Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Small breathability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alpha and beta two-phase magnesium lithium alloy with excellent casting performance and heat transfer performance

The invention discloses a dual-phase α+β magnesium-lithium alloy with excellent casting performance and heat transfer performance and a processing technology thereof. According to weight percentage, the composition of the alloy is: Li: 8.0‑10.0wt.%, Ge: 0.2‑0.8wt.%, Cd: 0.6‑0.8wt.%, Bi: 0.2‑0.5wt.%, Zr: 0.4‑ 0.8wt.%, Pd: 0.1‑0.2wt.%, Cu: 0.3‑0.5wt.%, Al: 1.8‑3.4wt.%, Fe: 0.2‑0.5wt.%, Mn: 0.1‑0.4wt.%, The balance is magnesium. The magnesium-lithium alloy for die-casting has high thermal conductivity that traditional magnesium-lithium alloys do not possess. This enables the alloy to have further specific applications in the occasions where the heat generation is large and the weight of the device is required, and it is convenient for large-scale industrial application.

Owner:GUANGZHOU YUZHI TECH CO LTD

Multi-function soft wall and manufacturing method thereof

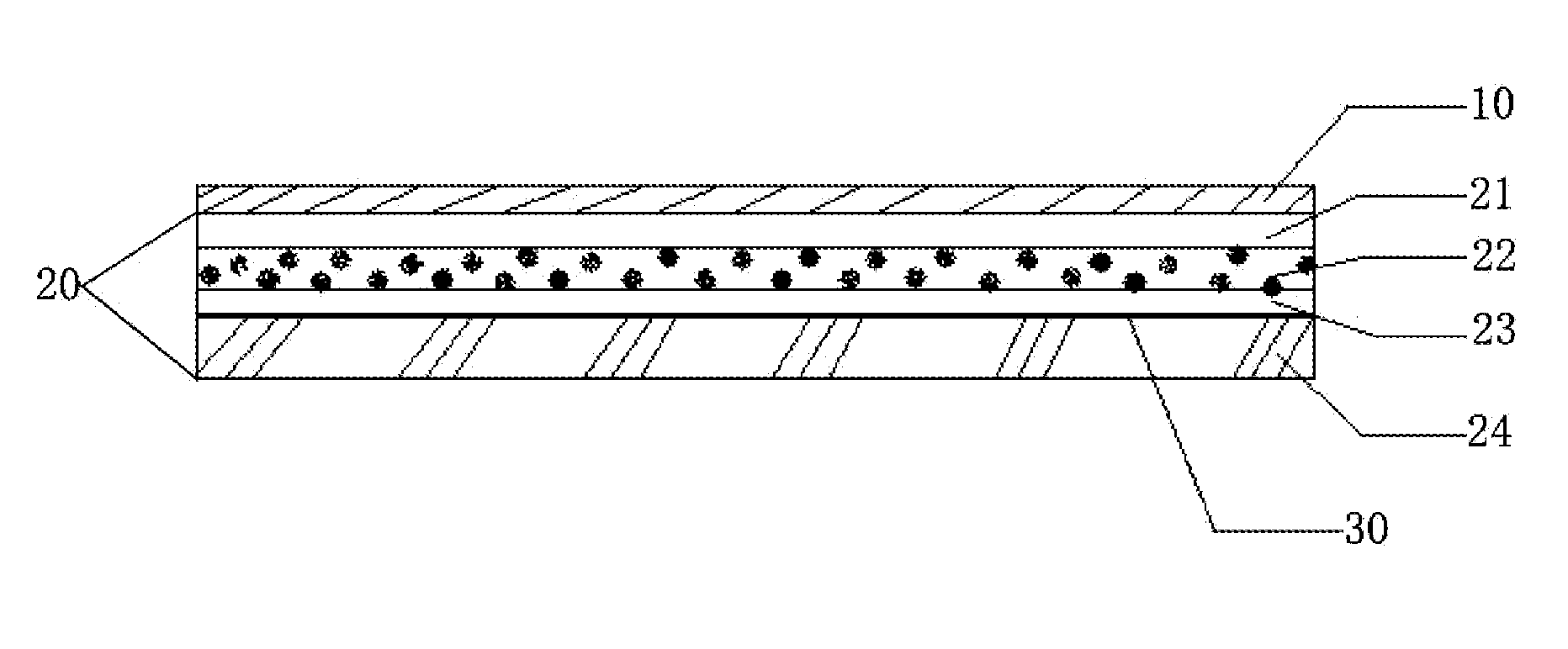

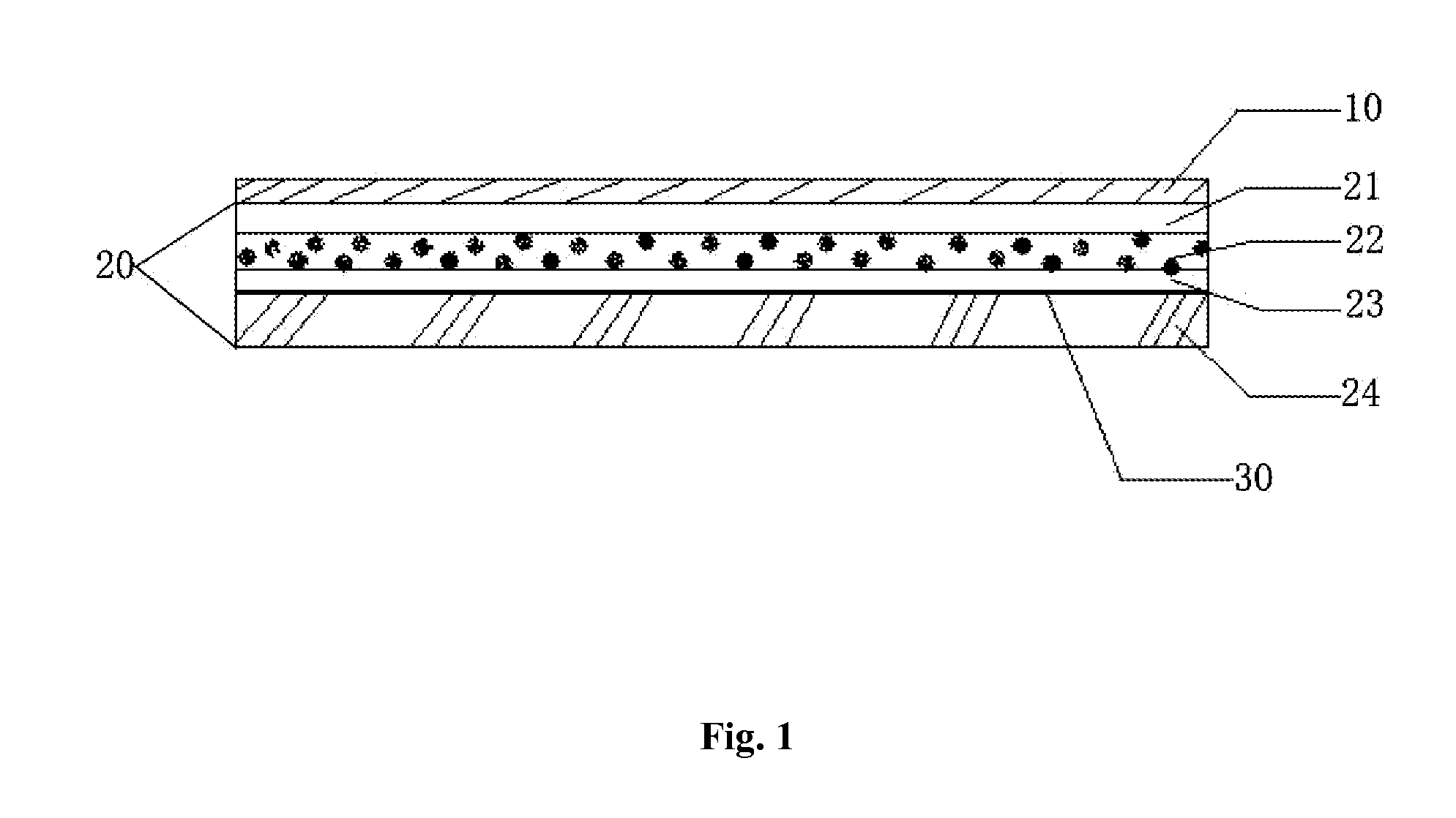

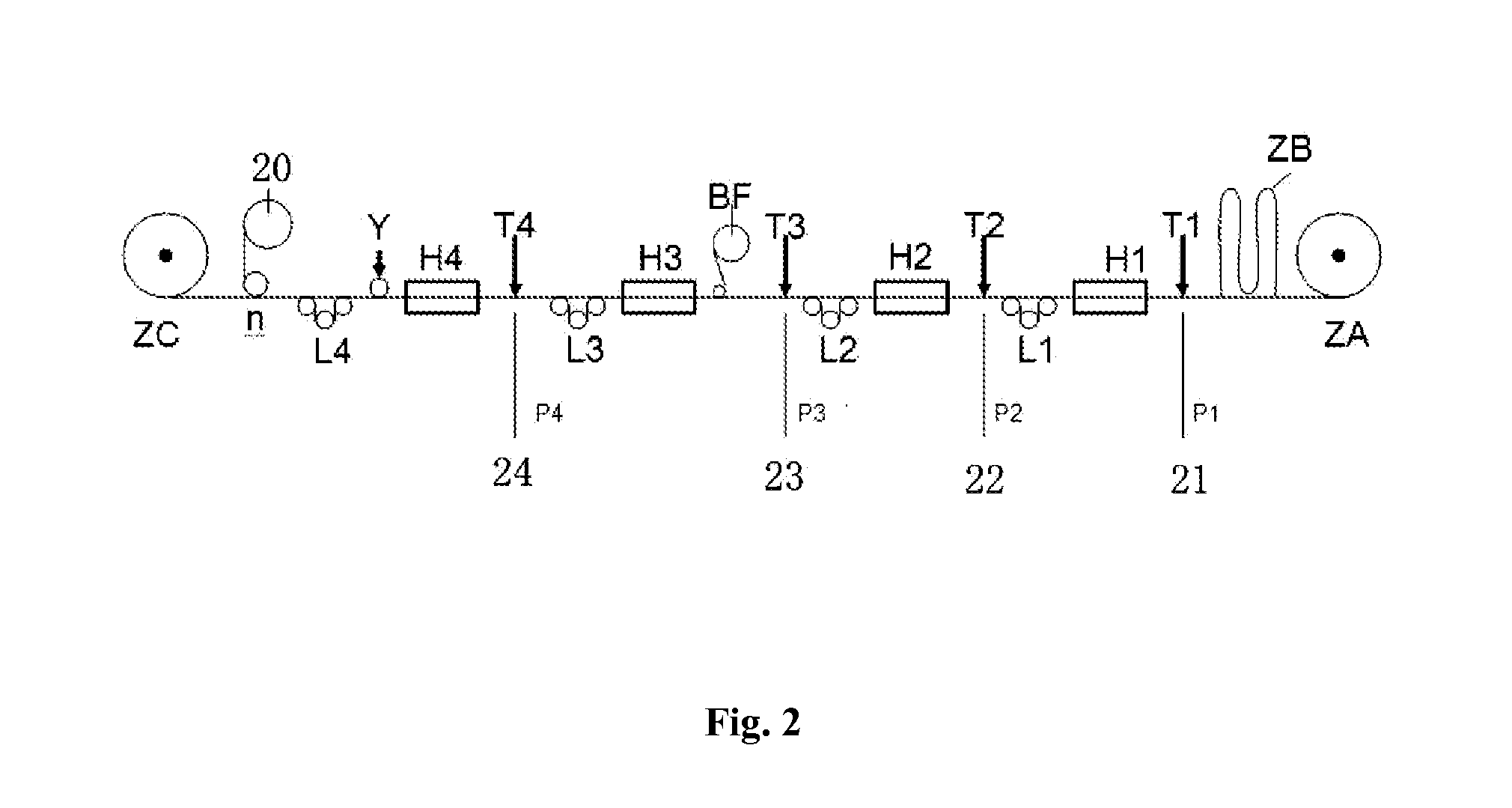

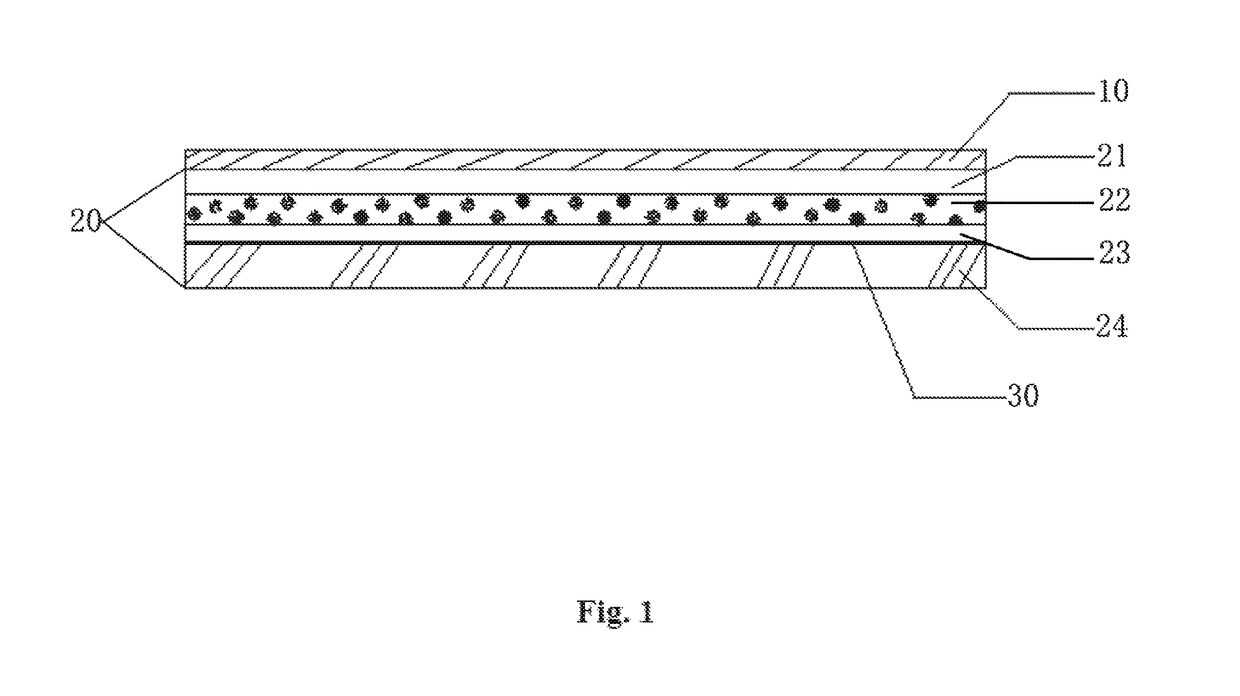

InactiveUS20160130465A1Small breathabilityEfficient releaseDecorative surface effectsDuplicating/marking methodsEngineeringCoating

The invention discloses a multi-function soft wall, comprising a surface printing layer and a base material, the base material further including a top layer, and a second layer, a third layer and a bottom layer that are all foaming layers, wherein both the second layer and the third layer have a foaming ratio less than that of the bottom layer, and a fiber layer is disposed between the third layer and the bottom layer. The invention further provides a method of manufacturing a multi-function soft wall, comprising: sequentially coating a top layer, a second layer, a third layer, a fiber layer and a bottom layer on a release paper, respectively, and then obtaining a base material, and performing a foaming process with respect to the second layer, the third layer and the bottom layer, respectively, and performing a drying and cooling process after the coating step; and separating the base material from the release paper, and printing a surface printing layer on the top layer. The multi-function soft wall can release negative ions, and continuously eliminate various pollutions indoors.

Owner:NINGBO CALLDE BIOMIMETICS MATERIALS CO LTD

Mg-Ca-In magnesium alloy for pressure casting and with high damping characteristic

InactiveCN108220723AImprove flame retardant performanceCombustion hindrancePressure castingMagnesium calcium

The invention discloses Mg-Ca-In magnesium alloy for pressure casting and with high damping characteristic as well as a processing process thereof. The alloy comprises the following components in percentage by weight: 0.6 to 1.5 percent of Ca, 1.6 to 3.2 percent of In, 3.0 to 4.5 percent of Sn, 0.8 to 1.5 percent of Sb, 0.4 to 0.8 percent of Zr, 0.2 to 0.5 percent of Be and the balance of magnesium. The magnesium calcium alloy has excellent pressure casting property and also has excellent damping property. The bottom layer property of the traditional magnesium for casing is expected to be innovated and optimized, so positive significance in development and improvement of the magnesium alloy pressure casting process, even the whole pressure casting industry and the technology thereof is achieved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Aluminum lithium alloy with extremely excellent pressure-casting performance

The invention discloses an aluminum-lithium alloy with extremely excellent die-casting performance when smelted between 700-800 degrees and a processing technology thereof. In terms of weight percentage, the chemical composition of the alloy is: Li: 4.0‑8.0wt.%, Sr: 1.0‑1.5wt.%, Si: 2.0‑3.0wt.%, Mg: 1.0‑1.5wt.%, Ge: 0.5 ‑1.2wt.%, Th: 0.1‑0.3wt.%, Nd: 0.2‑0.5wt.%, B: 0.5‑1.2wt.%, and the balance is aluminum. The aluminum-lithium alloy material has good casting properties and is suitable for pressure casting of thin-walled parts under a protective atmosphere. It is especially suitable for casting lightweight structural materials that require lightweight features, and has a huge market prospect.

Owner:GUANGZHOU YUZHI TECH CO LTD

High damping Ca and Mg containing aluminum alloy for pressure casting and processing technology thereof

InactiveCN108384995AImprove flame retardant performanceCombustion hindrancePressure castingAluminium alloy

The invention discloses high damping Ca and Mg containing aluminum alloy for pressure casting and a processing technology thereof. The alloy is prepared from the following components in percentage byweight: 0.8-1.5wt% of Ca, 2.0-8.0wt% of Mg, 3.0-5.0wt% of Sn, 0.5-1.2wt% of Y, 0.4-0.6wt% of Mo, 0.2-0.5wt% of Be and the balance of aluminum. The aluminum-calcium alloy has excellent pressure castingperform and excellent damping perform and is expected to have positive significance of development and promotion of an aluminum alloy pressure casting technology and even the whole pressure casting industry and a technology thereof.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-strength aluminum-yttrium alloy containing Ca and Hf for pressure casting

The invention discloses a high-strength aluminum-yttrium alloy containing Ca and Hf for pressure casting and a processing process thereof. The high-strength aluminum-yttrium alloy containing Ca and Hfis prepared from chemical components: by weight percent, 0.8-2.0 wt.% of Y, 0.6-0.8 wt.% of Ba, 2.5-3.2 wt.% of Zn, 0.6-1.5 wt.% of Ca, 0.4-0.9 wt.% of Cu, 0.1-0.2 wt.% of Zr, 0.2-0.5 wt.% of Hf, 0.6-0.8 wt.% of Er and the balance aluminum. The aluminum-yttrium alloy material has good casting performance, and is suitable for pressure casting of thin-wall parts under a protective atmosphere. The aluminum-yttrium alloy material is especially suitable for casting light-type-structure materials requiring lightweight characteristics, and has broad market prospects.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-heat-conductivity Ba and Se including aluminum alloy for copper-clad aluminium conductor and processing process of high-heat-conductivity Ba and Se including aluminum alloy

InactiveCN108220702AReduce weightImprove flame retardant performanceCopper-clad aluminium wireHeat conducting

The invention discloses a high-heat-conductivity Ba and Se including aluminum alloy for a copper-clad aluminium conductor and a processing process of the high-heat-conductivity Ba and Se including aluminum alloy. The alloy is prepared from, by weight percent, 0.5-1.2 wt.% of Ba, 0.2-0.6 wt.% of Ge, 0.2-0.4 wt.% of Hf, 0.2-0.5 wt.% of Ru, 0.1-0.3 wt.% of Os, 0.4-0.8 wt.% of Se and the balance aluminum. The aluminum-barium alloy has the excellent mechanical property and heat conducting property failing to achieve on a traditional copper-clad aluminum conductor and has wide purposes in the electric appliance manufacturing industry, the electric wire industry and the radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

High temperature-resistant Ba-Re-Te zinc alloy applied to cold chamber die casting

The invention discloses a high temperature-resistant Ba-Re-Te zinc alloy applied to cold chamber die casting and a processing process thereof. The alloy is prepared from the following components in percentage by weight: 0.4-1.2wt% of Ba, 0.4-0.8wt% of Re, 0.6-0.8wt% of Te, 2.0-4.0wt% of Ge, 0.5-0.8wt% of V, 0.2-0.4wt% of Pr and the balance of zinc. The zinc-barium alloy has excellent die-casting performance and can be used for producing long thin-walled parts; meanwhile, in the die casting process, the zinc-barium alloy can be casted by using cold chamber; the production efficiency is greatlyimproved; the energy consumption is reduced; the obtained products can be widely used in electric appliance manufacturing industry and radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

Silver alloy with hydrogen sulfide corrosion resistance and excellent die casting performance for jewelry

The invention discloses a silver alloy with hydrogen sulfide corrosion resistance and excellent die casting performance for jewelry. The alloy comprises, by weight, 0.1%-0.2% of B, 1.2%-1.5% of Ca, 2.0%-3.0% of Al, 1.6%-1.8% of Ni, 3.0%-5.0% of In, 1.0%-1.2% of Ge, 1.5%-1.8% of Sn and the balance silver. According to the silver alloy, a material solution is provided for sulphide discoloration of the silver alloy on the current market. Not only is the production cost reduced, but also the relevant production technology and equipment requirements are simplified greatly. It can be estimated thatrich economic results and social benefits can be achieved through implementation and industrialization of the silver alloy.

Owner:GUANGZHOU YUZHI TECH CO LTD

A single-phase beta magnesium-lithium alloy having excellent castability and heat transfer performance

InactiveCN107893180AReduce usageGood casting performance and heat transfer performanceSingle phaseThermal conductivity

The invention discloses a single-phase β-magnesium-lithium alloy with excellent casting performance and heat transfer performance and a processing technology thereof. According to weight percentage, the composition of the alloy is: Li: 13.0‑18.0wt.%, Cu: 1.2‑2.3wt.%, Bi: 0.4‑0.6wt.%, Sb: 0.2‑0.5wt.%, V: 0.1‑ 0.2wt.%, W: 0.1‑0.2wt.%, Ag: 0.8‑1.2wt.%, Ge: 0.3‑0.6wt.%, Co: 0.1‑0.2wt.%, and the balance is magnesium. The magnesium-lithium alloy for die-casting has high thermal conductivity that traditional magnesium-lithium alloys do not have. This enables the alloy to have further specific applications in the occasions where the heat generation is large and the weight of the device is required, and it is convenient for large-scale industrial application.

Owner:GUANGZHOU YUZHI TECH CO LTD

Aluminum strontium alloy with extremely excellent die casting performance

The invention discloses an aluminum-strontium alloy with extremely excellent die-casting performance when smelted between 700-800 degrees and a processing technology thereof. In terms of weight percentage, the chemical composition of the alloy is: Sr: 1.0‑1.6wt.%, Ca: 0.4‑0.5wt.%, Ge: 1.2‑1.5wt.%, Ru: 0.4‑0.6wt.%, V: 0.2 ‑0.5wt.%, Ti: 0.1‑0.2wt.%, Sm: 0.2‑0.3wt.%, Eu: 0.1‑0.2wt.%, and the balance is aluminum. The aluminum-strontium alloy material has good casting properties and is suitable for pressure casting of thin-walled parts under a protective atmosphere. It is especially suitable for casting lightweight structural materials that require lightweight features, and has a huge market prospect.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-thermal-conductivity Ge-containing magnesium alloy suitable for cold chamber die casting and processing technology thereof

InactiveCN108251728AImprove flame retardant performanceCombustion hindranceDie castingPromotion effect

The invention discloses high-thermal-conductivity Ge-containing magnesium alloy suitable for cold chamber die casting and a processing technology thereof. The alloy is prepared from the following components in percentage by weight: 0.5-1.2wt.% of Ca, 2.4-3.5wt.% of Ge, 1.0-2.5wt.% of Mn, 2.4-3.8wt.% of Ni, 0.5-1.2wt.% of Y, 0.2-0.6wt.% of Nb and the balance of magnesium. The magnesium-calcium alloy has excellent die casting properties and excellent thermal conductivity and is expected to have a promotion effect of enabling fine new materials independently researched and developed in China to occupy the market of international fine new materials.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-electric-conductivity Ba and Re-contained aluminum alloy for copper-clad aluminum conductor and machining process thereof

InactiveCN108300908AImprove flame retardant performanceCombustion hindranceConductive materialMetal/alloy conductorsRheniumMachining process

The invention discloses a high-electric-conductivity Ba and Re-contained aluminum alloy for a copper-clad aluminum conductor and a machining process thereof. The alloy comprises the following components in percentage by weight: 0.8-1.5 wt.% of Ba, 0.2-0.4 wt.% of Re, 0.2-0.3 wt.% of Zr, 0.5-0.8 wt.% of Zn, 0.1-0.2 wt.% of Pd, 0.5-0.8 wt.% of Te, and the balance of aluminum. The aluminum rhenium alloy achieves excellent mechanical performances and electric conductivity, which are not possessed by a traditional aluminum alloy for the copper-clad aluminum conductor. The alloy achieves wide purposes in the electric appliance manufacturing industry, the electric wire and cable industry and the radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-strength W-containing magnesium alloy applicable to cold chamber die casting and machining process of high-strength W-containing magnesium alloy

InactiveCN108277408AImprove flame retardant performanceCombustion hindranceDie castingHigh intensity

The invention discloses high-strength W-containing magnesium alloy applicable to cold chamber die casting and a machining process of the high-strength W-containing magnesium alloy. The high-strength W-containing magnesium alloy comprises the following components in percentage by weight: 1.2wt% to 1.6wt% of Ca, 0.4wt% to 0.8wt% of W, 0.2wt% to 0.5wt% of Cr, 1.2wt% to 1.8wt% of Sc, 0.4wt% to 0.6wt%of Ta, 1.2wt% to2.6 wt% of In and the balance of magnesium. The magnesium-calcium alloy is excellent in die casting property and is also excellent in mechanical property. Expectedly, the high-strengthW-containing magnesium alloy plays a promotion role for our country to independently research and develop competitive new materials and occupy the international competitive new material markets.

Owner:GUANGZHOU YUZHI TECH CO LTD

High thermal conductivity Ca and Re containing aluminum alloy for pressure casting and machining technology thereof

The invention discloses a high thermal conductivity Ca and Re containing aluminum alloy for pressure casting and a machining technology thereof. The high thermal conductivity Ca and Re containing aluminum alloy for pressure casting is prepared from the components of, in percentage by weight, 0.6-1.5% of Ca, 1.6-3.2% of Re, 3.0-4.5% of In, 0.8-1.5% of Sc, 0.4-0.8% of Mn, 0.2-0.5% of Be, and the balance of aluminum. The kalzium metal has the excellent pressure casting property, and excellent thermal conductivity performance. The invention is predicted that the aluminum alloy has active meaning on the aluminum alloy pressure casting technology even the whole pressure casting industry and development and improvement of the technique of pressure casting.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-temperature-resisting Y containing lead-lithium alloy with extremely low machining hardening rate

The invention discloses a high-temperature-resisting Y containing lead-lithium alloy with an extremely low machining hardening rate and a machining technology of the high-temperature-resisting Y containing lead-lithium alloy. The high-temperature-resisting Y containing lead-lithium alloy comprises components including, by weight percent, 0.8 wt.%-1.5 wt.% of Li, 0.3 wt.%-0.5 wt.% of Y, 0.2 wt.%-0.4 wt.% of Nb, 0.5 wt.%-0.8 wt.% of Ge, 0.3 wt.%-0.5 wt.% of W, 0.2 wt.%-0.3 wt.% of Te and the balance lead. The lead-lithium alloy has the extremely low machining hardening rate and excellent high-temperature performance. The performance exceeds a traditional shielding material lead alloy, and the high-temperature-resisting Y containing lead-lithium alloy is widely applied to the military and civil fields.

Owner:GUANGZHOU YUZHI TECH CO LTD

In and Ba containing zinc alloy suitable for pressure casting and processing technology thereof

The invention discloses a zinc alloy containing In and Ba suitable for die casting. By weight percentage, the chemical composition of the alloy is: Ba:0.8‑1.2wt.%,In:1.2‑1.5wt.%,Pd:0.2‑0.3wt.%,Cu:0.6‑0.8wt.%,Ge:0.5‑ 1.0wt.%, Y: 0.1‑0.3wt.%, Mo: 0.2‑0.4wt.%, Hf: 0.1‑0.2wt.%, Gd: 0.2‑0.5wt.%, and the balance is zinc. Compared with traditional zinc alloys, the material has excellent casting properties and mechanical properties.

Owner:GUANGZHOU YUZHI TECH CO LTD

Palladium alloy and production method thereof

Owner:SHENZHEN GMOND JEWELRY

High-strength die casting zinc alloy containing Ca and Be for ocean platform

The invention discloses a high-strength die casting zinc alloy containing Ca and Be for an ocean platform and a processing technology of the high-strength die casting zinc alloy. The zinc alloy is prepared from the following components by weight percent: 1.0 to 1.5 percent of Ca, 0.5 to 0.8 percent of Be, 1.5 to 2.0 percent of Cu, 0.5 to 0.9 percent of Sc, 1.5 to 2.8 percent of Co, 0.4 to 0.8 percent of Te, and the balance of zinc. The zinc-calcium alloy has excellent die casting performance and excellent mechanical performance. The high-strength die casting zinc alloy containing Ca and Be isexpected to be widely applied to the industry of novel ocean platforms.

Owner:GUANGZHOU YUZHI TECH CO LTD

Ba-Pt-Cr aluminum alloy applied to corrosion-resistant copper-clad aluminum wire

InactiveCN108165838AGood flame retardant performanceGood liquidityCopper-clad aluminium wireCorrosion resistant

The invention discloses Ba-Pt-Cr aluminum alloy applied to a corrosion-resistant copper-clad aluminum wire and a machining process of the Ba-Pt-Cr aluminum alloy. The Ba-Pt-Cr aluminum alloy comprisesthe following components in percentage by weight: 0.5-0.8 wt% of Ba, 0.2-0.4 wt% of Pt, 0.5-0.6 wt% of Cr, 0.2-0.4 wt% of Sn, 0.8-1.2 wt% of Y, 0.1-0.3 wt% of Th and the balance of aluminum. The aluminum-barium alloy has excellent mechanical properties and corrosion resistance which the traditional aluminum alloy applied to the copper-clad aluminum wire does not have. The Ba-Pt-Cr aluminum alloyis widely applied to the electric appliance manufacturing industry, the electric wire and cable industry and the radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

Multi-function soft wall and manufacturing method thereof

InactiveUS10202520B2Small breathabilityEfficient releaseLamination ancillary operationsLaminationEngineeringSoft mass

The invention discloses a multi-function soft wall, comprising a surface printing layer and a base material, the base material further including a top layer, and a second layer, a third layer and a bottom layer that are all foaming layers, wherein both the second layer and the third layer have a foaming ratio less than that of the bottom layer, and a fiber layer is disposed between the third layer and the bottom layer. The invention further provides a method of manufacturing a multi-function soft wall, comprising: sequentially coating a top layer, a second layer, a third layer, a fiber layer and a bottom layer on a release paper, respectively, and then obtaining a base material, and performing a foaming process with respect to the second layer, the third layer and the bottom layer, respectively, and performing a drying and cooling process after the coating step; and separating the base material from the release paper, and printing a surface printing layer on the top layer. The multi-function soft wall can release negative ions, and continuously eliminate various pollutions indoors.

Owner:NINGBO CALLDE BIOMIMETICS MATERIALS CO LTD

High-wear-resistant Ba-Re-Ge zinc alloy suitable for cold chamber die casting

InactiveCN108165825AImprove flame retardant performanceCombustion hindranceWear resistantDie casting

The invention discloses a high-wear-resistant Ba-Re-Ge zinc alloy suitable for cold chamber die casting, and a processing technology thereof. The alloy is prepared from the components in percentage byweight: 0.8 to 1.2 percent of Ba, 0.4 to 0.6 percent of Re, 1.5 to 2.4 percent of Ge, 1.2 to 1.6 percent of Sc, 0.5 to 0.6 percent of Nb, 0.2 to 0.3 percent of Ce, and the balance of zinc. The zinc-barium alloy has an excellent die casting performance, and can be used for growing a long thin-wall parts. In addition, during a die casting process, a cold chamber can be adopted for casting, so thatthe production efficiency is greatly improved, and the energy consumption is reduced. The obtained product is widely used in an electric appliance manufacturing industry and a radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

Corrosion resistant silver alloy with purple appearance for jewelry and processing process thereof

A corrosion resistant silver alloy with purple appearance for jewelry and a processing process thereof are disclosed. The silver alloy includes, by weight, 0.1-0.2 wt% of B, 1.4-1.6 wt% of Ca, 34.0-35.0 wt% of Al, 6.2-8.5 wt% of Ni, 0.4-0.6 wt% of W, 0.1-0.2 wt% of Sm and 2.5-2.8 wt% of Si, with the balance being silver. A new variety having purple gloss is provided for colorful silver in the present market, and the silver alloy has excellent discoloration resistance. The production cost is reduced, and the related production process and equipment requirements are greatly simplified, and it can be predicted that application and industrialization of the silver alloy will yield substantial achievements and social benefit.

Owner:GUANGZHOU YUZHI TECH CO LTD

Nickel-free Miao silver alloy with excellent die-casting performance for corrosion-resistant jewelry

InactiveCN108796342AReduced shrinkage deformationImprove thermal cracking resistanceSolid state diffusion coatingDie castingCopper

The invention discloses a nickel-free Miao silver alloy with excellent die-casting performance for corrosion-resistant jewelry. The nickel-free Miao silver alloy comprises the compositions of, by weight, 0.5-0.8% of P, 3.0-3.5% of Bi, 4.0-5.0% of Sn, 0.4-0.6% of Te, 2.0-3.5% of Al, 5.0-8.0% of Fe, 40.0-50.0% of Ag, and the balance copper. According to the nickel-free Miao silver alloy, a materialscience solution is provided for a Miao silver alloy in China, thus a Miao silver product can be environmentally friendly and has no phenomenon of allergy after being processed, and the alloy has theexcellent die-casting performance; and through implementation and industrialization of the alloy, the demands of product renewal and industry upgrading in the jewelry industry in China can be effectively pushed.

Owner:GUANGZHOU YUZHI TECH CO LTD

Copper-yttrium alloy for pressure casting and processing technology of copper-yttrium alloy

The invention discloses a copper-yttrium alloy for pressure casting and a processing technology of the copper-yttrium alloy. Chemical components of the alloy comprise, by weight percent, 0.2%-0.6% ofY, 1.2%-2.5% of Sr, 0.6%-0.8% of Ba, 0.1%-0.2% of Ga, 0.5%-0.8% of In, 0.1%-0.2wt% of Yb, 0.4%-0.5% of Th, 0.1%-0.2% of B and the balance copper. Relative to a traditional copper alloy, the material has excellent casting performance and heat conduction performance.

Owner:GUANGZHOU YUZHI TECH CO LTD

Scandium copper alloy for die casting, and processing technology thereof

The invention discloses a copper-scandium alloy for die-casting and a processing technology thereof. In terms of weight percentage, the chemical composition of the alloy is: Sc:0.8‑1.2wt.%, Li:0.4‑0.8wt.%, Ba:0.5‑0.9wt.%, Ge:0.5‑0.9wt.%, Sn:0.4 ‑1.2wt.%, Th: 0.4‑0.6wt.%, Ce: 0.2‑0.5wt.%, B: 0.2‑0.5wt.%, and the balance is copper. Compared with traditional copper alloys, this material has excellent casting performance and corrosion resistance.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-thermal-conductivity Co-containing lead-lithium alloy with excellent die-casting performance

The invention discloses a high-thermal-conductivity Co-containing lead-lithium alloy with the excellent die-casting performance and a processing technology thereof. The lead-lithium alloy comprises the following components of, by weight, 1.2-1.8 wt% of Li, 0.8-1.2 wt% of Co, 0.2-0.4 wt% of Y, 0.3-0.5 wt% of In, 0.2-0.4 wt% of Eu, 0.4-0.8 wt% of Mn and the balance lead. Compared with a lead alloy for a traditional shielding material lacking excellent casting performance, the lead-lithium alloy has the excellent casting performance and the high thermal conductivity; and the Co-containing lead-lithium alloy and the processing technology thereof can be widely applied to the military and civilian fields and are significant.

Owner:GUANGZHOU YUZHI TECH CO LTD

958 alloy for die casting and red silver jewelry and processing technology thereof

InactiveCN108796288ARelaxed Freezing Temperature RangeGood castabilitySolid state diffusion coatingSocial benefitsDie casting

The invention discloses a 958 alloy for die casting and red silver jewelry and a processing technology thereof. The alloy comprises, by weight, 0.2-0.3% of C, 0.5-0.6% of B, 1.2-1.4% of Ba, 0.4-0.8% of Ti, 0.8-1.2 % of Mo, 0.3-0.5% of Sb, 95-96% of Ag, and the balance copper. A new material with red appearance is provided for the 958 silver alloy for the jewelry in China, and the material has an excellent die casting characteristic. The implementation and industrialization of the material can effectively promote the demands of product updating and industry upgrading in the jewelry industry ofChina, and rich economic gains and social benefits are obtained when the industry problems are solved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Tibetan silver alloy with characteristics of low density and corrosion resistance for casting and process thereof

The invention discloses a Tibetan silver alloy with the characteristics of low density and corrosion resistance for casting and a process thereof. The Tibetan silver alloy comprises the following components of, by weight, 0.2wt.%-0.3wt.% of B, 5.0wt.%-6.0wt.% of Li, 5.0wt.%-8.0wt.% of Ge, 0.3wt.%-0.5wt.% of Te, 30.0wt.%-40.0wt.% of Mg, 4.0wt.%-6.0wt.% of Cr, 29.0wt.%-31.0wt.% of Ag and the balancecopper. The Tibetan silver alloy a solution in the aspect of material science for the Tibetan silver alloy in China, the alloy has light-weight characteristic, and the alloy has excellent casting performance. The implementation and industrialization of the material can effectively promote the product updating and industry upgrading requirements of the jewelry industry in China.

Owner:GUANGZHOU YUZHI TECH CO LTD

Jewelry silver alloy having blue gloss and corrosion resistance and technology of silver alloy

The invention discloses a jewelry silver alloy having blue gloss and corrosion resistance and a technology of the silver alloy. The alloy comprises compositions including, by weight, 0.1%-0.2% of P, 1.0%-1.2% of Mg, 4.0%-5.0% of In, 3.2%-4.8% of Co, 0.4%-0.6% of Mo, 0.1%-0.2% of Th, 1.5%-1.8% of Ge and the balance silver. A new type capable of having the blue gloss is provided for colorful silveron the market at present by means of the material, and in addition, the material further has the excellent color-changing-resistant characteristic. The production cost is reduced, and the related production technology and equipment meets are greatly simplified. It can be predicted that material implementation and industrialization can obtain plenteous economic gains and social benefits.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com