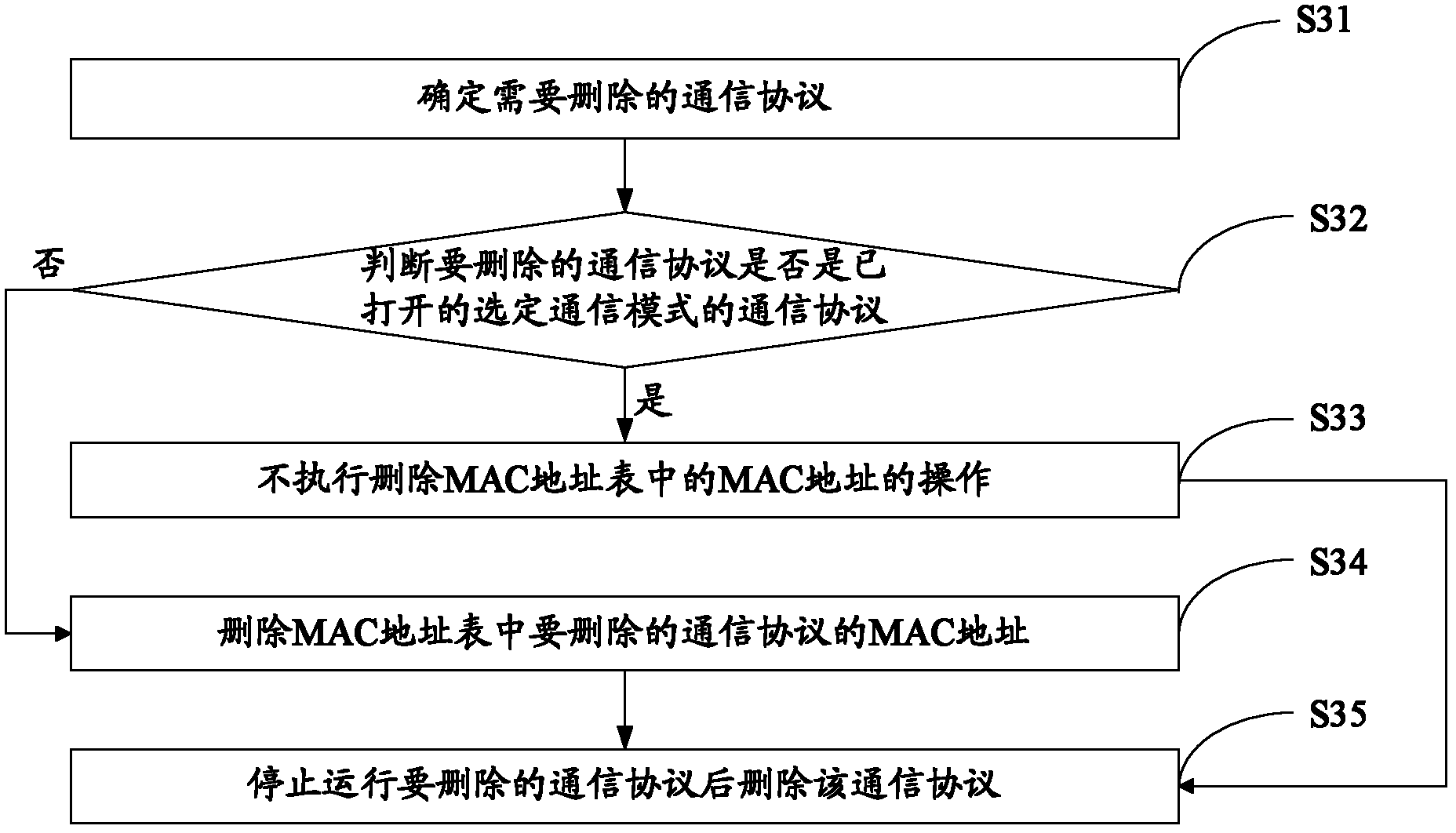

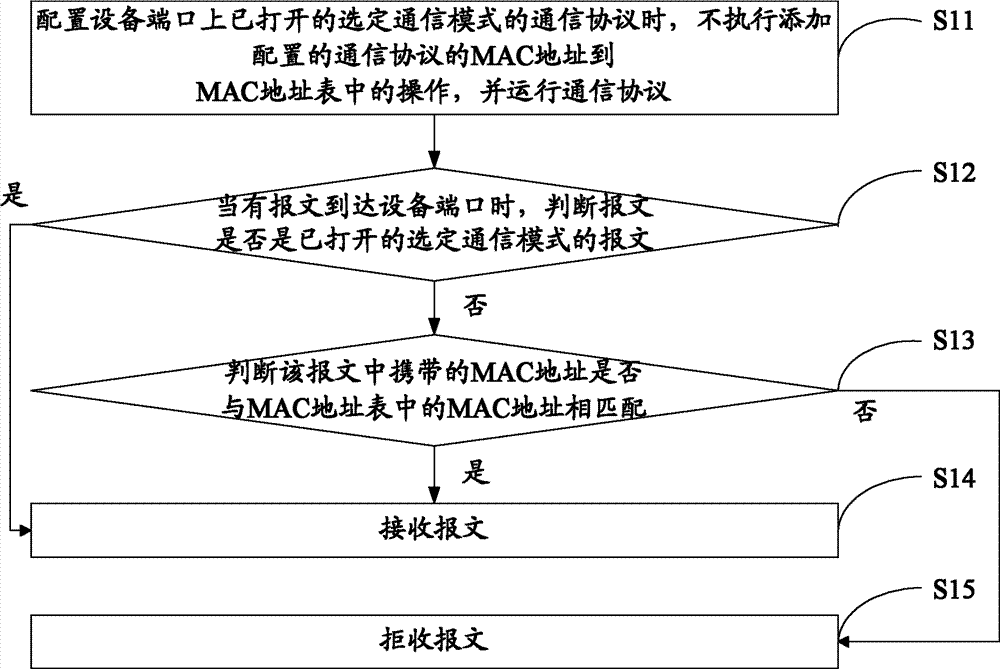

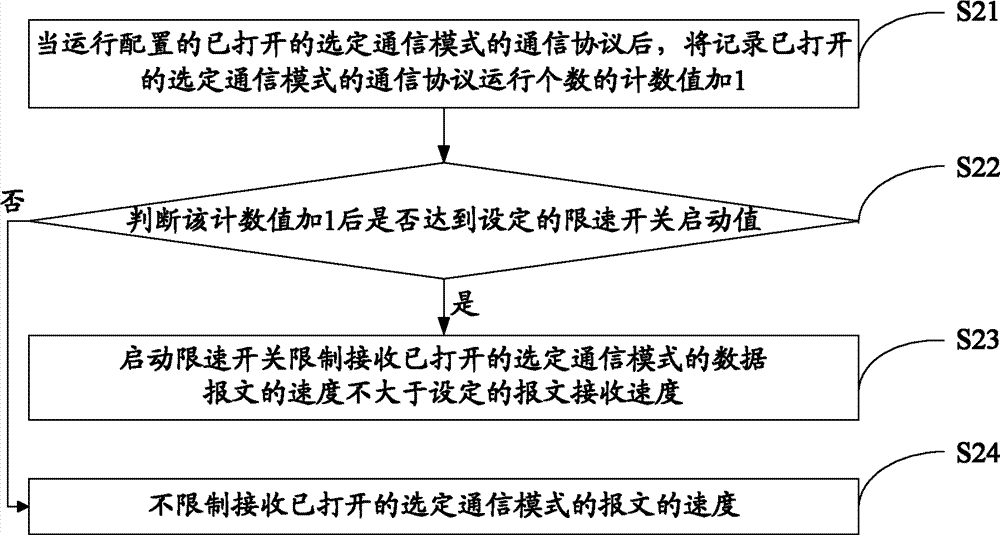

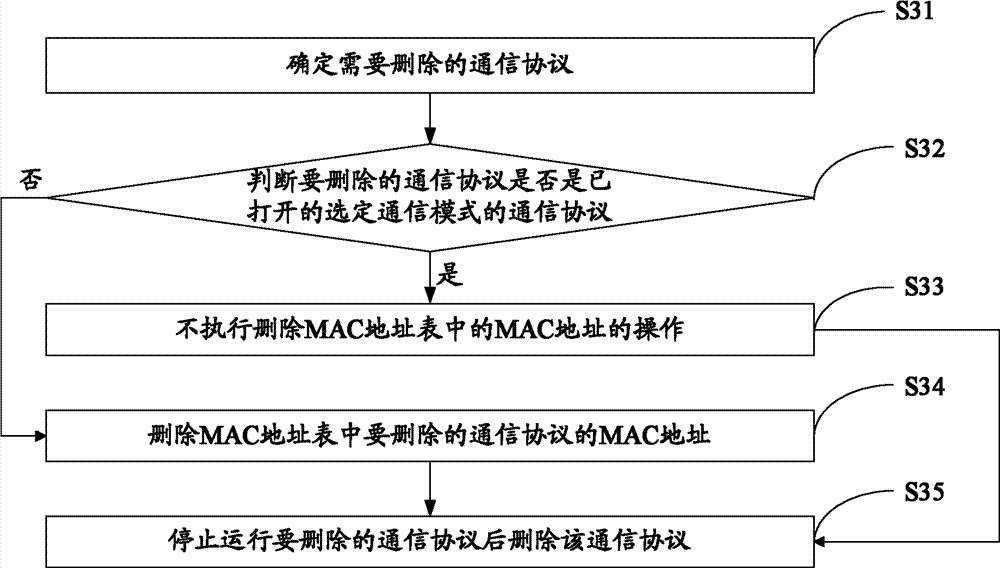

MAC (Media Access Control) address table access control method, as well as apparatus and network device for the same

InactiveCN102355511ASave spaceSolve the problem of small capacityData switching networksComputer hardwareNetwork Communication Protocols

The invention discloses an MAC (Media Access Control) address table access control method, as well as an apparatus and a network device for the same. The method comprises the following steps of: refusing to execute the operation of adding the MAC address of a configured communication protocol to an MAC address table while configuring the communication protocol which is opened already on a device port and has a selected communication mode, and running the communication protocol; and when some messages reach the port, receiving the messages while judging that the messages are opened already and have a selected communication mode. With the method, space in the MAC address table is saved, and the problem of smaller capacity of the MAC address table is solved; and memory occupation ratio is reduced, speed and efficiency of message forwarding are improved and performance of the device is improved.

Owner:RUIJIE NETWORKS CO LTD

Single-sided printed laminated battery and printed battery pack

PendingCN112736308ASolve the problem of small capacityPrinted circuit aspectsCells structural combinationElectrical batteryEngineering

The invention discloses a single-sided printing laminated battery which sequentially comprises a substrate, a lower electrode layer and a unit layer from bottom to top. The unit layer sequentially comprises an insulating layer and an upper electrode layer from bottom to top, the upper electrode layer is electrically connected with an upper tab, and the lower electrode layer is electrically connected with a lower tab; the upper tab and the lower tab are printed on the substrate, and the upper tab and the lower tab are arranged in an insulating manner. According to the single-sided printed laminated battery, the positive electrode and the negative electrode of the single-sided printed laminated battery are laminated and are isolated by the insulating layer, so that the single-sided arrangement of the positive electrode and the negative electrode is realized, the battery can be directly printed on a corresponding substrate to be integrated with an electric appliance, and the connection firmness and the production efficiency of the battery and the electric appliance are guaranteed; in addition, compared with a common coplanar structure battery, the single-sided printed laminated battery provided by the invention has a larger electrode effective active area in a same projection area, so that the theoretical capacity of the battery is larger.

Owner:ZINERGY SHENZHEN LTD

Glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips and production method thereof

InactiveCN104743850AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

The invention relates to a glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips, which comprises an upper glass and a lower glass, 1-4 extraction openings are arranged on the upper glass, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are respectively provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

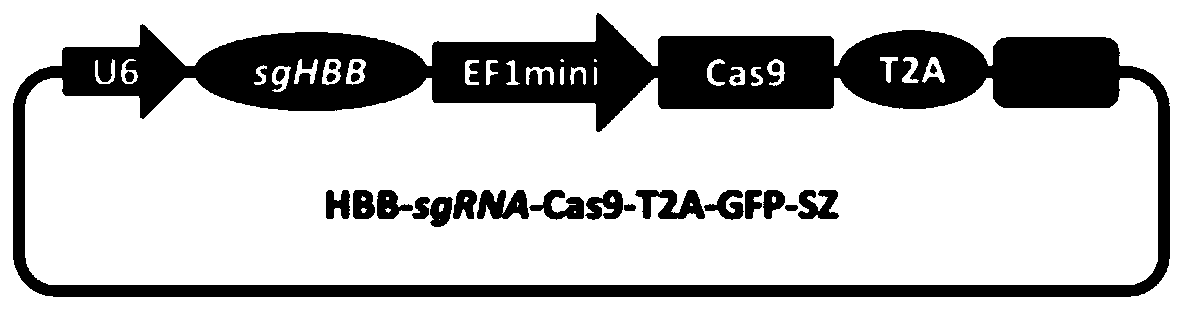

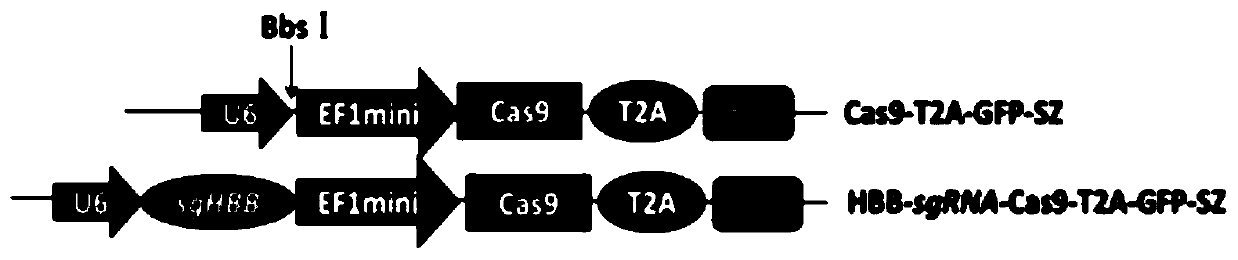

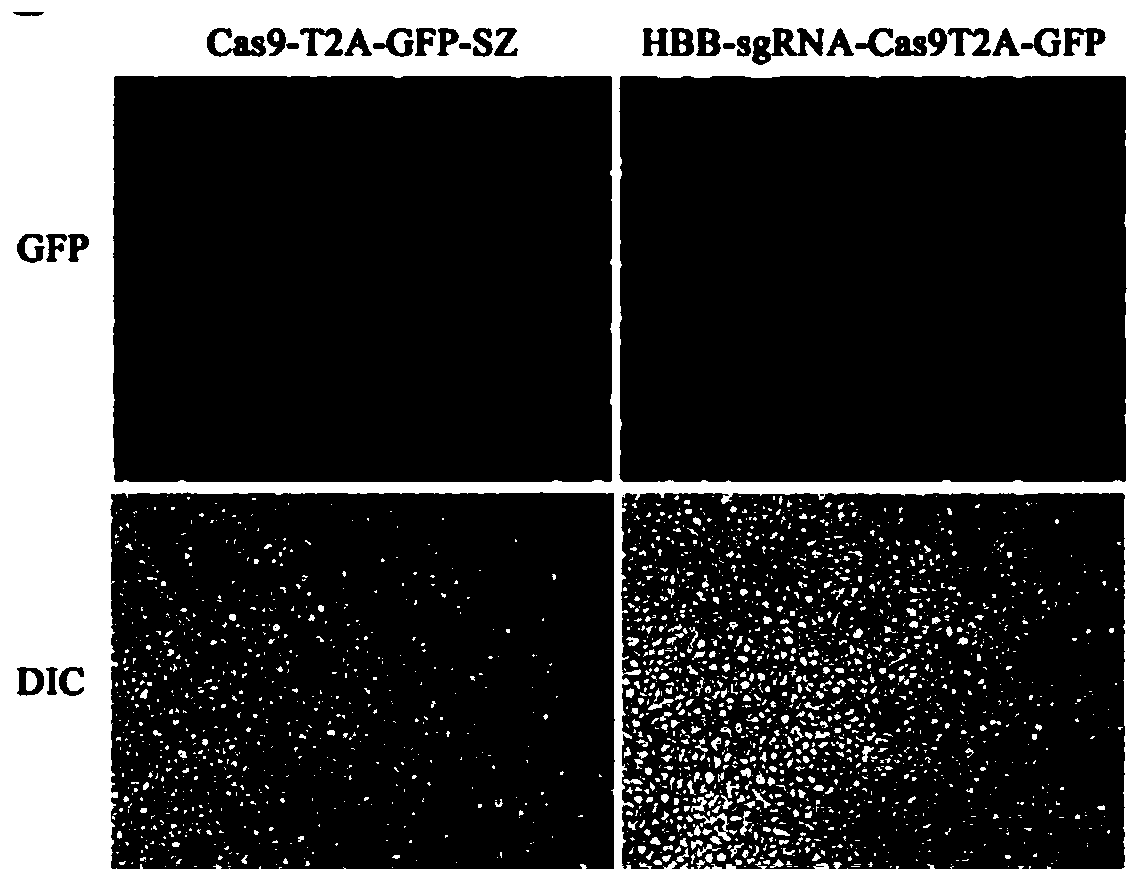

Method for introducing CRISPR-Cas9 system into human stem cells

InactiveCN110951785ASurvival rate exceededHigh transfection efficiencyHydrolasesStable introduction of DNAMesenchymal stem cellElectroporation

The invention relates to a method for efficiently introducing a CRISPR-Cas9 gene editing system into human stem cells. The method comprises the following steps: (1) constructing and obtaining HBB-sgRNA-Cas9-T2A-GFP-SZ recombinant plasmid; (2) using a Neon system to introduce the HBB-sgRNA-Cas9-T2A-GFP-SZ recombinant plasmid into human stem cells, wherein conditions of electroporation transfectionare as follows: when the human stem cells are human mesenchymal stem cells: a pulse voltage is 1300-1700 V, a pulse duration is less than 30 ms, and a pulse number is at least once; when the human stem cells are human hematopoietic stem cells: a pulse voltage is 1450-1550 V, a pulse duration is 40 ms, and a pulse number is at least once; and (3) performing cell culture. The method uses an electroporation method to introduce the CRIPSR-Cas9 gene editing system into stem cells, and can effectively improve the survival rate of the stem cells after electroporation transfection.

Owner:SHENZHEN CHANGENE MEDICAL TECH CO LTD

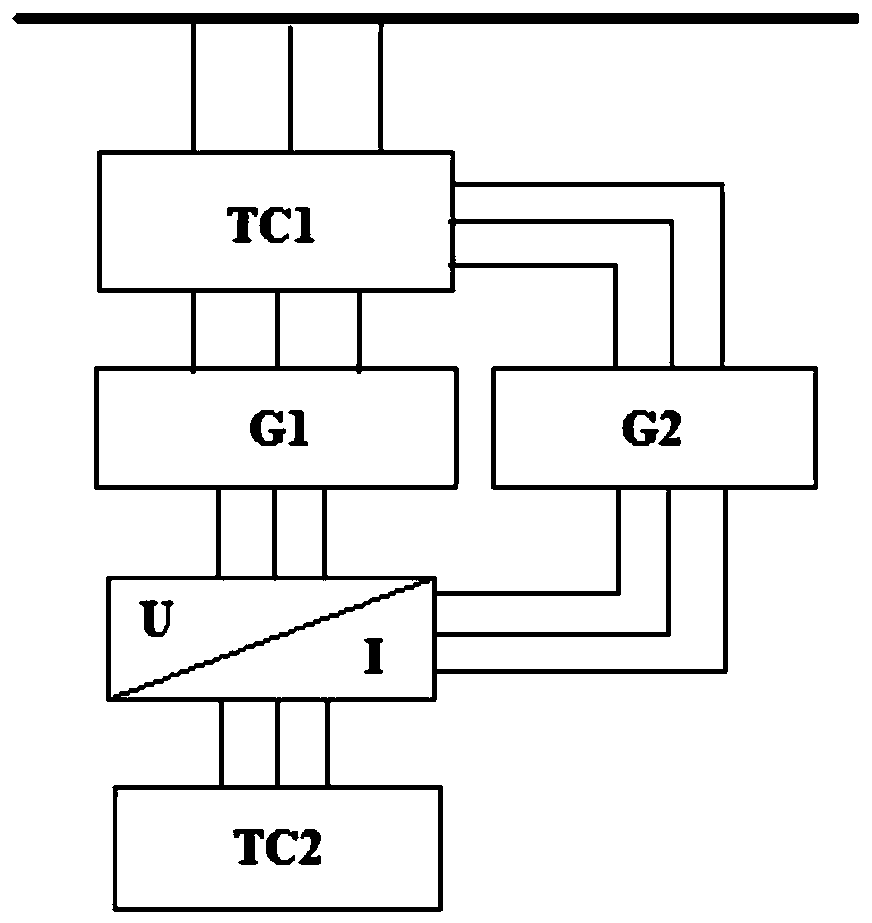

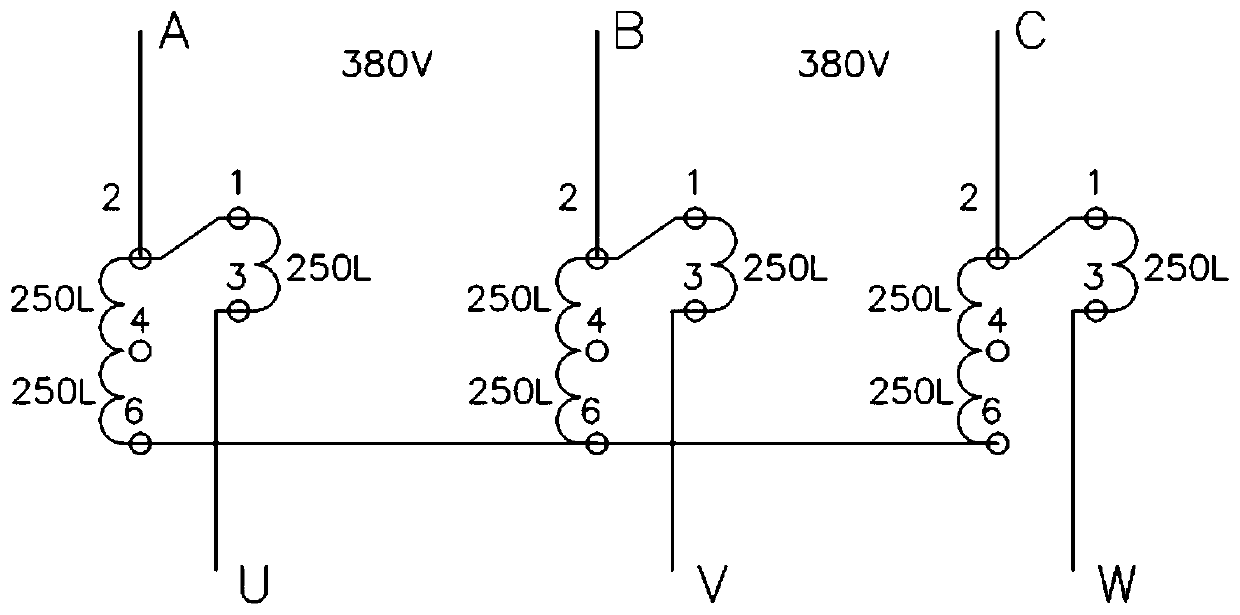

Frequency converter maintenance test system

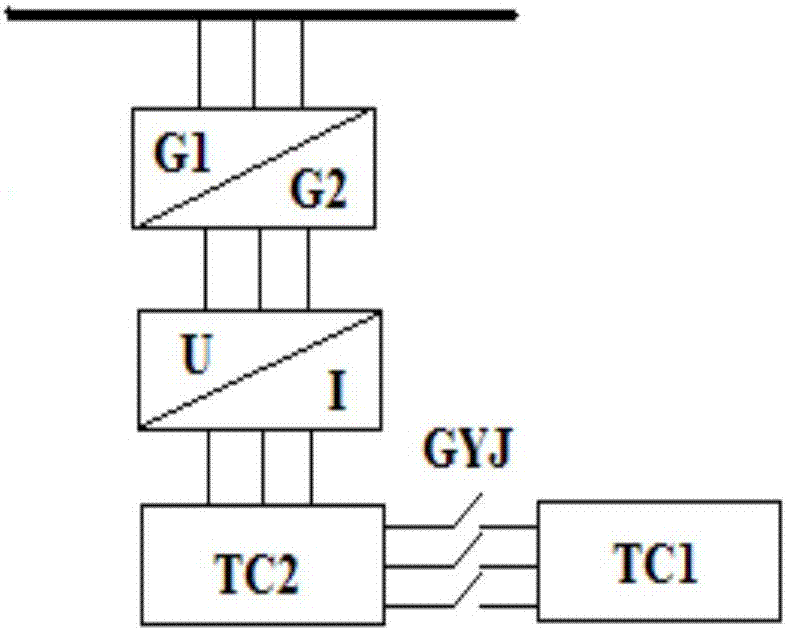

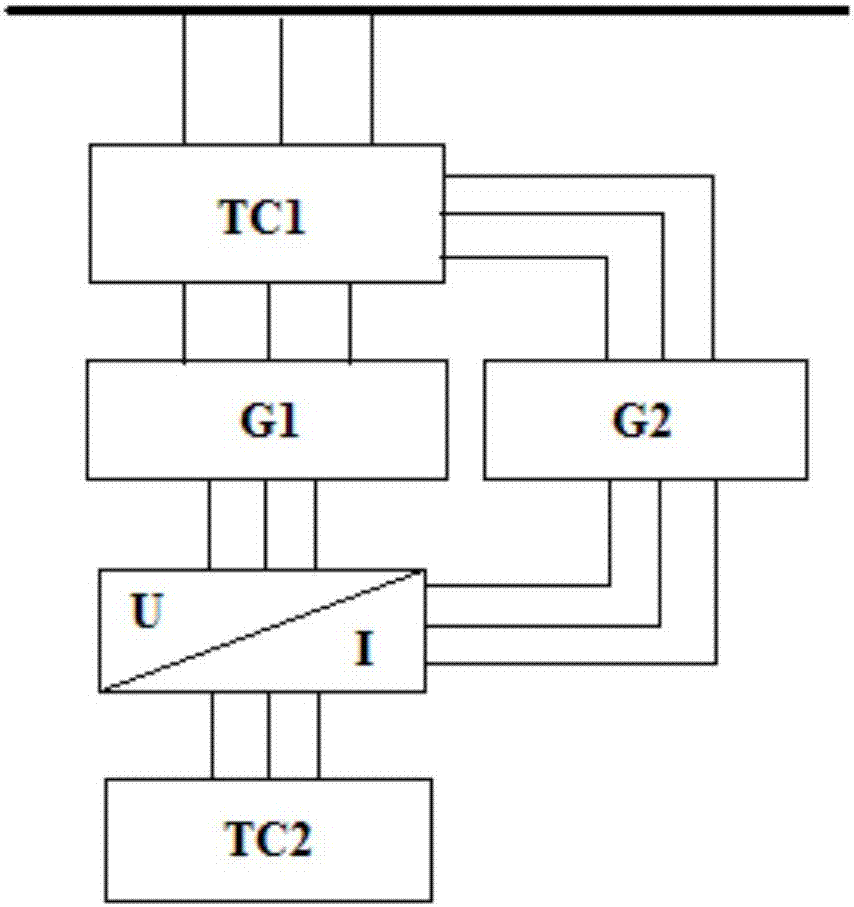

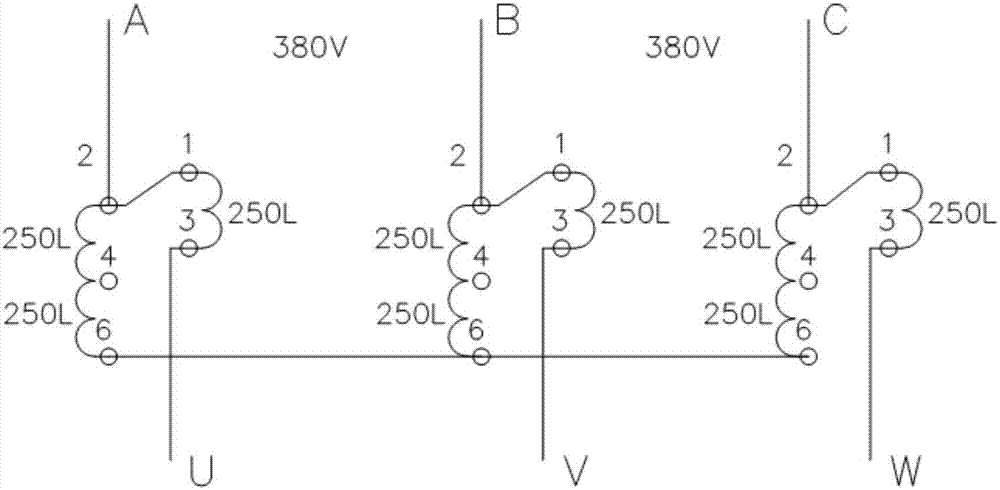

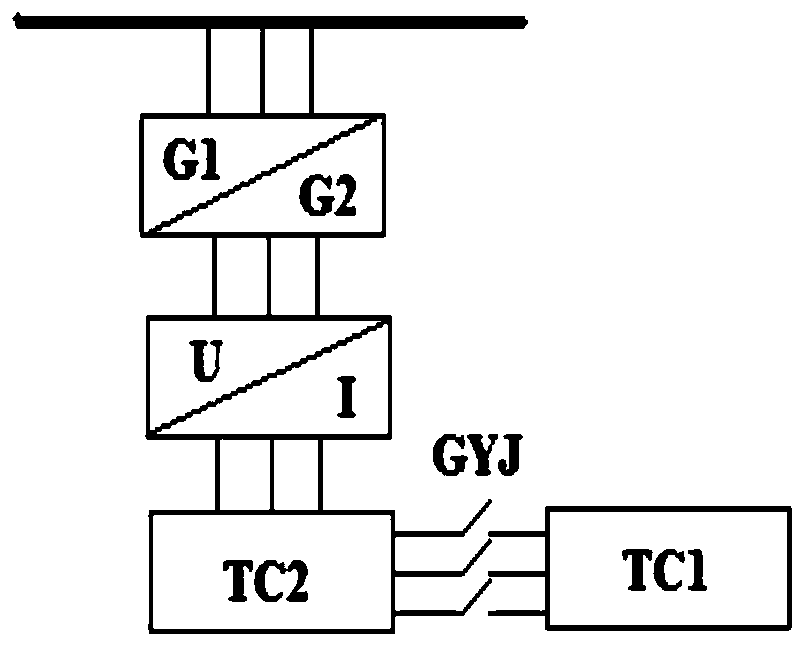

ActiveCN106896288AMeet the test needsSolve access difficultiesElectrical testingMulti inputFrequency changer

The present invention provides a frequency converter maintenance test system, and belongs to the frequency converter maintenance test technology field. The system comprises dry type transformers TC1 and TC2, and frequency converter test control cabinets G1 and G2. The tap of the dry type transformer TC1 is regulated to perform conversion output of input power to the frequency converter test control cabinets G1 and G2, the dry type transformers TC1 employs a self-coupling mode to output voltage, the frequency converter test control cabinets G1 and G2 provide various types of power supplies of the frequency converter test and provide protective measures in the frequency converter maintenance test process, and the dry type transformer TC2 supplies heavy current load for the frequency converter and supplies low-frequency heavy current load basis. The frequency converter maintenance test system solves the problems that multi-input power supply, direct-current source and control power in the low, medium and high voltage frequency converter debugging are difficult to obtain and cannot perform heavy current load test; only one set of the system can satisfy the frequency converter test requirement of each voltage grade, and the frequency converter maintenance test system is suitable for low-frequency debugging test of a high-power frequency converter having heavy current load with limited test condition, and small in energy consumption and saved in energy.

Owner:BEIJING SOLY TECH

A frequency converter maintenance test system

ActiveCN106896288BReliable output for inductive loadsSolve the problem of small capacityElectrical testingFrequency changerMulti input

The present invention provides a frequency converter maintenance test system, and belongs to the frequency converter maintenance test technology field. The system comprises dry type transformers TC1 and TC2, and frequency converter test control cabinets G1 and G2. The tap of the dry type transformer TC1 is regulated to perform conversion output of input power to the frequency converter test control cabinets G1 and G2, the dry type transformers TC1 employs a self-coupling mode to output voltage, the frequency converter test control cabinets G1 and G2 provide various types of power supplies of the frequency converter test and provide protective measures in the frequency converter maintenance test process, and the dry type transformer TC2 supplies heavy current load for the frequency converter and supplies low-frequency heavy current load basis. The frequency converter maintenance test system solves the problems that multi-input power supply, direct-current source and control power in the low, medium and high voltage frequency converter debugging are difficult to obtain and cannot perform heavy current load test; only one set of the system can satisfy the frequency converter test requirement of each voltage grade, and the frequency converter maintenance test system is suitable for low-frequency debugging test of a high-power frequency converter having heavy current load with limited test condition, and small in energy consumption and saved in energy.

Owner:BEIJING SOLY TECH

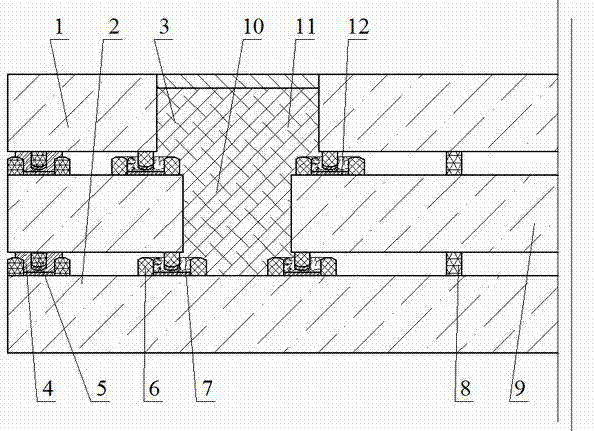

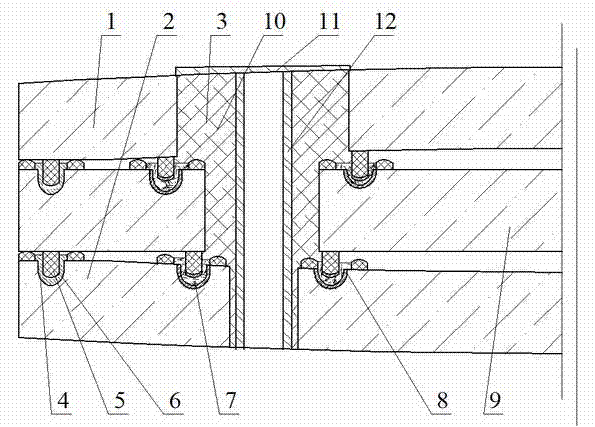

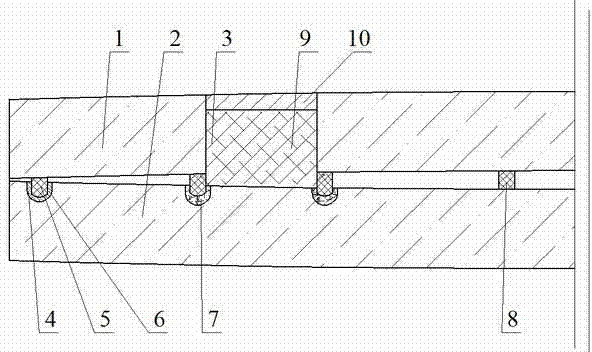

Metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips

The invention relates to a metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through an alloy solder in an atmosphere heating furnace, and the extraction opening is enclosed by using metal solder in vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass. The upper glass and the middle glass are provided with one to four air extracting holes. The lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. Two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded convex vacuum glass having installing holes with edge sealed by sealing strips

InactiveCN104743852AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

The invention relates to a glass-welded convex vacuum glass having installing holes with edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

MAC (Media Access Control) address table access control method, as well as apparatus and network device for the same

InactiveCN102355511BSave spaceSolve the problem of small capacityData switching networksComputer hardwareNetwork Communication Protocols

The invention discloses an MAC (Media Access Control) address table access control method, as well as an apparatus and a network device for the same. The method comprises the following steps of: refusing to execute the operation of adding the MAC address of a configured communication protocol to an MAC address table while configuring the communication protocol which is opened already on a device port and has a selected communication mode, and running the communication protocol; and when some messages reach the port, receiving the messages while judging that the messages are opened already and have a selected communication mode. With the method, space in the MAC address table is saved, and the problem of smaller capacity of the MAC address table is solved; and memory occupation ratio is reduced, speed and efficiency of message forwarding are improved and performance of the device is improved.

Owner:RUIJIE NETWORKS CO LTD

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass which are plain glass. The upper glass and the middle glass are provided with one to four air extracting holes. The periphery of the lower surface of the upper glass, the periphery of the lower surface of the middle glass and the periphery of each air extracting hole are respectively provided with at least one sealing strip. The peripheries of the upper surfaces of the middle glass and the lower glass are provided with at least two sealing strips. A position on the lower glass, which is corresponding to each air extracting hole, is provided with at least one sealing strip. Peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. A manufacturing method of the plain double-vacuum-layer glass is simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

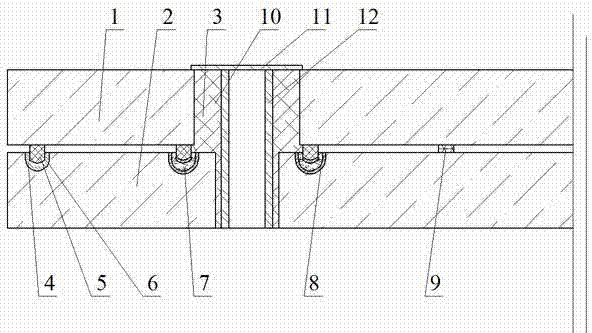

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the convex double-vacuum-layer glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each mounting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743795AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the upper surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and two vacuum layers are formed among the upper glass, the lower glass and the middle glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: the convex vacuum glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the upper glass and the lower glass are convex glass; peripheries of the upper glass and the mounting hole(s) are provided with sealing strips; corresponding positions of the periphery of the lower glass and the mounting hole(s) are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743833AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the lower surfaces of the upper glass and the middle glass are provided with sealing strips; the peripheries of the upper surfaces of the middle glass and the lower glass are provided with the sealing grooves; after being rapidly heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

InactiveCN104743815AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination sealed plain double-vacuum-layer glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743809AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination sealed plain double-vacuum-layer glass with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass. The upper glass and the middle glass are provided with one to four air extracting holes. The lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. Two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded convex vacuum glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

InactiveCN104743836AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded convex vacuum glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass. The convex vacuum glass is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the upper glass and the lower glass are convex glass; the peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the middle glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace; and one sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded sealed convex vacuum glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743828AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

Glass-welded sealed convex vacuum glass with edges sealed by sealing grooves is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting hole. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the lower glass and each air extracting hole are provided with the sealing grooves. After being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743808AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing strips and manufacturing method thereof

InactiveCN104743782AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing strips is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are respectively provided with at least one sealing strip. The periphery of the lower glass is provided with at least two sealing strips. A position on the lower glass, which is corresponding to each air extracting hole, is provided with at least one sealing strip. The sealing strip of the upper glass is inserted between or into the sealing strips of the lower glass. After being rapidly heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

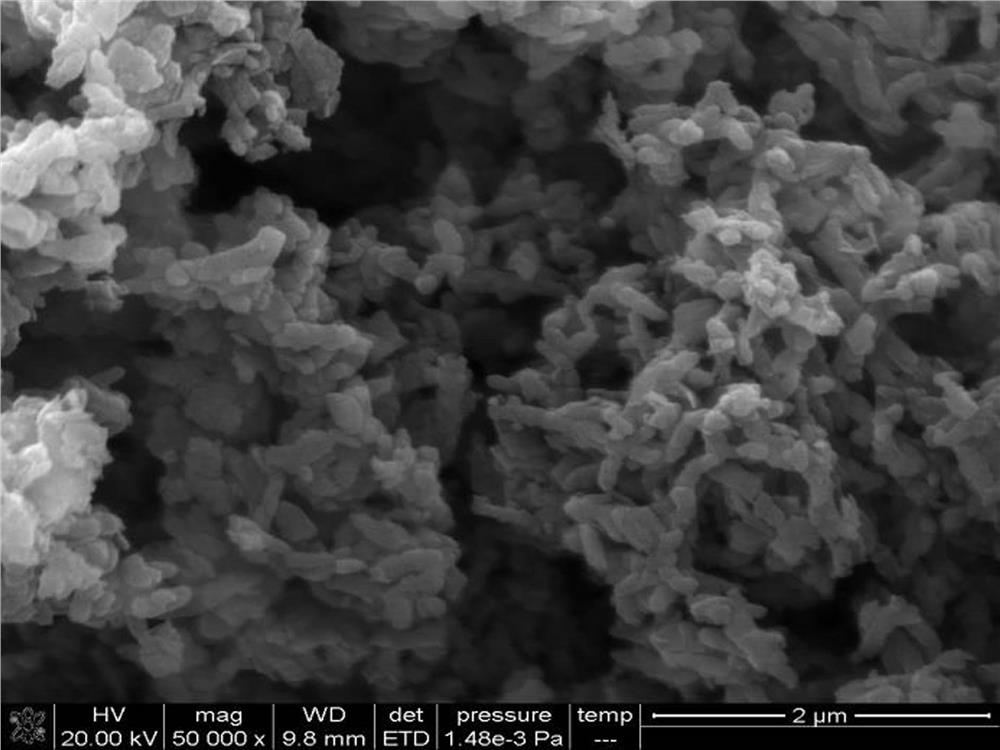

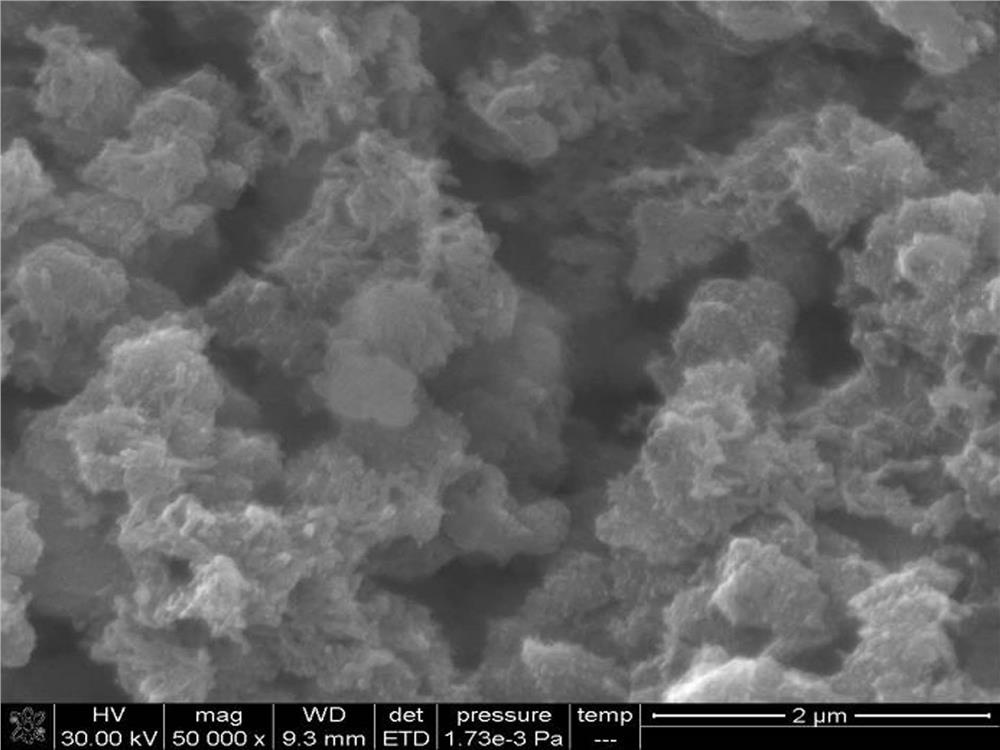

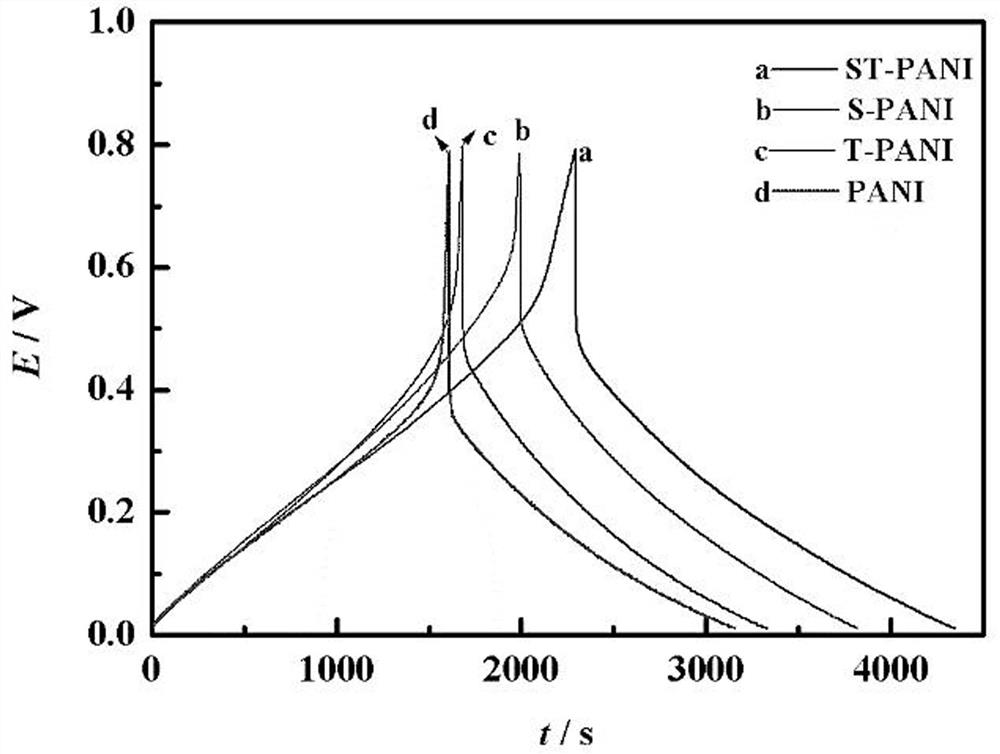

Polyaniline-doped electrode material for supercapacitor, and preparation method and application thereof

PendingCN113161162ARegular shapeEvenly dispersedHybrid capacitor electrodesHybrid/EDL manufactureActive agentSupercapacitor

The invention discloses a polyaniline-doped electrode material for a supercapacitor, and a preparation method and an application thereof. A nonionic surfactant and an anionic surfactant are used as double soft templates, aniline is used as a monomer, an oxidizing agent is adopted to promote aniline polymerization, and polyaniline (ST-PANI) with a nanofiber structure is prepared; and the method is high in reaction speed, simple to operate and small in pollution, and the polyaniline-doped electrode material prepared by the method is high in specific capacity, good in thermal stability, excellent in reversibility and cycle performance, has specific morphology and can be applied to an electrode material of a button type supercapacitor.

Owner:GUANGXI NORMAL UNIV

Metal-welded sealed convex double-vacuum-layer glass with installing holes and edges sealed by sealing grooves and strips

InactiveCN104743934ASolving the annealing problemSolve productivityHigh volume manufacturingEngineering

The invention relates to a metal-welded sealed convex double-vacuum-layer glass with installing holes and edges sealed by sealing grooves and strips, which comprises an upper glass, a lower glass and an intermediate glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, the sealing strips are provided at lower surfaces of the upper glass, the intermediate glass and circumference of the extraction opening, the sealing grooves and the sealing strips are arranged on the upper surface periphery of the intermediate glass and the lower glass as well as the position corresponding to the extraction opening, three glasses are rapidly heated, the circumference can be welded together by pressurizing through an alloy solder in an atmosphere heating furnace, the extraction opening is enclosed in a vacuum furnace by a metal solder, and two enclosing vacuum layers are formed between the upper glass and the intermediate glass as well as between the intermediate glass and the lower glass. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

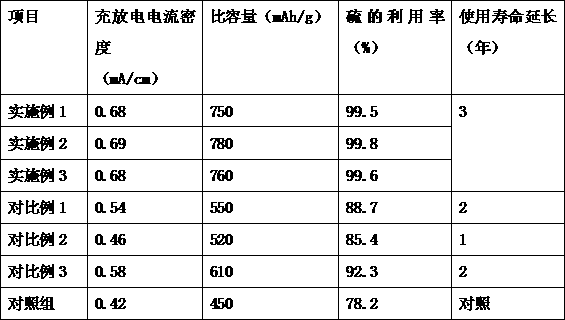

Positive electrode material capable of improving capacitance of lithium battery

InactiveCN107946580ASolve the problem of small capacityIncrease capacityCell electrodesLi-accumulatorsCapacitancePolyvinyl alcohol

The invention relates to the technical field of research and development of a lithium battery, and discloses a positive electrode material capable of improving capacitance of a lithium battery. By adopting a method of compounding polyvinyl alcohol, furfural acetone resin and elementary sulfur, a sulfur-containing composite organic material with a conjugate structure is generated; in a fusion state, the organic material is in contact with a conductive polymer in the molecular level; and after the organic material is adsorbed with an electrolyte, the material has relatively high conductivity andhigh mechanical performance, thereby greatly enlarging the actual area of an electrode action, improving the sulfur utilization rate, increasing the number of times of charging and discharging, solving the problem of low capacitance of the positive electrode material of a sulfide battery, and realizing operation at a relatively high temperature without being corroded.

Owner:安徽零度新能源科技有限公司

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing strips and provided with mounting hole(s)

InactiveCN104743908AShorten the timeSolving the annealing problemHigh volume manufacturingEngineering

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing strips and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the periphery of the lower surface of the upper glass, the periphery of the lower surface of the middle glass and the periphery of each air extracting hole are respectively provided with at least one sealing strip; peripheries of the upper surfaces of the middle glass and the lower glass are respectively provided with at least two sealing strips; a position on the lower glass, which is corresponding to each air extracting hole, is provided with at least one sealing strip; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace; and each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com