Aluminum plate surface treatment technology

A processing technology and technology for aluminum plates, which are applied in the field of processing technology on the surface of aluminum plates, can solve the problems of high processing risk and easy occurrence of safety accidents, and achieve the effects of strong versatility, simplified operation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

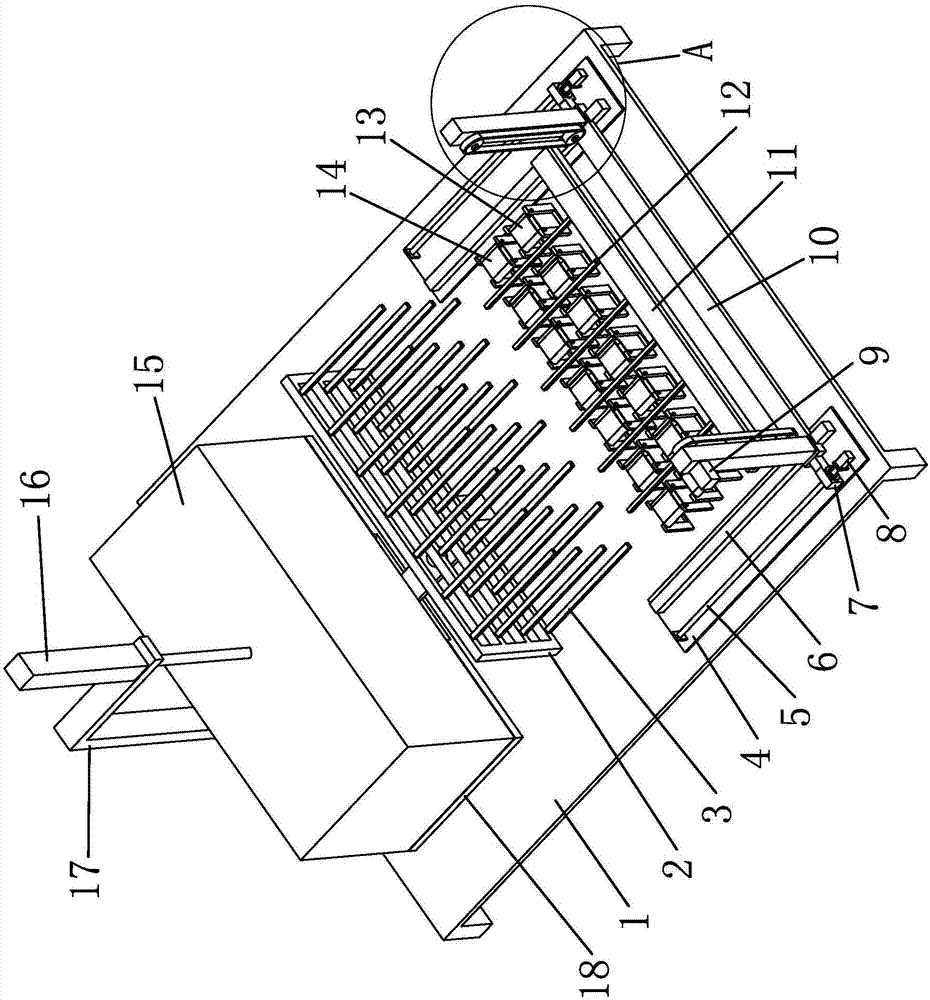

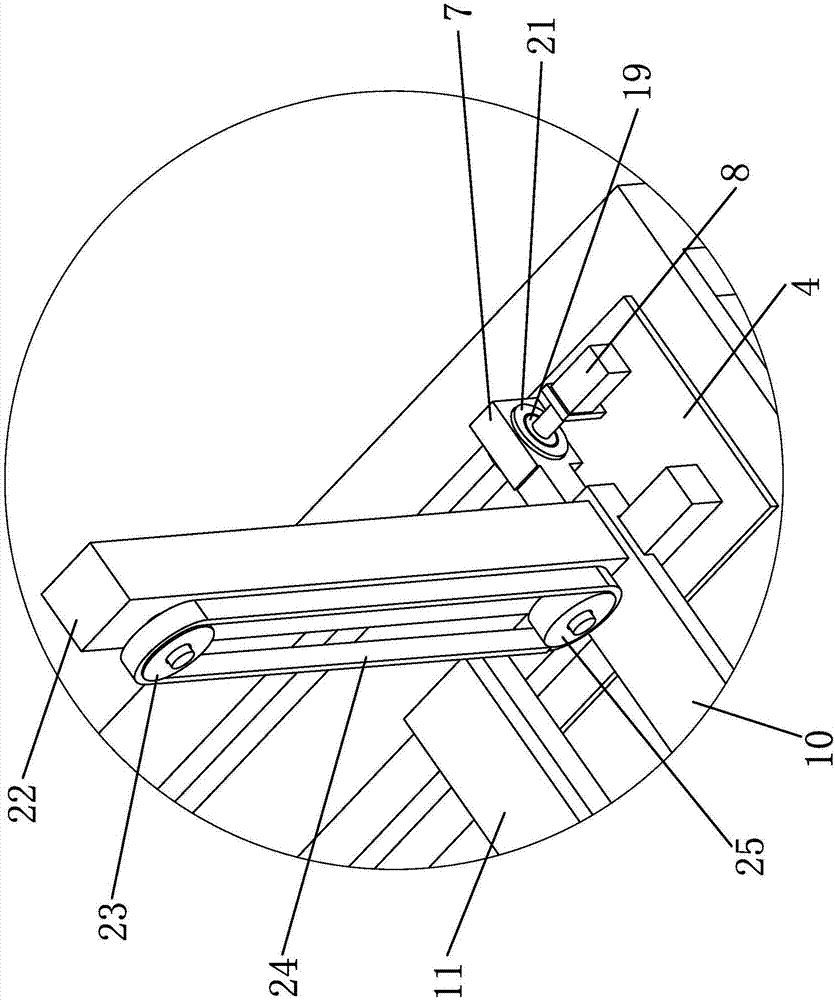

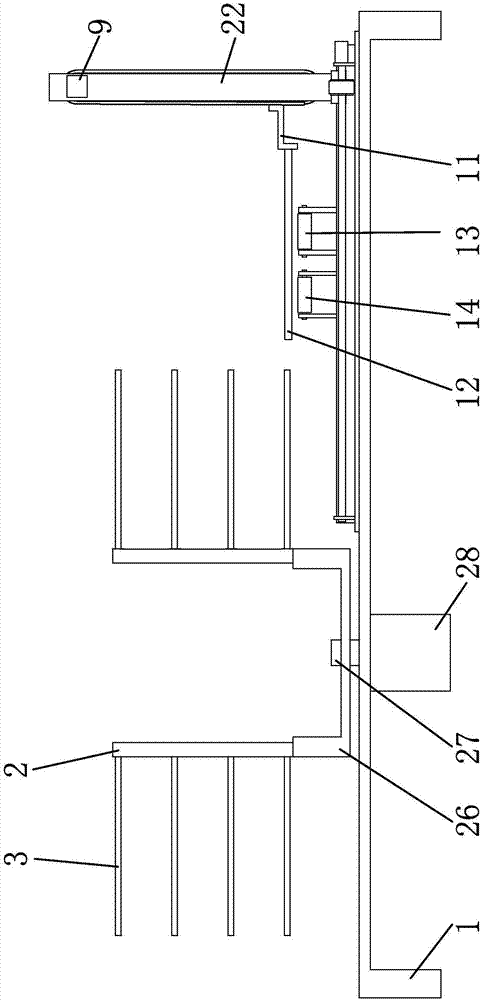

Image

Examples

Embodiment Construction

[0055] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0056] The surface treatment process of the aluminum plate includes the following steps:

[0057] a. Level the surface of the aluminum plate and remove the burrs;

[0058] b. Put the aluminum plate in water with degreasing and degreasing agent, the water temperature is 40-60°C, and vibrate and clean for 2-3 times to remove impurities and grease on the surface of the aluminum plate; in this embodiment, put the aluminum plate in Add degreasing and degreasing agent to the water, the water temperature is 48°C, vibrate and clean, and the number of cleaning is 2 times, to remove impurities and grease on the surface of the aluminum plate;

[0059] c. Immerse the aluminum plate in the lye, the temperature of the lye is 60-70°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com