Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Simplify job difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum plate surface treatment technology

ActiveCN107201525AEasy to operateSimplify job difficultyDrying machines with non-progressive movementsDrying solid materialsTime rangeStrong acids

The invention provides an aluminum plate surface treatment technology. The aluminum plate surface treatment technology solves the technical problems that in an existing treatment technology, strong acid and strong base need to be used, safety accidents are likely to happen, and the treating dangerousness is high. The aluminum plate surface treatment technology comprises the following steps that a, the surface of an aluminum plate is leveled; b, the aluminum plate is placed in water in which a degreased oil removal agent is added, the water temperature ranges from 40 DEG C to 60 DEG C, vibration cleaning is conducted, and the number of cleaning times ranges from 2 to 3; c, the aluminum plate is immersed in alkaline liquor, the temperature of the alkaline liquor ranges from 60 DEG C to 70 DEG C, and the immersing time ranges from 1 min to 3 min; d, the aluminum plate is washed; e, the aluminum plate is immersed in a weak acid solution at the temperature ranging from 40 DEG C to 55 DEG C for 2-4 min, wherein the weak acid solution comprises following raw materials including, by weight, 30-40 parts of diluted hydrochloric acid, 15-30 parts of butanoic anhydride, 4-8 parts of ammonium bifluoride, 2-4 parts of boric acid and 2-3 parts of diammonium hydrogen phosphate; f, the aluminum plate is subjected to spraying and washing, and the weak acid solution on the surface of the aluminum plate is removed; and g, the aluminum plate is dried through a drying system, the drying temperature ranges from 80 DEG C to 120 DEG C, and the drying time ranges from 8 min to 12 min. The aluminum plate surface treatment technology has the beneficial effect of being safe in treatment.

Owner:重庆哈韦斯特铝业有限公司

Acoustic material manufacturing method

ActiveCN107160539AEasy to operateSimplify job difficultyAntifouling/underwater paintsPaints with biocidesFiberGlass fiber

The invention provides an acoustic material manufacturing method, and solves such technical problems as no corresponding manufacturing method for a traditional acoustic material, need of manufacturing by dint of experiences and complicated manufacturing. The acoustic material manufacturing method comprises the following steps: (a) the following raw materials are weighed in parts by weight: 14-20 parts of cotton fibers, 6-7 parts of glass fibers, 10-14 parts of aluminum fibers, 8-12 parts of gypsum powder, 6-9 parts of asbestos powder, 3-10 parts of wood fibers, 2-6 parts of nanocarbon, 3-5 parts of magnesium oxide, and 1-3 parts of antiaging agent; (b) the raw materials are poured in a stirring machine to prepare a mixture; the stirring time is 5-15 min; and the stirring speed is 150-350 r / min; (c) the mixture is hot pressed as a strip-shaped plate; and the thickness of the strip-shaped plate is 60-120 mm; (d) protective liquid is sprayed to the surface of the strip-shaped plate through spraying equipment; a drying system is used for drying; the drying temperature is 40-60 DEG C; and the drying time is 15-25 min; and (e) the strip-shaped plate is cut as a needed shape to obtain an acoustic material. The acoustic material manufacturing method has the advantage of convenience in manufacturing.

Owner:卓后桥

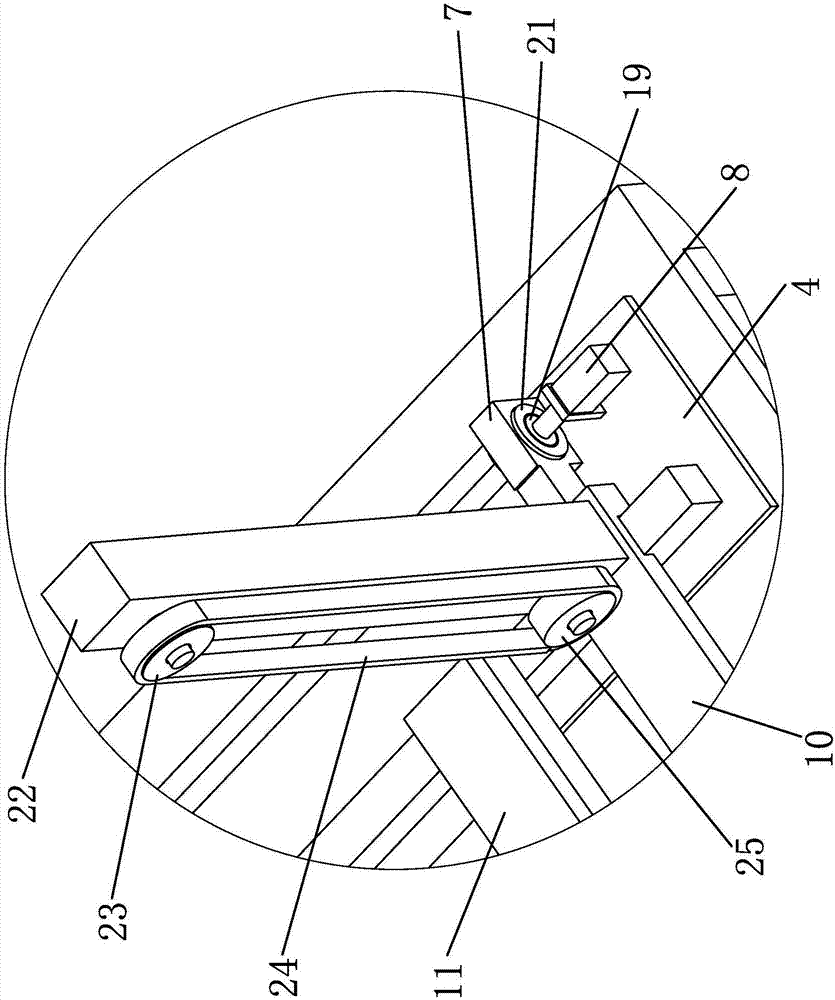

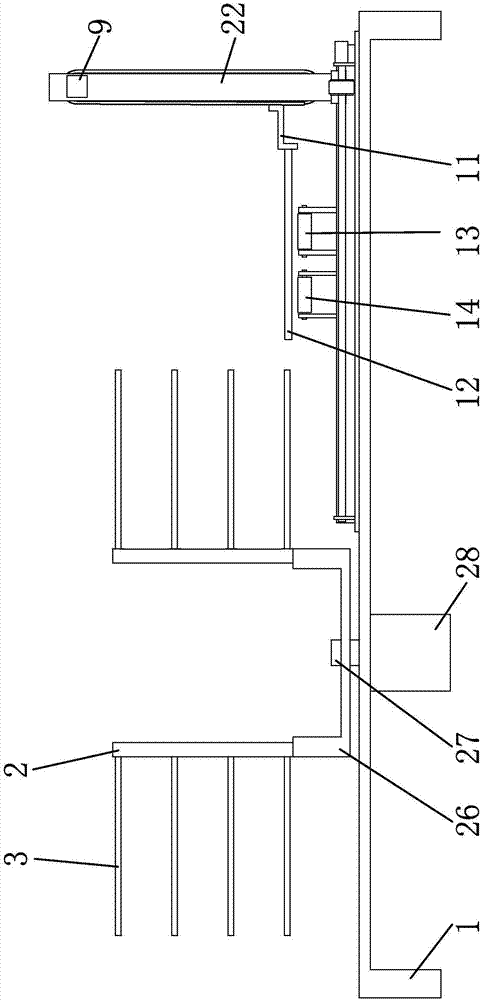

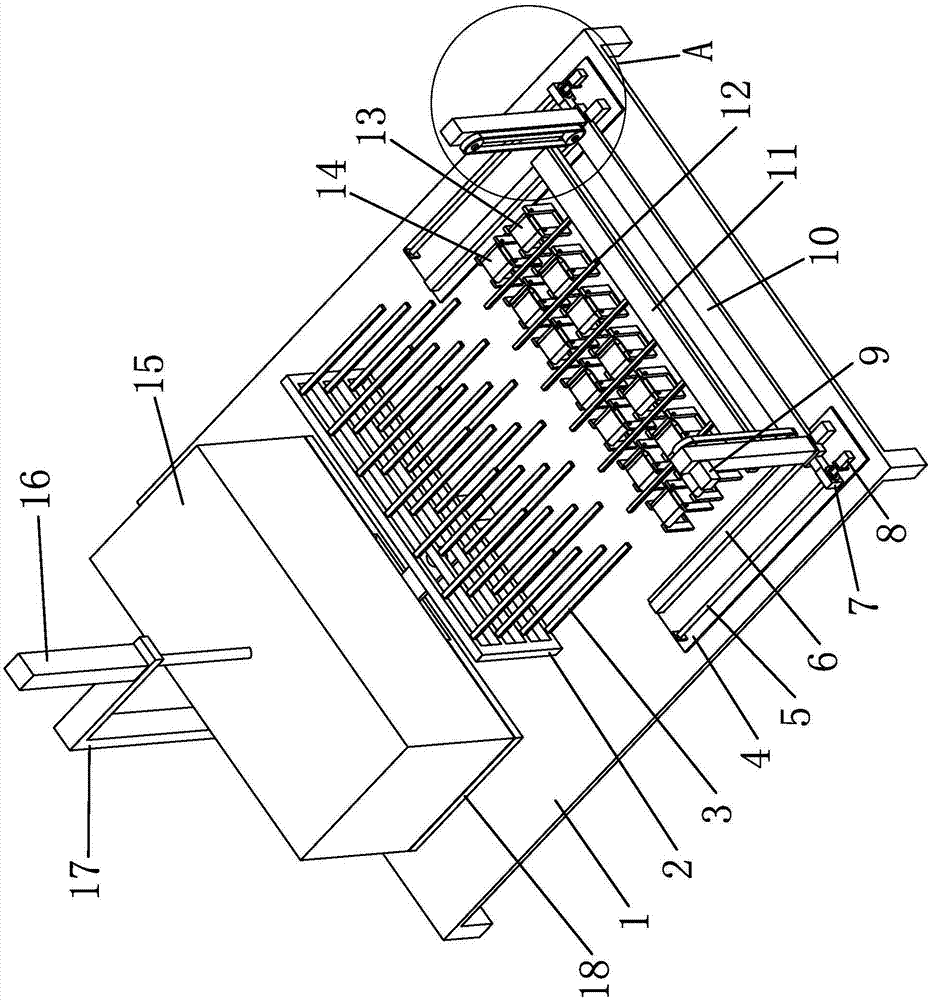

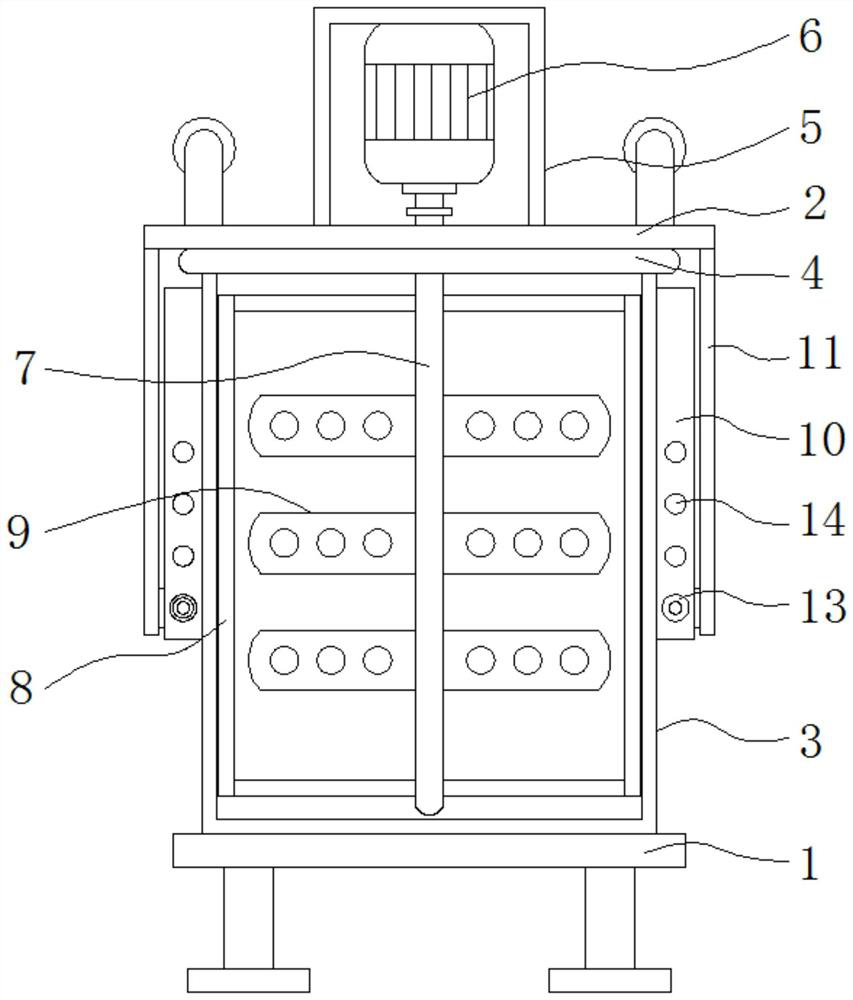

AOI detection method and system

InactiveCN110160959AImprove detection efficiencyOvercoming the technical problem of low detection efficiencyOptically investigating flaws/contaminationConveyor partsJob difficultiesAssembly line

The invention discloses an AOI detection method and system. The AOI detection system comprises a first positioning device, a first feed mechanism, a first AOI detection mechanism, a first blanking mechanism, an overturning mechanism, a second positioning device, a second feed mechanism, a second AOI detection mechanism and a second blanking mechanism which are arranged in order; the AOI detectionis performed on two surfaces of a circuit board in order, thereby realizing the assembly line AOI detection way; due to the work division, the job difficulty is simplified, the job degree of proficiency is easy to improve, and partial internal time is converted into external time, the AOI detection efficiency is effectively improved, and the maximum capacity is improved. The technical problem thatthe AOD detection efficiency is low in the prior art is overcome; and the AOI detection method effectively improves the AOI detection efficiency through the assembly line type AOI detection flow.

Owner:深圳明阳电路科技股份有限公司

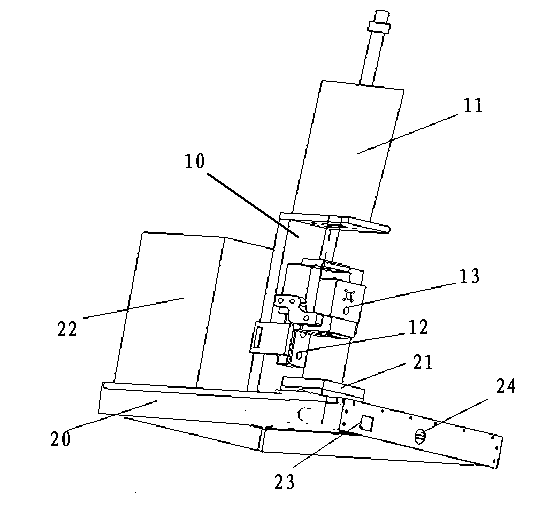

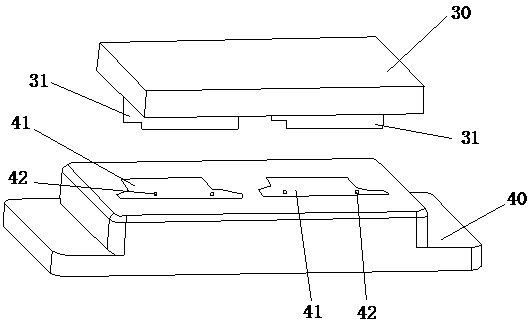

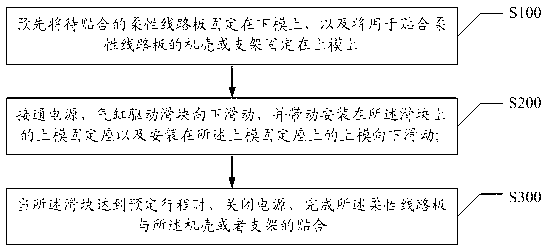

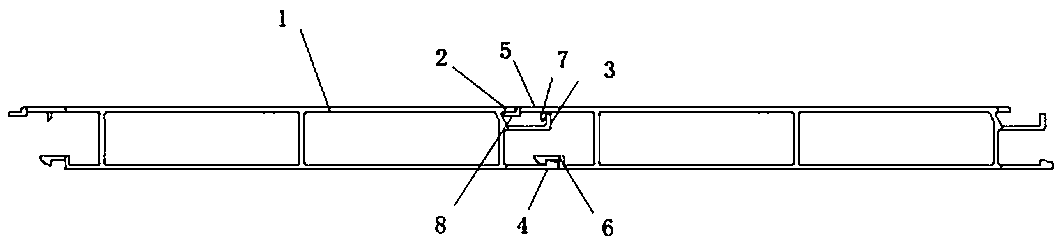

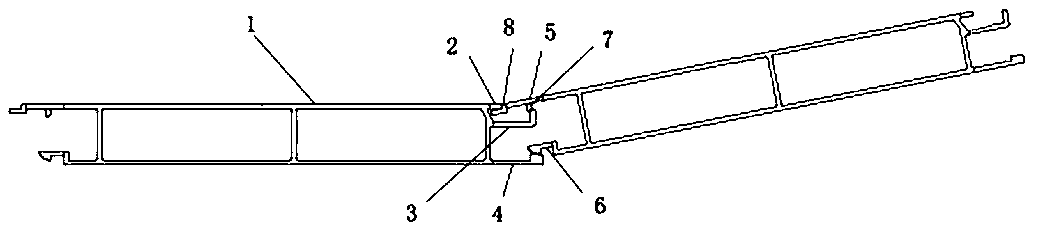

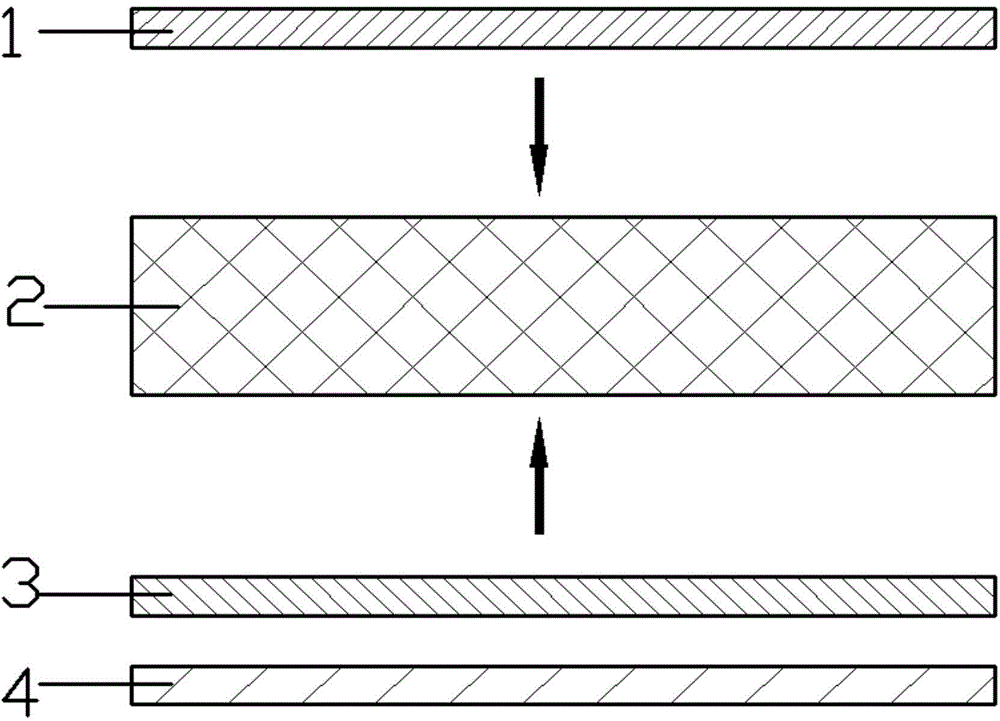

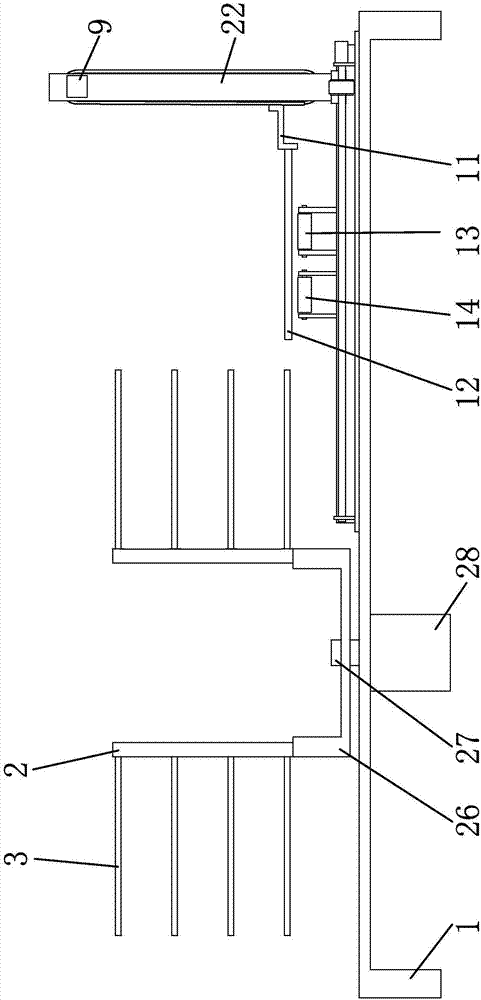

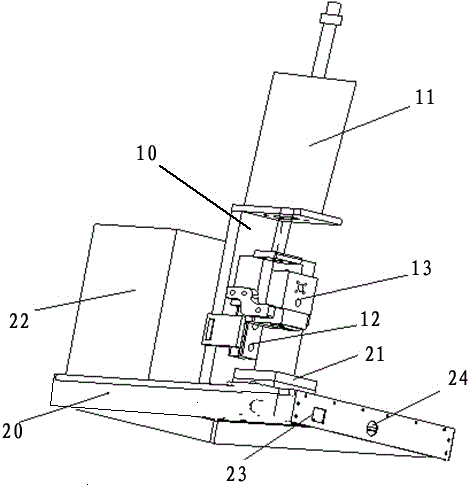

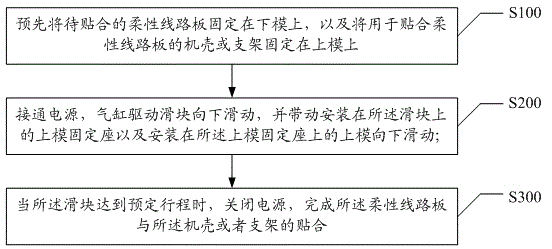

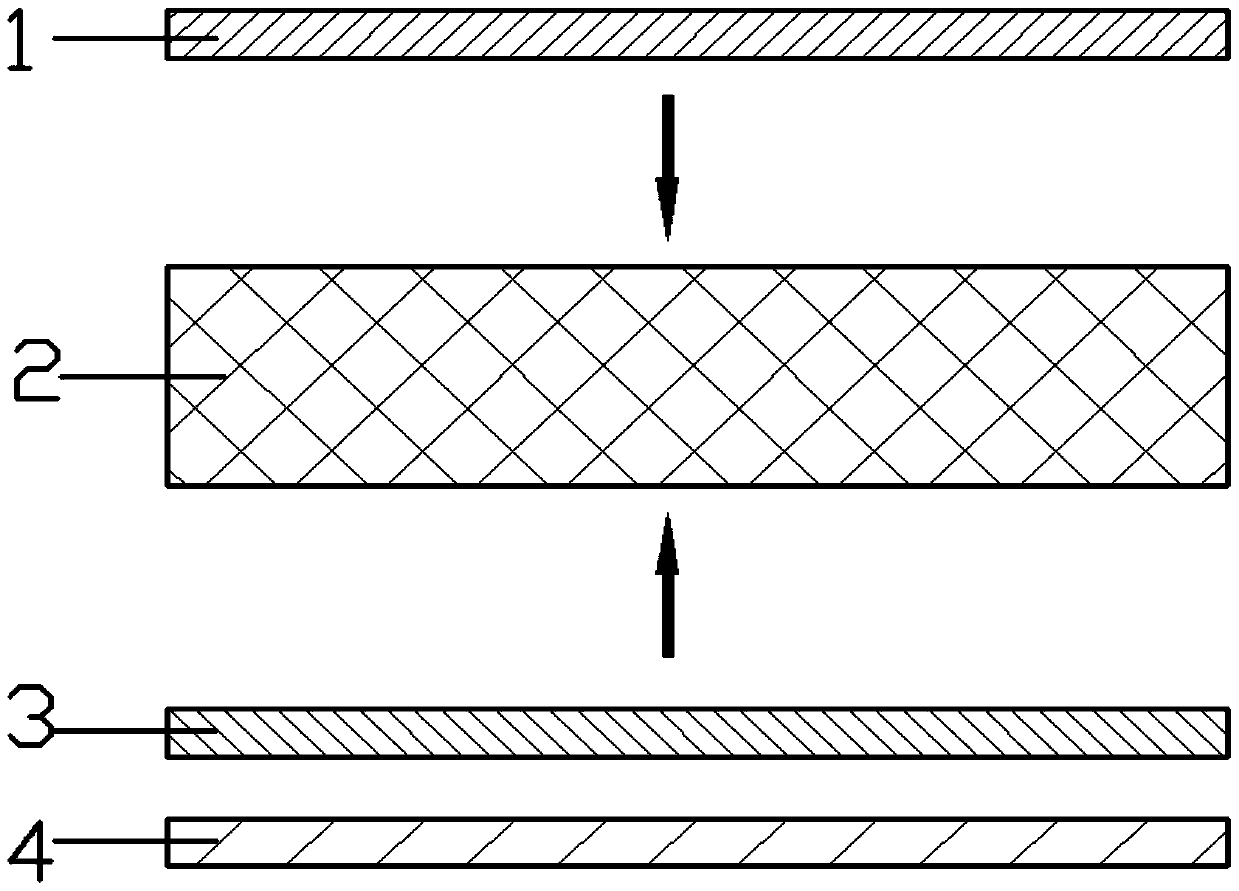

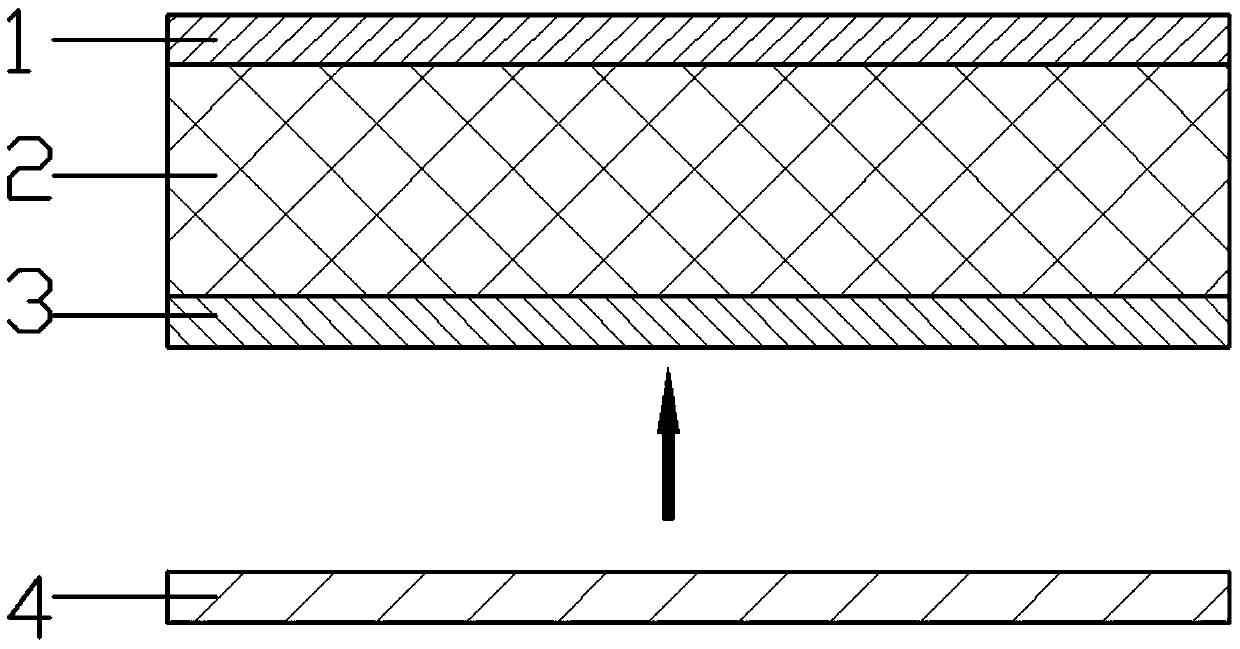

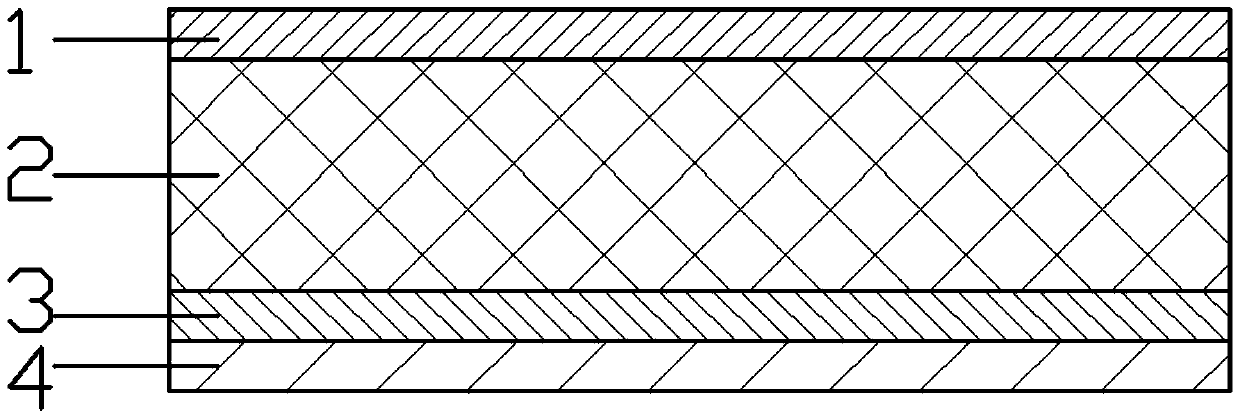

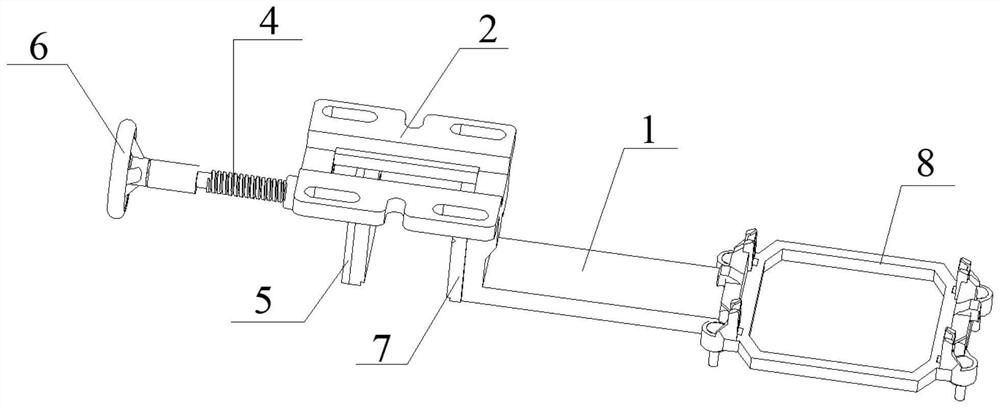

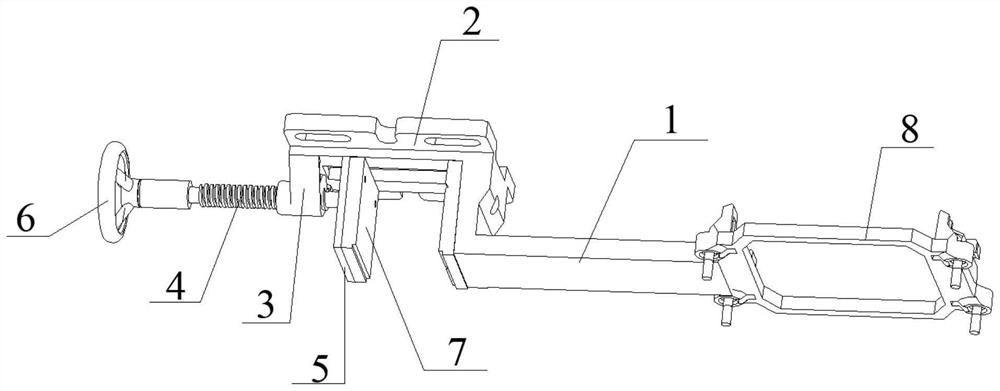

Flexible circuit board bonding device and method for bonding flexible circuit board

ActiveCN103025076AAvoid stickinessSimplify job difficultyPrinted circuit assemblingFlexible circuitsEngineering

The invention discloses a flexible circuit board bonding device and a method for bonding a flexible circuit board. The flexible circuit board bonding device comprises a vertical support, a base, a sliding block capable of sliding vertically on the vertical support, an upper mould fixing seat installed on the sliding block, a cylinder installed on the vertical support and used for driving the sliding block to slide vertically, a lower mould fixing seat installed on the base and a module. The module comprises a lower mould for fixing the flexible circuit board and an upper mould for fixing a machine casing or the support, the upper mould is installed on the upper mould fixing seat, and the lower mould is installed on the lower mould fixing seat. The flexible circuit board bonding device replaces the traditional mode of manually bonding the flexible circuit board, and is high in production efficiency, high in product consistency, low in manufacture cost and strong in practicability.

Owner:SHENZHEN VLG WIRELESS TECH

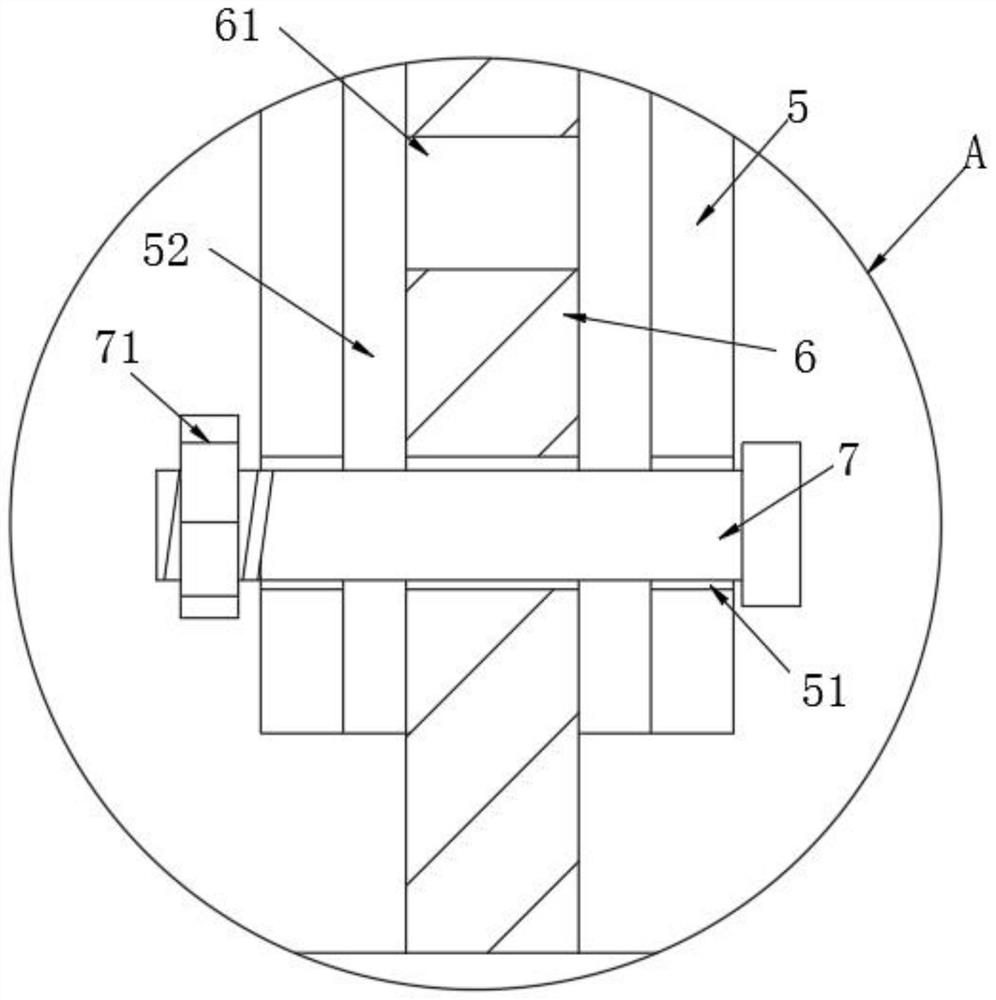

Lever type buckling assembly carriage plate

PendingCN110937029AImprove the limit effectSimplify job difficultyLoading-carrying vehicle superstructuresClassical mechanicsCarriage

The invention discloses a lever type buckling assembly carriage plate. The carriage plate comprises a carriage bottom plate, a limiting plate, a first L-shaped plate, an upper clamping plate, a fixingplate and a second L-shaped plate. The limiting plate is fixed to the top of one side of the carriage bottom plate. The first L-shaped plate is fixed to the middle of the side, provided with the limiting plate, of the carriage bottom plate. A lower clamping plate is fixed to the side face of the carriage bottom plate and located below the first L-shaped plate, a connecting plate is fixed to the top of the other side of the carriage bottom plate, a second L-shaped plate matched with the limiting plate is fixed to the end, away from the carriage bottom plate, of the connecting plate, and a fixing plate matched with the first L-shaped plate is fixed to the middle of the bottom of the connecting plate. By means of the lever principle, when buckling and pressing fit is conducted, workers do not need to apply too large force, on-site assembling operation can be achieved, assembling of the device is irreversible (cannot be normally disassembled), fastening machining links such as bolt locking do not need to be conducted any more, the operation difficulty is simplified, and the efficiency is improved.

Owner:GUANGDONG HAOMEI ALUMINUM

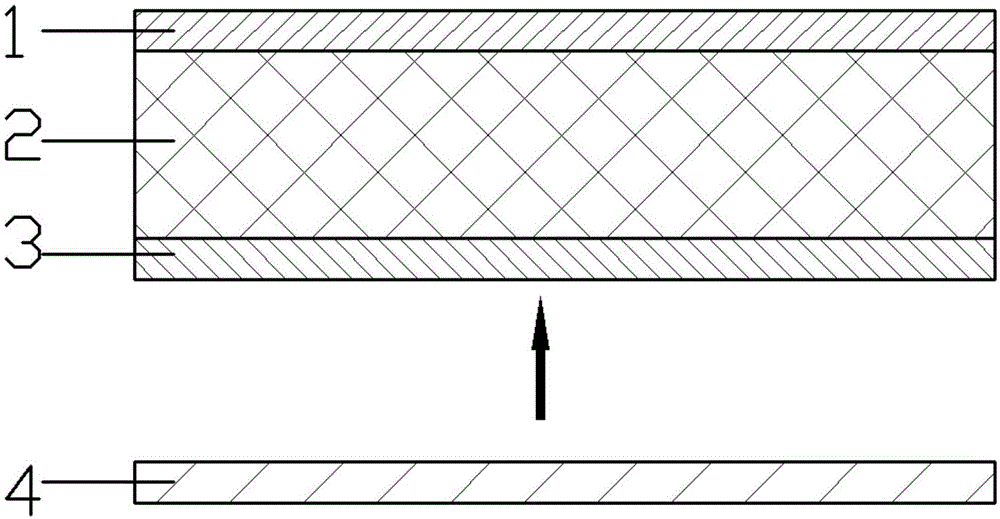

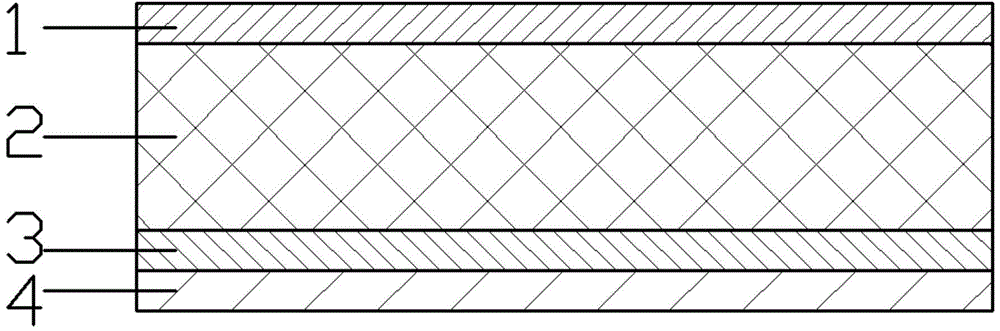

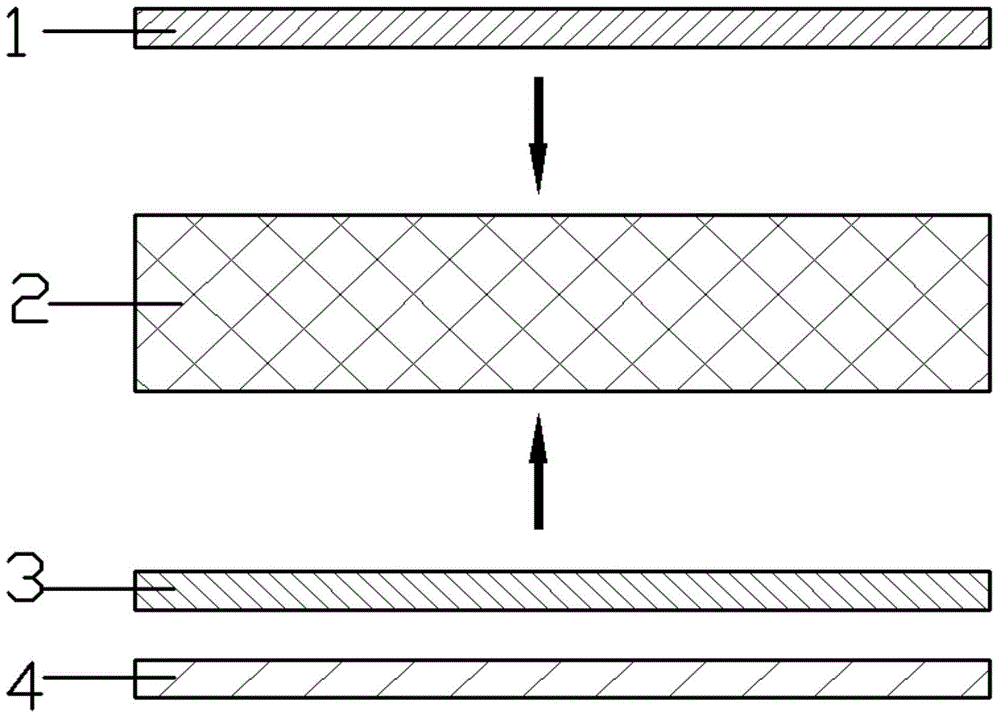

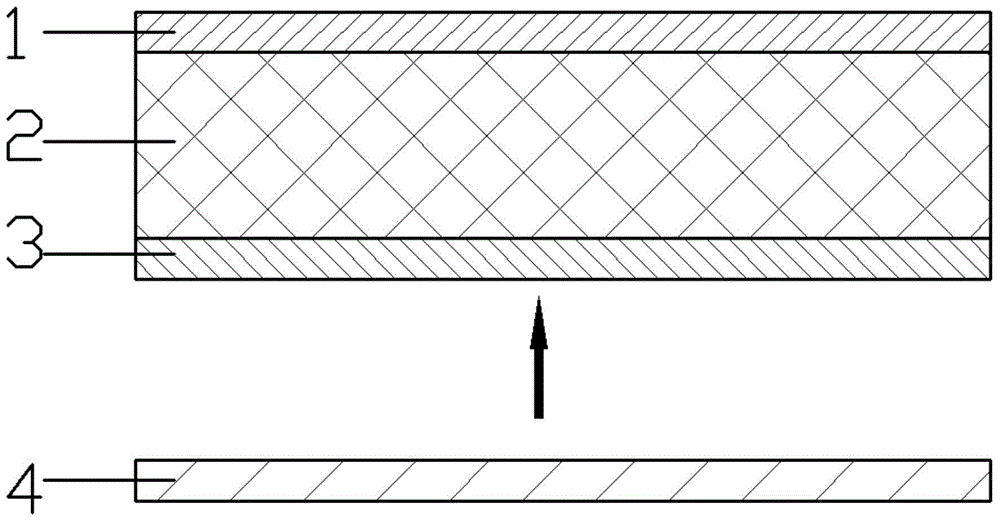

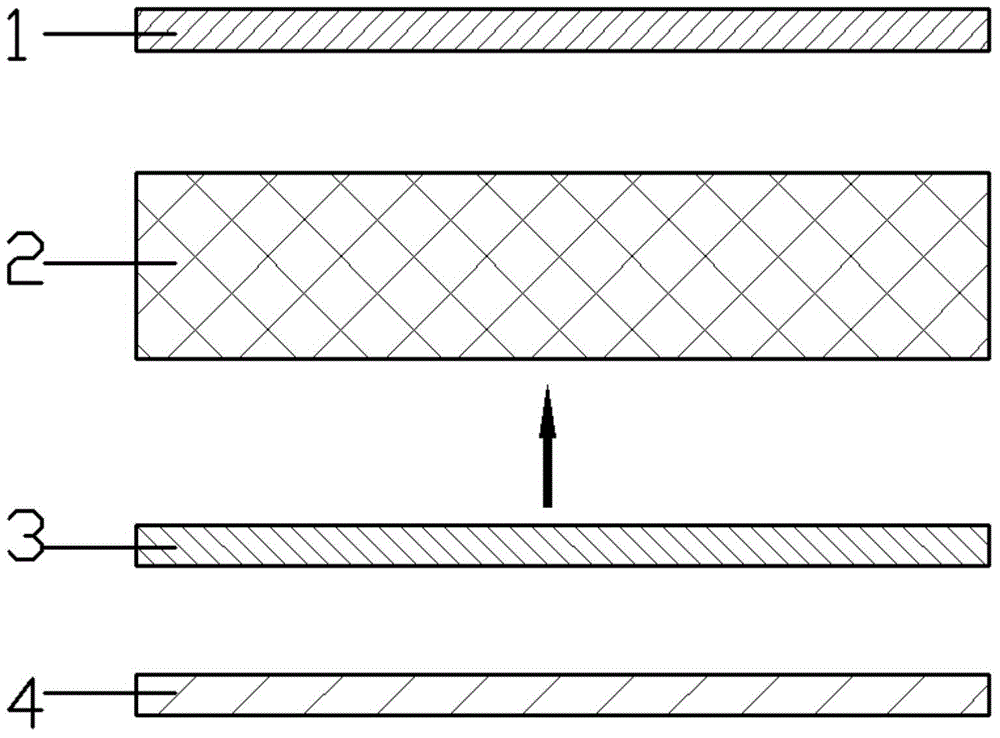

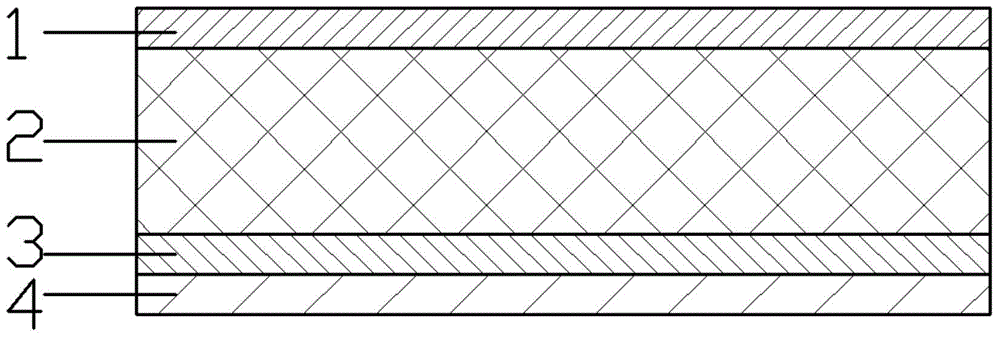

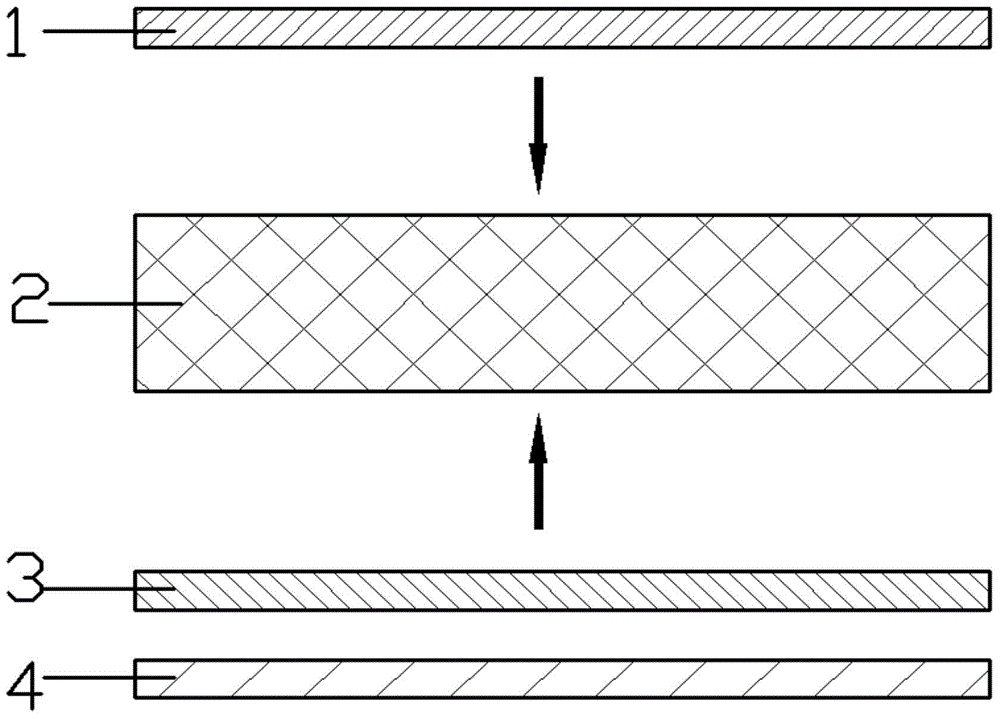

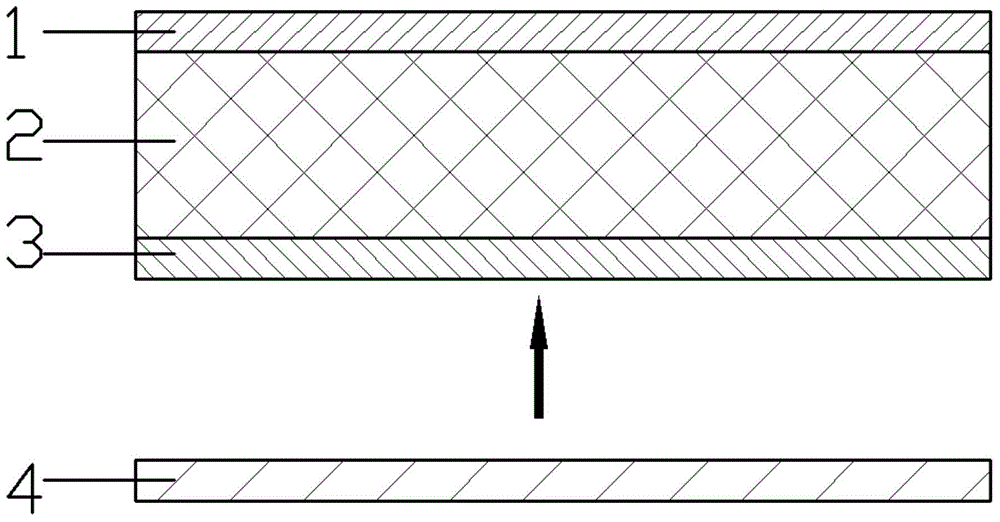

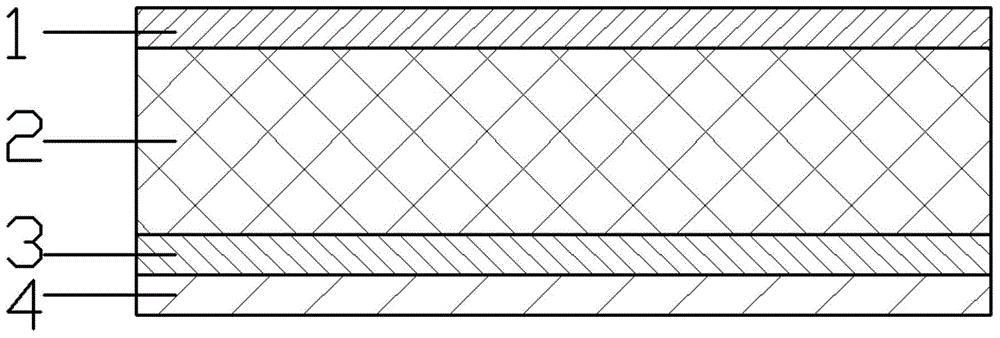

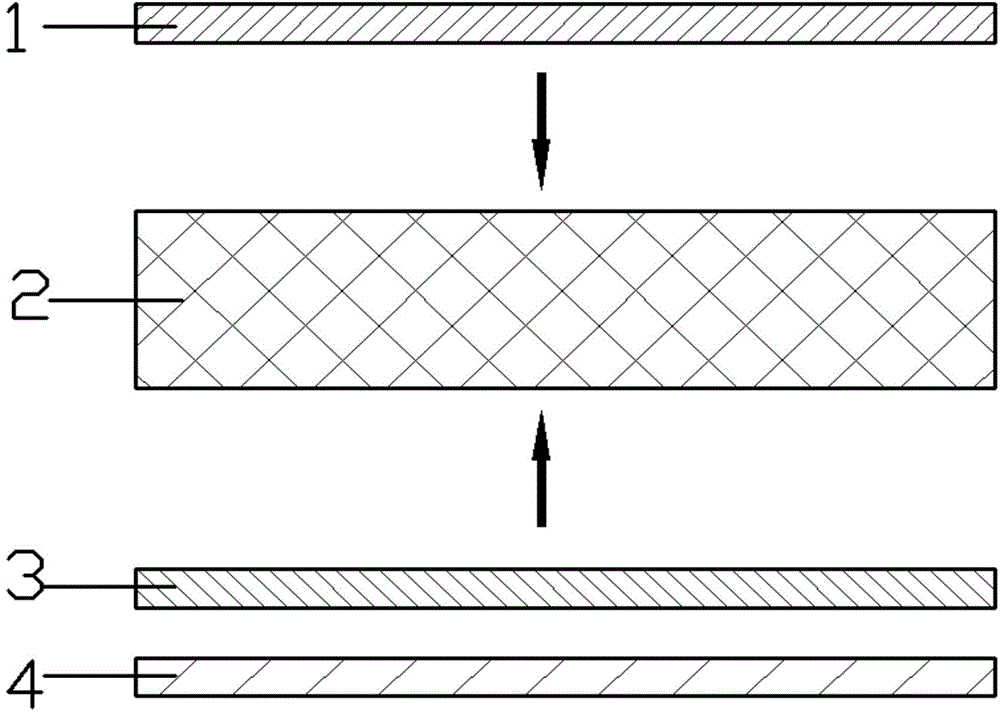

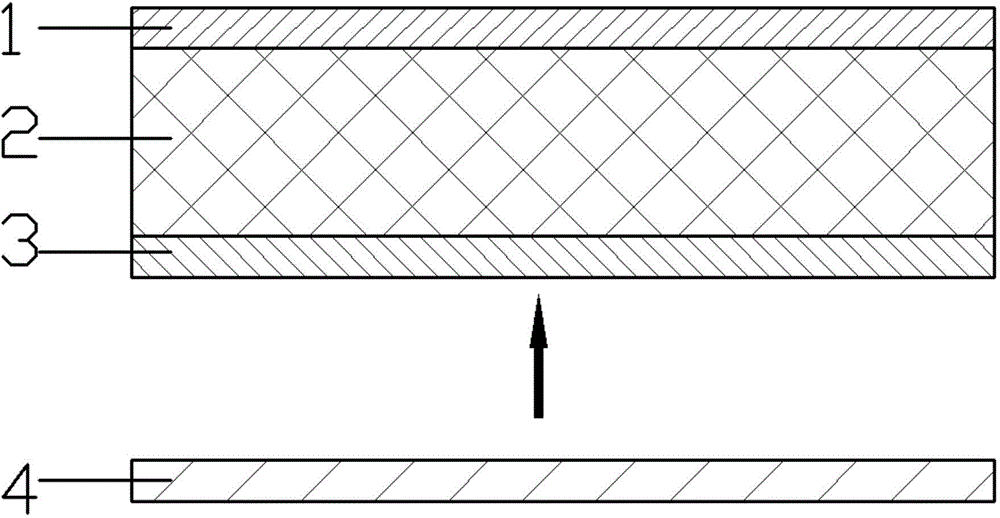

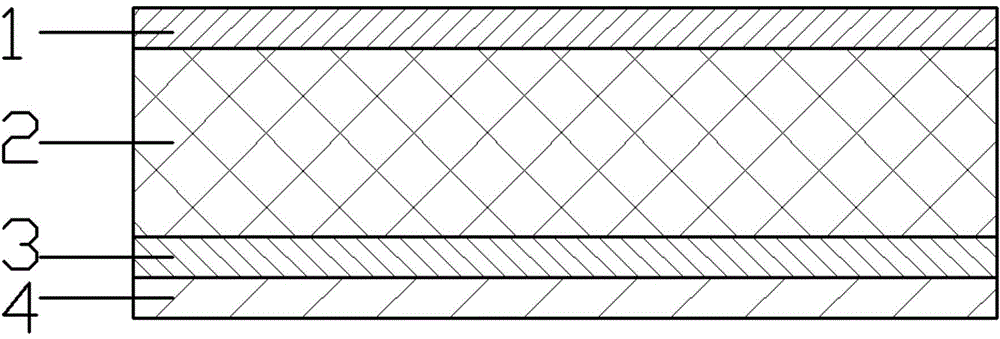

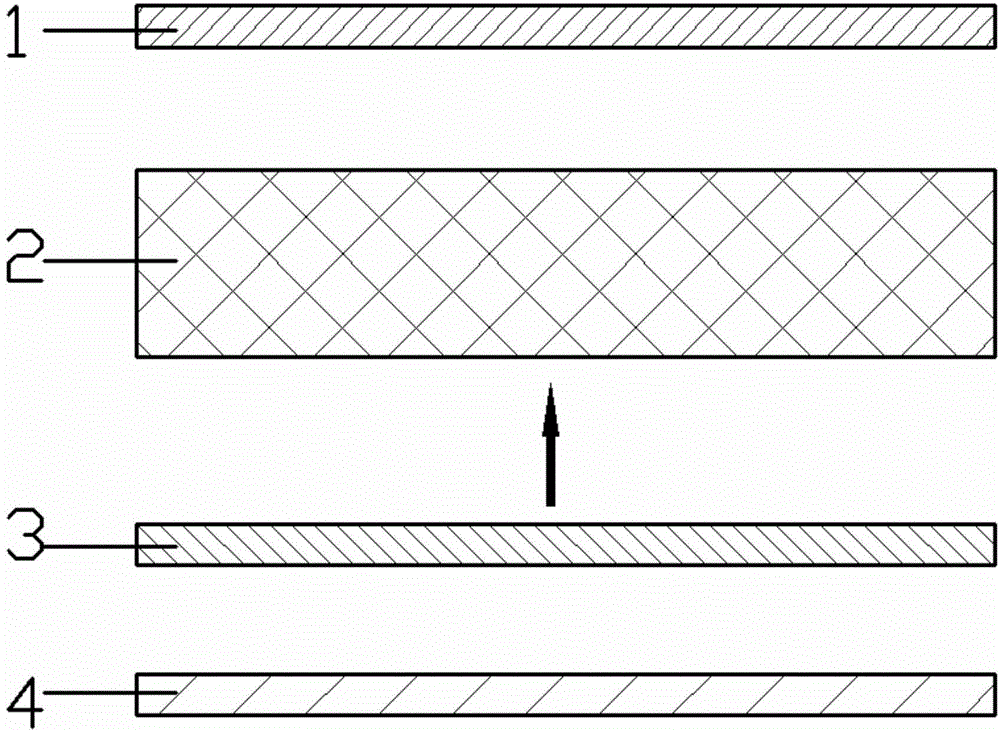

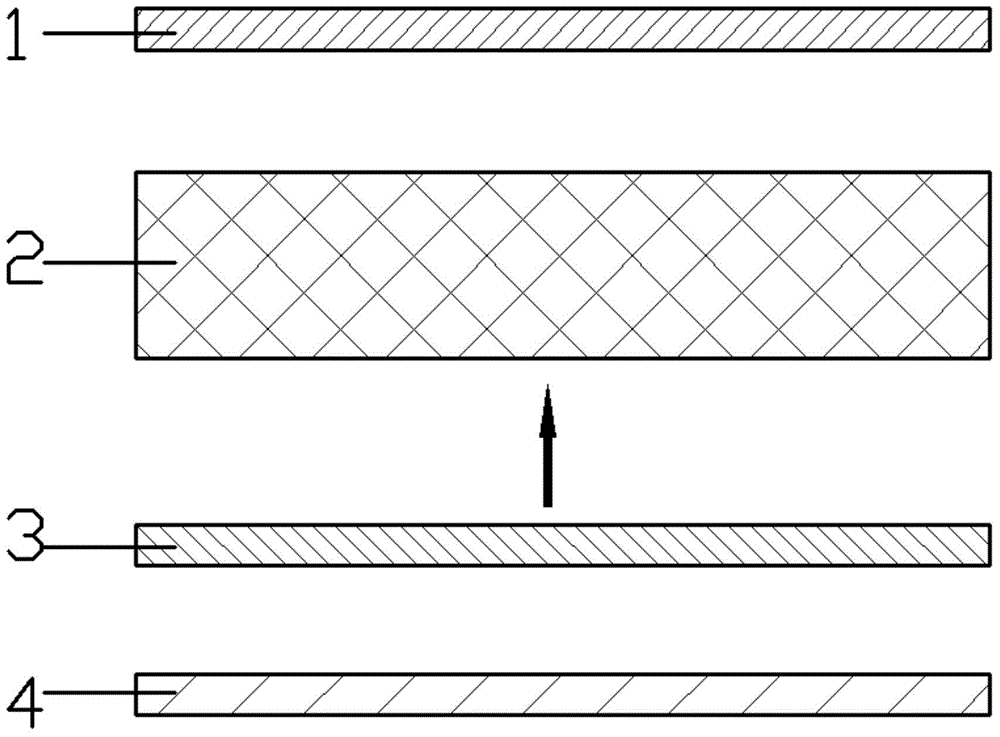

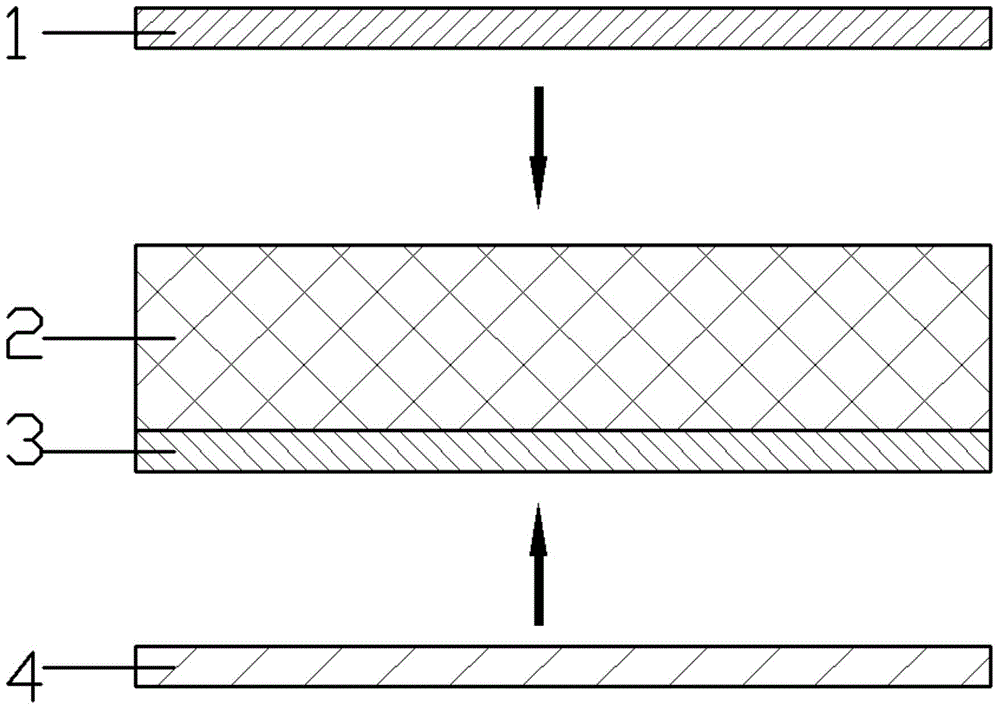

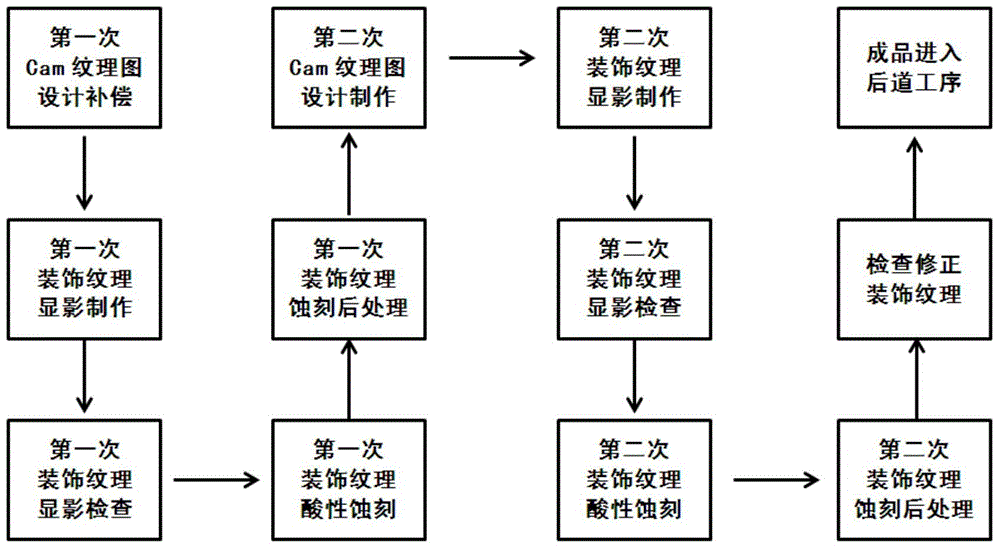

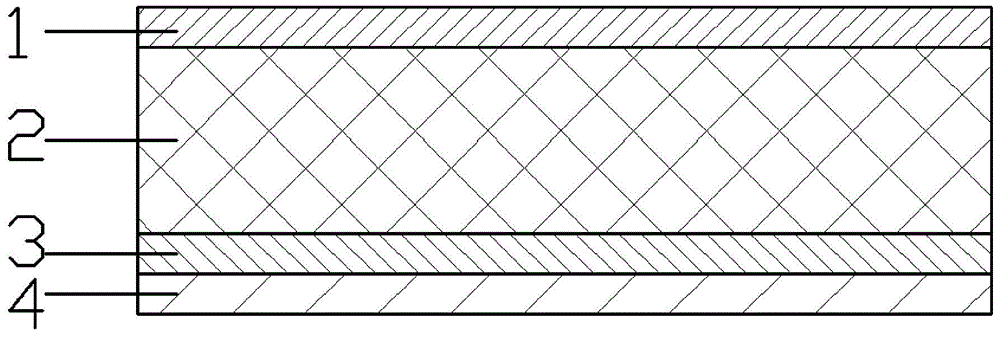

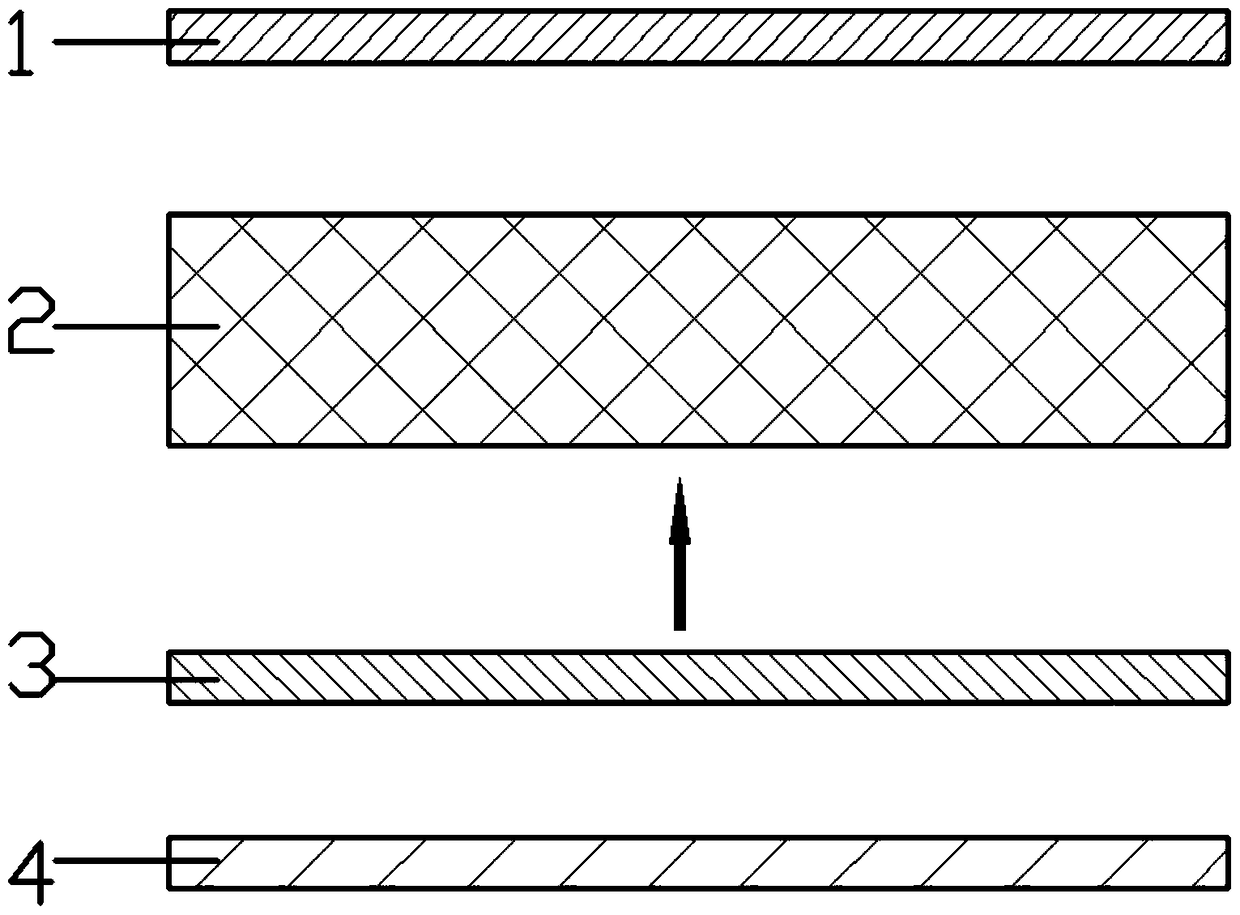

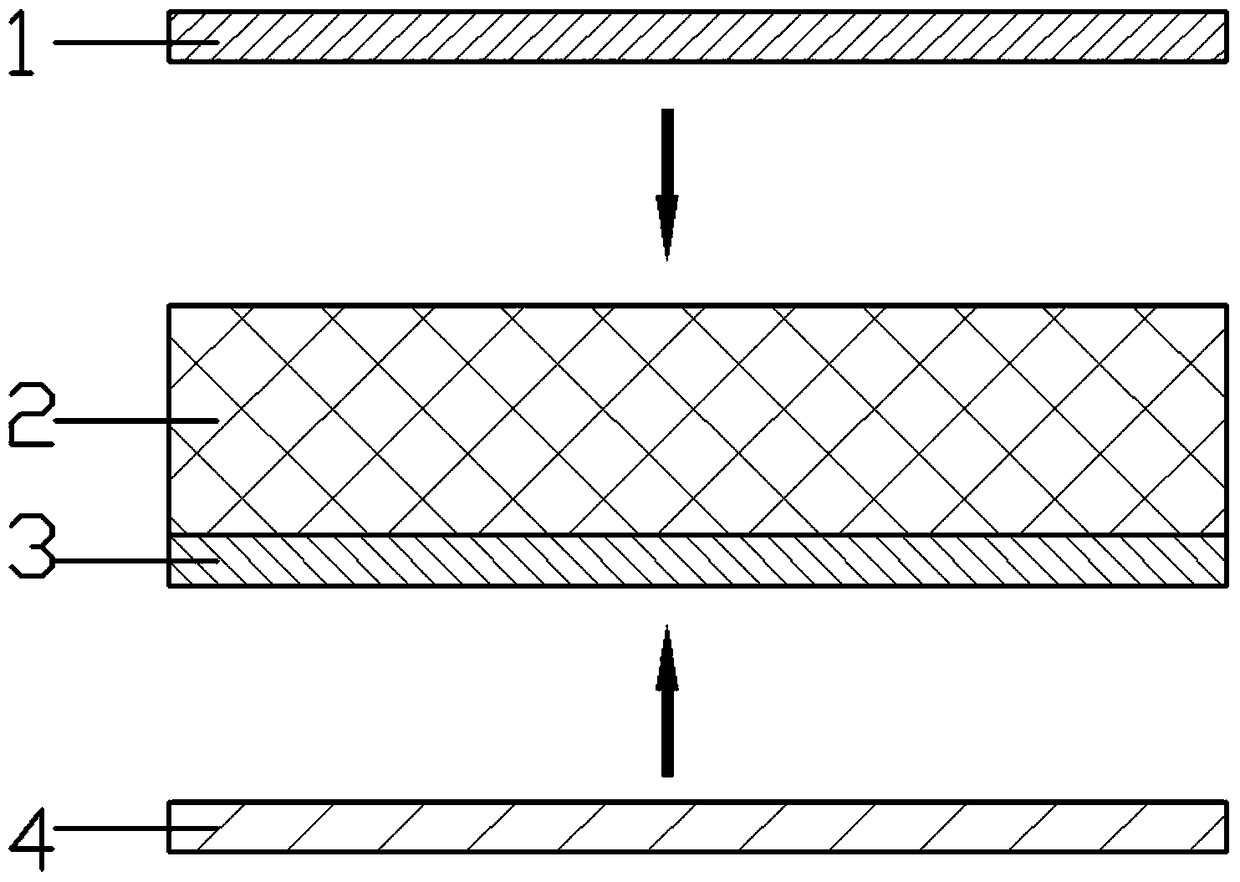

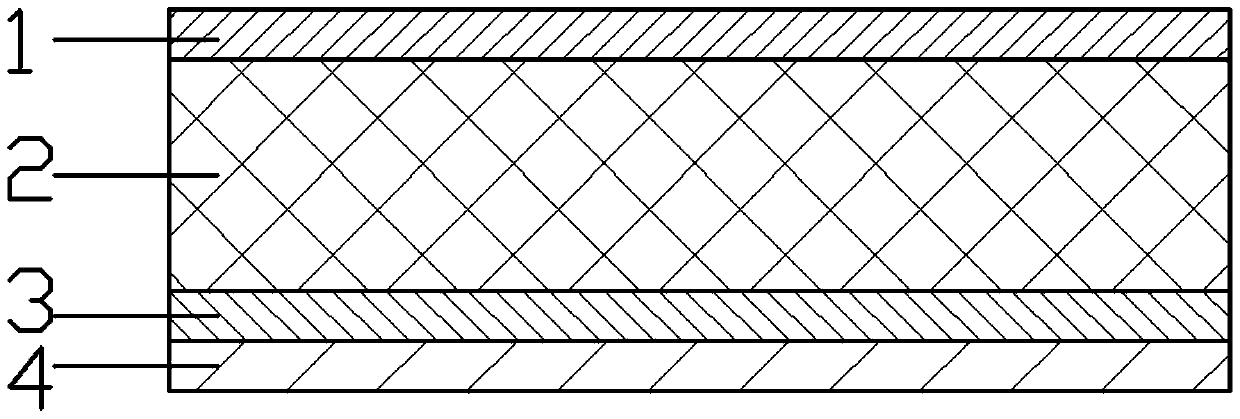

Double-sided textured multilayer metal texture interlaced decorative sheet and production process thereof

InactiveCN104589885AReduce generationReduce manufacturing costDecorative surface effectsSpecial ornamental structuresEtchingCam

The invention discloses a double-sided textured multilayer metal texture interlaced decorative sheet and a production process thereof. The double-sided metal texture interlaced decorative sheet comprises a first side texture, a transparent insulating plastic layer and a second side step surface texture, wherein the second side step surface texture comprises a second side inner texture and a second side outer texture; the first side texture and the second side inner texture are simultaneously connected with the transparent insulating plastic layer; the second side outer texture covers the second side inner texture. The production process of the double-sided textured multilayer metal texture interlaced decorative sheet also comprises the following operating steps: first texture making, texture developing and cam compensating, texture checking, etching, second texture making, texture developing and cam compensating, texture checking, etching, texture checking and subsequent procedure performing. The double-sided textured multilayer metal texture interlaced decorative sheet and the production process have the beneficial effects that twice making is only needed, so that the input is low; the production flow and the operation difficulty are simplified, thus improving the production efficiency, reducing the production cost, reducing the reject ratio of the product and shortening the production cycle of the product.

Owner:SUZHOU ZZH INTPROP SERVICES

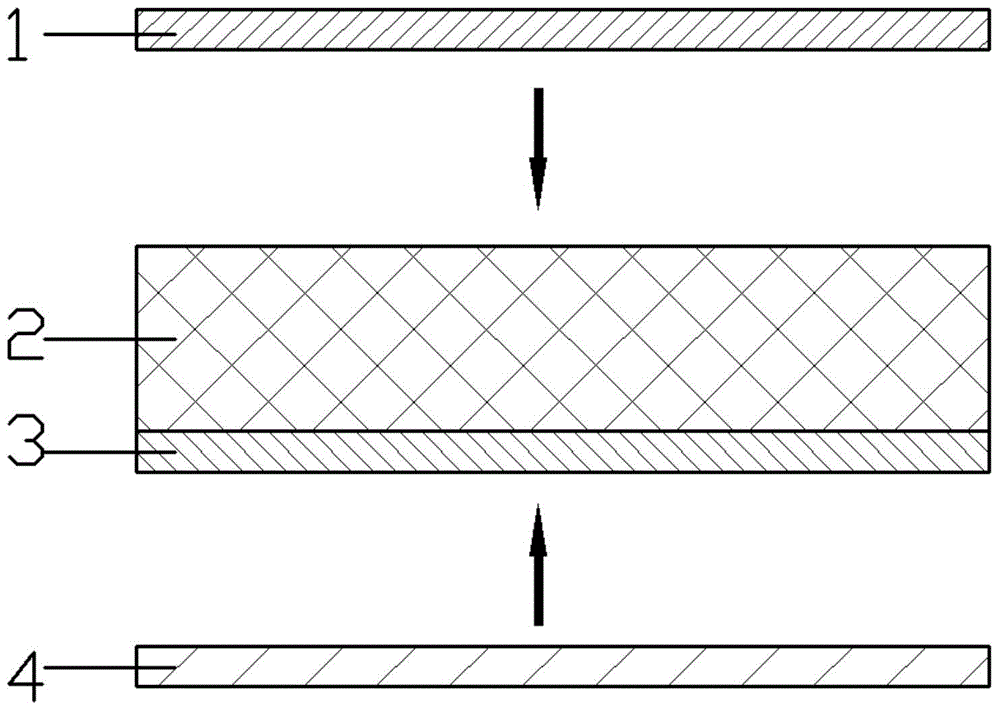

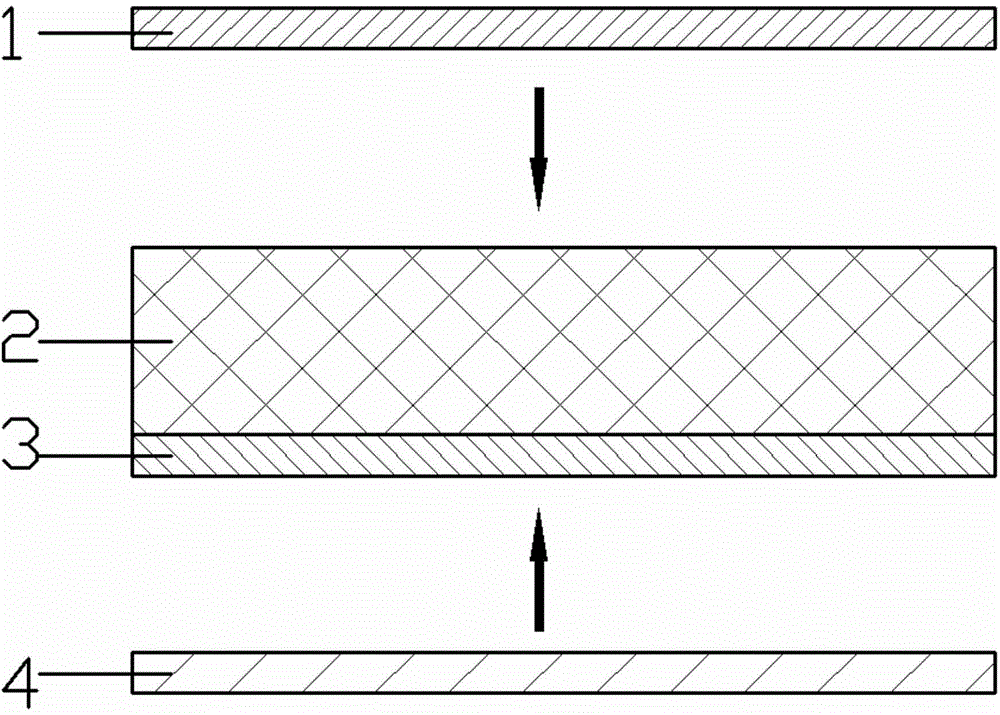

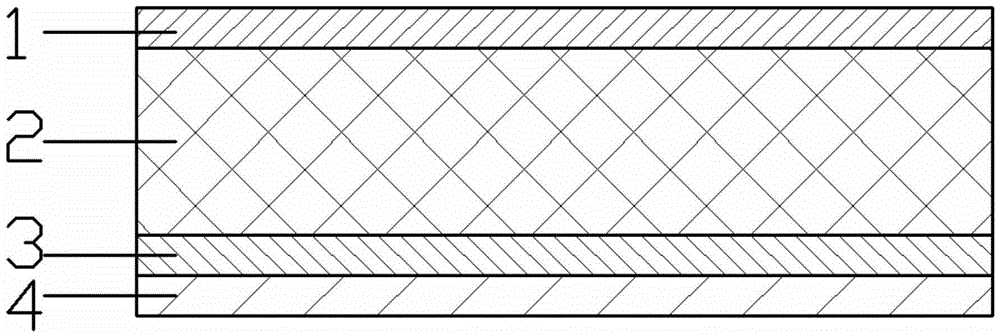

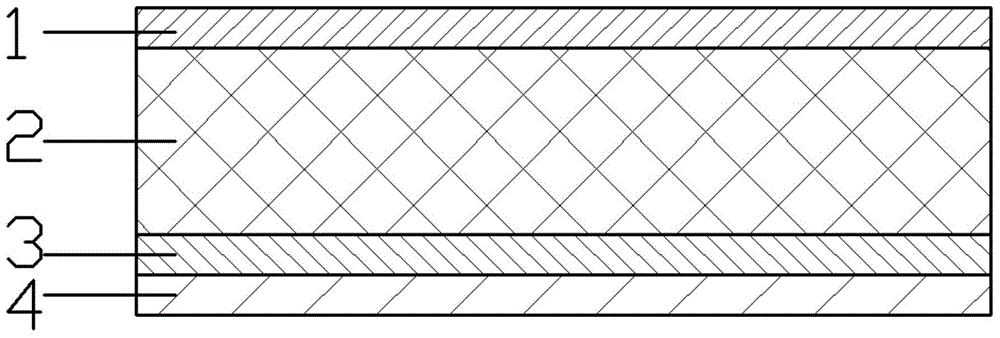

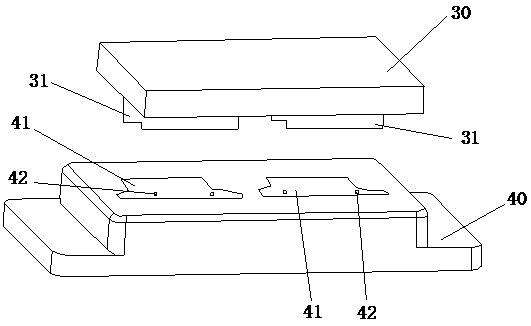

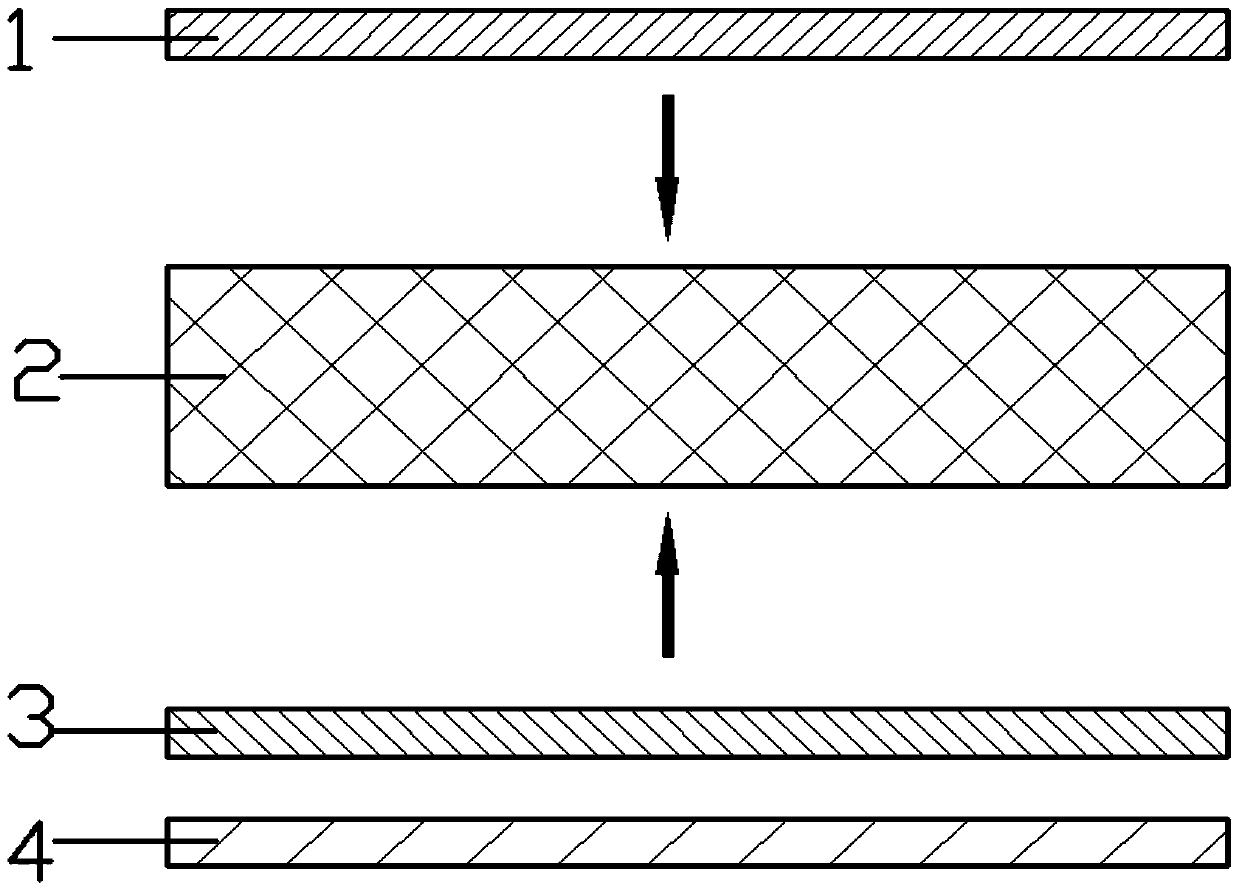

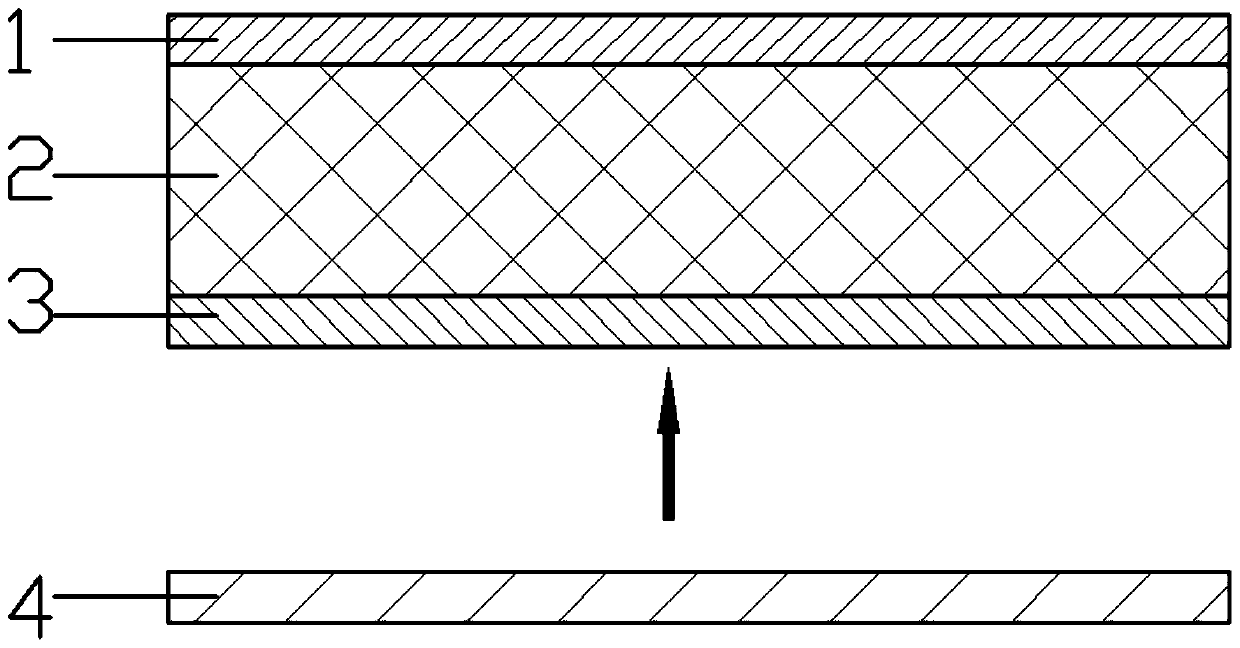

Secondary-etching double-sided circuit board and processing technology thereof

ActiveCN105578707AReduce generationReduce production, greatly reduce PCB production costPrinted circuit detailsConductive material chemical/electrolytical removalElectricityEtching

The invention discloses a secondary-etching double-sided circuit board and a processing technology thereof. The secondary-etching double-sided circuit board comprises a GTL line layer, an insulation PP layer and a GBL step surface line layer. The GBL step surface line layer is formed by a GBL inner line layer and a GBL outer line layer. The GTL line layer and the GBL inner line layer are simultaneously connected to the insulation PP layer. The GBL outer line layer covers the GBL inner line layer. The secondary-etching double-sided circuit board processing technology comprises the following steps of first line making; line development cam compensation; line inspection; etching; second line making; line development cam compensation; line inspection; etching; open-short-circuit electric measurement; back-end processing. In the invention, second making is only needed, an investment is less, a production process and working difficulty are simplified, production efficiency is increased, production cost is reduced, a reject ratio of a product is decreased and a production period of the product is shortened.

Owner:苏州市三生电子有限公司

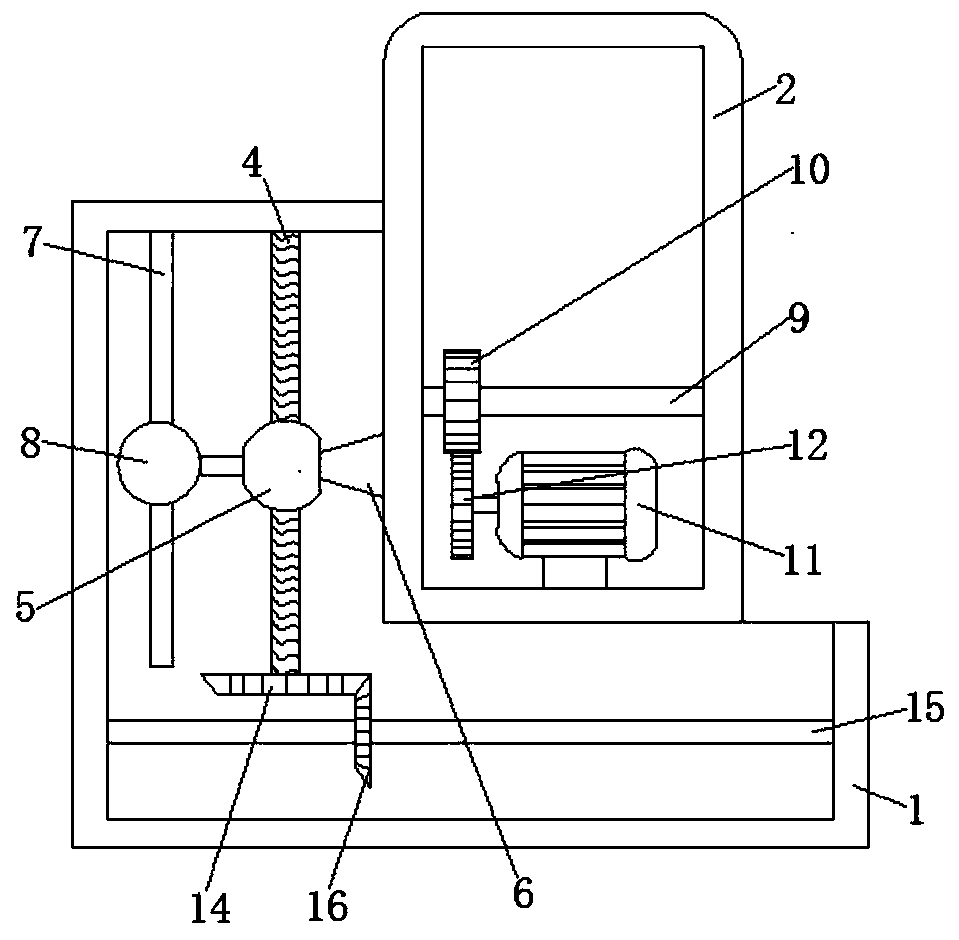

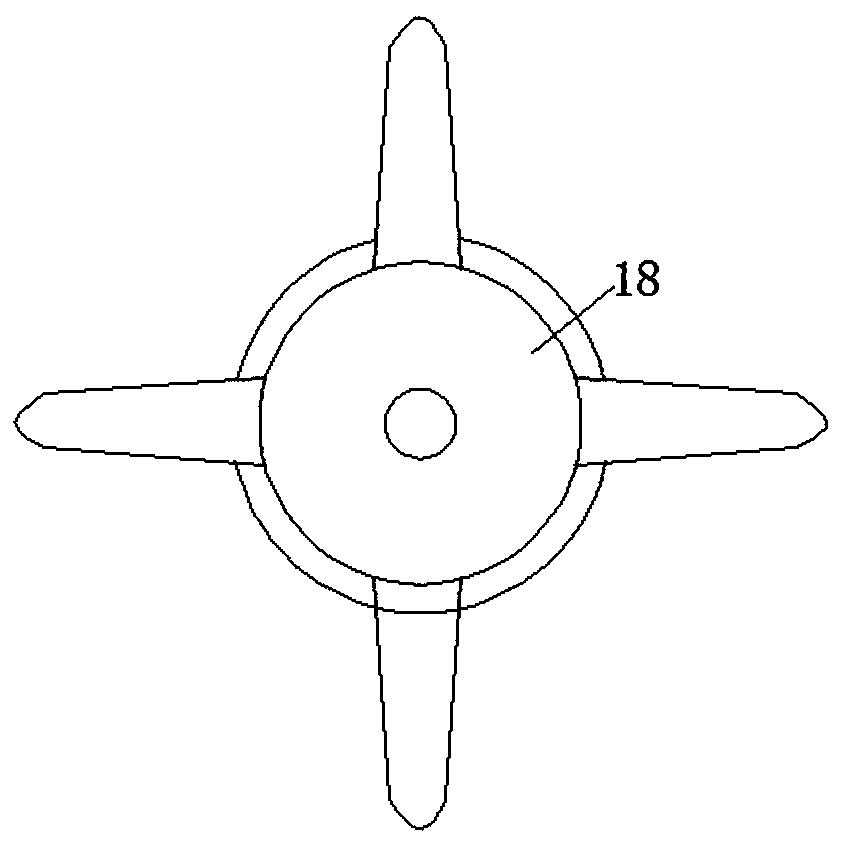

Manufacturing method for runner plate

ActiveCN107099765AEasy to operateSimplify job difficultyMolten spray coatingDrying solid materialsTime rangeBiochemical engineering

The invention provides a manufacturing method for a runner plate. The technical problems that the environment parameter requirement of the existing production technology is too high, environment parameters are easy to fluctuate, and the product quality consistency is poor are solved. The manufacturing method for the runner plate comprises the following steps that firstly, a base plate to be sprayed is placed in a cleaning tank, the interior of the cleaning tank is heated, the cleaning tank is inflated with air, and stirring is conducted, wherein the temperature of the interior of the cleaning tank ranges from 80 DEG C to 100 DEG C, and the cleaning time ranges from 2 min to 4 min; secondly, the base plate is immersed in acid oil removing liquid, and the oil removing time ranges from 1 min to 3 min; thirdly, the base plate is immersed in clean water, the cleaning temperature ranges from 40 DEG C to 50 DEG C, and the cleaning time ranges from 3 min to 5 min; fourthly, the base plate is dried through a drying system, the drying temperature ranges from 60 DEG C to 70 DEG C, and the drying time ranges from 6 min to 10 min; fifthly, the base plate is subjected to corona treatment; and sixthly, coating powder is sprayed to the surface of the base plate through a plasma spraying method, and the spraying thickness ranges from 0.5 mm to 0.8 mm. The manufacturing method has the beneficial effect of being high in product quality.

Owner:东营市东凯新材料技术研发有限责任公司

Secondary-etching double-sided circuit board structure and processing technique thereof

ActiveCN105578765AReduce generationReduce manufacturing costPrinted circuit manufactureElectricityEtching

The invention discloses a secondary-etching double-sided circuit board structure and a processing technique thereof. The secondary-etching double-sided circuit board structure comprises a GTL line layer, an insulating PP layer and a GBL stepped surface line layer. The GBL stepped surface line layer is formed by a GBL inner line layer and a GBL outer line layer; the insulating PP layer is arranged between the GTL line layer and the GBL inner line layer; and the GBL outer line layer is arranged on the other surface of the GBL inner line layer. In addition, The processing technique consists of a first line manufacturing process and a secondary line manufacturing process; the first line manufacturing process includes steps of first line graph manufacturing, line development cam compensation, line examination, and etching; and the secondary line manufacturing process includes steps of secondary line graph manufacturing, line development cam compensation, line examination, etching, and electric detection on an open circuit and a short circuit, and a post procedure. According to the invention, only two-times manufacturing is carried out; the investment is low; the production flow is simplified and the working difficulty is reduced; the production efficiency is improved; the production cost is lowered; the reject ratio is reduced; and the product production period is reduced.

Owner:苏州市三生电子有限公司

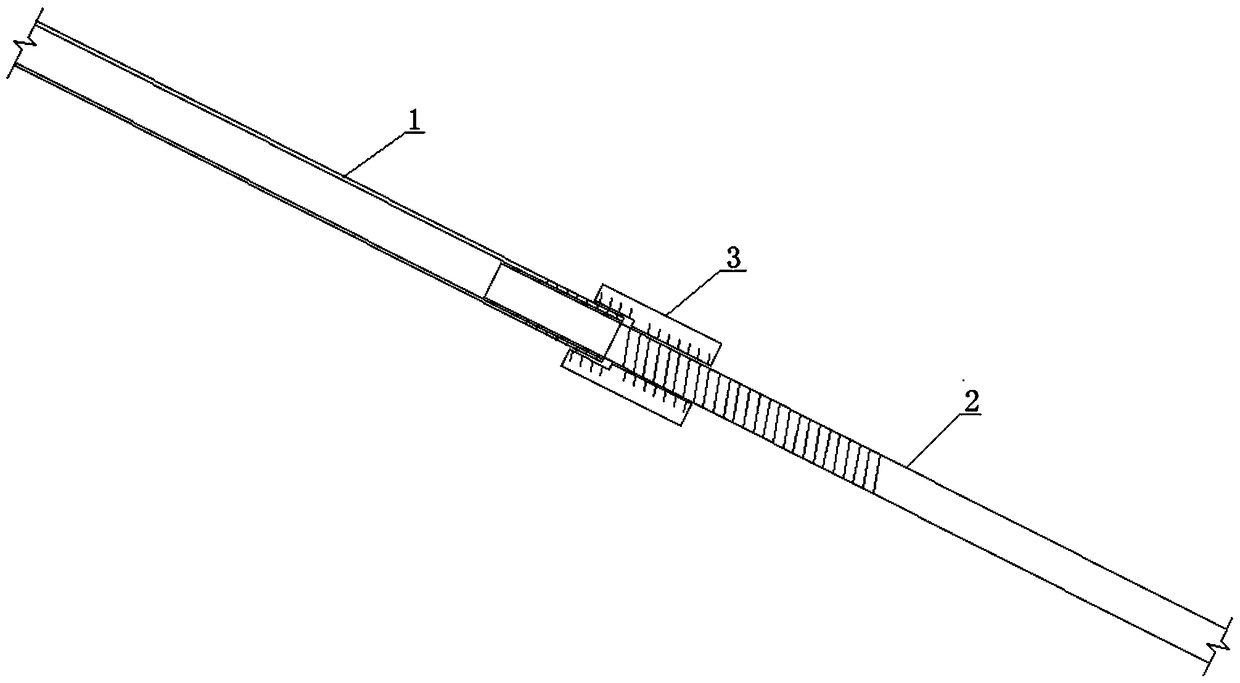

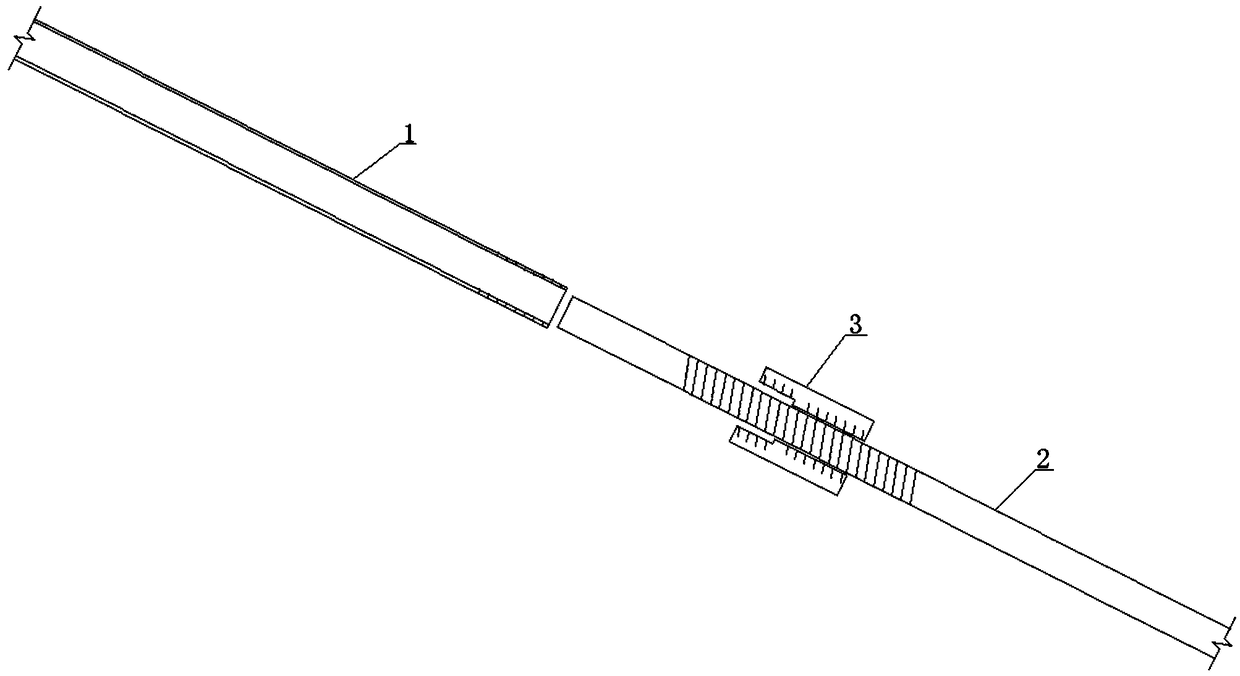

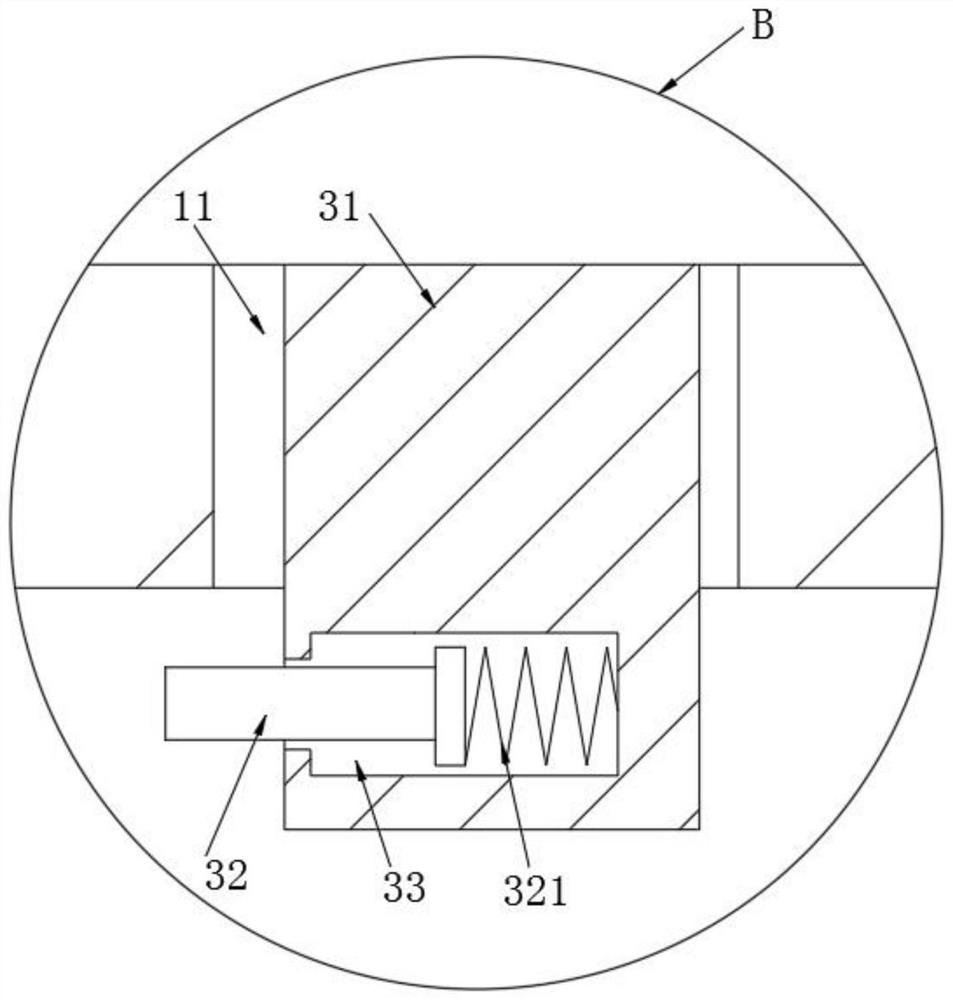

Sleeve type telescopic steel support for lift-up story adding of building

InactiveCN109113365AReduce generationReduce workloadBuilding repairsArchitectural engineeringWorkload

A sleeve type telescopic steel support for lift-up story adding of a building comprises a big diagonal rod (1) and a small diagonal rod (2); the upper part of the small diagonal rod (2) can sleeve thelower part of the big diagonal rod (1) in a freely sliding manner; an external thread is arranged at the lower part of the big diagonal rod (1); an external thread is arranged at the upper part of the small diagonal rod (2); a sleeve (3) is arranged on the small diagonal rod (2); the interior of the sleeve (3) is arranged as a step structure matched with the big diagonal rod (1) and the small diagonal rod (2); an internal thread is arranged on the step structure; and the internal thread on the step structure of the sleeve (3) is correspondingly matched with the external thread of the big diagonal rod (1) and the external thread of the small diagonal rod (2). The sleeve type telescopic steel support for lift-up story adding of the building can expand and retract with lift-up story adding,the workload of continuously changing the steel supports is reduced, unnecessary building wastes generated in the construction process are reduced, and the operation difficulty of arranging the support in the lift-up story adding reconstruction is simplified.

Owner:WUDA JUCHENG STRUCTURE CO LTD

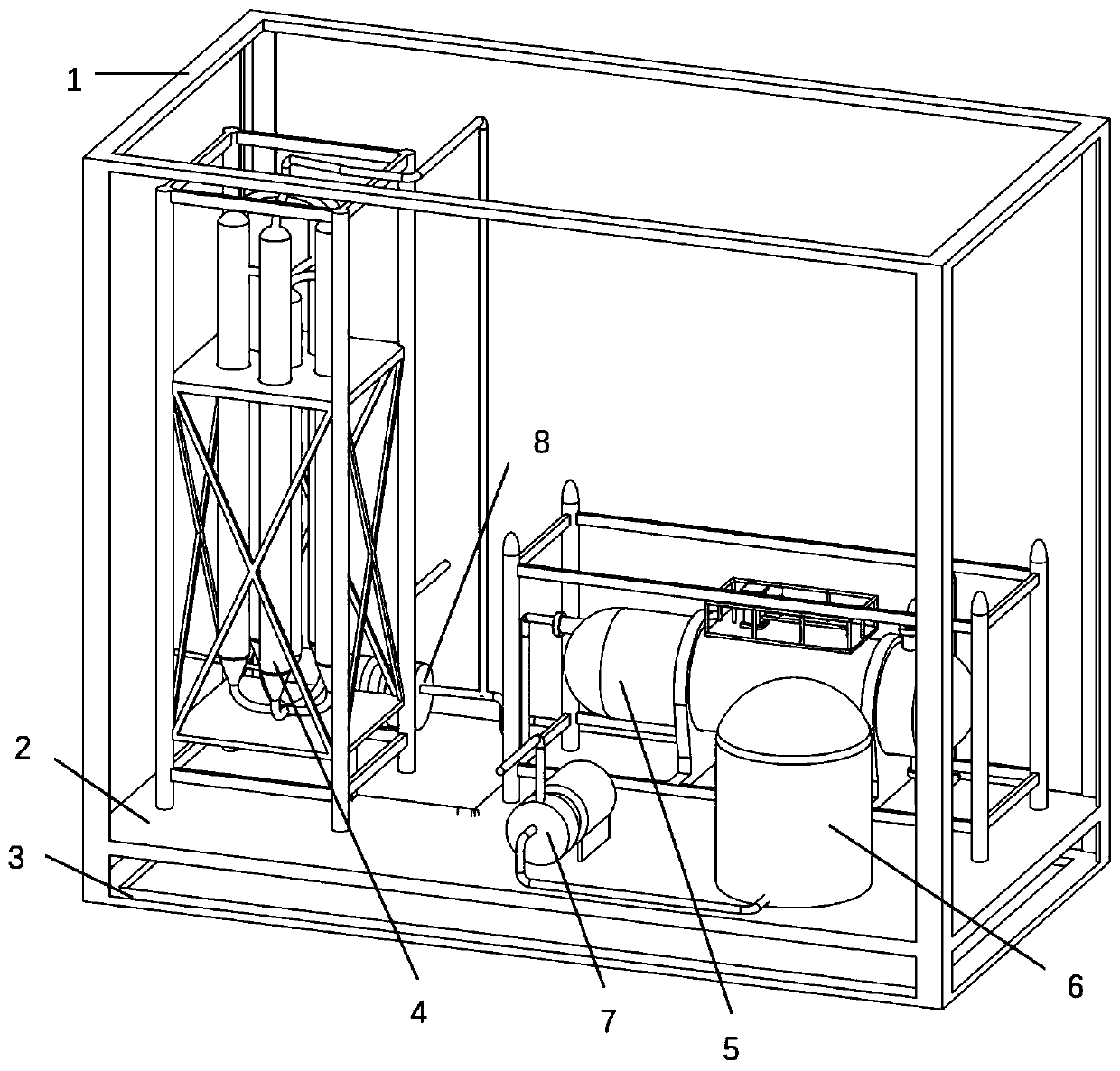

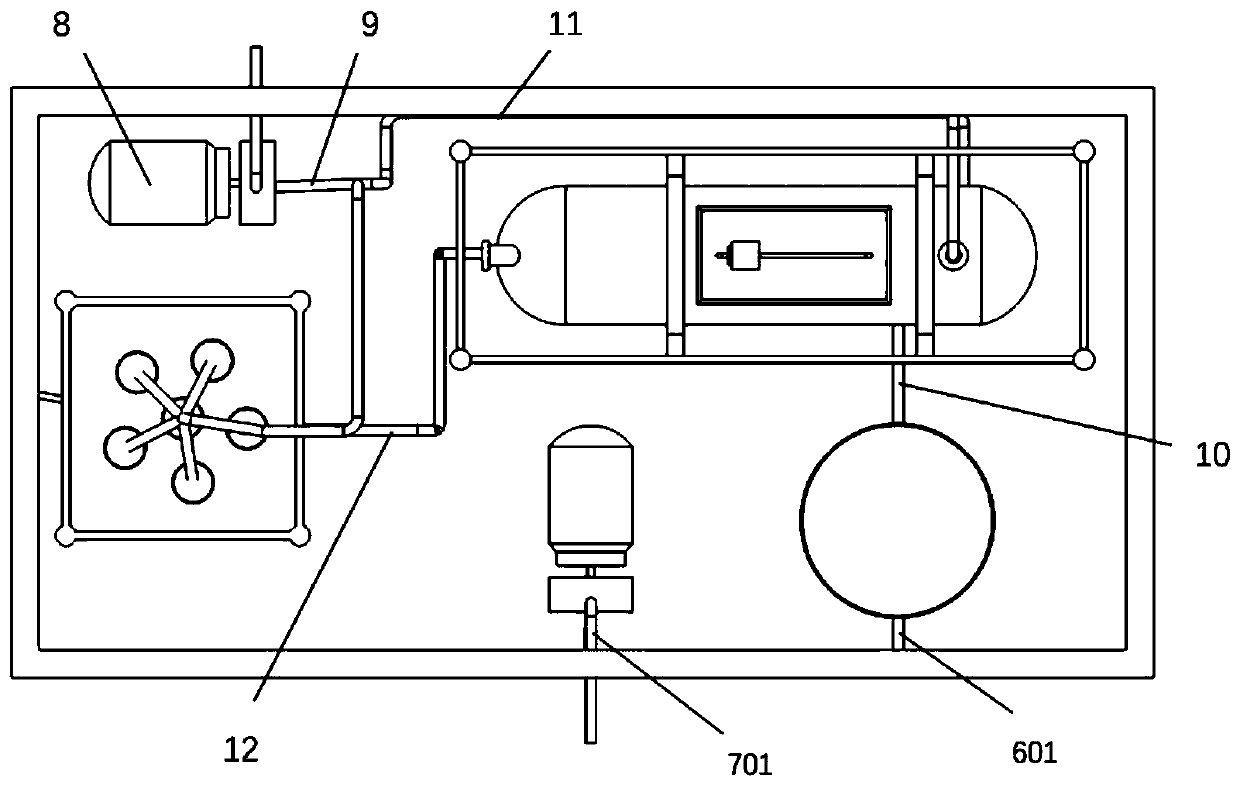

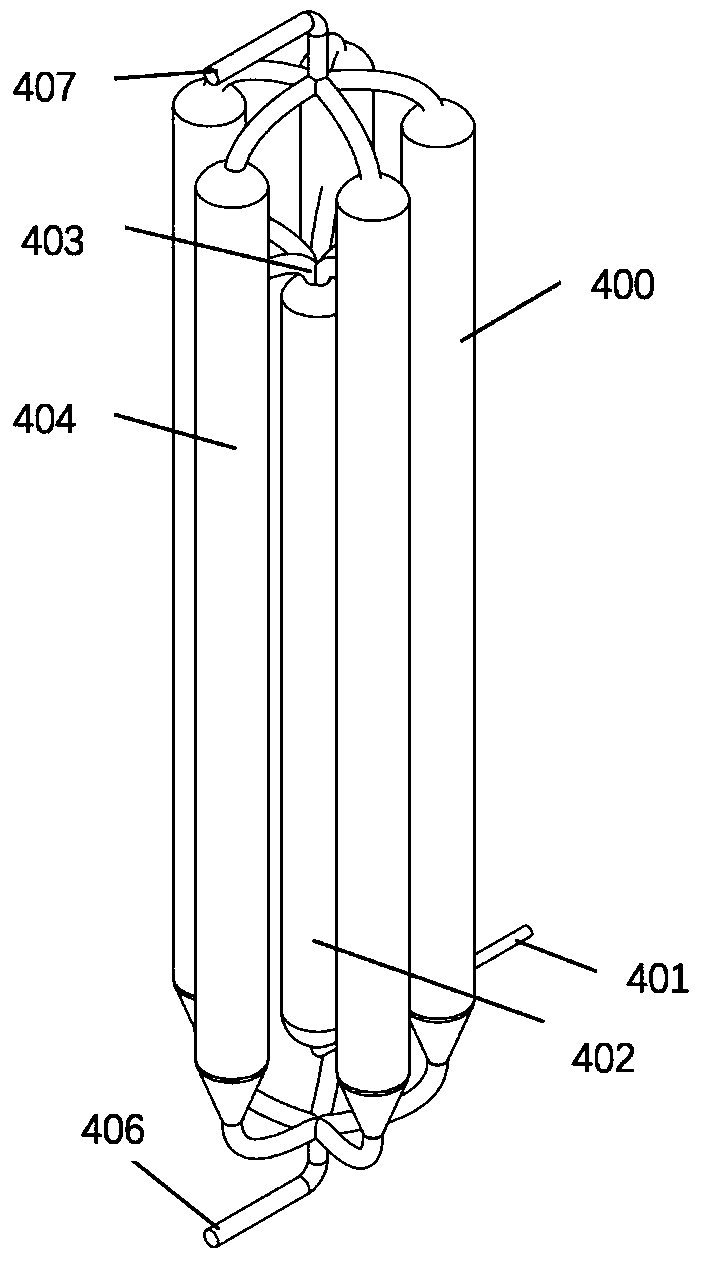

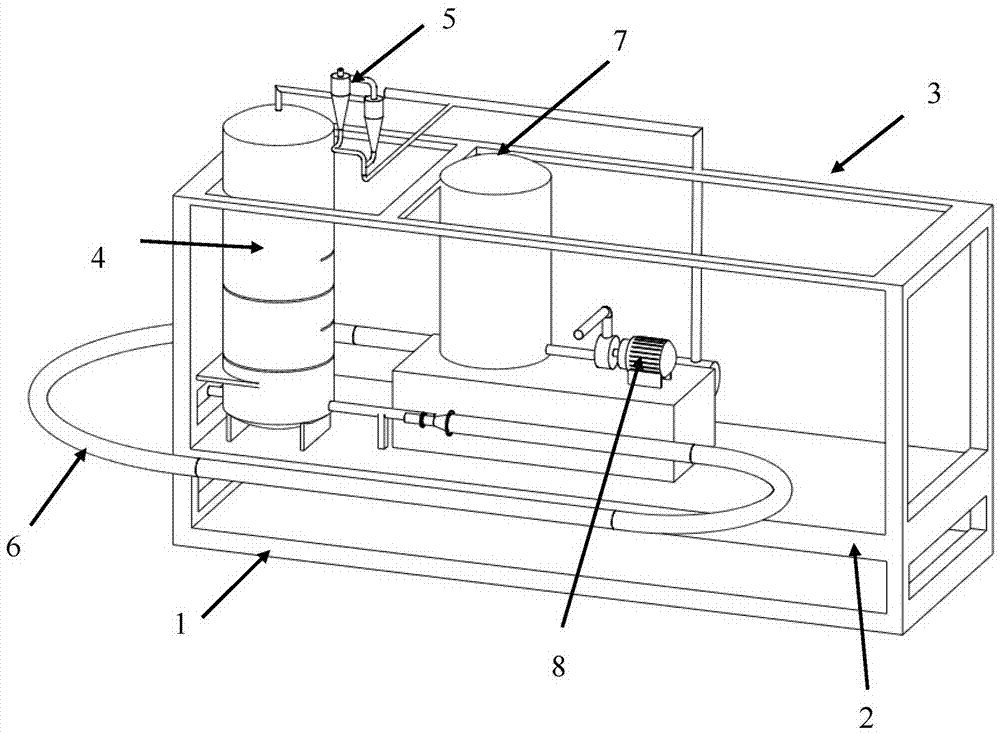

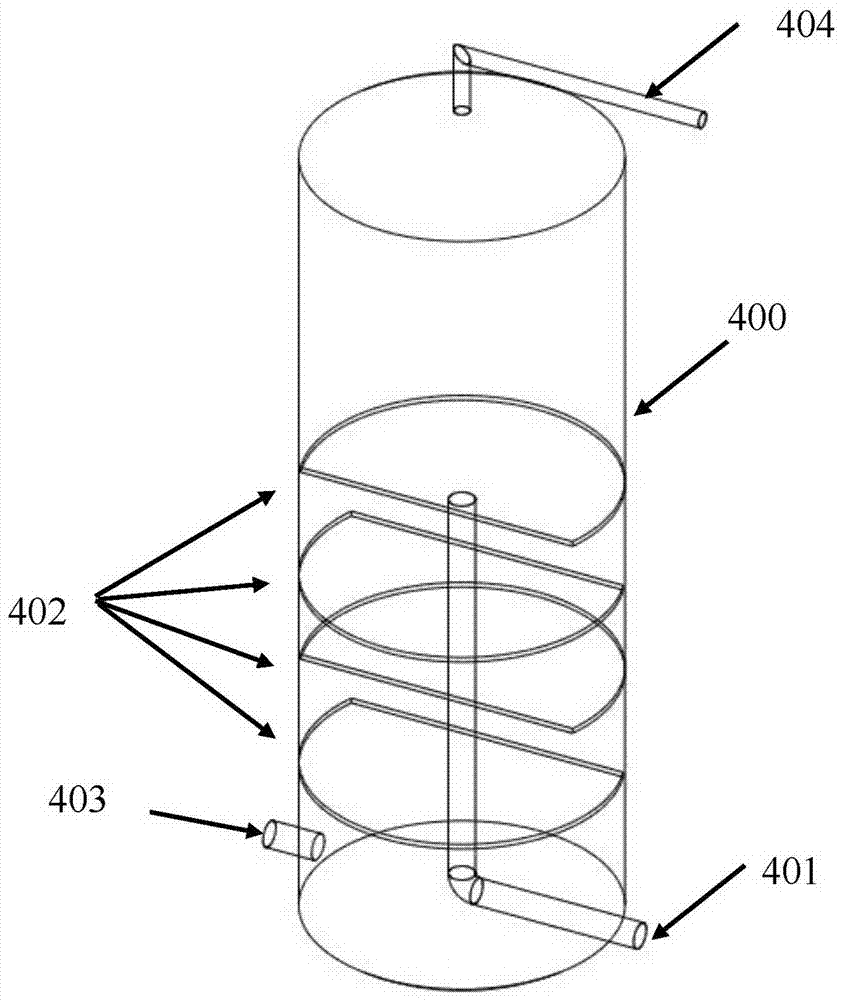

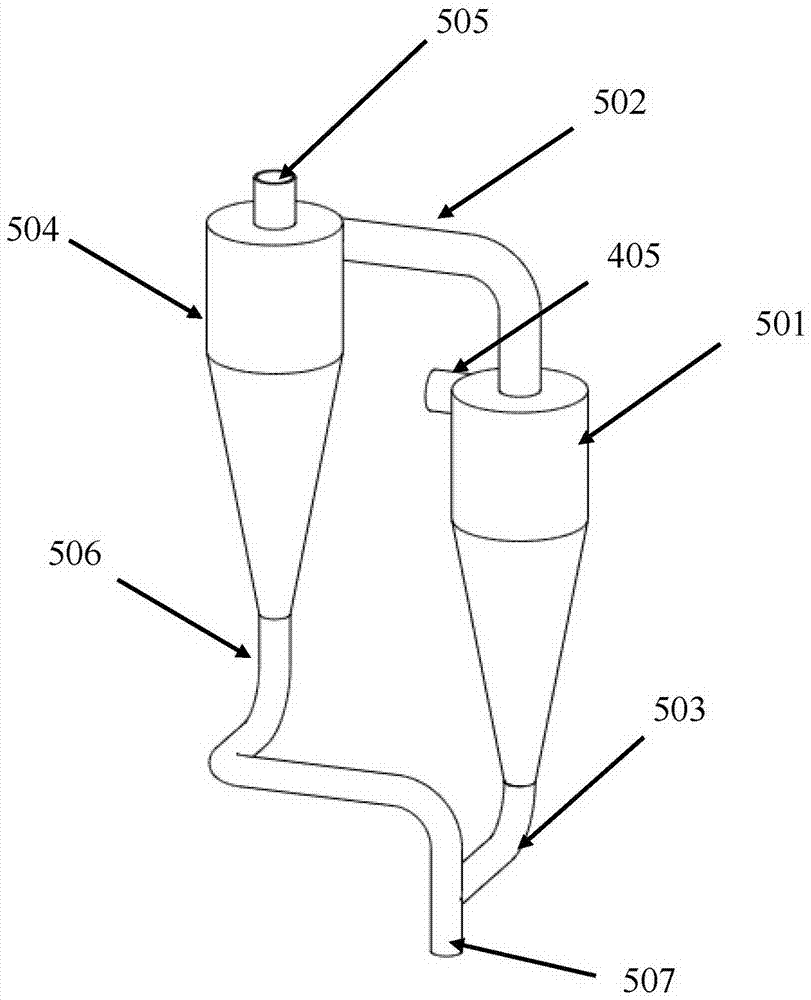

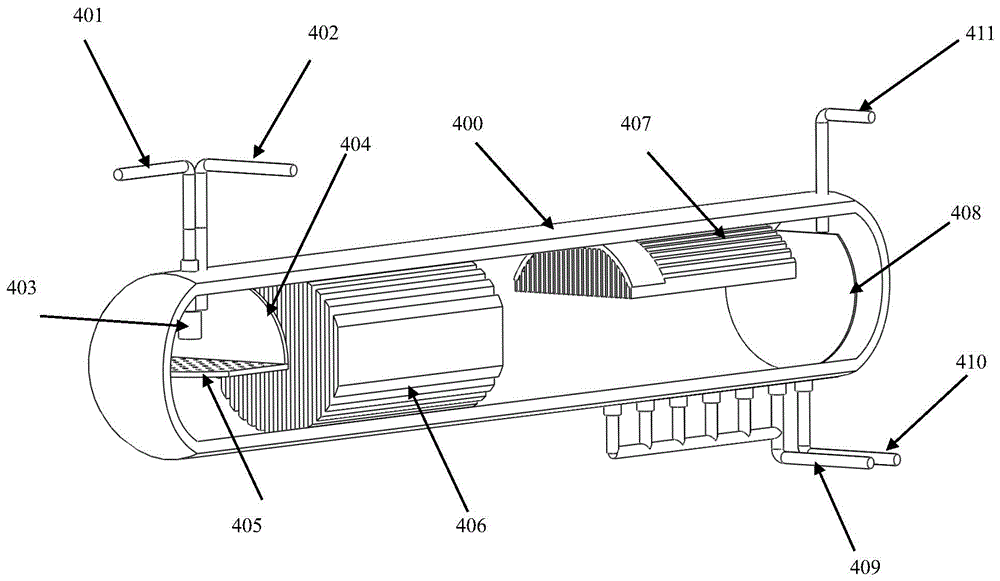

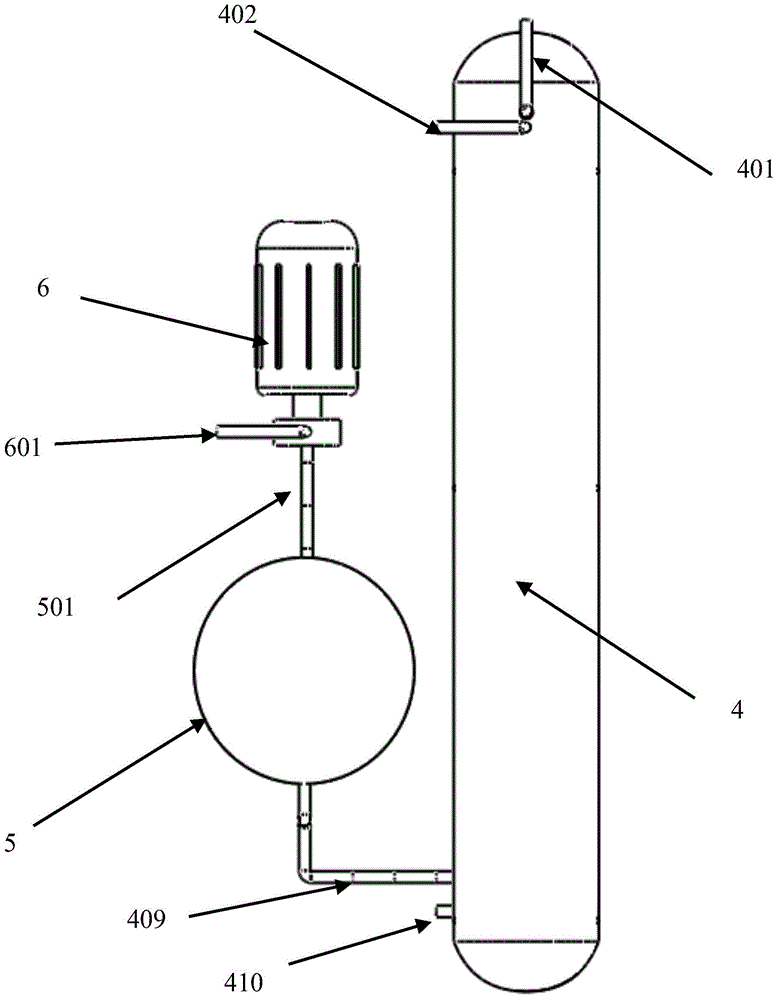

Deep sea parallel multiphase multistage separation reinjection system

The invention relates to a deep sea parallel multiphase multistage separation reinjection system. The deep sea parallel multiphase multistage separation reinjection system comprises a base platform, avertical parallel separator, a horizontal gravity separator, a buffer tank, a pressurized reinjection pump and a pressurized reinfusion pump, wherein the vertical parallel separator, the horizontal gravity separator, the buffer tank, the pressurized reinjection pump and the pressurized reinfusion pump are fixedly arranged on the base platform; a delivery line of an undersea christmas tree is connected with a mixture inlet of the vertical parallel separator; produced liquid is fed into the deep sea parallel multiphase multistage separation reinjection system from the mixture inlet; a horizontal gravity separator inlet is connected with a vertical gravity separator liquid outlet; a horizontal gravity separator oil phase outlet is connected with a delivery line two-way pressurized reinfusionpump; and oil is delivered to an offshore platform for processing through an oil passage. The deep sea parallel multiphase multistage separation reinjection system is arranged on deep-sea underwaterand directly separates produced liquid of an oil well in close distance without first lifting, so that great area of the offshore platform is prevented from being occupied and the stabilization of production is facilitated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Double-sided textured multilayer metal texture interlaced decorative sheet and production process thereof

InactiveCN104589894AReduce manufacturing costReduce investmentDecorative surface effectsSpecial ornamental structuresEtchingCam

The invention discloses a double-sided textured multilayer metal texture interlaced decorative sheet and a production process thereof. The metal texture interlaced decorative sheet comprises a first side texture, a transparent insulating plastic layer and a second side step surface texture, wherein the second side step surface texture comprises a second side inner texture and a second side outer texture; the first side texture and the second side inner texture are simultaneously connected with the transparent insulating plastic layer; the second side outer texture covers the second side inner texture. The production process of the twice etched double-sided metal texture interlaced decorative sheet also comprises the following operating steps: first texture making, texture developing and cam compensating, texture checking, etching, second texture making, texture developing, texture checking, etching, texture checking and subsequent procedure performing. The double-sided textured multilayer metal texture interlaced decorative sheet and the production process have the beneficial effects that twice making is only needed, so that the input is low; the production flow and the operation difficulty are simplified, thus improving the production efficiency, reducing the production cost, reducing the reject ratio of the product and shortening the production cycle of the product.

Owner:SUZHOU ZZH INTPROP SERVICES

Secondary-etching double-sided circuit board and processing technique thereof

ActiveCN105578705AReduce generationReduce manufacturing costPrinted circuit manufactureElectricityAcid etching

The invention discloses a secondary-etching double-sided circuit board and a processing technique thereof. The secondary-etching double-sided circuit board comprises a GTL line layer, an insulating PP layer and a GBL line layer. The GBL line layer is formed by a GBL inner line layer and a GBL outer line layer; the GTL line layer and the GBL inner line layer are connected with the insulating PP layer simultaneously; and the GBL outer line layer covers the GBL inner line layer. The secondary-etching double-sided circuit board is generated by a two-times circuit processing technique. The processing technique consists of a first line manufacturing process and a secondary line manufacturing process; the first line manufacturing process includes steps of first line graph manufacturing, line development, line examination, acid etching, and surface processing; and the secondary line manufacturing process includes steps of secondary line graph manufacturing, line development, line examination, etching, and electric detection on an open circuit and a short circuit, and a post procedure. According to the invention, only two-times manufacturing is carried out; the investment is low; the production flow is simplified and the working difficulty is reduced; the production efficiency is improved; the production cost is lowered; the reject ratio is reduced; and the product production period is reduced.

Owner:苏州市三生电子有限公司

Double-sided textured multilayer metal texture interlaced decorative sheet and production process thereof

InactiveCN104589895AReduce manufacturing costReduce investmentDecorative surface effectsSpecial ornamental structuresAcid etchingMaterials science

The invention discloses a double-sided textured multilayer metal texture interlaced decorative sheet and a production process thereof. The metal texture interlaced decorative sheet comprises a first side texture, a transparent insulating plastic layer and a second side step surface texture, wherein the second side step surface texture comprises a second side inner texture and a second side outer texture; the first side texture and the second side inner texture are simultaneously connected with the transparent insulating plastic layer; the second side outer texture covers the second side inner texture. The production process of the twice etched double-sided metal texture interlaced decorative sheet also comprises the following operating steps: first texture making, texture developing, texture checking, acid etching, second texture making, texture developing, texture checking, etching, texture checking and subsequent procedure performing. The double-sided textured multilayer metal texture interlaced decorative sheet and the production process have the beneficial effects that twice making is only needed, so that the input is low; the production flow and the operation difficulty are simplified, thus improving the production efficiency, reducing the production cost, reducing the reject ratio of the product and shortening the production cycle of the product.

Owner:SUZHOU ZZH INTPROP SERVICES

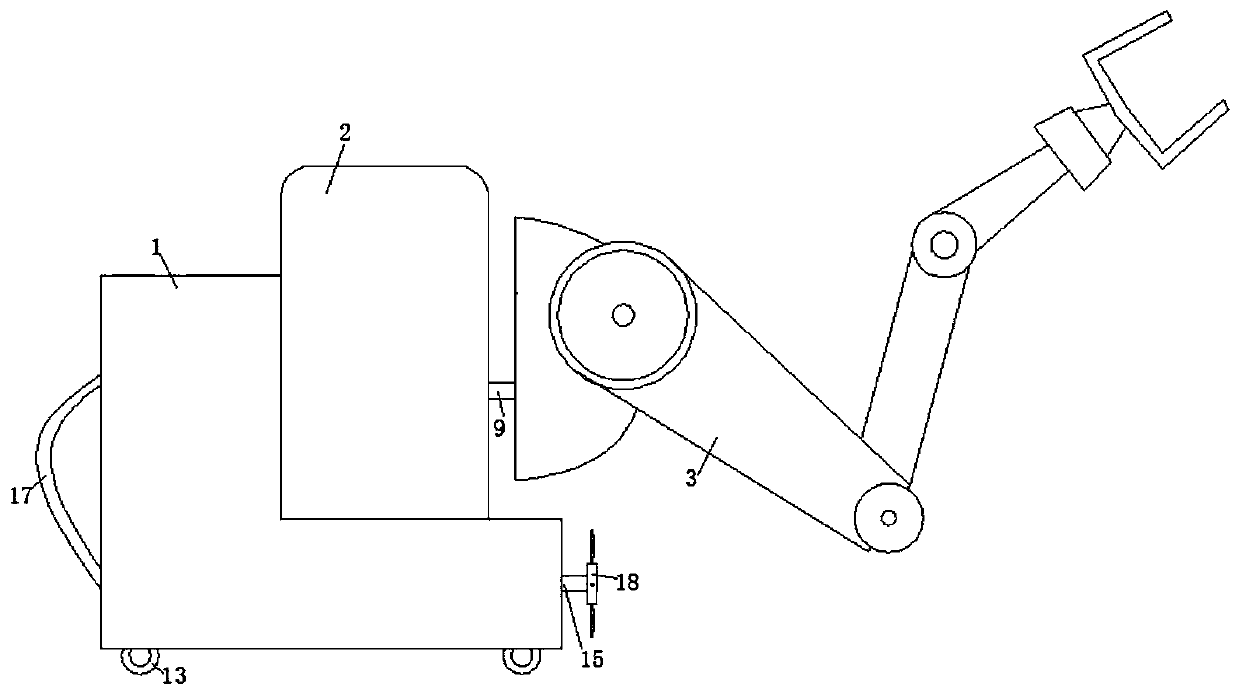

Intelligent connecting rod type manipulator

InactiveCN111136643AImprove stabilityEasy to adjustProgramme-controlled manipulatorArmsIntelligent machineManipulator

The invention belongs to the technical field of manipulators, and particularly relates to an intelligent connecting rod type manipulator. In order to solve the problems that an existing intelligent manipulator cannot stretch out and draw back and adjust the height at the same time, use of the manipulator is limited, and the working efficiency is poor, the following scheme is provided, when the position of the manipulator needs to be adjusted, a threaded column is rotated, the threaded column drives a threaded body to move on the threaded column, the threaded body drives a limiting block to slide on a limiting rod, the stability of the threaded body is stabler, then the stability of the manipulator is improved, and the threaded body drives a driving box to move up and down through a liftingrod, so that the manipulator body moves up and down, the height of the manipulator body is conveniently adjusted, different operators can work conveniently, the working efficiency is improved, a first round plate gear wheel drives a rotating and connecting rod to rotate, then the manipulator body rotates, the operation difficulty of the manipulator body is simpler, and the practicability of the manipulator is improved.

Owner:SHANDONG POLYTECHNIC COLLEGE

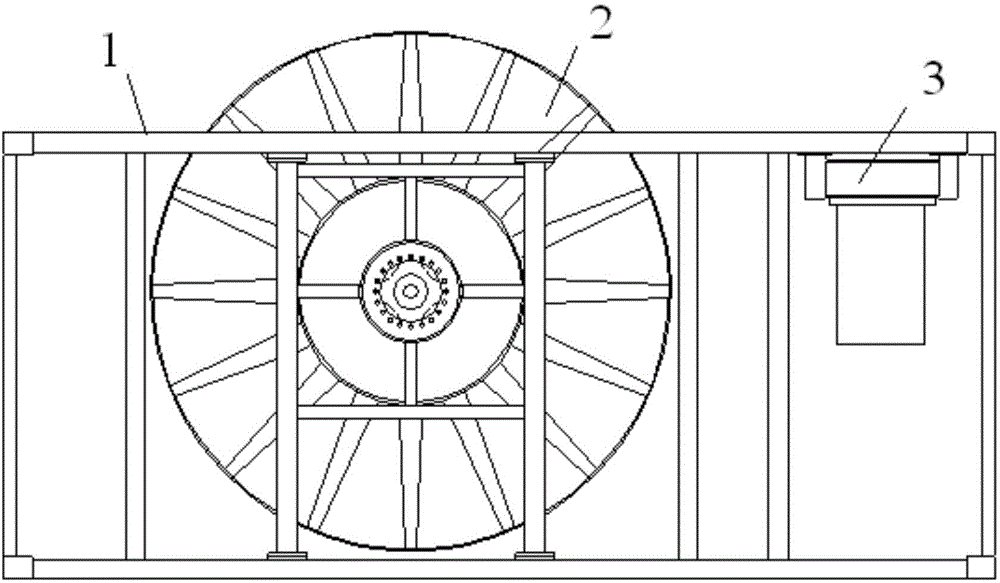

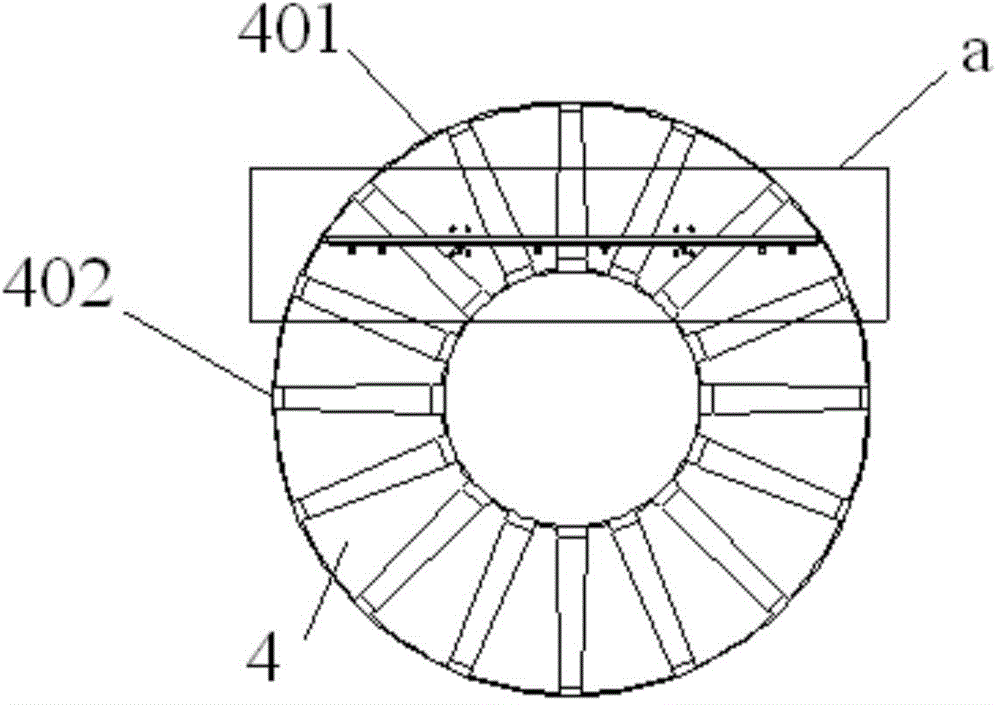

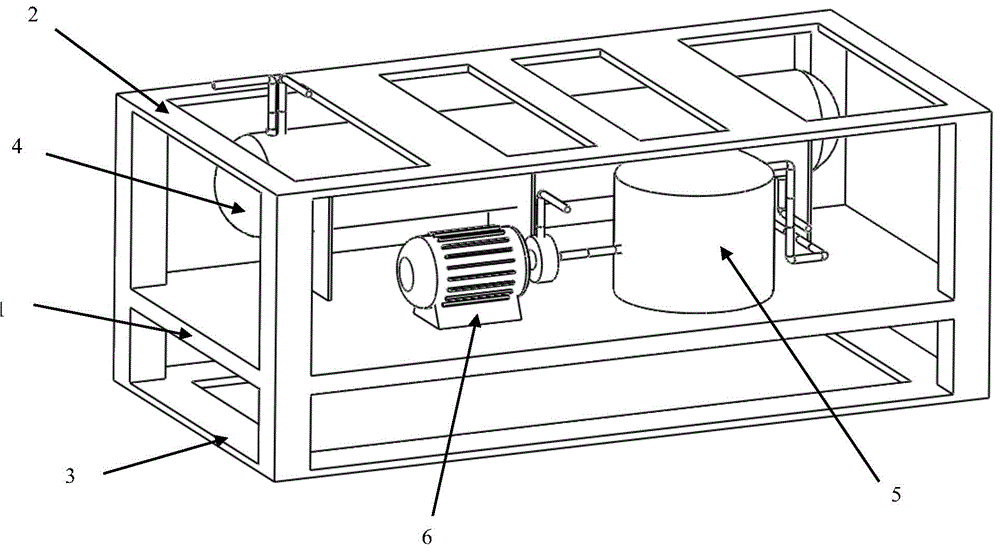

Modular winch

InactiveCN104444903AGuaranteed to move normallyIncreased cable capacityWinding mechanismsEngineeringWinch

A modular winch comprises a container framework, a winch body arranged in the middle of the container framework, and a cable arranger arranged at the front end of the container framework. The winch body comprises two side plates and an inner cylinder arranged between the two side plates. The two side plates extend outwards from the interior of the container framework. The portions, extending out of the container framework, of the two side plates can be folded towards the inner side or the outer side of the winch body. The cable capacity of the modular winch is improved without changing the size of the container framework.

Owner:CHINA NAT OFFSHORE OIL CORP +1

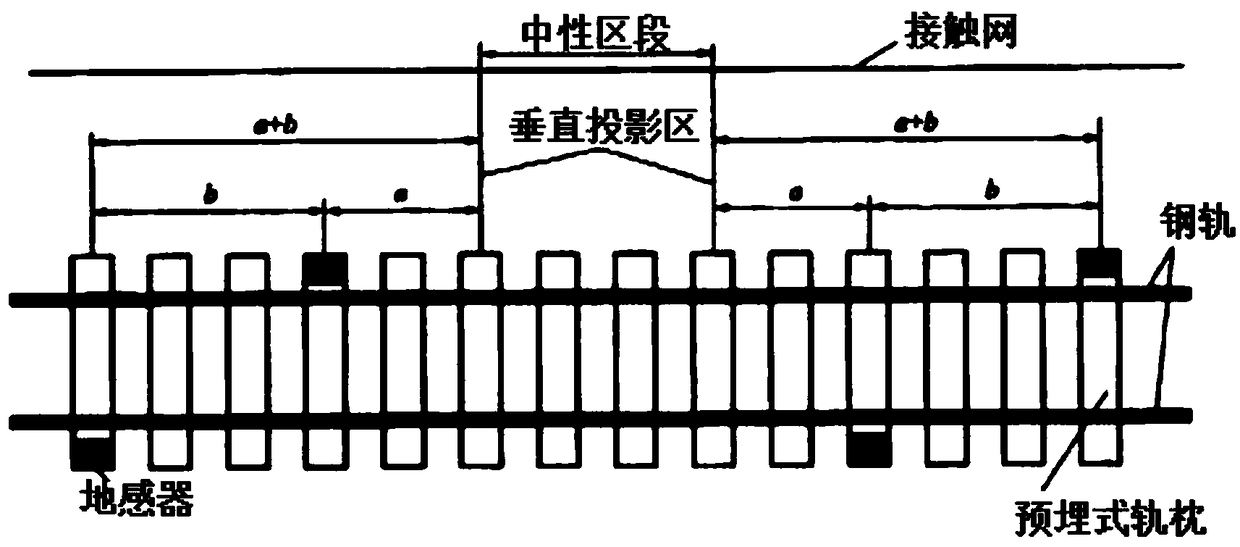

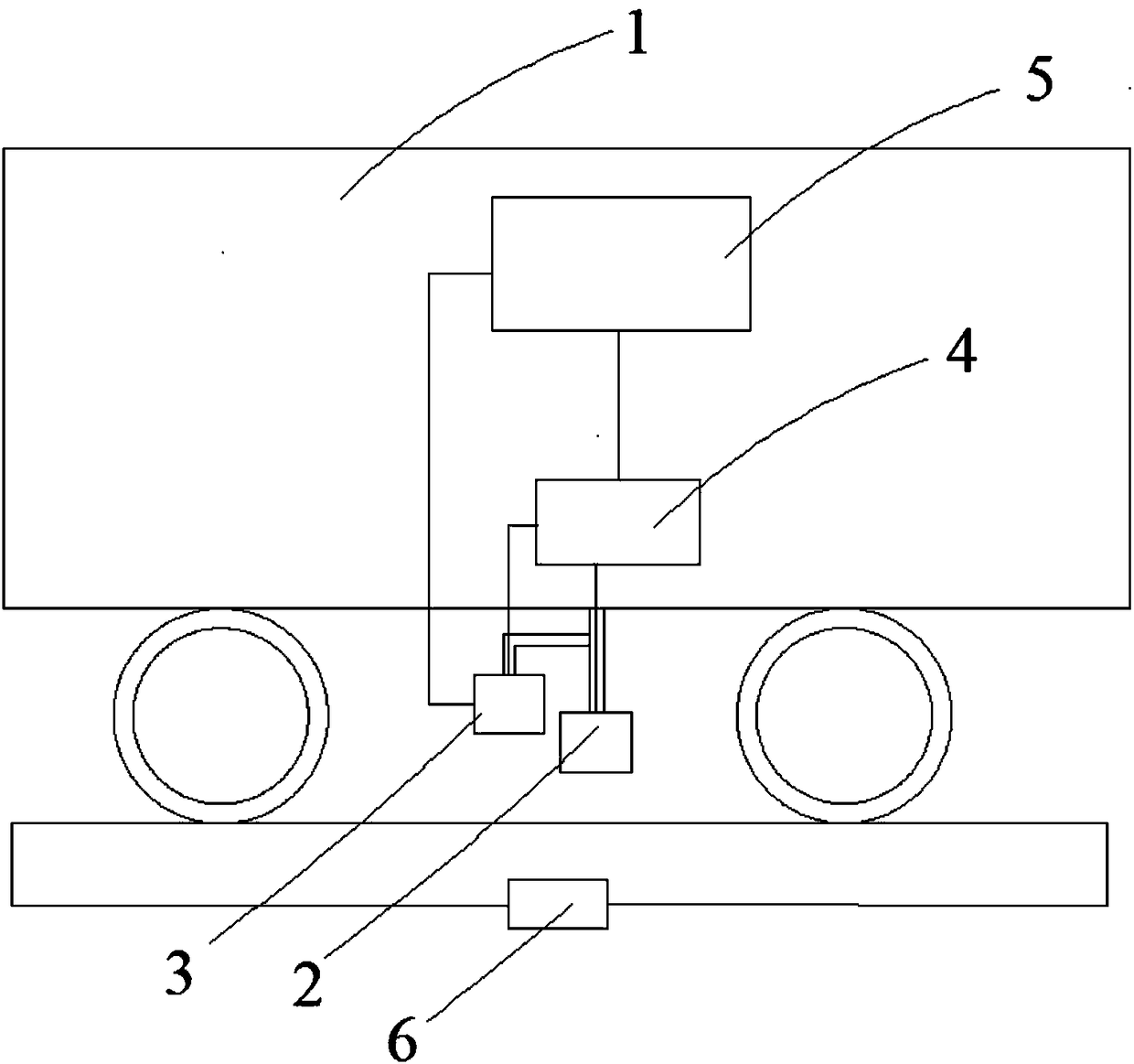

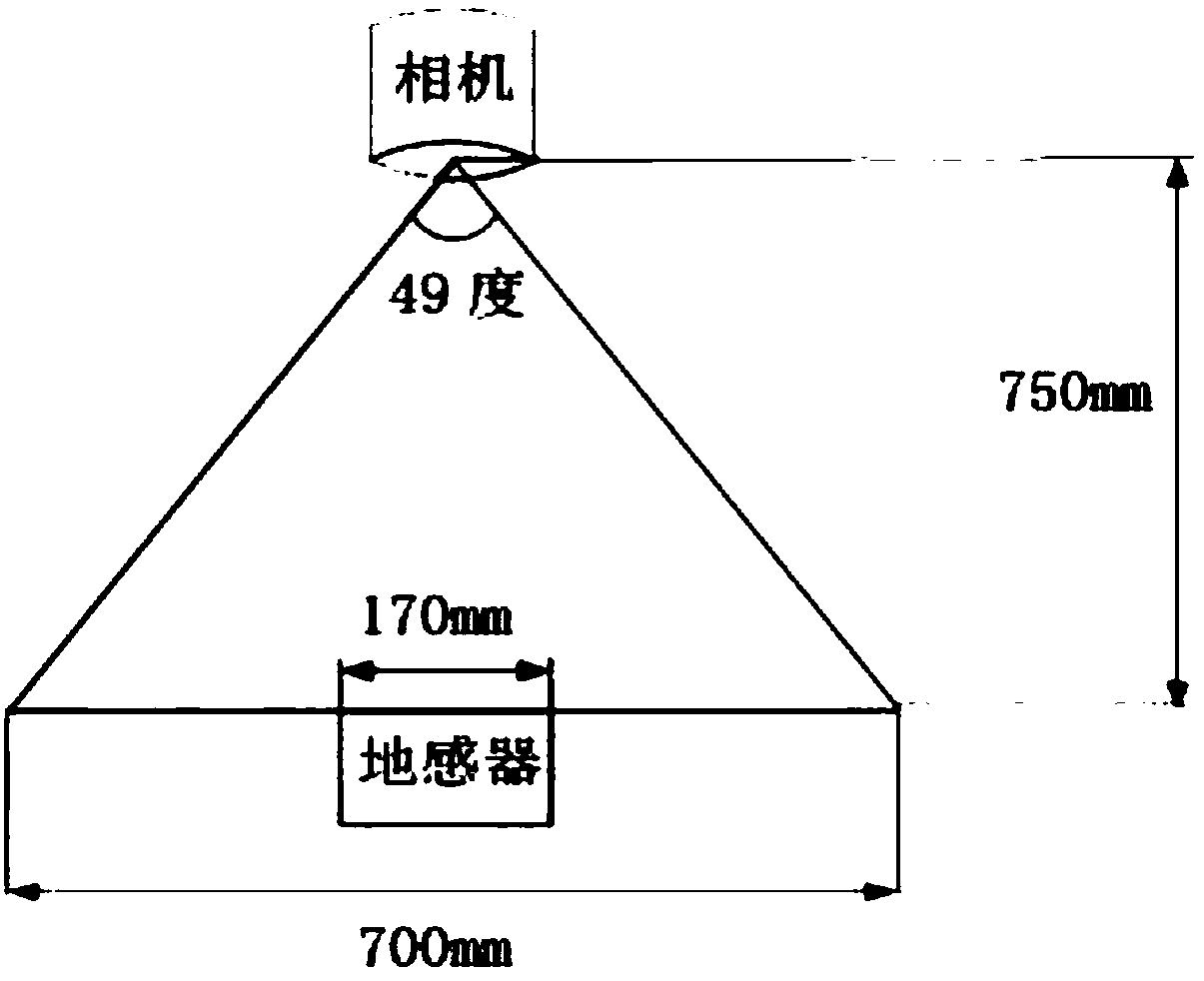

Automatic split phase passing ground sensing device detection system

PendingCN108146466AImprove reliabilitySimplify work intensityElectrical testingRailway vehicle testingEngineeringPersonal computer

The invention discloses an automatic split phase passing ground sensing device detection system which comprises a magnetic field detection probe (2), a camera (3), a control box (4) and an industrialpersonal computer (5). The magnetic field detection probe (2) and the camera (3) are mounted on the left side and the right side of the outside of a train (1), and the control box (4) and the industrial personal computer (5) are mounted inside the train (1); the magnetic field detection probe (2) is connected with the control box (4) by RS385 bus, the control box (4) is connected with the camera (3) by a power line and is connected with the industrial personal computer (5) by RS232 bus, and the industrial personal computer (5) is connected with the camera (3) by a network cable. The automaticsplit phase passing ground sensing device detection system has the advantages that magnetic fields of a ground sensor can be dynamically measured by the magnetic field detection probe; images of the ground sensor can be acquired by the camera; the appearance and the performance of the ground sensor can be detected, accordingly, substandard ground sensors can be timely discovered, electrified splitphase passing accidents due to problems of the ground sensors can be effectively prevented, the reliability of automatic split phase passing systems can be improved, the operation intensity can be relieved for field staffs, and the operation difficulty can be lowered for the field staffs.

Owner:CHENGDU KNIGHT TECH

Double-sided textured multilayer metal texture interlaced decorative sheet and production process thereof

InactiveCN104589893AReduce human resource investmentSimplify production process and operation difficultyDecorative surface effectsSpecial ornamental structuresElectrical testingMetal

The invention discloses a double-sided textured multilayer metal texture interlaced decorative sheet and a production process thereof. The metal texture interlaced decorative sheet comprises a first side texture, a transparent insulating plastic layer and a second side step surface texture, wherein the second side step surface texture comprises a second side inner texture and a second side outer texture; the first side texture and the second side inner texture are simultaneously connected with the transparent insulating plastic layer; the second side outer texture covers the second side inner texture. The production process of the double-sided textured multilayer metal texture interlaced decorative sheet also comprises the following operating steps: first texture making, texture developing, texture checking, acid etching, second texture making, texture developing, texture checking, etching, open and short circuit electrical testing and subsequent procedure performing. The double-sided textured multilayer metal texture interlaced decorative sheet and the production process have the beneficial effects that twice making is only needed, so that the input is low; the production flow and the operation difficulty are simplified, thus improving the production efficiency, reducing the production cost, reducing the reject ratio of the product and shortening the production cycle of the product.

Owner:SUZHOU ZZH INTPROP SERVICES

Internet of vehicles data acquisition system based on embedded software secondary development

PendingCN111896943ASolve the problem of inconvenient external power supplyImprove pollutionTransmission systemsRadio wave reradiation/reflectionData acquisitionEmbedded software

The invention belongs to the technical field of Internet of Vehicles data acquisition, and particularly relates to an internet of vehicles data acquisition system based on embedded software secondarydevelopment. The system comprises an acquisition mechanism, the interior of the acquisition mechanism is fixedly connected with a main processor and a vehicle exhaust analysis module, and the vehicleexhaust analysis module is in signal connection with the main processor; through the arrangement of a vehicle speed measuring radar, the speeds of passing vehicles are collected; vehicle exhaust information is collected through the vehicle exhaust analysis module. The subsequent analysis on the tail gas pollution of the village and town vehicle is facilitated; the acquired information is transmitted to the main processor and is preliminarily stored through a storage module; and after the main processor receives the acquired information of the vehicle speed measuring radar, the acquired information is transmitted to an external information receiving terminal through a wireless data transmission module for processing and analysis, so that the operation difficulty of speed information acquisition and calculation is reduced, and the speed information acquisition and calculation are faster than a manual calculation mode.

Owner:杭州恒领科技有限公司

Deep sea multiphase multistage separation and reinjection system

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Deepwater seabed oil and water separation and reinjection device

The invention relates to a deepwater seabed oil and water separation and reinjection device which comprises a base platform, an upper support, a lower support, a separator, a buffer tank and a booster reinjection pump. The separator, the buffer tank and the booster reinjection pump are arranged on the base platform; a rear gas outlet pipeline of the separator is mounted on the top of the rear of the separator; the buffer tank is close to a water outlet pipeline of the separator, the booster reinjection pump is close to an inlet pipeline of the separator, the water outlet pipeline of the separator is connected with the buffer tank and extends into the buffer tank, the buffer tank is connected with the booster reinjection pump by an outlet pipeline of the buffer tank, and the booster reinjection pump drains boosted water via an outlet pipeline. The deepwater seabed oil and water separation and reinjection device has the advantages that the device is mounted in deep sea water, produced liquid of wells does not need to be lifted to an offshore platform to be processed, accordingly, occupation of precious platform areas can be prevented, and a large quantity of energy can be saved for the oil wells positioned on seabed at the depth of thousands of meters; static pressures of risers and back pressures of wellheads can be greatly lowered, risks of pipeline leakage, deformation and the like can be reduced, and the deepwater seabed oil and water separation and reinjection device is favorable for stabilizing production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

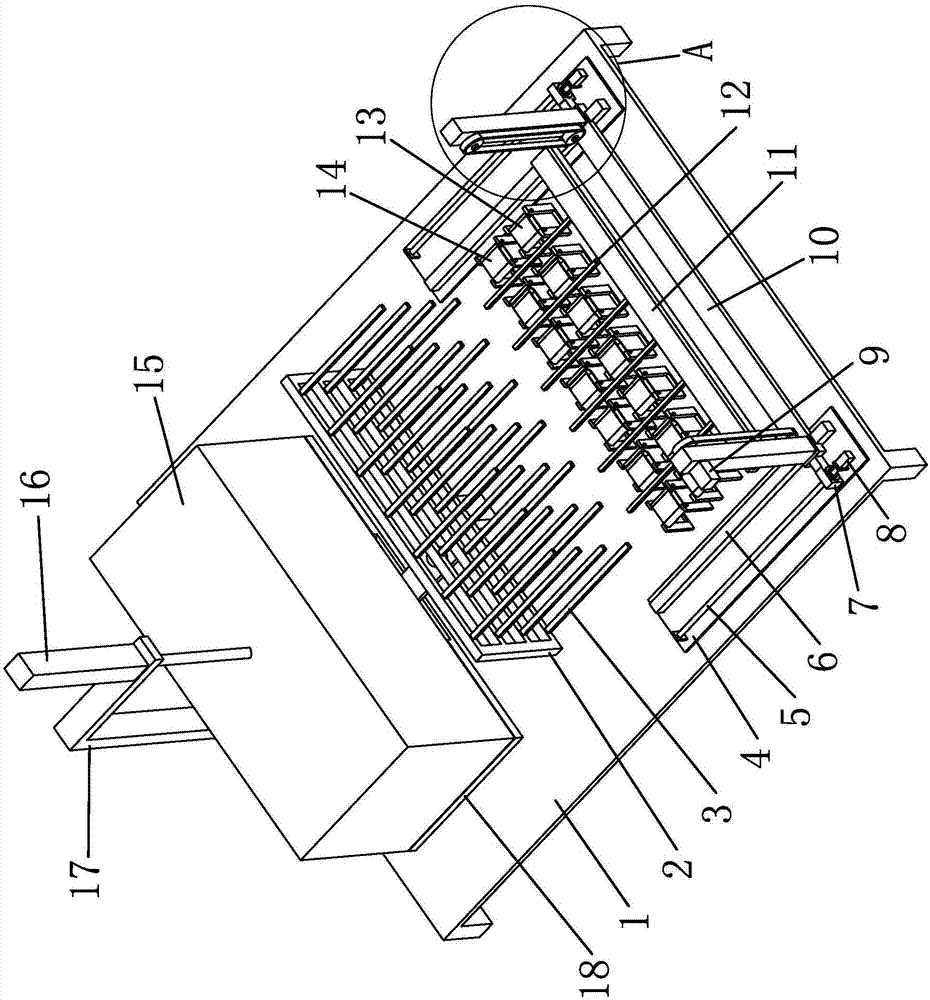

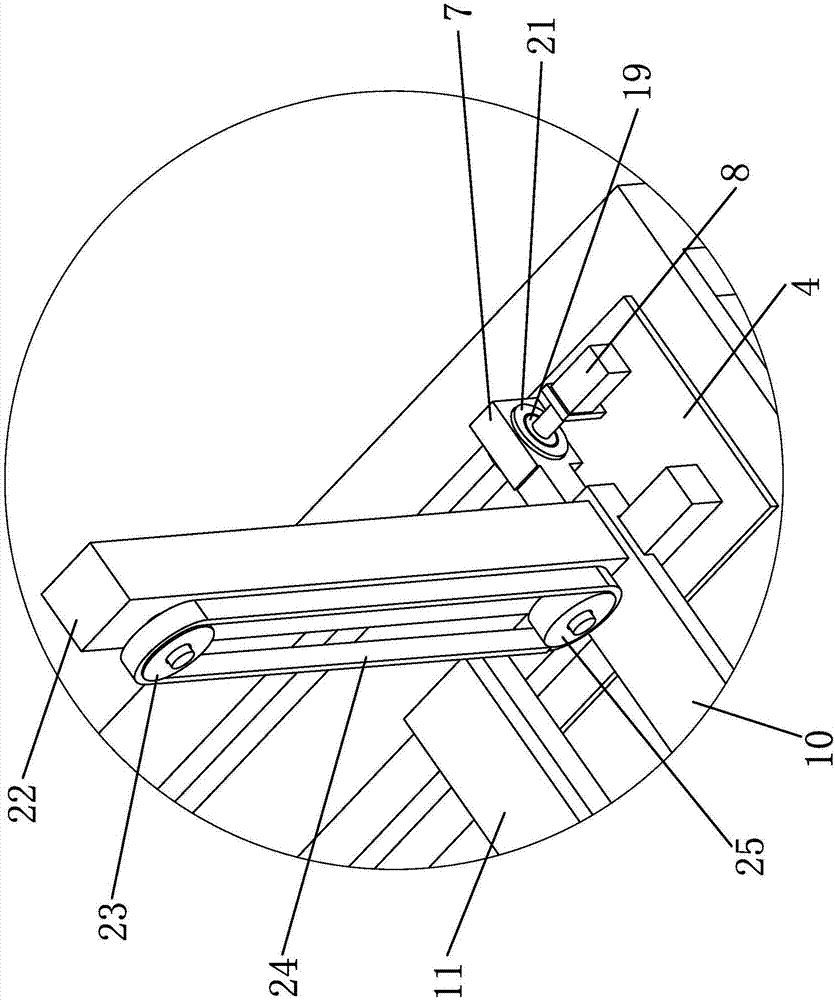

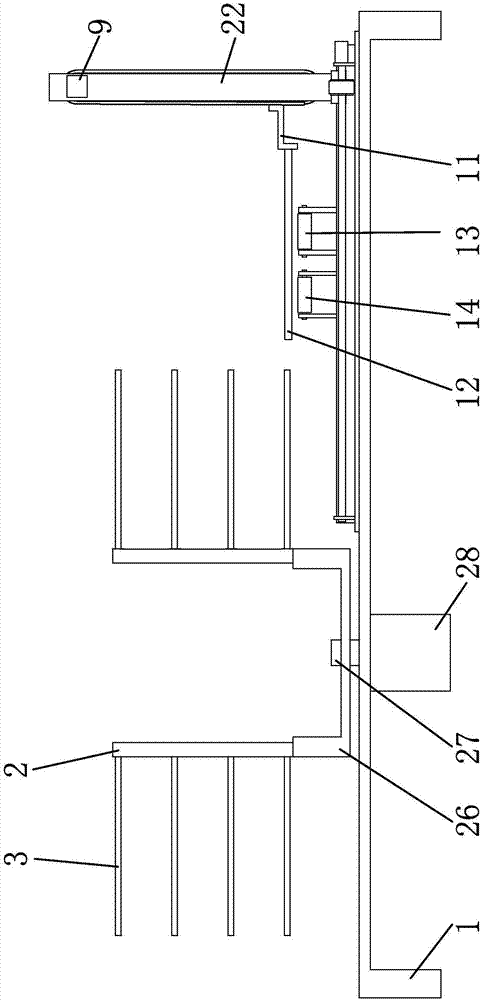

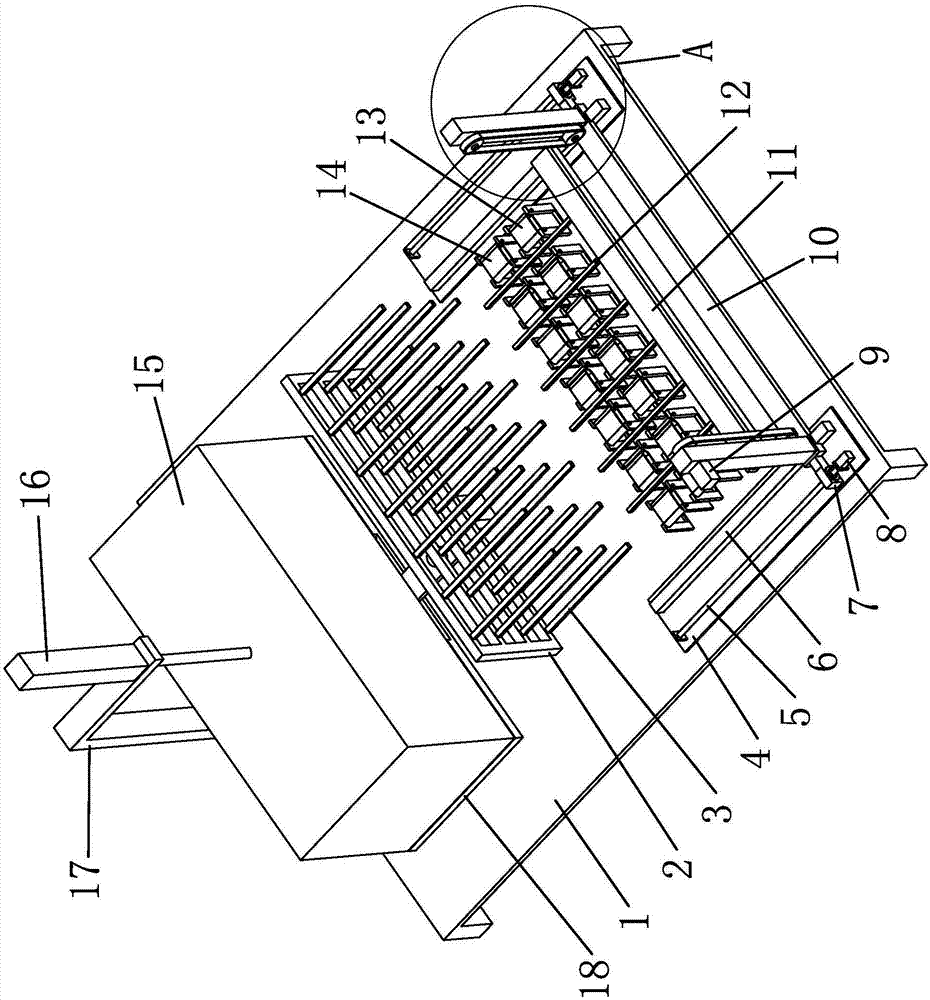

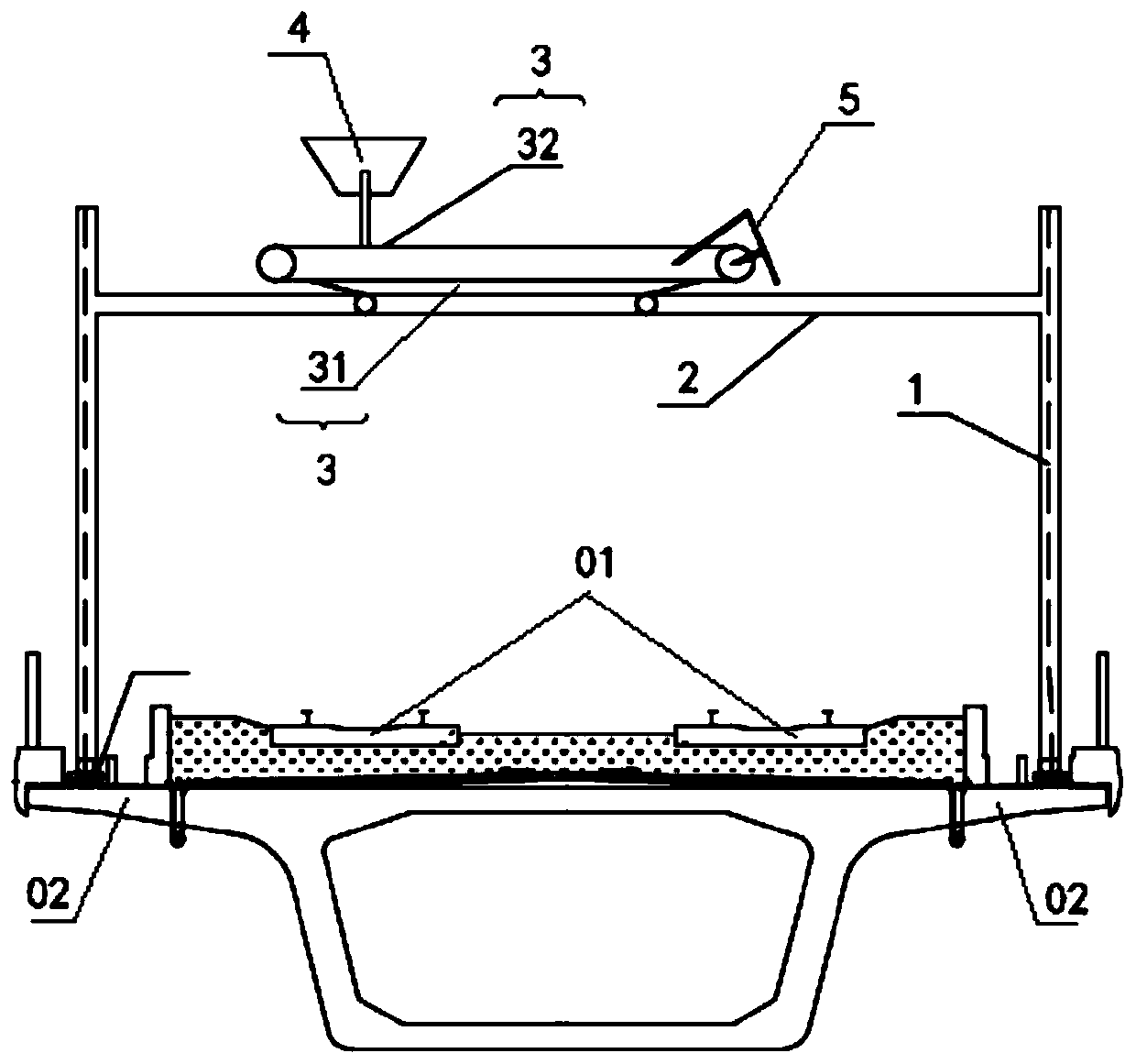

Multi-line rail ballast installing device

The invention discloses a multi-line rail ballast installing device. The multi-line rail ballast installing device comprises an upper ballast conveying device; a walking device which is installed tightly adjacent to a tail end of the upper ballast conveying device and erected above total rails, and used for moving in the length direction of the total rails; and a ballast transferring device whichis slidably connected to the walking device, and used for conveying ballast to right above any one of the rails so as to realize vertical loading and unloading. While the walking device is moved in the length direction of the total rails, the ballast transferring device slidably connected to the walking device is moved relative to the length direction of the rails, single-line operation of the arbitrary rail can be completed, and the ballast transferring device itself can be moved along the walking device so that a position of the ballast transferring device relative to a width direction of the rails is changed, thereby multi-line operation is realized on the basis of the single-line operation. The device is simple in structure, convenient to operate, and capable of simplifying multi-lineballast installing so as to save cost and improve efficiency.

Owner:3TH ENG CO LTD OF CHINA RAILWAY CONSTR 11TH BUREAU GRP +1

An etching process of a multilayer-metal-texture interlaced decorative plate by a two-step subtractive method and a production process of the decorative plate

InactiveCN104786718AReduce manufacturing costReduce investmentDecorative surface effectsSpecial ornamental structuresAcid etchingEngineering

An etching process of a multilayer-metal-texture interlaced decorative plate by a two-step subtractive method is disclosed. The decorative plate is formed by sequentially connecting a first-side texture, a transparent insulating plastic layer, a second-side inner texture and a second-side outer texture. The etching process comprises following steps in order: subjecting a decorative texture figure to cam compensation, performing the first time of decorative texture manufacturing, developing decorative textures, checking the decorative textures, performing acid etching, performing the second time of decorative texture manufacturing, developing decorative textures, checking the decorative textures, etching, trimming textures, and performing after steps. By adopting the etching process, the decorative plate originally needing three times of etching can be prepared only by two times of etching, thus reducing investment, simplifying production processes, reducing working difficulty, increasing the production efficiency, reducing the production cost, reducing the reject ratio of products and shortening the production period of products.

Owner:SUZHOU ZZH INTPROP SERVICES

A secondary etching double-sided circuit board structure and its production process

ActiveCN105578765BReduce generationReduce manufacturing costPrinted circuit manufactureEngineeringBoard structure

The invention discloses a secondary etching double-sided circuit board structure and its production process. The double-sided circuit board structure of the invention comprises: a GTL circuit layer, an insulating PP layer and a GBL step surface circuit layer, and the GBL step surface circuit layer It is composed of GBL inner line layer and GBL outer line layer, the insulating PP layer is located between the GTL line layer and the GBL inner line layer, the GBL outer line layer is located on the other side of the GBL inner line layer, a secondary etching double The surface circuit board production process includes the following steps: the first circuit production - - - line development cam compensation - - - line inspection - - - etching - - - the second circuit production - - - line development cam compensation - - - circuit Inspection--etching--electrical open and short circuit--after process. The invention only needs secondary production, requires less investment, simplifies the production process and operation difficulty, improves the production efficiency, reduces the production cost, reduces the defective rate of products, and shortens the production cycle of products.

Owner:苏州市三生电子有限公司

Secondary etching double-face circuit board structure and production technology thereof

ActiveCN105517319AReduce generationReduce manufacturing costPrinted circuit detailsConductive material chemical/electrolytical removalAcid etchingElectricity

The invention discloses a secondary etching double-face circuit board structure and the production technology thereof. The structure comprises a GTL circuit layer, an insulation PP layer and a GBL step surface circuit layer. The GBL step face circuit layer is formed by a GBL inner circuit layer and a GBL outer circuit layer. The GTL circuit layer and the GBL inner circuit layer are simultaneously connected with the insulation PP layer. The GBL outer circuit layer covers the GBL inner circuit layer. The production technology comprises following steps of primary circuit manufacture; circuit developing; circuit examination; acid etching; secondary circuit manufacture; circuit developing; circuit examination; etching; open short circuit electrical logging; and following working procedures. According to the invention, only the secondary manufacture is required; investment is less; production processes are simplified; task difficulty is reduced; production efficiency is improved; production cost is reduced; reject ratio of products is reduced; and production period of the products is shortened.

Owner:苏州市三生电子有限公司

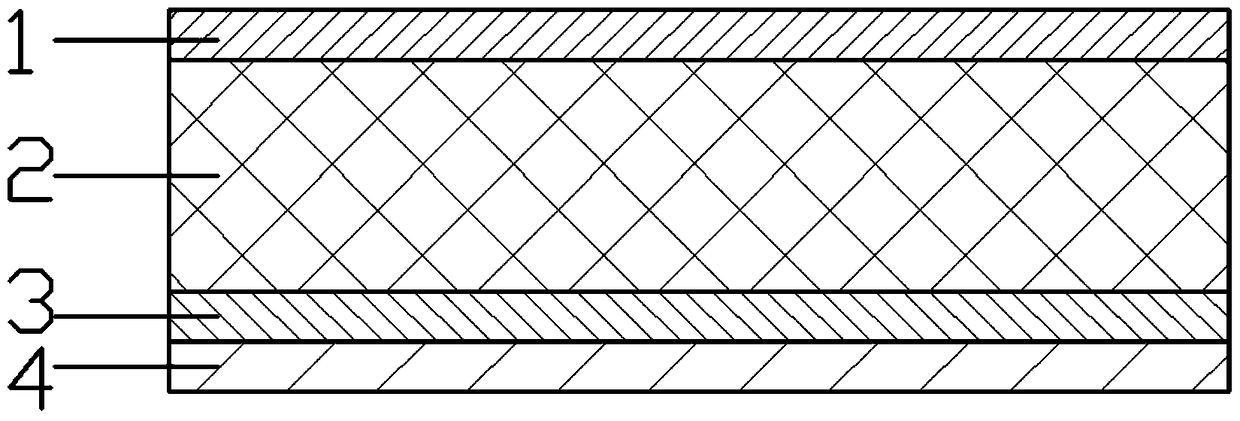

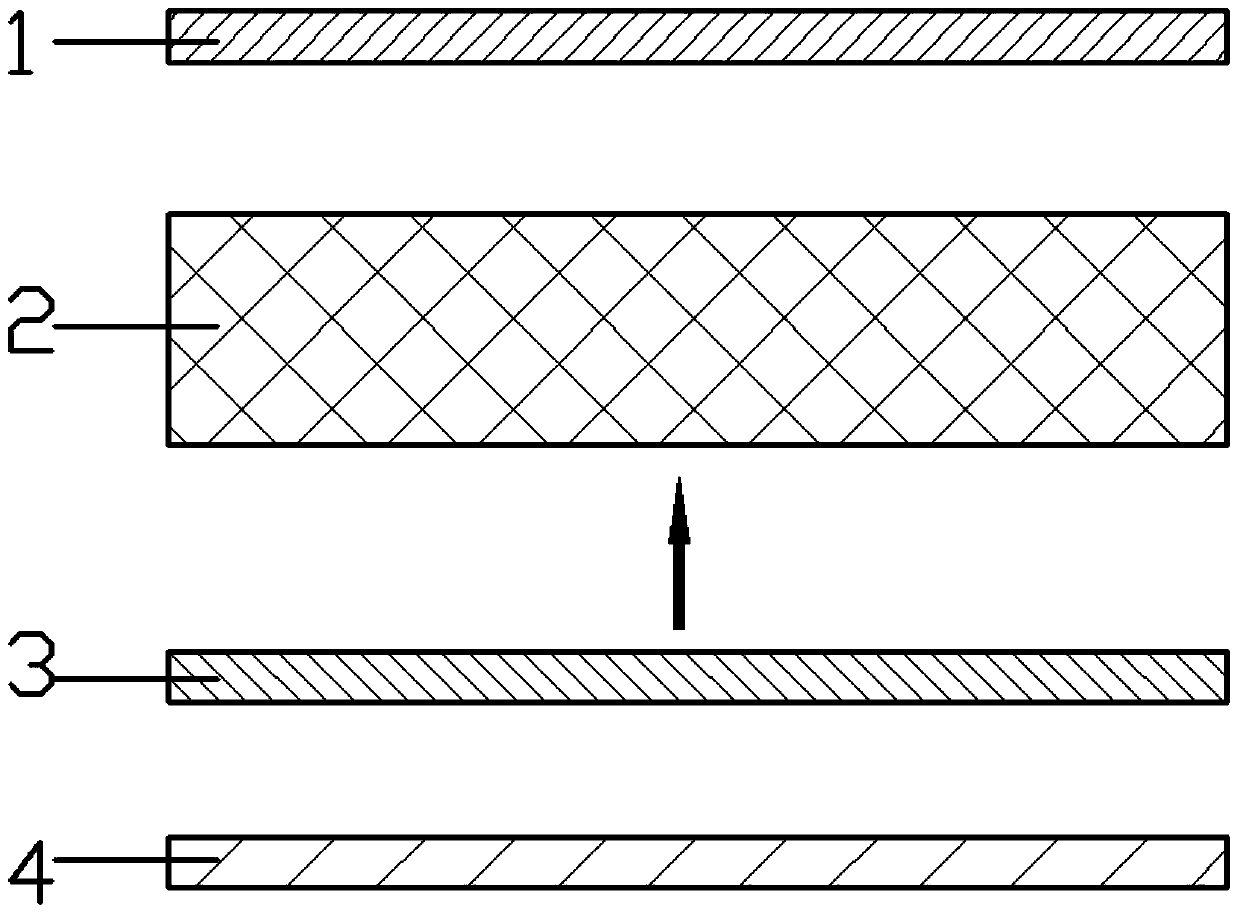

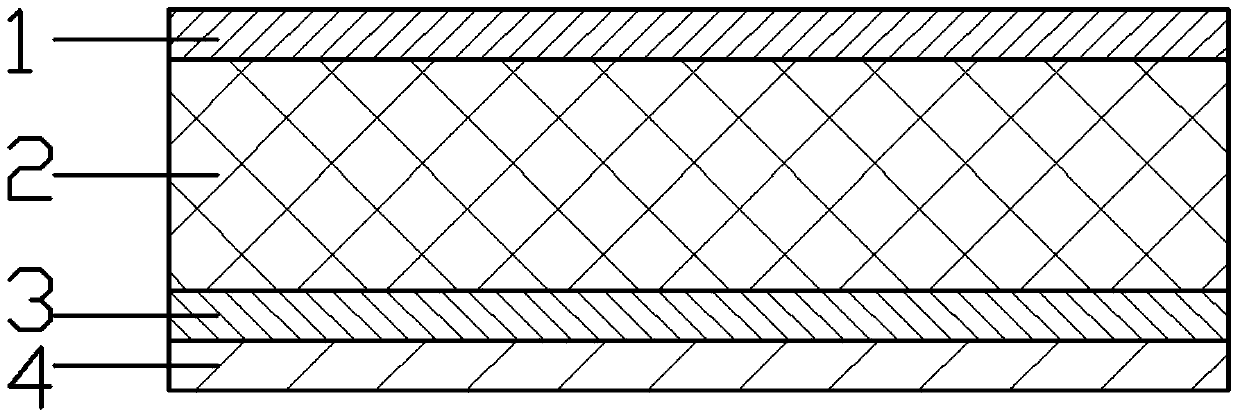

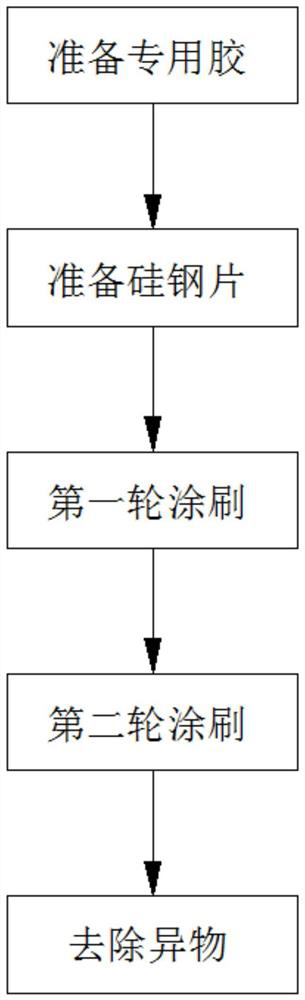

A kind of bonding method for magnetic shielding of fuel tank

ActiveCN111075811BEvenly paintedSimplify job difficultyMaterial gluingInductances/transformers/magnets manufactureFuel tankBonding process

The invention provides an oil tank magnetic shield bonding method. The magnetic shielding bonding method of the fuel tank comprises the following steps: S1, taking the special glue for the end face of the silicon steel sheet, then putting the special glue for the end face of the silicon steel sheet into the inside of the paint mixing bucket, and stirring the special glue for the end face of the silicon steel sheet through the paint mixing bucket; S2 1. Prepare the silicon steel sheets, and then stack the prepared silicon steel sheets according to the requirements of the drawings, and place a piece of paper in the middle of each magnetic shield, and separate each magnetic shield through the paper; Glue, evenly brush all cut surfaces of the stacked magnetic shielding silicon steel sheet in S2; S4, stand still for a period of time, after the special glue for the end face of the silicon steel sheet automatically penetrates into the silicon steel sheet. The method for bonding the magnetic shield of the fuel tank provided by the invention simplifies the difficulty and strength of the production of the magnetic shield of the fuel tank through the improvement of the bonding technology of the magnetic shield of the fuel tank, improves the production efficiency, and reduces the production cost.

Owner:TIANWEI BAOBIAN HEFEI TRANSFORMER

A flexible circuit board bonding equipment and method for bonding flexible circuit boards

ActiveCN103025076BAvoid stickinessSimplify job difficultyPrinted circuit assemblingFlexible circuitsStructural engineering

The invention discloses a flexible circuit board bonding device and a method for bonding a flexible circuit board. The flexible circuit board bonding device comprises a vertical support, a base, a sliding block capable of sliding vertically on the vertical support, an upper mould fixing seat installed on the sliding block, a cylinder installed on the vertical support and used for driving the sliding block to slide vertically, a lower mould fixing seat installed on the base and a module. The module comprises a lower mould for fixing the flexible circuit board and an upper mould for fixing a machine casing or the support, the upper mould is installed on the upper mould fixing seat, and the lower mould is installed on the lower mould fixing seat. The flexible circuit board bonding device replaces the traditional mode of manually bonding the flexible circuit board, and is high in production efficiency, high in product consistency, low in manufacture cost and strong in practicability.

Owner:SHENZHEN VLG WIRELESS TECH

A kind of secondary etching double-sided circuit board and its processing technology

ActiveCN105578705BReduce generationReduce manufacturing costPrinted circuit manufactureProduction lineInsulation layer

The invention discloses a secondary etching double-sided circuit board and its processing technology. The secondary etching double-sided circuit board comprises: a GTL circuit layer, an insulating PP layer and a GBL circuit layer, and the GBL circuit layer consists of a GBL inner circuit layer Layer and GBL outer circuit layer, the GTL circuit layer and the GBL inner circuit layer are connected to the insulating PP layer at the same time, the GBL outer circuit layer is covered on the GBL inner circuit layer, and the double-sided circuit board is etched twice Secondary circuit processing process formation, including the first circuit production - - - line development - - - line inspection - - - acid etching - - - surface treatment, the second circuit production - - - line development - line inspection - - etching ‑‑‑Electric open and short circuit—after process. The invention only needs secondary production, requires less investment, simplifies the production process and operation difficulty, improves the production efficiency, reduces the production cost, reduces the defective rate of products, and shortens the production cycle of products.

Owner:苏州市三生电子有限公司

Efficient street lamp construction formwork and construction process using same

PendingCN113931219AEasy to embedPrecise positioningPaving gutters/kerbsBulkheads/pilesArchitectural engineeringStructural engineering

Owner:江苏登峰建设工程有限公司

A kind of secondary etching double-sided circuit board and its processing technology

ActiveCN105578707BReduce generationReduce manufacturing costPrinted circuit detailsConductive material chemical/electrolytical removalProduction lineInsulation layer

The invention discloses a secondary etching double-sided circuit board and its processing technology. The secondary etching double-sided circuit board of the present invention comprises: a GTL circuit layer, an insulating PP layer and a GBL stepped surface circuit layer, and the GBL stepped surface circuit layer The layer is composed of GBL inner line layer and GBL outer line layer. The GTL line layer and GBL inner line layer are connected to the insulating PP layer at the same time. The GBL outer line layer is covered on the GBL inner line layer. A secondary etching double The surface circuit board processing process follows the following steps: the first circuit production - - - line development cam compensation - - - line inspection - - - etching - - - the second circuit production - - - line development cam compensation - - - circuit Check--etching--electrical open and short-circuit--after process. The invention only needs secondary production, requires less investment, simplifies the production process and operation difficulty, improves the production efficiency, reduces the production cost, reduces the defective rate of products, and shortens the production cycle of products.

Owner:苏州市三生电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com