Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Small installation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

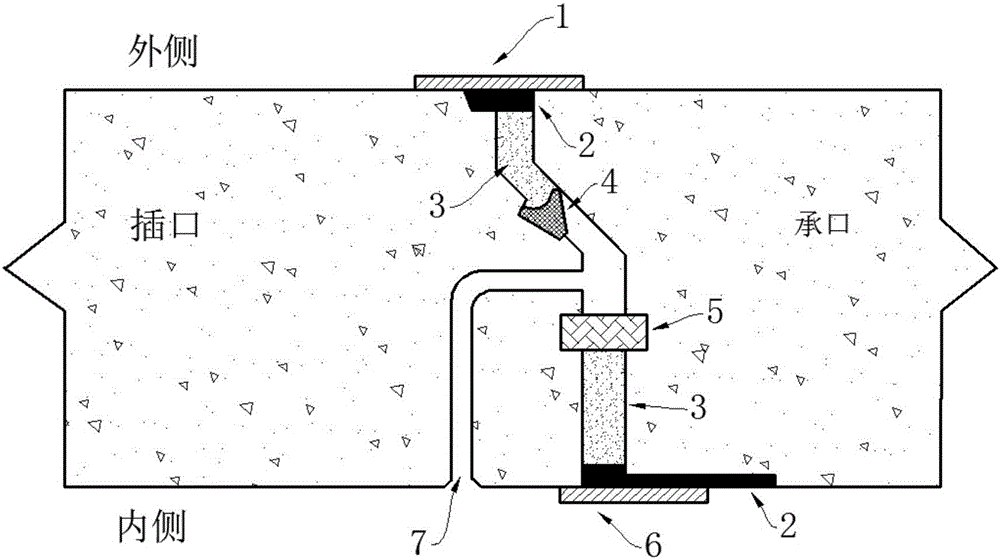

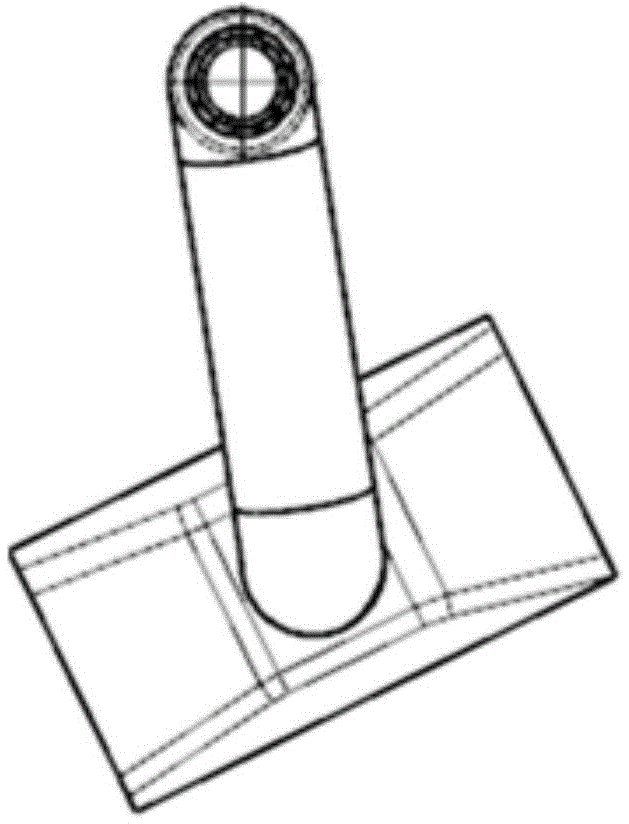

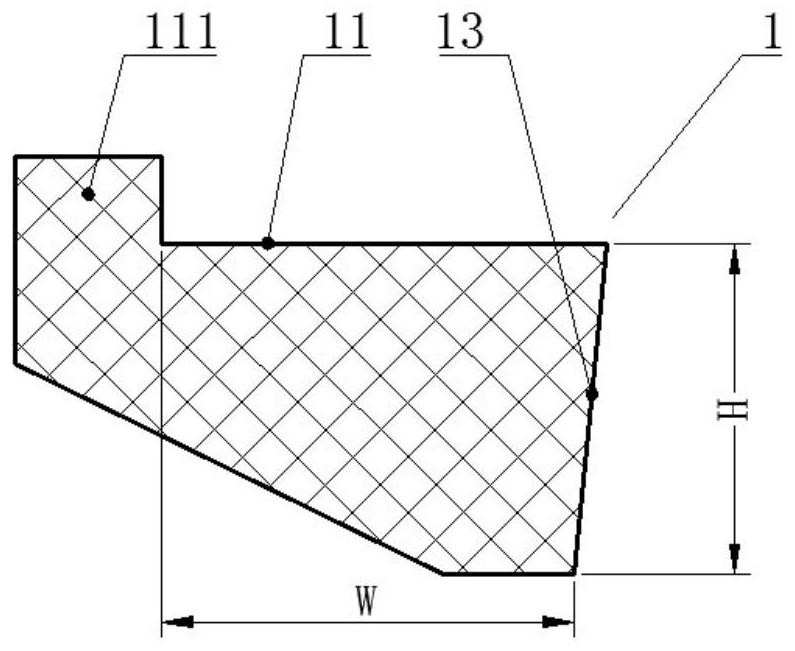

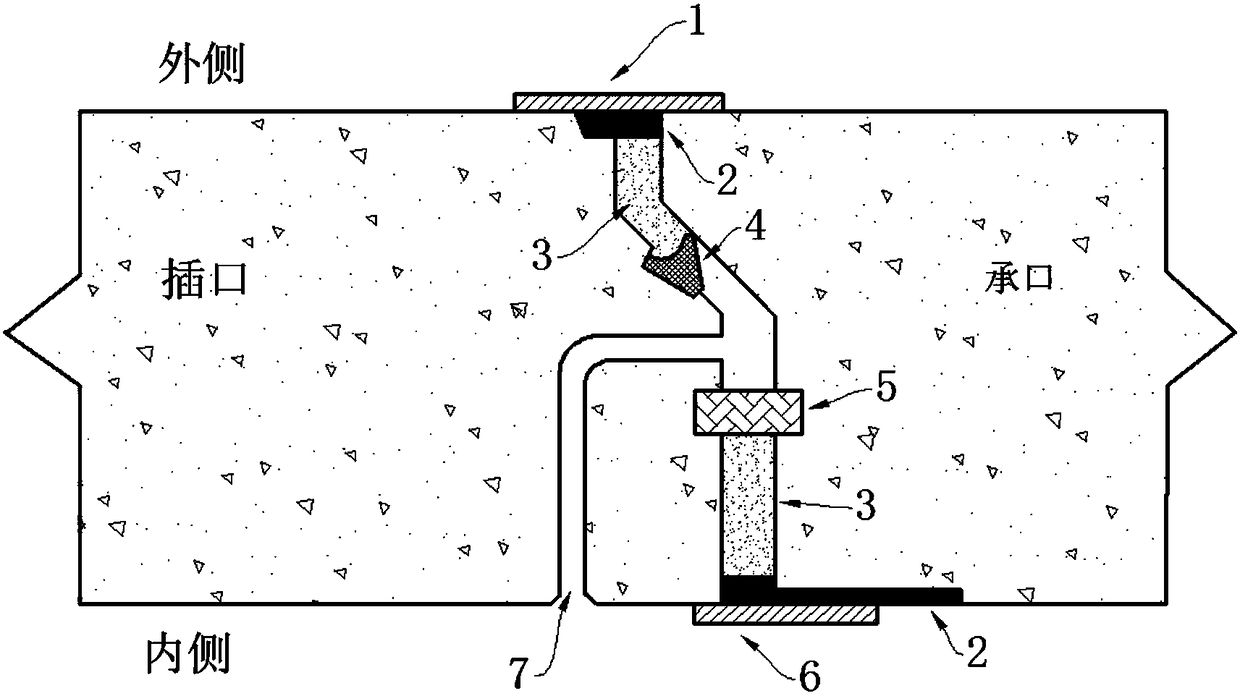

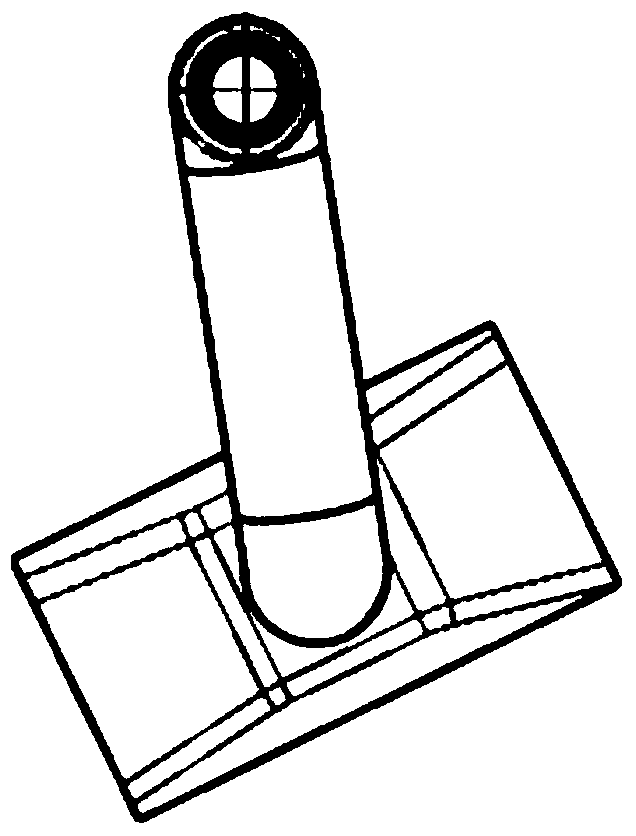

Precast splice comprehensive pipe gallery bell and spigot waterproof structure

ActiveCN106149764ASmall installation resistanceEasy to installArtificial islandsProtective foundationPolymer modifiedArchitectural engineering

The invention discloses a precast splice comprehensive pipe gallery bell and spigot waterproof structure. The precast splice comprehensive pipe gallery bell and spigot waterproof structure comprises a seam composed of a pipe gallery spigot and a pipe gallery bell. At the seam, waterproof construction bodies composed of a PCM waterproof roll with the thickness of 1.5 mm to 3.0 mm, JS-211 double-component sealants, a polyethylene foam filling plate, an EPDM wedge-shaped sealing ring, a hydrophilic expansion elastic rubber body, a polyethylene foam filling plate, JS-211 double-component sealants and EPIIR self-adhesion waterproof adhesive tape with the thickness of 1.5 mm to 2.0 mm are sequentially arranged from the outer side of the seam to the inner side of the seam. Multiple waterproof guards are constructed, the outer side PCM self-adhesion polymer modified asphalt waterproof roll has the waterproof function, further can prevent plant roots from being punctured and protects the outer seam; double-component sealant cording seams achieve the waterproof and anti-seepage effects; the inner side EPIIR self-adhesion waterproof adhesive tape has the waterproof and anti-seepage functions, further achieves the effects of insect and rat damage prevention effects and mainly plays a role in protecting the inner seam; through the multiple waterproof guards, the waterproof structure is long in service life and can reach 100 years.

Owner:SICHUAN JUST RUBBER

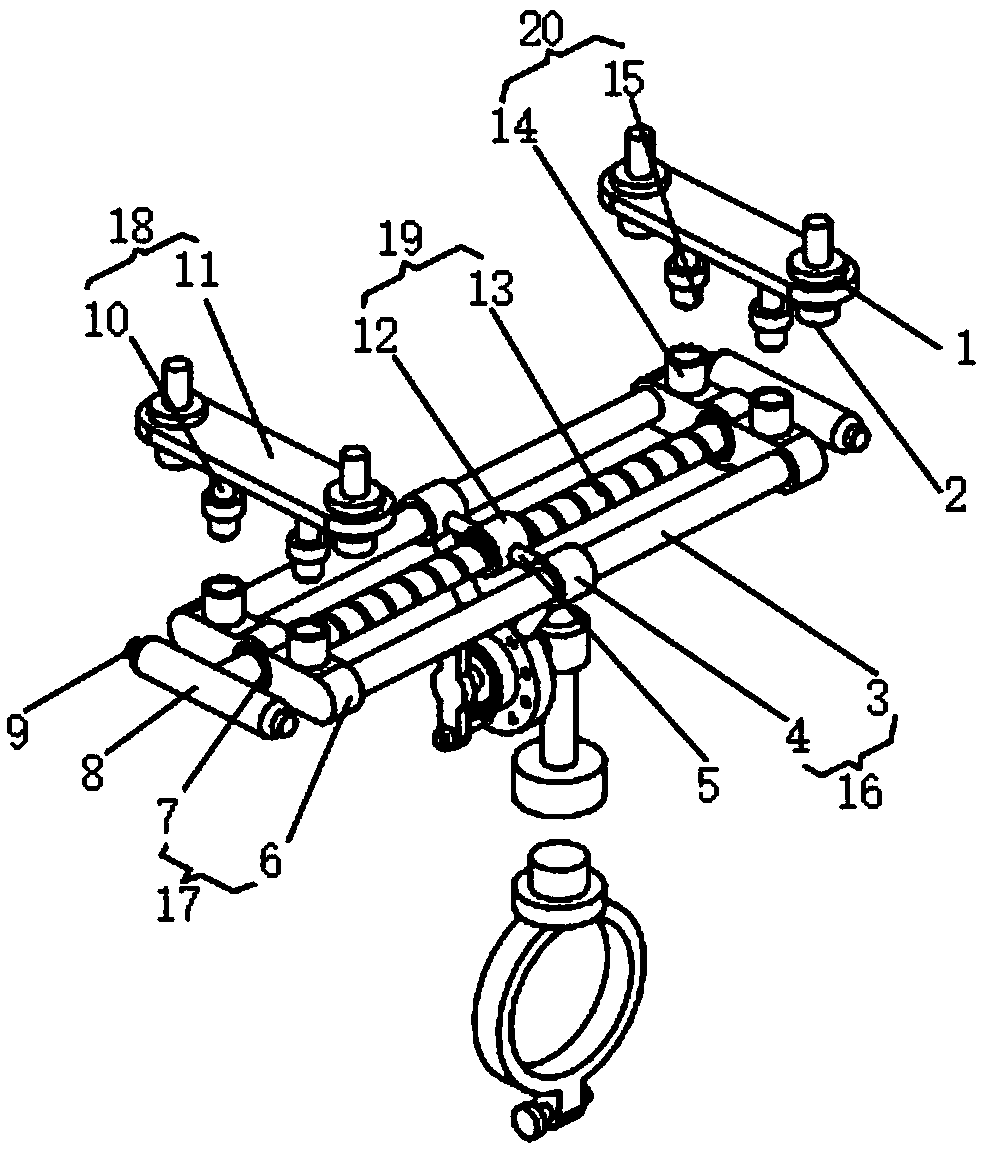

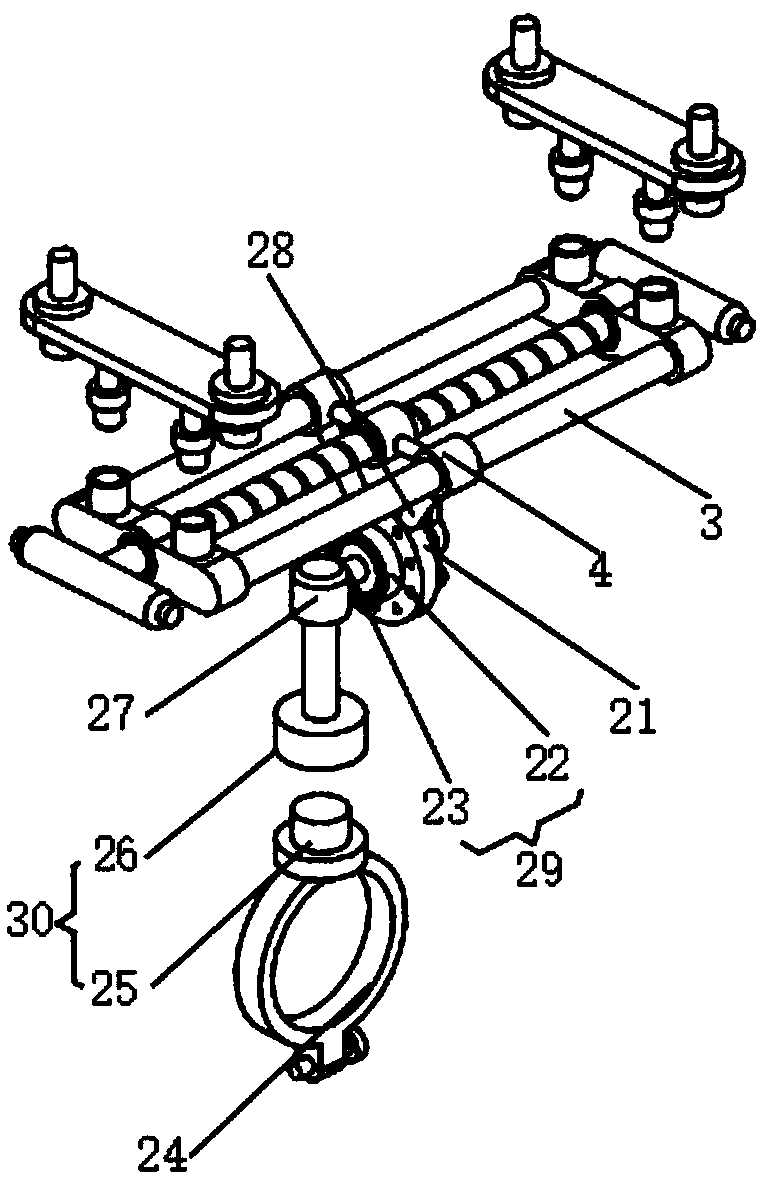

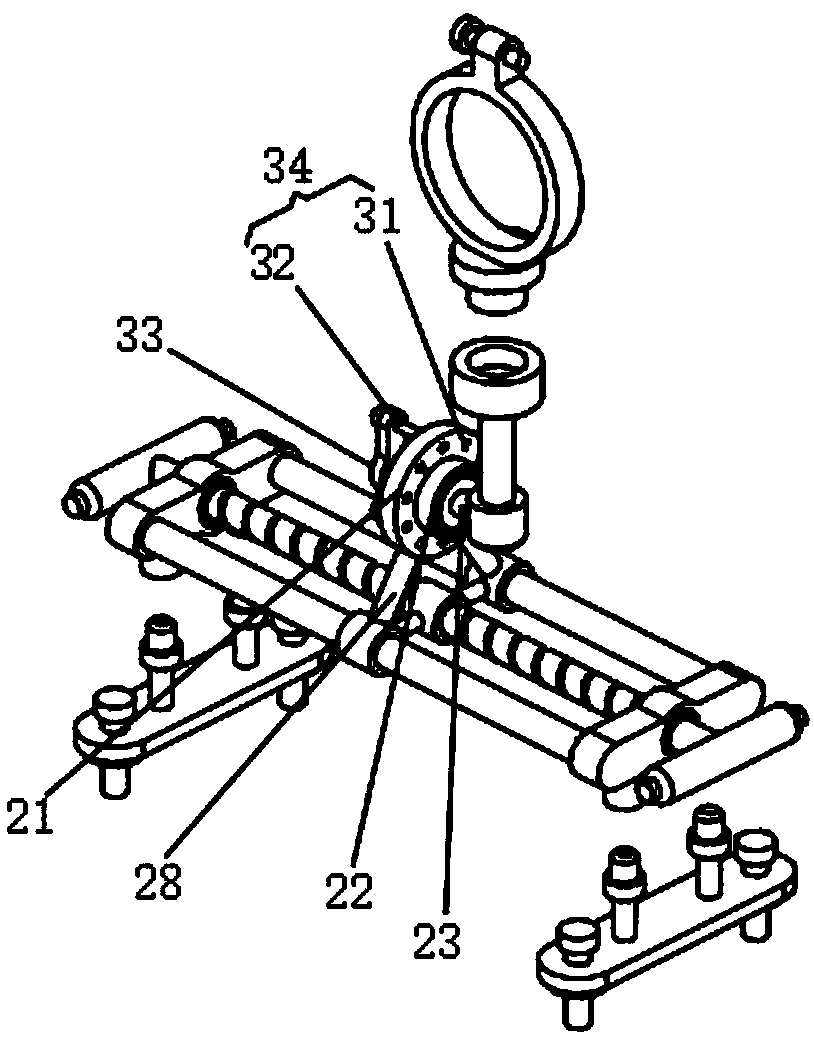

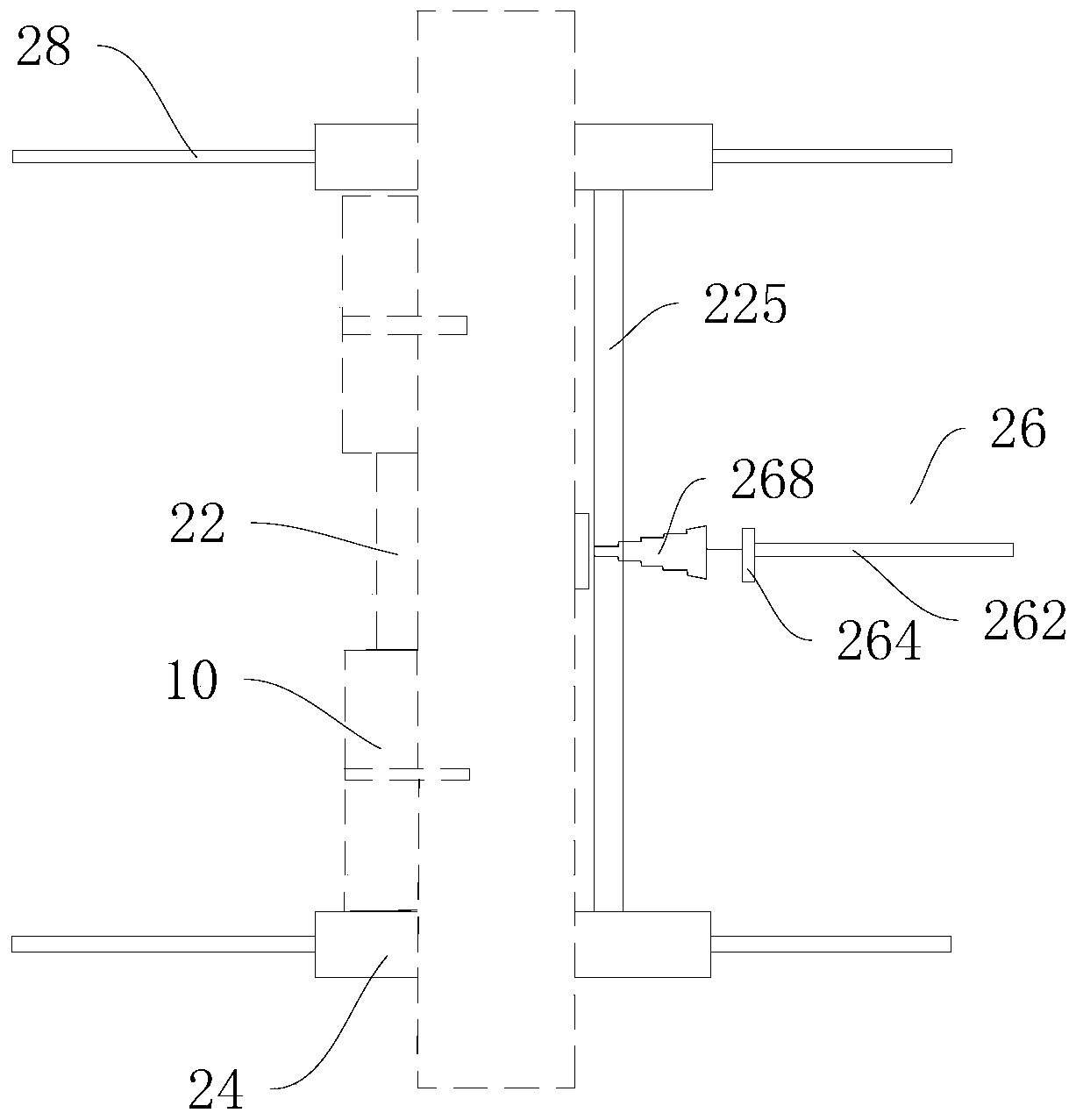

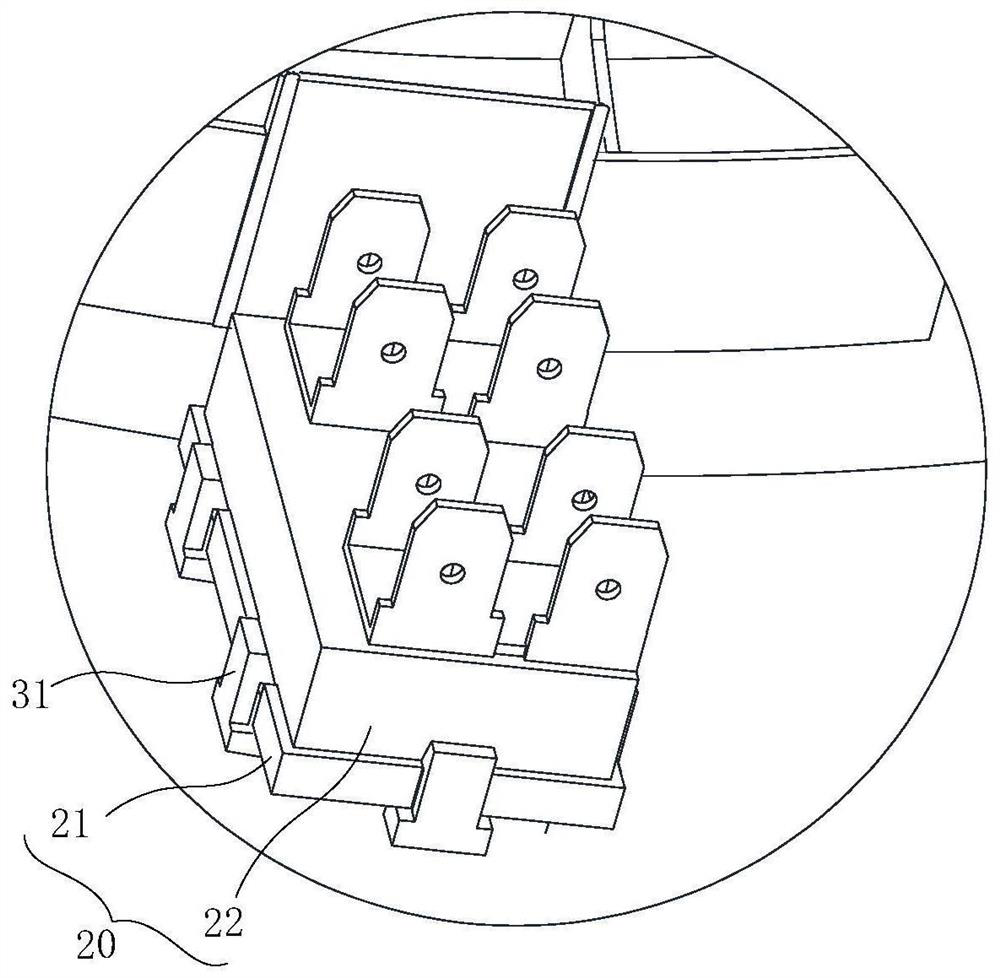

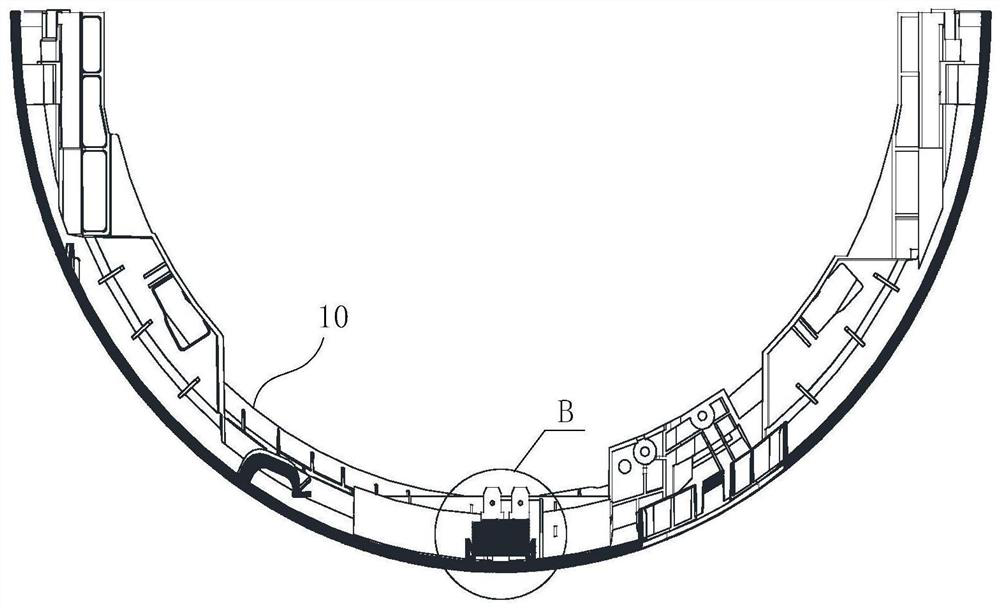

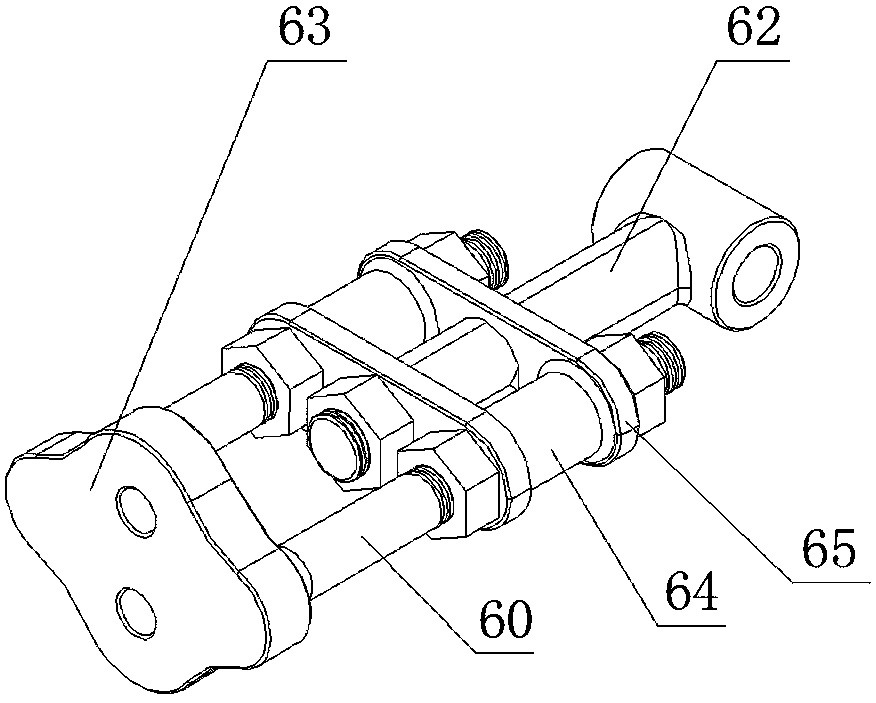

Anti-seismic suspension bracket with function of adjusting fixing positions of pipelines

InactiveCN108730629ABad vibration eliminationImprove seismic performancePipe supportsEngineeringFixed position

The invention discloses an anti-seismic suspension bracket with a function of adjusting fixing positions of pipelines. The anti-seismic suspension bracket comprises anchor seats. The anchor seats aremovably connected with anchor bolts and equipped with seismic reduction devices. Bottoms of the seismic reduction devices are in snap joint with support devices through first snap joint mechanisms. The side surfaces of the support devices are equipped with guide mechanisms and transverse adjusting mechanisms. The transverse adjusting mechanisms are connected with guide mechanisms through connecting rods and connected with a connecting seat through a connecting rack. Adverse shock to a pipe clip is eliminated by the seismic reduction devices so that the anti-seismic performance of the anti-seismic suspension bracket is greatly improved. A bearing seat and anti-seismic supports are assembled through the first snap joint mechanisms. Installation and detachment are convenient. During installation, the anchor seats are firstly installed and the support devices are then installed. Installation resistance is reduced by assembly. The difficulty of installation is not added by overall loads. Therefore, construction efficiency is substantially raised.

Owner:镇江安华电气集团有限公司

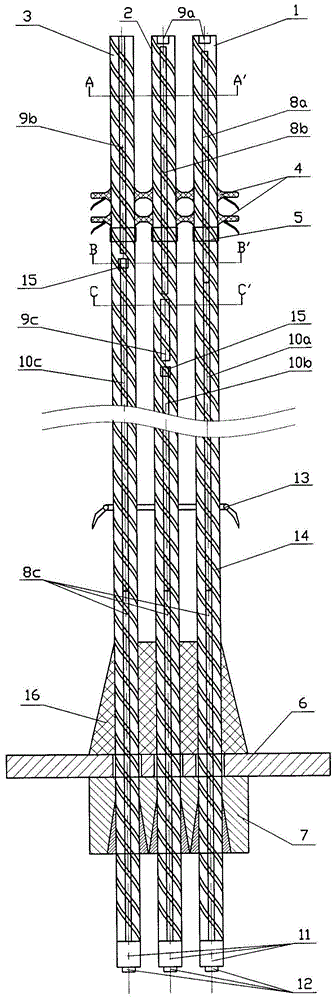

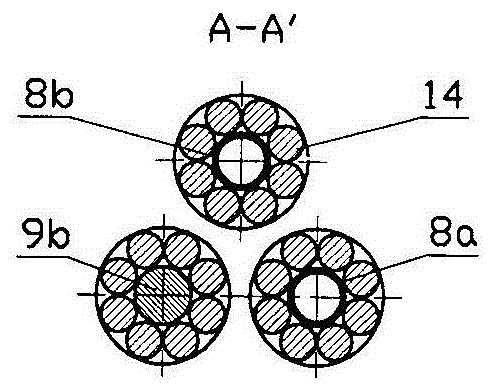

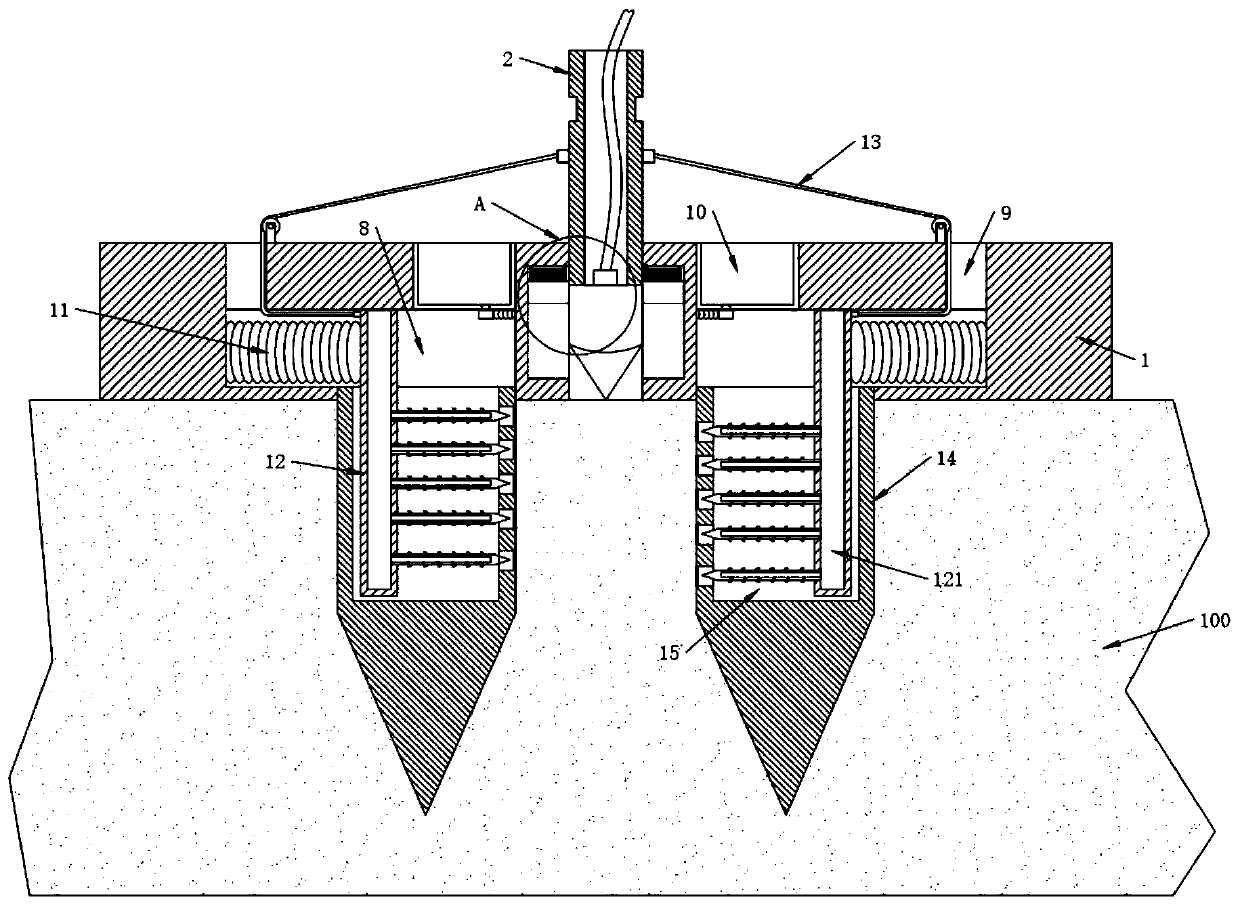

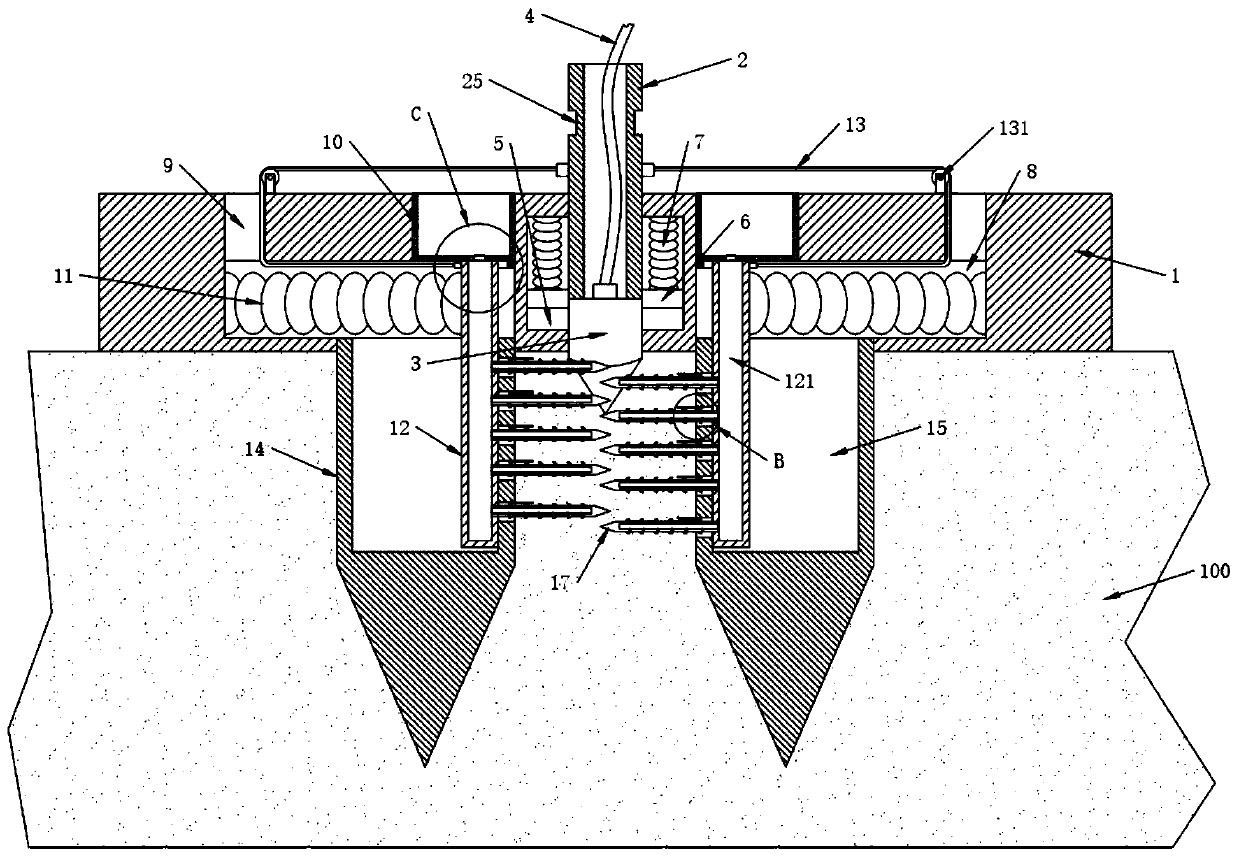

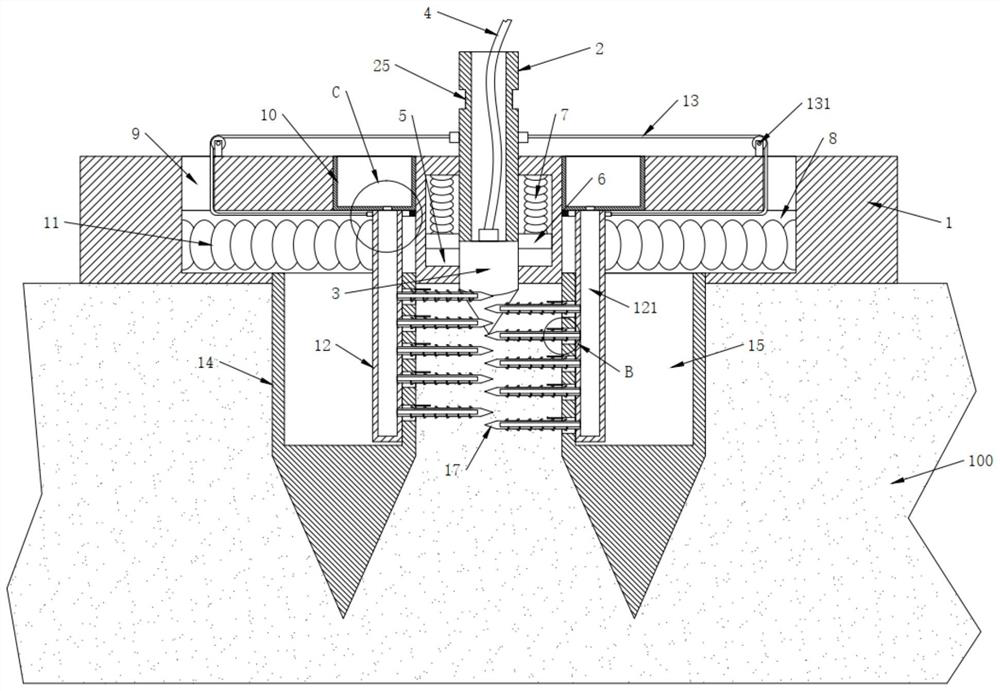

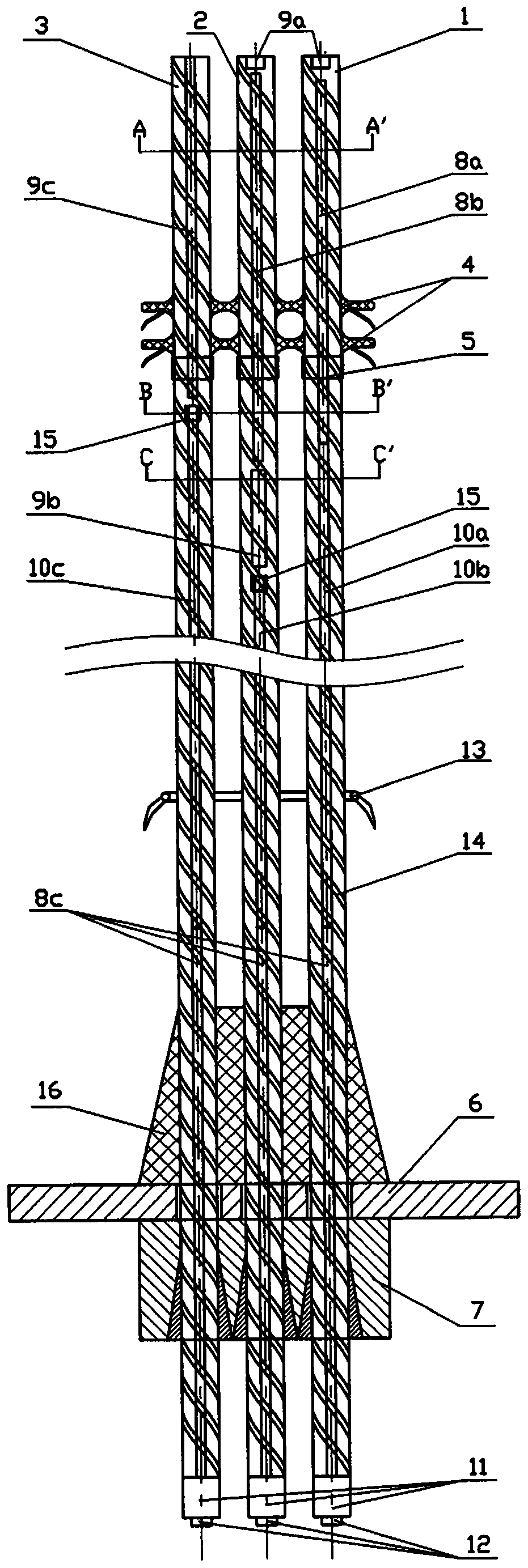

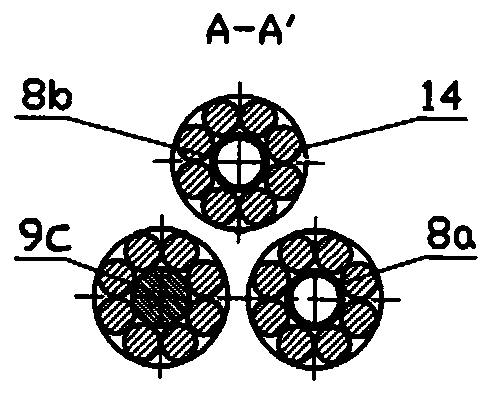

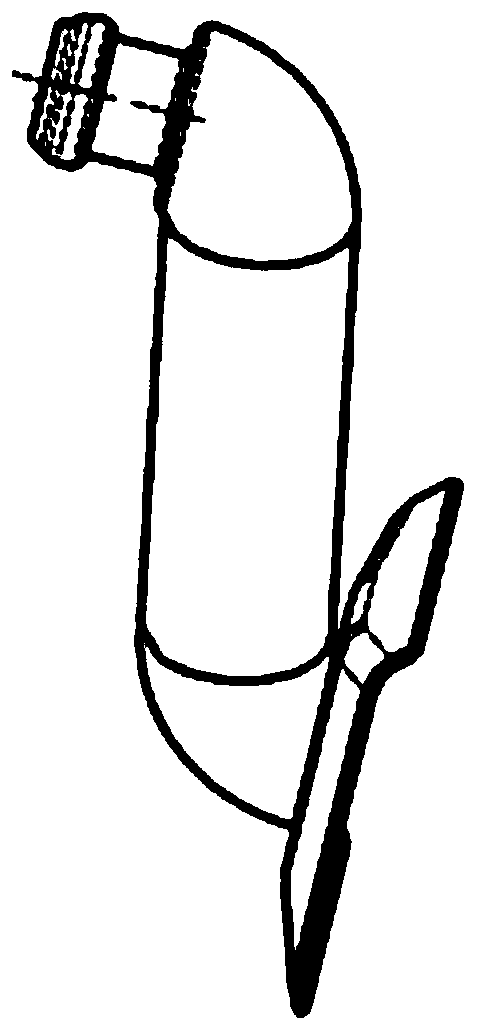

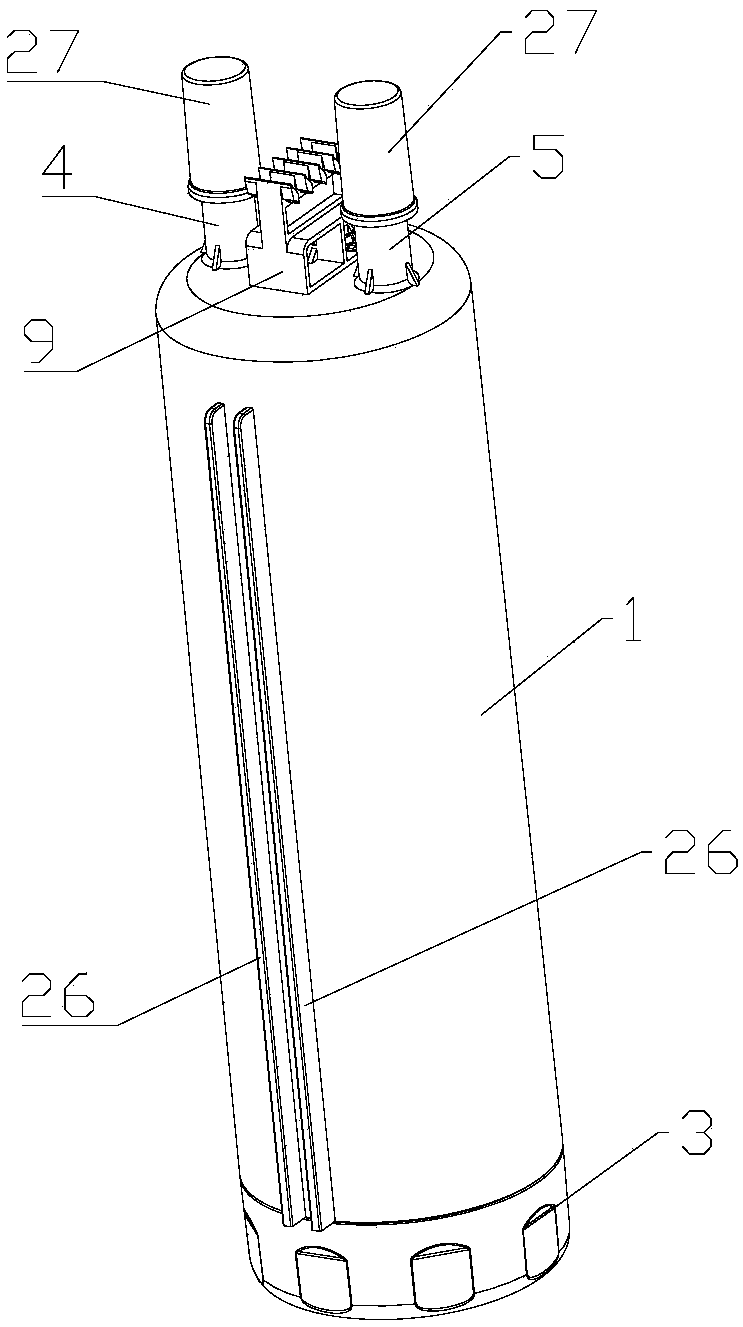

Mine grouting anchor cable supporting method

ActiveCN106321124AGuaranteed support strengthTension and pretension in timeAnchoring boltsHigh stressDrill hole

A mine grouting anchor cable supporting method comprises the steps of manufacturing a grouting anchor cable tie, wherein the grouting anchor cable tie is composed of multiple anchor cable bodies, a conical grouting stopping plug, a tray, a lock, an end anchor grouting stopping plug, an anchor cable fixing frame, a tightening ring and the like. An anchor cable body comprises an end anchor grouting anchor cable body, a full-anchor grouting anchor cable body and an exhaust grouting anchor cable body, and the three grouting anchor cable bodies are combined to replace a common anchor cable body; 2, installing and supporting the grouting anchor cable tie, wherein the end anchor grouting stopping plug is sleeved with the end anchor section of the anchor cable tie, the grouting anchor cable tie is fed into a drilled hole, a barb hook hooks the wall of the hole, and the conical grouting stopping plug, the tray and the lock are sequentially installed; grouting of the end anchor section is performed by means of the end anchor grouting cable body, and air is exhausted through the full-anchor grouting anchor cable body; after grouting of the end anchor section is solidified, the lock is used for tensioning and pre-tightening the anchor cable tie; the full-anchor grouting anchor cable body is used for performing grouting on the full anchor section, and the exhaust grouting anchor cable body is used for exhausting air. The method is applicable to ultra-soft cracking and deep high stress roadway supporting, and can achieve ultra-long deep strong anchoring. The cable body is provided with a core tube so that end anchoring, full-anchoring grouting and air exhausting can be achieved, and construction is greatly simplified.

Owner:中国平煤神马控股集团有限公司 +1

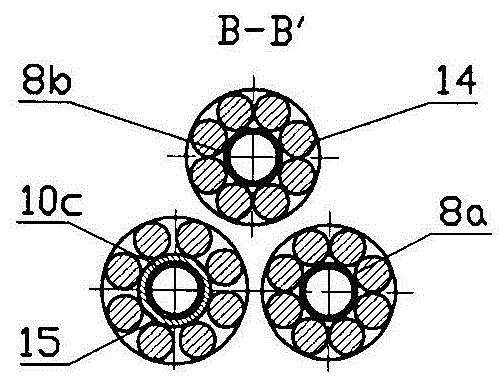

Lacrimal stent, and application method therefor

InactiveCN1692890AImprove stabilityConform to physiological structureSurgeryDilatorsMedicineSurgical site

A supporting frame of lacrimal passage is composed of a tubular body with an expanded head having a detachable drawing unit and a wound body on its external surface, a drawing cathether passing through said tubular body, and the tail thread on the side wall at tail end of tubular body. Its application includes such steps as local sterilizing, anesthesia, expanding lacrimal point, inserting drawing cathether connected to detachable drawing unit, tubular body and tail plate, drawing the supporting frame in lacrimal passage, removing the drawing cathether, tail plate and tail thread, and dropping the liquid to dissolving the detachable drawing unit.

Owner:张德玉

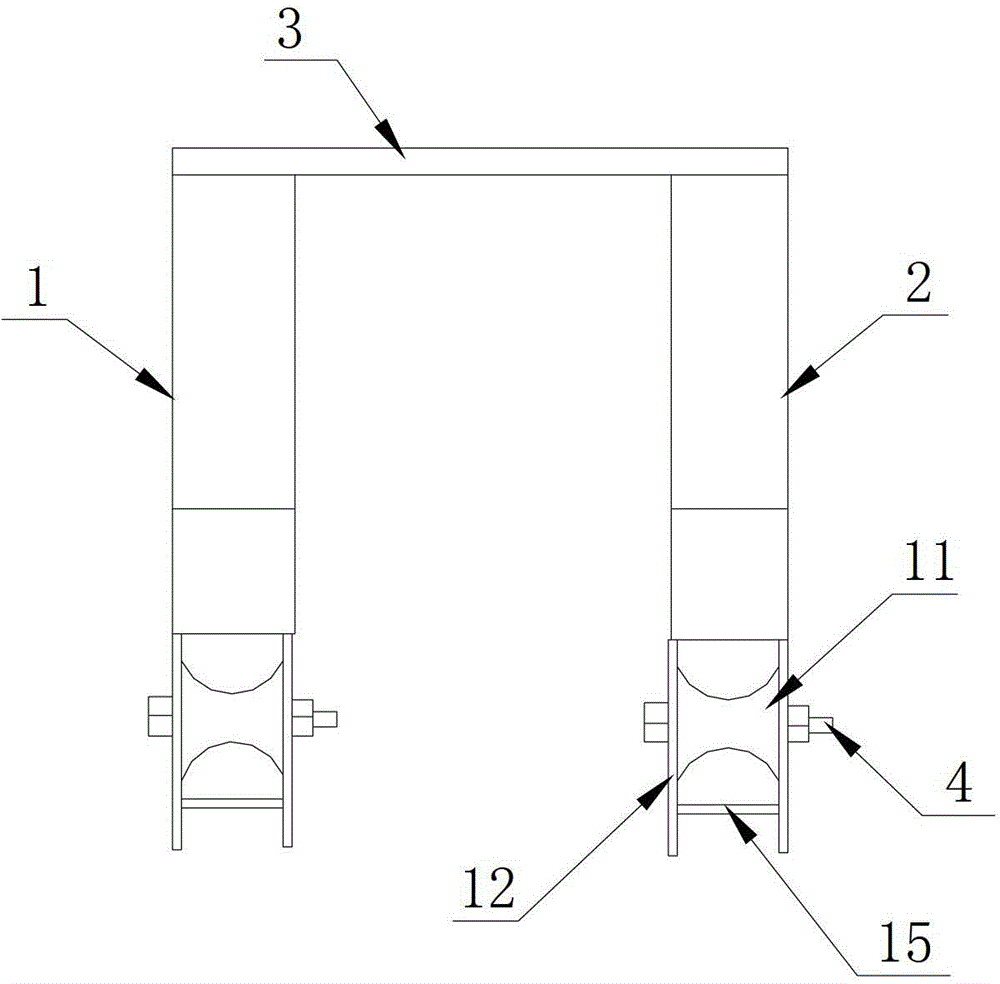

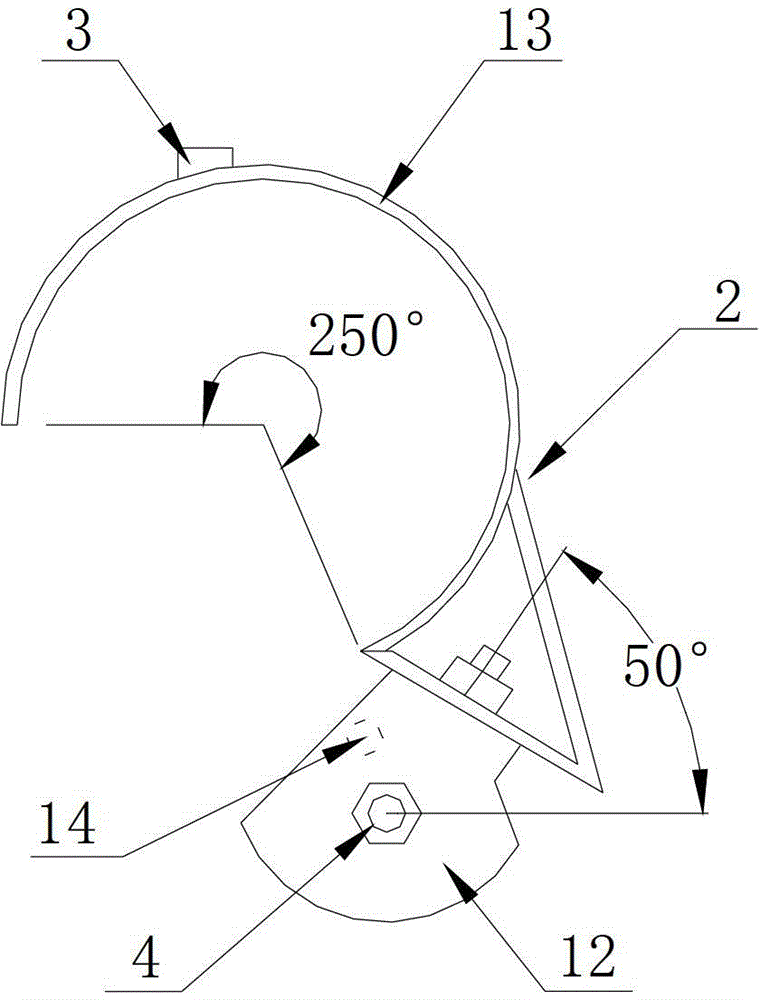

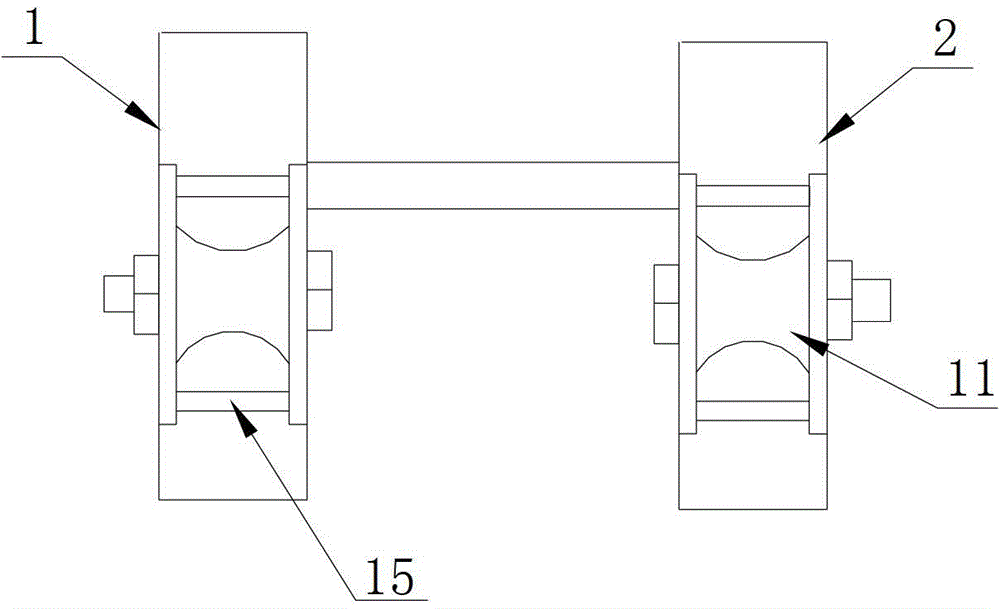

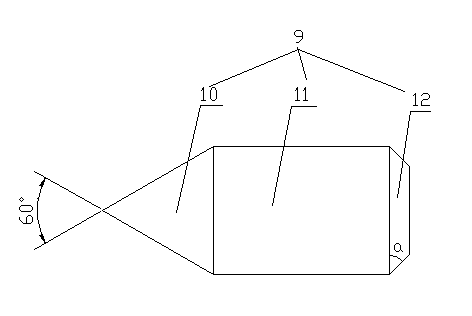

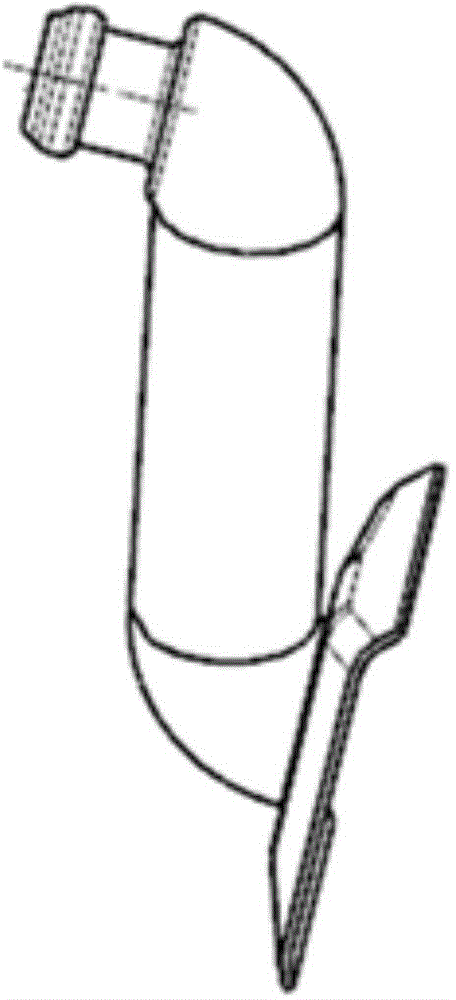

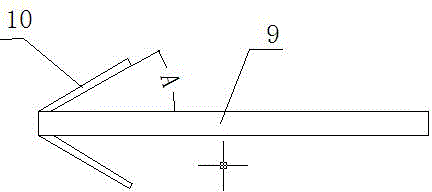

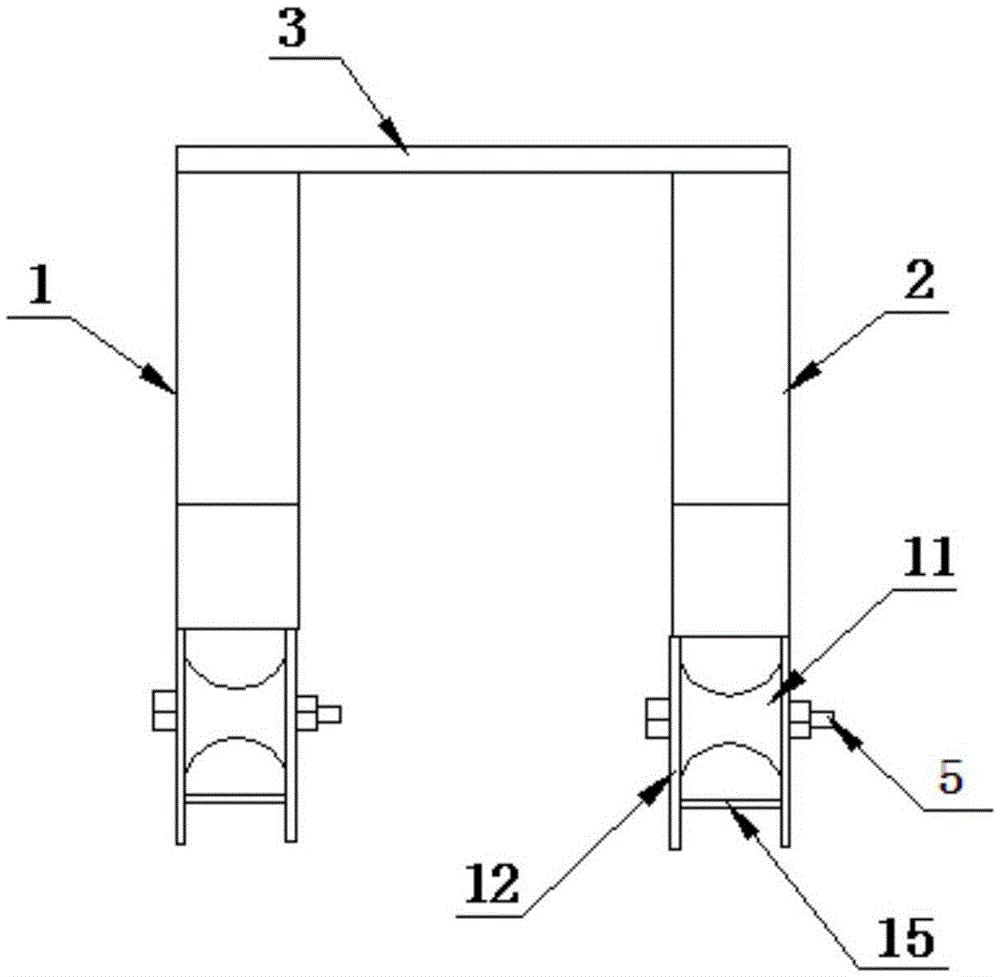

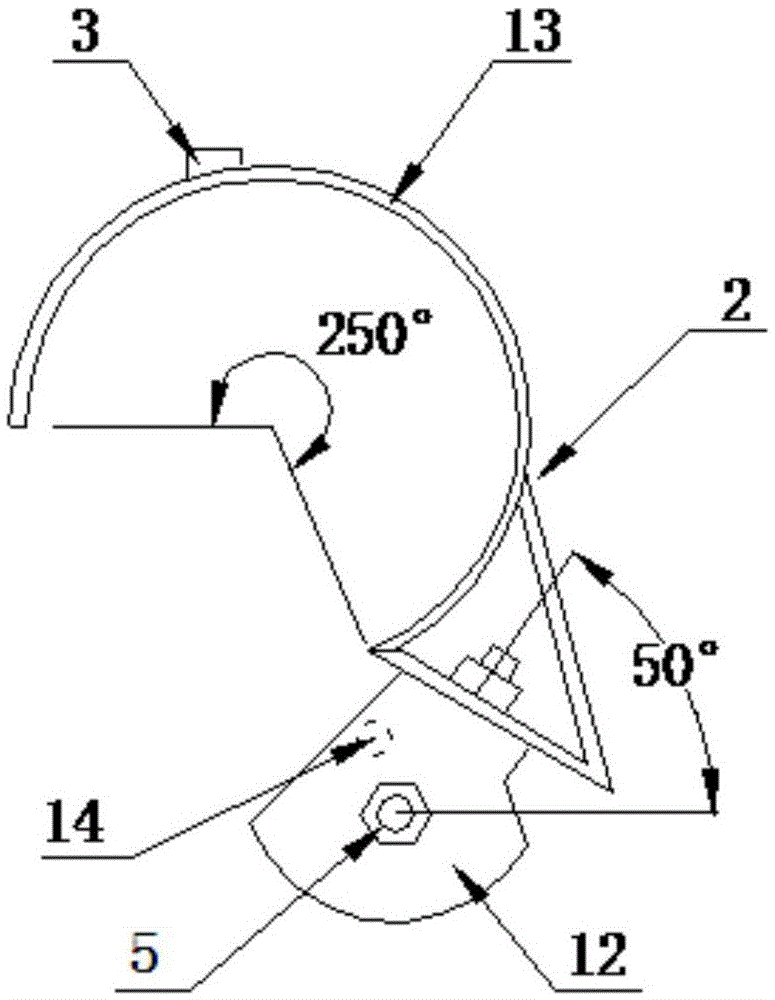

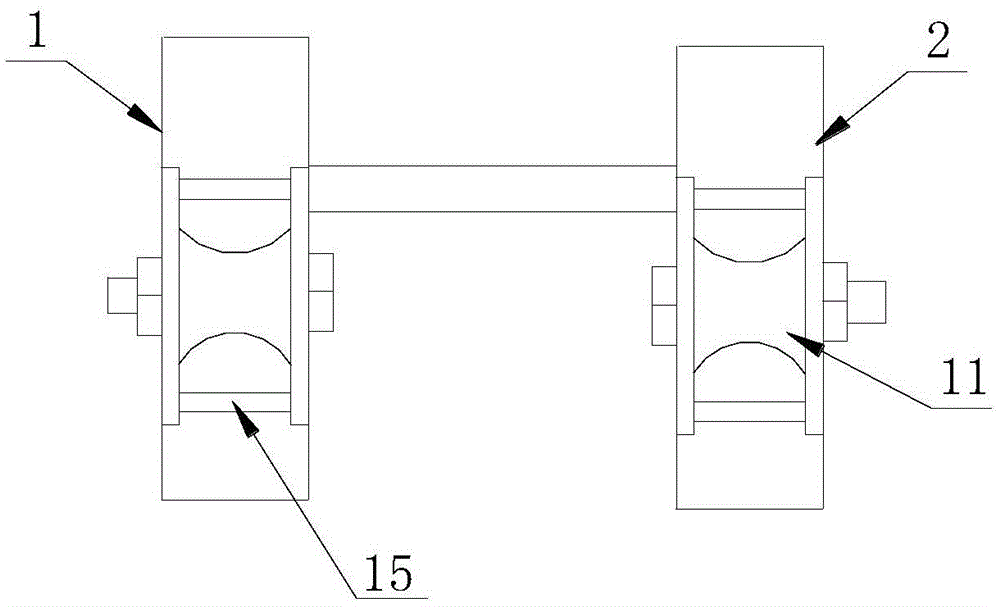

Pulley for high-altitude line or pipe diameter, and mounting method thereof

InactiveCN103332624AEasy to installSmall installation resistanceApparatus for overhead lines/cablesGearing elementsEngineeringHeavy weight

The invention provides a pulley for a high-altitude line or pipe diameter, and a mounting method thereof. The pulley for the high-altitude line or pipe diameter comprises a left pulley device, a right pulley device, and a transverse connecting rod for connecting the left pulley device and the right pulley device, wherein each pulley device comprises a fixed pulley, a fixed pulley component arranged on the two sides of the fixed pulley, and a hook arranged at the top of the fixed pulley component; and the transverse connecting rod is arranged at the tops of the hooks. The hooks of the pulley provided by the invention are in shapes of circular arcs with the angles of 250 DEG, connecting angles between the pulley components and arc surfaces are 50 DEG, the pulley can be mounted and fixed on the needed pipe diameter or line on the ground through a rope to hoist heavy weights to high altitude, and can be detached from the high-altitude pipe diameter or line on the ground, so that the pulley can be mounted and detached on the ground, ascending operation is not needed, and dangers of ascending operation are prevented from occurring.

Owner:BIJIE POWER SUPPLY BUREAU OF GUIZHOU POWER GRID CO LTD +1

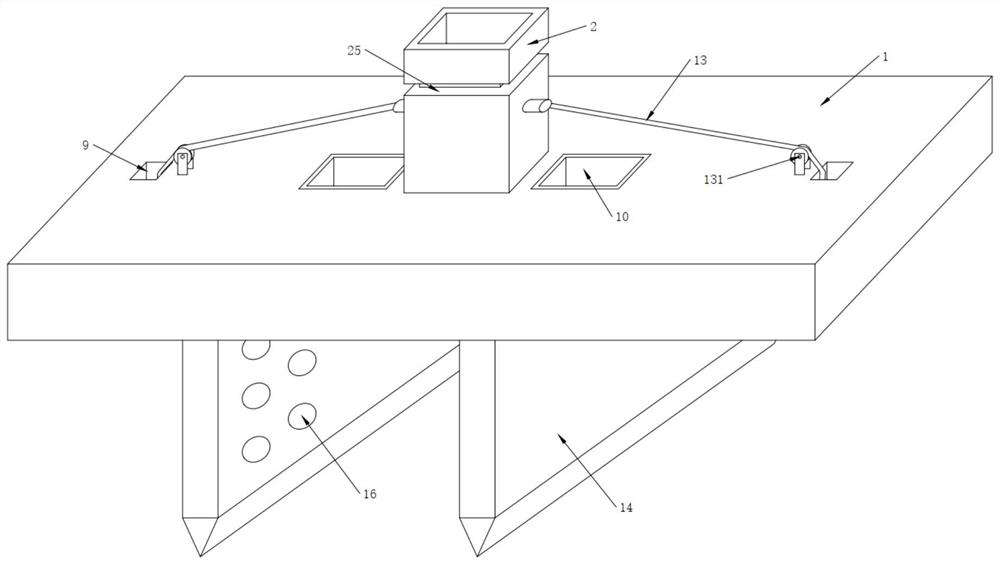

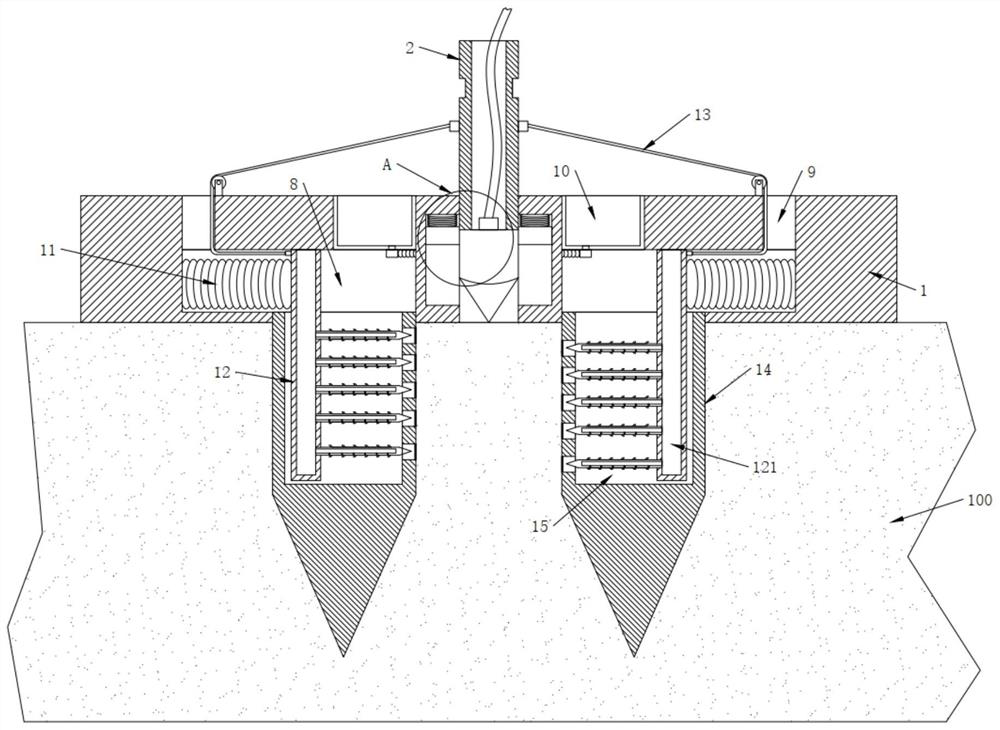

Distribution transformer grounding structure capable of changing soil resistivity

ActiveCN111355044ALow resistivityIncrease moisture contentConnection contact member materialSoil scienceDistribution transformer

The invention discloses a distribution transformer grounding structure capable of changing soil resistivity. The structure comprises a grounding plate, a lifting column and a grounding column, the lifting column is movably inserted into the grounding plate, the grounding column is fixedly connected to a bottom end of the lifting column, and the grounding column is connected with a connecting wire;side grooves are symmetrically formed in the positions, on the two sides of the lifting column, of the grounding plate, extrusion plates are movably arranged in the side grooves and fixedly connectedwith the lifting column, and lifting springs are connected to upper ends of the extrusion plates. Through the cooperative arrangement of ground inserting plates and pushing plates, a soil layer between the ground inserting plates can be extruded and tamped such that the effect of reducing the soil resistivity is achieved; and meanwhile, the relatively high concentration of conductive ions in thesoil and the water content in the soil are kept within a very long period of time such that the resistivity of the soil is reduced.

Owner:国能荥阳热电有限公司

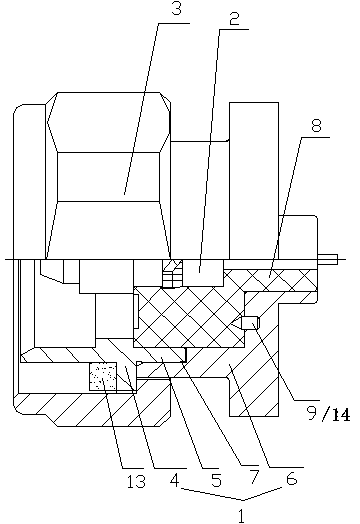

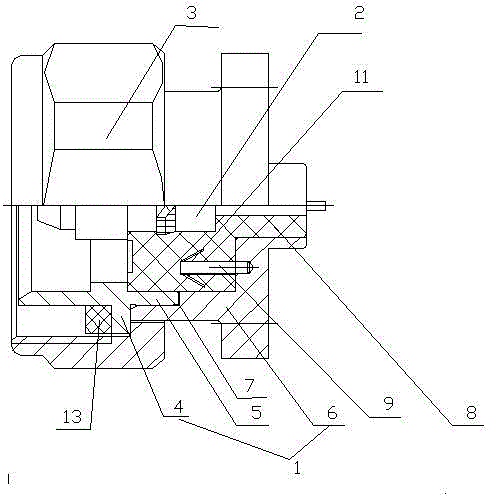

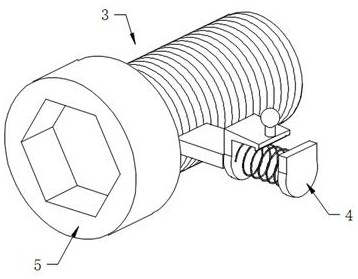

Anti-loosening radio frequency coaxial connector

InactiveCN104022389ASimple structurePrevent rotationCoupling device detailsTwo-part coupling devicesEngineeringRadio frequency

The invention relates to an anti-loosening radio frequency coaxial connector. The anti-loosening radio frequency coaxial connector comprises a casing, wherein the casing is internally provided with a pin and is externally provided with a thread sleeve, the casing comprises a first casing and a second casing, one end of the first casing is provided with a loop of first projections circumferentially, one end of the second casing is provided with a loop of first grooves circumferentially, the first projections and the first grooves are mutually matched, the thread sleeve is sleeved at an outer wall of a connection portion of the first casing and the second casing, a chamber formed by the casing and the pin is provided with an insulator, stop rotation holes are oppositely arranged between contact faces of the insulator and the second casing, the stop rotation holes are internally provided with stop rotation nails, and the stop rotation nails comprise stop rotation nail heads. The anti-loosening radio frequency coaxial connector has a simple structure, can effectively prevent the insulator in the radio frequency coaxial connector from rotating relatively, prevents loosening, excellently guarantees safety and prolongs service life.

Owner:镇江市明基电子有限公司

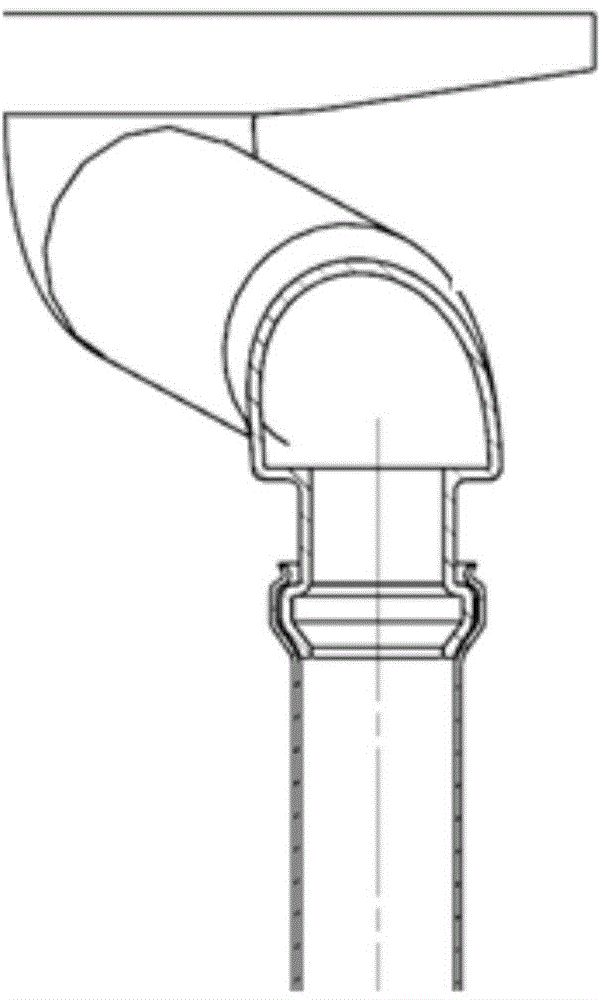

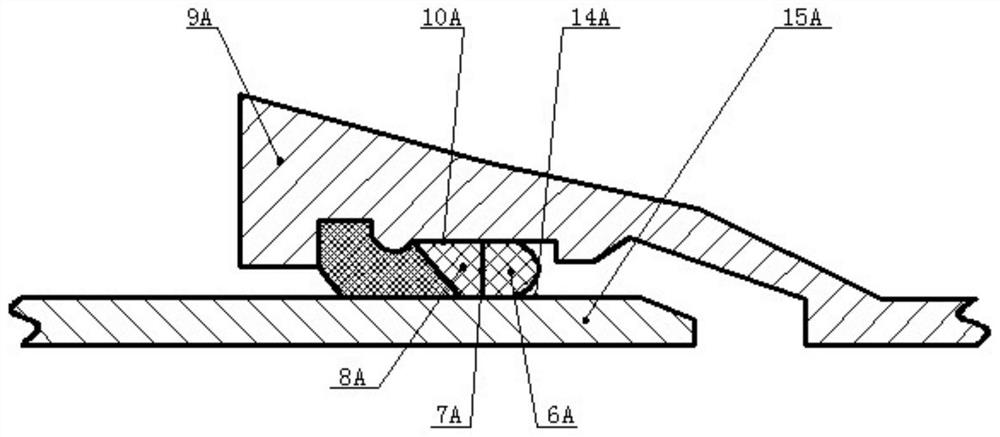

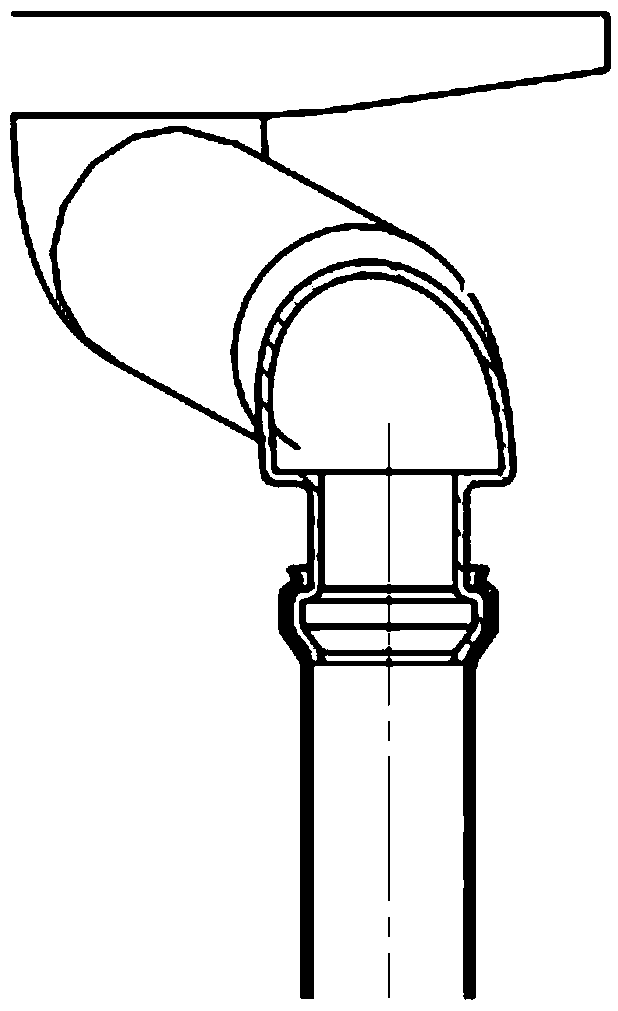

Drain pipe component and refrigerator

ActiveCN104864665AIncrease offset gapSmall installation resistanceLighting and heating apparatusDefrostingEngineeringRefrigerated temperature

The invention provides a drain pipe component and a refrigerator. The drain pipe component comprises a drain pipe and a drain pipe joint, wherein the drain pipe is provided with a clamping part, the drain pipe joint is provided with a connecting part, the connecting part is provided with a plurality of bulges which are spaced at intervals in a circumferential direction and the plurality of bulges are matched with the clamping part so that the drain pipe joint is arranged on the drain pipe. Compared with a technical scheme that the drain pipe is in contact with the drain pipe joint in a full circle, according to the technical scheme that the plurality of bulges which are spaced at intervals are cooperated with the connecting part, the contact area between the connecting part and the clamping part can be reduced, the bias gap formed when the drain pipe is arranged can be improved, the installation resistance of the drain pipe can be effectively reduced, the assembling force of the drain pipe can be reduced, and the assembling efficiency and the operation goodness of staffs can be effectively improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

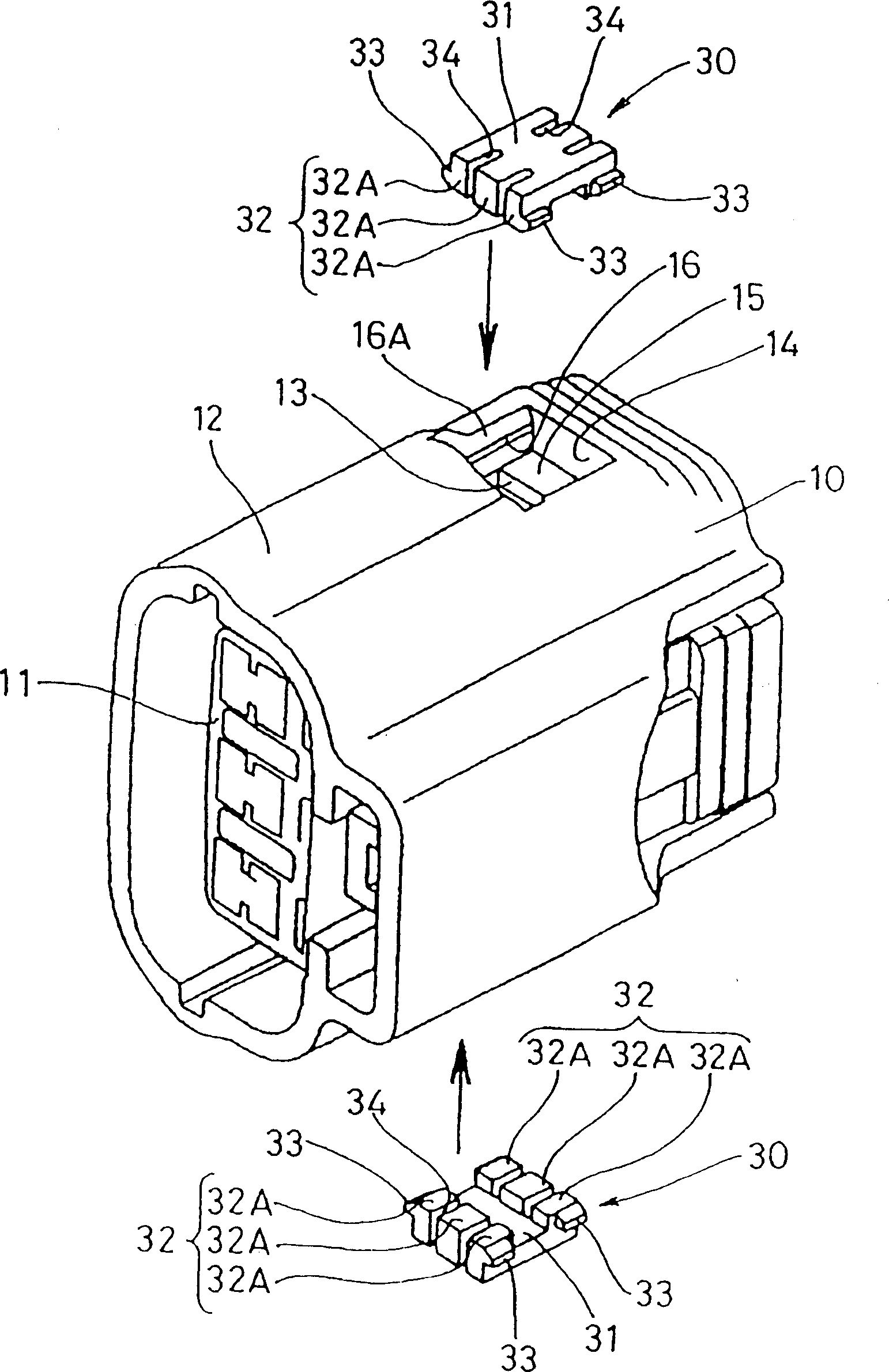

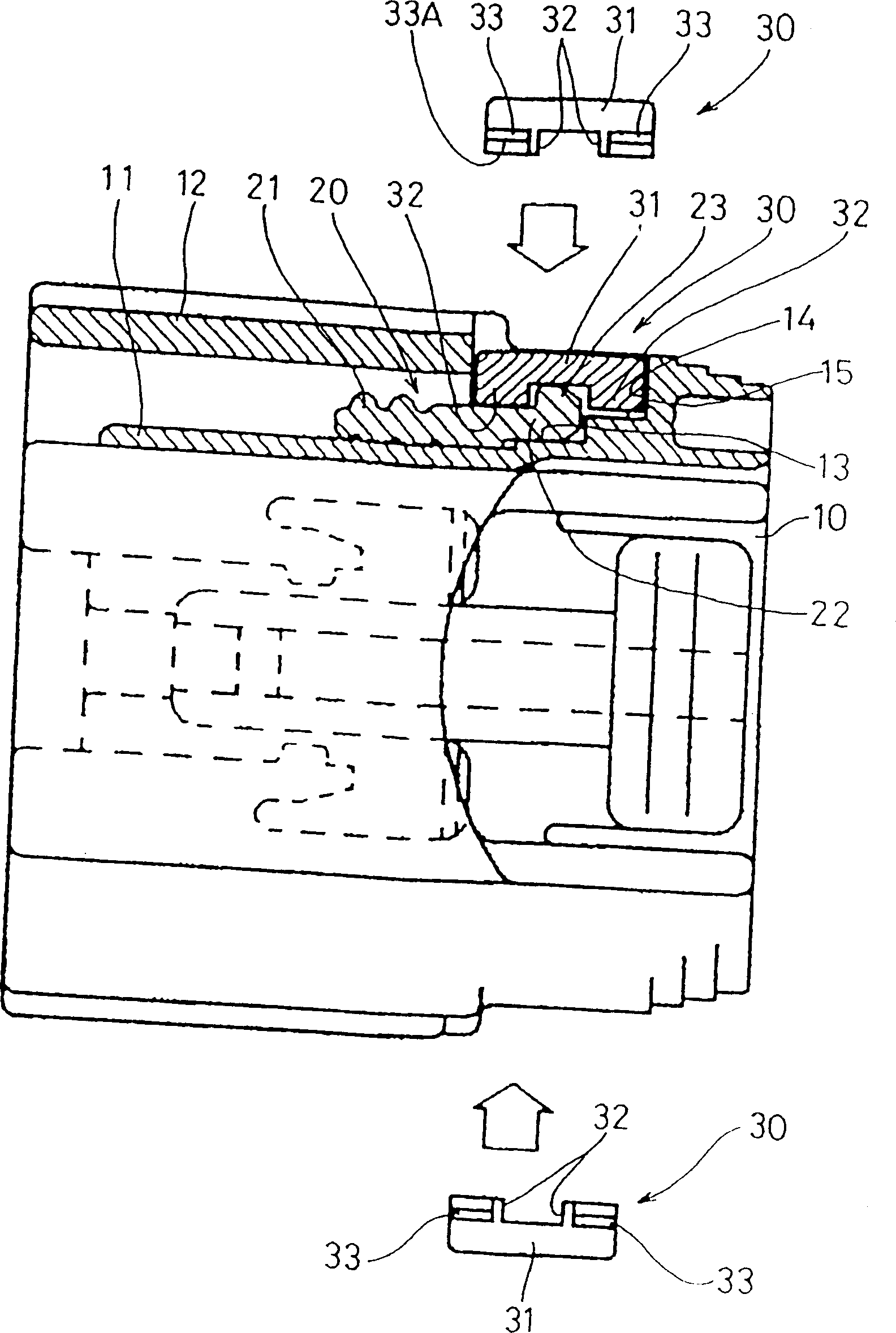

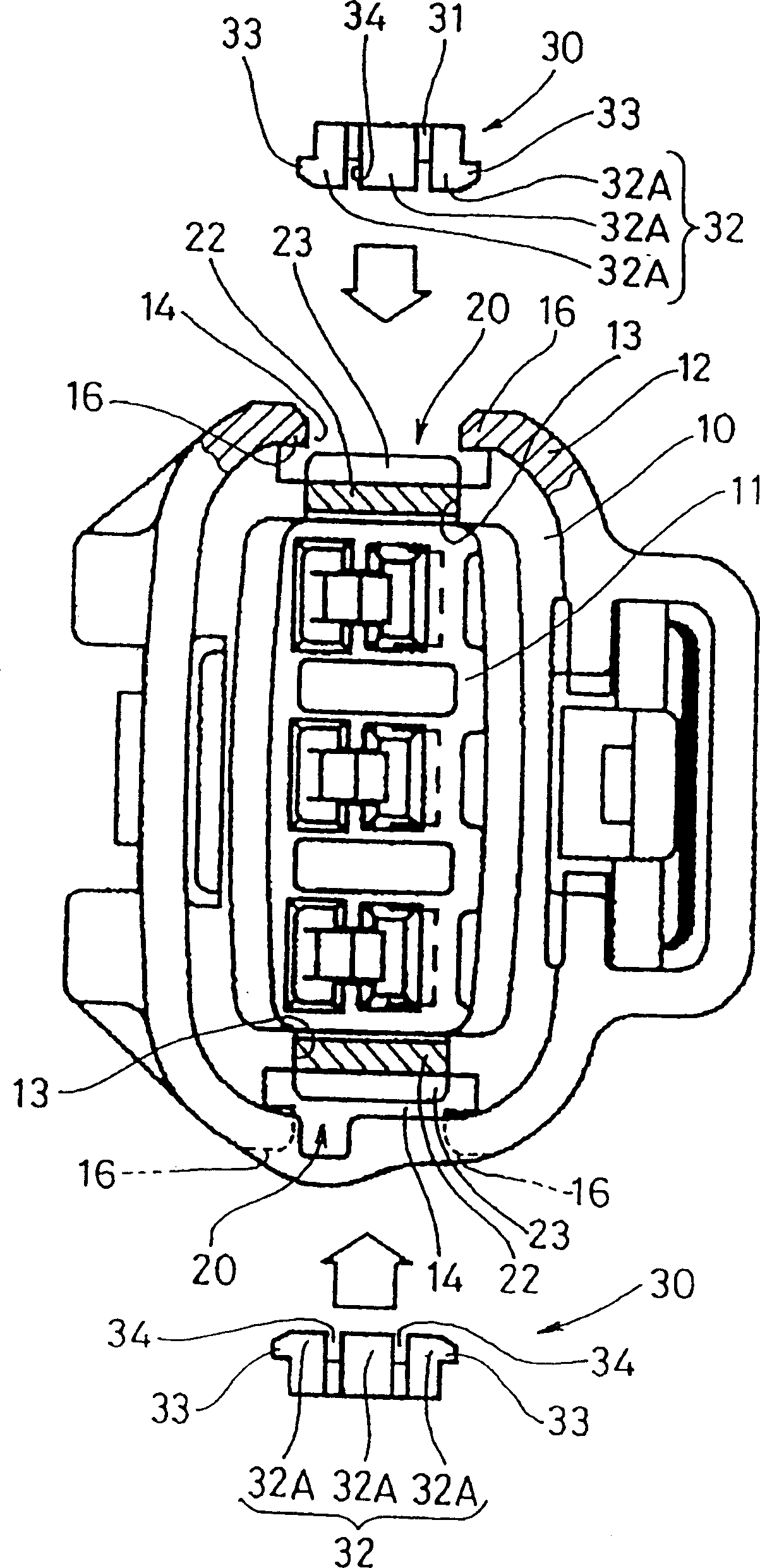

Water-proof connector

InactiveCN1110872CPrevent movementInhibit sheddingCouplings bases/casesEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

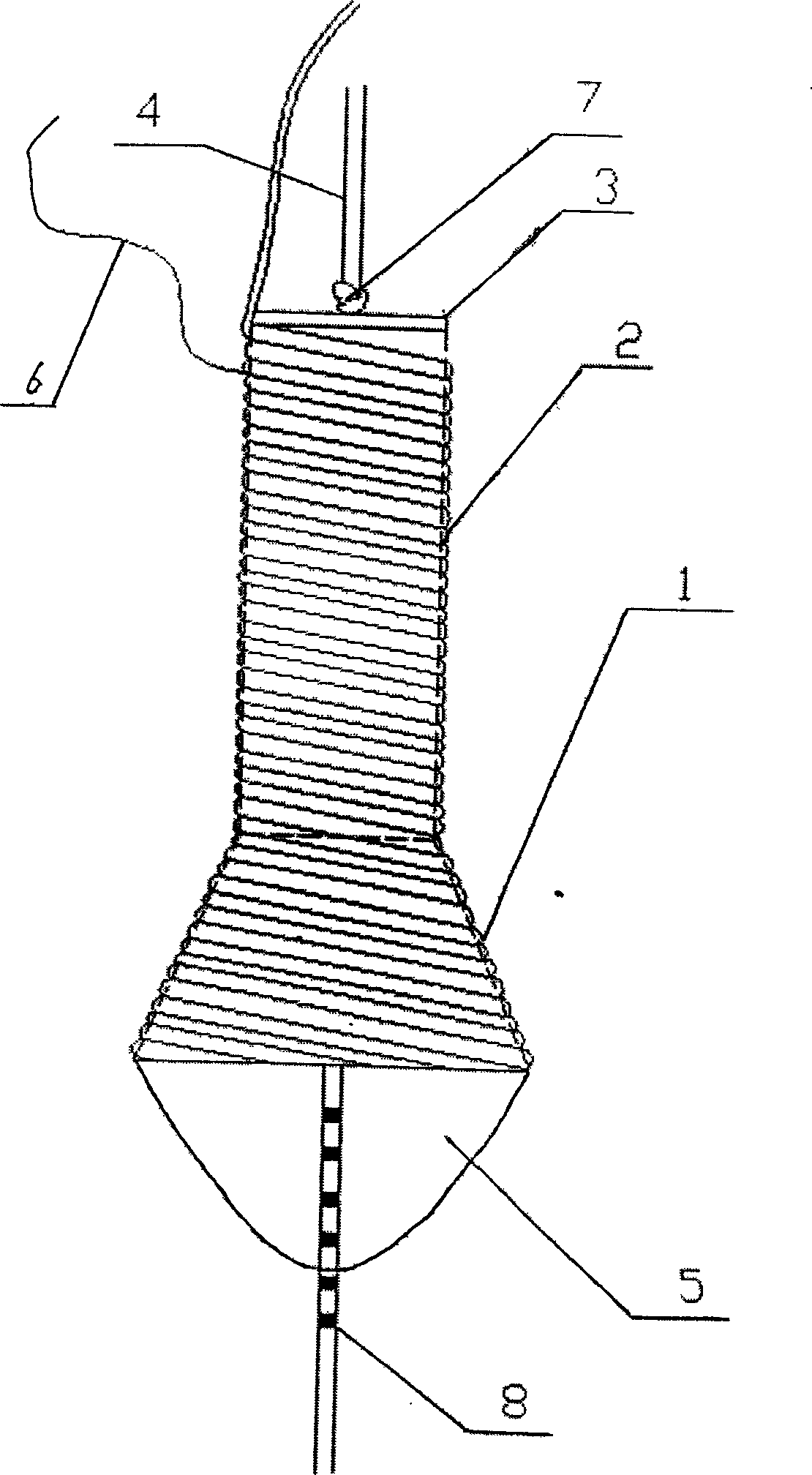

Valve type expanding head anchor rod bearing body

ActiveCN105839637AIncrease radiusImprove the pull-out capacityBulkheads/pilesAnchoring boltsEngineeringMechanical engineering

The invention discloses a valve type expanding head anchor rod bearing body. The valve type expanding head anchor rod bearing body comprises an anchor rod, fixing clamps, first lifting and pulling ropes, second lifting and pulling ropes and at least two valve type expanding heads arranged on the anchor rod in a sleeving manner; each valve type expanding head comprises a round steel pipe reinforcement body and a plurality of valve arc-shaped steel plates; the anchor rod is sleeved with the round steel pipe reinforcement bodies in a penetrating manner; the inner side ends of the multiple valve arc-shaped steel plates are evenly hinged to the peripheries of the round steel pipe reinforcement bodies; the outer side ends of the valve arc-shaped steel plates are connected with the first lifting and pulling ropes; each first lifting and pulling rope is connected with the outer side ends of the valve arc-shaped steel plates in the valve type expanding heads at the same circumferential position; the at least two fixing clamps are evenly hoisted and arranged around the anchor rod through the second lifting and pulling ropes; and the multiple first lifting and pulling ropes opposite to one side of one fixing clamp are connected to the fixing clamp in a gathering manner. The valve type expanding head anchor rod bearing body has higher uplift bearing capacity compared with an existing bearing body.

Owner:CHEM IND GEOTECHN ENG

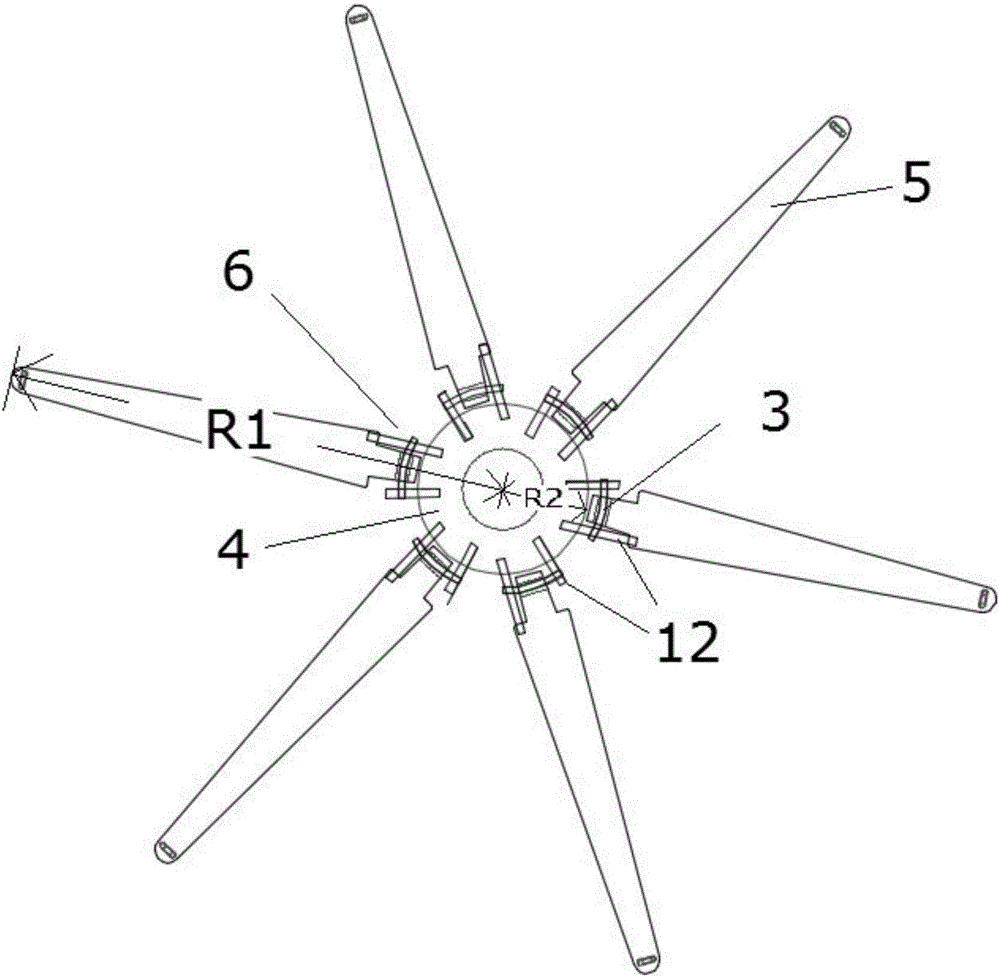

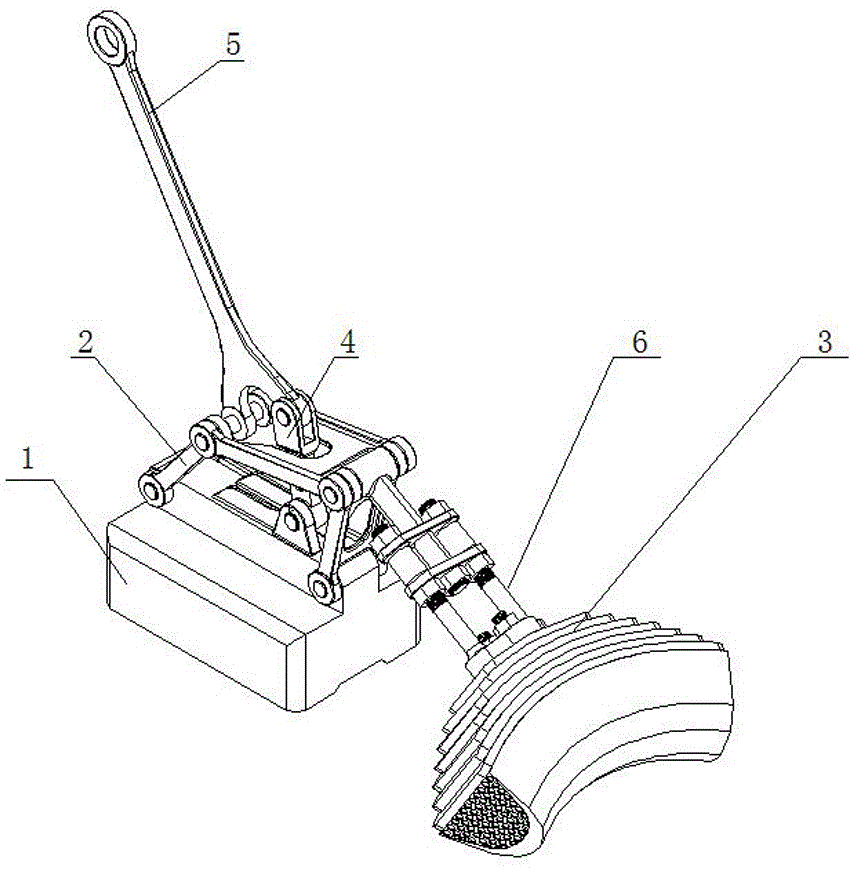

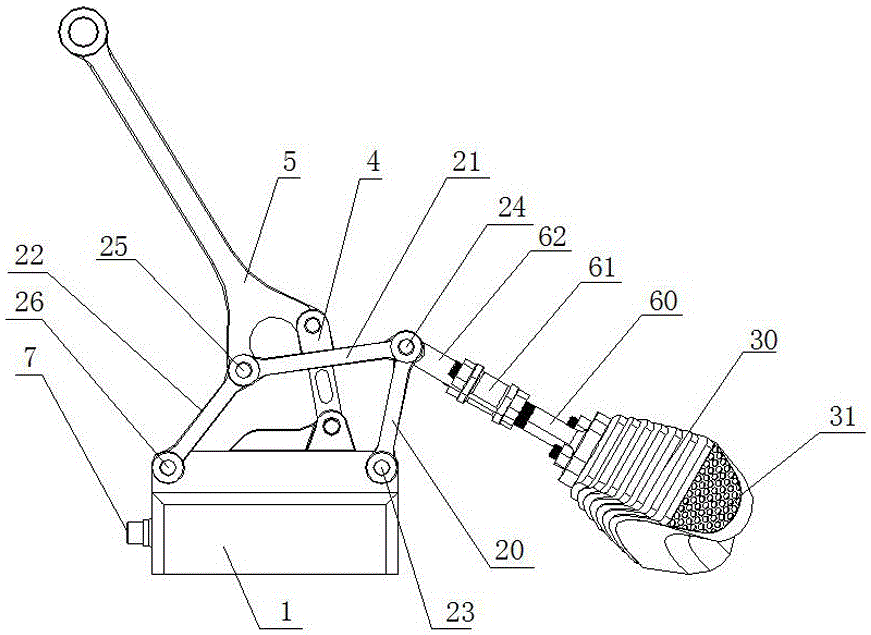

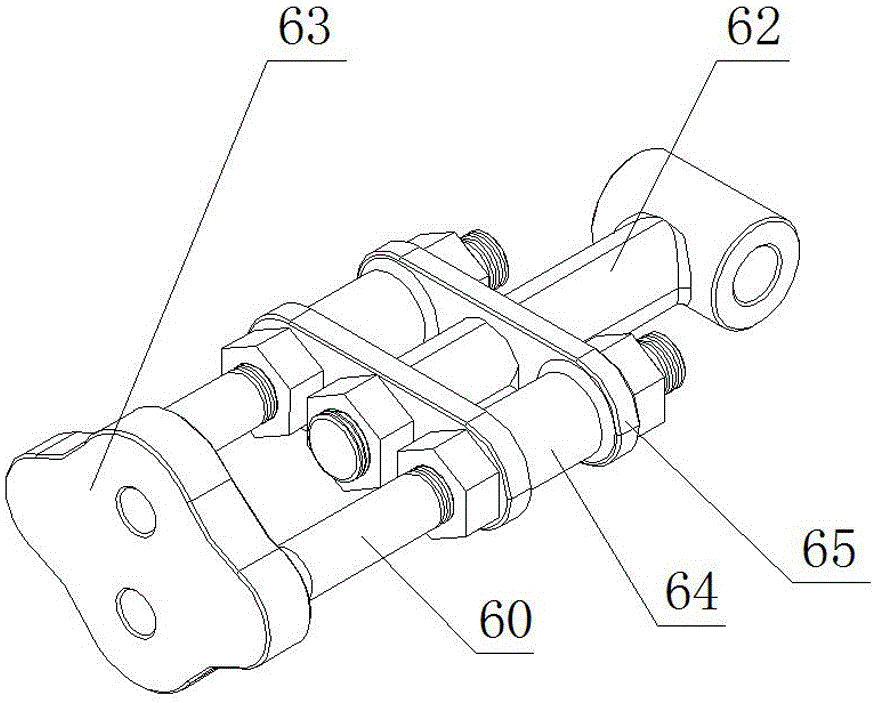

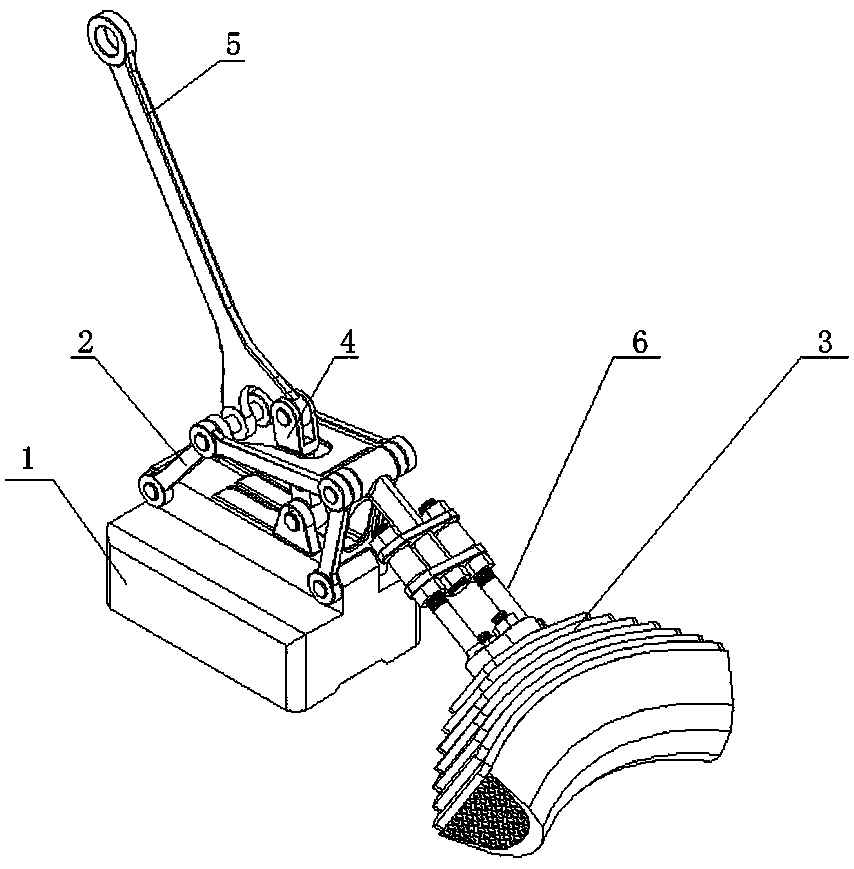

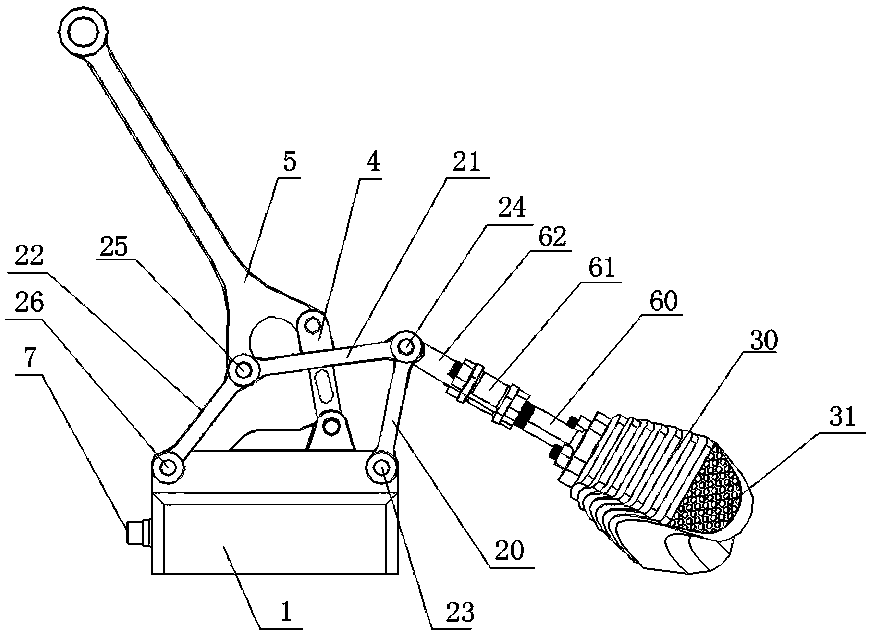

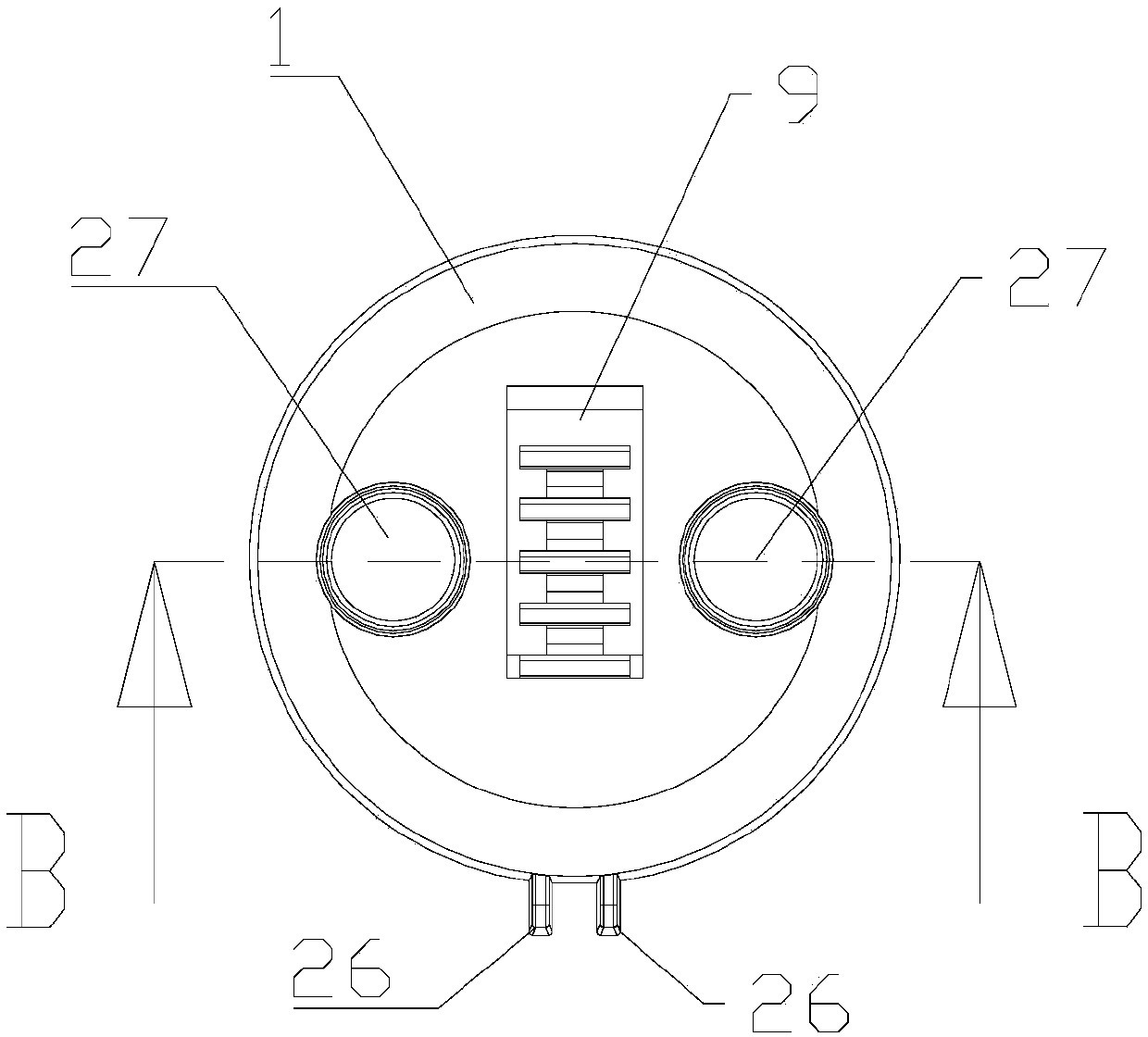

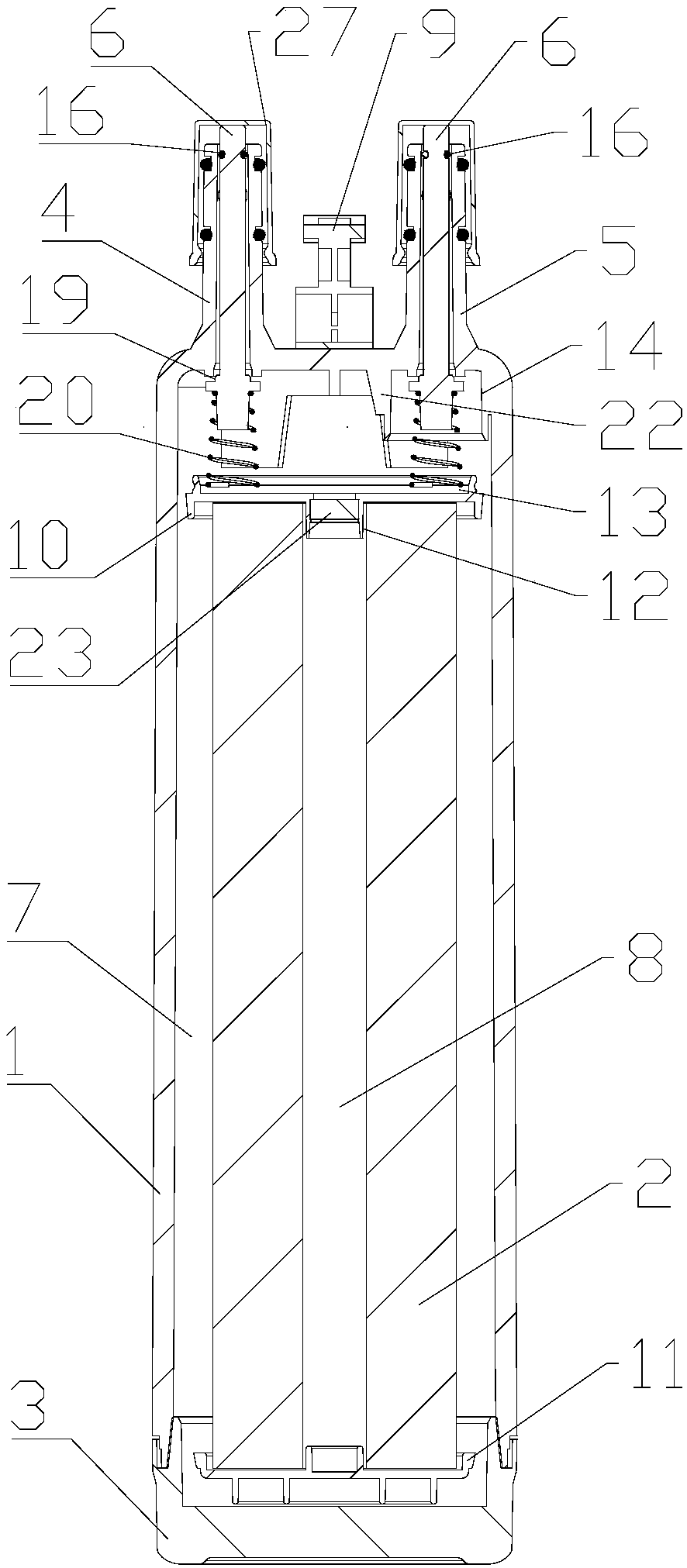

Permanent magnetism positioning emergency plugging device based on pressure vessel fillet weld leakage

The invention relates to a permanent magnetism positioning emergency plugging device based on pressure vessel fillet weld leakage, and belongs to the pipeline engineering field; the permanent magnetism positioning emergency plugging device based on pressure vessel fillet weld leakage uses a strong magnet to fix the plugging device in a to-be-plugged position; a linkage can press a plugging assembly in the leakage portion; a spring steel bar composite rubber layer and seal rubber layer deformation plugging mode can plug the large radian or surface variable leakage portion; the permanent magnetism positioning emergency plugging device based on pressure vessel fillet weld leakage comprises a strong magnetic mechanism, the linkage and the plugging assembly; the linkage is arranged above the strong magnetic mechanism so as to form a four-connecting rod structure with the strong magnetic mechanism; the strong magnetic mechanism is hinged to a drive pull rod; the top of the drive pull rod is provided with a handle; the handle is respectively hinged to the drive pull rod and a third hinge; the plugging assembly is connected with a second hinge.

Owner:ZHONGBEI UNIV

Novel radio frequency coaxial connector

InactiveCN104600475ASimple structurePrevent rotationCoupling device detailsTwo-part coupling devicesEngineeringRadio frequency

The invention discloses a novel radio frequency coaxial connector. The novel radio frequency coaxial connector comprises a housing; an inserting pin is arranged in the housing, and while a screw sleeve is arranged at the outside of the housing; the housing comprises a first housing body and a second housing body; an insulator is arranged in a cavity formed by the housing and the inserting pin; a plurality of rotating stopping parts which are symmetrically arranged along a center line of the housing are arranged between the insulator and the contact surface of the second housing body; one end of each rotating stopping part is inserted into the insulator, and while the other end of each rotating stopping part is fixedly arranged in the second housing body. The novel radio frequency coaxial connector is simple in structure; the rotating stopping parts are arranged between the insulator and the contact surface of the second housing, thus the insulator in the radio frequency coaxial connector can be effectively prevented from relative rotating as well as loosening, and as a result, the safety is ensured well, and the service life is prolonged.

Owner:镇江市明基电子有限公司

A Distribution Transformer Grounding Structure That Can Change Soil Resistivity

ActiveCN111355044BLow resistivityIncrease moisture contentConnection contact member materialSoil scienceDistribution transformer

The invention discloses a distribution transformer grounding structure capable of changing soil resistivity, comprising a grounding plate, a lifting column and a grounding column, the lifting column is movably plugged into the grounding plate, and the grounding column is fixedly connected to the bottom of the lifting column The grounding column is connected with connecting wires; side grooves are symmetrically opened in the grounding plates on both sides of the lifting column, and extruding plates are movable in the side grooves, and the extruding plates are fixedly connected to the lifting column. And the upper end of the extrusion plate is connected with a lifting spring. The present invention can compress and tamp the soil layer between the inserted floors through the cooperative arrangement of the inserted floor and the push plate, so as to achieve the effect of reducing soil resistivity; and at the same time, keep the soil in the The higher the concentration of conductive ions and the water content in the soil, the lower the soil resistivity.

Owner:国能荥阳热电有限公司

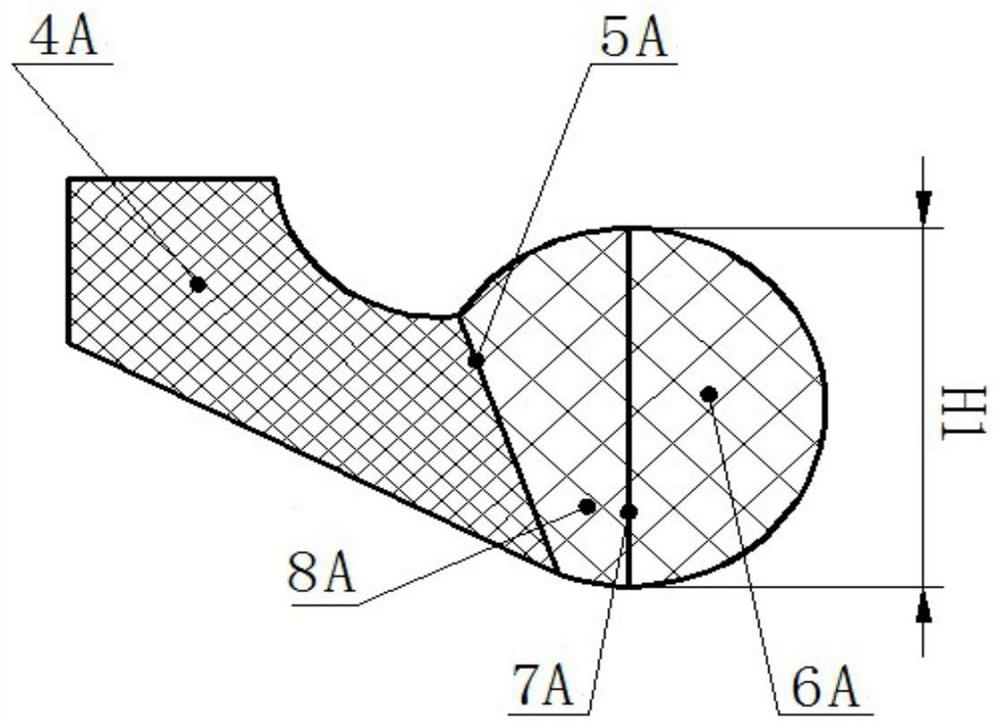

Pipeline interface sealing device and preparation method thereof

ActiveCN109667934BExtended service lifeEliminate the risk of separationEngine sealsPipe-jointsRubber ringTube socket

The invention discloses a pipe joint sealing device and a preparation method. The sealing device includes a pipe socket, a pipe socket and a sealing rubber ring placed at the joint of the two. The sealing rubber ring is integrally formed and has the same hardness throughout the body. The medium contact surface of the sealing rubber ring is an inclined surface or a wave surface. The present invention also provides a pipe joint method using the above-mentioned device. When in use, a groove matching the shape of the sealing rubber ring is formed on the pipe socket. During the process of pushing the pipe socket, the sealing rubber ring is compressed and deformed, and finally realized Sealed connections for pipes. In addition, a preparation method of the sealing device is provided, the purpose of which is to provide a pipe joint device equipped with a sealing rubber ring and a pipe joint method using the same, which has a simple structure and greatly reduces installation resistance while ensuring the sealing effect.

Owner:XINXING DUCTILE IRON PIPES CO LTD

A prefabricated and assembled comprehensive pipe gallery socket socket waterproof structure

ActiveCN106149764BSmall installation resistanceEasy to installArtificial islandsProtective foundationPolymer modifiedArchitectural engineering

The invention discloses a precast splice comprehensive pipe gallery bell and spigot waterproof structure. The precast splice comprehensive pipe gallery bell and spigot waterproof structure comprises a seam composed of a pipe gallery spigot and a pipe gallery bell. At the seam, waterproof construction bodies composed of a PCM waterproof roll with the thickness of 1.5 mm to 3.0 mm, JS-211 double-component sealants, a polyethylene foam filling plate, an EPDM wedge-shaped sealing ring, a hydrophilic expansion elastic rubber body, a polyethylene foam filling plate, JS-211 double-component sealants and EPIIR self-adhesion waterproof adhesive tape with the thickness of 1.5 mm to 2.0 mm are sequentially arranged from the outer side of the seam to the inner side of the seam. Multiple waterproof guards are constructed, the outer side PCM self-adhesion polymer modified asphalt waterproof roll has the waterproof function, further can prevent plant roots from being punctured and protects the outer seam; double-component sealant cording seams achieve the waterproof and anti-seepage effects; the inner side EPIIR self-adhesion waterproof adhesive tape has the waterproof and anti-seepage functions, further achieves the effects of insect and rat damage prevention effects and mainly plays a role in protecting the inner seam; through the multiple waterproof guards, the waterproof structure is long in service life and can reach 100 years.

Owner:SICHUAN JUST RUBBER

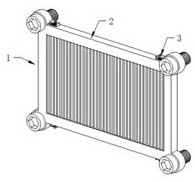

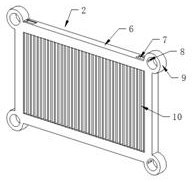

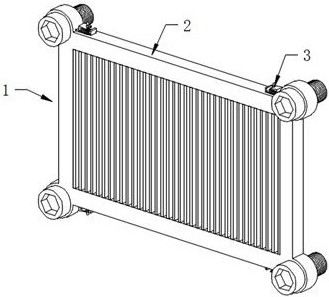

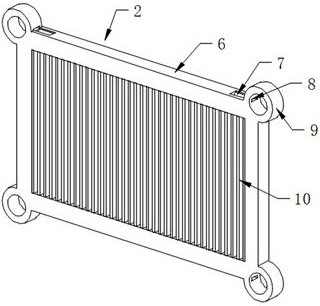

Connecting structure of radiator support and front longitudinal beam of automobile

InactiveCN114393986APrevent movementPrevent rotationPropulsion coolingEngineeringMechanical engineering

The invention discloses an automobile radiator support and front longitudinal beam connecting structure which comprises an automobile radiator support fixing mechanism, the automobile radiator support fixing mechanism comprises an automobile radiator support, the automobile radiator support comprises a radiator core, and the automobile radiator support fixing mechanism further comprises a fixing body. The fixing body and the automobile radiator support are fixedly installed together, the automobile radiator support further comprises a frame, the fixing body comprises a locking body and a bolt, the side end of the locking body is installed on the inner wall of the front portion of the bolt in a sliding and inserted mode, and the locking body comprises a sliding bolt, an elastic piece, a spring and a first clamping block. One end of the sliding bolt is fixedly installed at one side end of the spring, and one end of the elastic piece is fixedly installed on the upper side of the sliding bolt. The invention relates to the technical field of automobile radiator bracket mounting equipment, can prevent screws from loosening, is convenient to mount, and better meets the use requirements.

Owner:湖南宇恒汽车零部件有限公司

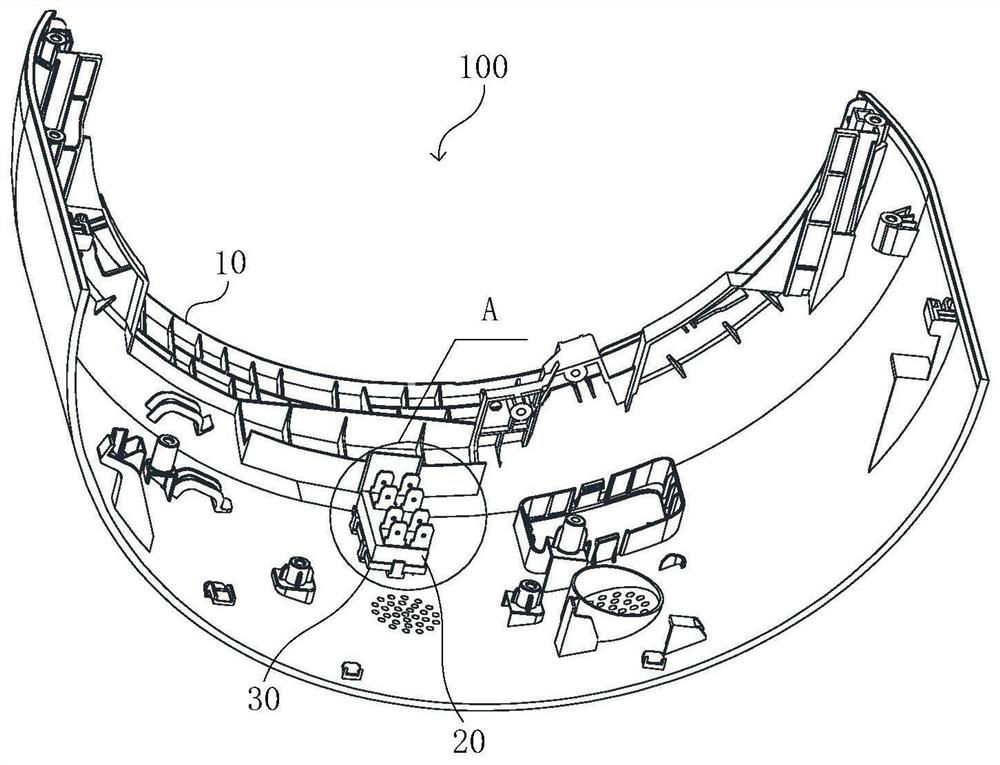

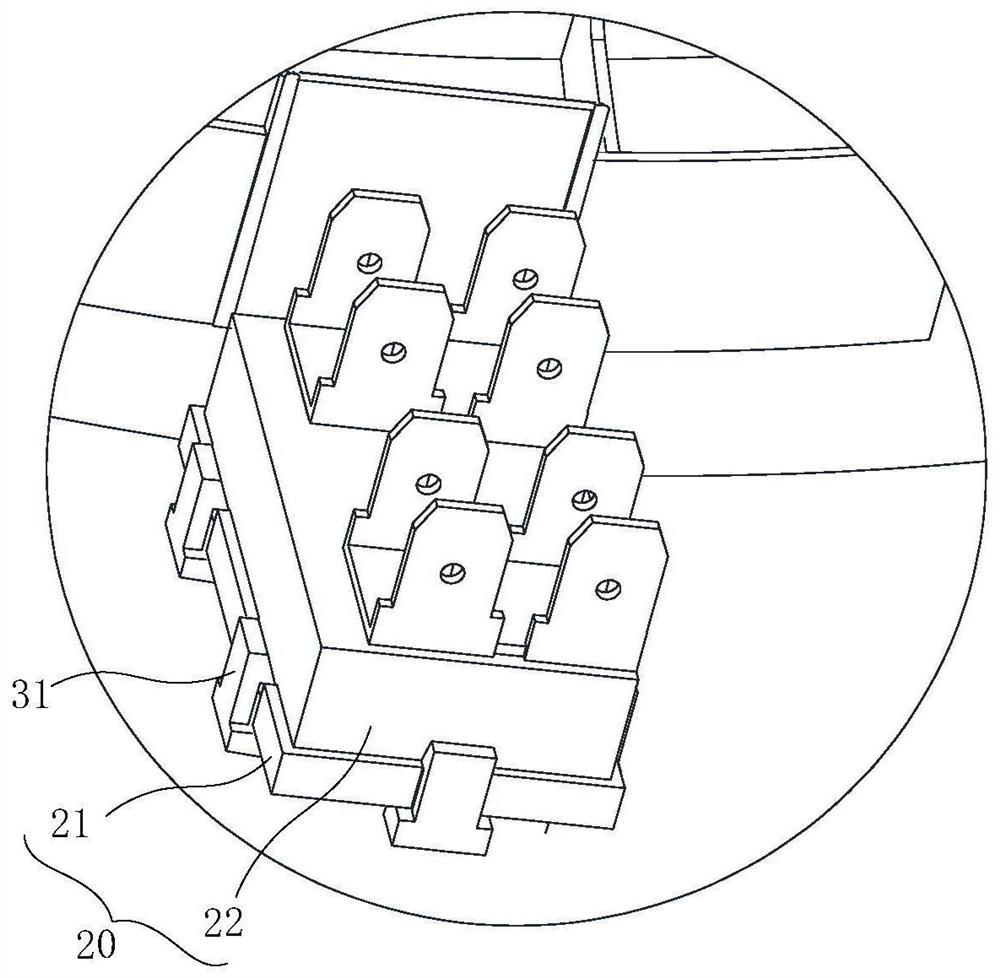

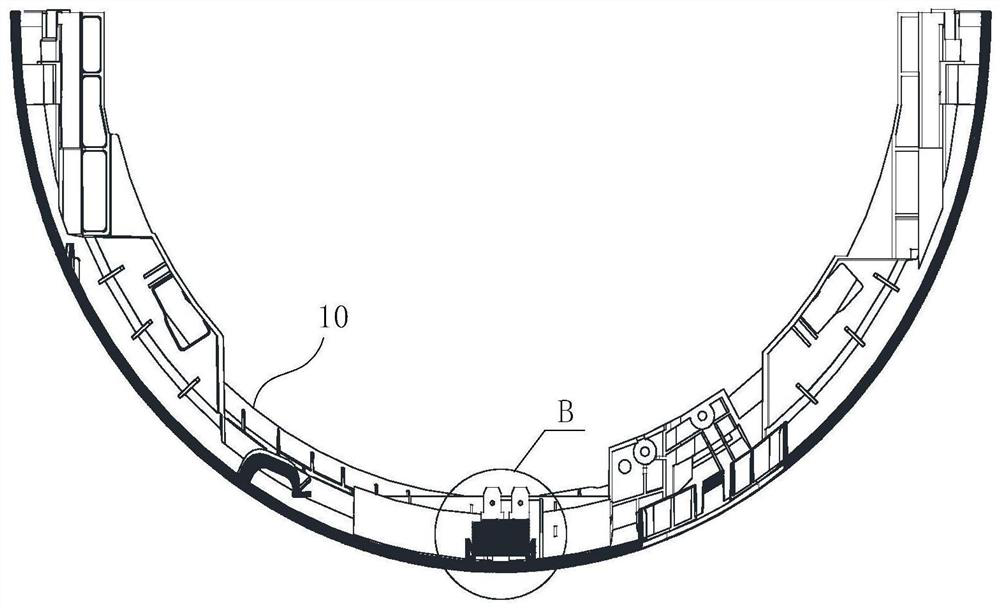

A rear panel structure and an air conditioner

ActiveCN113375328BEasy to installReduce electrostatic effectHeating and ventilation casings/coversElectrostatic chargesEngineeringBoard structure

Owner:NINGBO AUX ELECTRIC +1

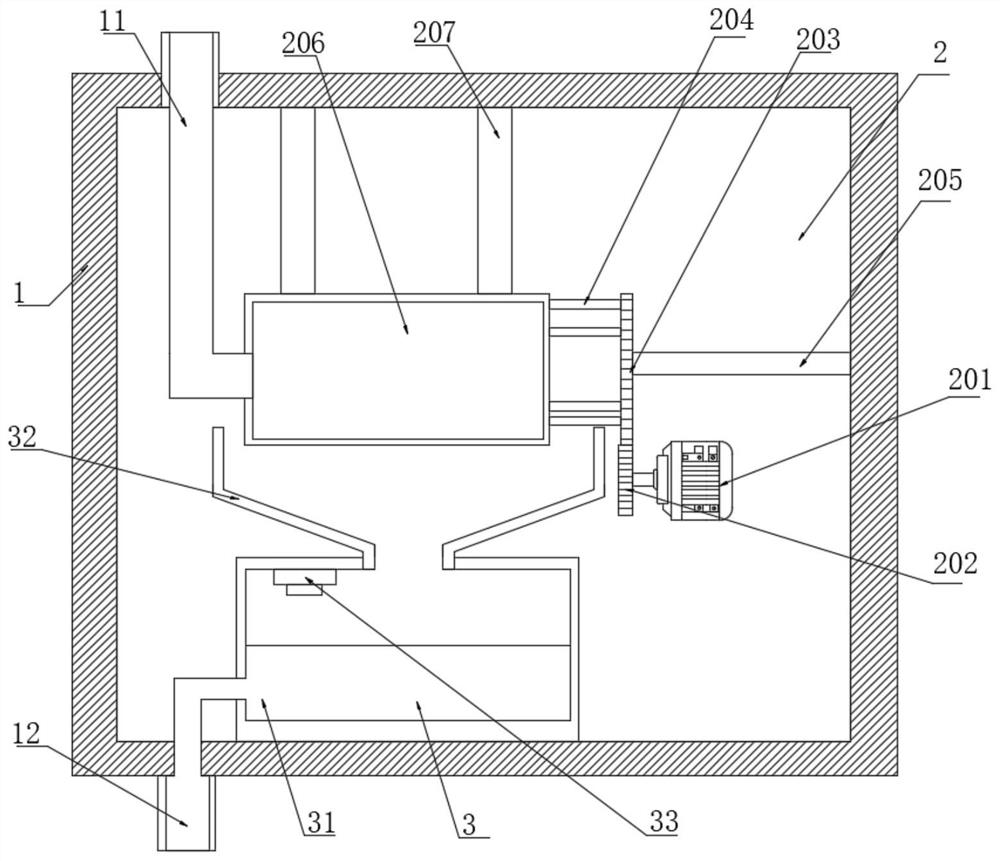

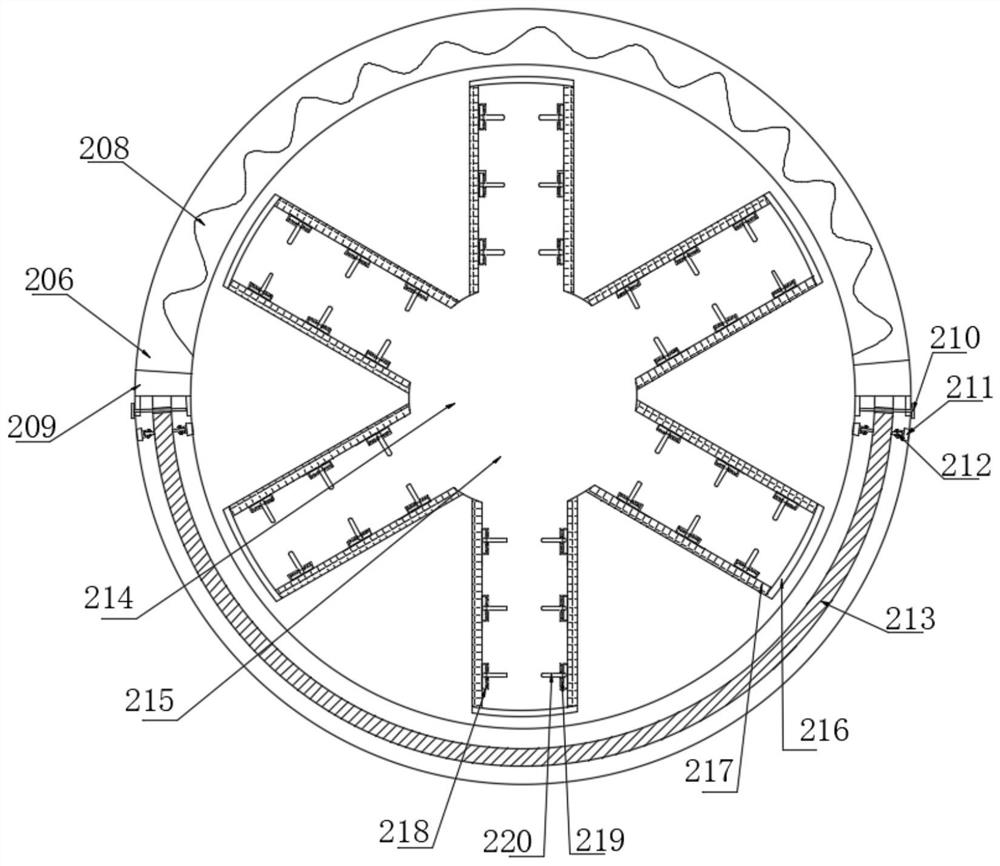

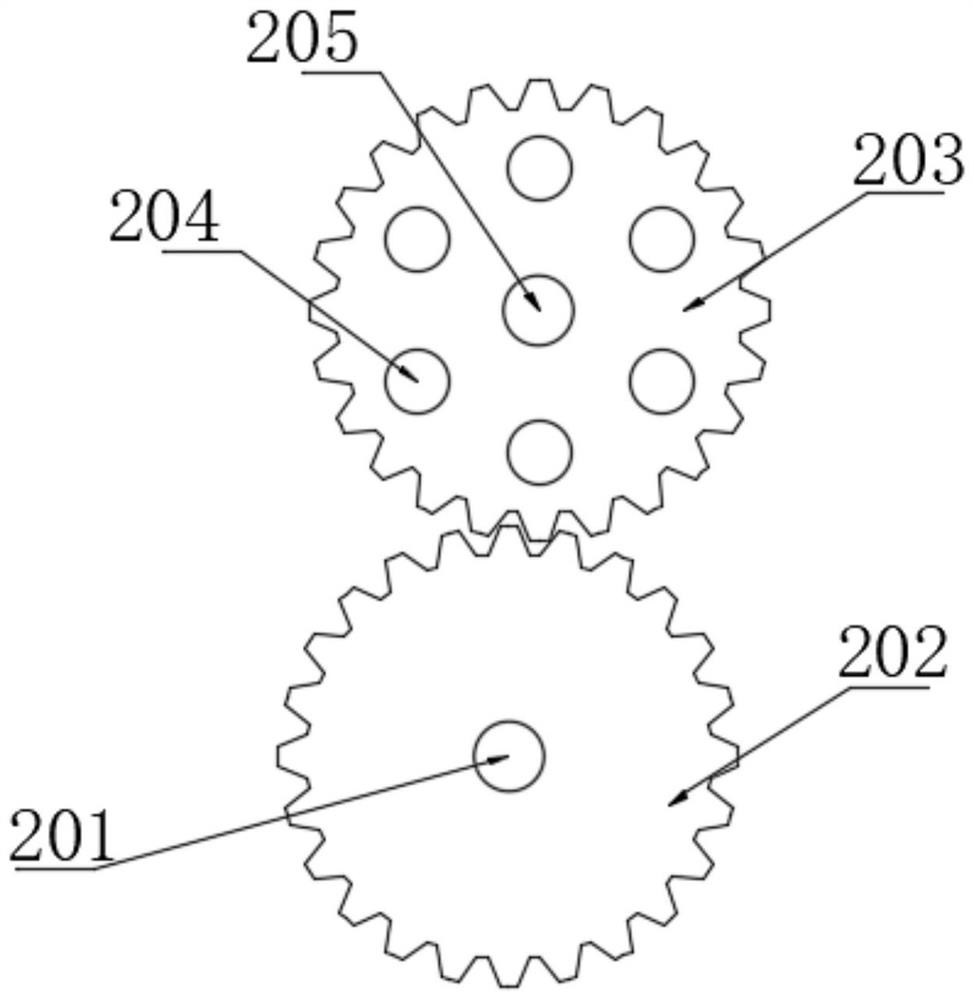

Zero-discharge treatment device for medical blood sewage

InactiveCN113072231AShorten the timeSmall installation resistanceWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentEngineeringMechanical engineering

The invention belongs to the field of sewage discharge treatment, and particularly relates to a zero-discharge treatment device for medical blood sewage. The device comprises a shell, a primary treatment mechanism and a secondary treatment mechanism, and the primary treatment mechanism comprises a motor, a first transmission gear, a second transmission gear, a connecting rod, a mounting rod, a primary treatment chamber, a fixed rod, a heating wire, a clamping block, a pin rod, a base, a roller, a primary filter membrane, a connector, a connecting pipe, a branch pipe and the like. The first transmission gear is driven by a motor to rotate so as to enable a primary treatment chamber to rotate, sewage in a connecting pipe enters a plurality of branch pipes due to the action of centripetal force, two springs are fixedly connected with a swing plate, so that the swing plate can delay the time of water flow rushing out of the branch pipes, and the water flow is more completely filtered by a secondary filtering membrane; and the primary filter membrane is fixedly mounted at the lower end of the inner wall of the secondary treatment chamber, and the top end of the roller is tangent to the side surface of the primary filter membrane, so that the mounting resistance of the primary filter membrane is conveniently reduced.

Owner:刘晓燕

Connecting structure between automobile radiator support and front longitudinal beam

InactiveCN112277628APrevent movementPrevent rotationPropulsion coolingEngineeringMechanical engineering

The invention discloses a connecting structure between an automobile radiator and a front longitudinal beam, which comprises an automobile radiator support fixing mechanism, the automobile radiator support fixing mechanism comprises an automobile radiator support, the automobile radiator support comprises a radiator core, and the automobile radiator support fixing mechanism further comprises a fixing body. The fixing body and the automobile radiator support are fixedly installed together, the automobile radiator support further comprises a frame, the fixing body comprises a locking body and abolt, the side end of the locking body is installed on the inner wall of the front portion of the bolt in a sliding and inserted mode, and the locking body comprises a sliding bolt, an elastic piece,a spring and a first clamping block. One end of the sliding bolt is fixedly installed at one side end of the spring, and one end of the elastic piece is fixedly installed on the upper side of the sliding bolt. The invention relates to the technical field of automobile radiator support mounting equipment, can prevent screws from loosening, is convenient to mount, and better meets the use requirements.

Owner:湖南宇恒汽车零部件有限公司

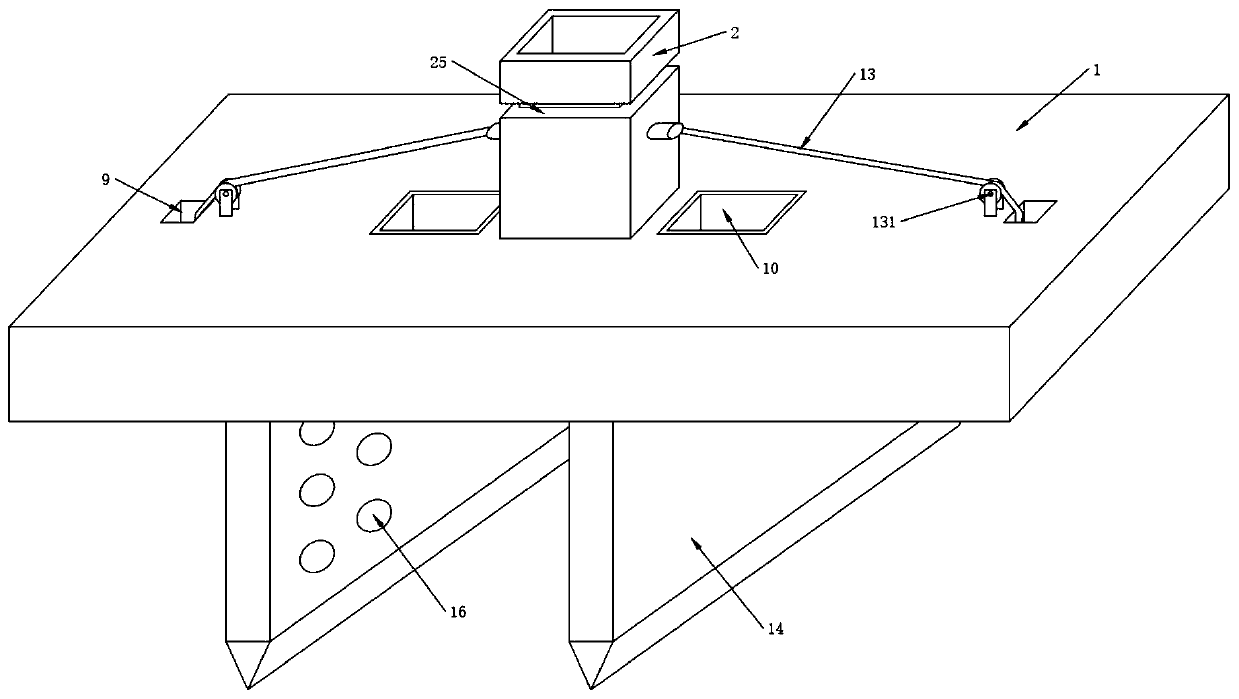

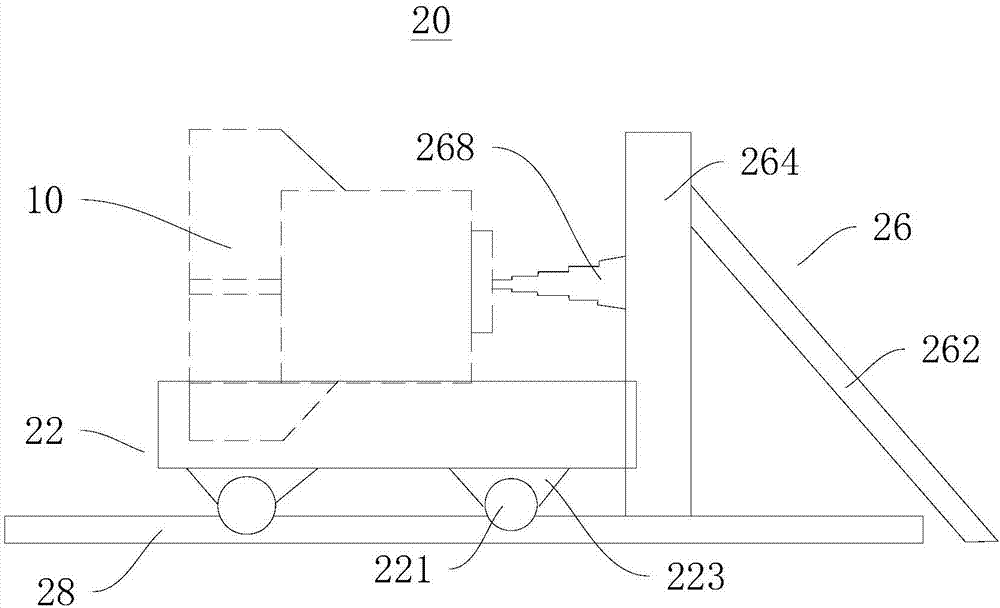

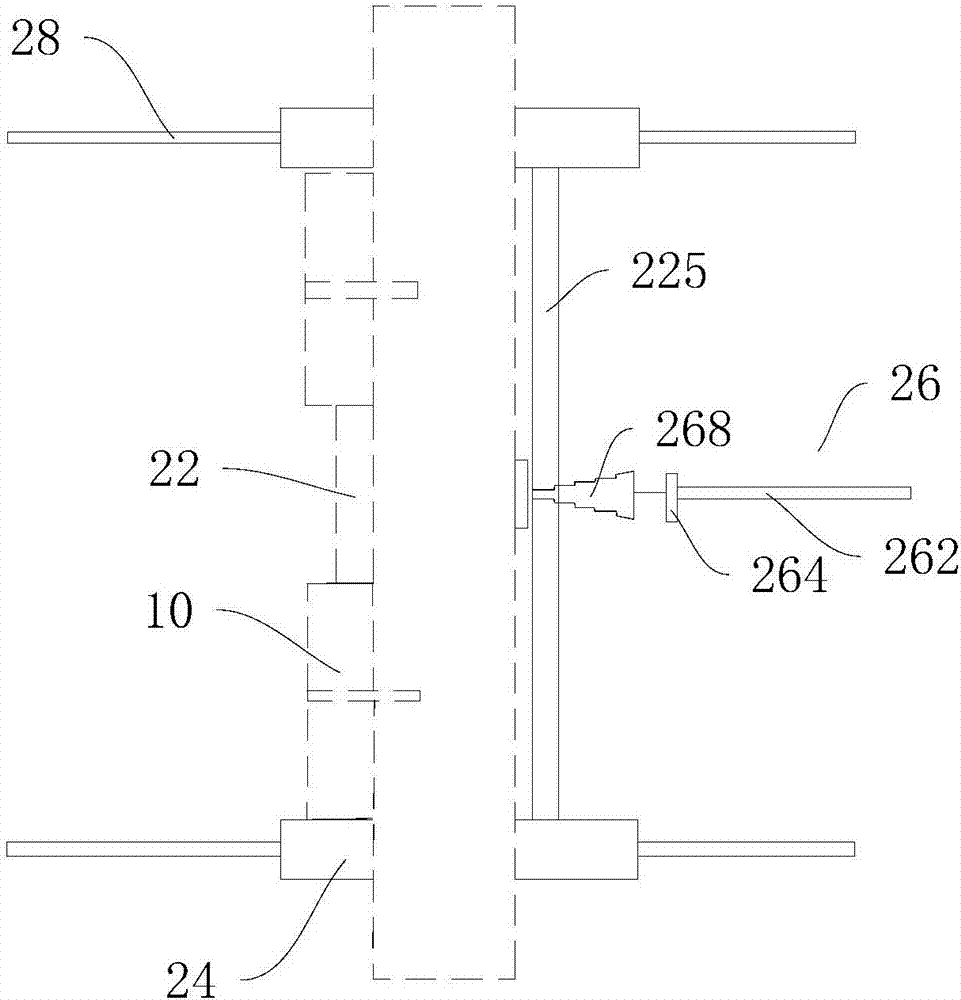

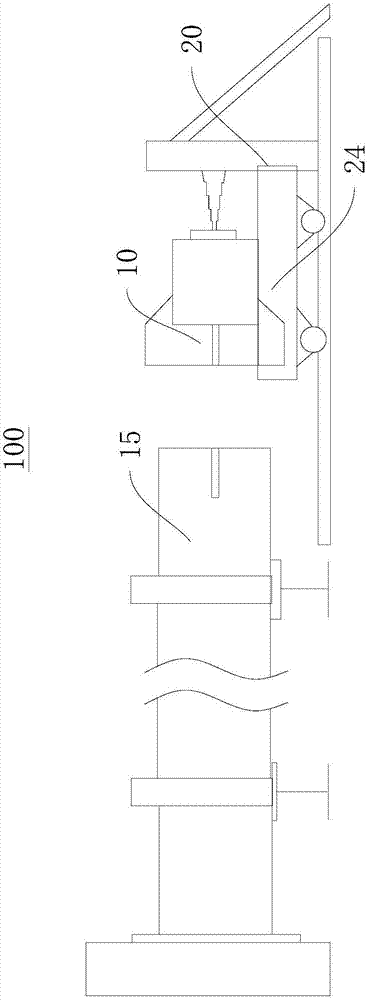

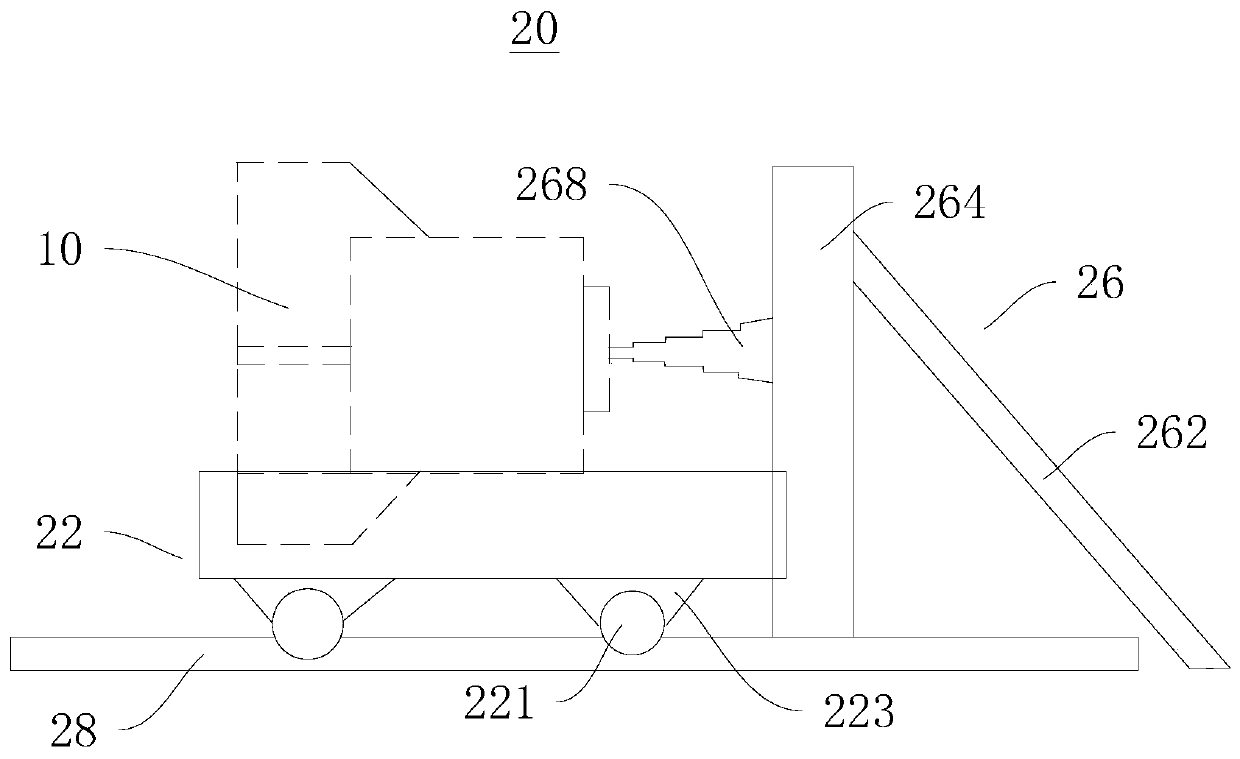

Sliding device, box-type beam stud assembling component, and method for mounting box-type beam stud in tubular pillars

ActiveCN107571194AFinish quicklyComplete efficientlyMetal-working hand toolsComputer engineeringSteel structures

The invention discloses a sliding device, a box-type beam stud assembly component, and a method for mounting a box-type beam stud in tubular pillars, and relates to the technical field of large-scalesteel-structure dual-tubular-pillar assembly. The sliding device comprises a sliding component, a supporting platform frame and a positioning-pushing component, wherein the sliding component can slideon a workbench; the supporting platform frame is fixedly arranged on one side of the sliding component; and the positioning-pushing component is fixedly arranged on the workbench and can be propped against the box-type beam stud, so that the box-type beam stud can be driven by the sliding component to slide and to be assembled with the tubular pillars. The box-type beam stud assembly component comprises the box-type beam stud and the sliding device, wherein the box-type beam stud is fixedly arranged on the supporting platform frame; the cross assembly end of the box-type beam stud can be matched with the tubular pillars; and the propping end of the box-type beam stud is propped against the positioning-pushing component. According to the sliding device and the box-type beam stud assembly component, the design is reasonable, the structure is simple, the assembly is convenient, the labor intensity is reduced, and the assembly work that cross grooves are formed in the two tubular pillarsfor the mounting of the box-type beam stud can be quickly and efficiently completed.

Owner:KOCEL STEEL STRUCTURE CO LTD

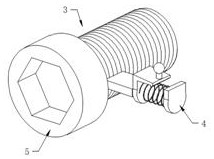

Composite anchor, pipeline connection device using the anchor, and installation method thereof

The invention discloses a combined anchoring body, a pipeline connection device using the same and a mounting method of the pipeline connection device. An elastomer in the combined anchoring body is a wide-end-down straight-strip-shaped polyhedron, the bottom face, the left end face and the right end face of the polyhedron are planes, the bottom face is in an isosceles trapezoid shape, the top face of the polyhedron is a curved surface formed by connecting one plane with another plane in a curved manner, a plurality of racks are inlaid into the elastomer along the length direction at intervals, the tooth crest direction of sawteeth of the racks are parallel to the long sides of the planes which are connected to form the curved surface, the horizontal surface of the elastomer is provided with a plurality of withdrawing portions uniformly distributed along the length direction of the elastomer, and one of the racks is adjacent to at least one of the withdrawing portions along the width direction of the elastomer. After multiple combined anchoring bodies are connected end to end to form an annular anchoring body and the annular anchoring body is placed into an anchoring chamber of a bellmouth of the pipeline connection device, the sawteeth mesh with the outer wall of an insertion opening. The combined anchoring body and the pipeline connection device are simple to produce, convenient to use, good in anchoring effect and adaptive to different diameters of pipes, and the mounting method of the pipeline connection device is simple to operate and high in working efficiency.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Sliding device, box corbel assembly component and method for installing box corbels with circular pipe column

The invention discloses a sliding device, a box-type beam stud assembly component, and a method for mounting a box-type beam stud in tubular pillars, and relates to the technical field of large-scalesteel-structure dual-tubular-pillar assembly. The sliding device comprises a sliding component, a supporting platform frame and a positioning-pushing component, wherein the sliding component can slideon a workbench; the supporting platform frame is fixedly arranged on one side of the sliding component; and the positioning-pushing component is fixedly arranged on the workbench and can be propped against the box-type beam stud, so that the box-type beam stud can be driven by the sliding component to slide and to be assembled with the tubular pillars. The box-type beam stud assembly component comprises the box-type beam stud and the sliding device, wherein the box-type beam stud is fixedly arranged on the supporting platform frame; the cross assembly end of the box-type beam stud can be matched with the tubular pillars; and the propping end of the box-type beam stud is propped against the positioning-pushing component. According to the sliding device and the box-type beam stud assembly component, the design is reasonable, the structure is simple, the assembly is convenient, the labor intensity is reduced, and the assembly work that cross grooves are formed in the two tubular pillarsfor the mounting of the box-type beam stud can be quickly and efficiently completed.

Owner:KOCEL STEEL STRUCTURE CO LTD

Mine Grouting Anchor Bundle Supporting Method

ActiveCN106321124BGuaranteed support strengthTension and pretension in timeAnchoring boltsHigh stressDrill hole

A mine grouting anchor cable supporting method comprises the steps of manufacturing a grouting anchor cable tie, wherein the grouting anchor cable tie is composed of multiple anchor cable bodies, a conical grouting stopping plug, a tray, a lock, an end anchor grouting stopping plug, an anchor cable fixing frame, a tightening ring and the like. An anchor cable body comprises an end anchor grouting anchor cable body, a full-anchor grouting anchor cable body and an exhaust grouting anchor cable body, and the three grouting anchor cable bodies are combined to replace a common anchor cable body; 2, installing and supporting the grouting anchor cable tie, wherein the end anchor grouting stopping plug is sleeved with the end anchor section of the anchor cable tie, the grouting anchor cable tie is fed into a drilled hole, a barb hook hooks the wall of the hole, and the conical grouting stopping plug, the tray and the lock are sequentially installed; grouting of the end anchor section is performed by means of the end anchor grouting cable body, and air is exhausted through the full-anchor grouting anchor cable body; after grouting of the end anchor section is solidified, the lock is used for tensioning and pre-tightening the anchor cable tie; the full-anchor grouting anchor cable body is used for performing grouting on the full anchor section, and the exhaust grouting anchor cable body is used for exhausting air. The method is applicable to ultra-soft cracking and deep high stress roadway supporting, and can achieve ultra-long deep strong anchoring. The cable body is provided with a core tube so that end anchoring, full-anchoring grouting and air exhausting can be achieved, and construction is greatly simplified.

Owner:中国平煤神马控股集团有限公司 +1

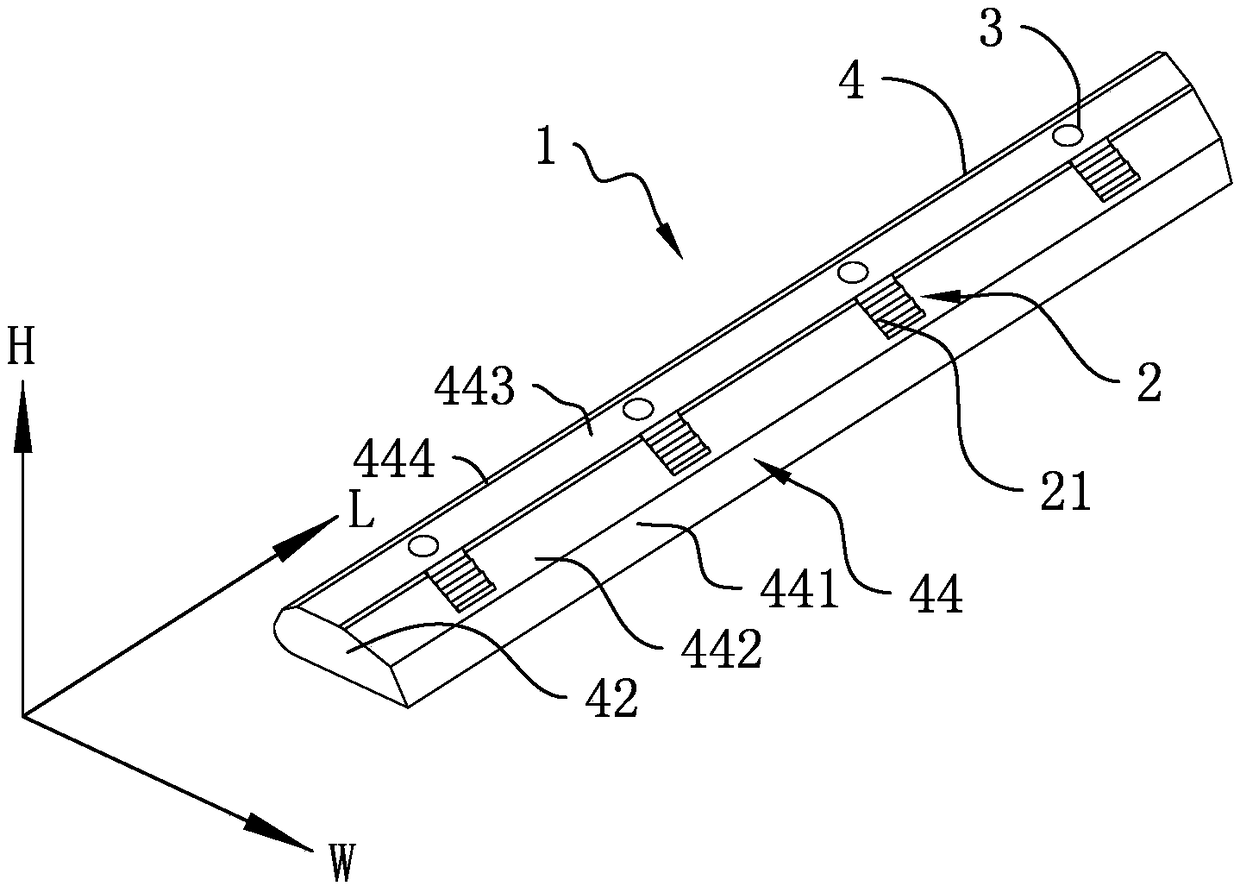

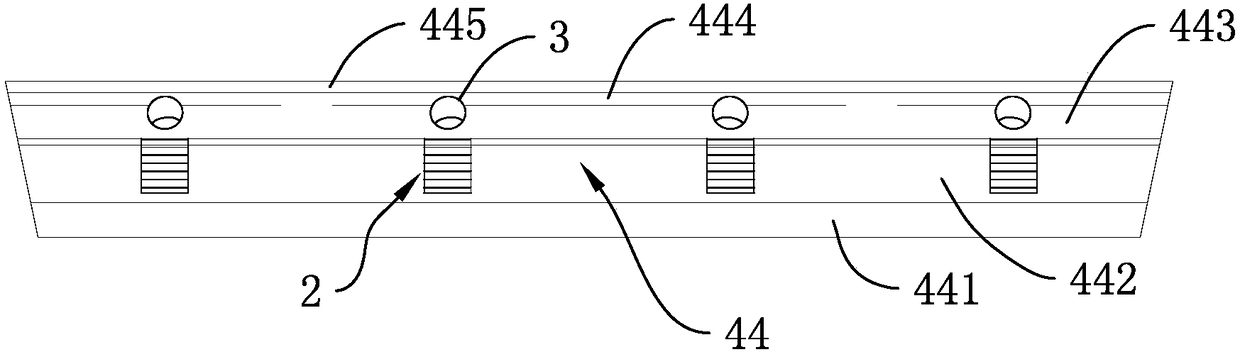

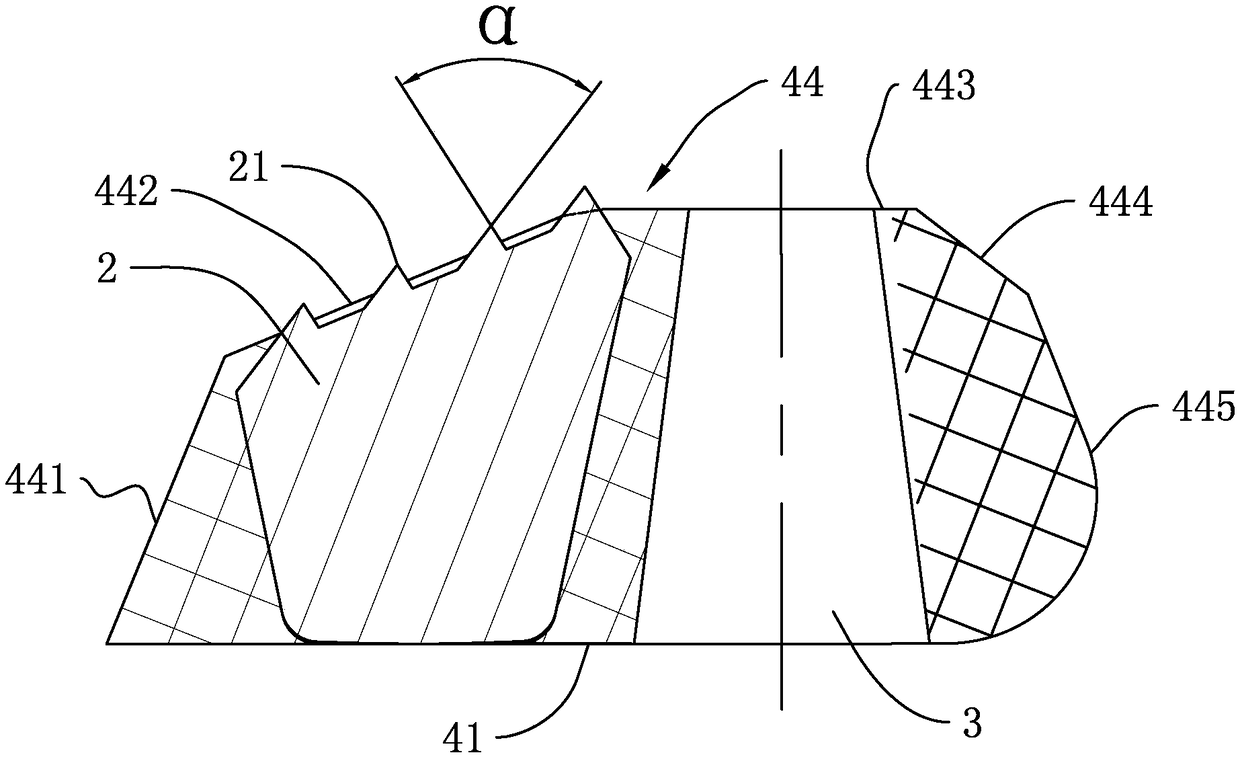

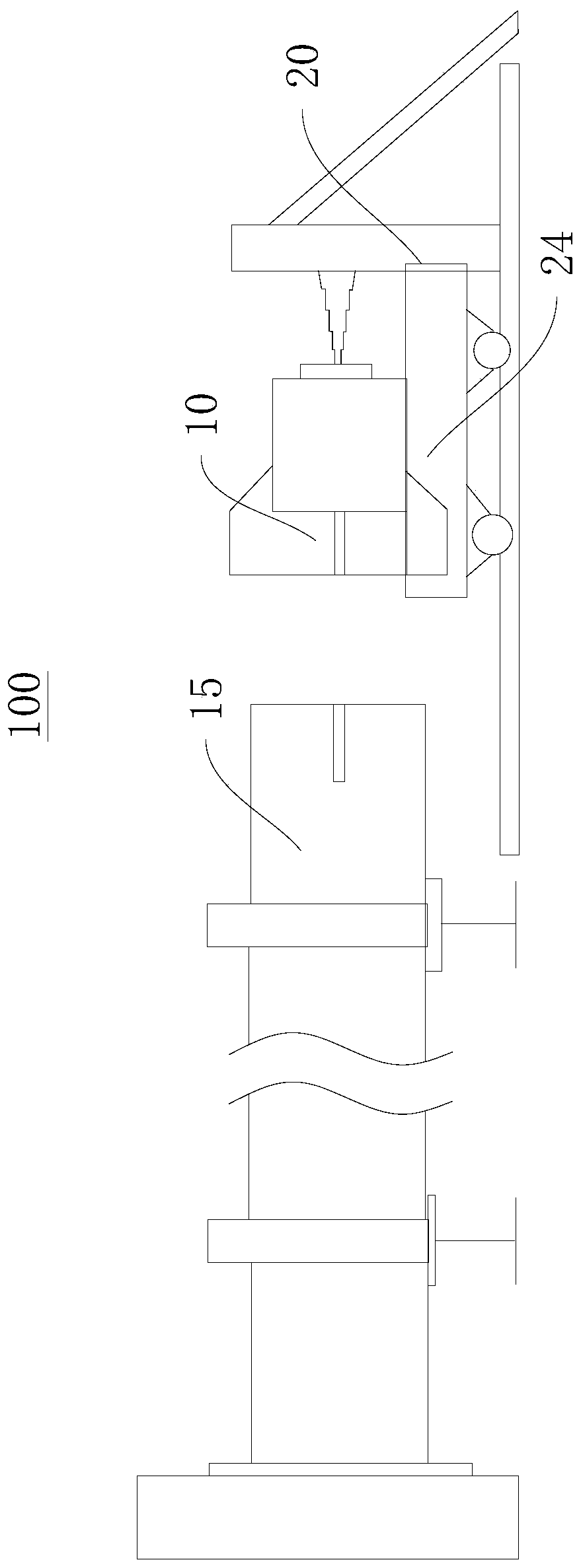

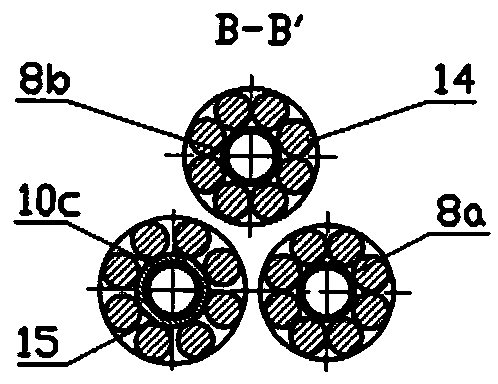

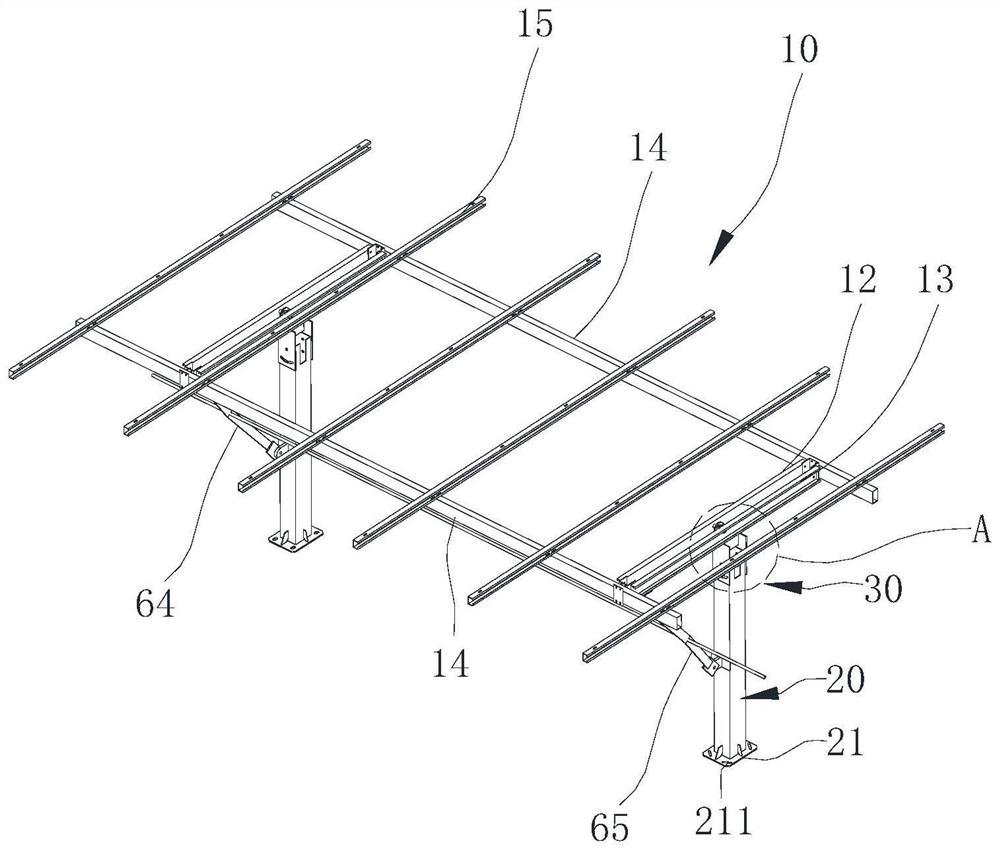

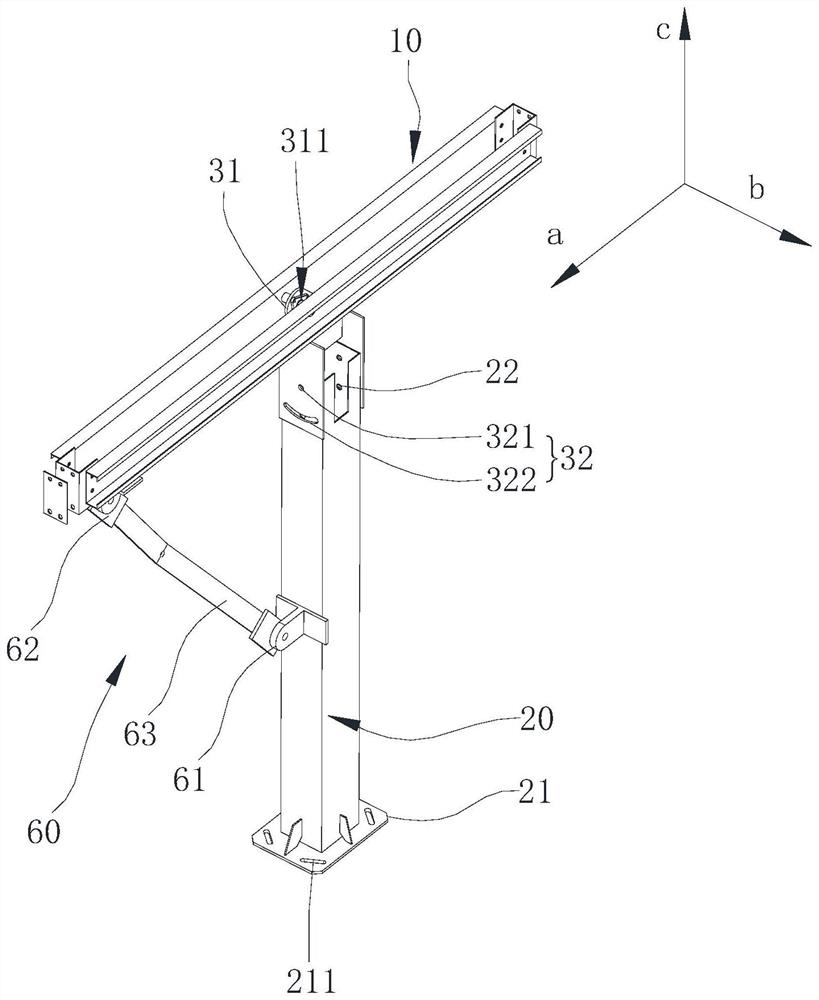

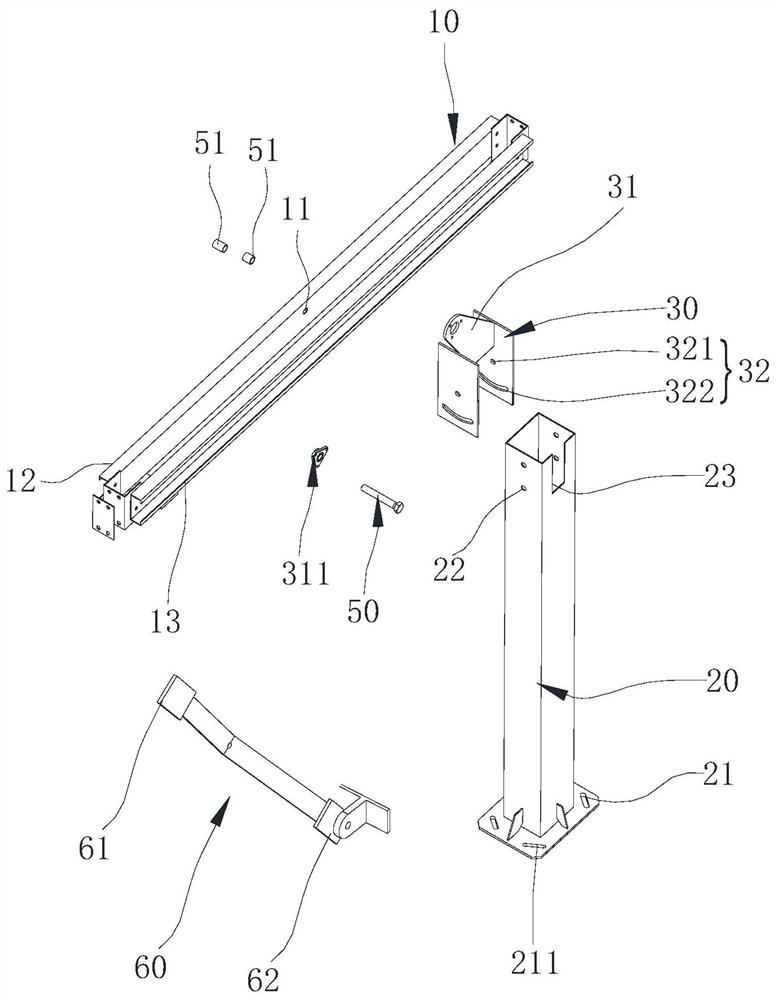

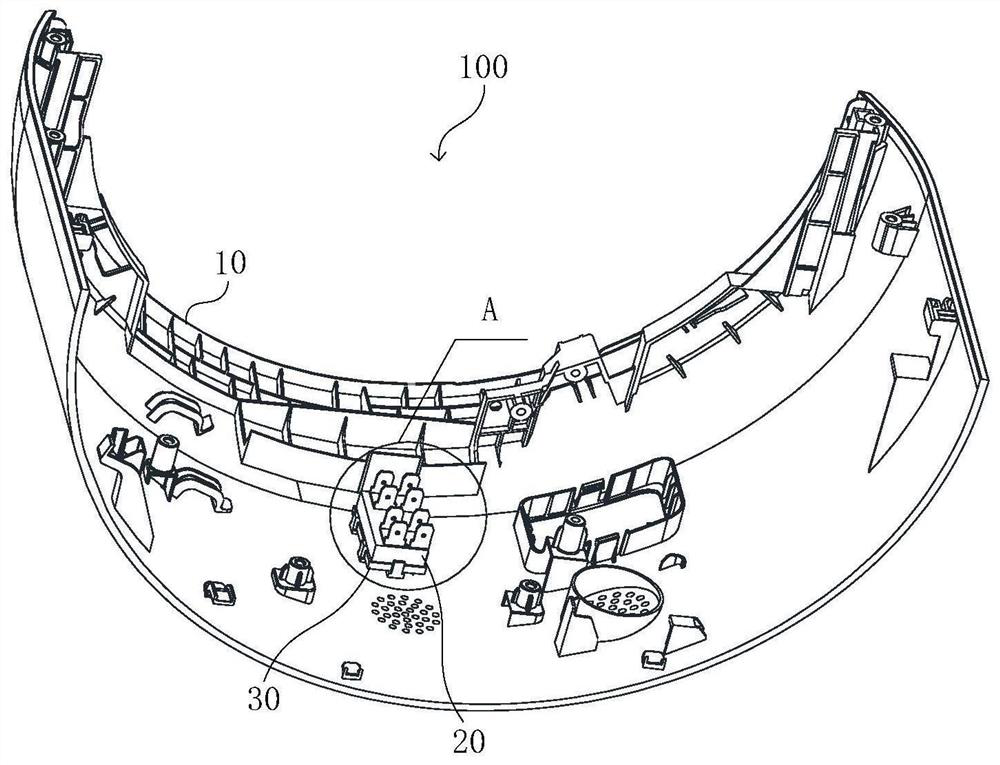

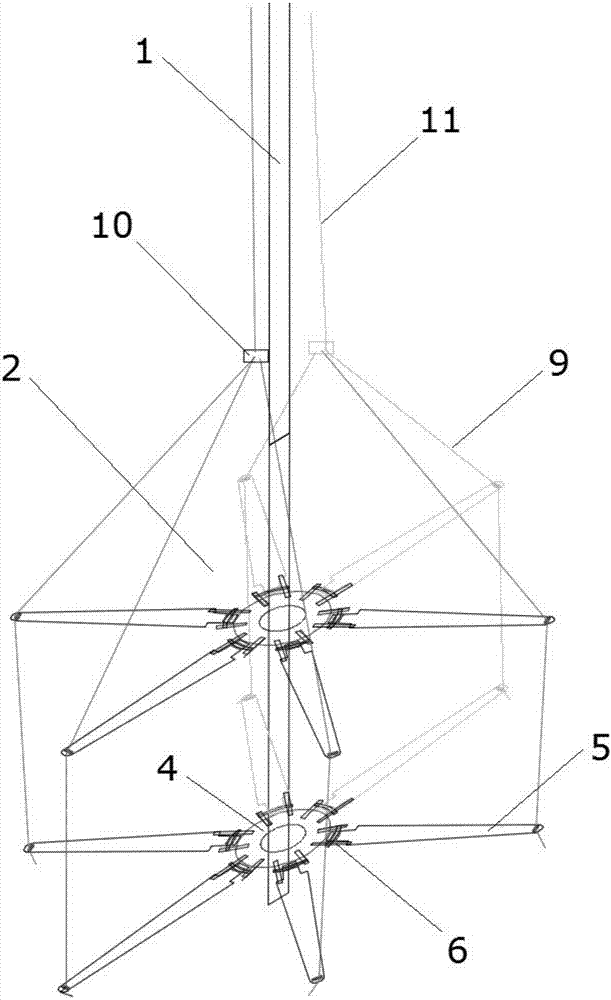

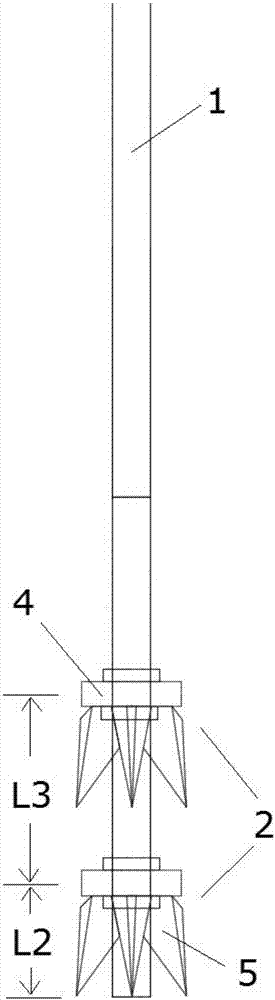

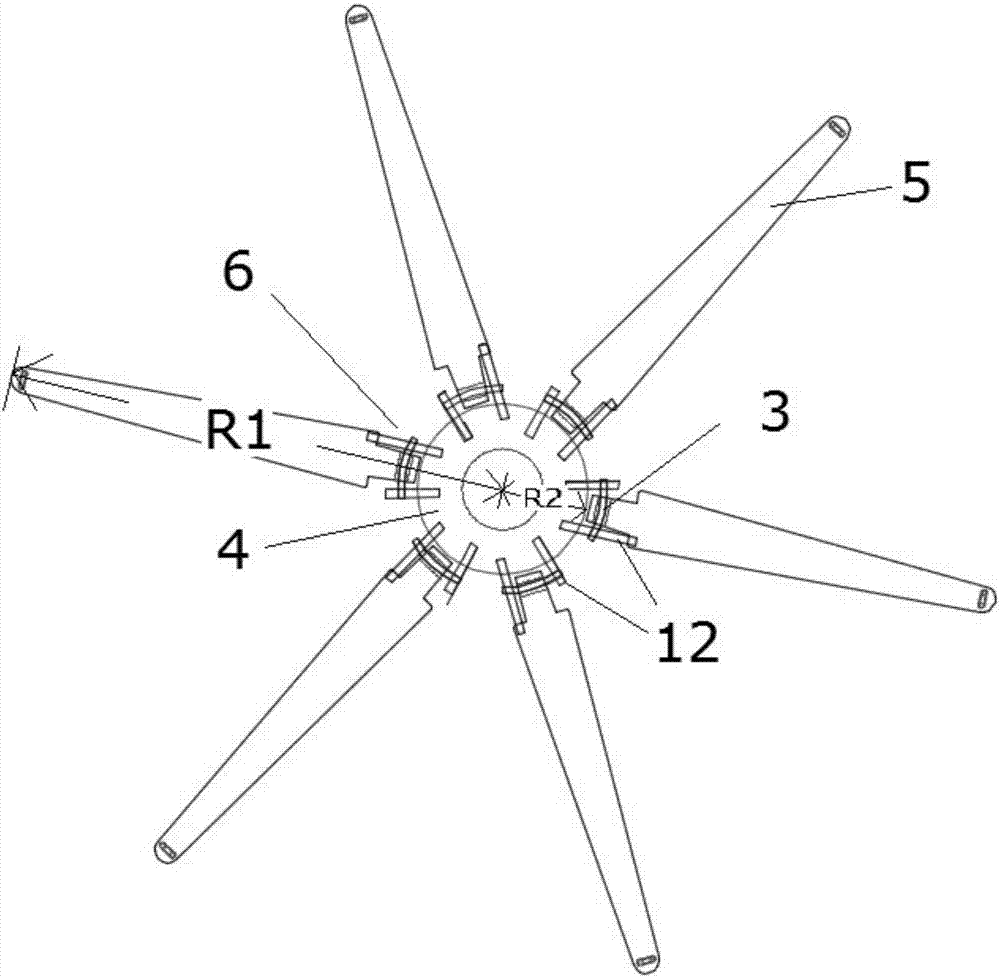

Adjustable angle bracket and photovoltaic device

ActiveCN110677104BSmall installation resistanceTroubleshoot installation adjustment issuesPhotovoltaic supportsPhotovoltaic energy generationEngineeringStructural engineering

An embodiment of the invention discloses an angle-adjustable support and a photovoltaic device. The angle-adjustable support comprises a double-beam mounting frame; stand columns, wherein each stand column comprises a first fine adjustment structure, the first fine adjustment structures being used for adjusting the relative positions of the stand columns; mounting bases, wherein each mounting basecomprises a second fine adjustment structure and a third fine adjustment structure, the second fine adjustment structure being used for adjusting the position of the double-beam mounting frame relative to the mounting base, the third fine-adjustment structure being used for adjusting the position of the mounting base relative to the stand column; and a left-handed adjustment structure and a right-handed adjustment structure. Through mutual cooperative work of the first fine adjustment structures, the second fine adjustment structures and the third fine adjustment structures, the installationresistance and / or the adjustment resistance between the double-beam mounting frame and the stand columns can be obviously reduced, and the installation adjustment problem of the double-beam mounting frame and the stand columns in a complex state is solved; and the left-handed rotation adjusting structure and the right-handed rotation adjusting structure are arranged to be hinged to different standcolumns, so that adjustment of the relative positions of the double-beam mounting frame and the stand columns is achieved, and the angle-adjustable support convenient and reliable to use is formed.

Owner:ATEC ENERGY&ENVIRONMENT CO LTD

Drain Assembly and Refrigerator

ActiveCN104864665BIncrease offset gapSmall installation resistanceLighting and heating apparatusDefrostingEngineeringRefrigerated temperature

The invention provides a drain pipe component and a refrigerator. The drain pipe component comprises a drain pipe and a drain pipe joint, wherein the drain pipe is provided with a clamping part, the drain pipe joint is provided with a connecting part, the connecting part is provided with a plurality of bulges which are spaced at intervals in a circumferential direction and the plurality of bulges are matched with the clamping part so that the drain pipe joint is arranged on the drain pipe. Compared with a technical scheme that the drain pipe is in contact with the drain pipe joint in a full circle, according to the technical scheme that the plurality of bulges which are spaced at intervals are cooperated with the connecting part, the contact area between the connecting part and the clamping part can be reduced, the bias gap formed when the drain pipe is arranged can be improved, the installation resistance of the drain pipe can be effectively reduced, the assembling force of the drain pipe can be reduced, and the assembling efficiency and the operation goodness of staffs can be effectively improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Rear panel structure and air conditioner

ActiveCN113375328AEasy to installReduce electrostatic effectHeating and ventilation casings/coversElectrostatic chargesEngineeringStructural engineering

The invention provides a rear panel structure and an air conditioner. The rear panel structure comprises a rear panel body, an anti-static structure is further arranged on the rear panel body, the rear panel structure comprises a fixing device, and the anti-static structure is connected with the fixing device through buckles. The rear panel structure aims to solves the problem that static electricity generated on a sliding door of the air conditioner is weakened so as to avoid potential safety hazards. In addition, the anti-static structure can be efficiently installed on the back panel body, and the step of disassembling the anti-static structure from the back panel body can be simplified.

Owner:NINGBO AUX ELECTRIC +1

A permanent magnetic positioning emergency sealing device based on leakage of pressure vessel fillet welds

The invention relates to a permanent magnetism positioning emergency plugging device based on pressure vessel fillet weld leakage, and belongs to the pipeline engineering field; the permanent magnetism positioning emergency plugging device based on pressure vessel fillet weld leakage uses a strong magnet to fix the plugging device in a to-be-plugged position; a linkage can press a plugging assembly in the leakage portion; a spring steel bar composite rubber layer and seal rubber layer deformation plugging mode can plug the large radian or surface variable leakage portion; the permanent magnetism positioning emergency plugging device based on pressure vessel fillet weld leakage comprises a strong magnetic mechanism, the linkage and the plugging assembly; the linkage is arranged above the strong magnetic mechanism so as to form a four-connecting rod structure with the strong magnetic mechanism; the strong magnetic mechanism is hinged to a drive pull rod; the top of the drive pull rod is provided with a handle; the handle is respectively hinged to the drive pull rod and a third hinge; the plugging assembly is connected with a second hinge.

Owner:ZHONGBEI UNIV

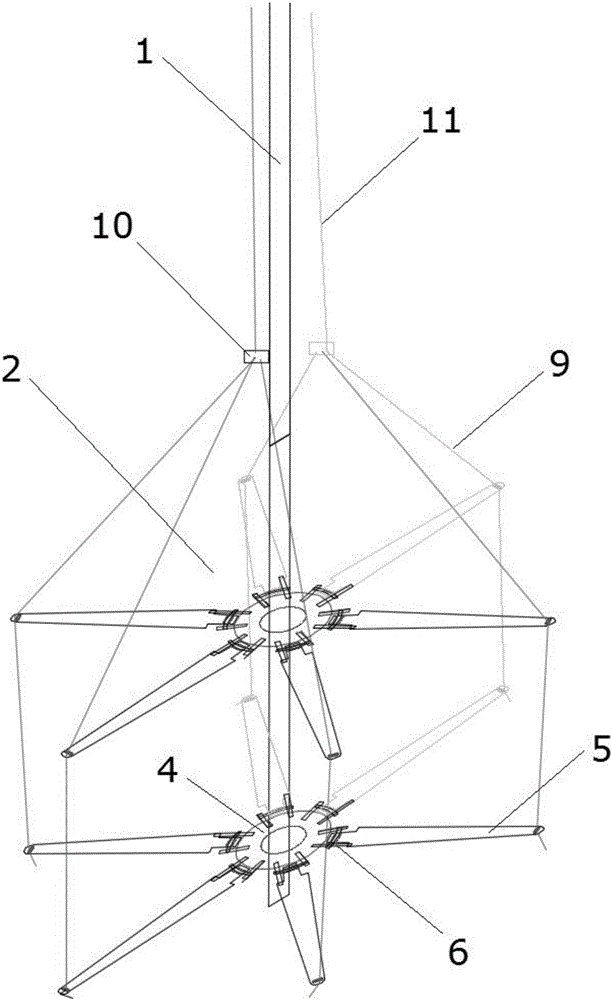

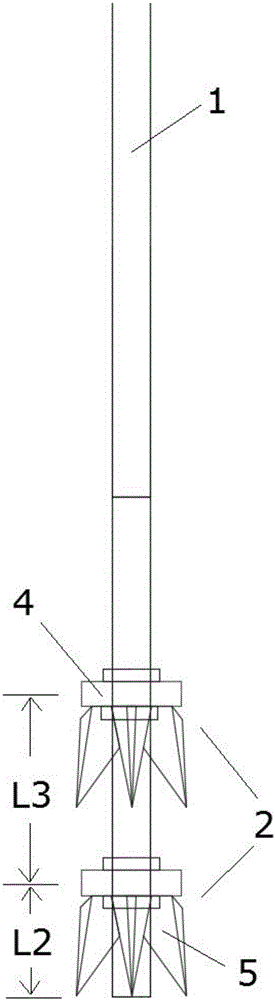

A valve type expanding head anchor rod bearing body

ActiveCN105839637BIncrease radiusImprove the pull-out capacityBulkheads/pilesAnchoring boltsEngineeringMechanical engineering

The invention discloses a valve type expanding head anchor rod bearing body. The valve type expanding head anchor rod bearing body comprises an anchor rod, fixing clamps, first lifting and pulling ropes, second lifting and pulling ropes and at least two valve type expanding heads arranged on the anchor rod in a sleeving manner; each valve type expanding head comprises a round steel pipe reinforcement body and a plurality of valve arc-shaped steel plates; the anchor rod is sleeved with the round steel pipe reinforcement bodies in a penetrating manner; the inner side ends of the multiple valve arc-shaped steel plates are evenly hinged to the peripheries of the round steel pipe reinforcement bodies; the outer side ends of the valve arc-shaped steel plates are connected with the first lifting and pulling ropes; each first lifting and pulling rope is connected with the outer side ends of the valve arc-shaped steel plates in the valve type expanding heads at the same circumferential position; the at least two fixing clamps are evenly hoisted and arranged around the anchor rod through the second lifting and pulling ropes; and the multiple first lifting and pulling ropes opposite to one side of one fixing clamp are connected to the fixing clamp in a gathering manner. The valve type expanding head anchor rod bearing body has higher uplift bearing capacity compared with an existing bearing body.

Owner:CHEM IND GEOTECHN ENG

A pulley for high-altitude lines or pipe diameters and its installation method

InactiveCN103332624BEasy to installSmall installation resistanceApparatus for overhead lines/cablesGearing elementsEngineeringHeavy weight

The invention provides a pulley for a high-altitude line or pipe diameter, and a mounting method thereof. The pulley for the high-altitude line or pipe diameter comprises a left pulley device, a right pulley device, and a transverse connecting rod for connecting the left pulley device and the right pulley device, wherein each pulley device comprises a fixed pulley, a fixed pulley component arranged on the two sides of the fixed pulley, and a hook arranged at the top of the fixed pulley component; and the transverse connecting rod is arranged at the tops of the hooks. The hooks of the pulley provided by the invention are in shapes of circular arcs with the angles of 250 DEG, connecting angles between the pulley components and arc surfaces are 50 DEG, the pulley can be mounted and fixed on the needed pipe diameter or line on the ground through a rope to hoist heavy weights to high altitude, and can be detached from the high-altitude pipe diameter or line on the ground, so that the pulley can be mounted and detached on the ground, ascending operation is not needed, and dangers of ascending operation are prevented from occurring.

Owner:BIJIE POWER SUPPLY BUREAU OF GUIZHOU POWER GRID CO LTD +1

Filtration apparatus with characteristics of convenient installation and water leakage prevention

The invention provides a filtration apparatus with characteristics of convenient installation and water leakage prevention. The filtration apparatus comprises a shell, a filtration core arranged in the shell, and a base positioned on the bottom portion of the shell, wherein a water inlet pipe and a water outlet pipe are arranged on the top portion of the shell, valve rods capable of moving up anddown are respectively arranged in the water inlet pipe and the water outlet pipe, the upper ends of the valve rods extend into the water inlet pipe and the water outlet pipe, the valve rod parts closeto the top portions of the water inlet pipe and the water outlet pipe are respectively sleeved with a first sealing rubber ring, the middle cross section of the valve rod is +-shaped, the water inletpipe position corresponding to the middle position of the valve rod is provided with a water inlet, the water outlet pipe position corresponding to the middle of the valve rod is provided with a water outlet, the lower ends of the valve rods are snapped at the communication positions between the shell and the water inlet pipe and between the shell and the water outlet pipe, the snapping positionsare provided with second sealing rubber rings, and the valve rod lower end part positioned in the shell is sleeved with a spring. According to the present invention, by arranging the two sealing ribson the bush, the inclined surface sealing can be avoided.

Owner:TIANJIN YITAIJI AUTOMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com