Preparation method of composite membrane electrode materials applied to micro-electromechanical system (MEMS) supercapacitor

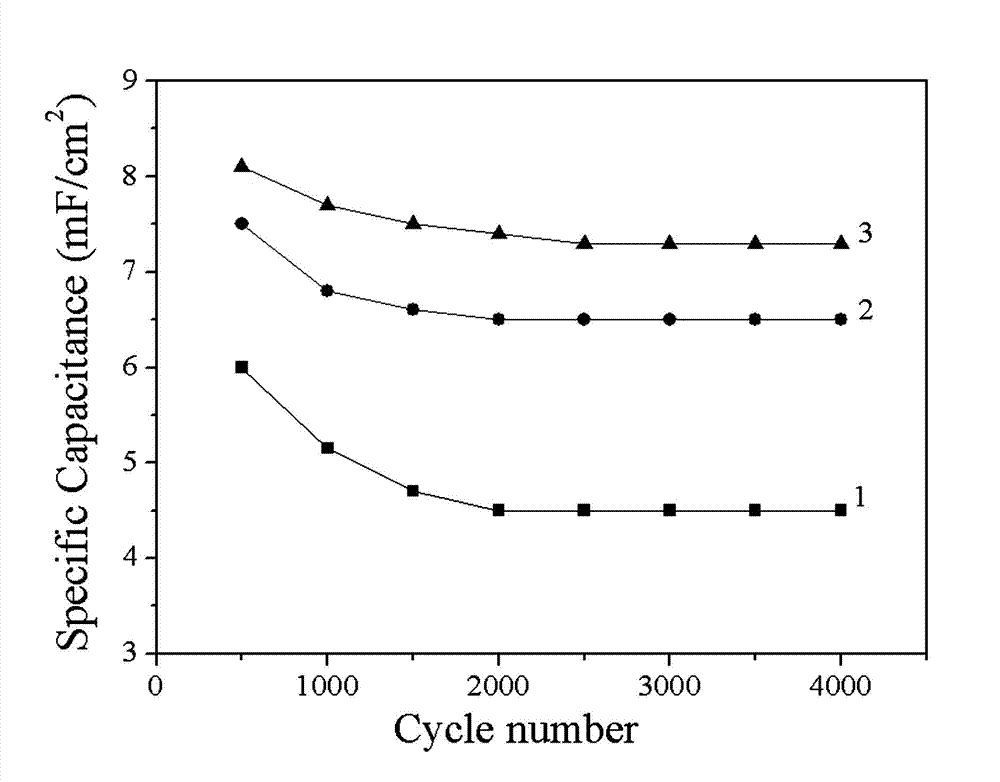

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, and can solve problems such as poor cycle stability and small specific capacity of conductive polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

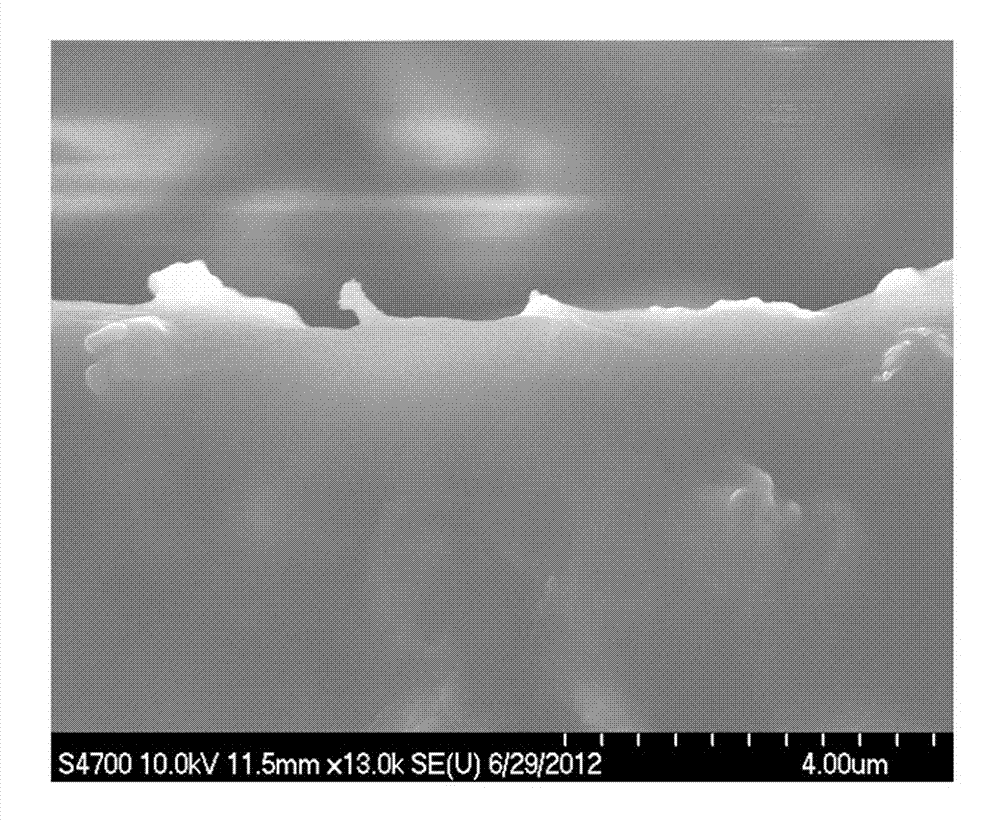

[0014] A method for preparing a composite membrane electrode material applied to a MEMS supercapacitor, the method is realized by the following steps:

[0015] 1) Add conductive polymer monomer to distilled water so that the concentration of conductive polymer monomer is 0.075mol / L; then add supporting electrolyte so that the concentration of supporting electrolyte is 0.2mol / L; finally add conductive carbon material, Ultrasonic oscillation at 25°C for 1.5 hours to prepare a composite solution for electrochemical deposition;

[0016] 2) Select the current collector of the MEMS supercapacitor as the working electrode; select the platinum sheet as the counter electrode, and select the saturated calomel electrode as the reference electrode; then place the working electrode, the counter electrode, and the reference electrode in the composite solution for electrochemical deposition at the same time Perform cyclic voltammetry electrochemical polymerization; when performing cyclic vol...

Embodiment 2

[0019] A method for preparing a composite membrane electrode material applied to a MEMS supercapacitor, the method is realized by the following steps:

[0020] 1) Add conductive polymer monomer to distilled water so that the concentration of conductive polymer monomer is 0.075mol / L; then add supporting electrolyte so that the concentration of supporting electrolyte is 0.2mol / L; finally add conductive carbon material, Ultrasonic oscillation at 25°C for 1.5 hours to prepare a composite solution for electrochemical deposition;

[0021] 2) Select the current collector of the MEMS supercapacitor as the working electrode; select the platinum sheet as the counter electrode, and select the saturated calomel electrode as the reference electrode; then place the working electrode, the counter electrode, and the reference electrode in the composite solution for electrochemical deposition at the same time Perform cyclic voltammetry electrochemical polymerization; when performing cyclic vol...

Embodiment 3

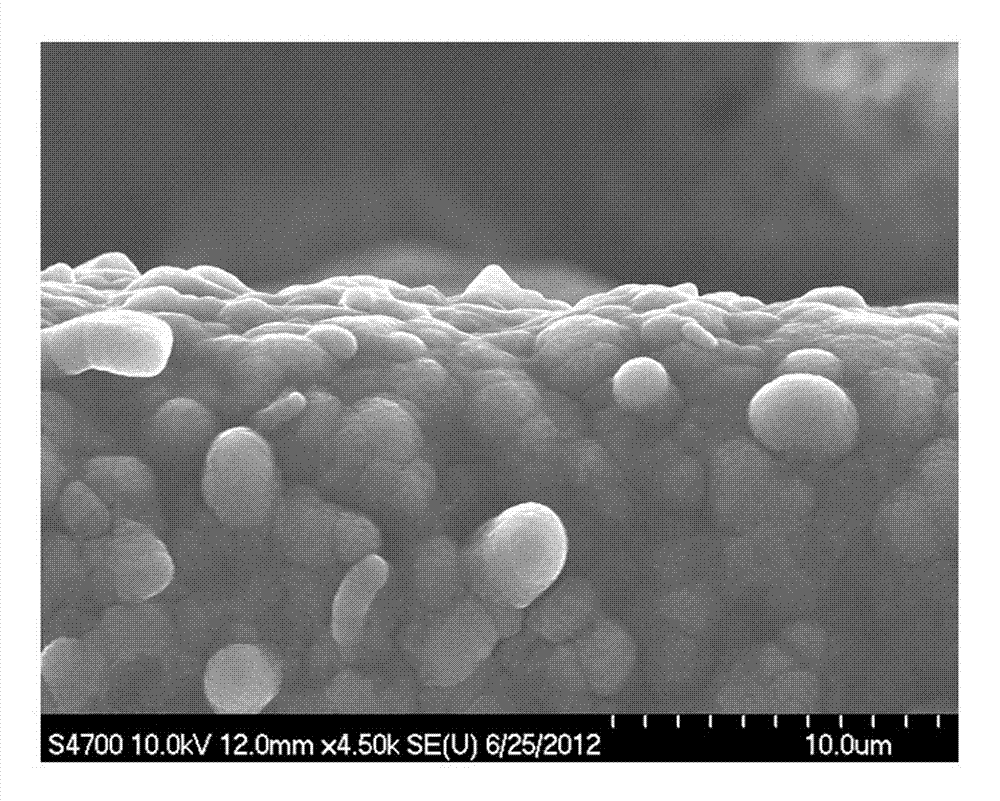

[0024] A method for preparing a composite membrane electrode material applied to a MEMS supercapacitor, the method is realized by the following steps:

[0025] 1) Add conductive polymer monomer to distilled water, so that the concentration of conductive polymer monomer is 0.05mol / L; then add supporting electrolyte, so that the concentration of supporting electrolyte is 0.1mol / L; finally add conductive carbon material, in Ultrasonic oscillation at 20°C for 1 hour to prepare a composite solution for electrochemical deposition;

[0026]2) Select the current collector of the MEMS supercapacitor as the working electrode; select the platinum sheet as the counter electrode, and select the saturated calomel electrode as the reference electrode; then place the working electrode, the counter electrode, and the reference electrode in the composite solution for electrochemical deposition at the same time Perform cyclic voltammetry electrochemical polymerization; when performing cyclic vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com