Deepwater seabed oil and water separation and reinjection device

An oil-water separation and deep-water technology, which is applied in the production of fluids, wellbore/well components, and earth-moving drilling, etc., can solve problems such as low separation efficiency, and achieve the effect of improving separation efficiency, saving energy, and avoiding blockage of flow channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

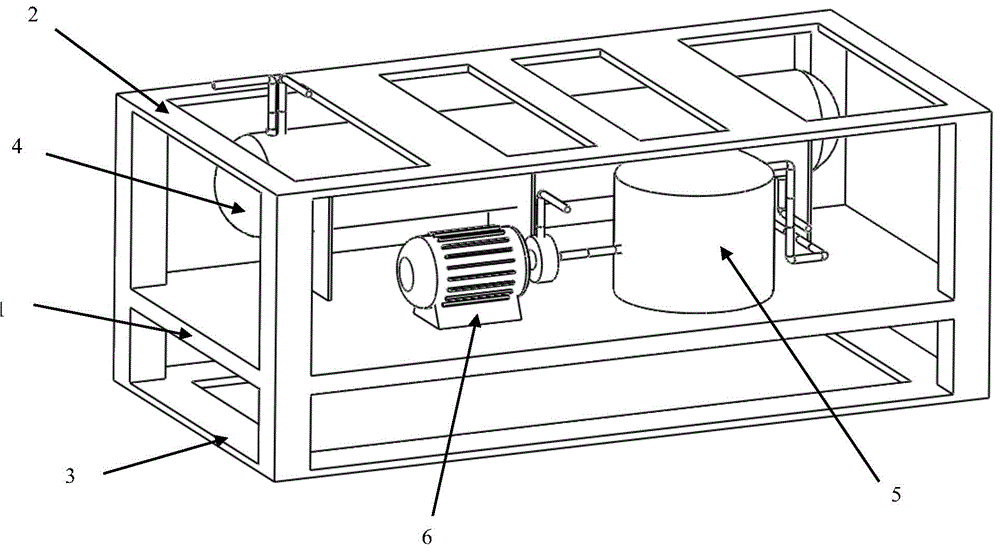

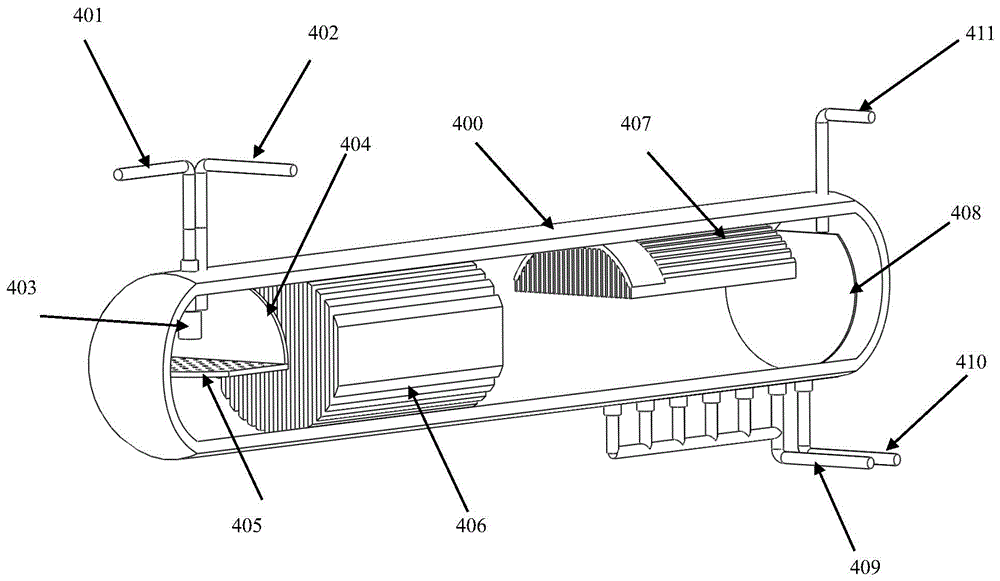

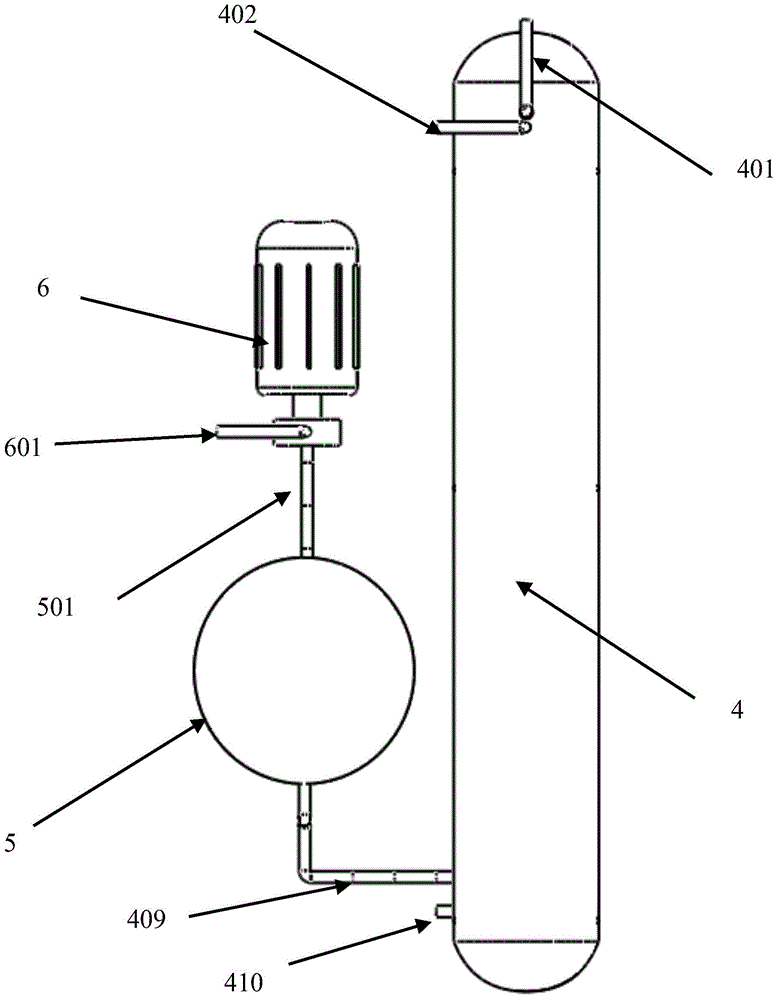

[0018] Such as figure 1 , figure 2 As shown, the deepwater seabed oil-water separation and reinjection device includes: a base platform 1 , an upper support 2 , a lower support 3 , a separator 4 , a buffer tank 5 and a pressurized reinjection pump 6 . exist figure 1 , figure 2 In the middle, the front is on the left and the rear is on the right.

[0019] The upper bracket 2, the lower bracket 3, and the base platform 1 are all rectangular flat structures. The four corners of the upper bracket 2, the lower bracket 3, and the base platform 1 are respectively connected to four bracket legs to form an overall structure. The upper bracket 2, the lower bracket 3. The base platforms 1 are arranged parallel to each other, the upper support 2 is located above the base platform, and the lower support 3 is located below the base platform 1 .

[0020] The upper bracket 2 has wide grooves to facilitate the layout of pipelines so that the upper bracket 2 can be connected with the rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com