Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Slow force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

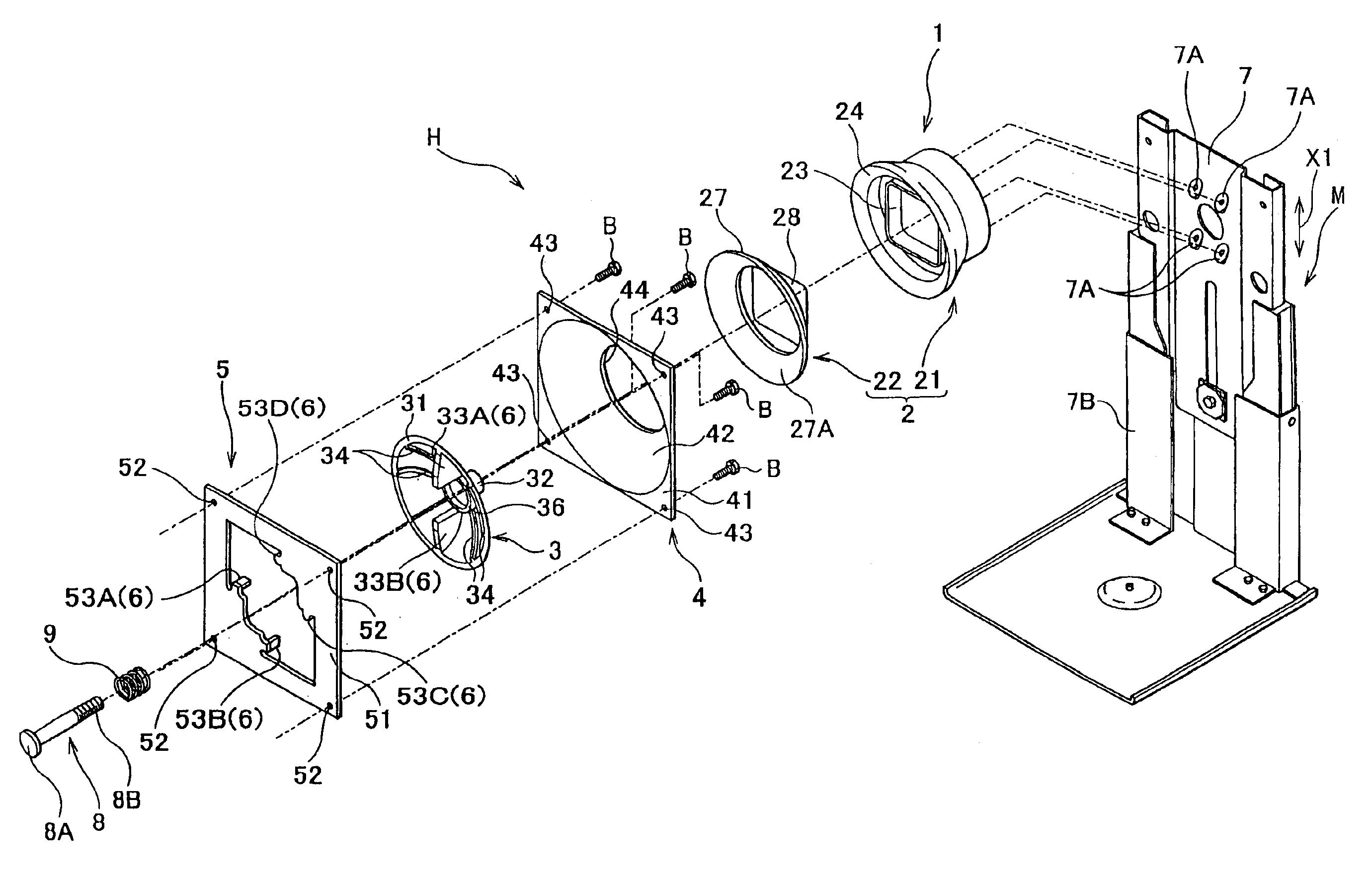

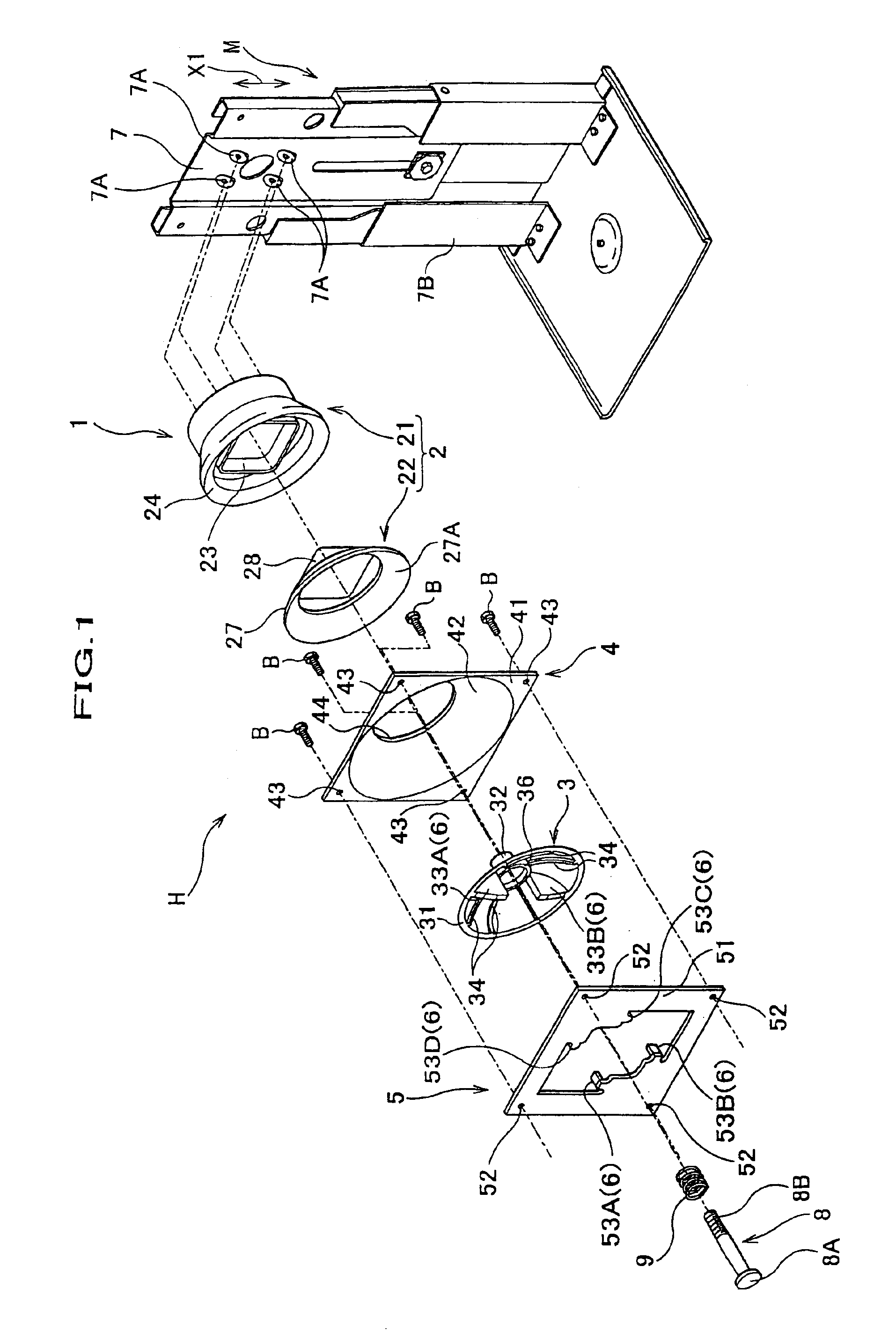

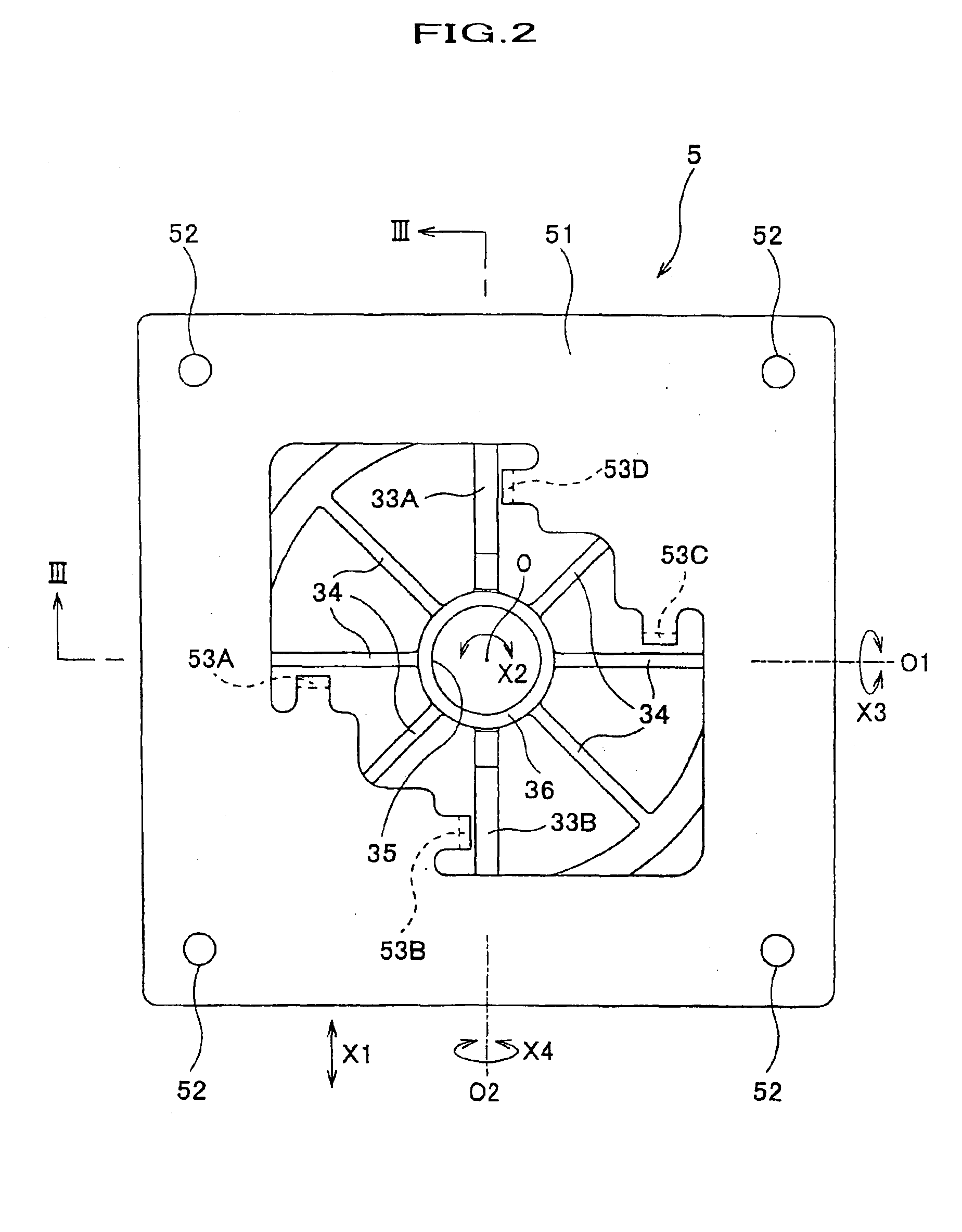

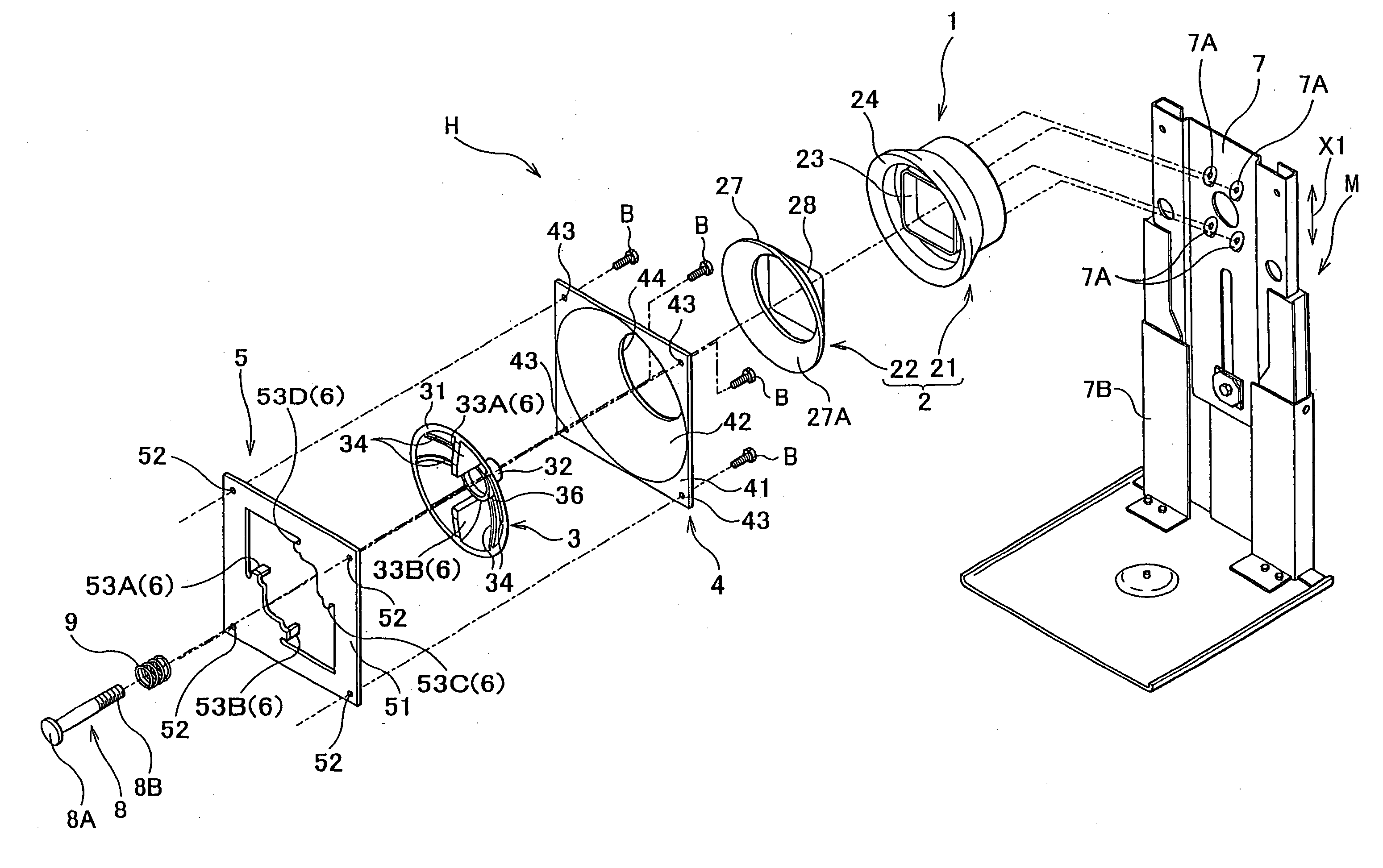

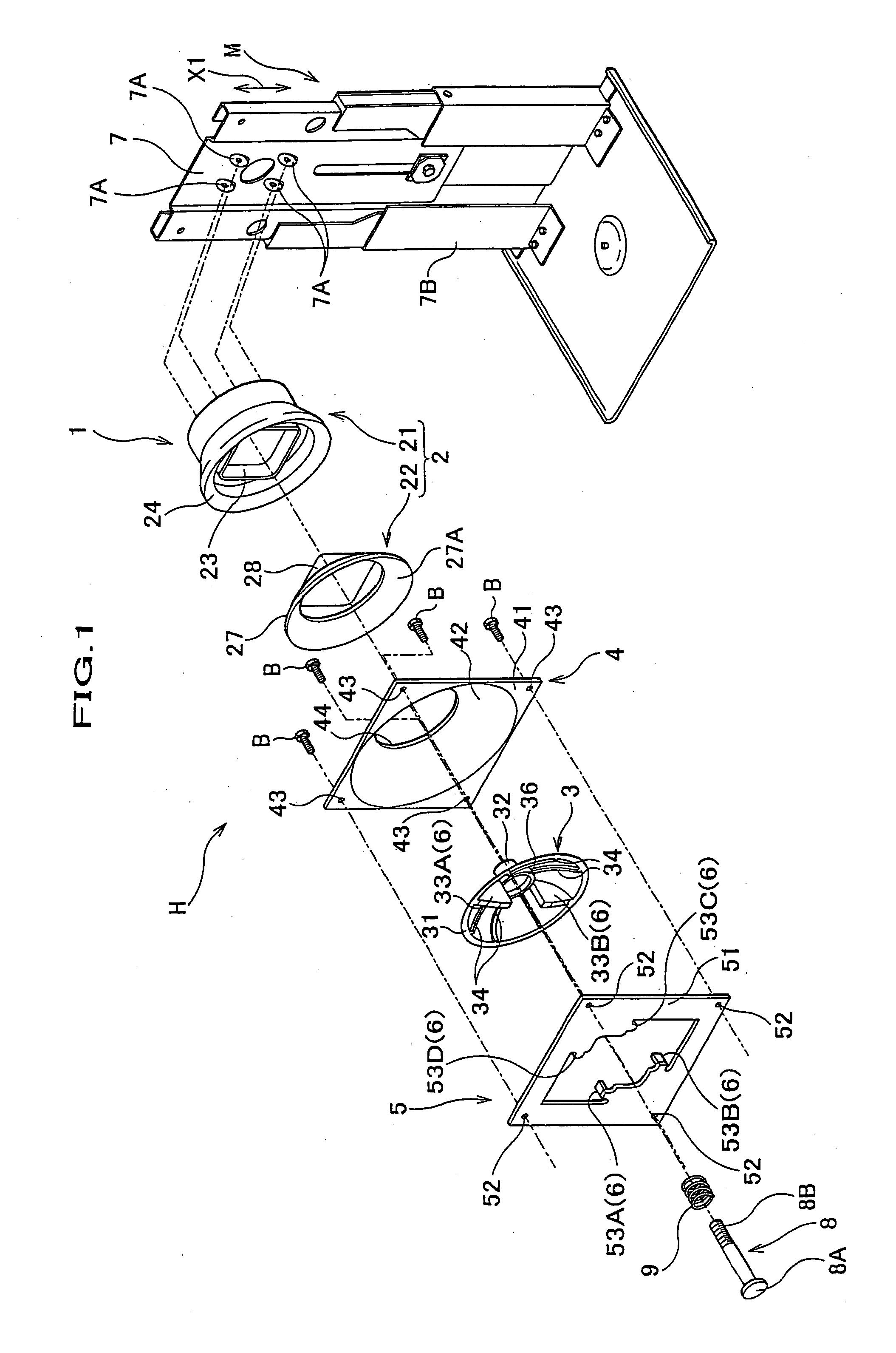

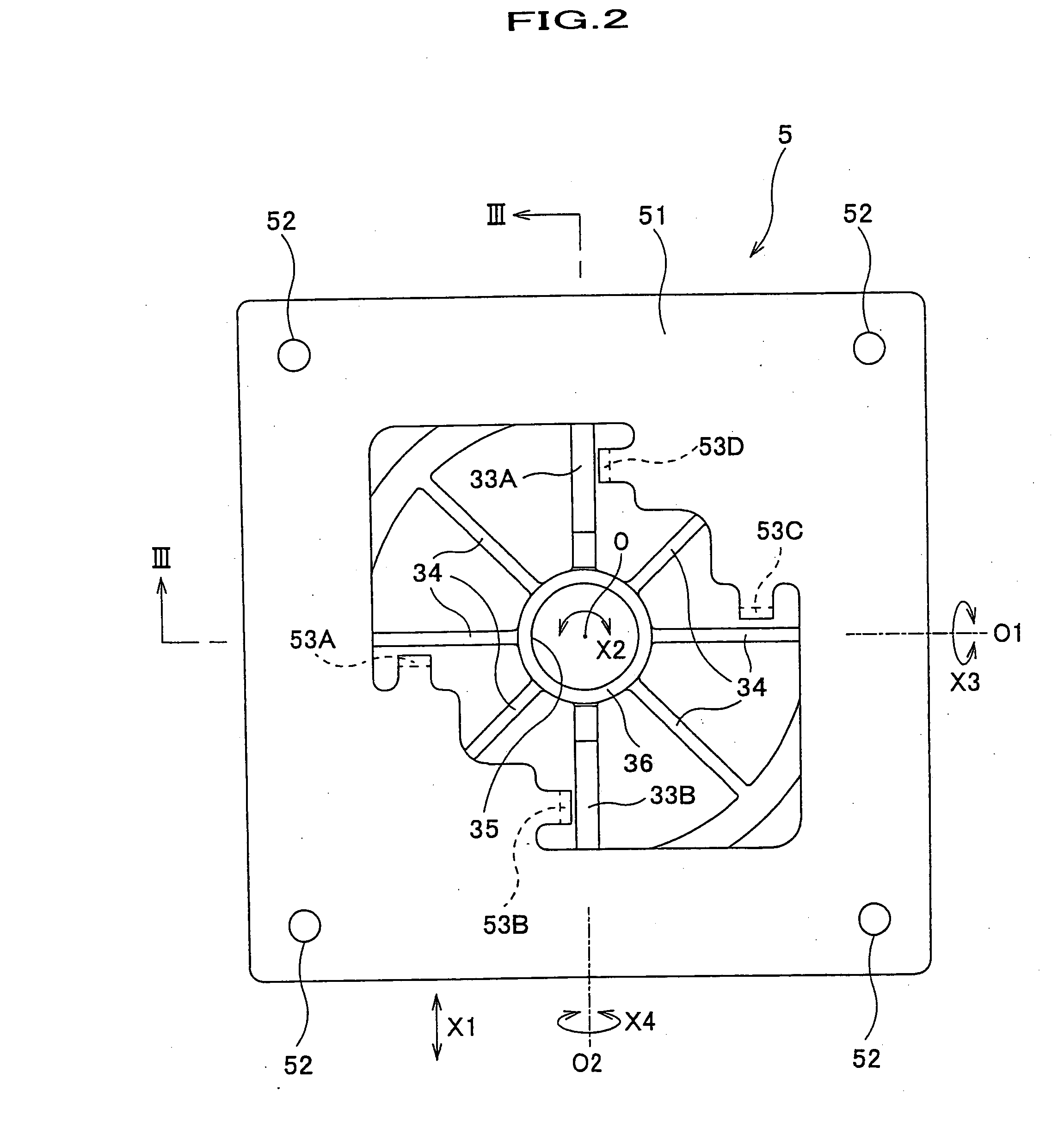

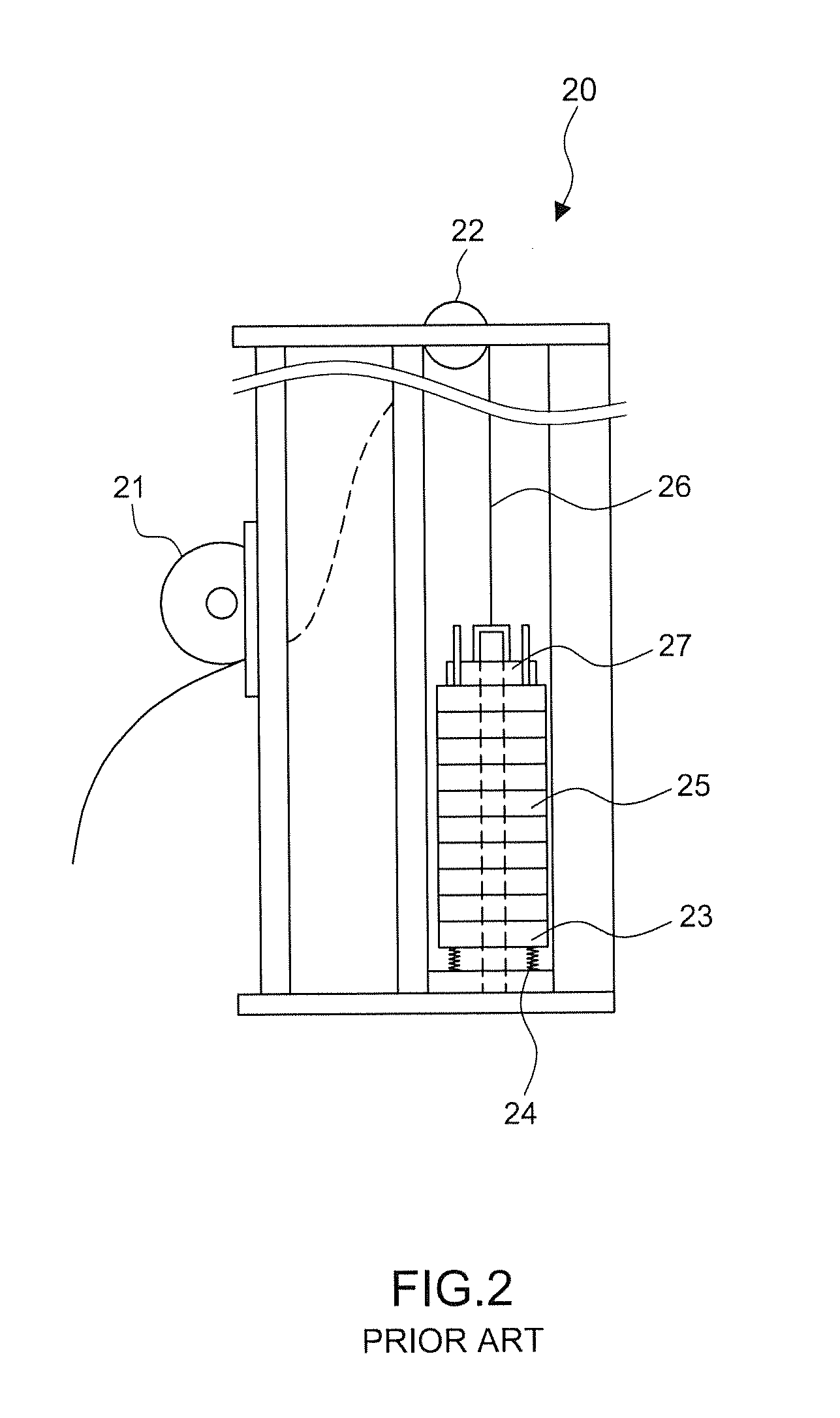

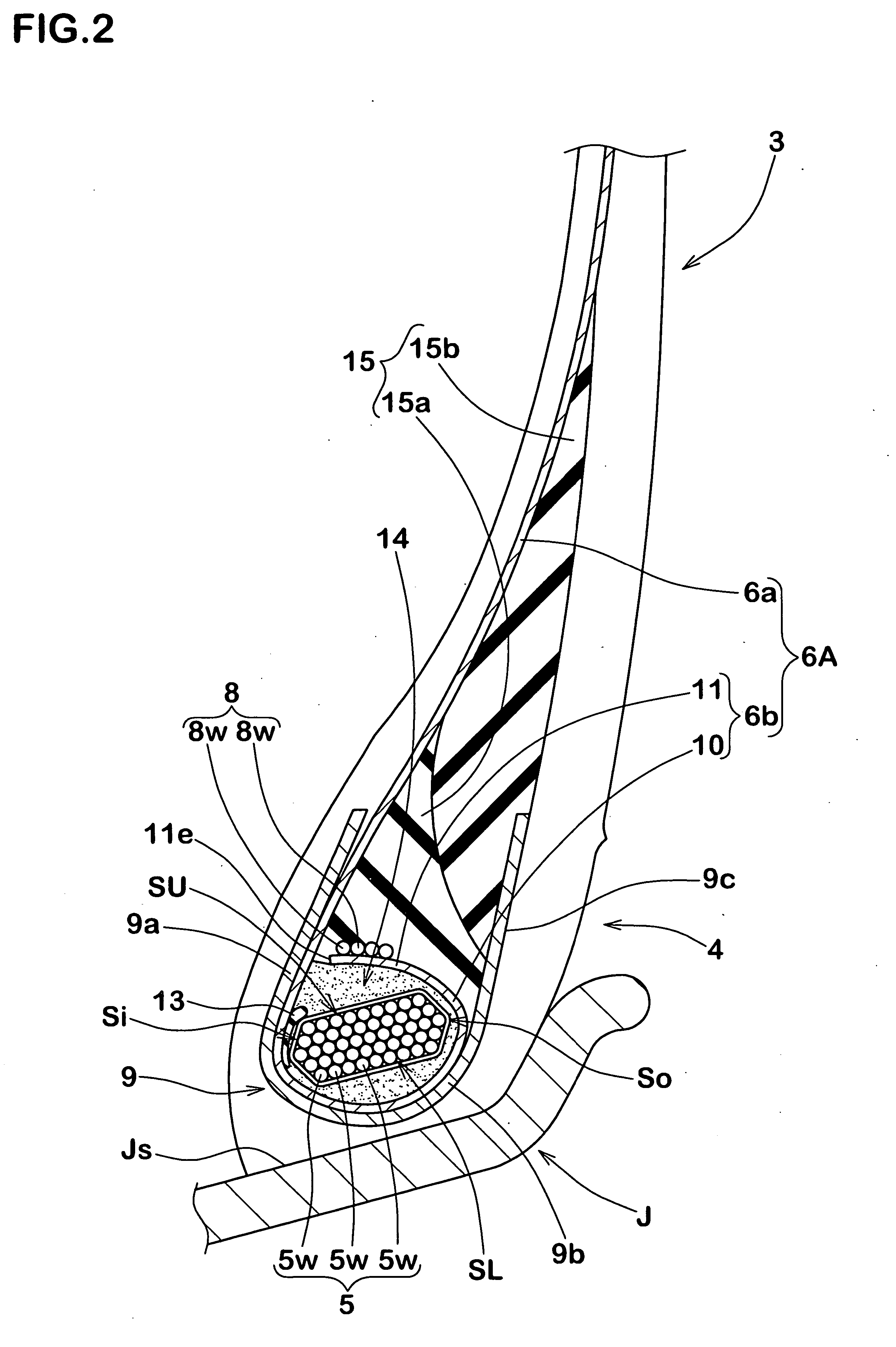

Direction regulator of display

InactiveUS6874743B2Reduce the number of partsReduce in quantityTelevision system detailsShutters/ movable grillesDisplay deviceEngineering

A direction regulator H of display, comprising a frame M mounting a member 7 capable of elevating / lowering in the height direction X1. A display fixing part 1 is provided to an upper part of the elevating / lowering member 7. The display fixing part 1 comprises a base member 2 having a spherical receiving face 27A. In front of the base member 2, a cap support 3 comprising a spherical cap body 31 having a curvature substantially identical to that of the receiving face 27A is provided to be urged by a spring 9 through the receiving face 27A of the base member 2. A flange 4 is clamped between the base member 2 and the cap support 3. The flange 4 is slidable along the spherical receiving face 27A of the base member 2. The flange 4 is fixed with a display D through an angle regulating member 5.

Owner:MURAKAMI CORP +1

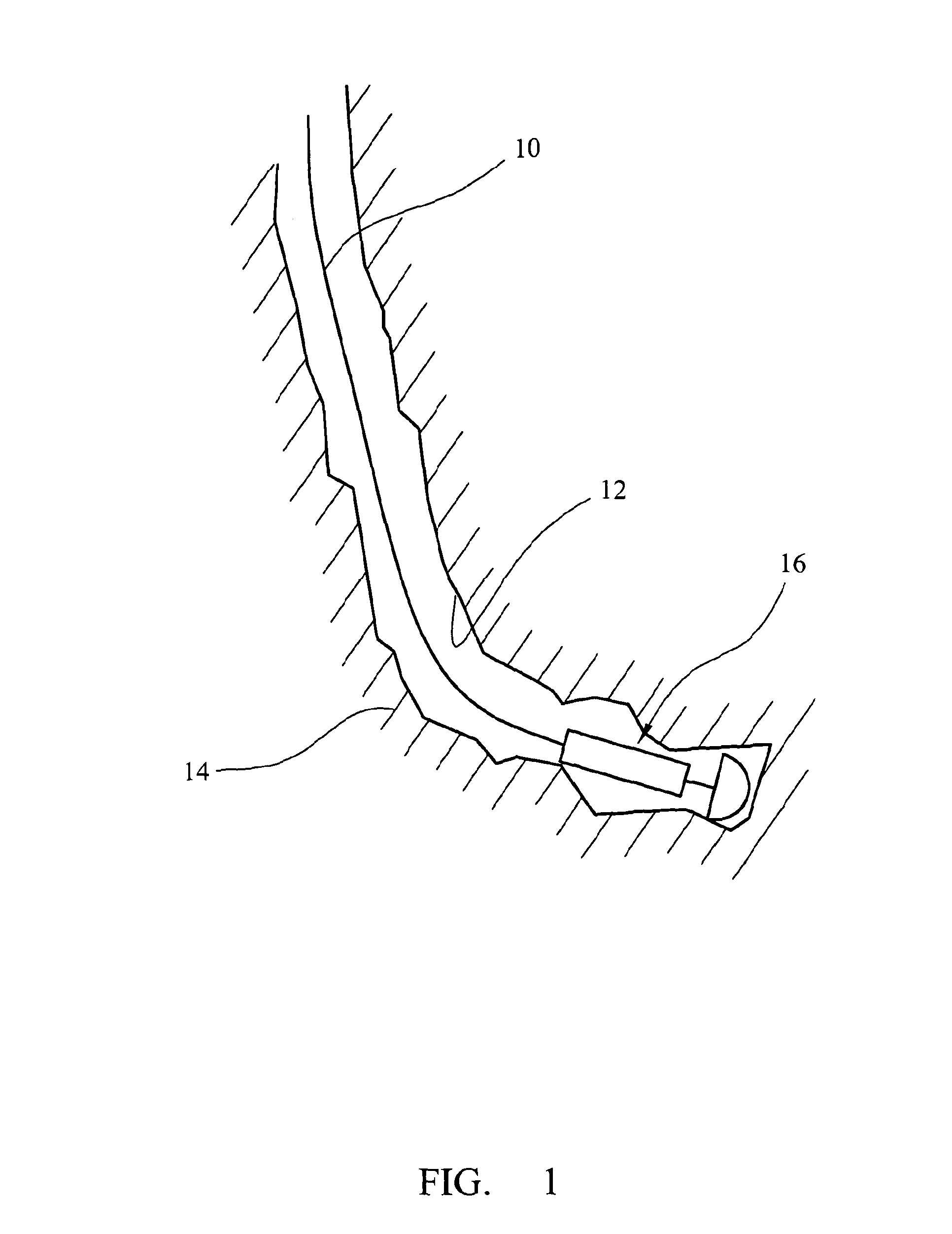

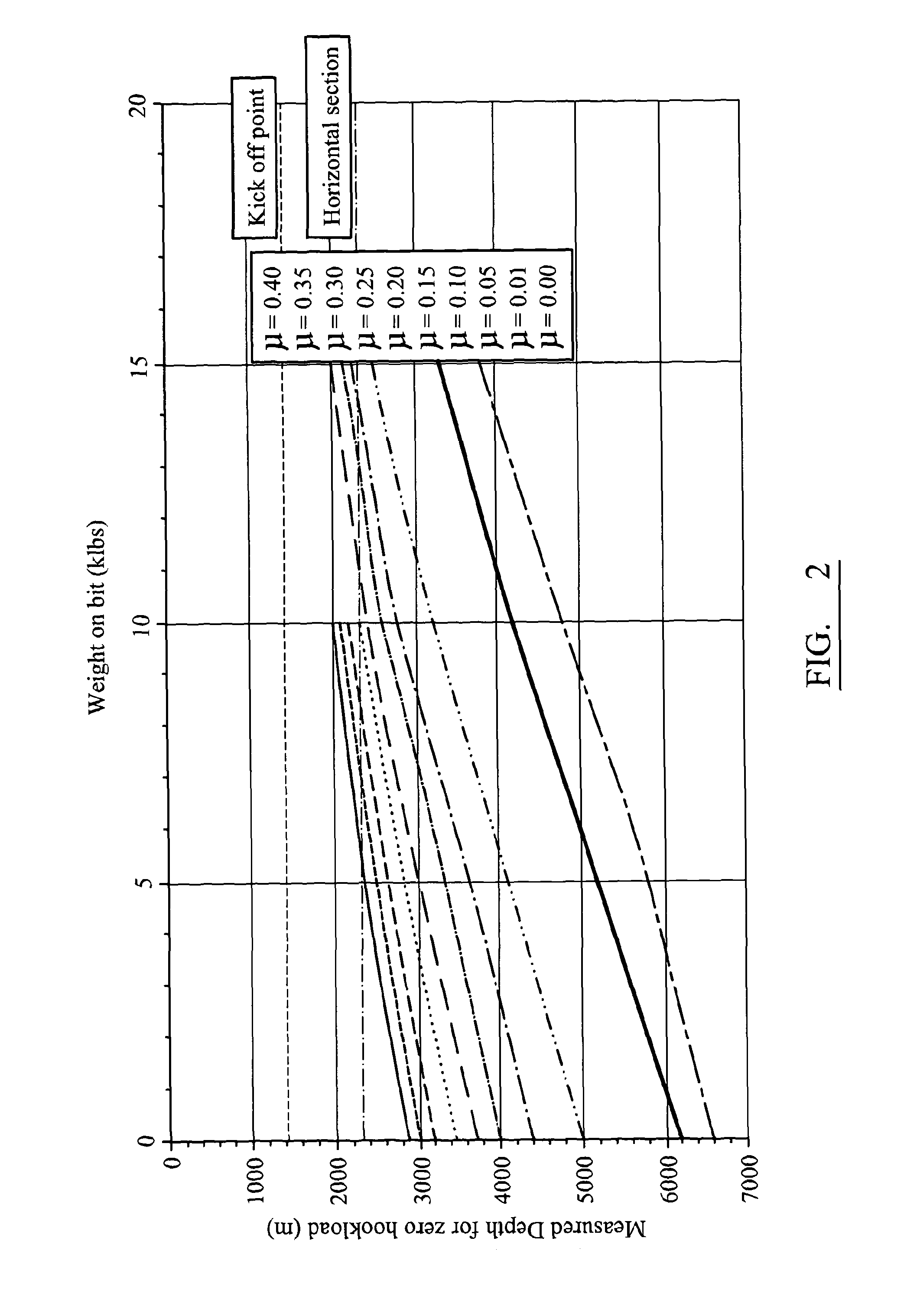

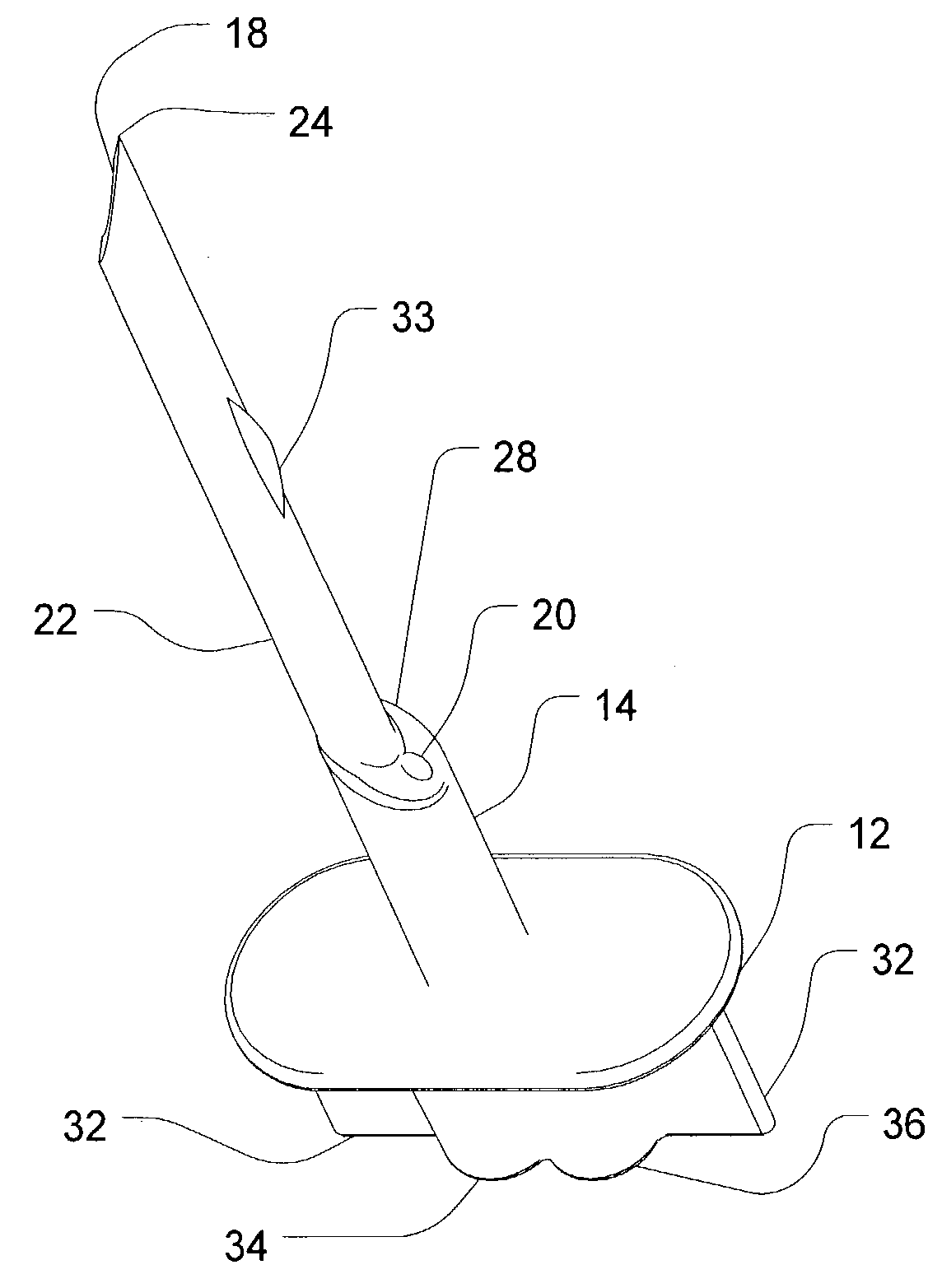

Method and apparatus for applying vibrations during borehole operations

A method of conducting borehole operations using a system including an elongate tubular conveyance that is moved through the borehole, the method comprising imposing a torsional vibration at a predetermined frequency on the tubular conveyance as it is moved through the borehole:wherein the predetermined frequency is obtained by determining the frequency-dependent mobility of the system based on the relationship between rotational velocity and torque for the system; and imposing torsional vibrations at a frequency where the relationship is optimised.

Owner:MISC

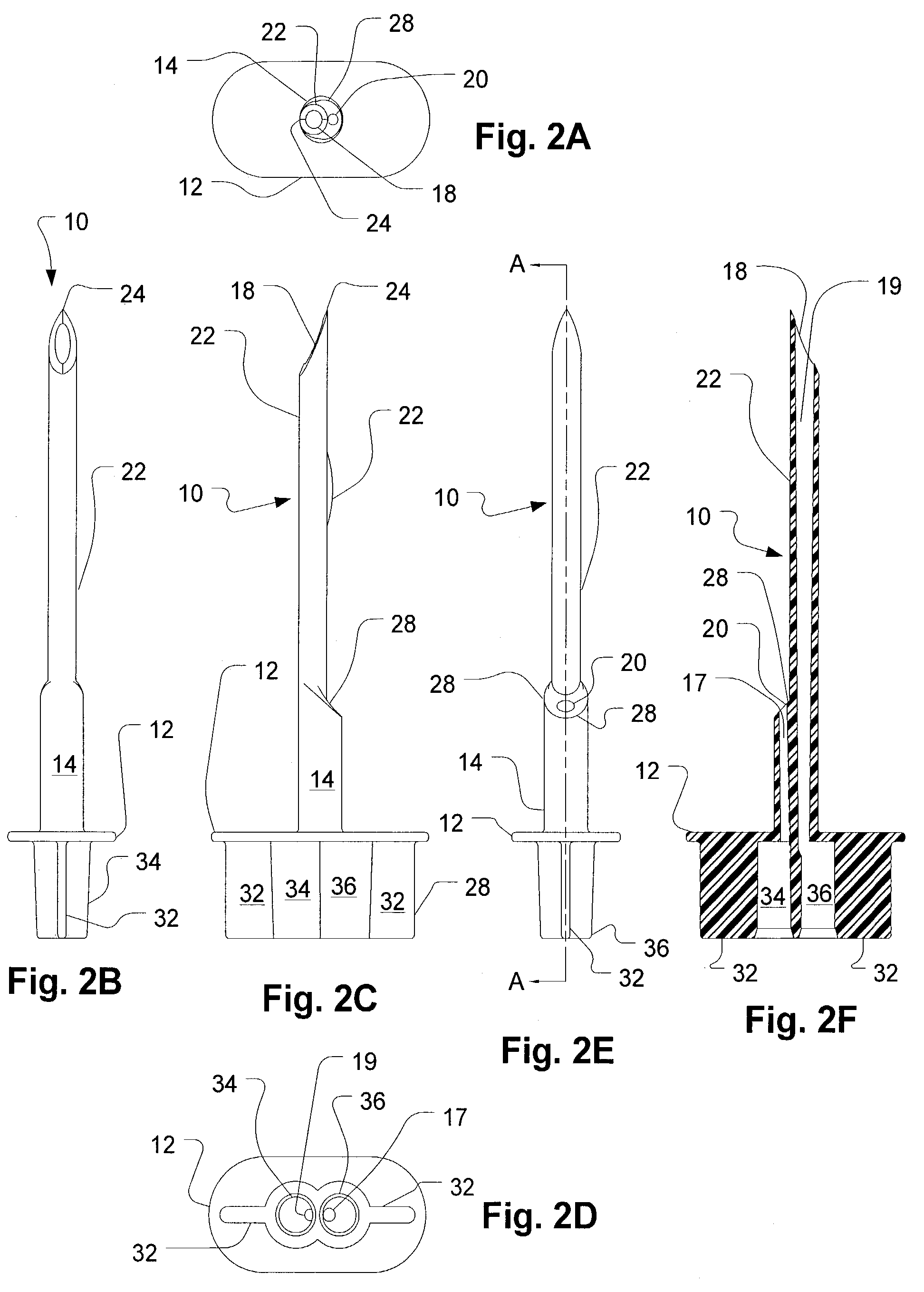

Dual access spike for infusate bags

ActiveUS7470265B2Reduce perforationEasy to insertDiagnosticsSurgeryDual accessMechanical engineering

Owner:NXSTAGE MEDICAL INC

Direction regulator of display

InactiveUS20040084585A1Reduce in quantityMovement position of the display is not easily displacedTelevision system detailsDigital data processing detailsEngineeringDisplay device

A direction regulator H of display, comprising a frame M mounting a member 7 capable of elevating / lowering in the height direction X1. A display fixing part 1 is provided to an upper part of the elevating / lowering member 7. The display fixing part 1 comprises a base member 2 having a spherical receiving face 27A. In front of the base member 2, a cap support 3 comprising a spherical cap body 31 having a curvature substantially identical to that of the receiving face 27A is provided to be urged by a spring 9 through the receiving face 27A of the base member 2. A flange 4 is clamped between the base member 2 and the cap support 3. The flange 4 is slidable along the spherical receiving face 27A of the base member 2. The flange 4 is fixed with a display D through an angle regulating member 5.

Owner:MURAKAMI CORP +1

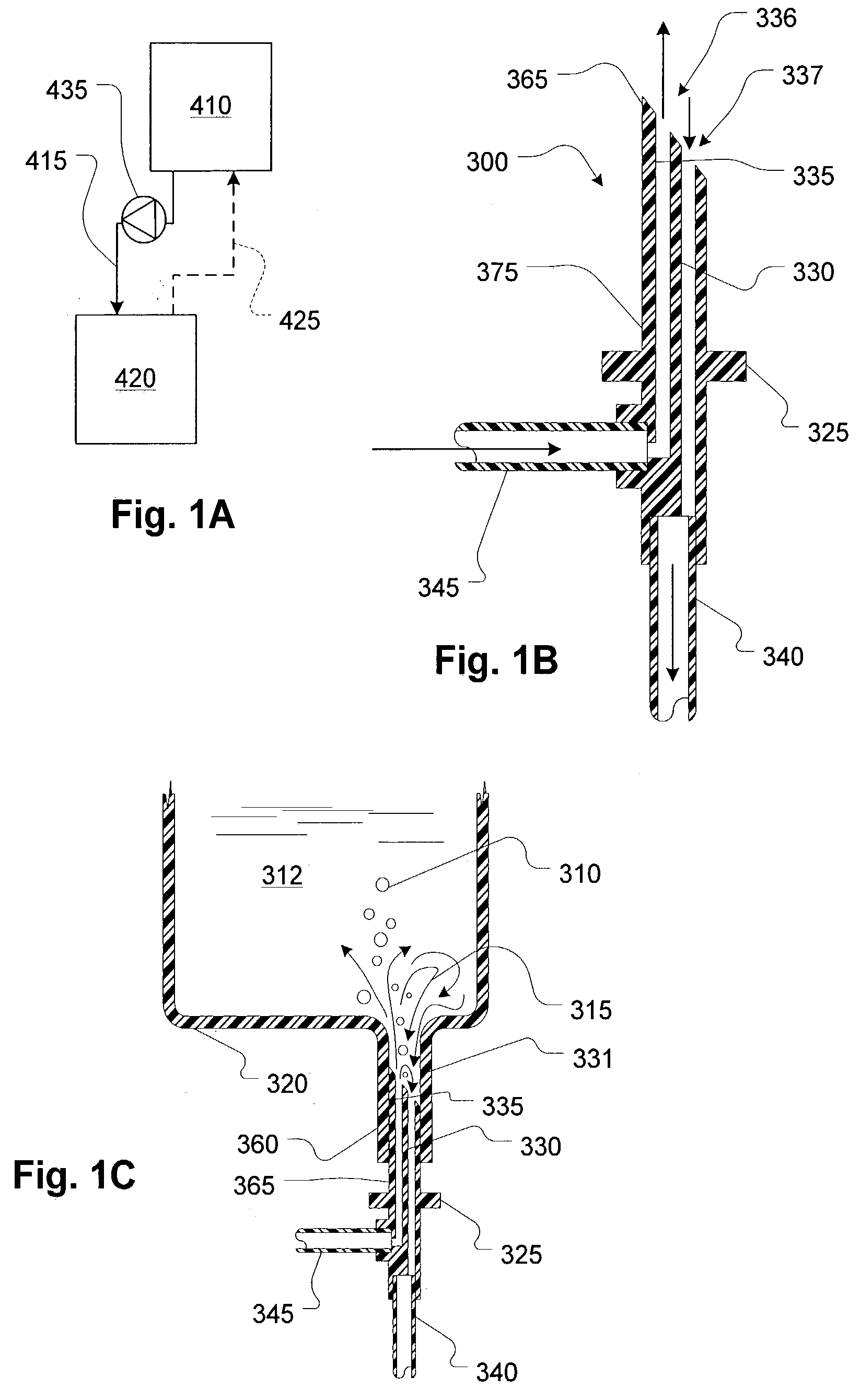

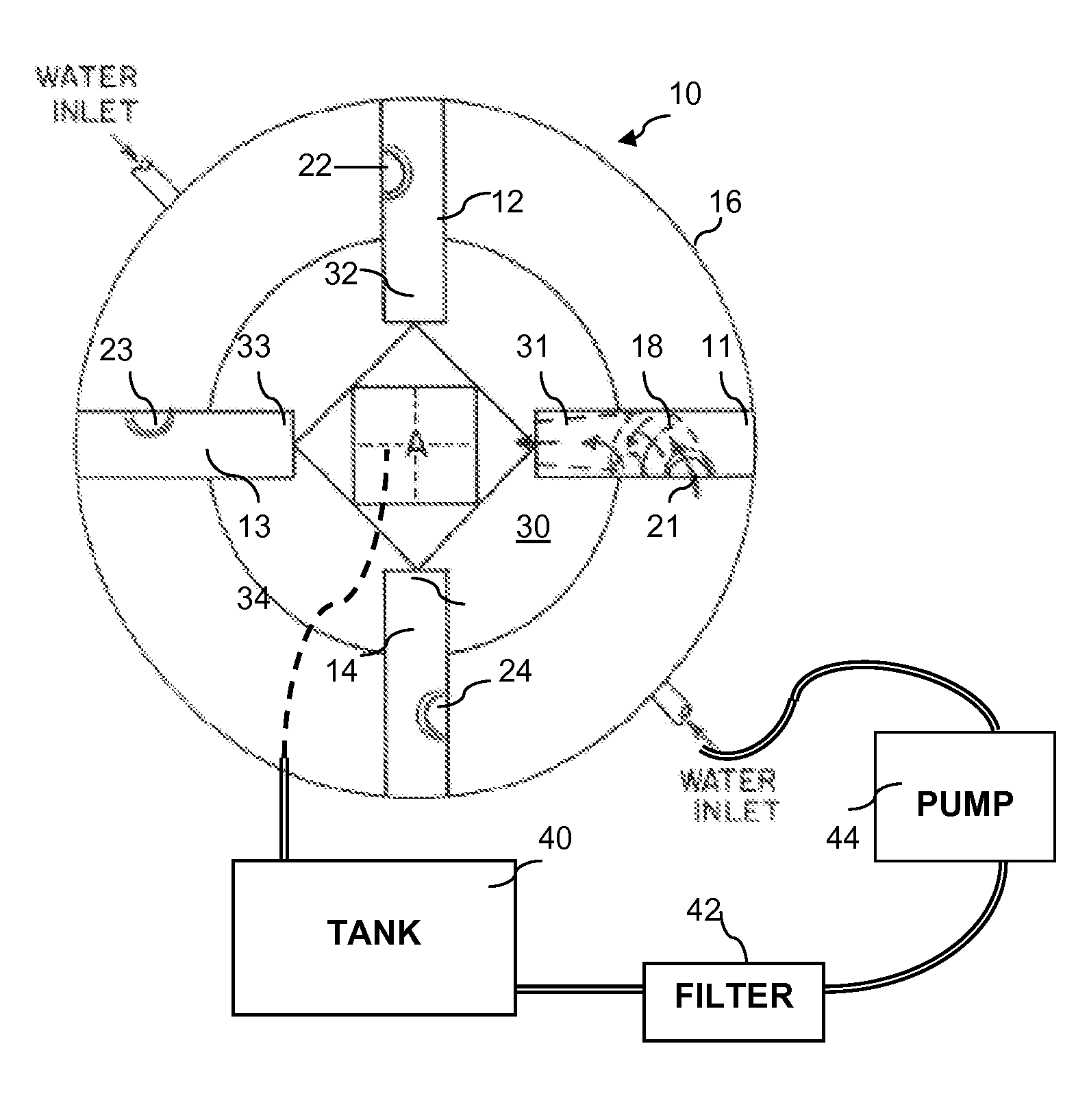

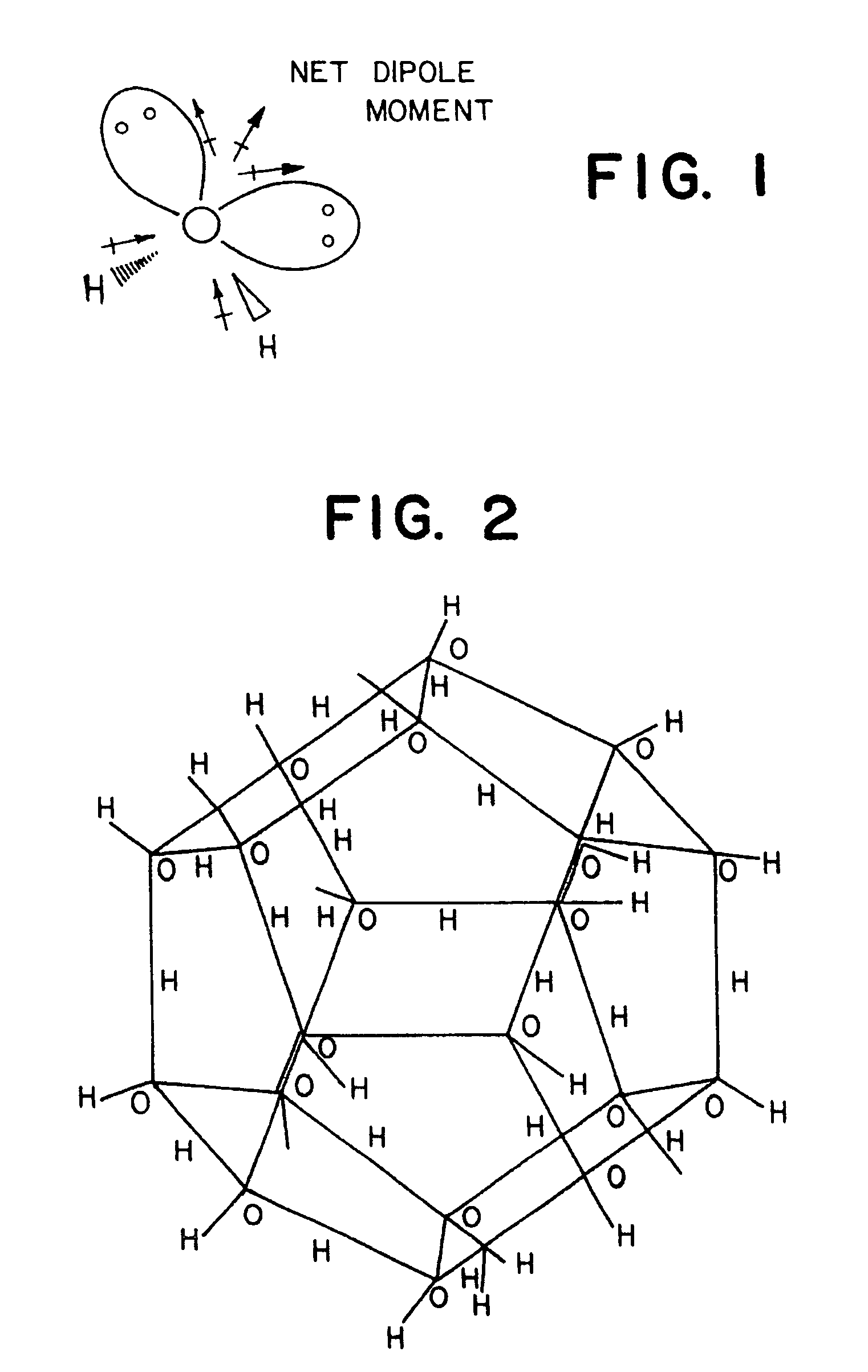

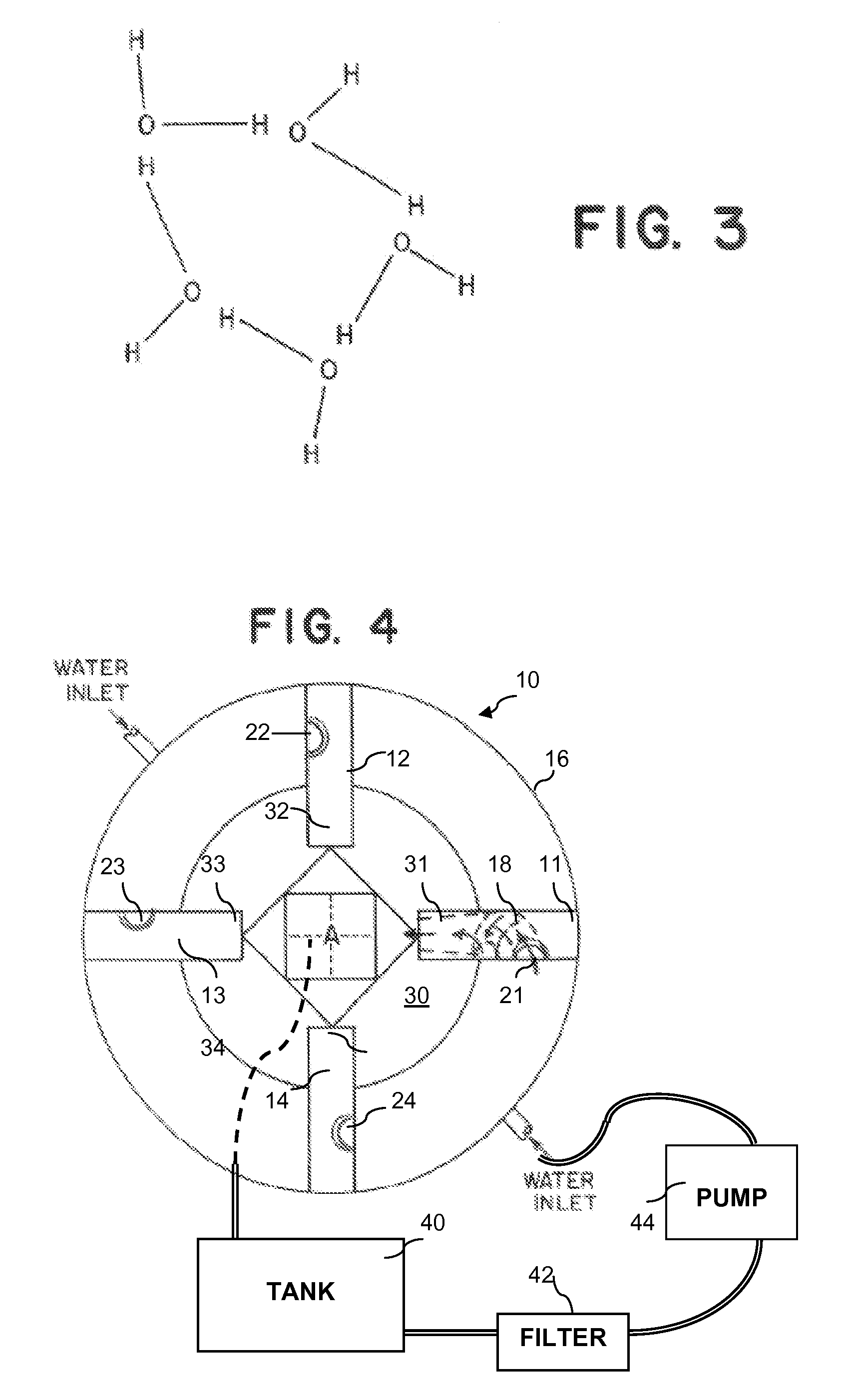

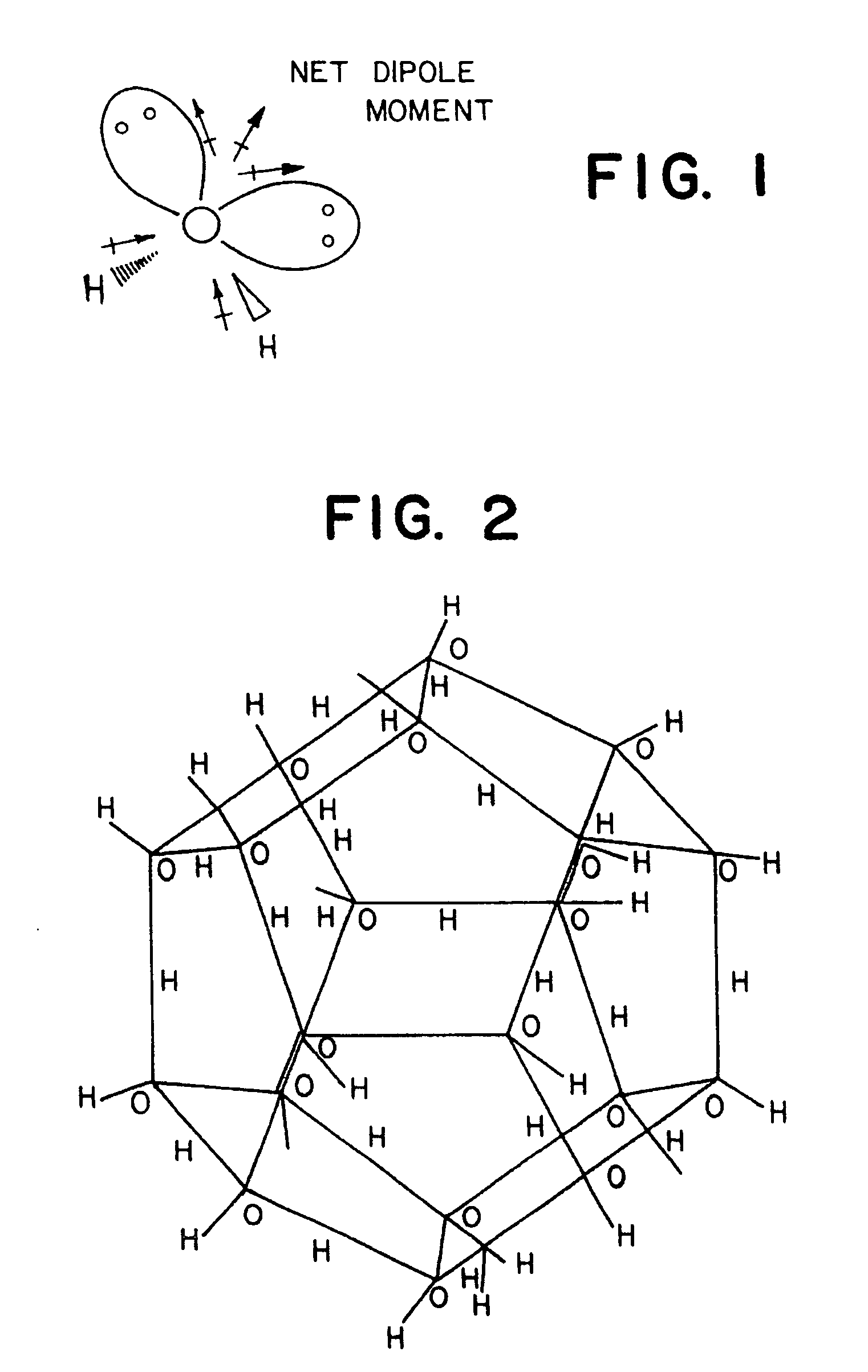

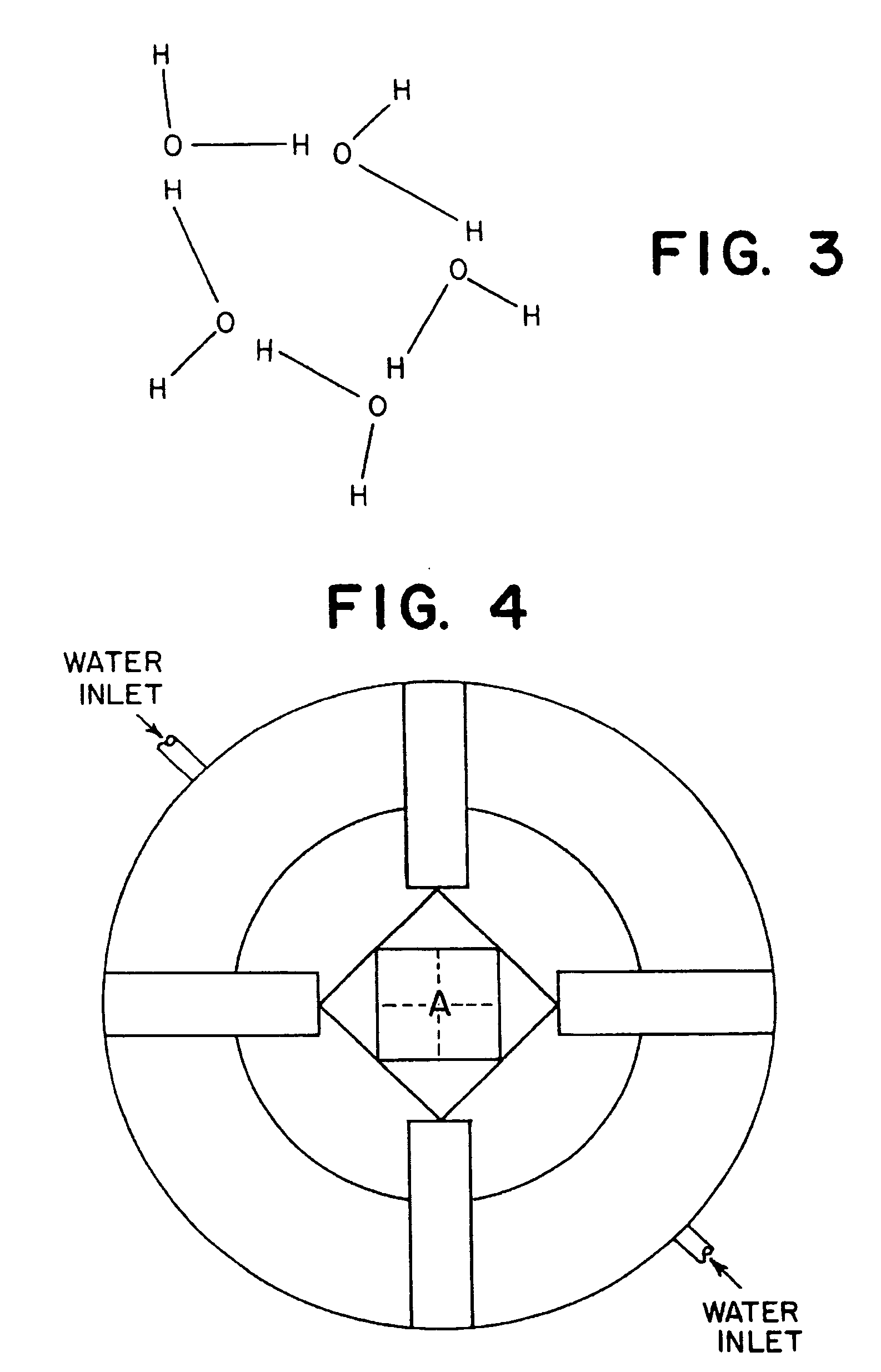

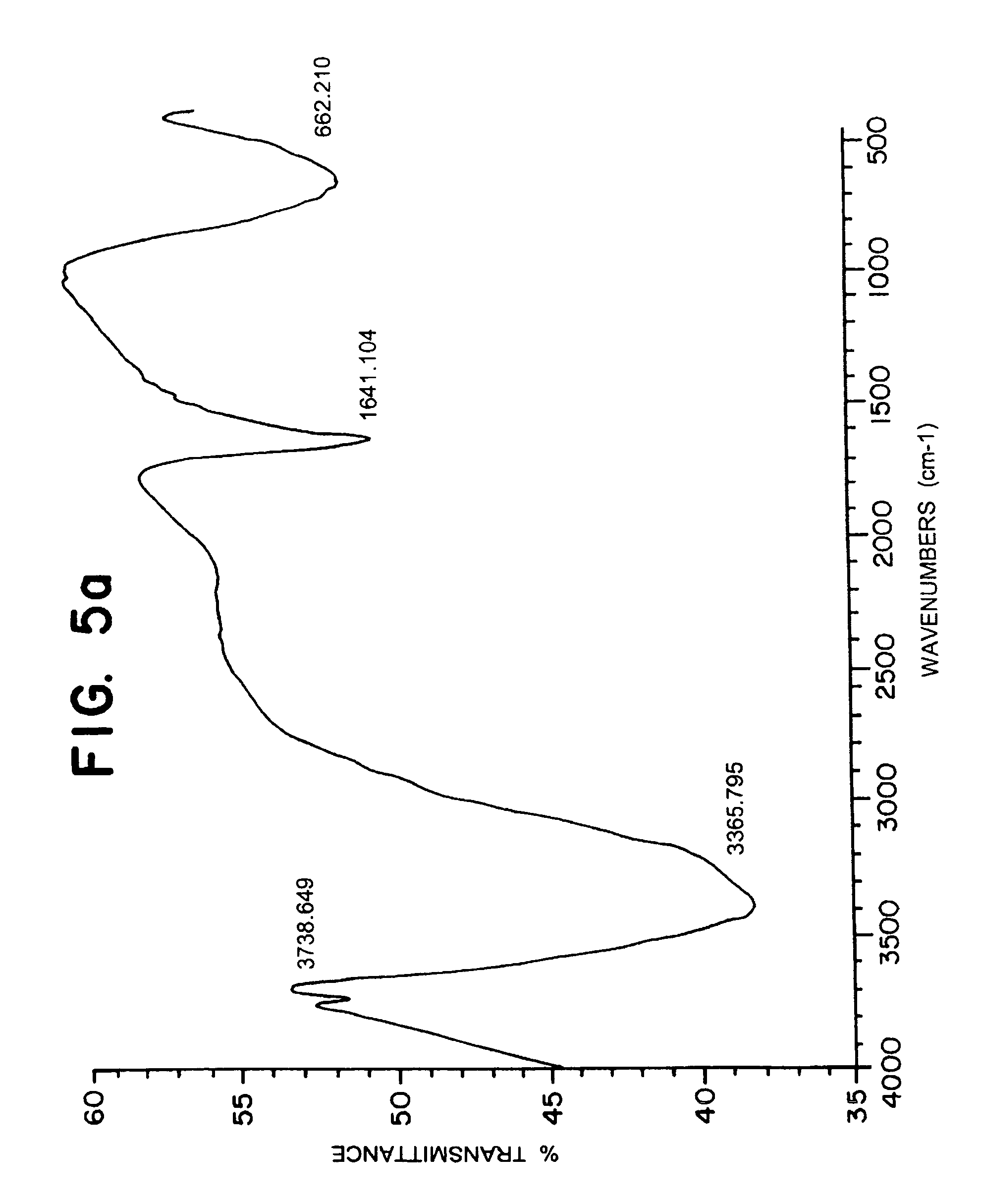

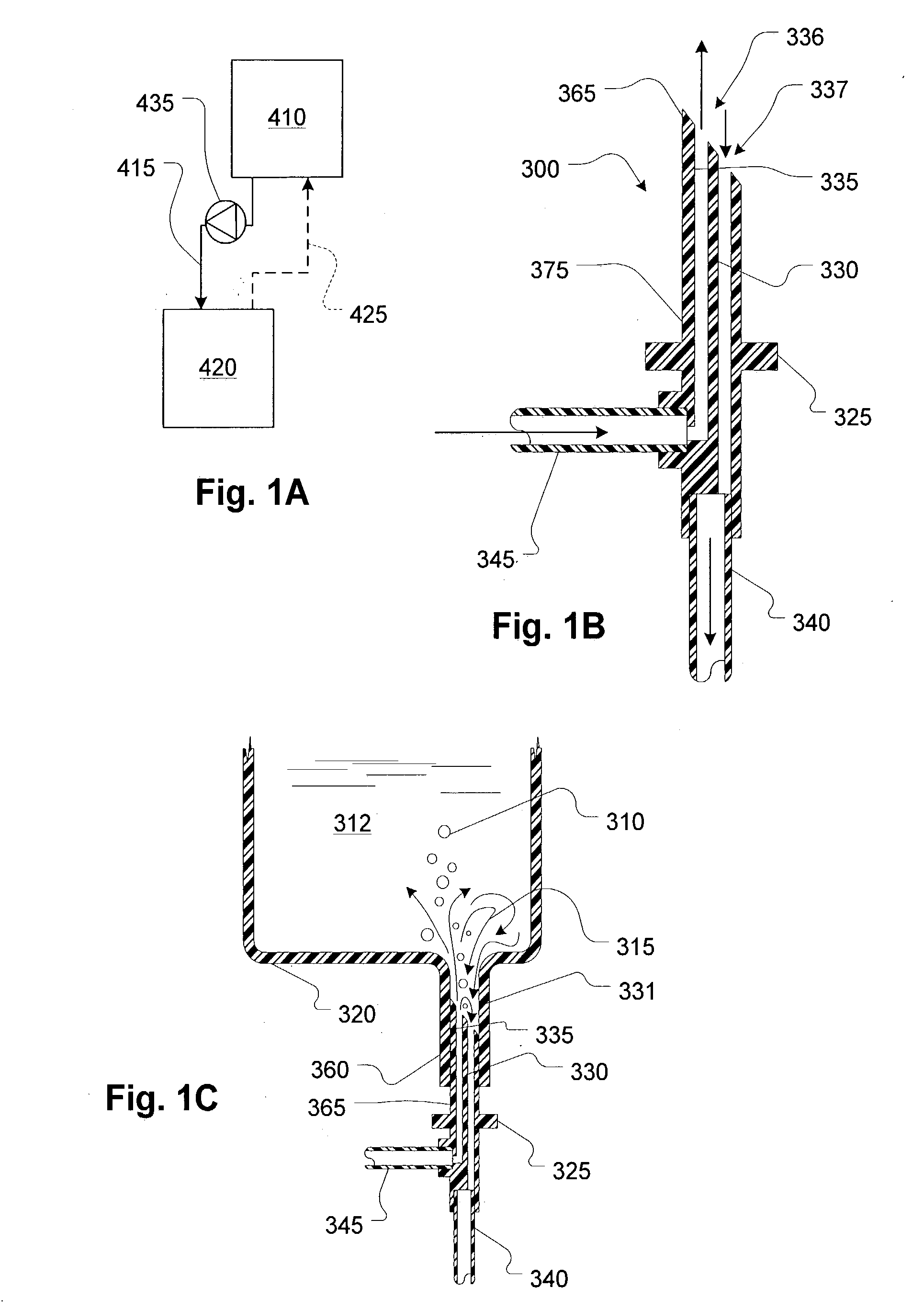

System for producing micro-cluster liquids

InactiveUS7198254B2Slow forceReduce restlessnessAntipyreticUsing liquid separation agentShock waveEngineering

The system for producing a micro-cluster liquid from a starting liquid utilizes a cavitation device with a plurality of reverse-fed pump volutes within a housing, where each volute establishes a rotational vortex for spinning the liquid in a circle and directing a liquid stream into a common chamber at a center of the housing. The starting liquid is pumped into the cavitation device at a first pressure and tangentially fed into each volute. The rotational vortex creates a partial vacuum within the spinning liquid so that cavitation bubbles are formed when the liquid exits the volute. The common chamber is maintained at a lower pressure so that the bubbles explode or implode upon exit from the volute to generate shock waves that break molecular bonds in the liquid. The volutes are oriented so that the liquid streams collide with each other within the common chamber, facilitating breakdown of molecular bonds. A discharge line connected to the common chamber carries the liquid out of the housing and into a tank for further processing.

Owner:AQUAPHOTONICS INC

Drugs, bio-affecting and body treating compositions

Micro-clustered water compositions of bio-affecting agents, body-treating agents, and adjuvants or carriers, pharmaceutical and diagnostic compositions thereof. Methods of using the compositions involving administering them ex vivo to cells, tissues or organs, or in vivo to living bodies; and methods of making the compositions.

Owner:AQUAPHOTONICS INC

System for producing micro-cluster liquids

InactiveUS20060146644A1Reduce restlessnessSlow forceAntipyreticUsing liquid separation agentChemistryMicro cluster

The invention provides novel micro-cluster liquids and methods for manufacturing and using them. The micro-cluster liquids comprise fractionized or micro-cluster liquids, (e.g. water, such as oxygenated micro-cluster water). The methods comprise causing cavitation of a liquid to form cavitation bubbles under a first pressure followed by depressurization to a second pressure to cause implosion and explosion of the cavitation bubbles such that acoustical energy shockwaves are created. The micro-cluster water (e.g., oxygenated micro-cluster water) is used to deliver hydration, oxygenation, or agents, such as nutritional agents or medications, and increasing overall cellular performance and exchanging liquids in the cell within minutes of consumption.

Owner:AQUAPHOTONICS INC

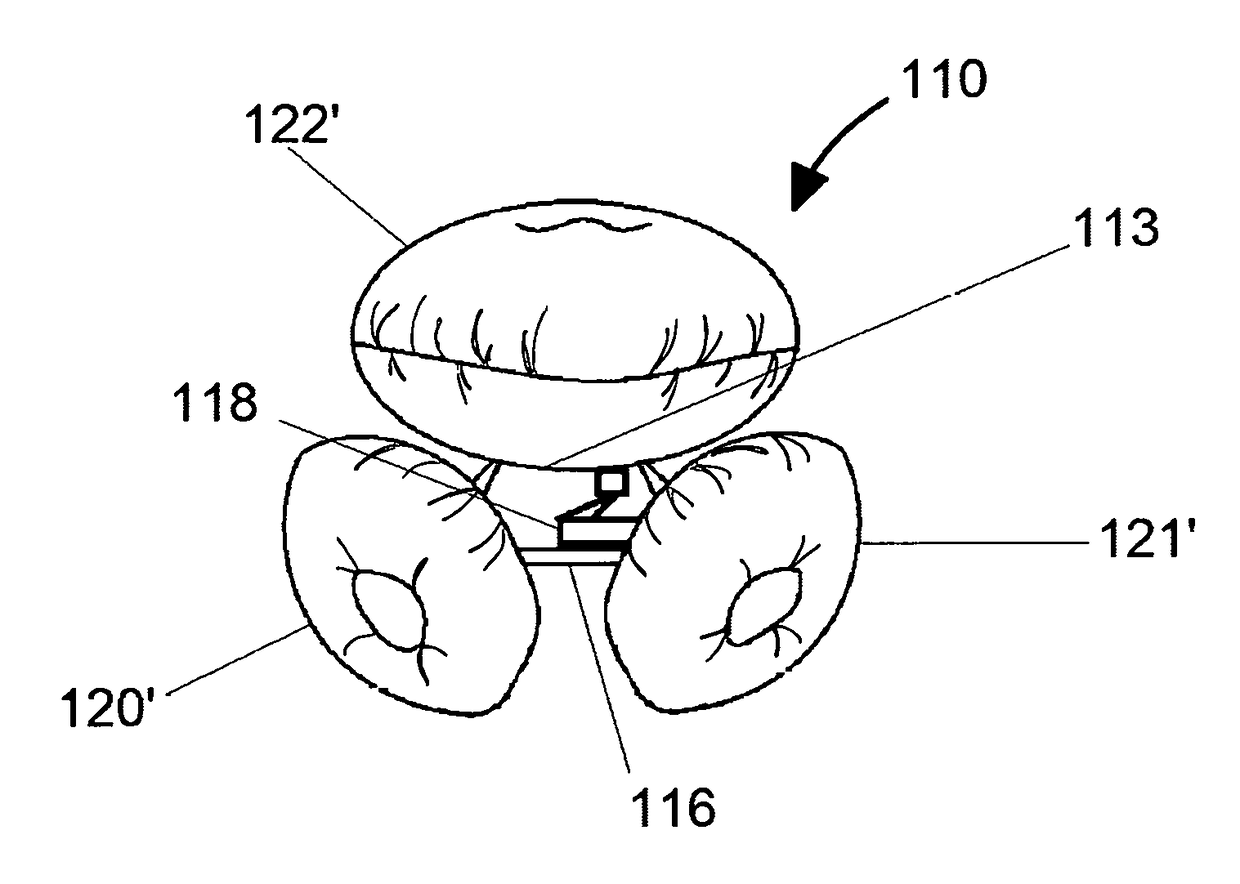

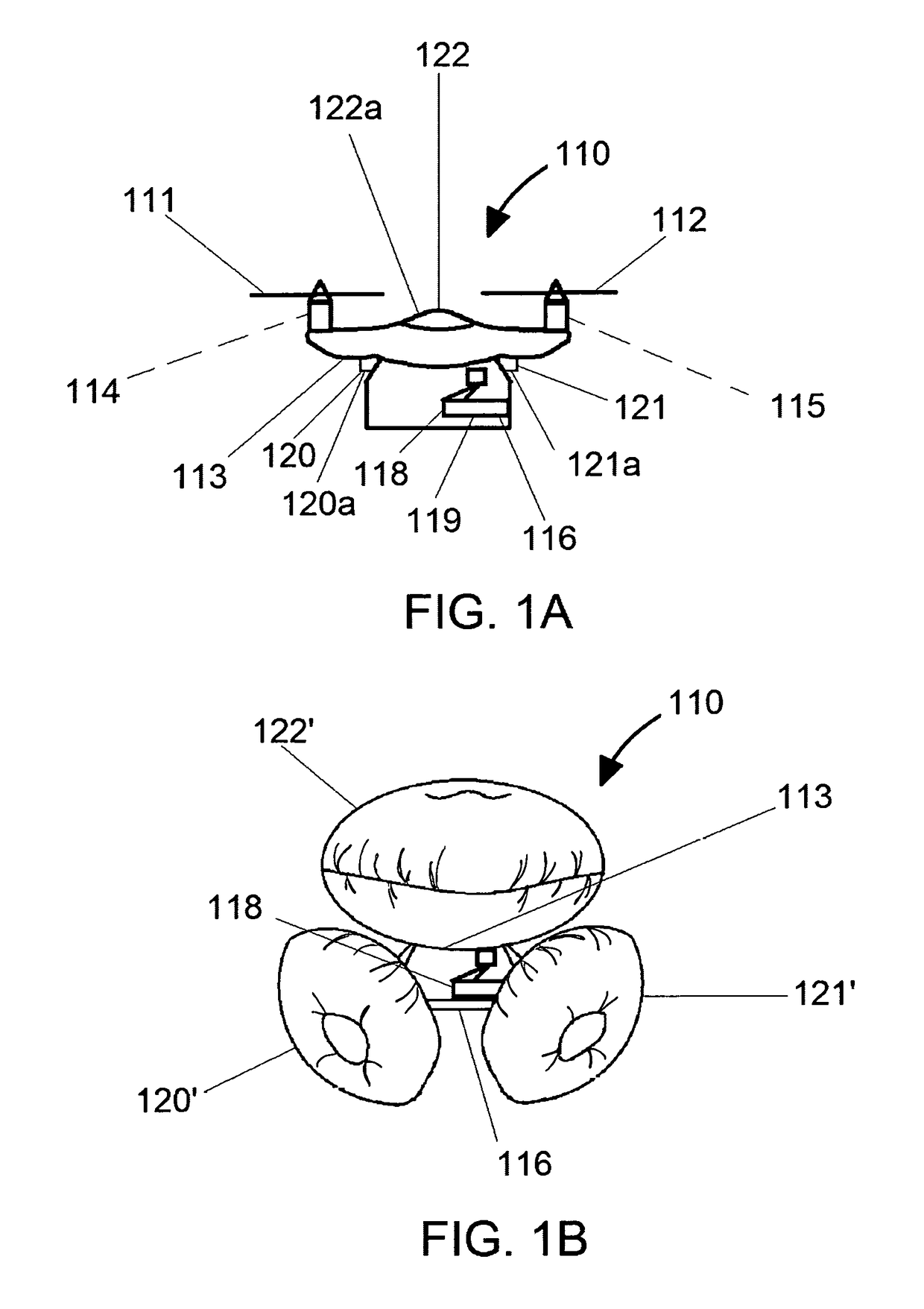

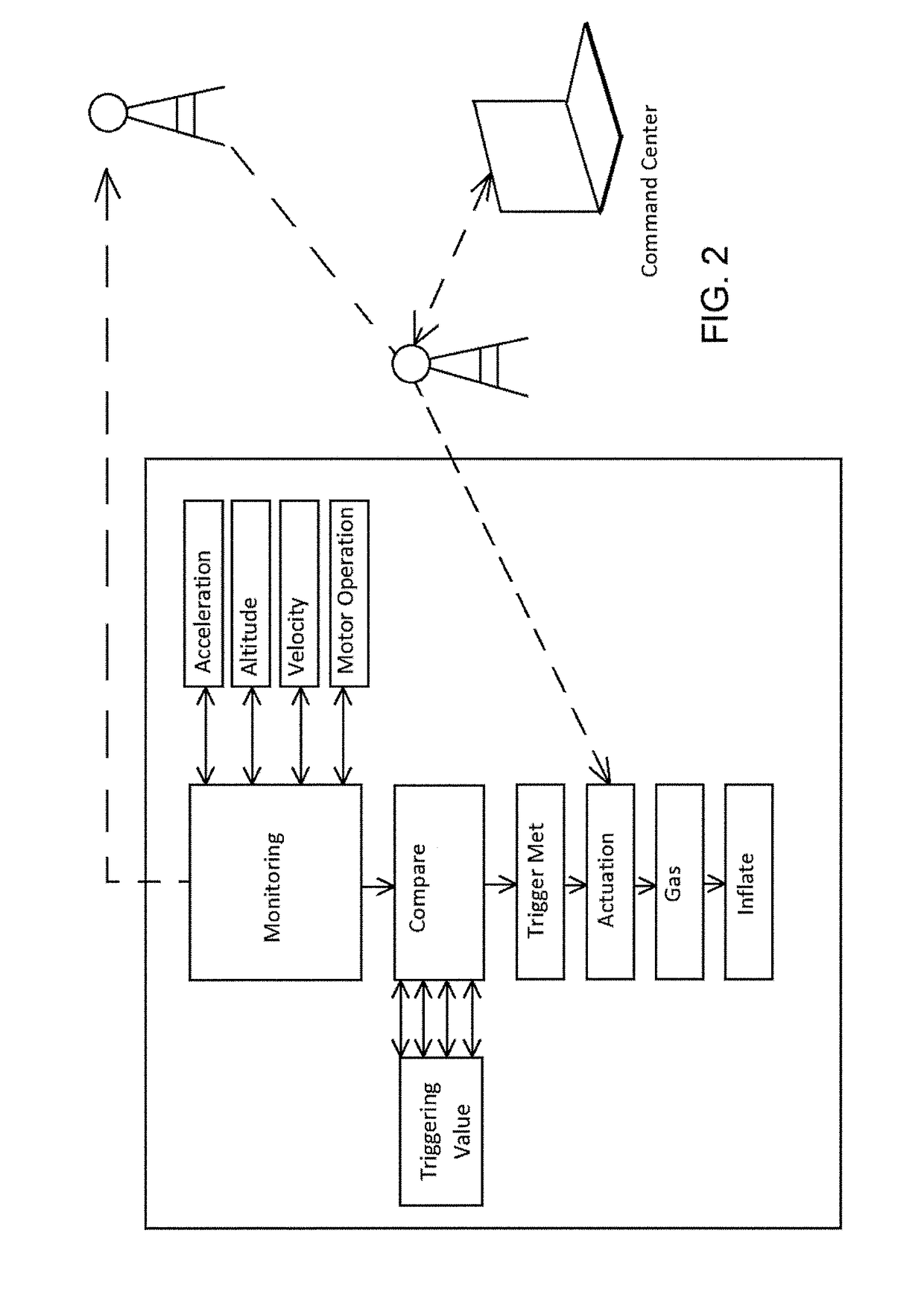

Airbag system for use with unmanned aerial vehicles

InactiveUS20180022310A1Slows decent and ultimate terminal velocityMinimize and prevent major massFloatsUnmanned aerial vehiclesUncrewed vehicleAirbag deployment

A system for deploying an airbag when an unmanned aerial vehicle (UAV) has failed or is no longer able to sustain flight, comprising a triggering means which releases compressed air into a bag or bags which are configured to expand around the UAV for the purpose of reducing the deceleration forces of the UAV on impact. UAV's are provided that are configured with a system that includes a triggering mechanism that deploys one or more bags when there is a failure or when flight is no longer sustainable.

Owner:RHOMBUS SYST GRP INC

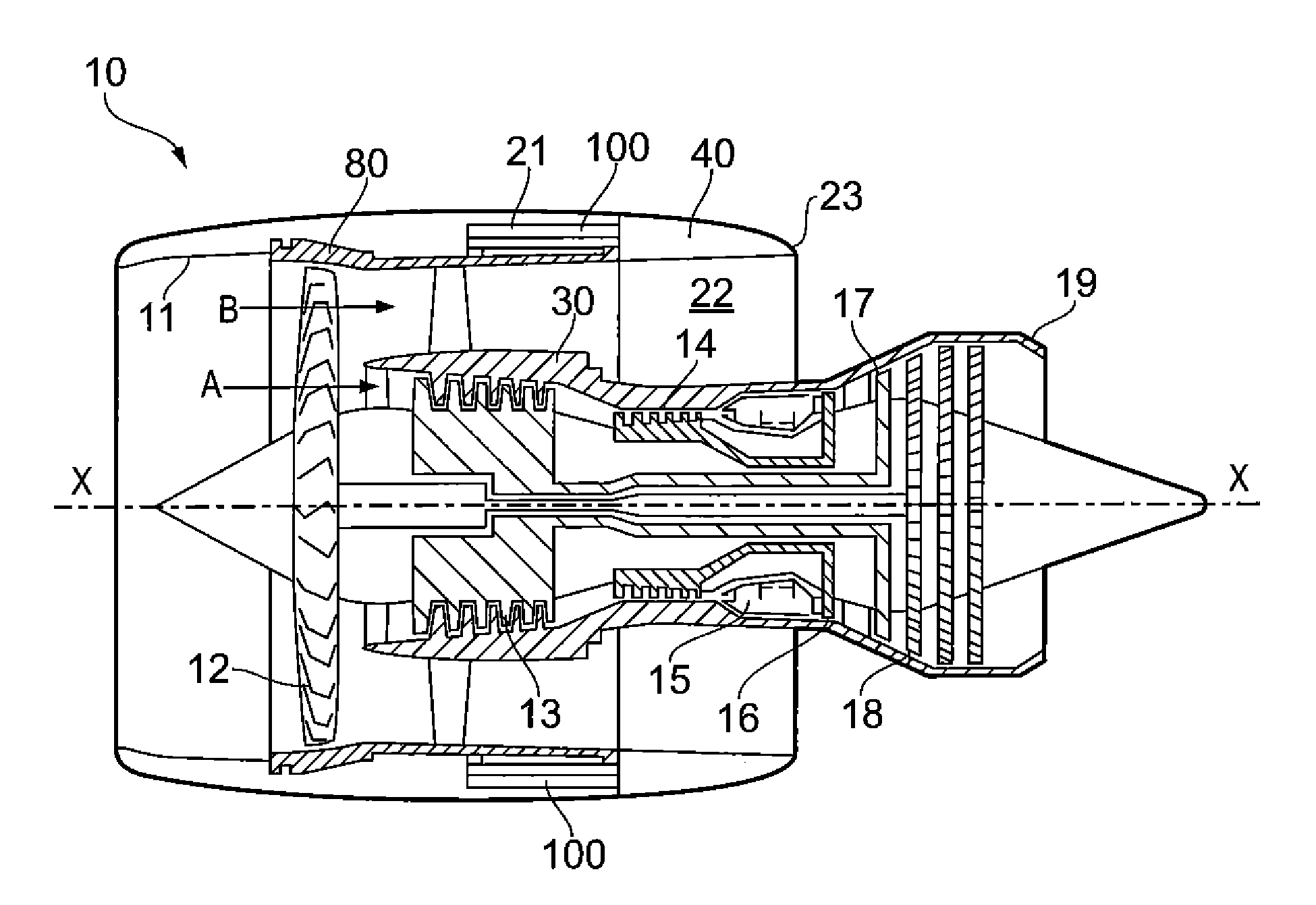

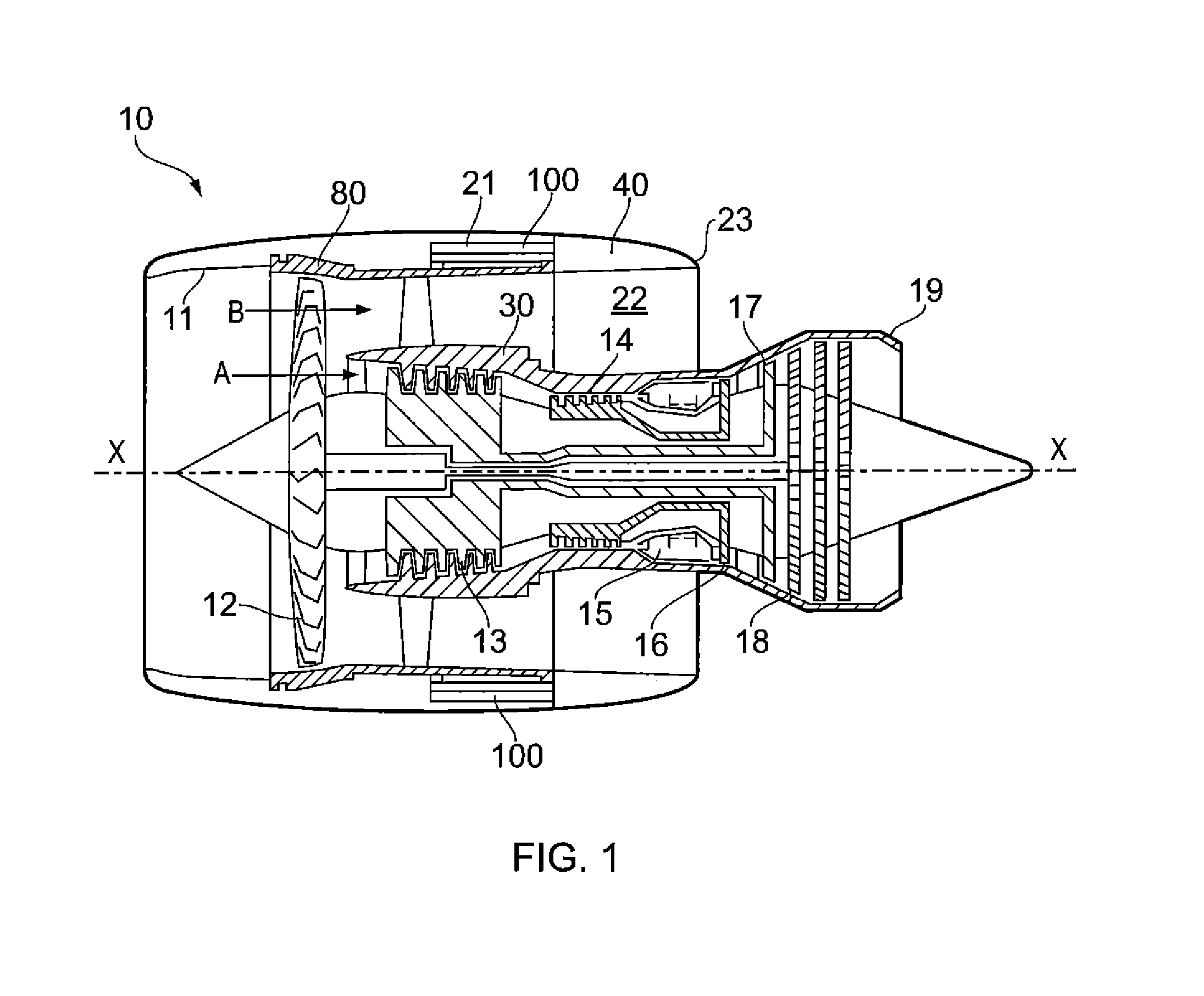

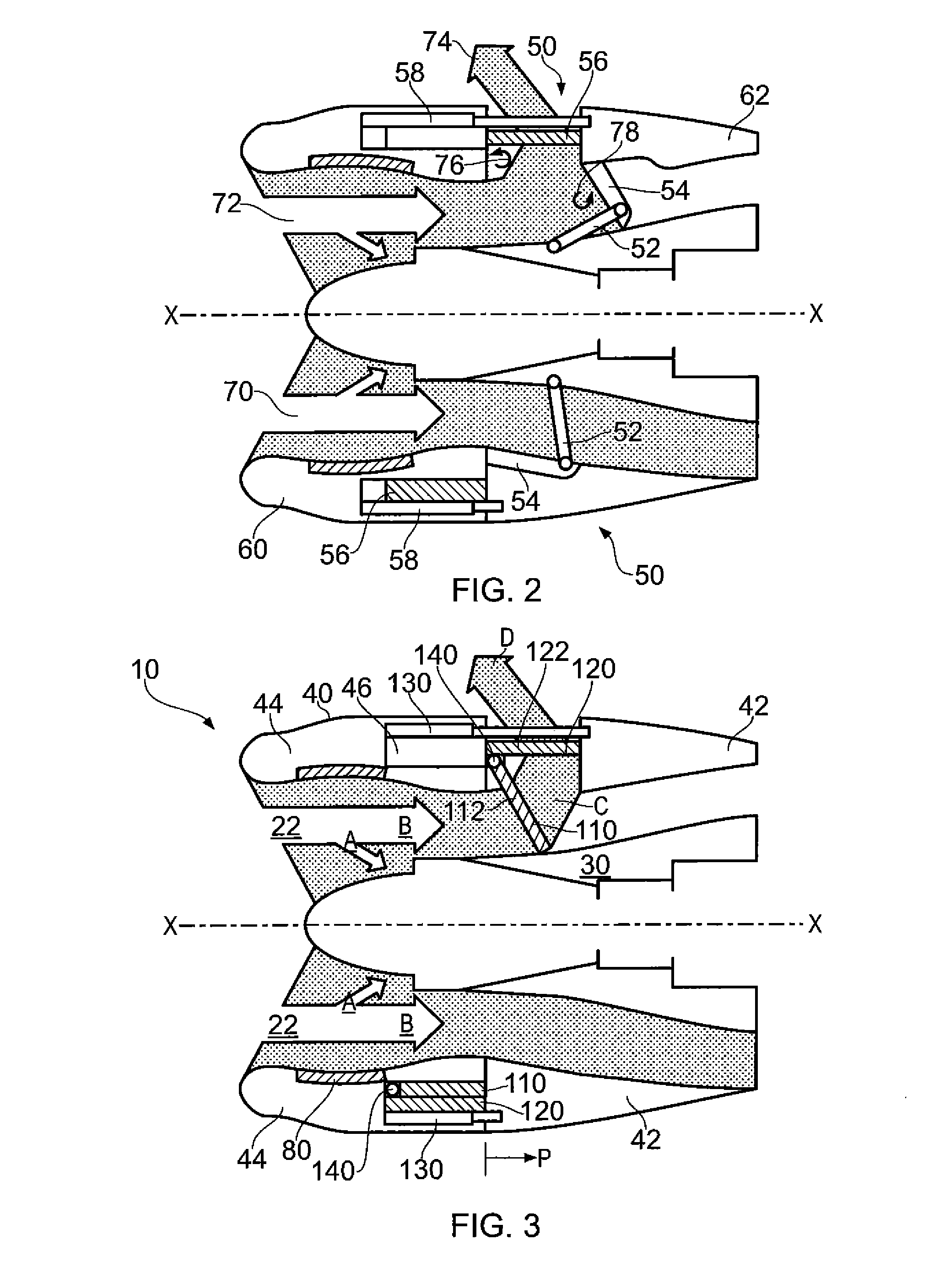

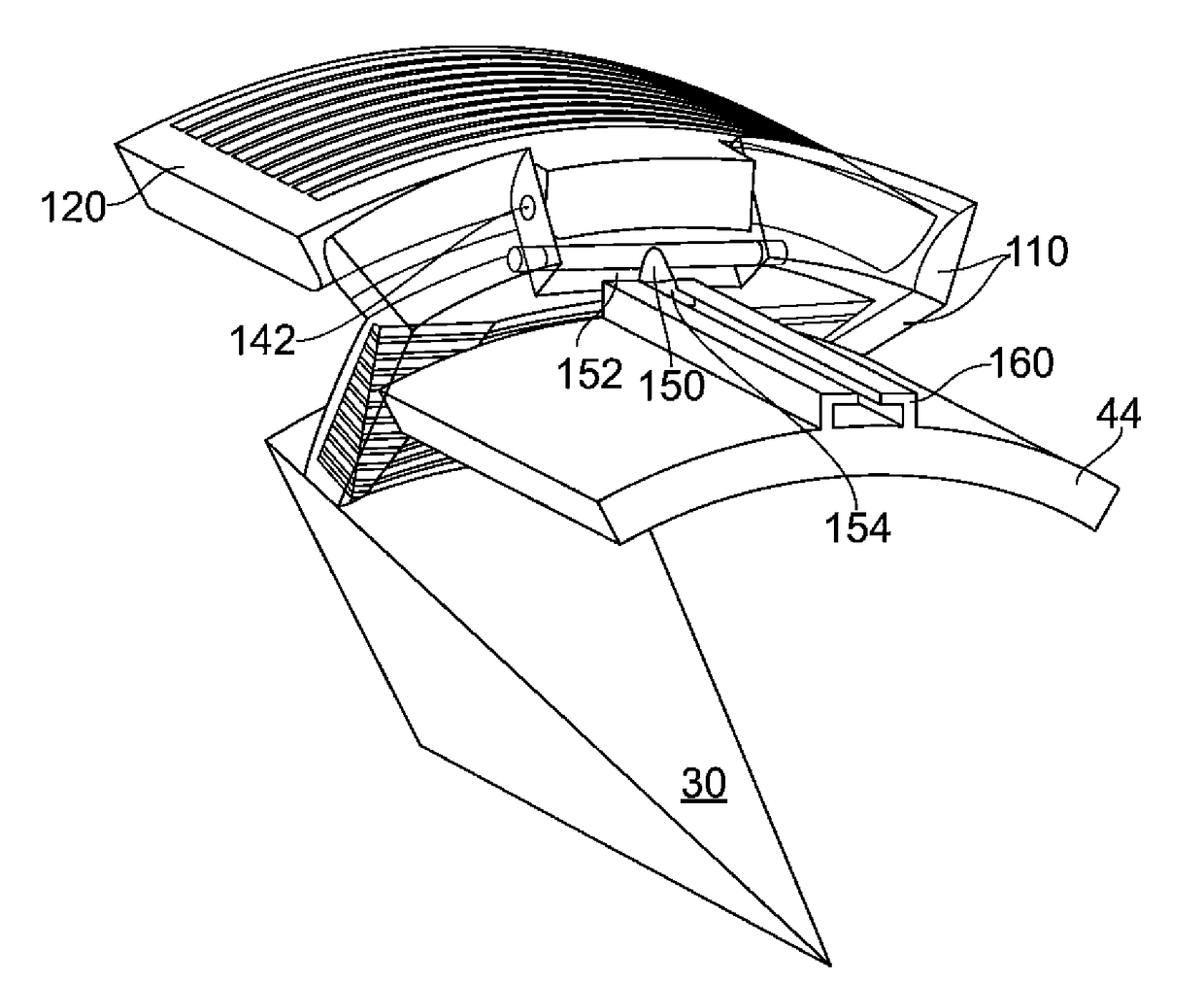

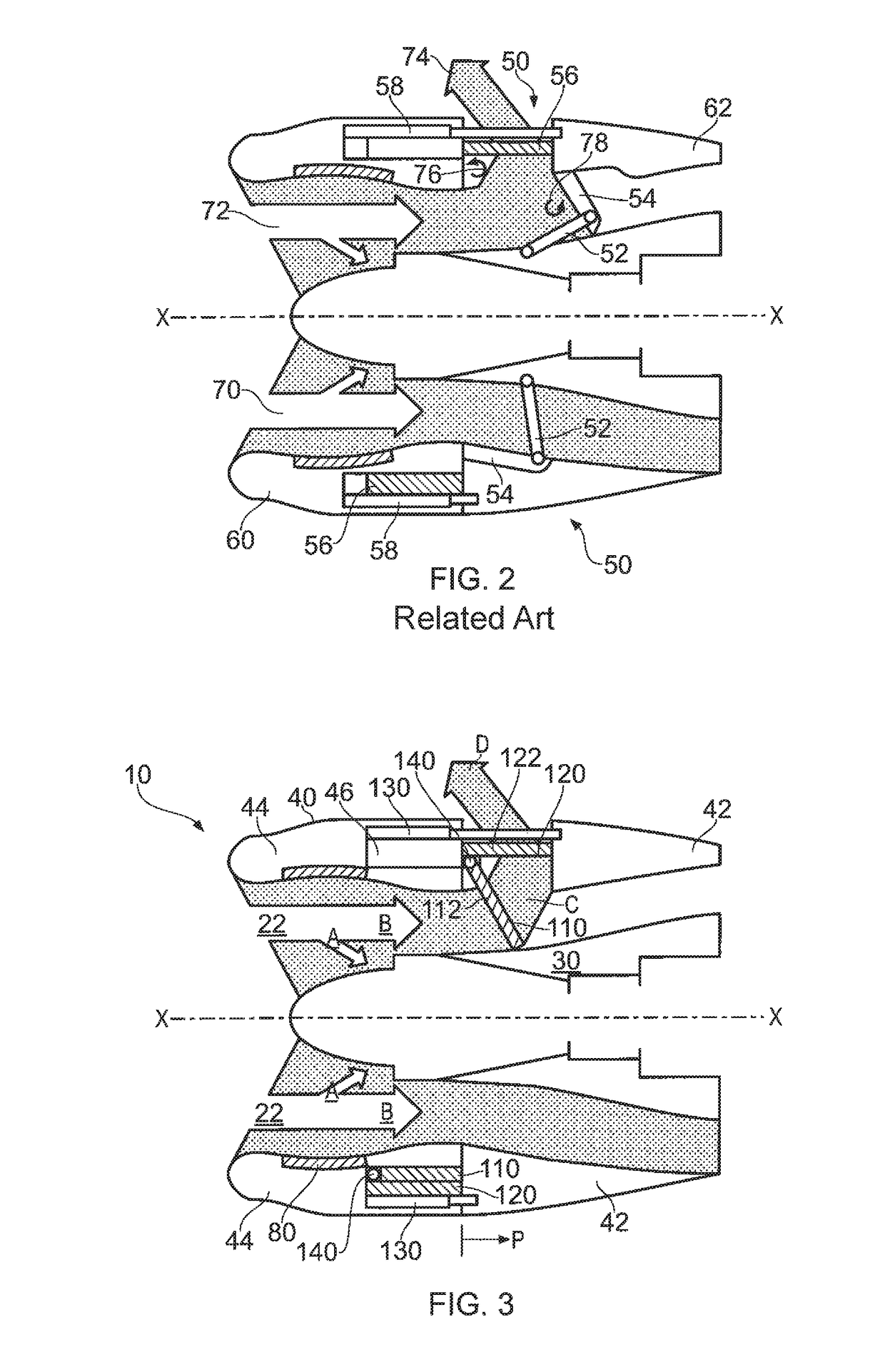

Thrust reverser unit

InactiveUS20160025037A1Robust and reliable arrangementImprove efficiencyEngine manufactureWind motor controlNacelleGas turbines

A thrust reverser unit (TRU) 100 for a gas turbine engine 10 is provided that has first and second cascade elements 110, 120. In a stowed configuration, both the first and second cascade elements, and the operating mechanism, are located inside the nacelle 40, meaning that the TRU has no detrimental impact on the flow through the bypass duct 22. In the deployed configuration, the first cascade element 110 extends across the bypass duct 22. The first cascade element 110 has flow passages 112 that allow the flow to pass through, redirecting the flow towards the second cascade element 120. The second cascade element 120 further turns the flow so as to provide decelerating reverse thrust.

Owner:ROLLS ROYCE DEUT LTD & CO KG

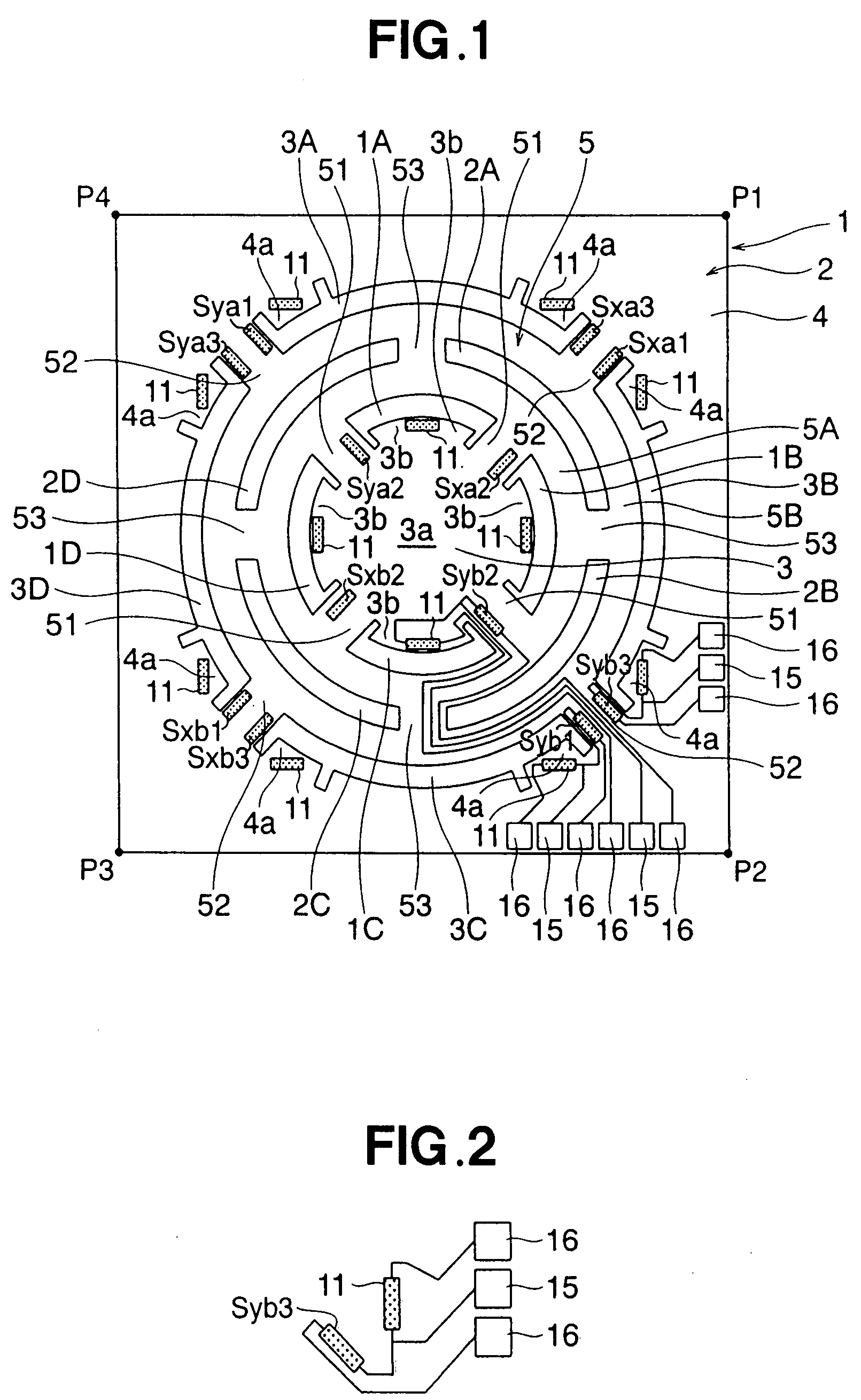

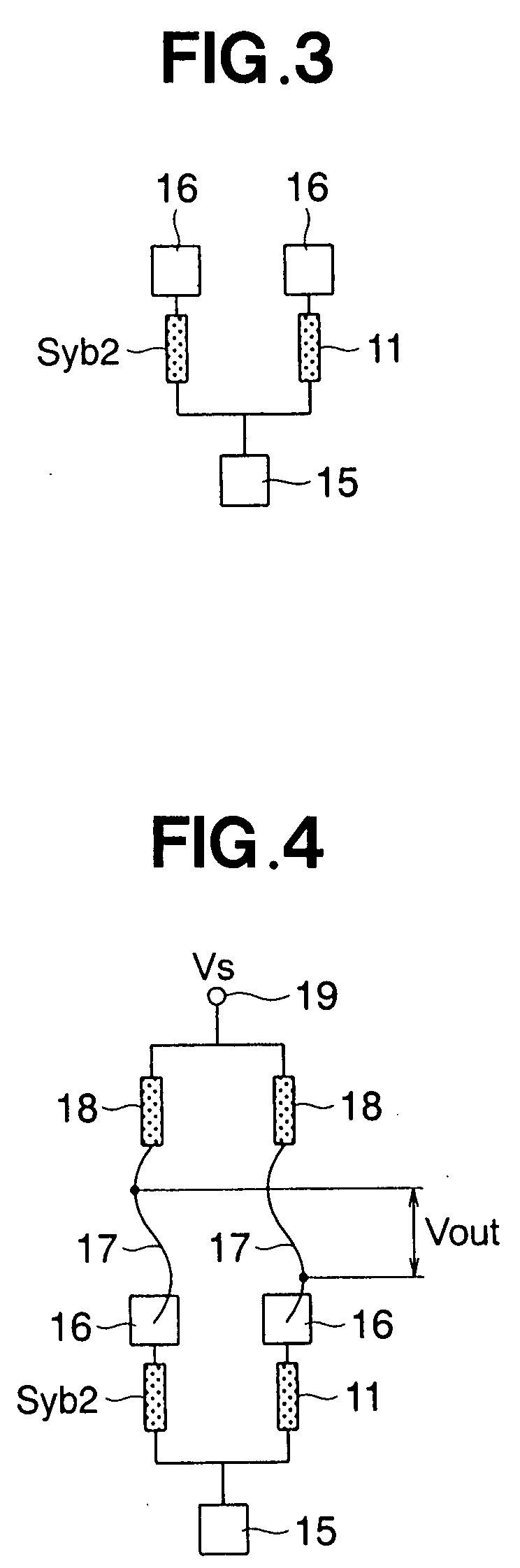

Force sensor chip

ActiveUS7490524B2Noise minimizationStable detectionApparatus for force/torque/work measurementForce measurement by elastic gauge deformationForce sensorMechanical engineering

In a force sensor chip, a base member, to which an external force is applied, includes: an operating part provided in a central portion of the base member and having an external-force acting area section; a supporting part provided, in an outer peripheral portion of the base member, for supporting the operating part; an intermediate part provided between the operating part and the supporting part; a first connecting arm section connecting the operating part and the intermediate section; a second connecting arm section connecting the intermediate part and the supporting part; and at least one strain resistance element provided on each of respective deformation-generating portions of the first and the second connecting arm sections.

Owner:HONDA MOTOR CO LTD

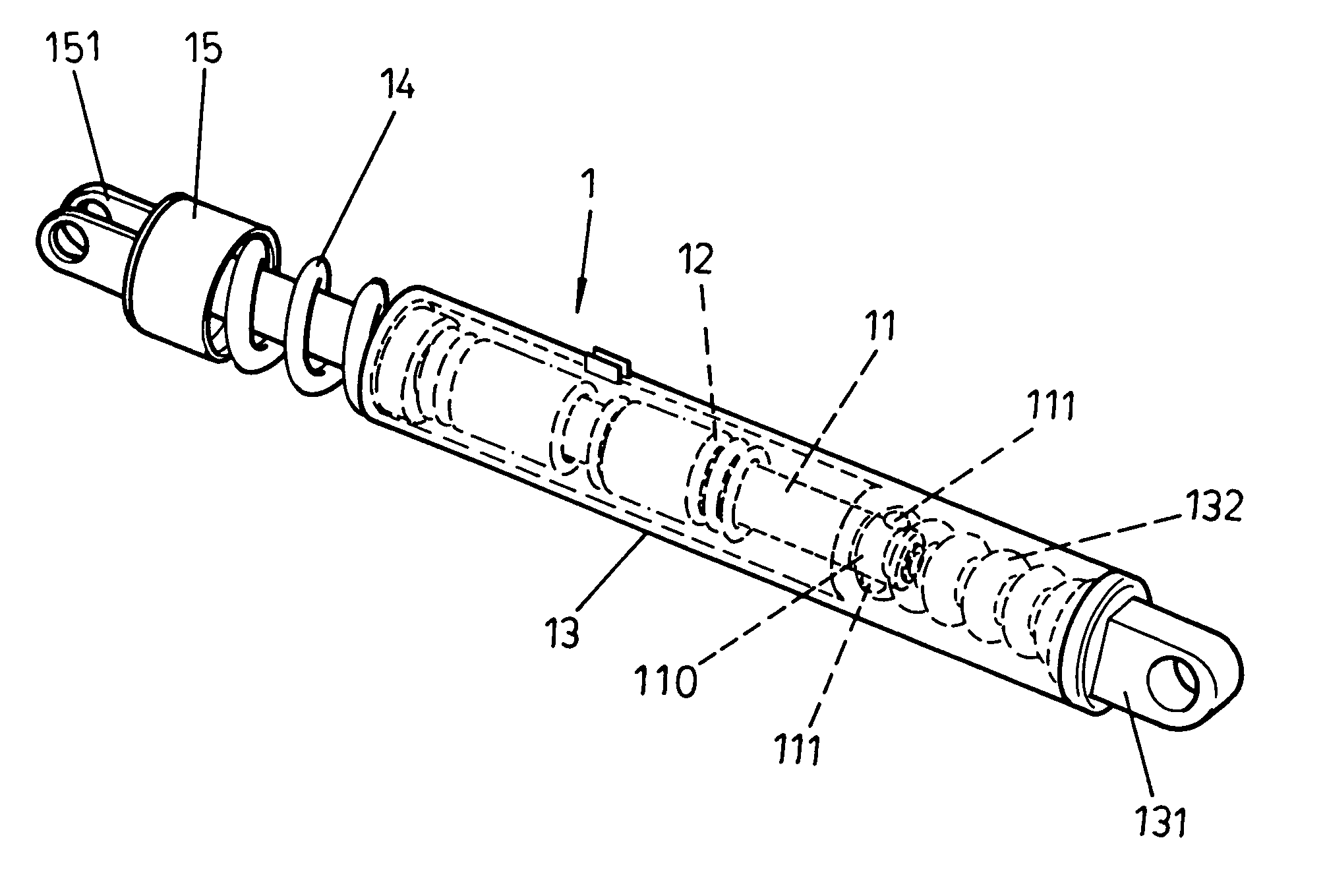

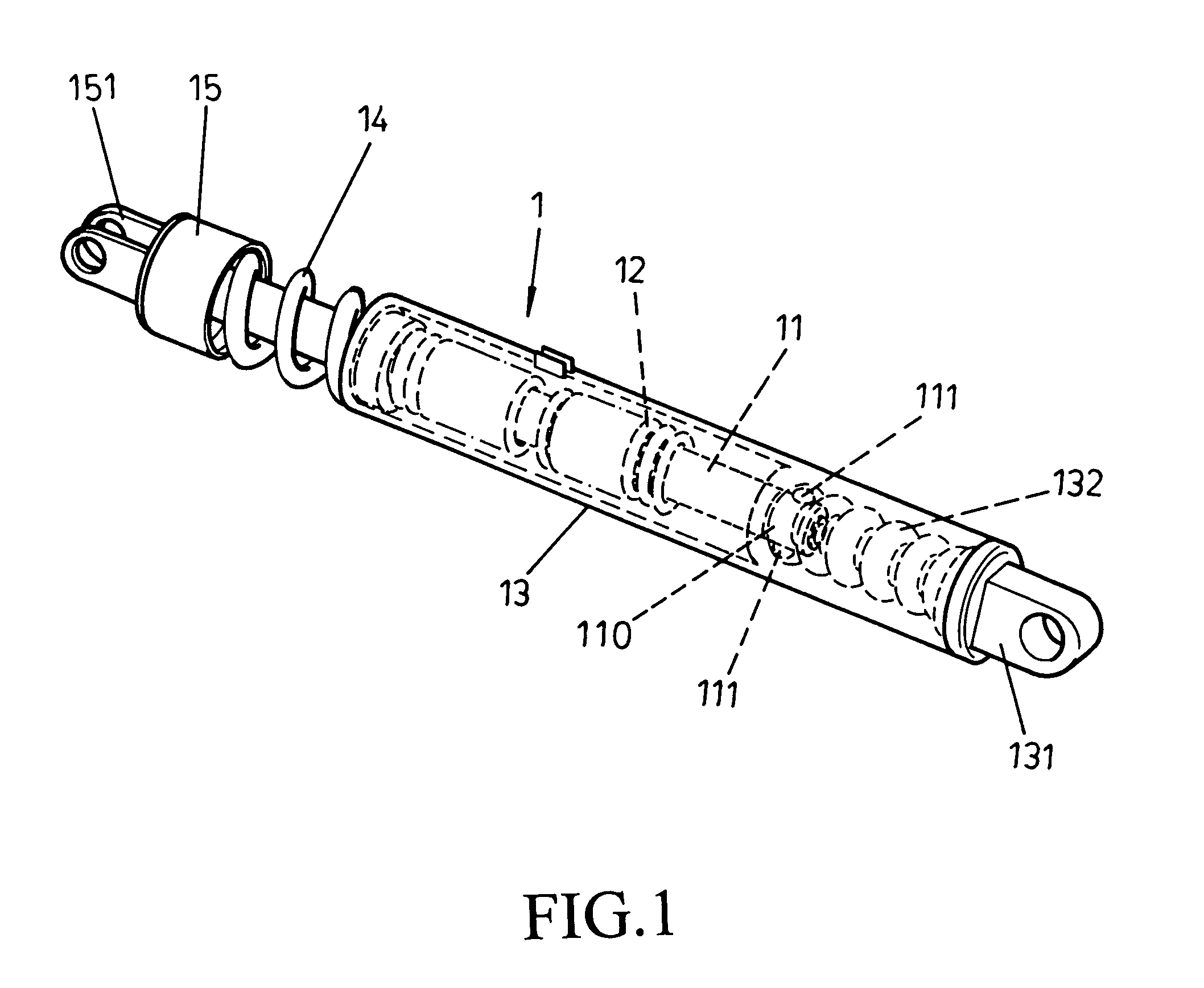

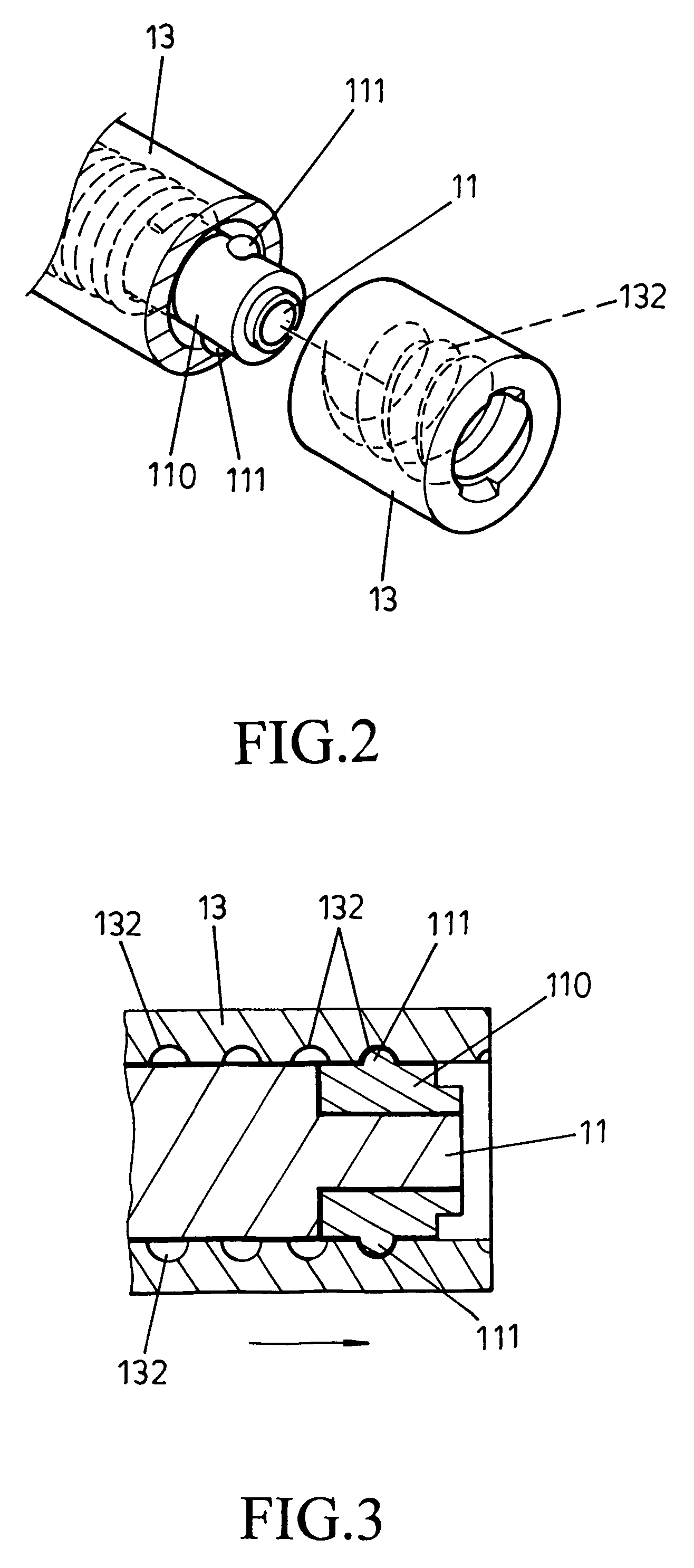

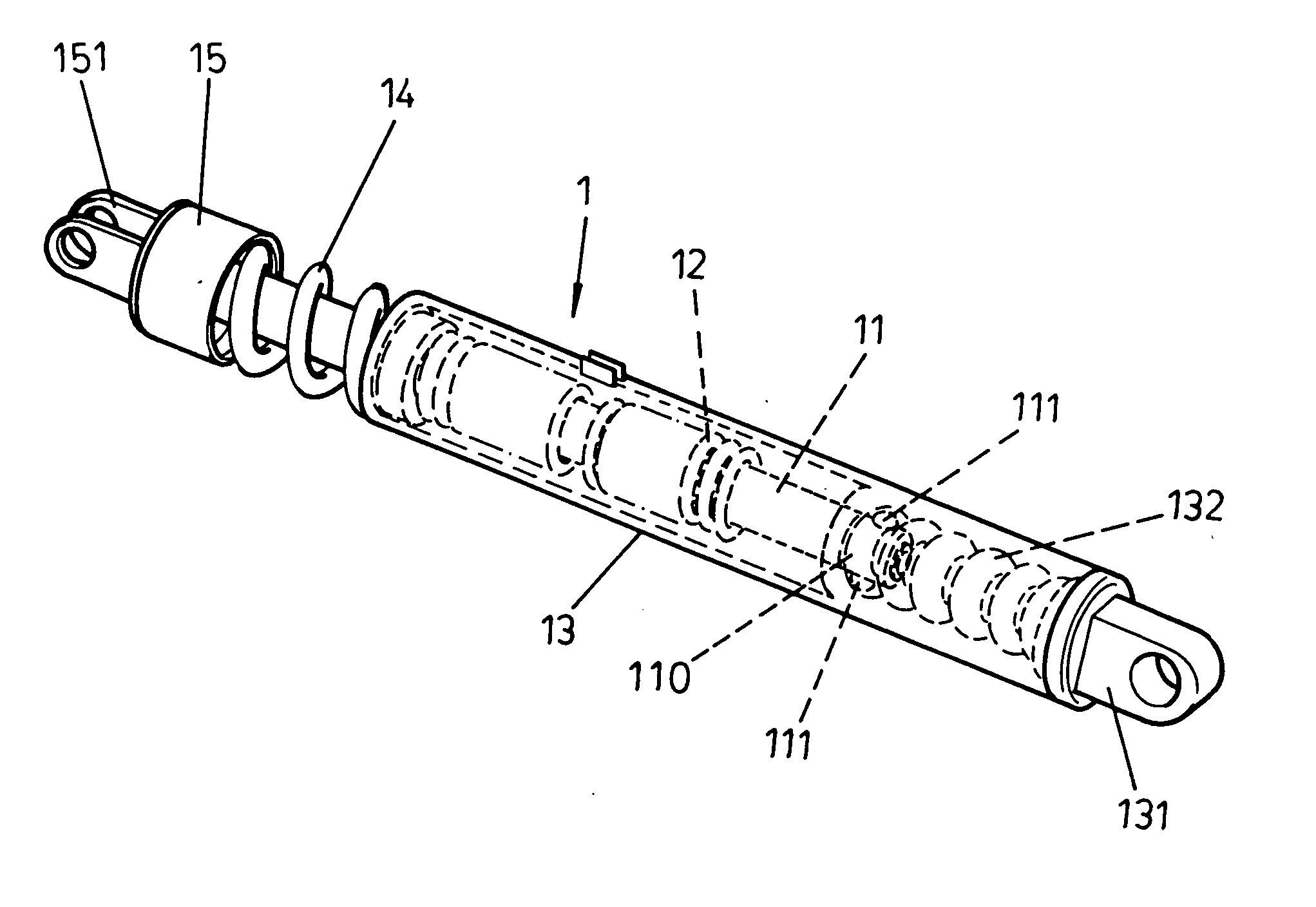

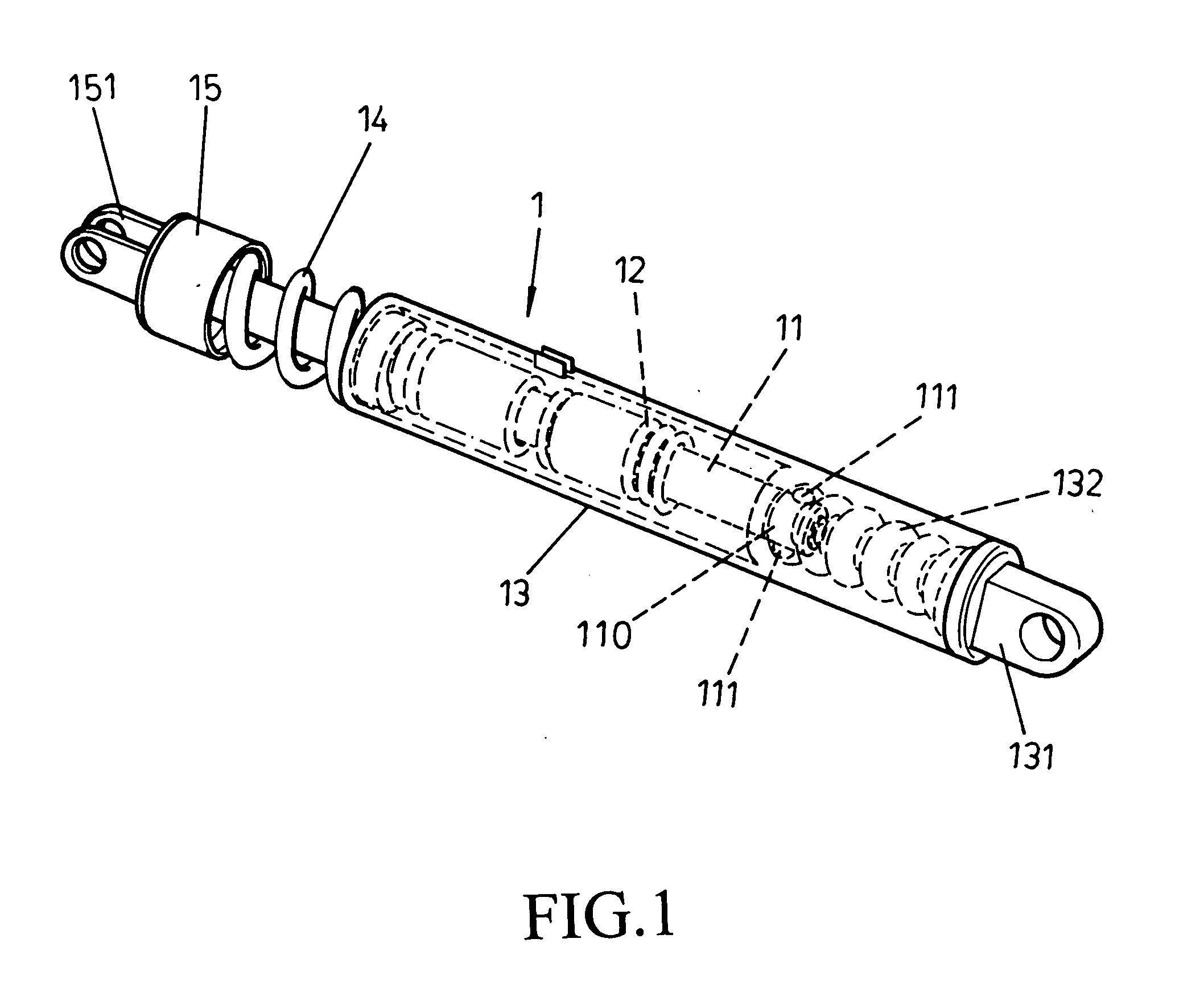

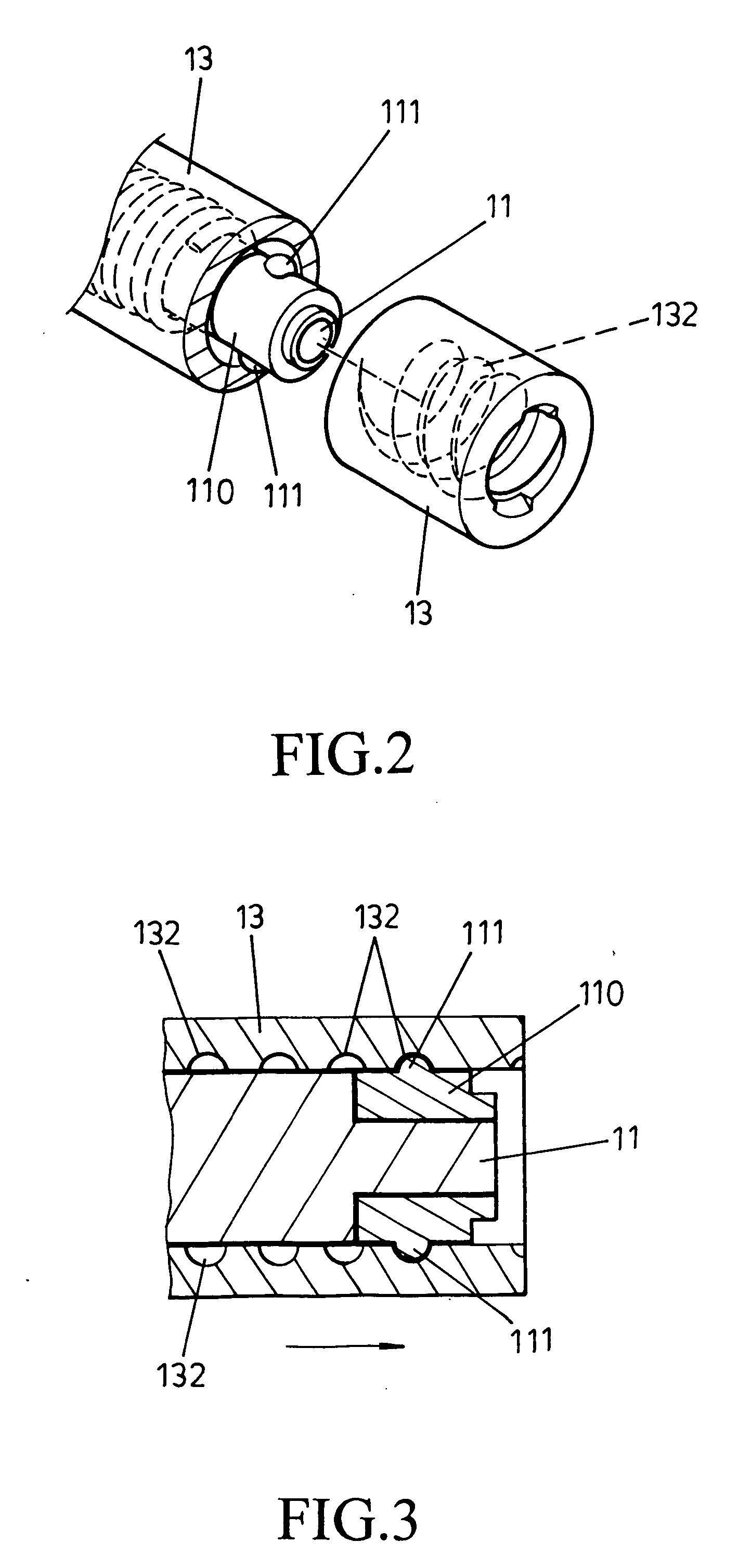

Mechanism type non-sectional locking buffer device

InactiveUS6978985B2Slow forceReduce failureMachine framesSprings/dampers design characteristicsBall bearingEngineering

Owner:PRO GLORY ENTERPRISES

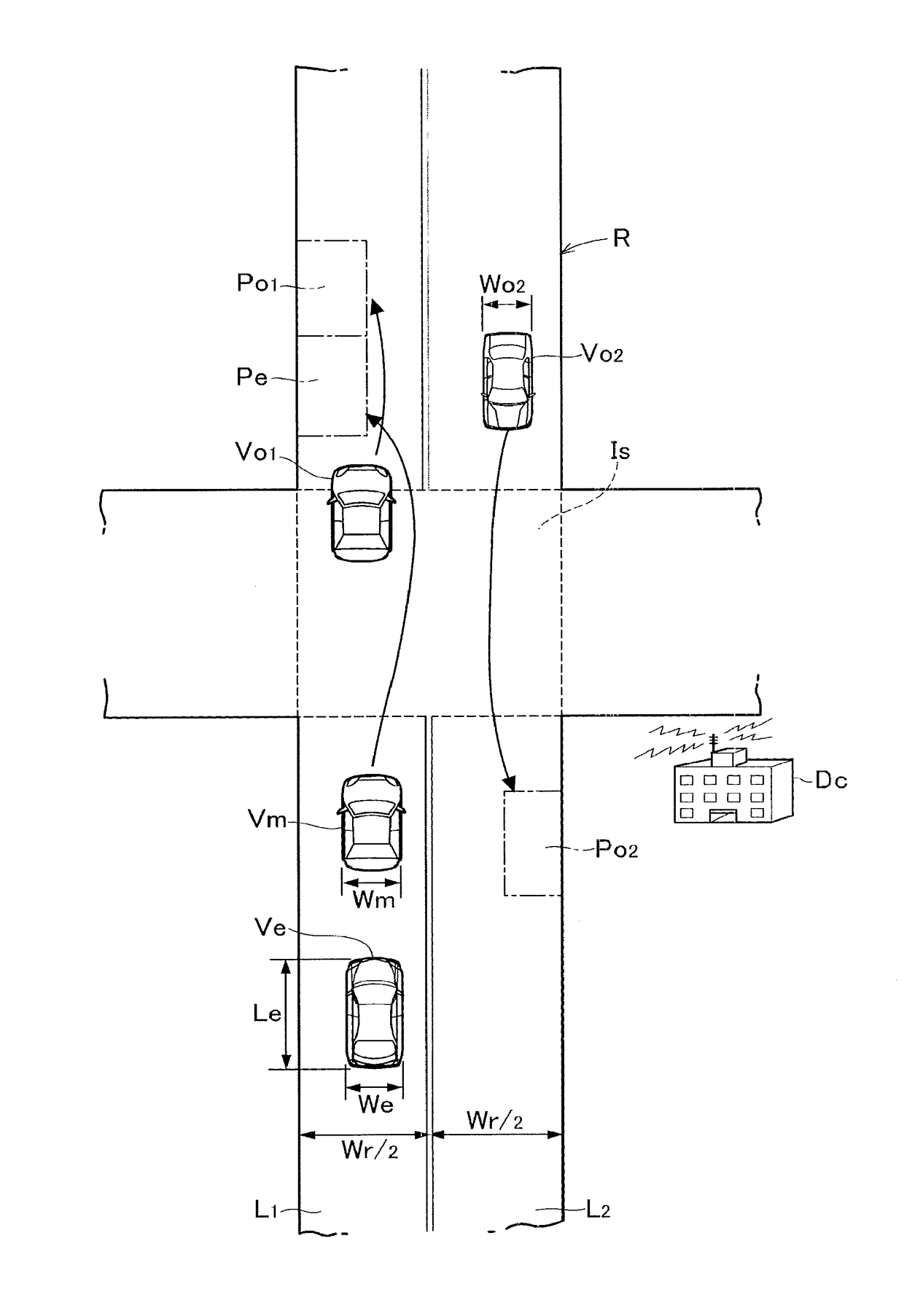

Yeilding action assistance system

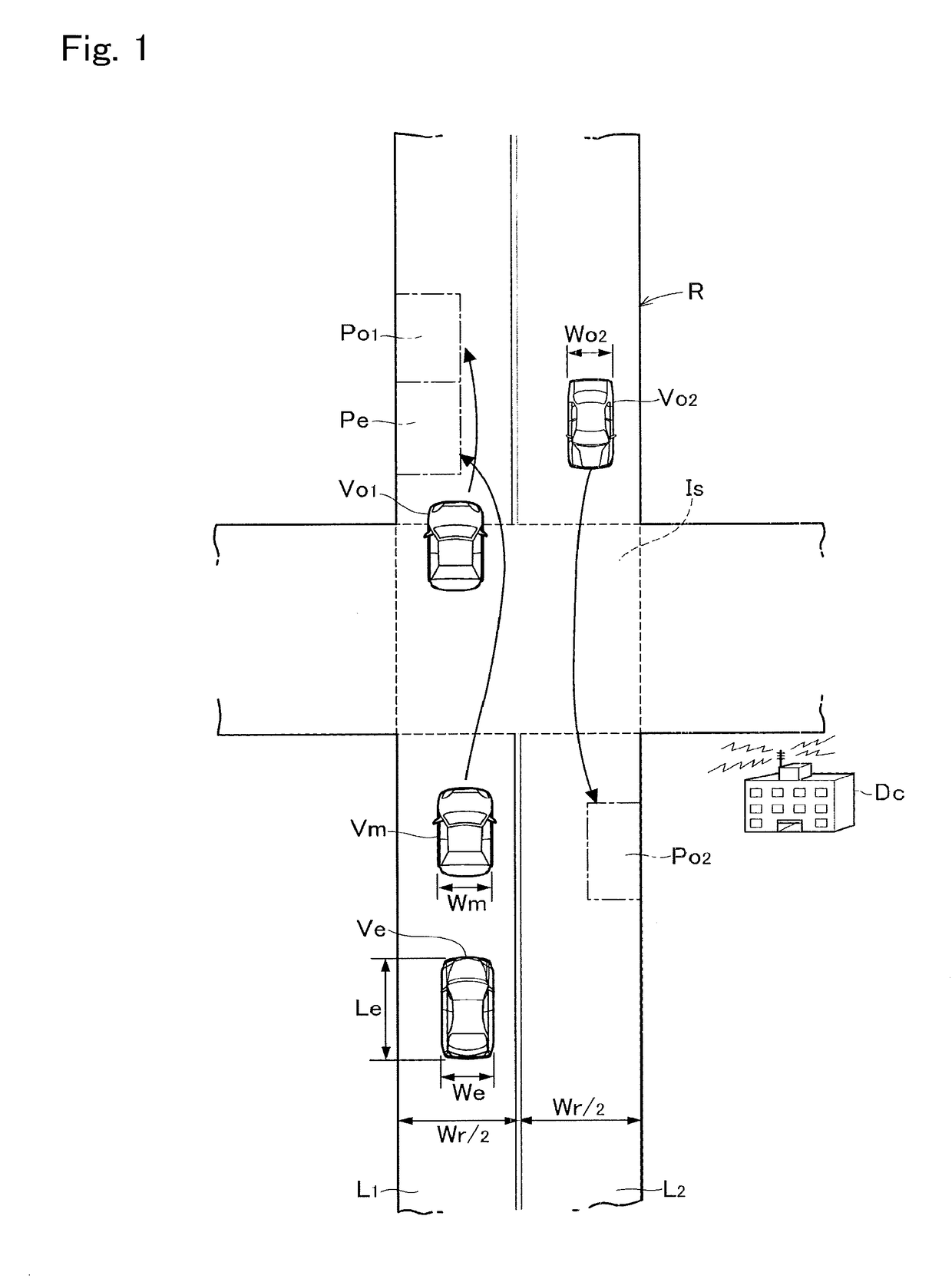

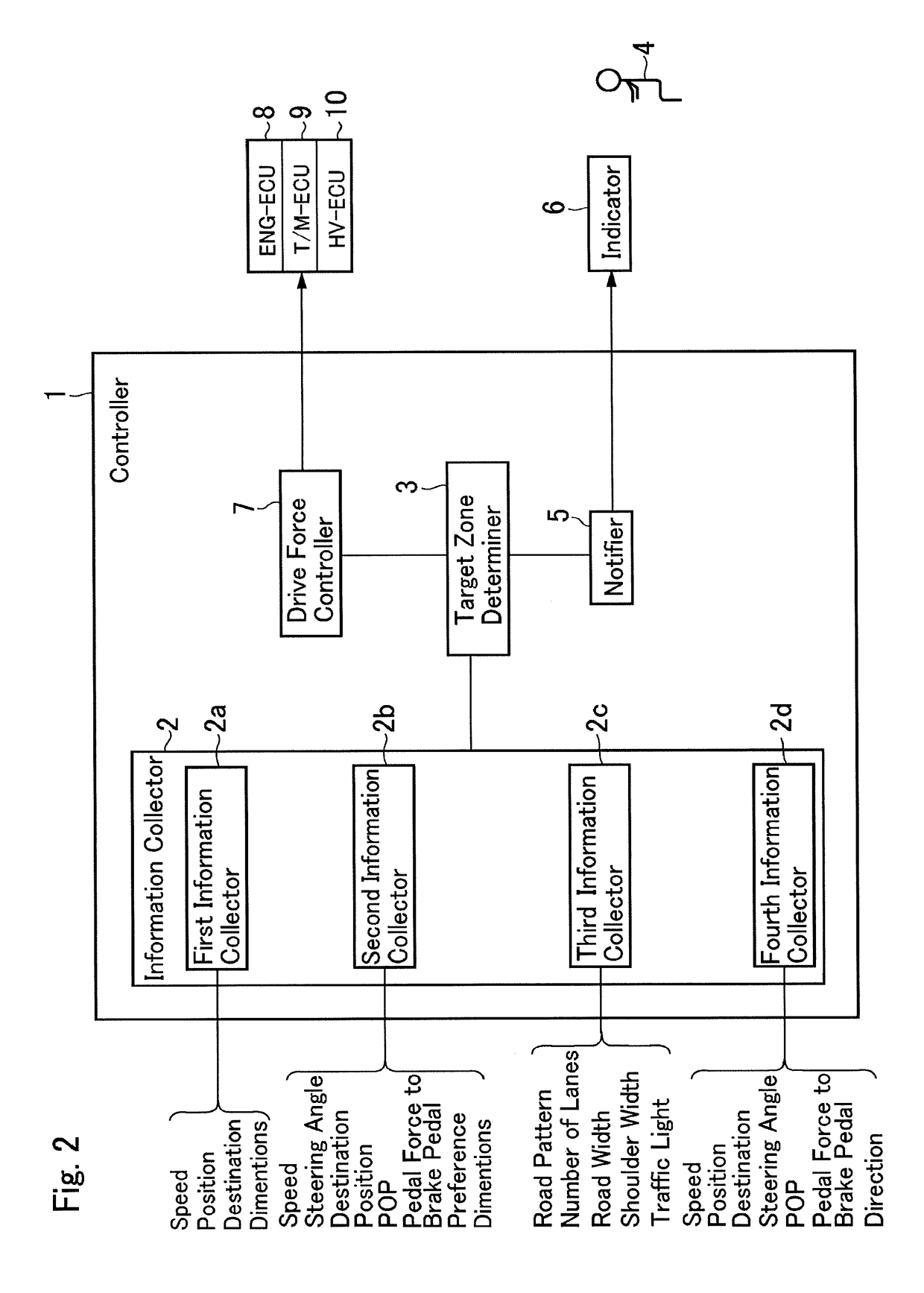

ActiveUS20180334161A1Shorten speedSlow forceExternal condition input parametersDriver input parametersDriver/operatorEngineering

A yielding action assistance system for assisting a vehicle driver to take an appropriate action in yielding to a passing emergency vehicle. The yielding action assistance system comprises: a detector that detects a proximity of the emergency vehicle; an information collector that collects a road information and information about the emergency vehicle and other vehicle; a target zone determiner that sets and updates a target zone to pull over the vehicle based on the information about the other vehicle and the road; and a notifier that informs a driver about the target zone.

Owner:TOYOTA JIDOSHA KK

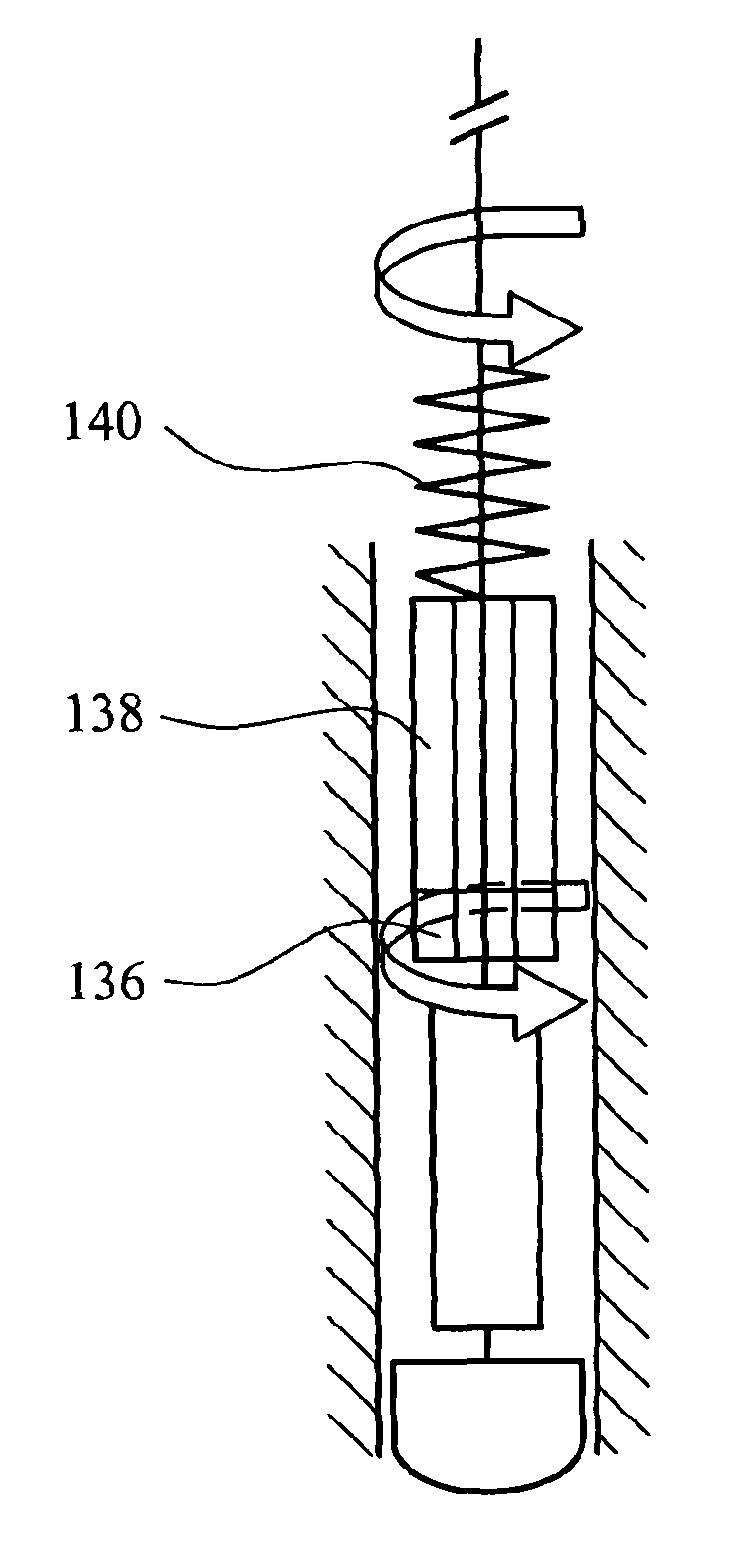

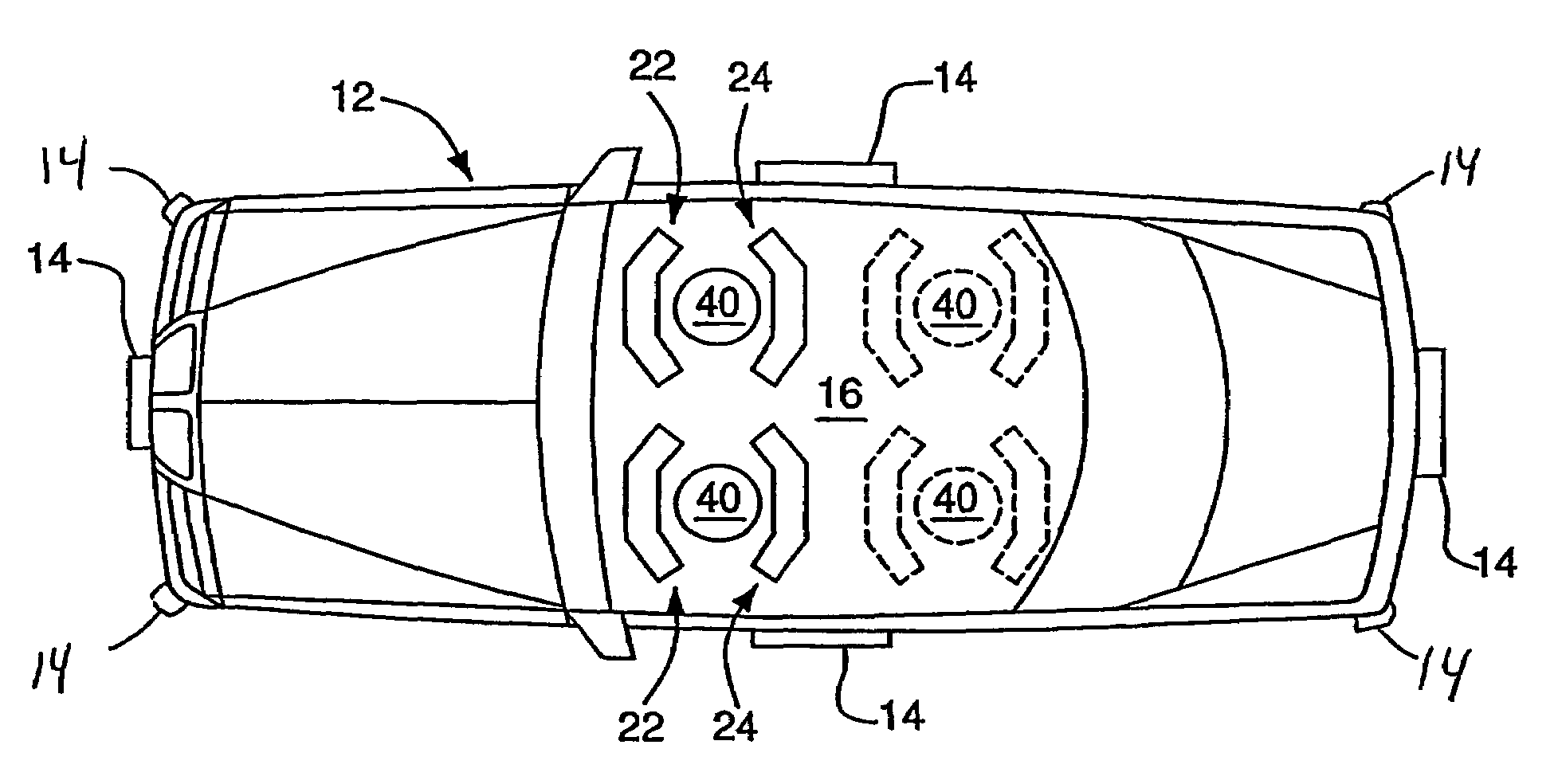

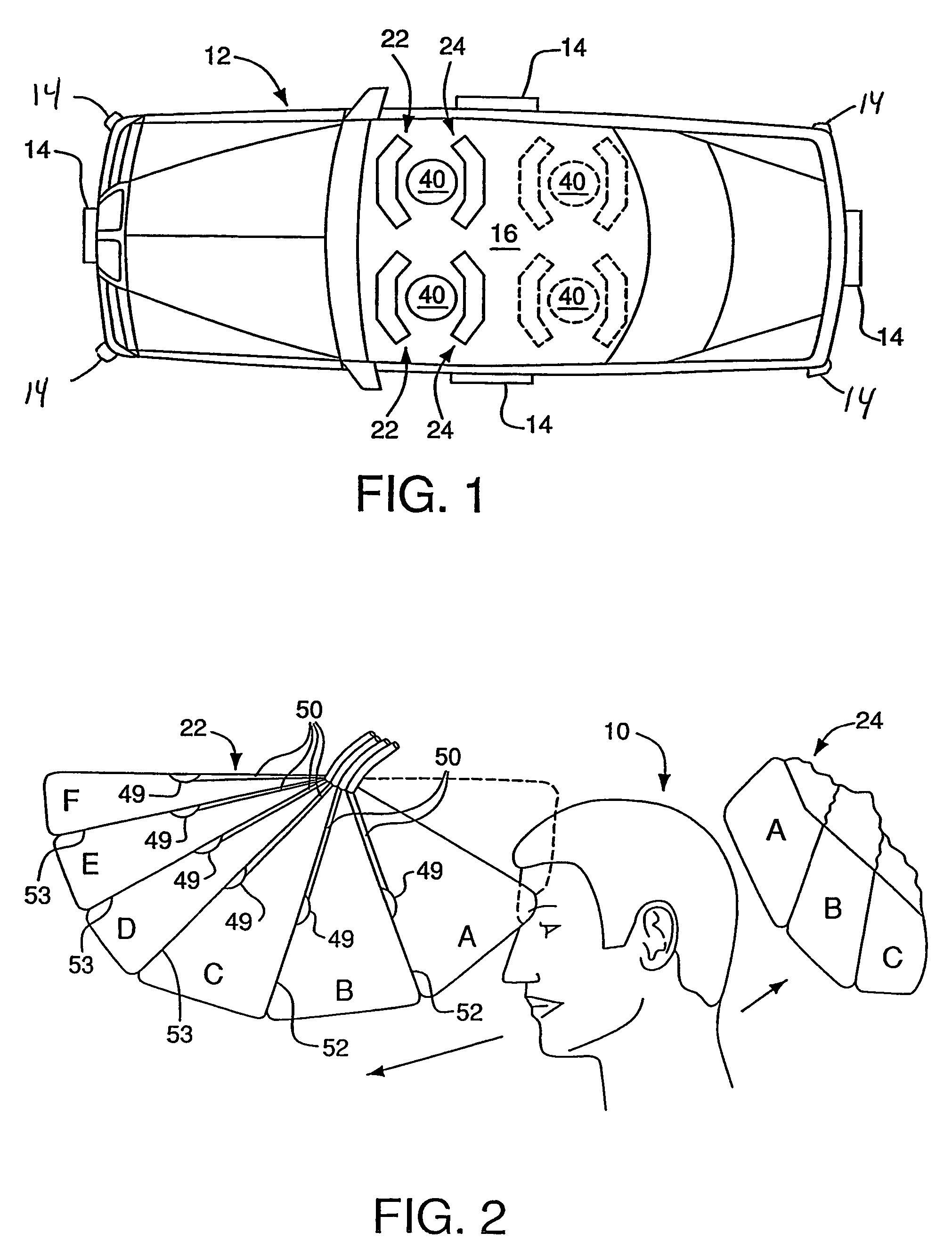

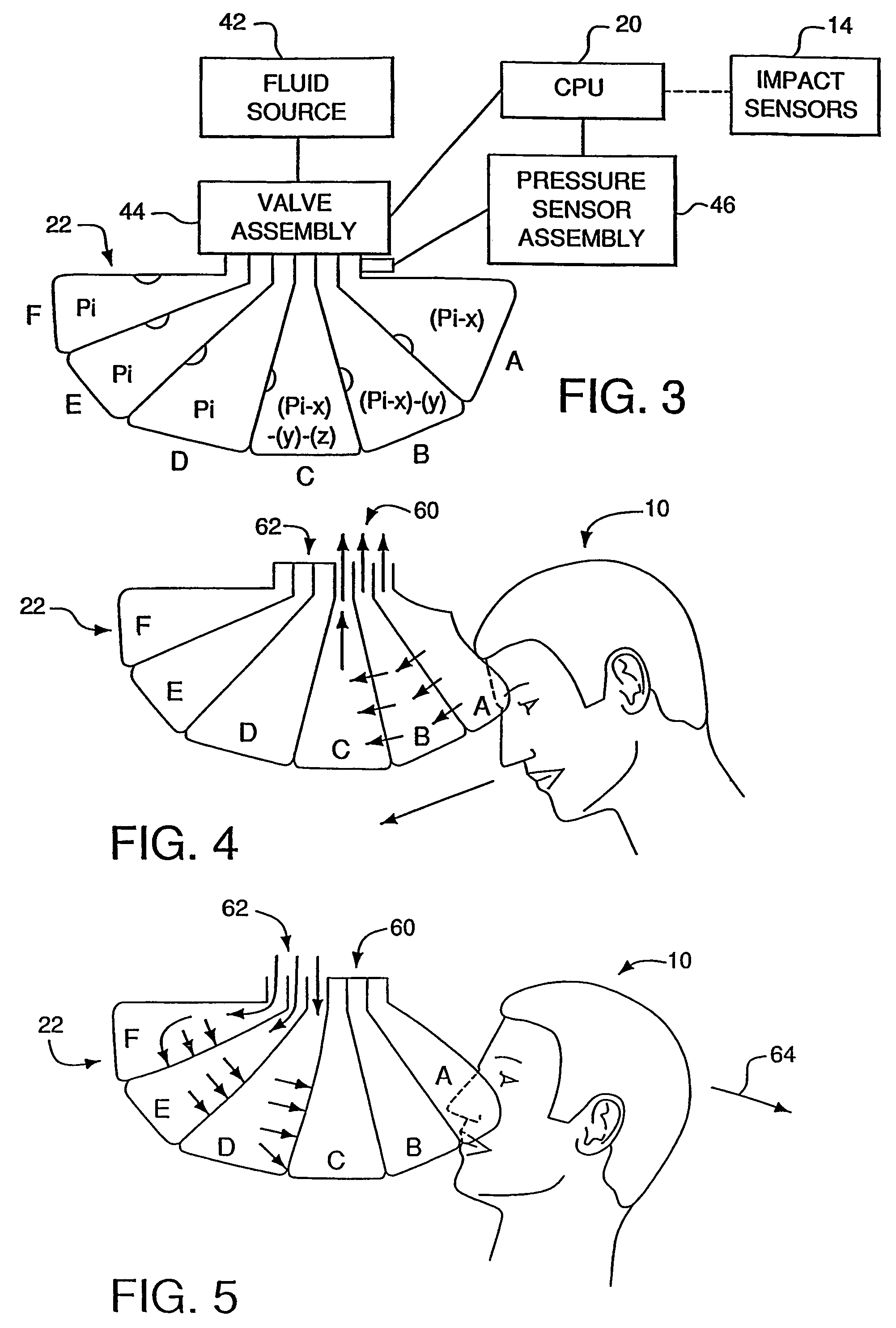

Inflatable restraint assembly for vehicles

InactiveUS7523956B2Slow forceReduce harmPedestrian/occupant safety arrangementChild seatsCritical positionEngineering

A plurality of inflatable members (136, 140, 142, 156′) are mounted at a plurality of strategic locations relative to a vehicle occupant. The occupant is restrained by a harness including a lap belt segment (124), a chest belt segment (126) and a diagonal belt segment (128). Upon the vehicle being impacted, a central processor automatically inflates the inflatable members (136, 140, 142, 156′). The processor is connected to valve assemblies that regulate air flow both into and out of the inflatable members (136, 140, 142, 156′), and is further responsive to a pressure sensor assembly, so as to actively regulate pressure within the inflatable members.

Owner:ZC HLDG

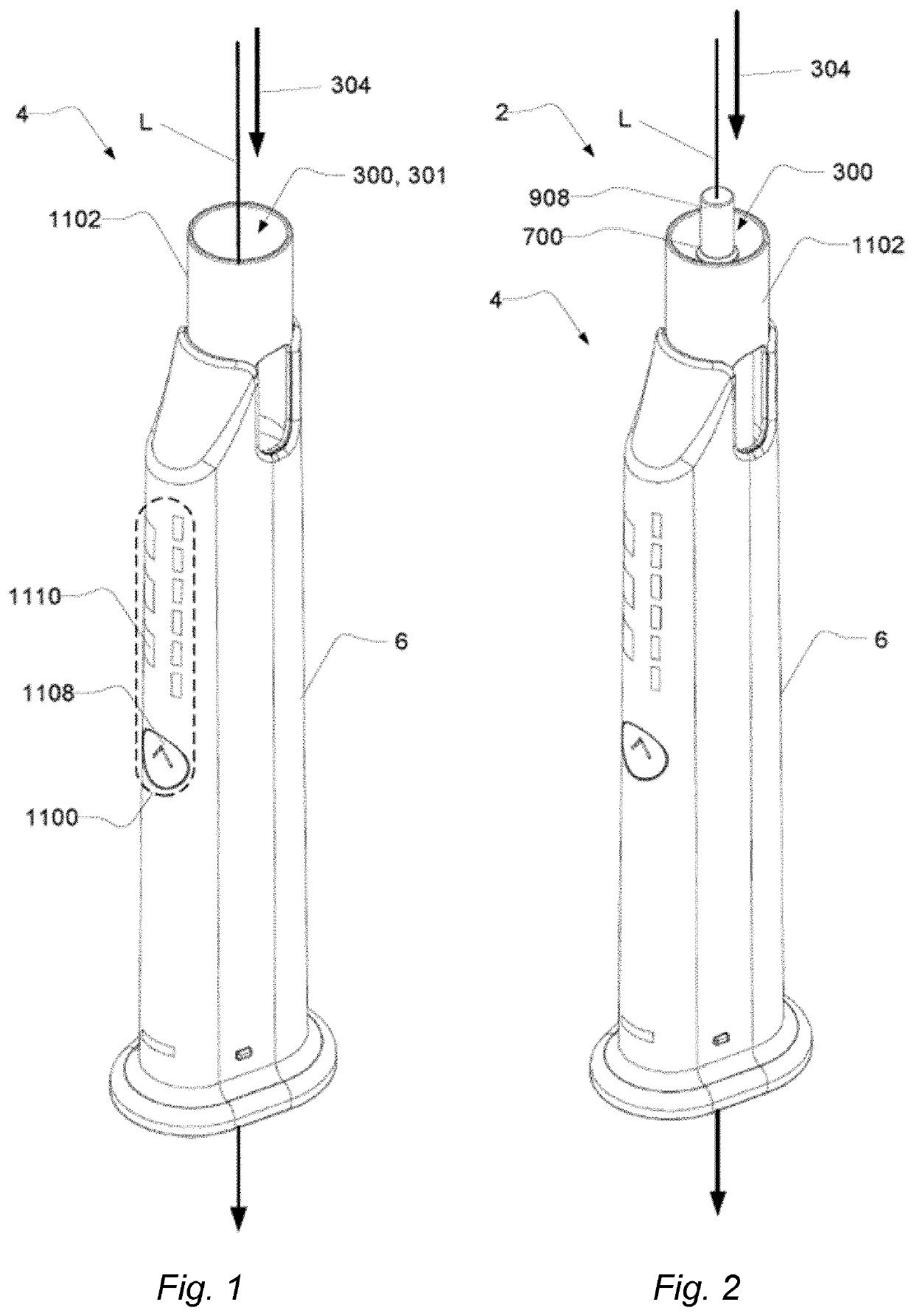

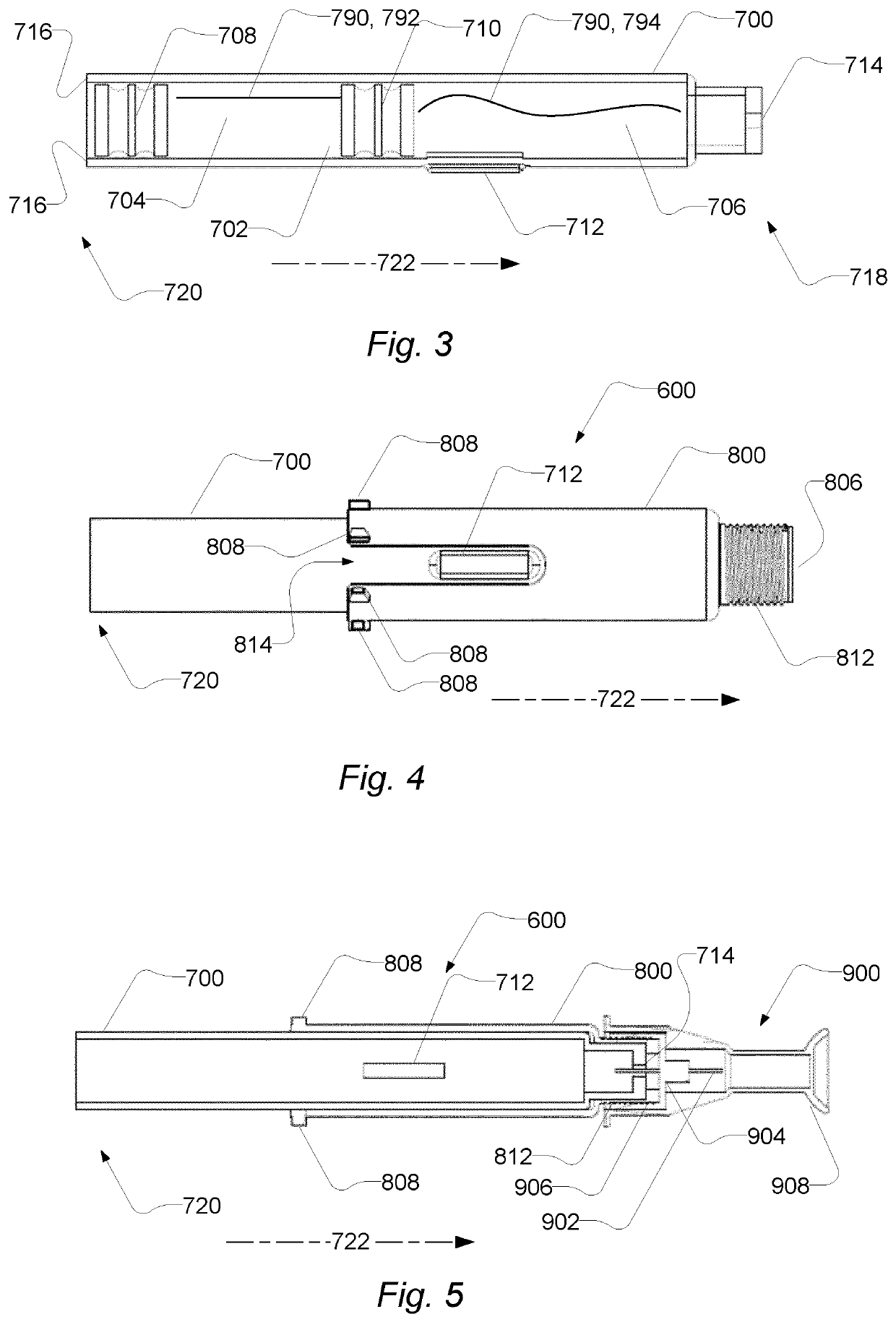

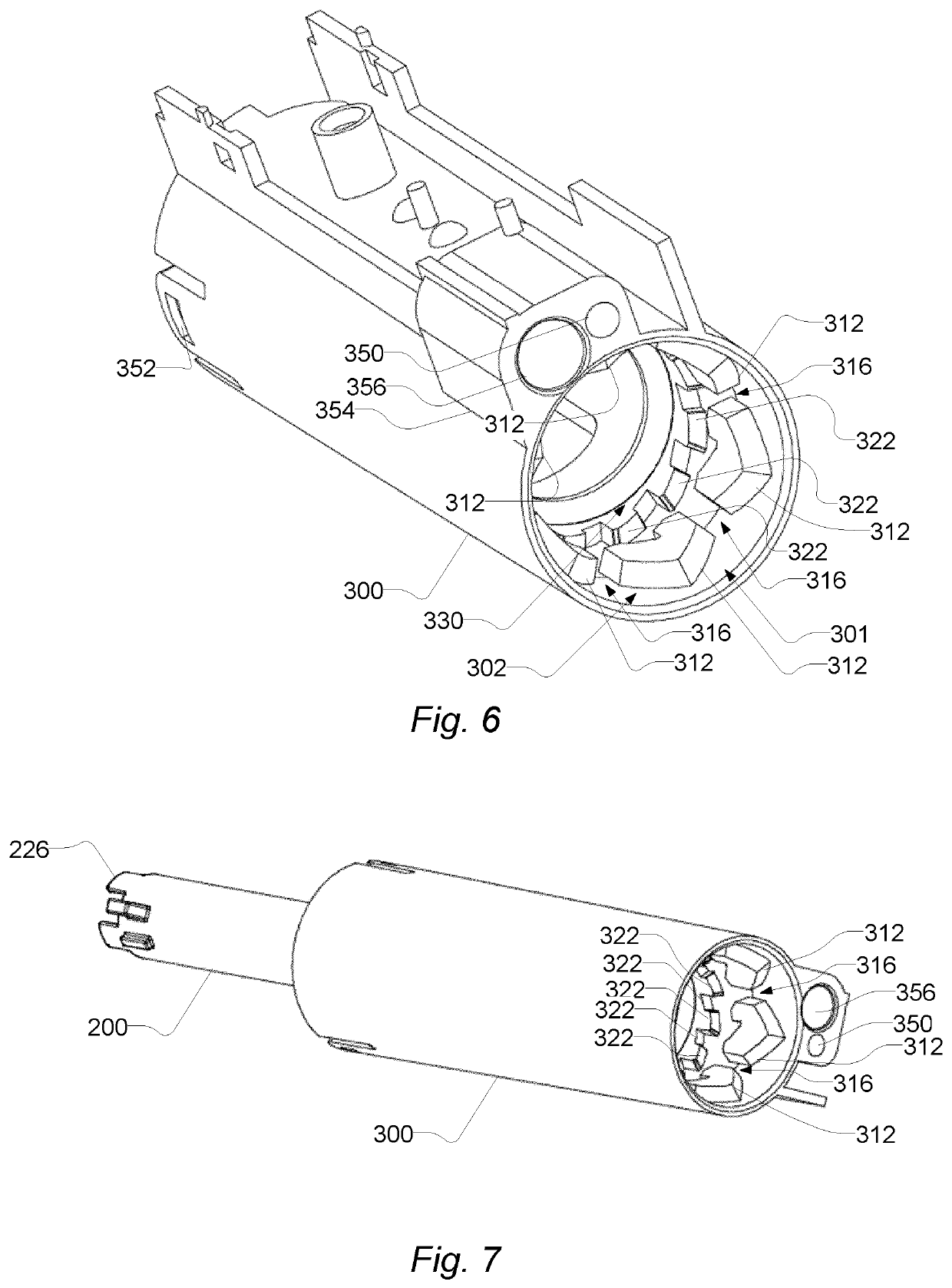

Auto injector with cartridge retention system

ActiveUS10835677B2Inhibit sheddingSlow forceAmpoule syringesAutomatic syringesCartridgeGeneral surgery

An auto injector (4) for administering injection of a medicament from a cartridge (700) containing the medicament, the auto injector comprising: a cartridge receiver (300) with a cartridge receiver compartment (302) configured to receive a cartridge assembly (600) with at least one cartridge retention member (808) when inserted through a cartridge receiver opening (302) along a longitudinal axis; and an ejector (200) configured to support the cartridge assembly (600) by being suspended to move along the longitudinal direction and being spring-loaded in the direction opposite of the receiving direction. The cartridge receiver compartment (302) has a first section (310), at a first distance from the cartridge receiver opening (301), with inwardly extending first guide members (312) that extends over first guide member angles (314) and are spaced apart to form a passage (316) at passage angles (318) between the inward first guide members (312); wherein the inward first guide members (312) form a first bore (320) accepting the cartridge assembly (600) when inserted through the cartridge receiver opening (301). The cartridge receiver compartment (302) has a second section (330) with an annular shape, at a second distance from the cartridge receiver opening (301), and with second guide members (322) with first faces (324) that are inclined about a radial axis to the longitudinal axis and angularly arranged to extend at least partly over the passage angles (318) and the first guide member angles (314).

Owner:ASCENDIS PHARM AS

Force sensor chip

ActiveUS20080034897A1Reduce noise in outputEase of implementationApparatus for force/torque/work measurementForce measurement by elastic gauge deformationMechanical engineeringForce sensor

In a force sensor chip, a base member, to which an external force is applied, includes: an operating part provided in a central portion of the base member and having an external-force acting area section; a supporting part provided, in an outer peripheral portion of the base member, for supporting the operating part; an intermediate part provided between the operating part and the supporting part; a first connecting arm section connecting the operating part and the intermediate section; a second connecting arm section connecting the intermediate part and the supporting part; and at least one strain resistance element provided on each of respective deformation-generating portions of the first and the second connecting arm sections.

Owner:HONDA MOTOR CO LTD

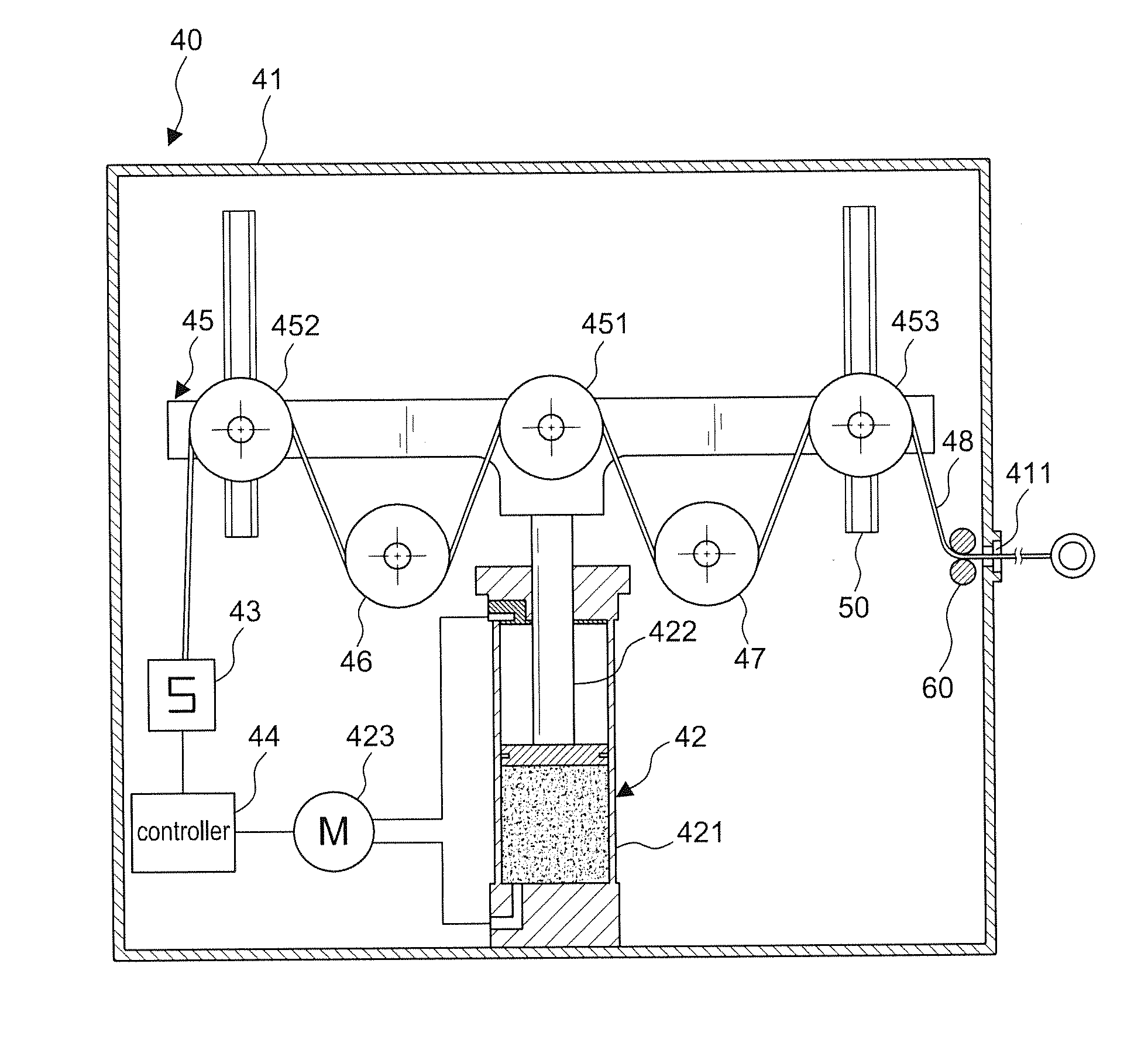

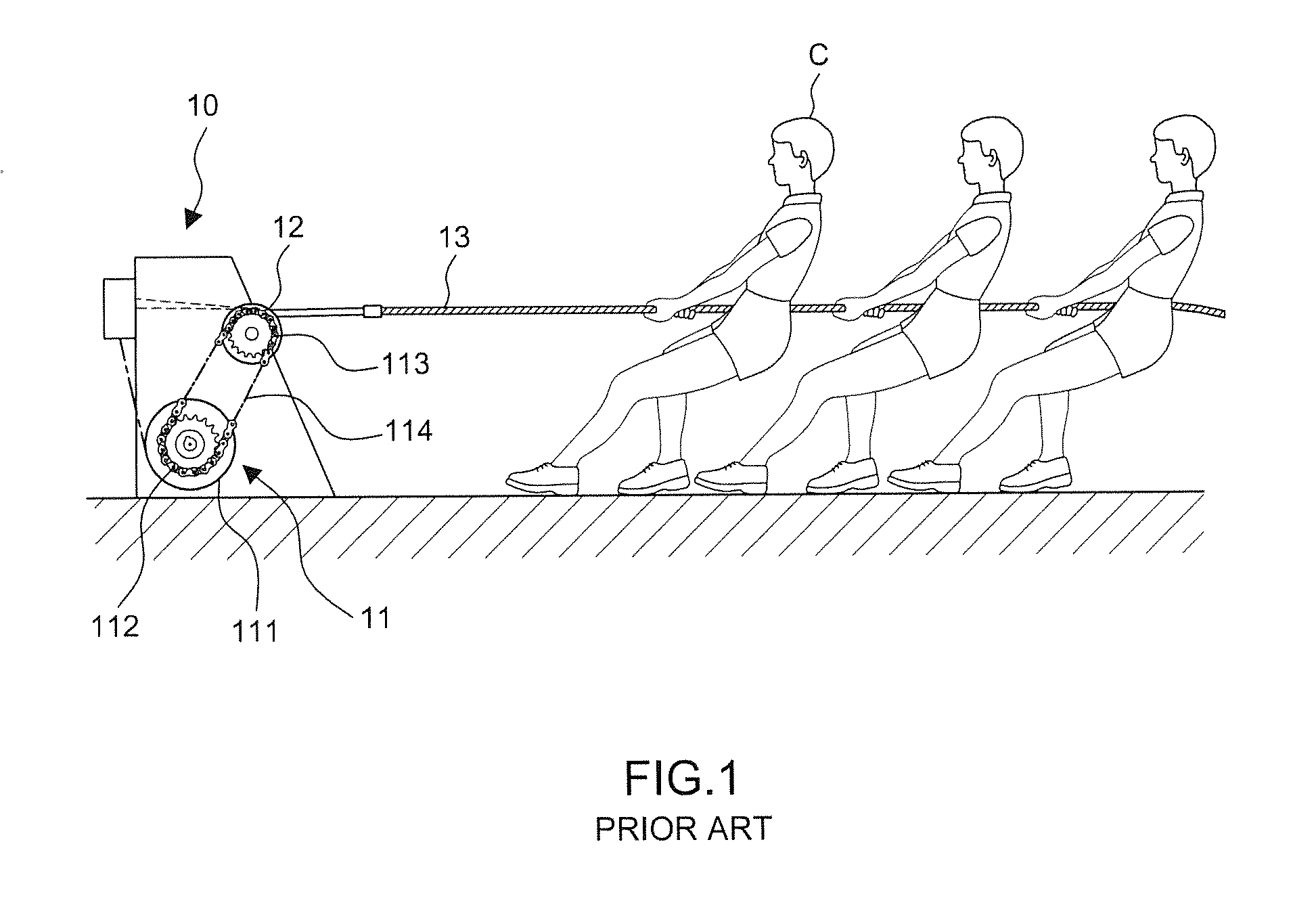

Training machine of load force simulation

A training machine of load force simulation has a damping unit comprises a press cylinder which includes a cylinder, a movable piston rod, and a press source; a controller is coupled to the press source of the damping unit and a load cell for calculating and controlling the load value of the load cell, allowing the elevating and lowering of a pulley system thereof by adjusting the damping force via the piston rod. Also, the pulley system comprises a plurality of movable pulleys to equally bear the load force from the rope, saving the efforts for operating and retarding the retrieving force of the rope for safety. The present invention is therefore able to replace complex decelerating machines and massive weight blocks in apparatus suchlike with features of small volumes as less space needed, less noises, and no restrictions of setting areas due to no need of electricity. Furthermore, it comprises an operation interface for direct controlling of the load force, featuring more conveniences and no interruption when practicing the operation.

Owner:PROTUG

Dual access spike for infusate bags

ActiveUS20050277906A1Increase the cross-sectional areaSlow forceDiagnosticsSurgeryDual accessMechanical engineering

Owner:NXSTAGE MEDICAL

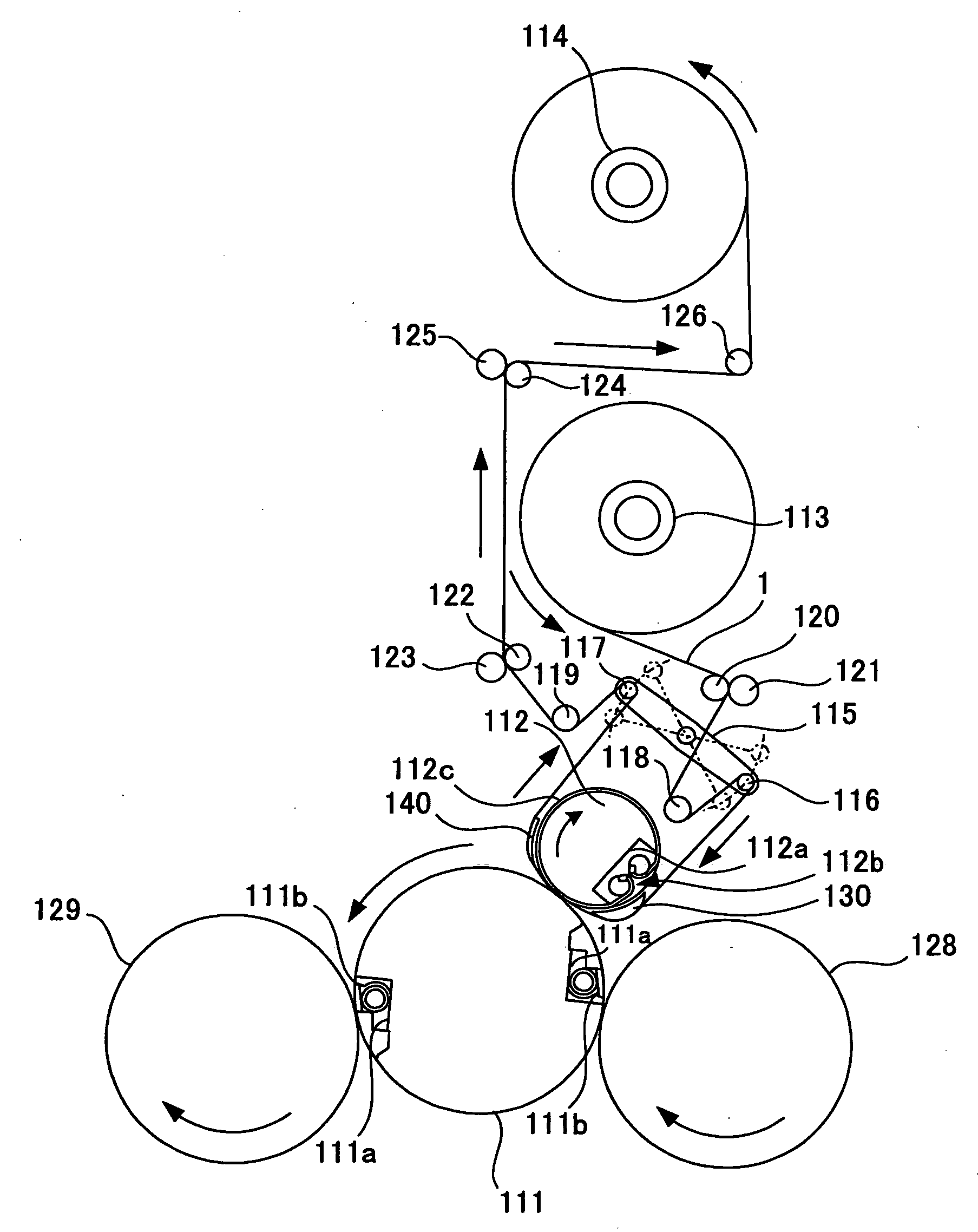

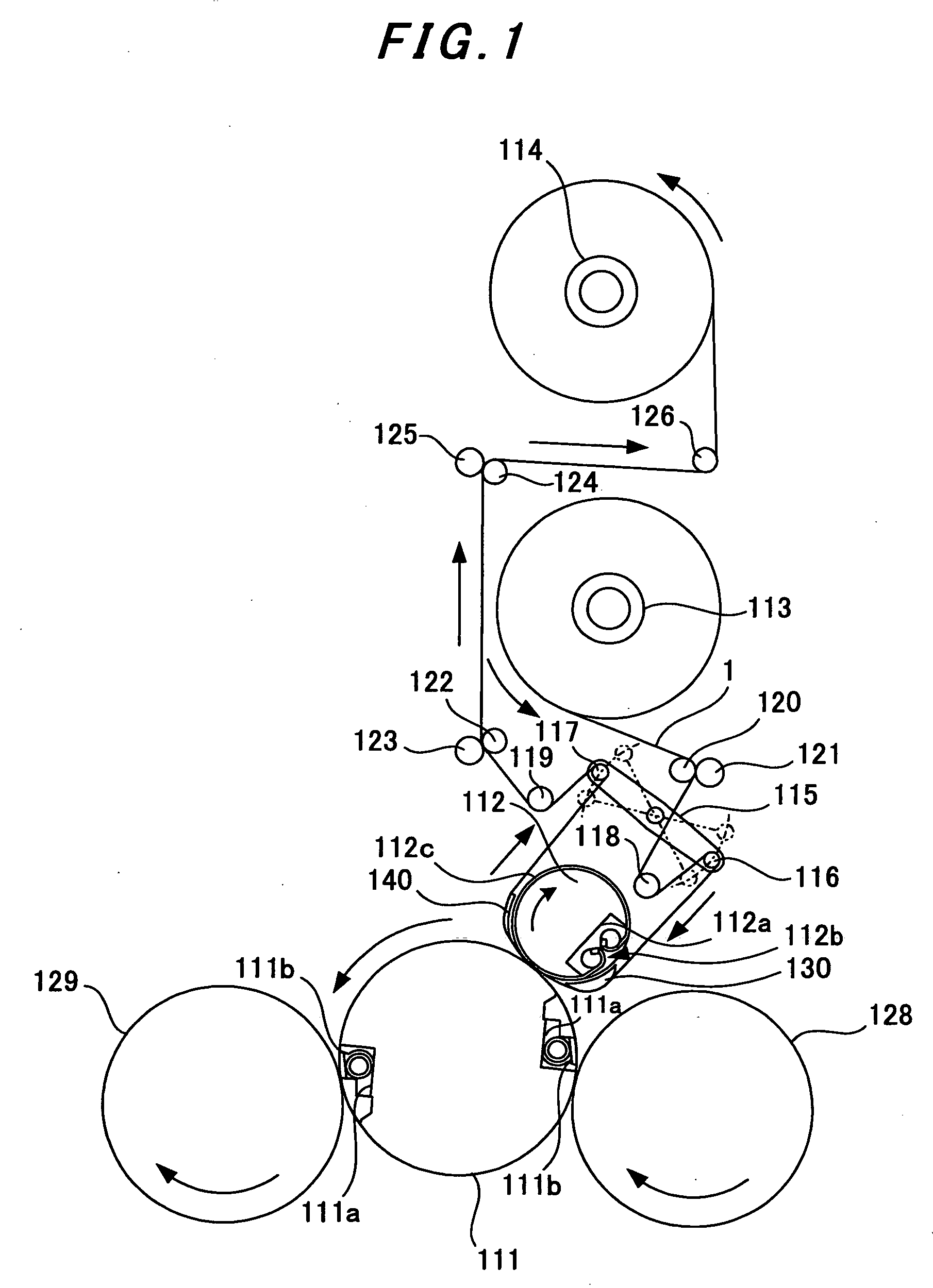

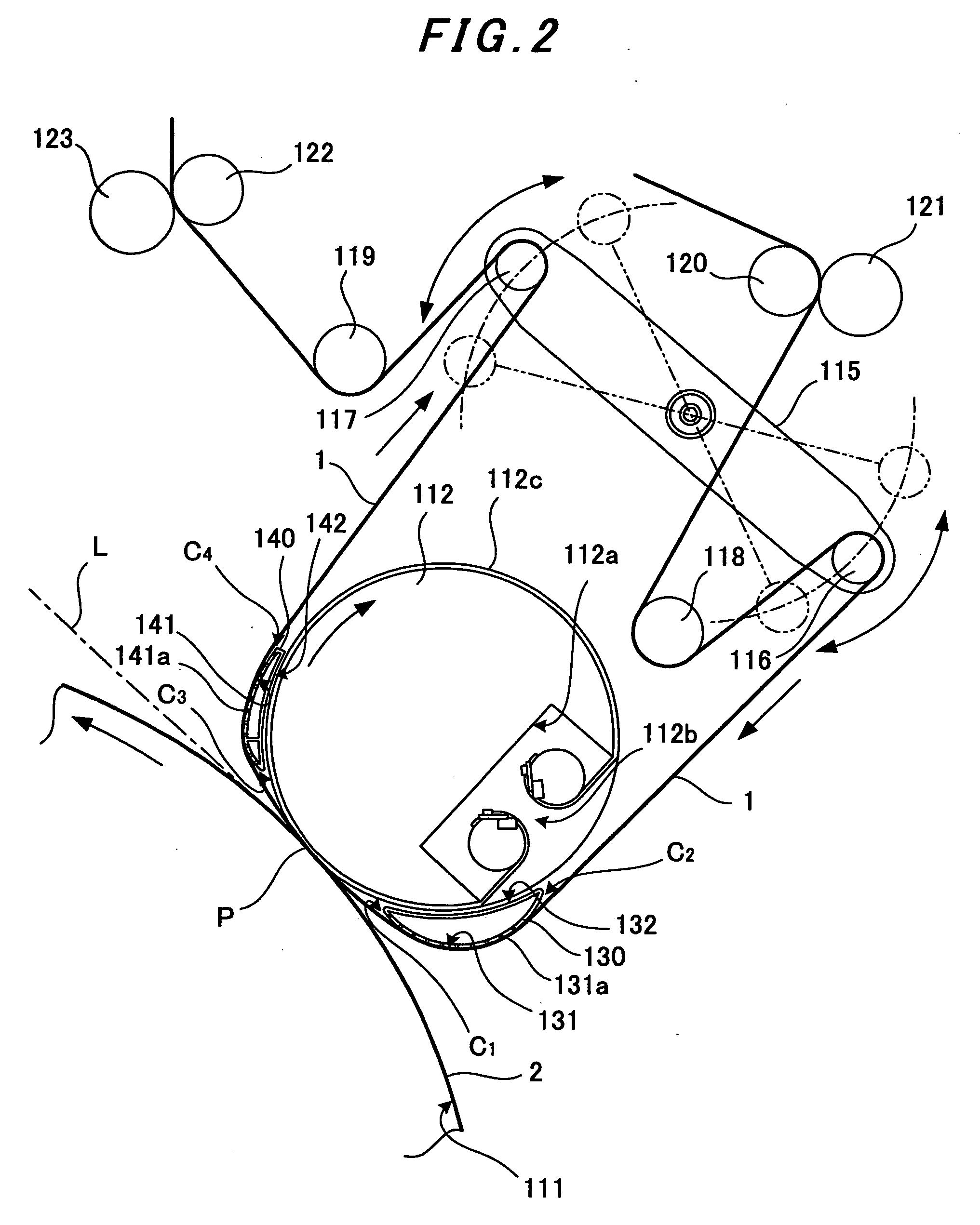

Foil transfer apparatus

InactiveUS20080295969A1Slow forceCarrying out foil saving securelyRotary pressesAdhesivesEngineeringPaper sheet

A foil transfer apparatus includes: a transport cylinder supporting a paper sheet on its outer circumferential surface; and a press roller opposing the transport cylinder and having a notch portion formed in its outer circumferential surface, wherein the paper sheet and a web-like transfer foil made by attaching foil on a base film travel through the nip between the transport cylinder and the press roller, thereby transferring the foil of the transfer foil onto the paper sheet. The foil transfer apparatus also includes a discharging guide disposed near a nip portion between the transport cylinder and the press roller, on the downstream side of the traveling direction of the transfer foil, at the press-roller side, in order to guide the transfer foil so that the transfer foil can travel closer to the press-roller side than a tangent line passing through the nip portion.

Owner:KOMORI CORP

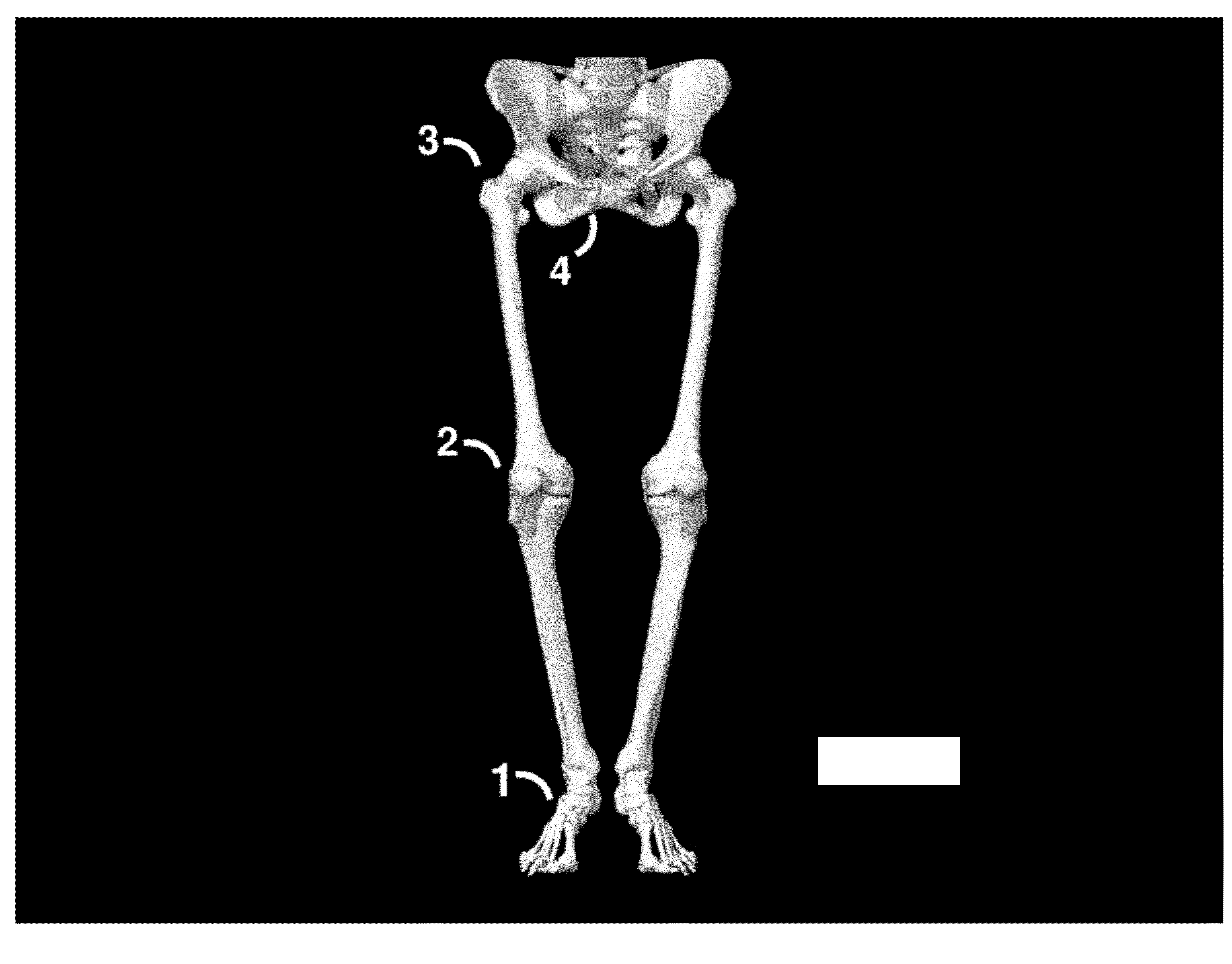

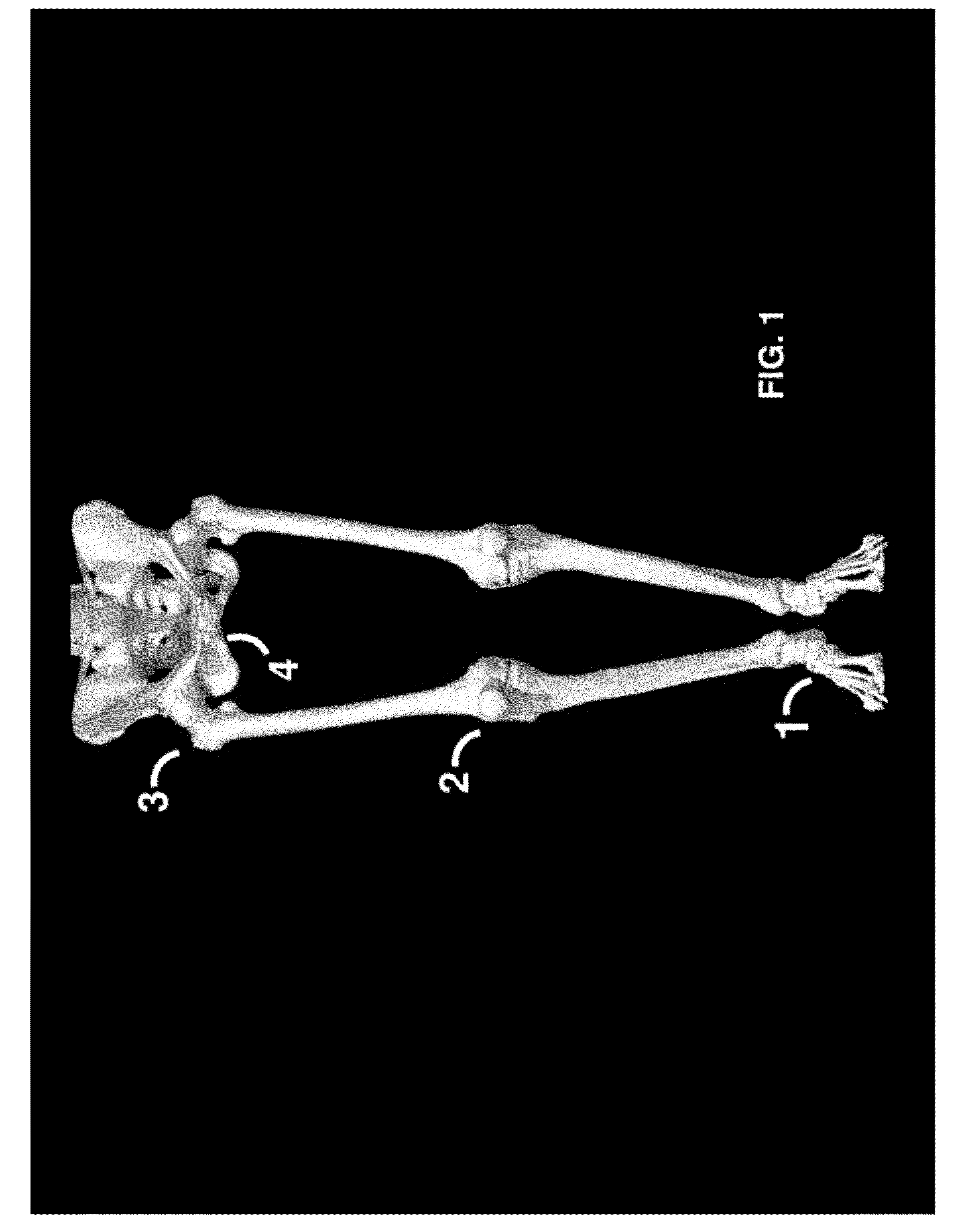

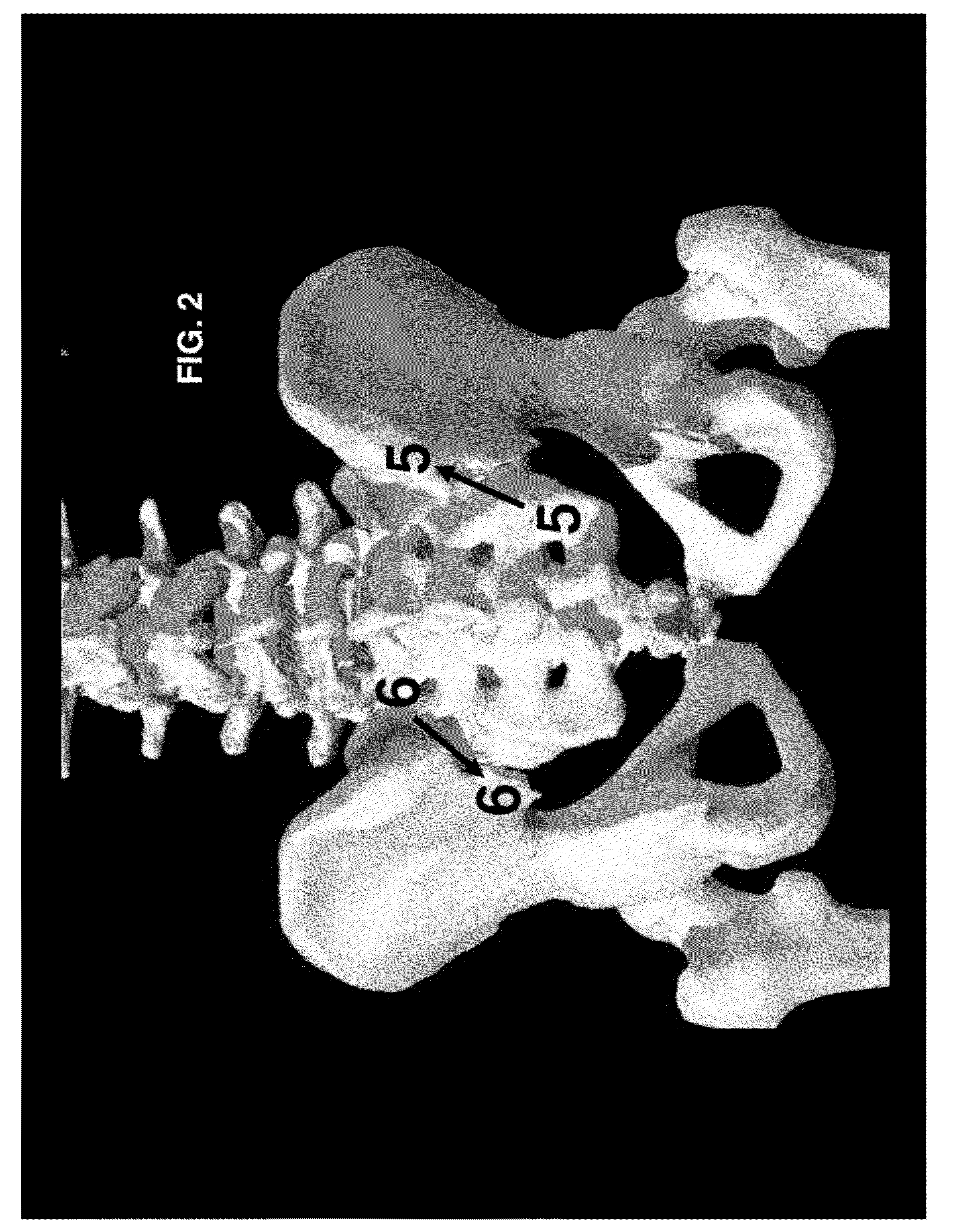

Method and system for treating patients

InactiveUS20120029563A1Increase in motilityIncrease flexibilityOperating tablesChiropractic devicesTreatment sequencePhysical Therapy Modality

There is provided a system and method for treating a patient by administering a predetermined sequence of adjustments to a patient's body. Unlike the unstructured or random application of adjustments used in prior art chiropractic treatments, the treatment sequences and provided for herein unlock function of dysfunctional joint systems in a manner analogous to a combination lock mechanism. Disciplines that may utilize embodiments of the present invention include chiropractic, naturopaths, sports medicine, physical therapy, professional and collegiate trainers, as well as aspects of veterinary medicine. Through applications of the method of the present invention, patients may receive a predetermined number of treatment applications, and have long-lived or substantially permanent results from the treatment without the need for ongoing adjustments to spine or other body structures.

Owner:SWANSON ANDREW

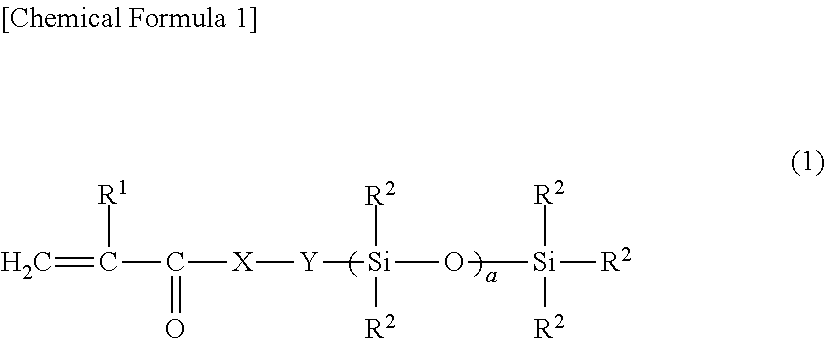

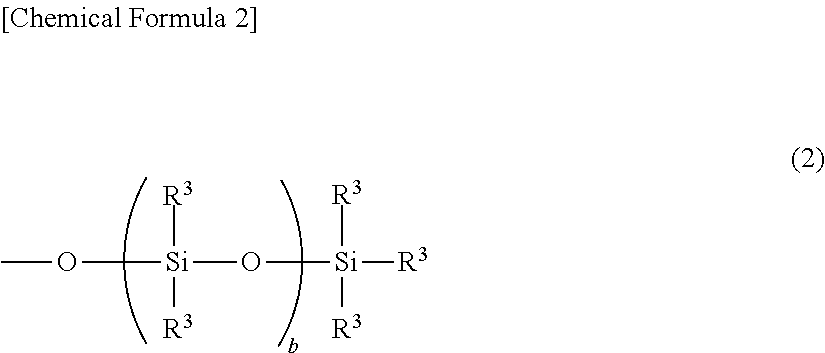

Light release additive for release sheet, organopolysiloxane composition for release sheet, and release sheet

InactiveUS20170306184A1High subsequent adhesion ratioEase release forceOther chemical processesFilm/foil adhesivesPolymer sciencePolymer chemistry

Provided is a light release additive for release sheets, the additive being capable of achieving a desired light release force with a small addition thereof to an organopolysiloxane composition for release sheets and of providing an excellent release coating such that the released adhesive sheet has a high subsequent adhesion. This light release additive for release sheets comprises an acryl-silicone-based graft copolymer with a weight-average molecular weight of 1,000 to 100,000 obtained by radical polymerization of (A) an organopolysiloxane compound having an acrylic group and / or a methacrylic group and (B) a radical polymerizable monomer having one radical polymerizable group per molecule.

Owner:SHIN ETSU CHEM IND CO LTD

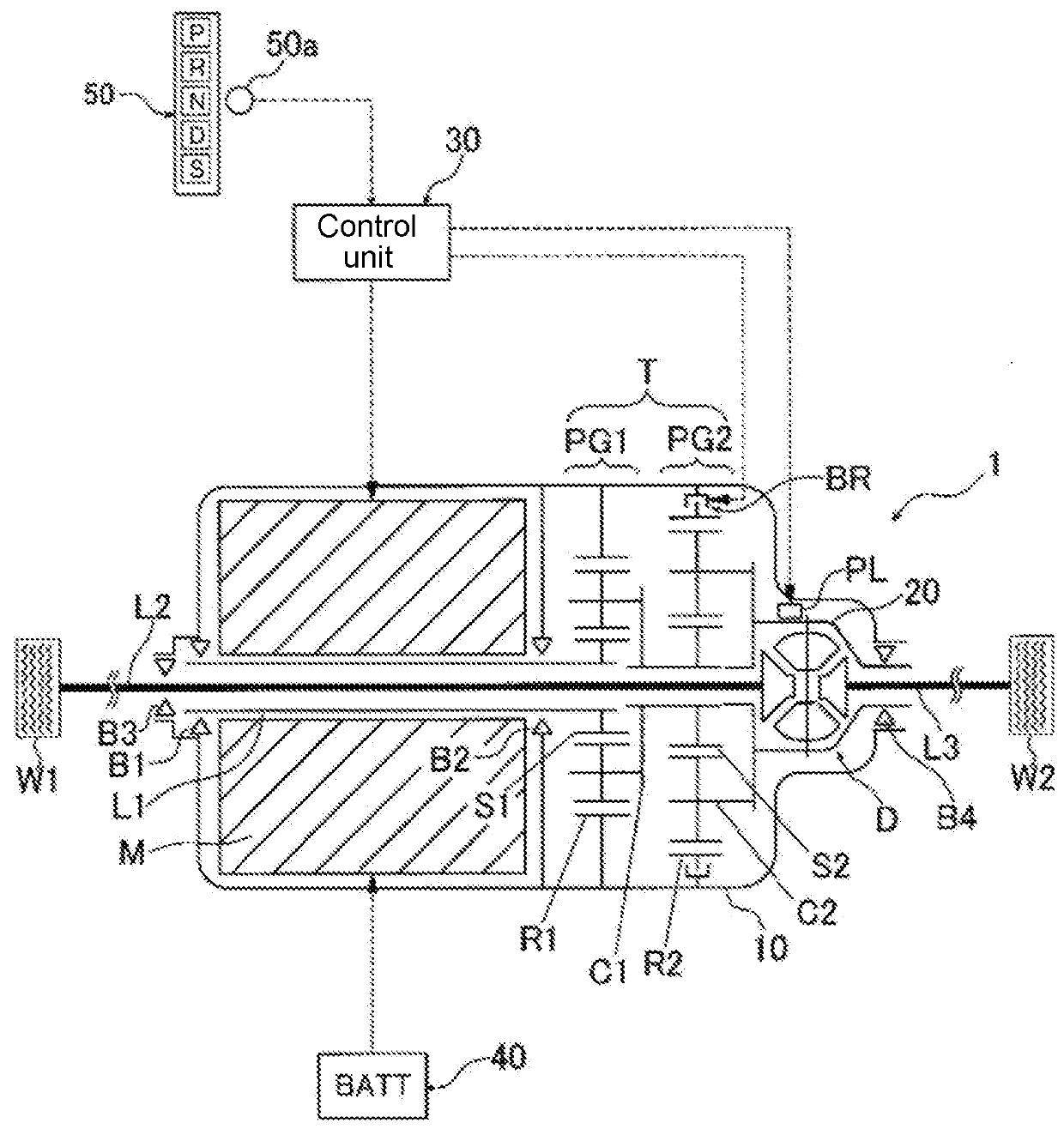

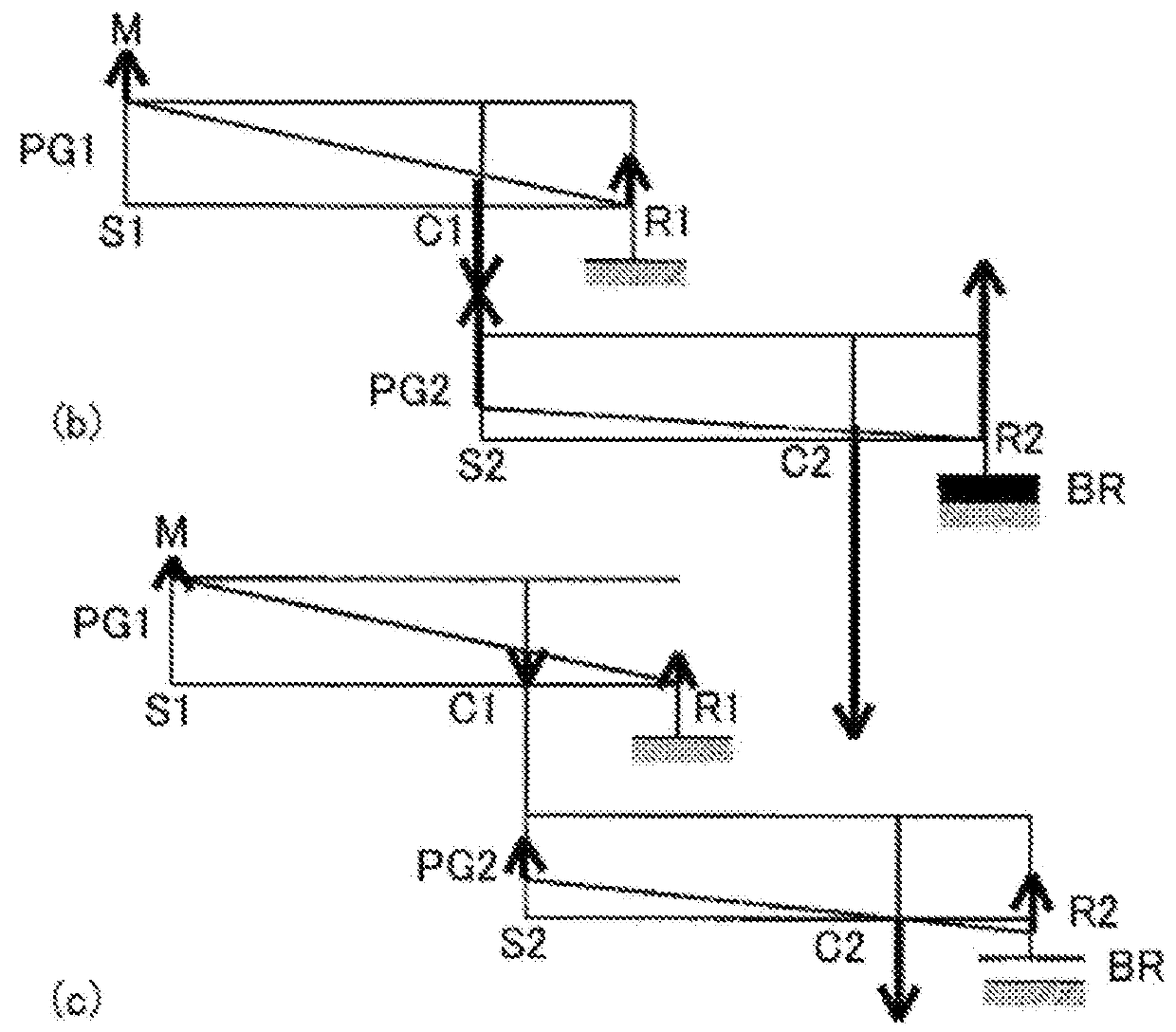

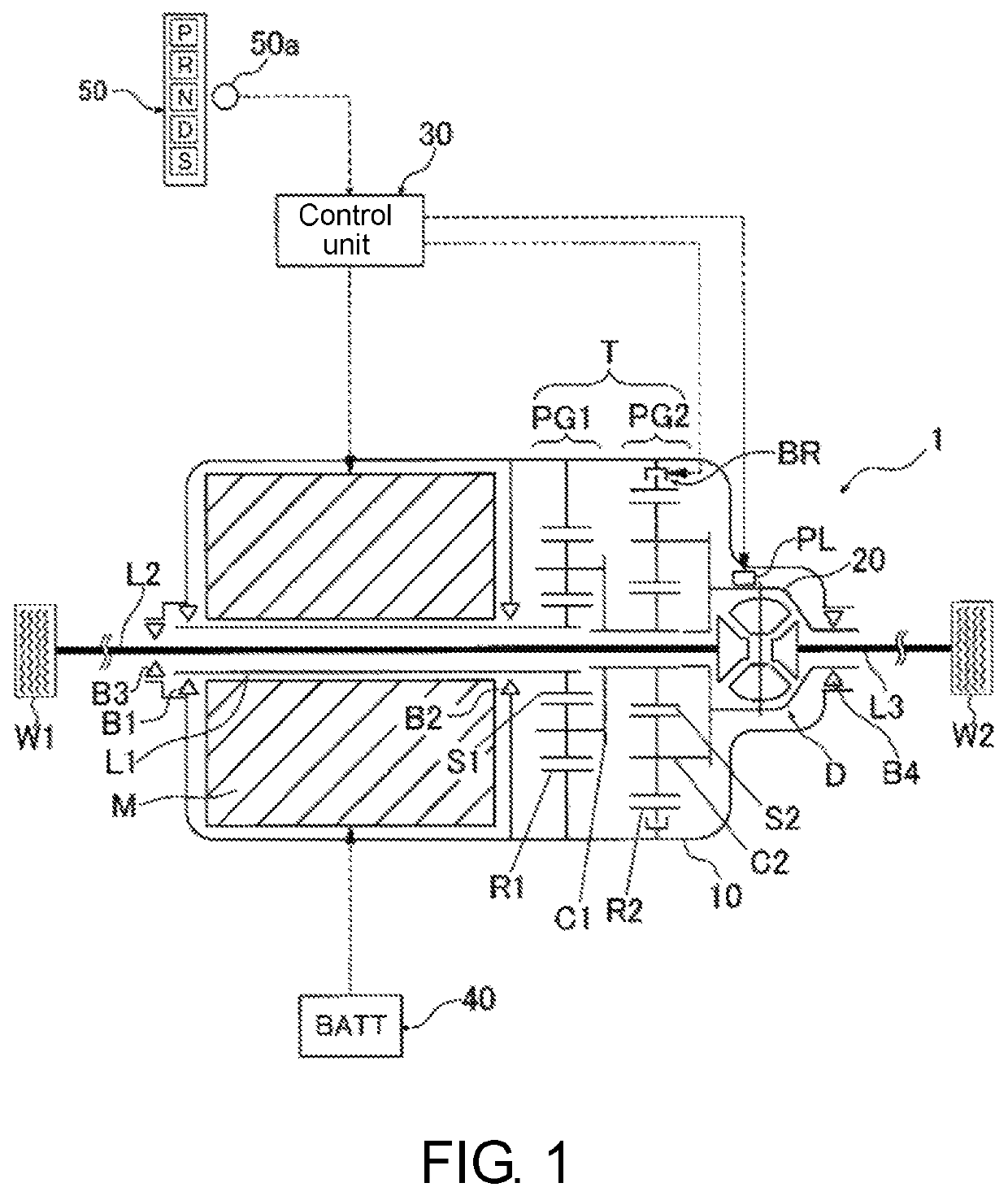

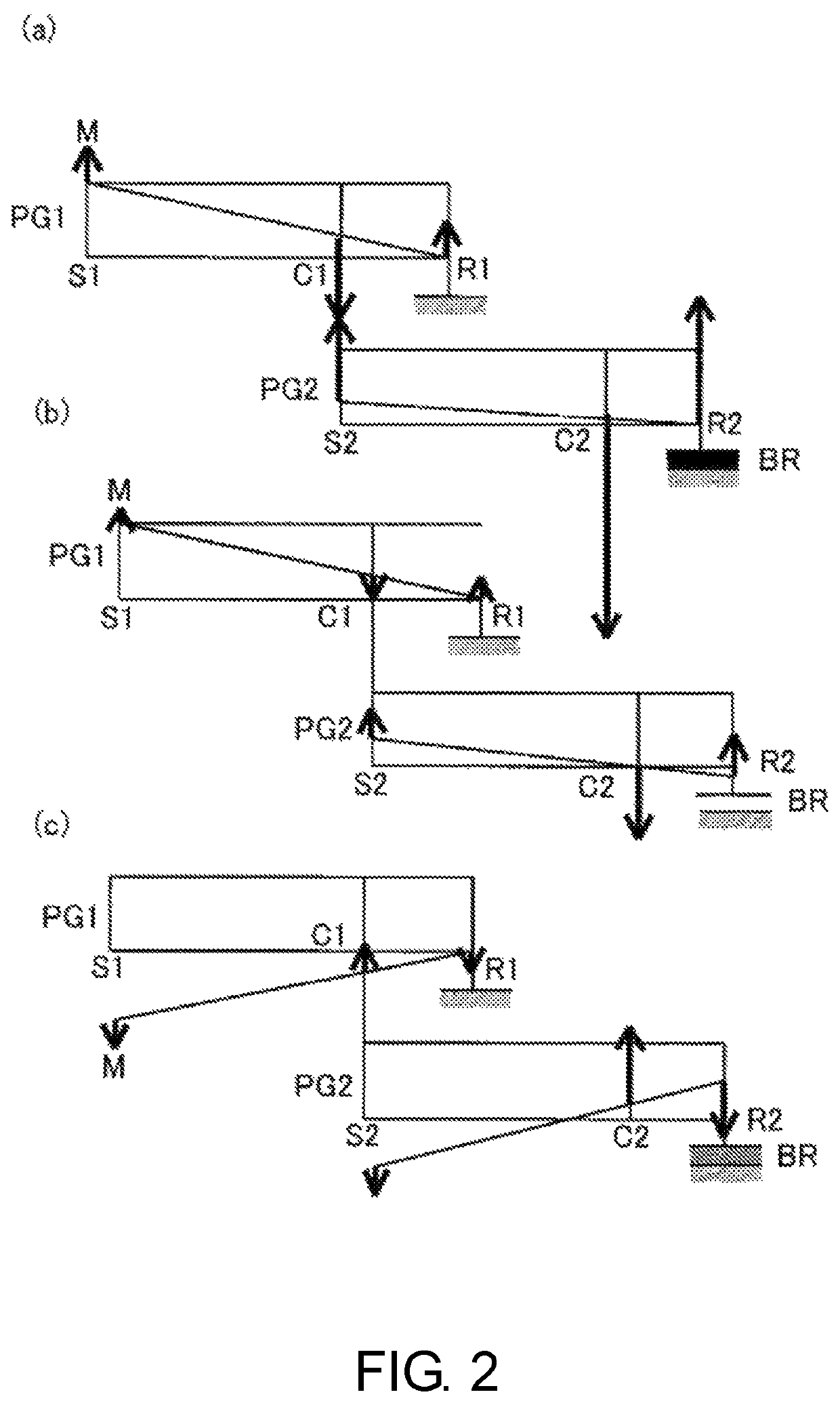

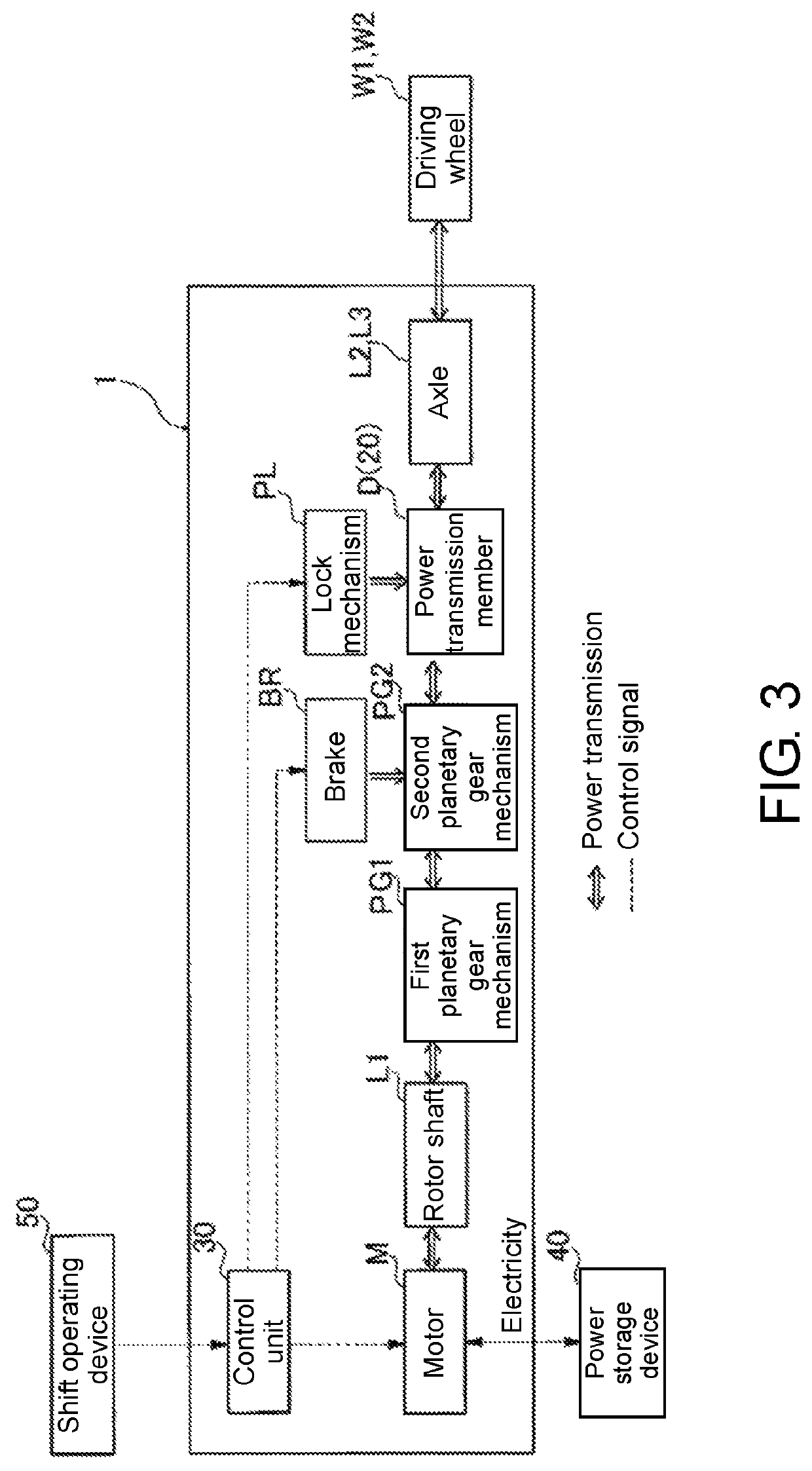

Driving device of vehicle

ActiveUS20190210589A1Consume electricitySlow forceHybrid vehiclesElectrodynamic brake systemsDrive wheelLocking mechanism

The disclosure provides a driving device of a vehicle, wherein even if a power storage device is fully charged, the driving device is capable of applying a corresponding decelerating force to a driving wheel. The driving device of the vehicle includes a motor as a driving source, a first planetary gear mechanism connected to the motor, a second planetary gear mechanism connected to the first planetary gear mechanism, and a differential mechanism connected with driving wheels from the second planetary gear mechanism, and further includes a brake detachably connecting a ring gear of the second planetary gear mechanism to a fixed-side member, and a lock mechanism capable of locking the differential mechanism.

Owner:HONDA MOTOR CO LTD

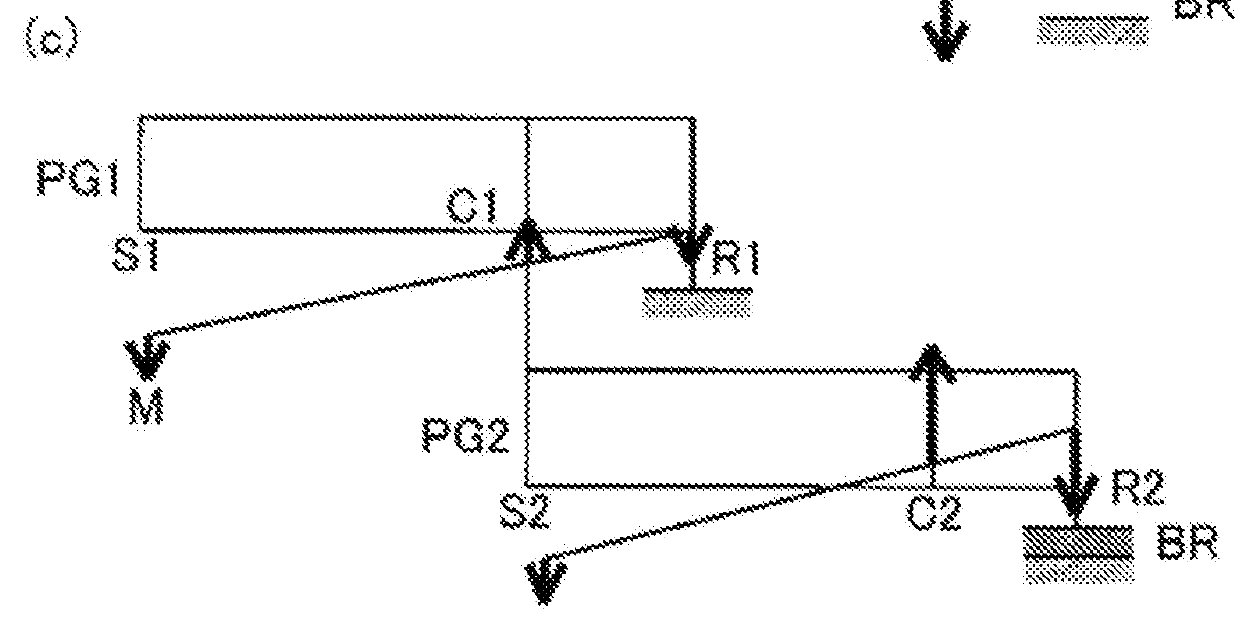

Thrust reverser unit having both nested cascades translating linearly and only one cascade rotational

InactiveUS9982627B2Improve efficiencySmall and lightEngine manufactureEngine fuctionsNacelleGas turbines

A thrust reverser unit (TRU) 100 for a gas turbine engine 10 is provided that has first and second cascade elements 110, 120. In a stowed configuration, both the first and second cascade elements, and the operating mechanism, are located inside the nacelle 40, meaning that the TRU has no detrimental impact on the flow through the bypass duct 22. In the deployed configuration, the first cascade element 110 extends across the bypass duct 22. The first cascade element 110 has flow passages 112 that allow the flow to pass through, redirecting the flow towards the second cascade element 120. The second cascade element 120 further turns the flow so as to provide decelerating reverse thrust.

Owner:ROLLS ROYCE DEUT LTD & CO KG

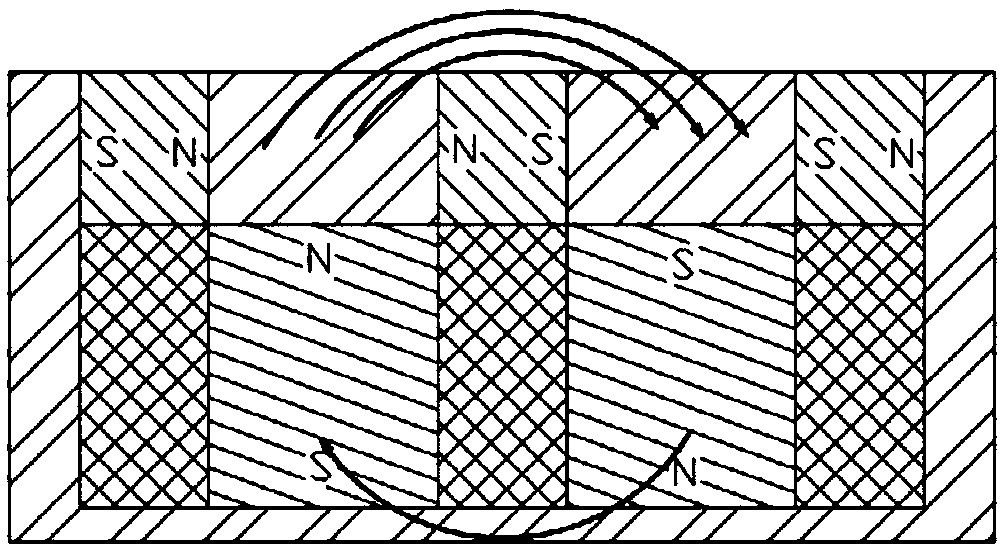

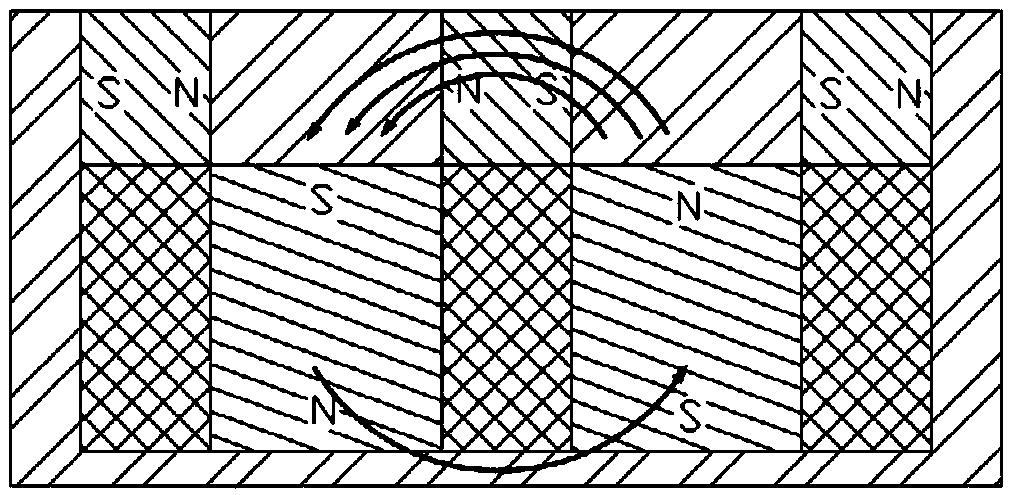

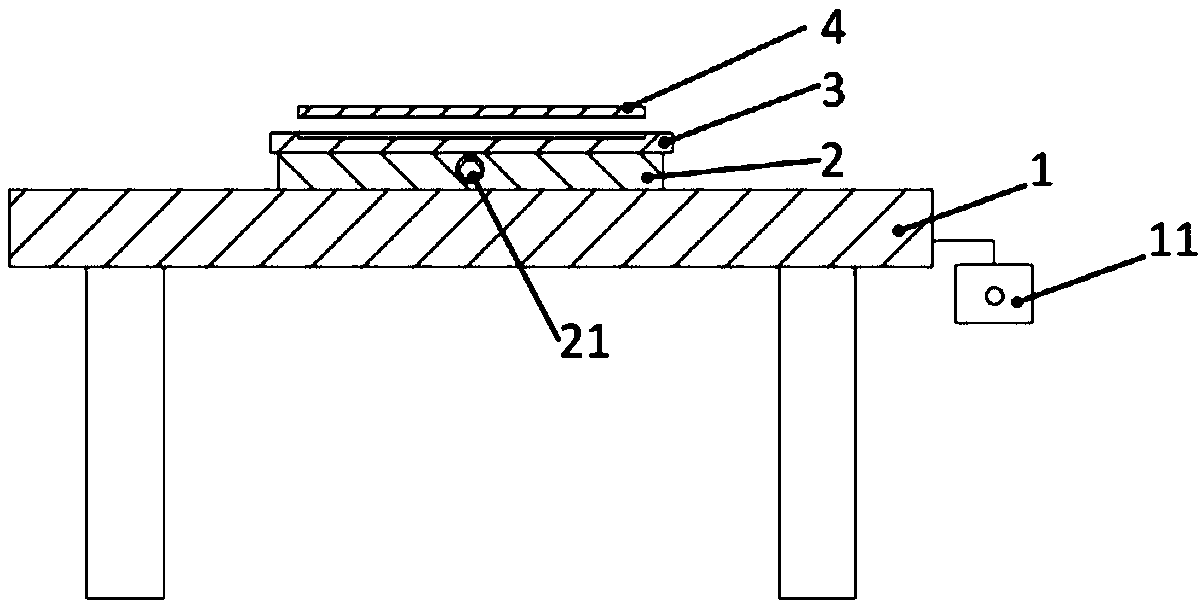

Welding method and device for large-area ferromagnetic target material

ActiveCN109590560AImprove welding rateImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesMagnetic effectFerromagnetism

The invention discloses a welding method and device for a ferromagnetic sputtering target material. According the welding method, through the magnetic effect of a permanent magnet chuck platform on the ferromagnetic sputtering target material, the target material, a solder and a backing plate are uniformly combined to improve the welding quality of the large-area ferromagnetic sputtering target material, so that the welded rate of the target material is high and the thickness uniformity of the target material is good. The welding method is easy to operate and has strong repeatability; the high-quality welding of the large-area ferromagnetic sputtering target material can be achieved by using a magnetic platform welding device; and the sputtering performance of the target material is significantly improved.

Owner:GRIKIN ADVANCED MATERIALS

Hoisting device and hoisting method for prefabricated panel

PendingCN109205463AImprove safety and reliabilityMeet the use requirementsLoad-engaging elementsEngineeringWall plate

The invention relates to the technical field of building construction, particular to a hoisting device and hoisting method for a prefabricated panel. The hoisting device comprises a hoisting portion for hoisting the prefabricated panel and a clamp portion for fixing the position of the prefabricated panel, wherein the clamp portion is connected with the lower end of the hoisting portion and is provided with an anchor bolt arranged in the penetrating a hoisting hole that is formed in the prefabricated panel. When the prefabricated panel is hoisted by using the hoisting device, the prefabricatedpanel is placed in the clamp portion at first, the hoisting anchor bolt is inserted into the hoisting hole, and the prefabricated panel is fixed onto the hoisting device; a combination of the clamp portion and the hoisting anchor bolt replaces hoisting rings for the prefabricated panel, so safety and reliability during hoisting are improved, and usage requirements of prefabricated panels with different thicknesses and different bore diameters on the hoisting device are met; and in use of the hoisting device, presetting of hoisting rings on prefabricated panel is not needed, so materials are saved.

Owner:HEFEI UNIV OF TECH

Driving device of vehicle

ActiveUS10632987B2Consume electricitySlow forceHybrid vehiclesElectrodynamic brake systemsDrive wheelGear wheel

The disclosure provides a driving device of a vehicle, wherein even if a power storage device is fully charged, the driving device is capable of applying a corresponding decelerating force to a driving wheel. The driving device of the vehicle includes a motor as a driving source, a first planetary gear mechanism connected to the motor, a second planetary gear mechanism connected to the first planetary gear mechanism, and a differential mechanism connected with driving wheels from the second planetary gear mechanism, and further includes a brake detachably connecting a ring gear of the second planetary gear mechanism to a fixed-side member, and a lock mechanism capable of locking the differential mechanism.

Owner:HONDA MOTOR CO LTD

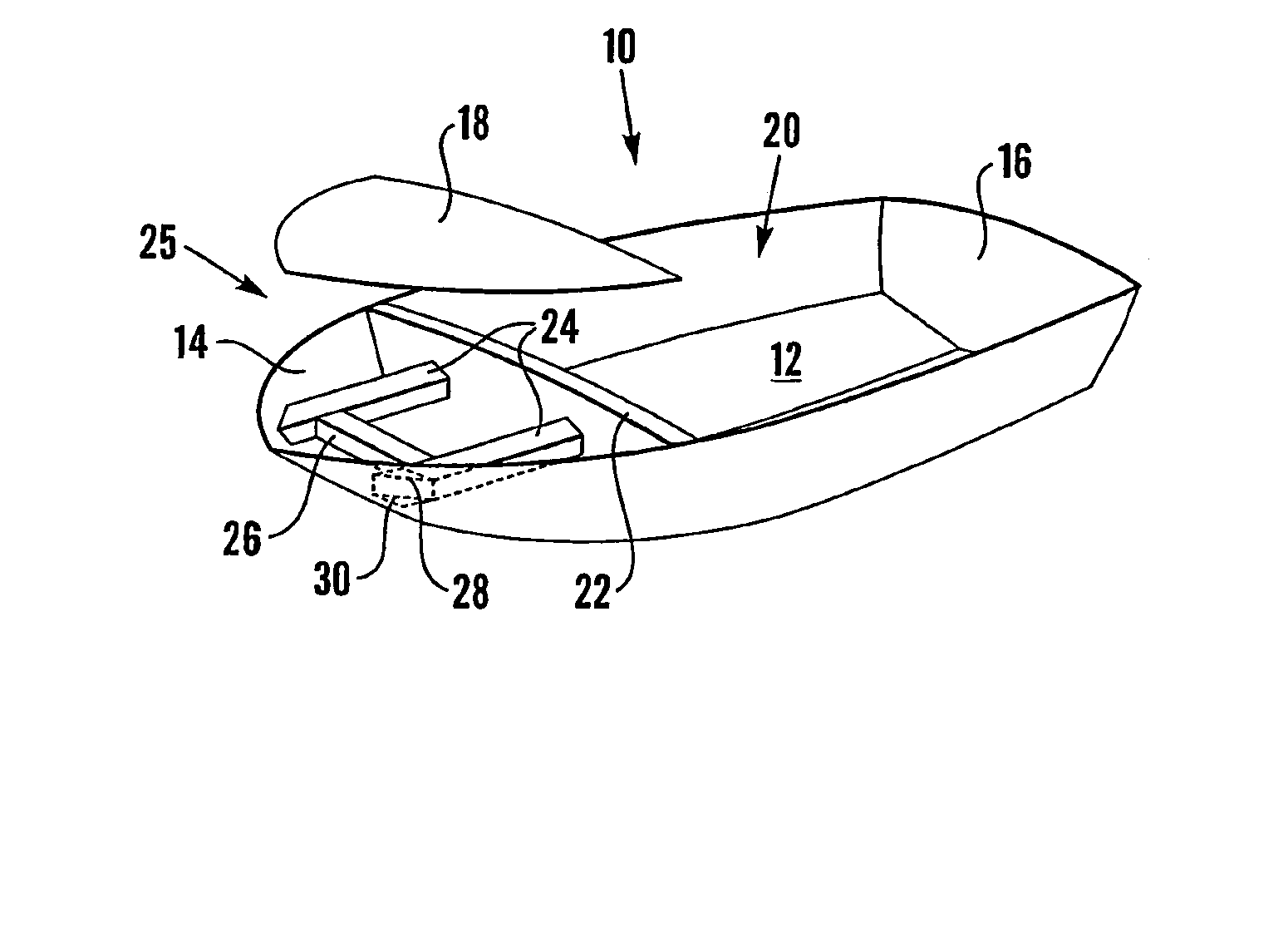

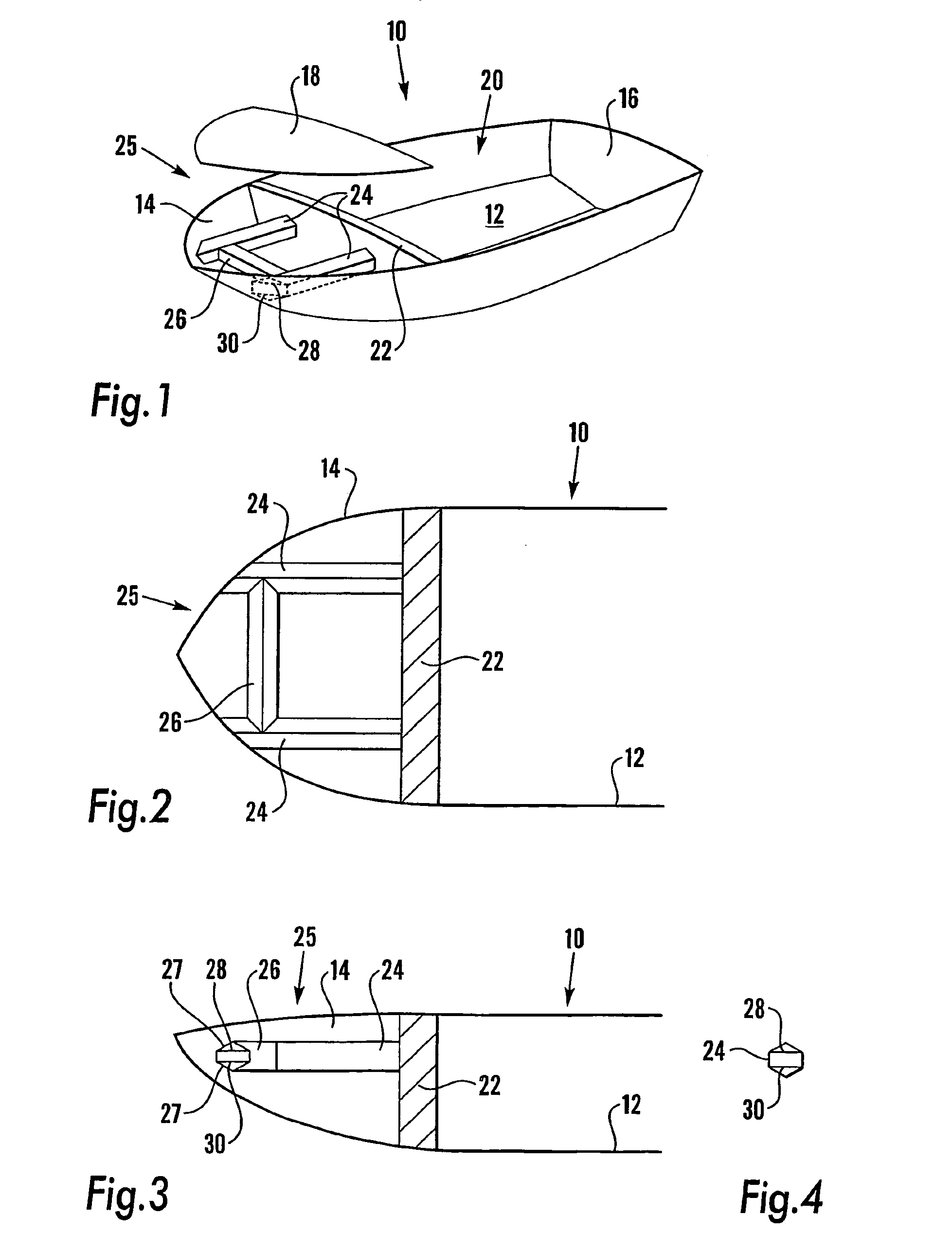

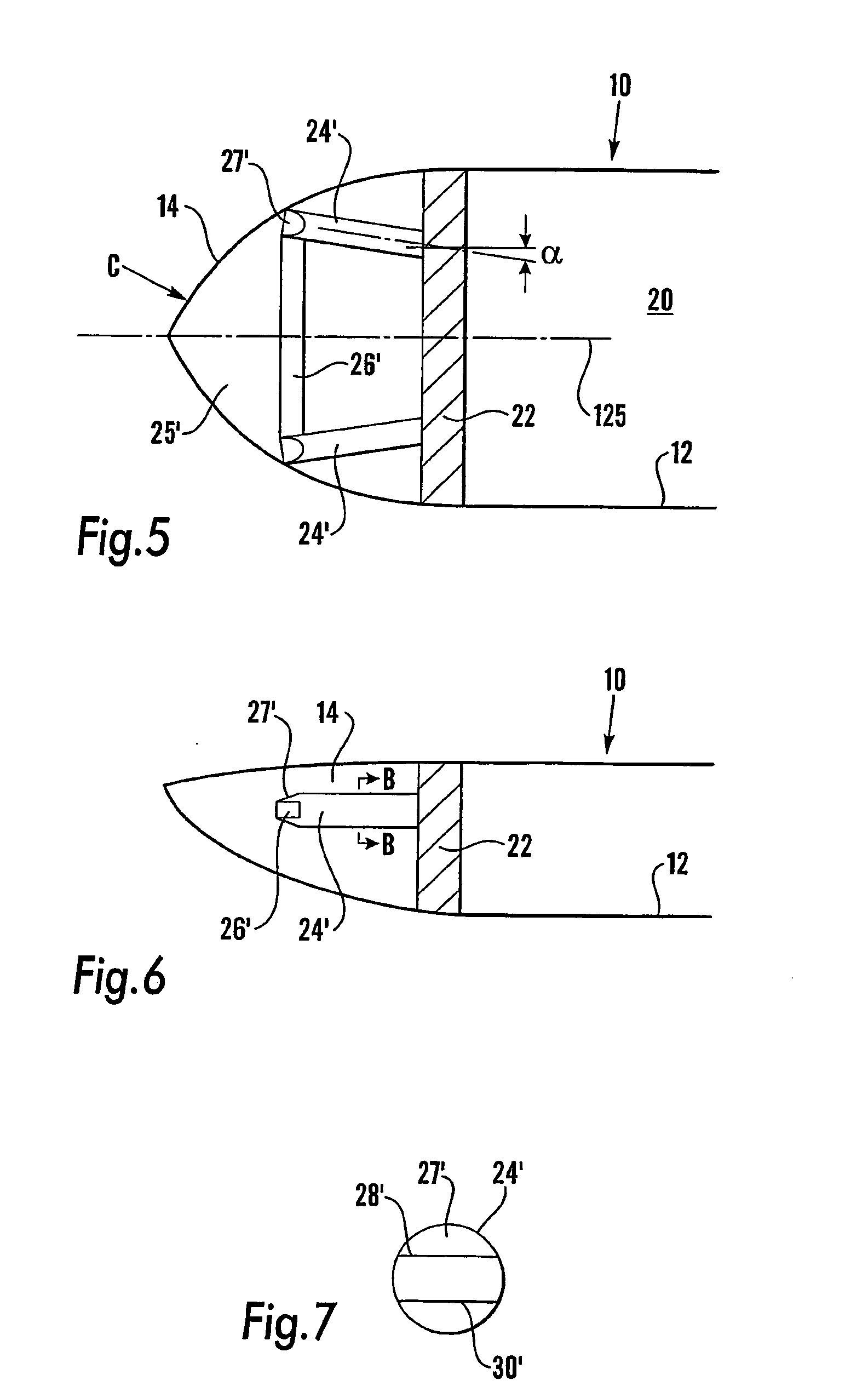

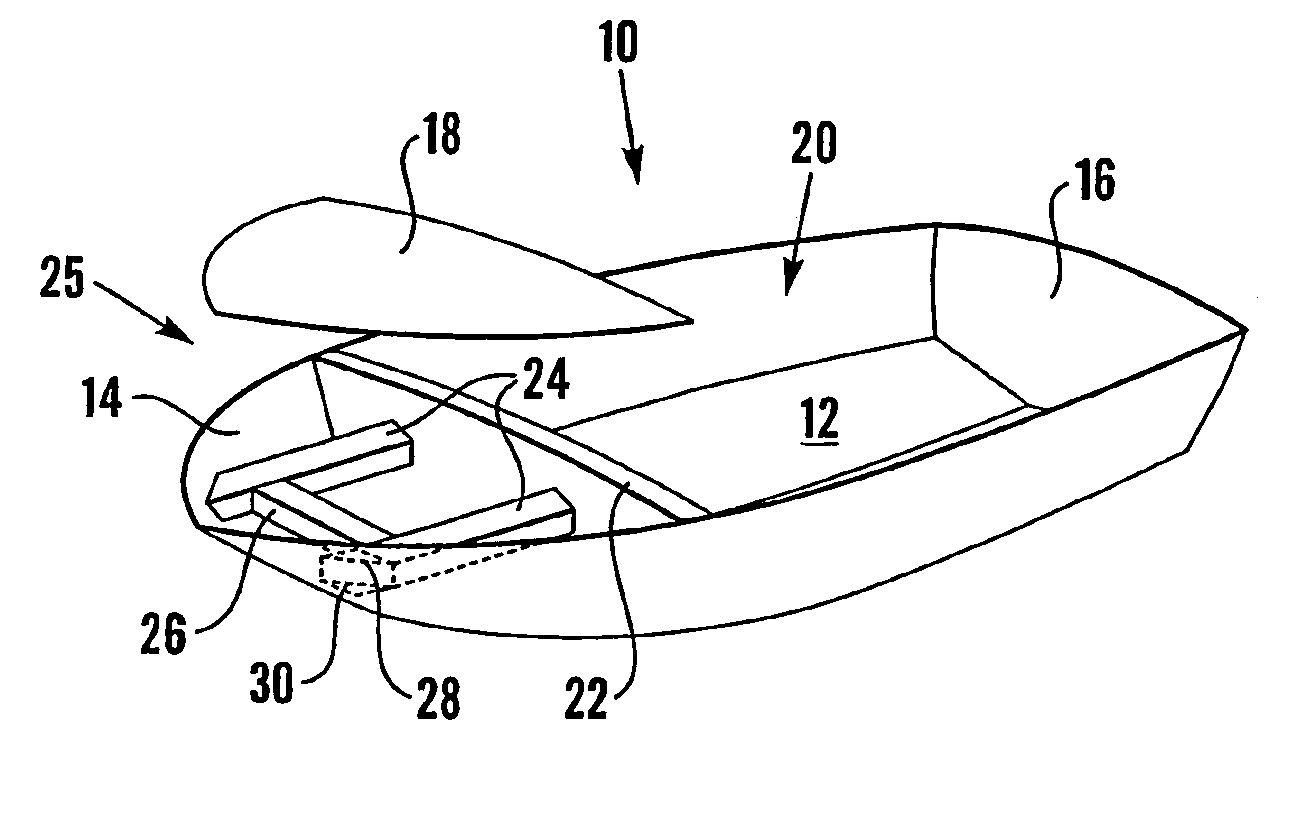

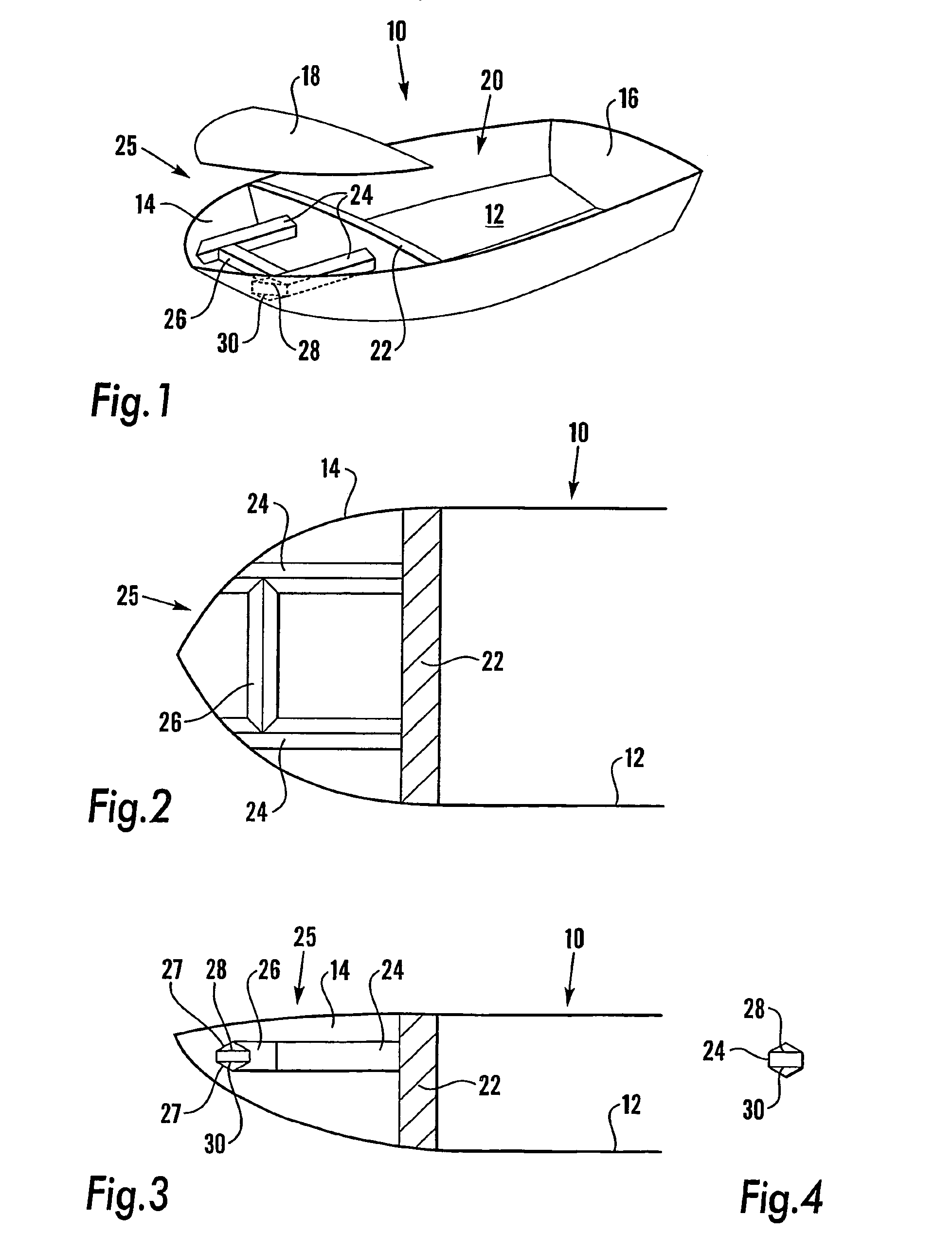

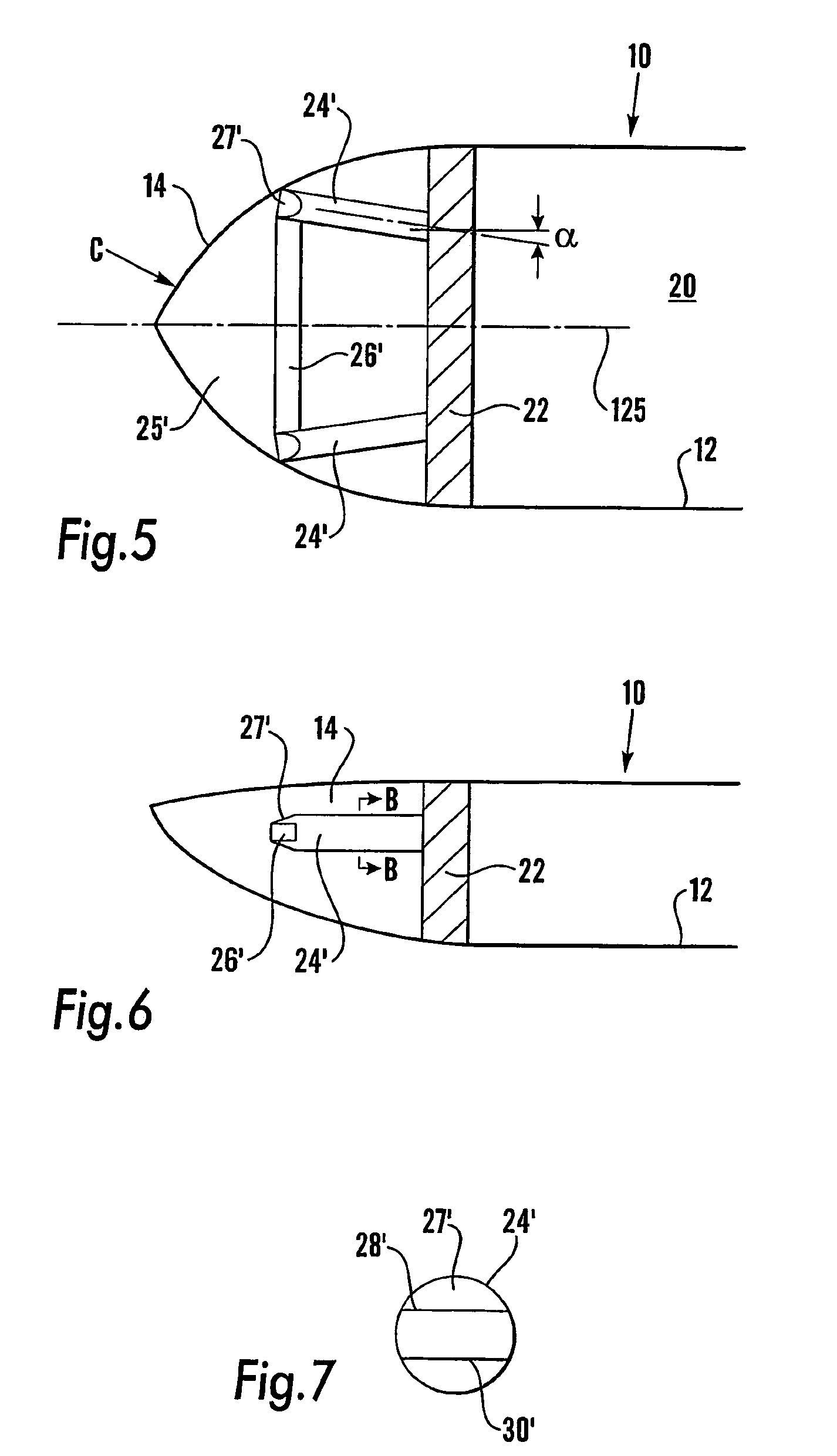

Marine craft impact protection

Marine craft has a crushable frontal impact protection structure, comprising transverse bulkhead protecting passenger area; longitudinal crushable tubes; and transverse member. Webs strengthen tubes, which may be made of extruded, heat treated aluminum; stainless steel; or plastic. Tubes are splayed to improve protection against angled impacts. The forward ends of tubes are tapered to initiate deformation. Tubes may be hexagonal, round, or oval in cross-section. Longitudinal bulkheads, and a transverse bulkhead may be used in place of tubes. Longitudinal corrugated sheets may be mounted transversely. The bow area may be filled with deformable cellular foam to act as a buoyancy aid. Side and rear impact protection is also provided.

Owner:GIBBS TECH

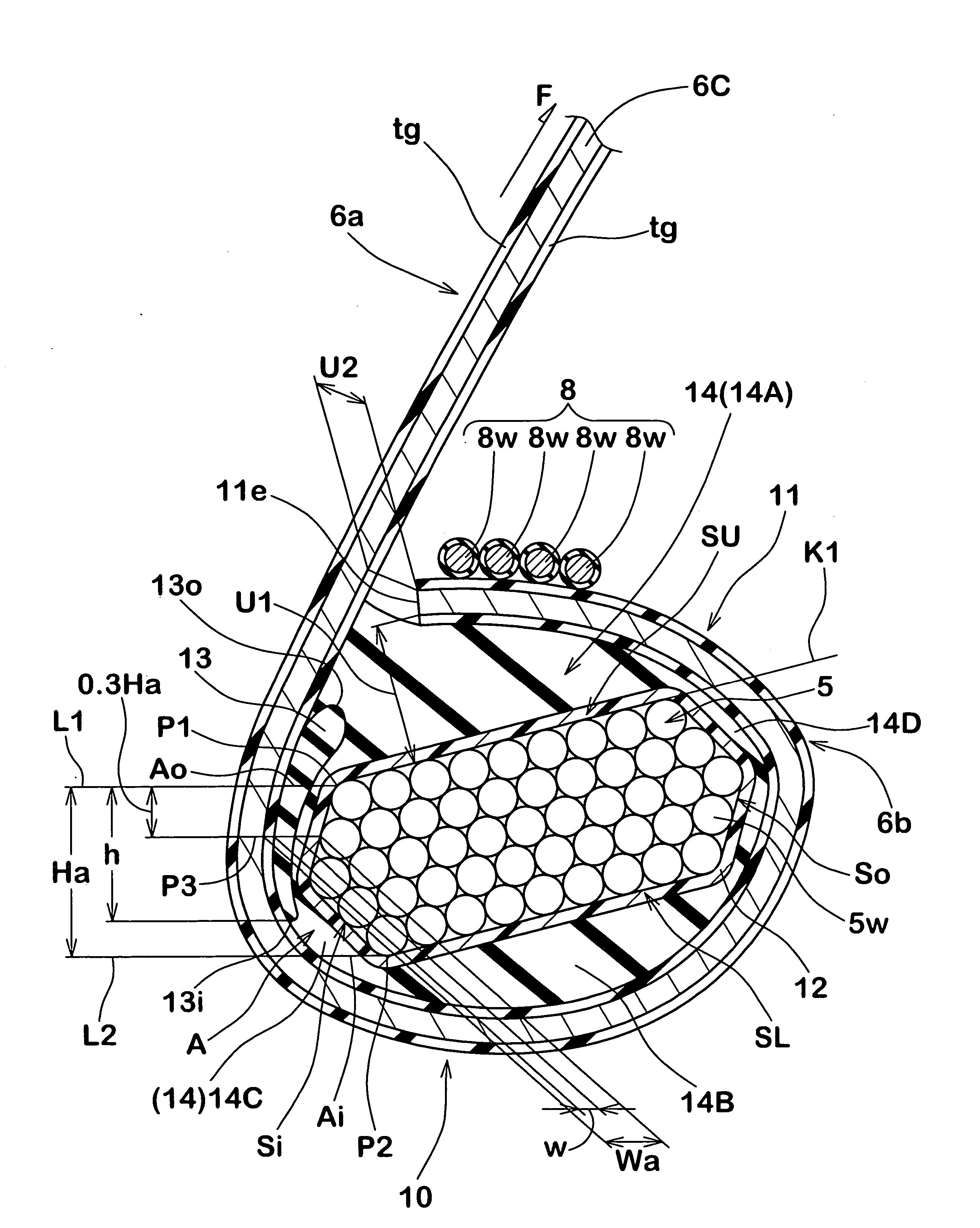

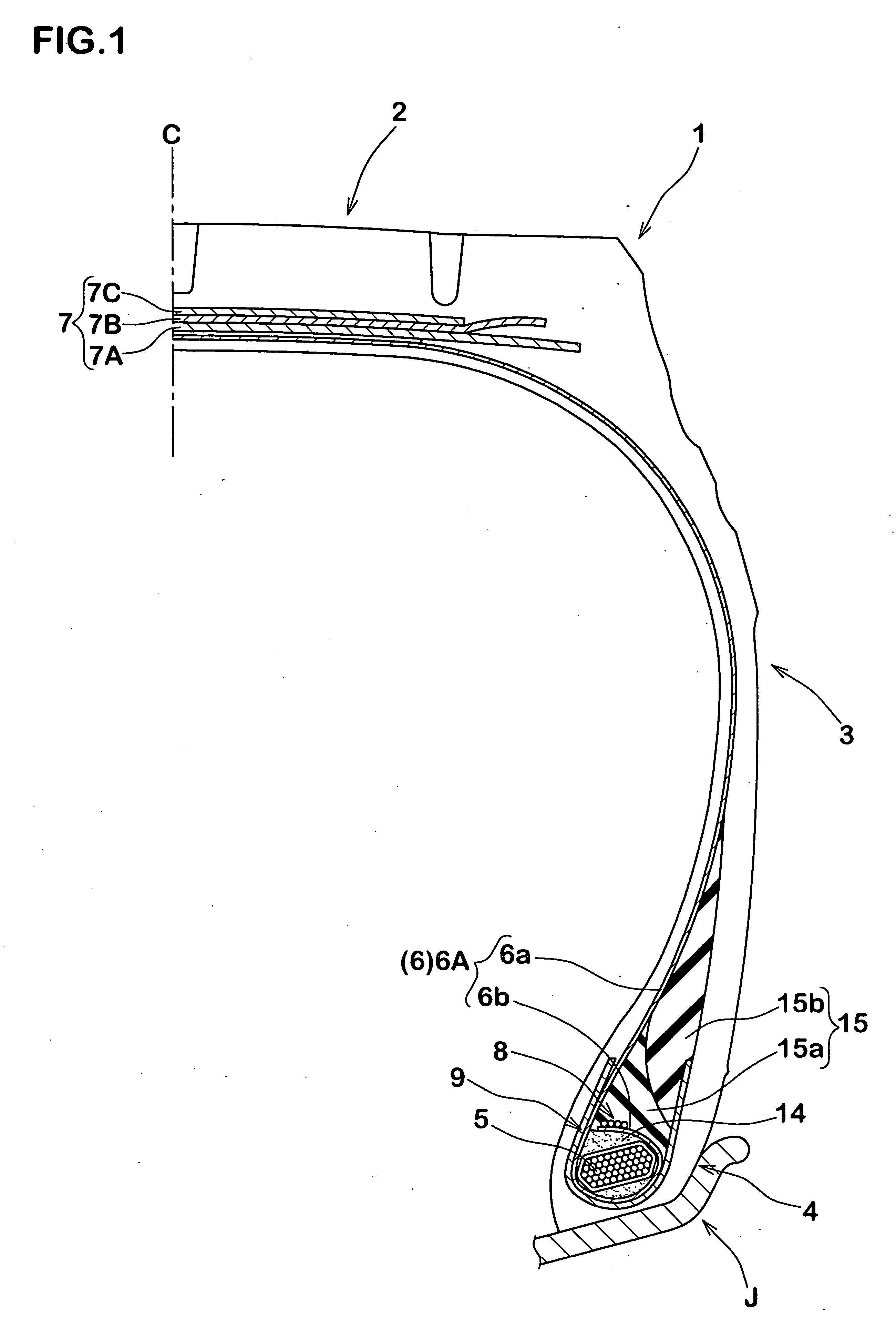

Heavy duty tire

InactiveUS20060249237A1Pulling out forceSuppression of deformationWithout separate inflatable insertsSpecial tyresHeavy dutyMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

Mechanism type non-sectional locking buffer device

InactiveUS20050082727A1Slow forceReduce failureMachine framesSprings/dampers design characteristicsBall bearingEngineering

Owner:PRO GLORY ENTERPRISES

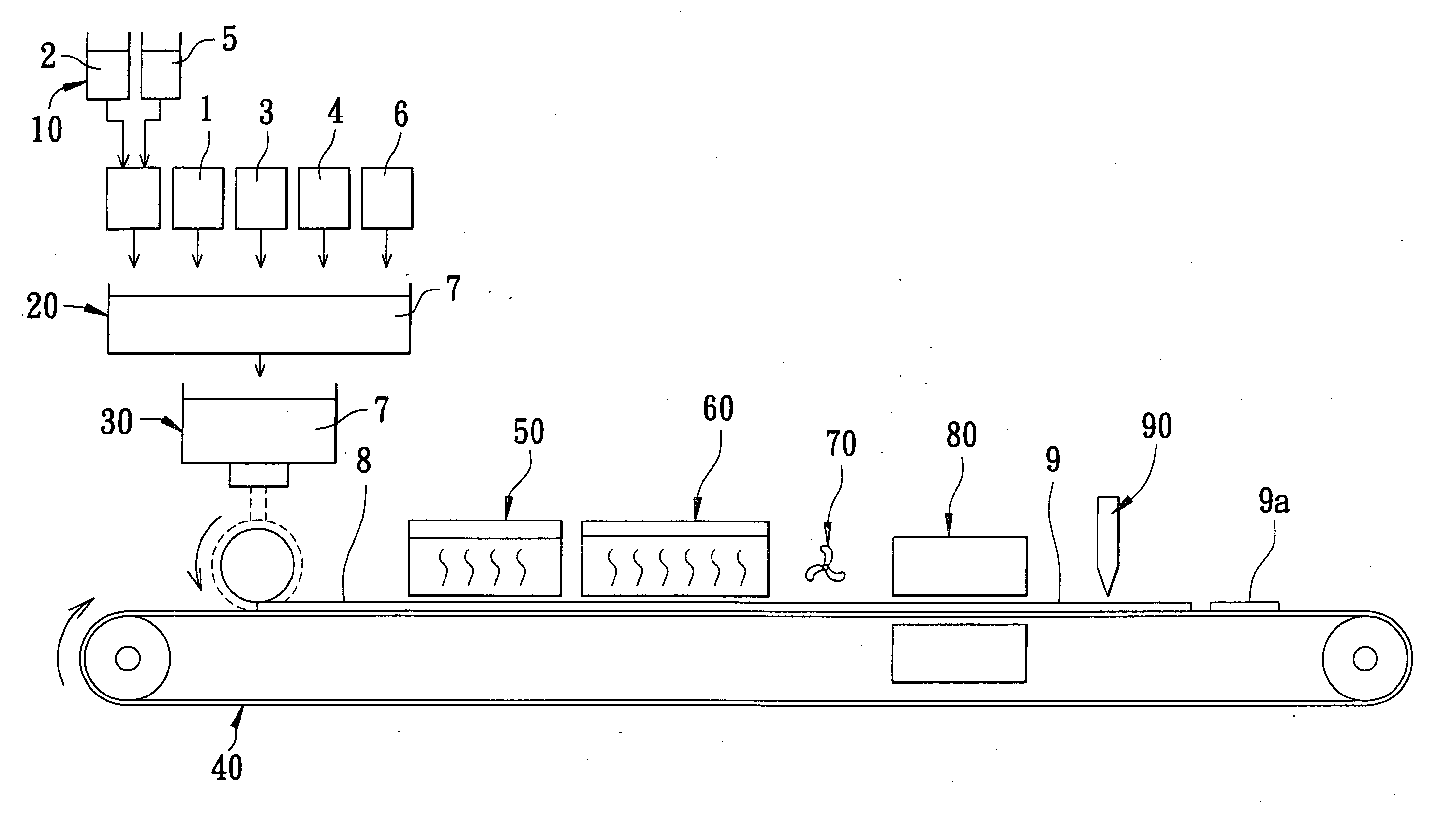

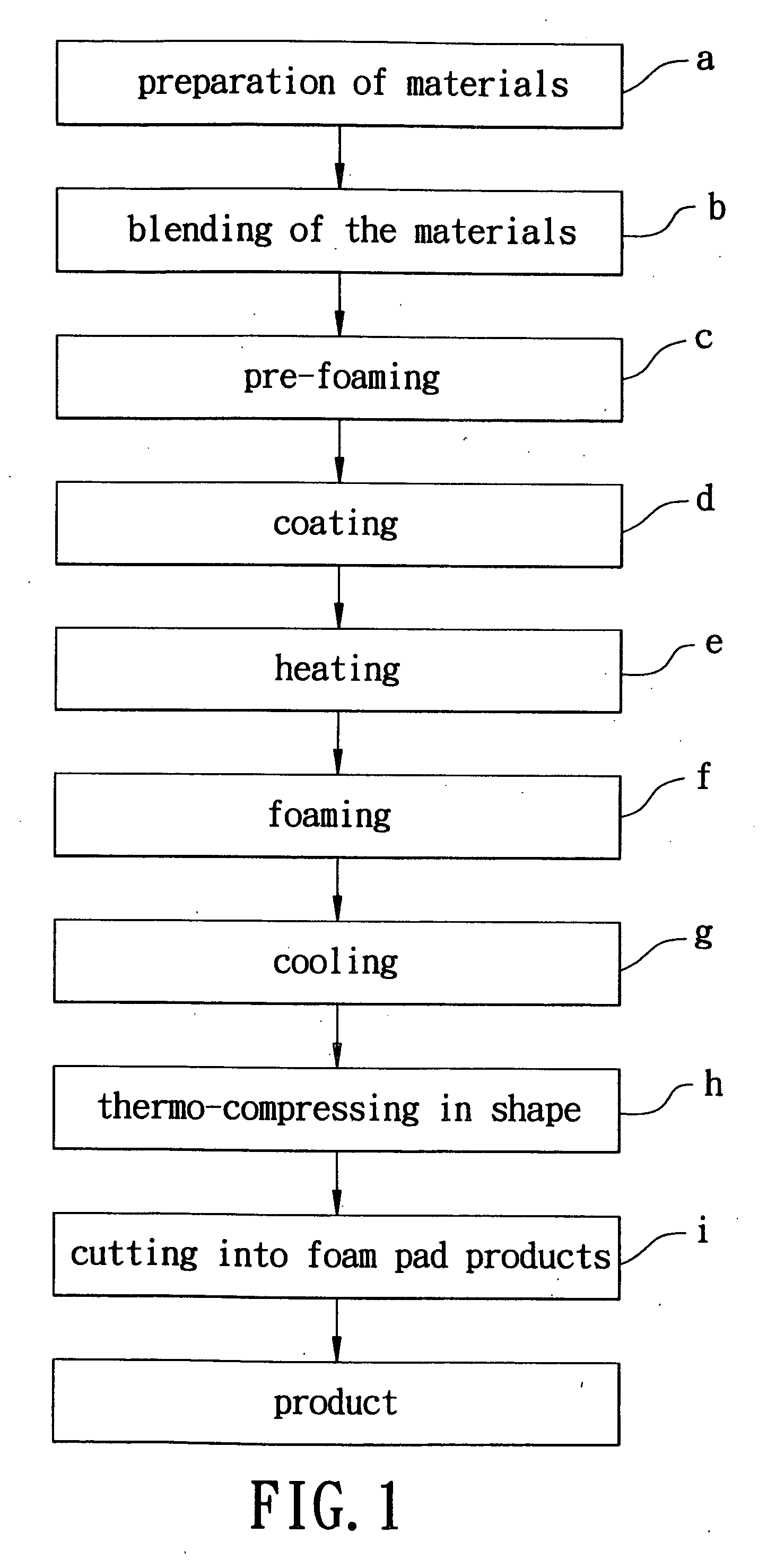

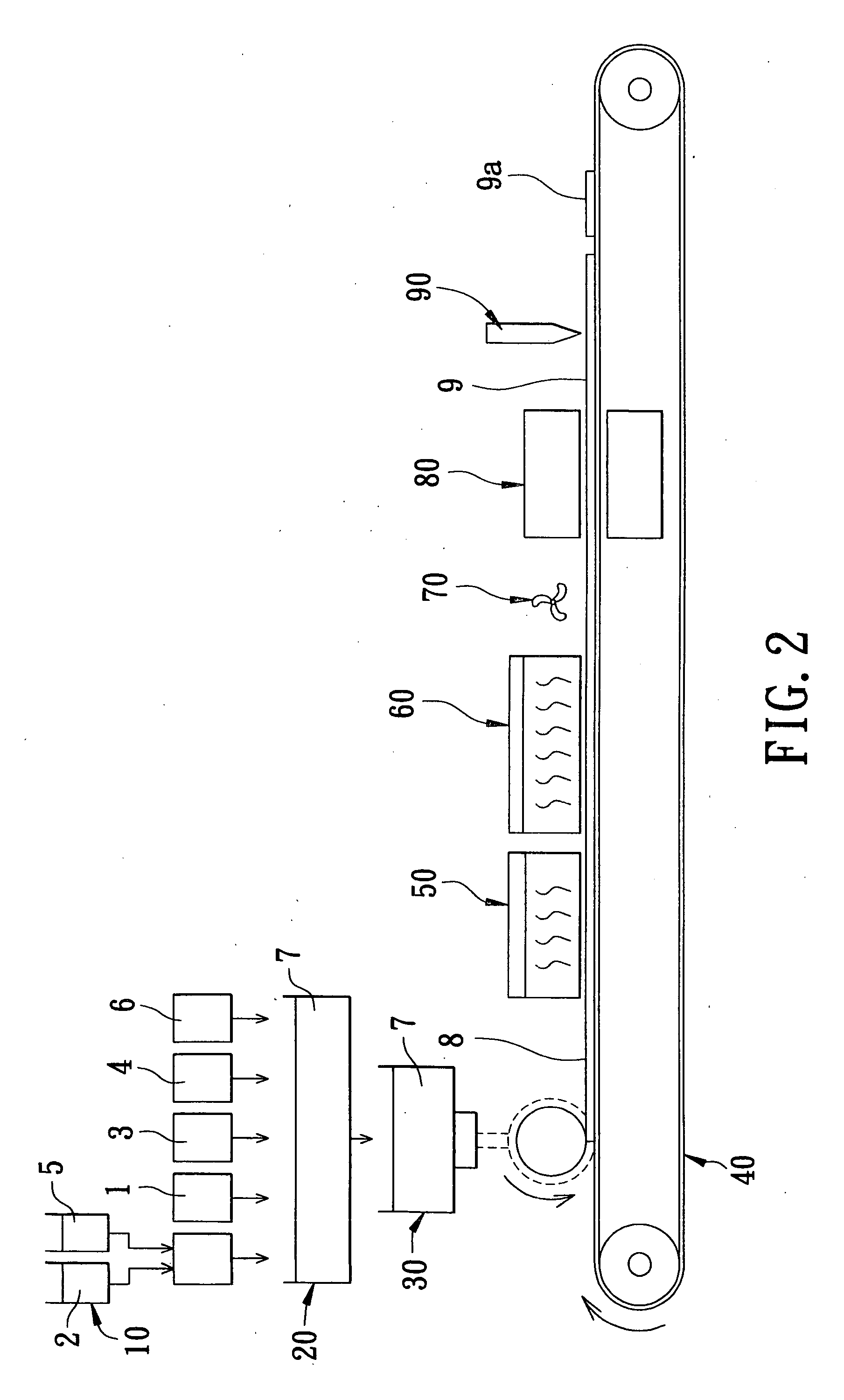

Method for manufacturing foam pads

ActiveUS20070069410A1Improve fatigue resistanceSlow forceSemi-permeable membranesInsolesFoaming agentPulp and paper industry

A method for manufacturing foam pads includes a first step of preparing a proper amount of PVC power, DOP curing agent, light calcium carbonate, kaolin, foaming agent and pigment and pouring them into a blending device to be blended and form a liquid starchy material. Next, the liquid starchy material is conveyed into an intermediate material barrel and kept stationary for pre-foaming at normal temperature for about 8 hours and then coated on a conveyer pelt to form a starchy material layer. Subsequently, the starchy material layer is kept stationary and heated at 80-90° C. for about 3-10 minutes and then continuously heated at 185-200° C. for about 20-30 minutes to form an integral-sheeted foam pad. After cooled, the integral-sheeted foam pad is thermo-compressed and cut into various foam pad products.

Owner:UNION LOOPER

Marine craft

Marine craft has a crushable frontal impact protection structure, comprising transverse bulkhead protecting passenger area; longitudinal crushable tubes; and transverse member. Webs and strengthen tubes, which may be made of extruded, heat treated aluminum; stainless steel; or plastic. Tubes in FIGS. 5 to 7 are splayed, to improve protection against angled impacts C. The forward ends of tubes are tapered, (FIG. 3) to initiate deformation. Tubes may be hexagonal, round, or oval in cross-section. FIG. 8 shows longitudinal bulkheads, and transverse bulkhead in place of tubes. FIG. 9 shows longitudinal corrugated sheets; these may be mounted transversely. FIG. 10 shows how area filled with deformable cellular foam, to act as a buoyancy aid if hull is breached. Side and roar impact protection is also disclosed.

Owner:GIBBS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com