Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Simple and convenient clamping operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

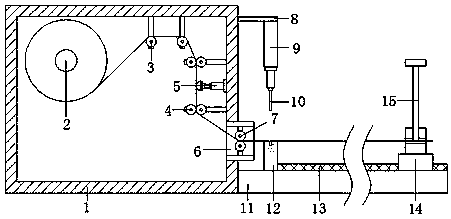

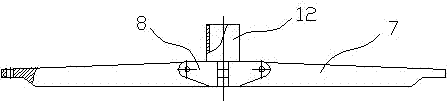

Short pitch film cutting machine

InactiveCN109019094AReduce pollutionReduced Possibility of ContaminationArticle deliveryWebs handlingEngineeringMechanical engineering

The invention discloses a short pitch film cutting machine. The short pitch film cutting machine comprises a material conveying box; a material conveying roll is arranged on the left side of an innercavity of the material conveying box; material guide rolls are symmetrically arranged on the left side and the right side of the top of the inner cavity of the material conveying box; an adjustment and material guide pair roll is arranged at the right side wall of the inner cavity of the material conveying box; an electric telescopic rod is arranged at the right side wall of the inner cavity of the material conveying box; a discharge port is formed at the bottom of the right side wall of the material conveying box; a parallel material guide pair roll is arranged at an inner cavity of the discharge port; a supporting frame is arranged at the top of the right side wall of the material conveying box; a pneumatic telescopic rod is arranged at the bottom of the supporting frame; a cutting knifeis arranged at the bottom of the pneumatic telescopic rod; a supporting base is arranged at the bottom of the right side wall of the material conveying box; a cutting table and a sliding rail are arranged at the top of the supporting base; the top of the sliding rail is connected with an electric sliding block in a sliding manner; and a film fixing mechanism is arranged at the top of the electricsliding block. The short pitch film cutting machine is reasonable in structural design, the probability of folding during film cutting can be reduced, an error during cutting is lowered, and adjustments can be made according to the requirement on the cut length.

Owner:HONGCHENG SCI & TECH LTD

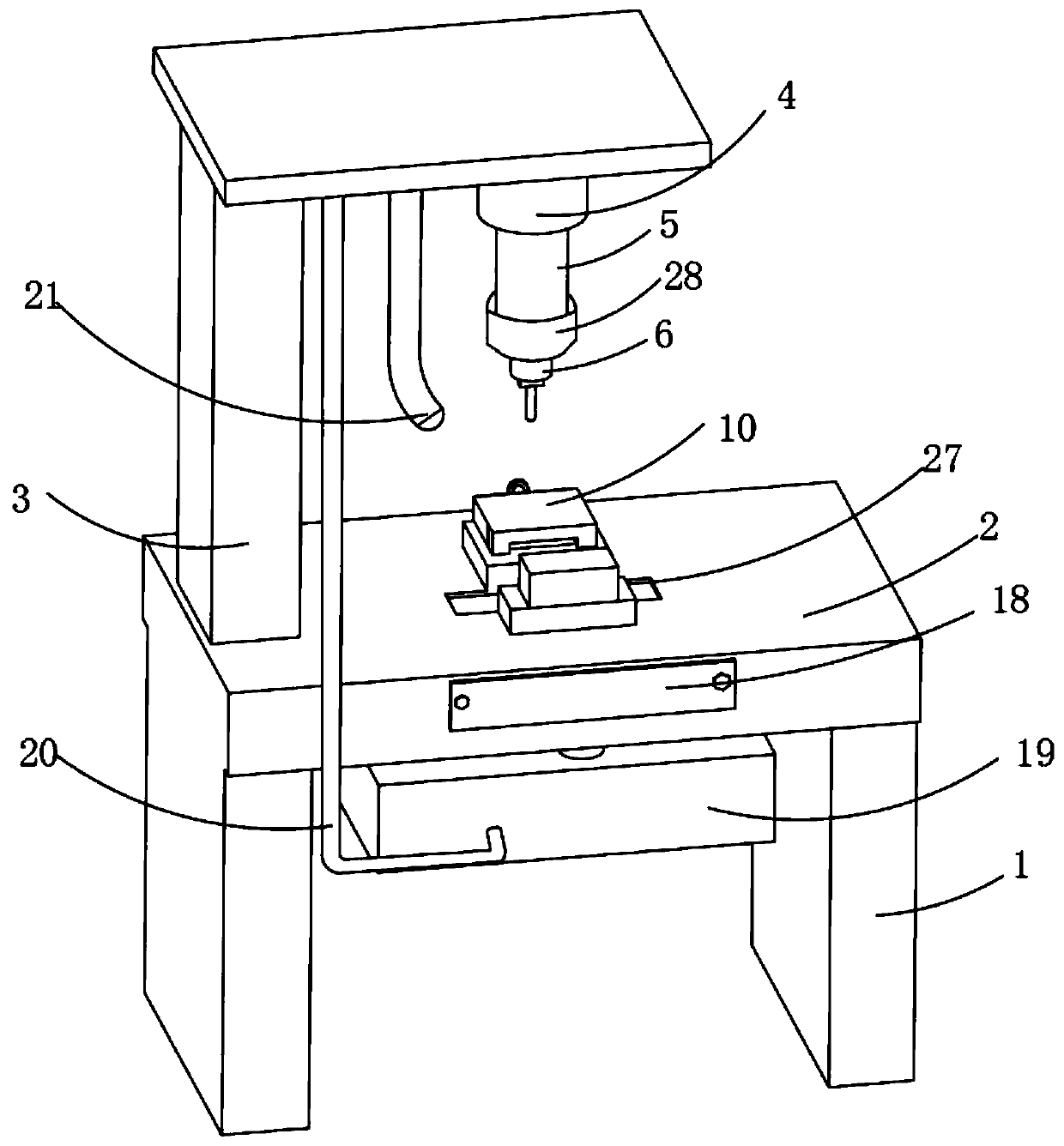

Drilling equipment used for machine parts

InactiveCN108031902AImprove processing efficiencySimple structureFeeding apparatusPositioning apparatusElectric machineryGeotechnical engineering

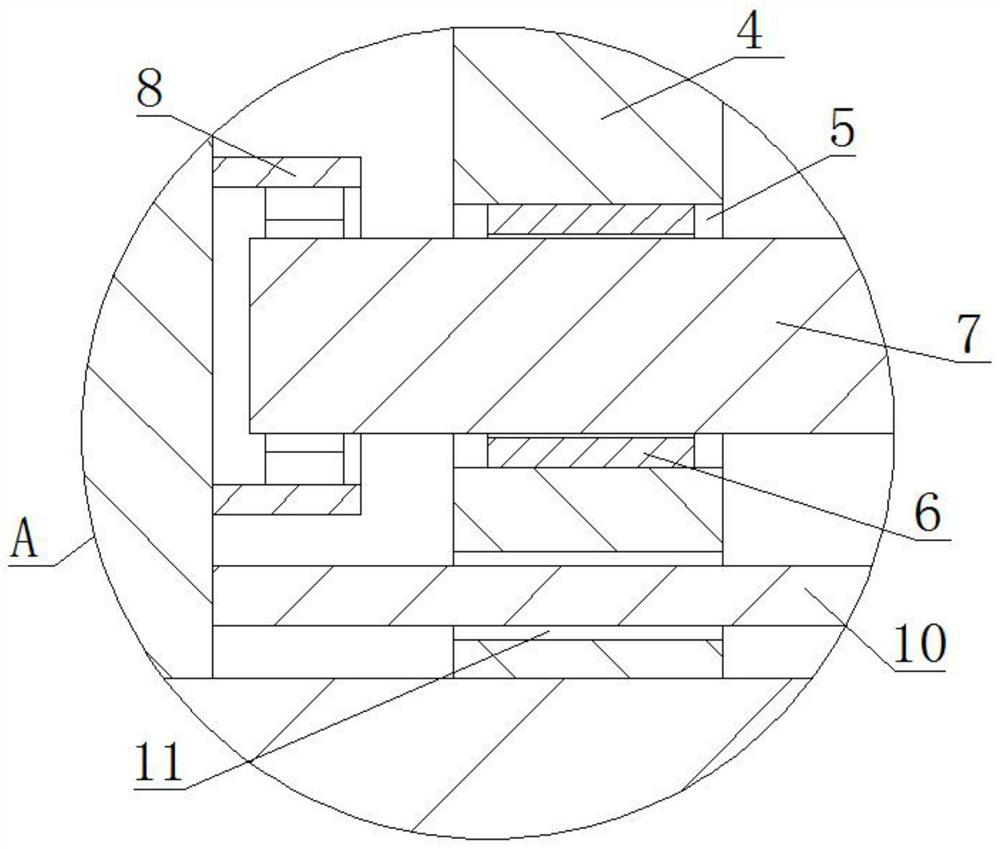

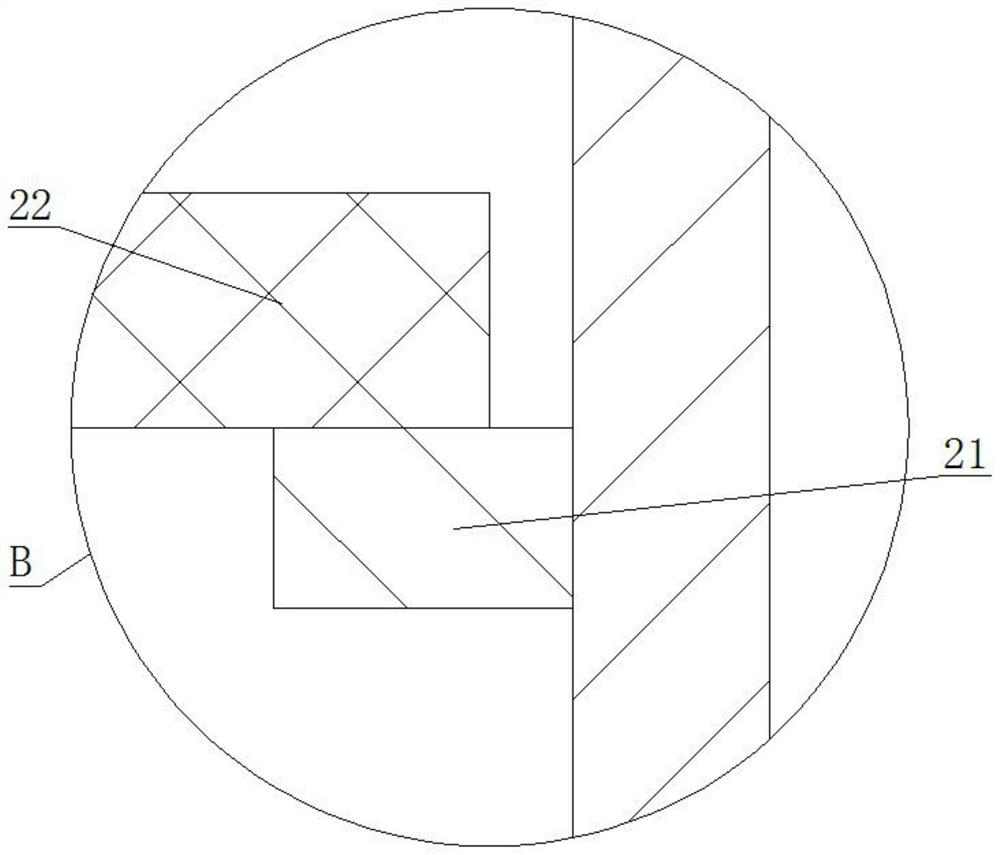

The invention belongs to the technical field of machining, and particularly discloses drilling equipment used for machine parts. The drilling equipment comprises a rack, a drilling unit and a clampingunit, the clamping unit is fixed to the rack and is located above the drilling unit, the drilling unit comprises a rigid corrugated pipe with the closed lower end, a threaded rod and a motor drivingthe threaded rod to rotate, the rigid corrugated pipe is rotationally connected to the rack, a spiral bit is fixed into the rigid corrugated pipe, and the axis of the spiral bit is coincident with theaxis of the rigid corrugated pipe in position; a strip-shaped groove is formed in the side wall of the threaded rod, the upper side of the threaded rod is connected into the spiral bit in a sliding manner, the axis of the threaded rod is coincident with the axis of the spiral bit, and a protrusion connected into the strip-shaped groove in a sliding manner is arranged in the spiral bit; and a pushing sleeve is in threaded connection to the threaded rod, a sliding groove is formed in the pushing sleeve, and a limiting rod with one end clamped into the sliding groove is fixed to the rack. By means of the drilling equipment, the problem that when placed on a working table, the machine parts are prone to being scrapped to be damaged by metal chippings is solved.

Owner:宁波德深机械设备有限公司

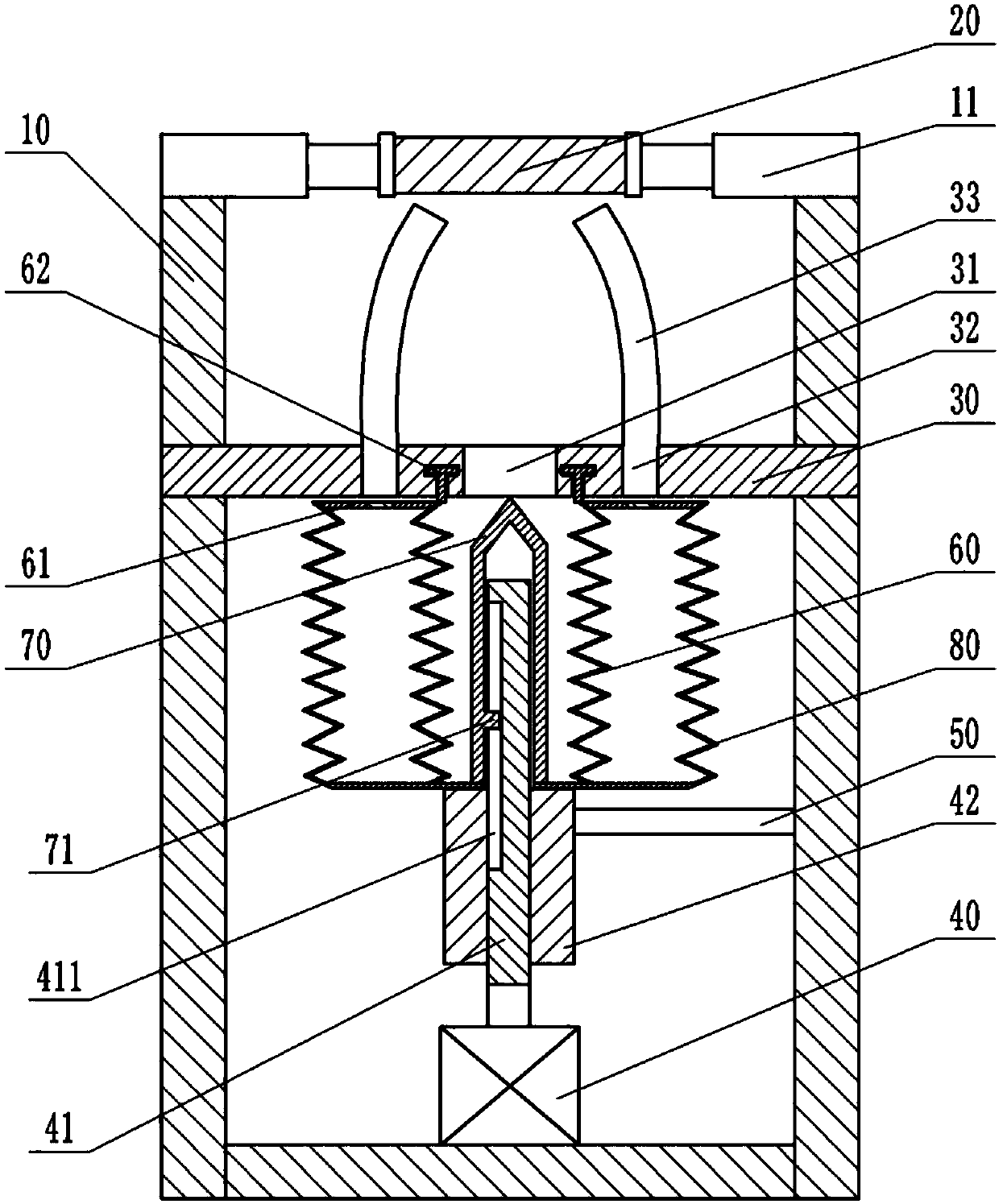

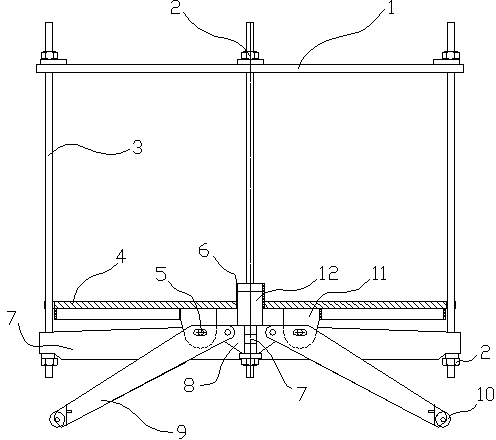

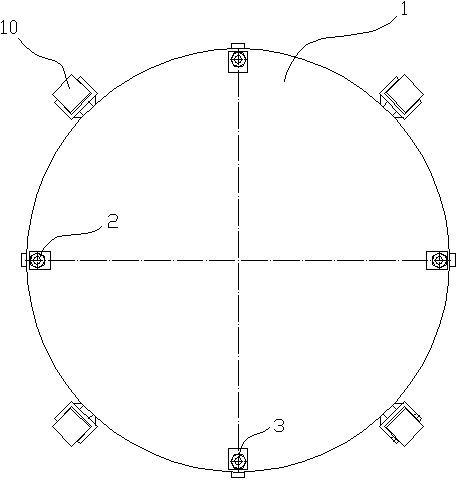

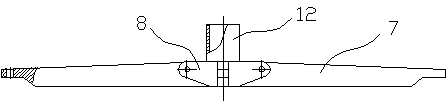

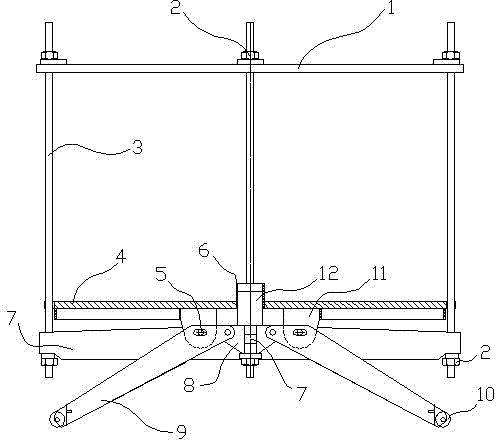

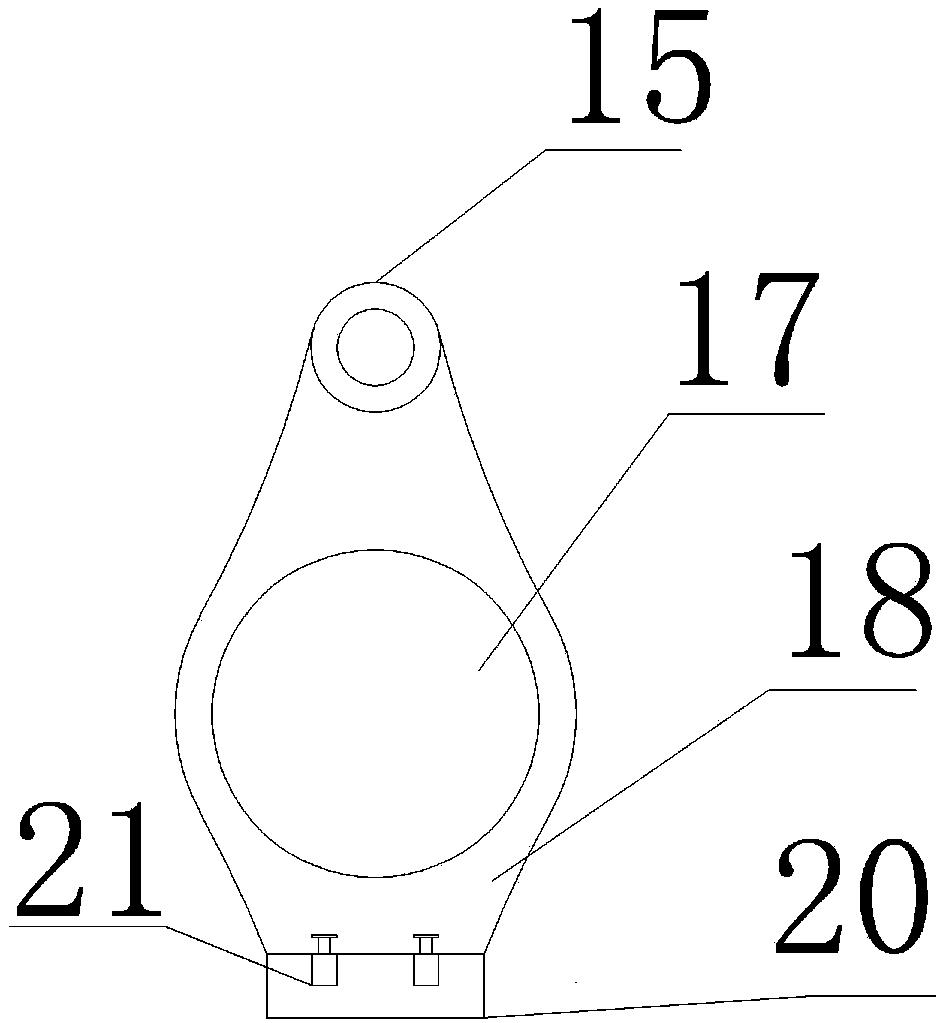

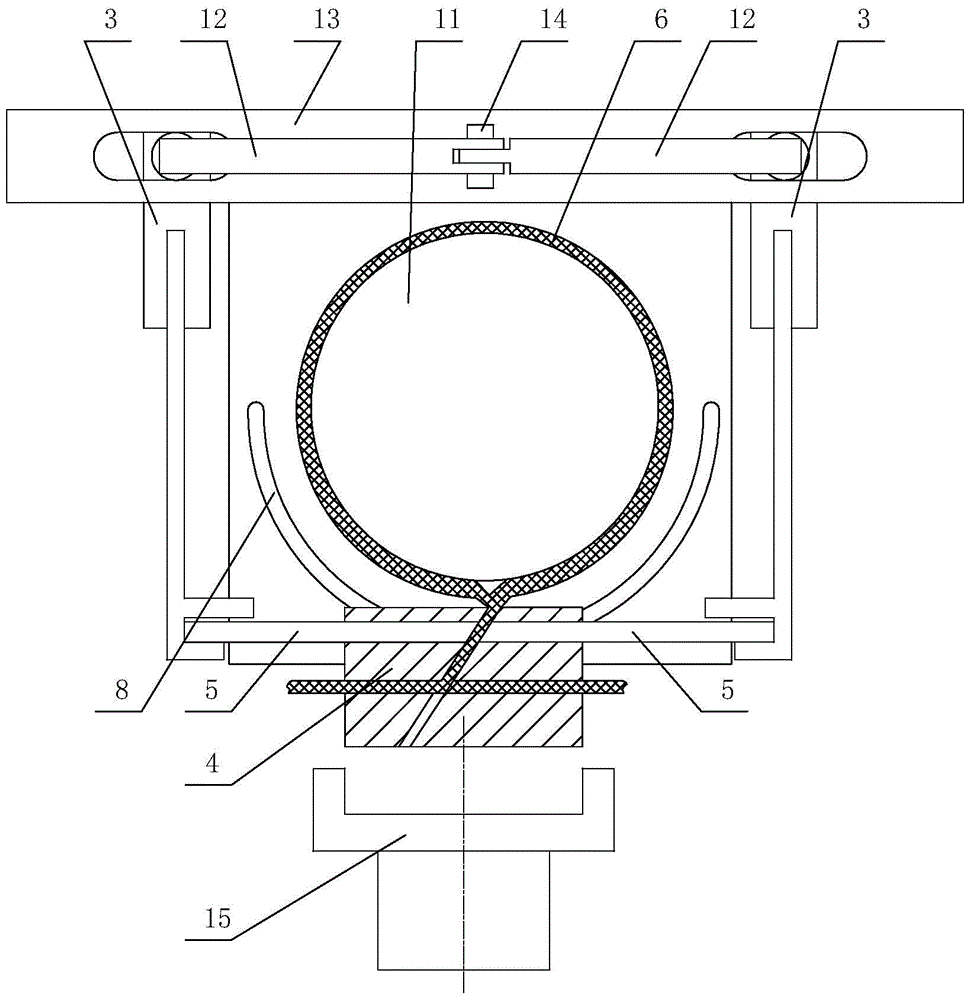

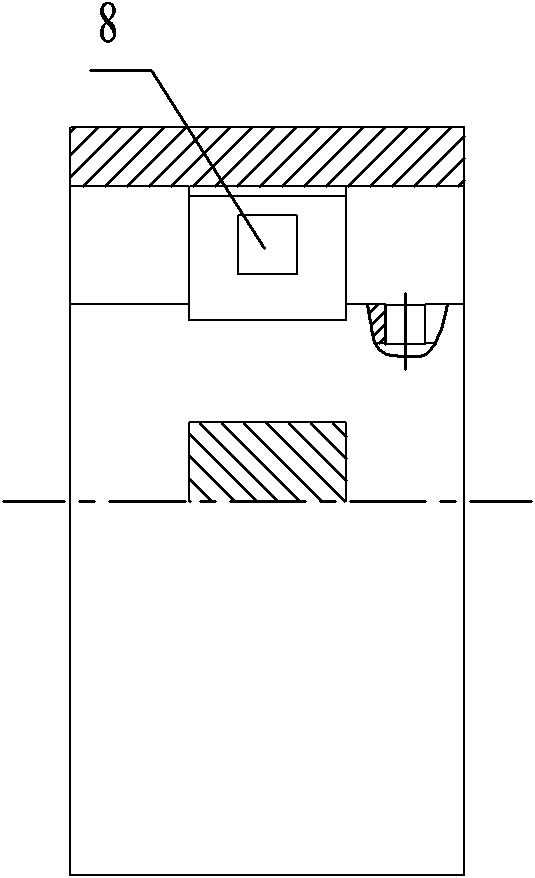

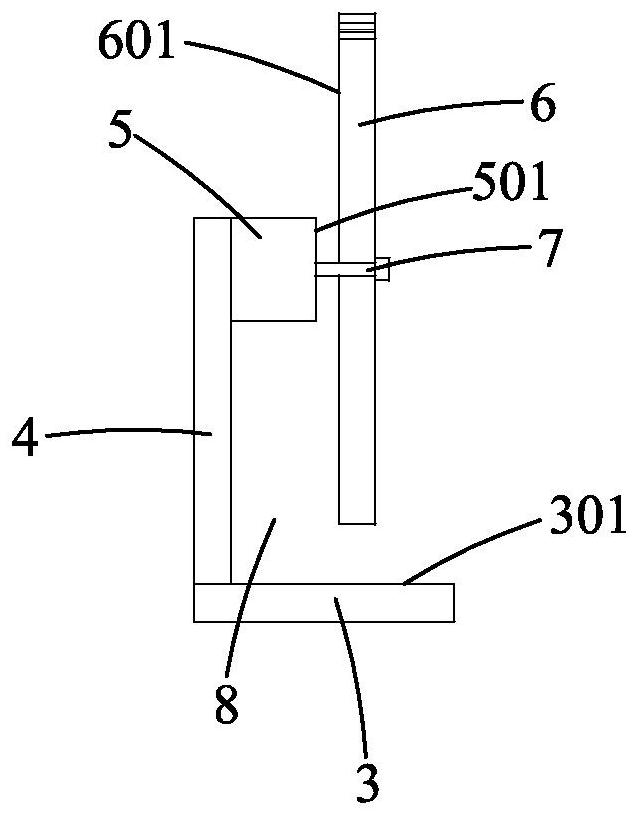

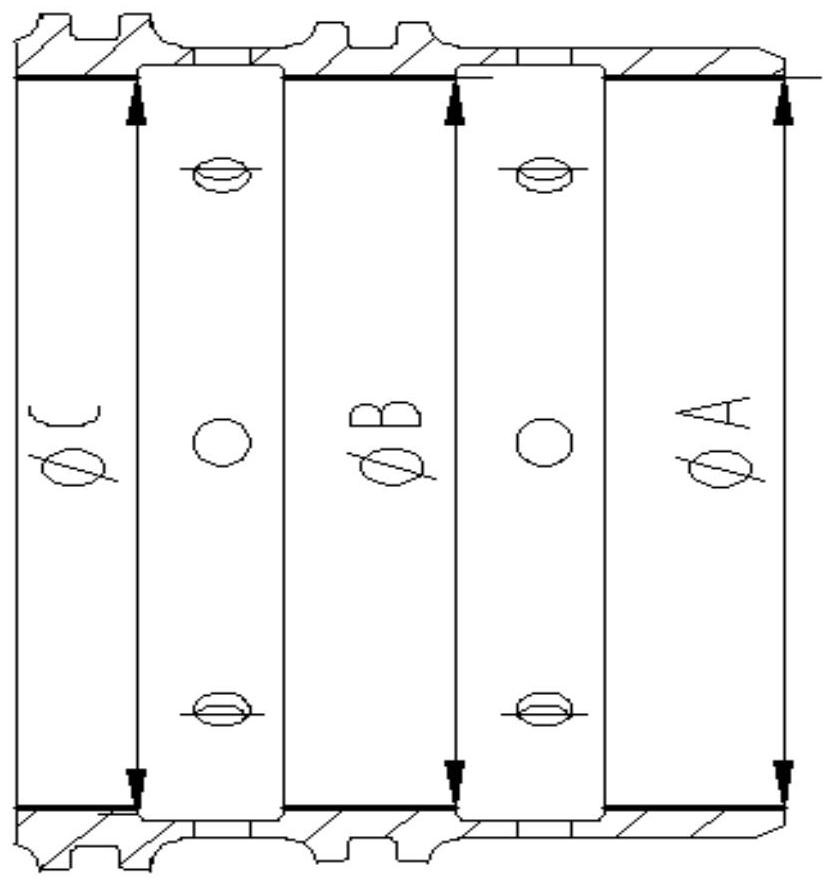

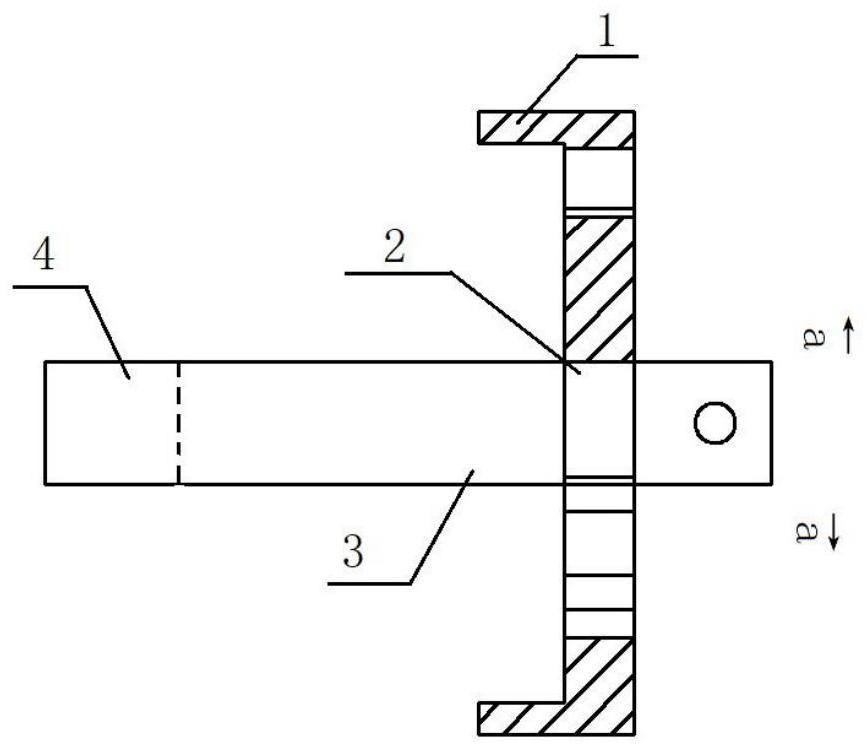

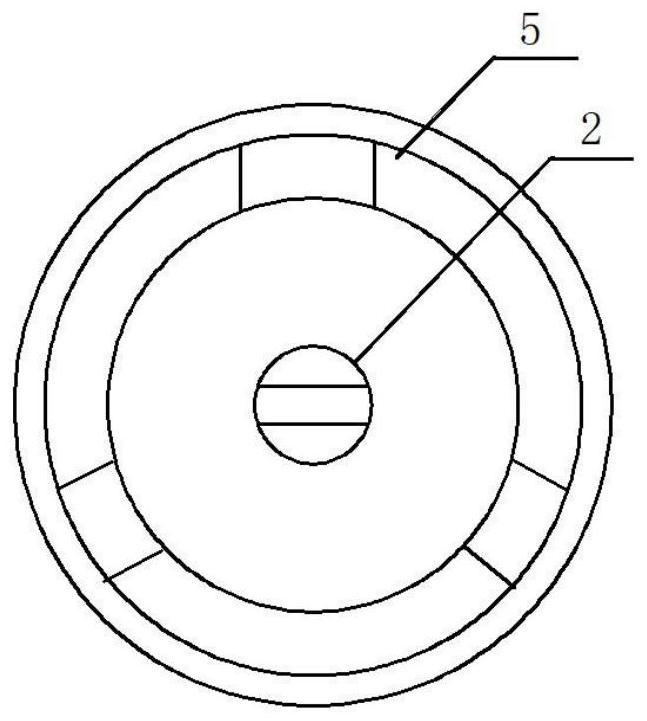

Constant pressing device for drying transformer windings

ActiveCN102709046AReliable compressionSimple and convenient clamping operationCoils manufactureConductor CoilMechanical engineering

The invention discloses a constant pressing device for drying transformer windings. The constant pressing device comprises an upper pressing disc, a lower pressing disc, pull rods, a force transmitting frame and at least three tripods, wherein rolling wheels are mounted at the outer ends of the tripods, and the inner ends of the tripods are simultaneously hinged with the force transmitting frame and the lower pressing disc; the tripods and the force transmitting frame are positioned right below the lower pressing disc; the outer end of the force transmitting frame is sleeved at the lower ends of the pull rods; and the upper pressing disc positioned right above the upper pressing disc is sleeved at the upper ends of the pull rods. The pressing device can exert a continuous and constant pressing force to the windings when the transformer windings are subject to vacuum drying.

Owner:CHONGQING NARI BORUI TRANSFORMER CO LTD

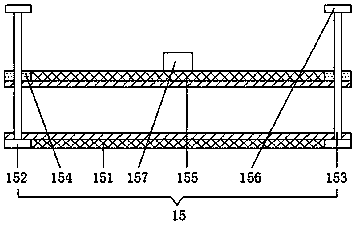

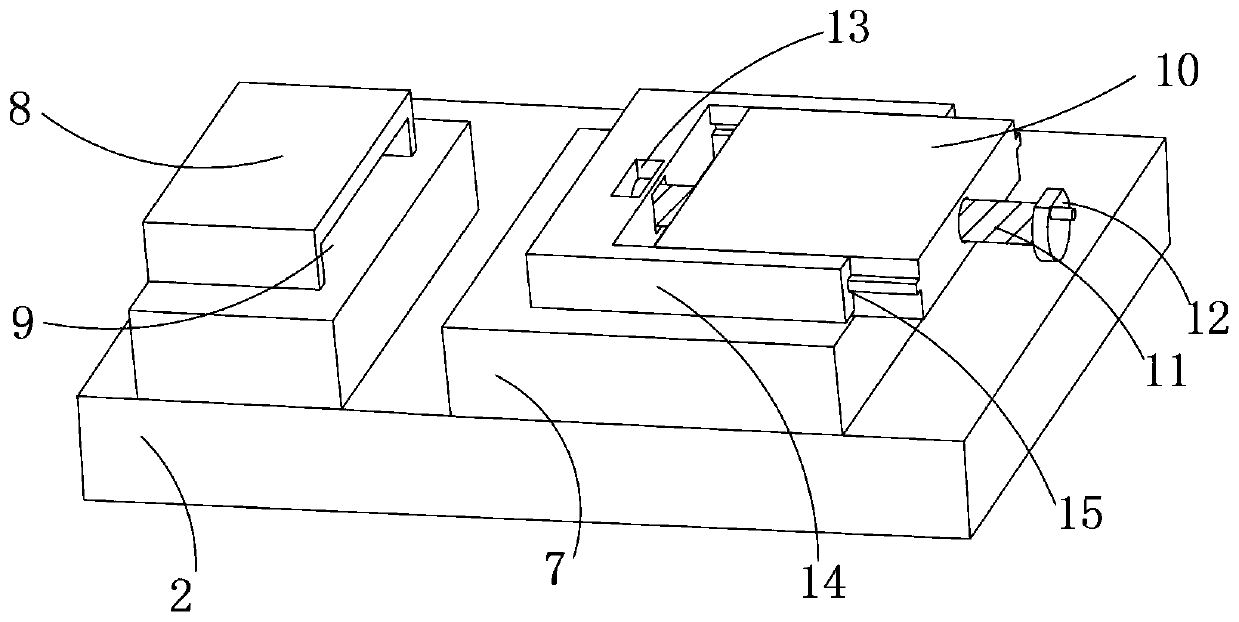

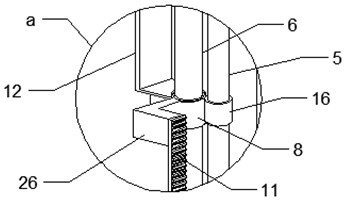

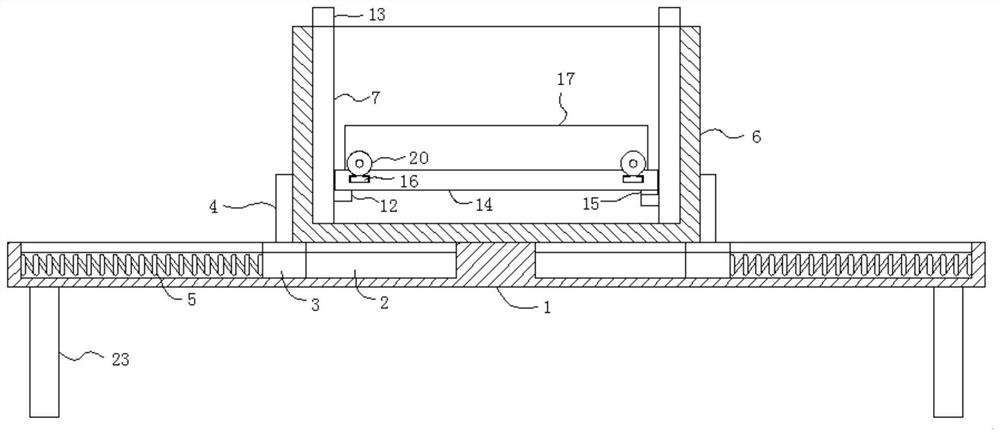

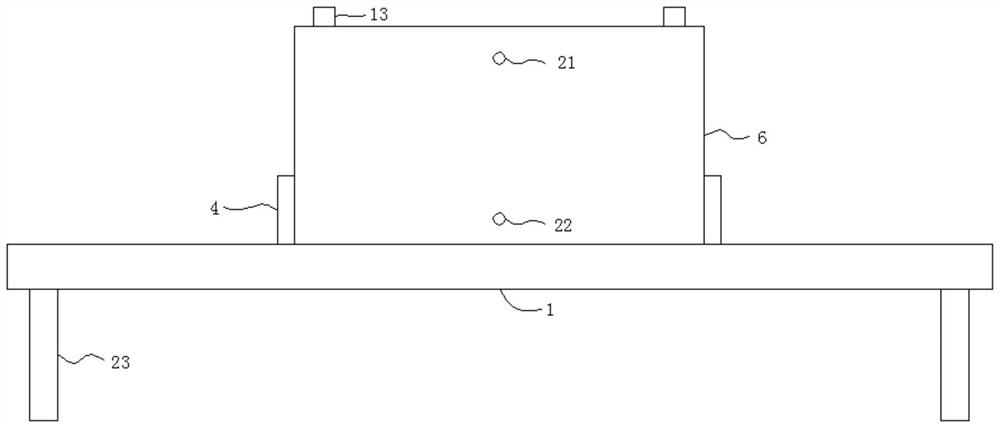

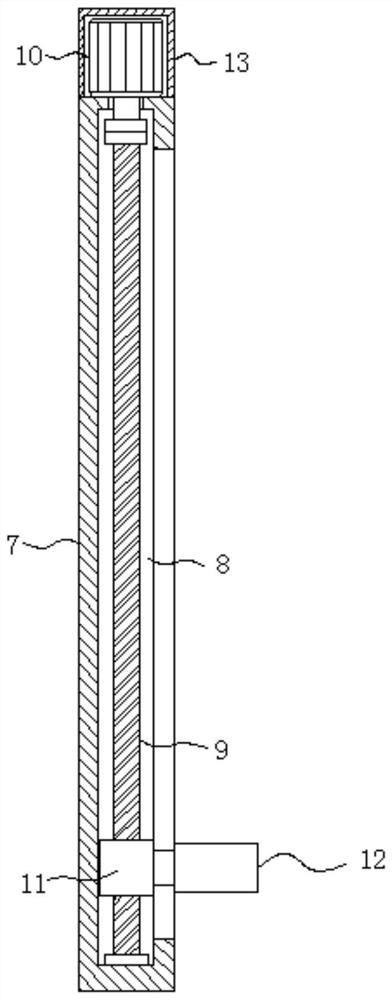

Car drum type brake gasket drilling device

InactiveCN110640183AScientific and reasonable structureEasy to usePositioning apparatusMaintainance and safety accessoriesBrakeStructural engineering

The invention discloses a car drum type brake gasket drilling device. A worktable is fixedly mounted on the top of a base, a rack is mounted on one side of the top of the worktable, an air cylinder isarranged on the bottom of the inner side of the top end of the rack, the bottom of the air cylinder is connected with a telescopic rod, the bottom of the telescopic rod is provided with a tool fixingsleeve, fixed bases are symmetrically mounted on the middle of the top end of the worktable, abutting blocks are connected to one ends of the tops of the fixed bases, fixed blocks are connected to the positions, corresponding to the abutting blocks, of the tops of the fixed bases, the surfaces of the fixed blocks are movably connected with clamping blocks, clamping grooves are formed in the clamping blocks, sliding grooves are symmetrically formed in the two ends of each clamping block, and screw rods are sleeved with the fixed blocks in a penetrating manner. Through screw rod feeding, the clamping blocks are extruded and clamp machining parts, the adjusting of the clamp position is improved, a placing hole is used for facilitating fixing of an arc gasket, stability during machining is ensured, and punching failures can be avoided.

Owner:长兴永润机械有限公司

Constant pressing device for drying transformer windings

ActiveCN102709046BReliable compressionSimple and convenient clamping operationCoils manufactureEngineeringConductor Coil

The invention discloses a constant pressing device for drying transformer windings. The constant pressing device comprises an upper pressing disc, a lower pressing disc, pull rods, a force transmitting frame and at least three tripods, wherein rolling wheels are mounted at the outer ends of the tripods, and the inner ends of the tripods are simultaneously hinged with the force transmitting frame and the lower pressing disc; the tripods and the force transmitting frame are positioned right below the lower pressing disc; the outer end of the force transmitting frame is sleeved at the lower ends of the pull rods; and the upper pressing disc positioned right above the upper pressing disc is sleeved at the upper ends of the pull rods. The pressing device can exert a continuous and constant pressing force to the windings when the transformer windings are subject to vacuum drying.

Owner:CHONGQING NARI BORUI TRANSFORMER CO LTD

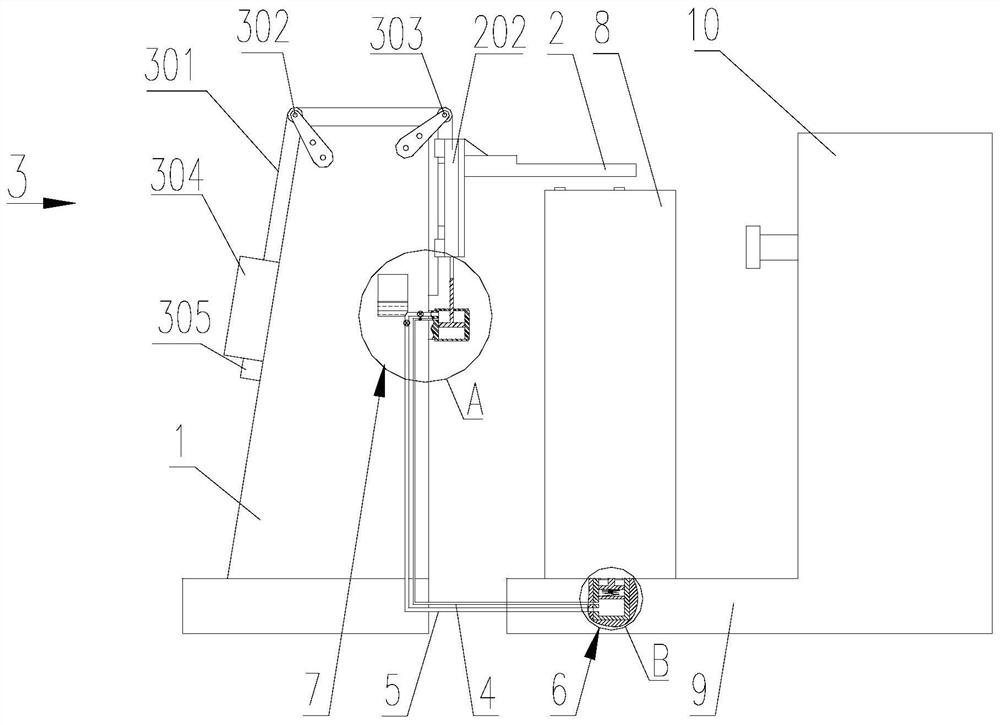

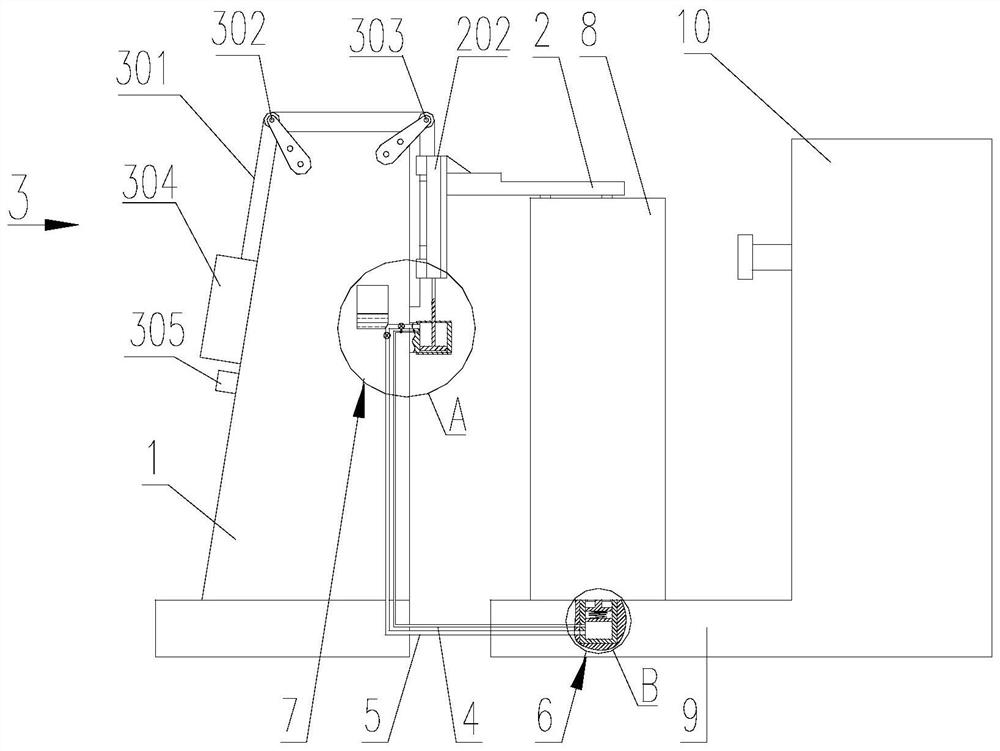

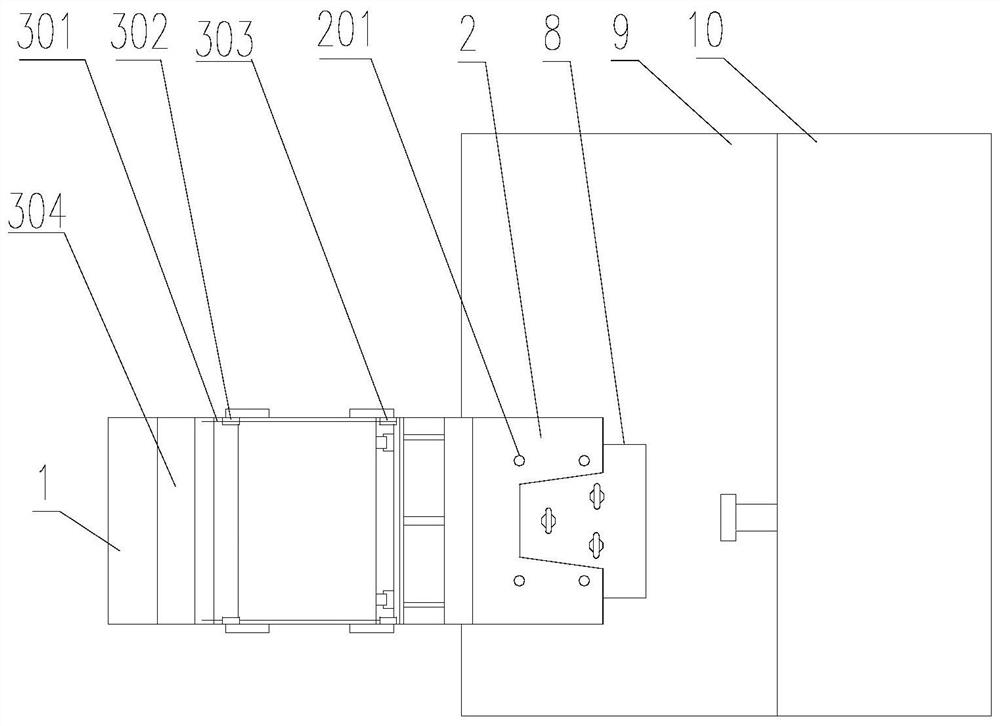

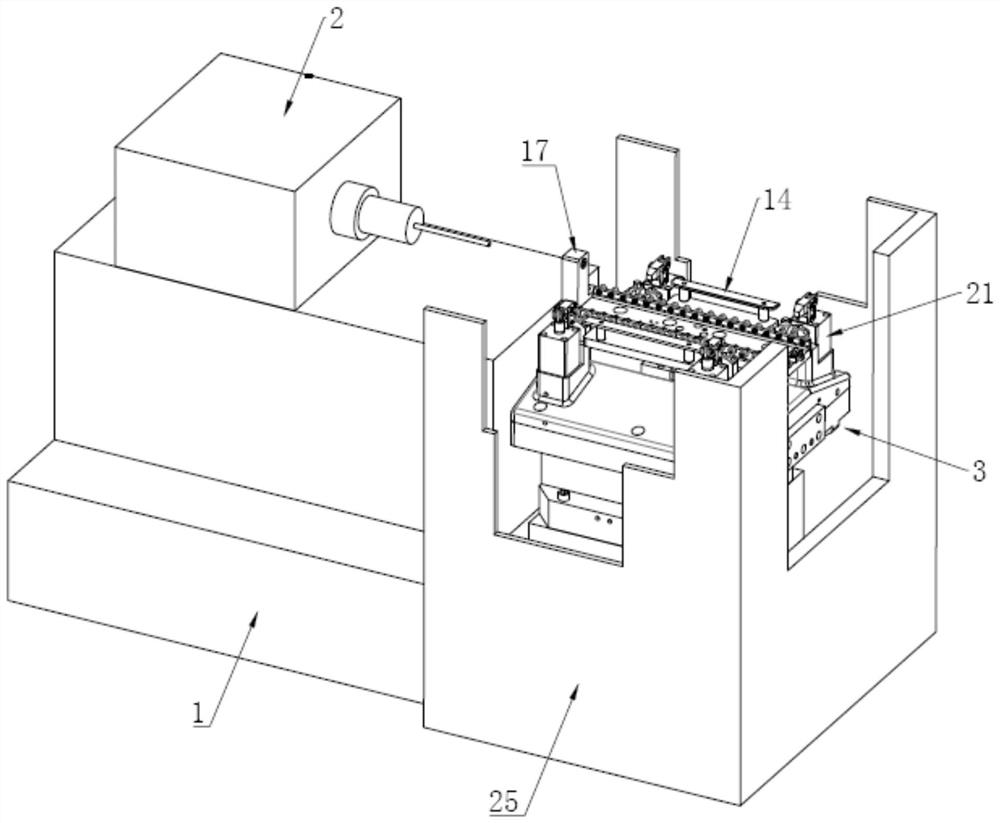

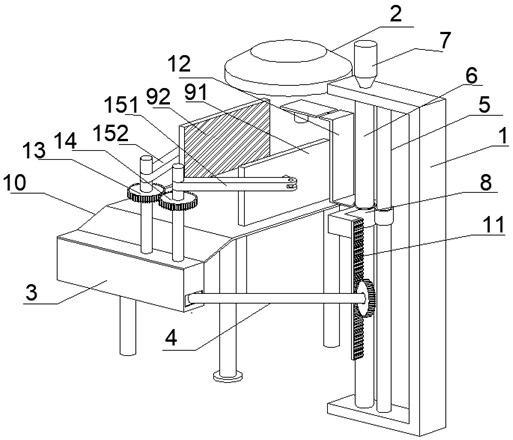

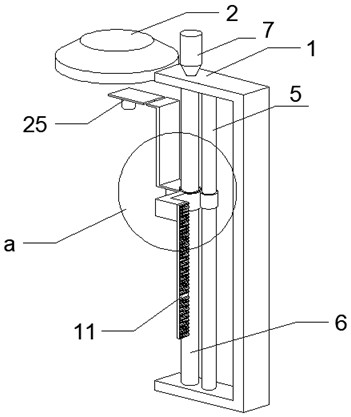

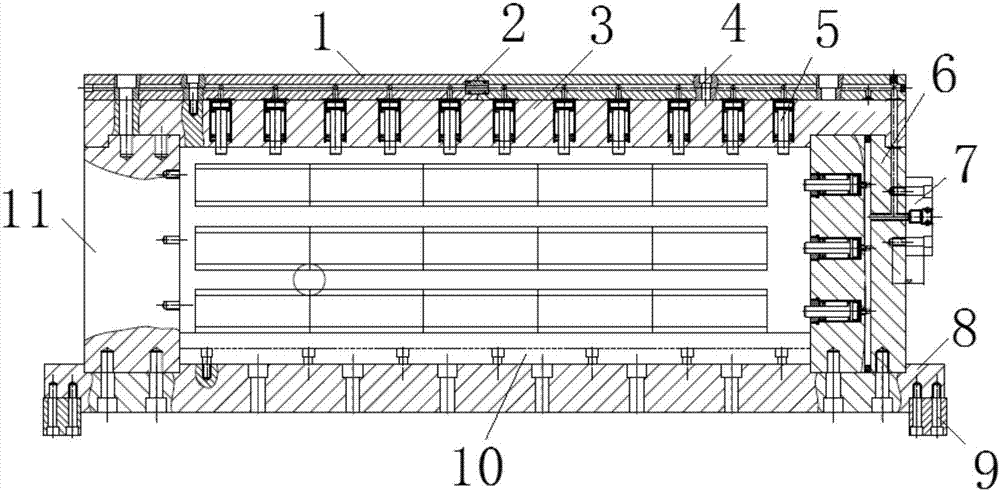

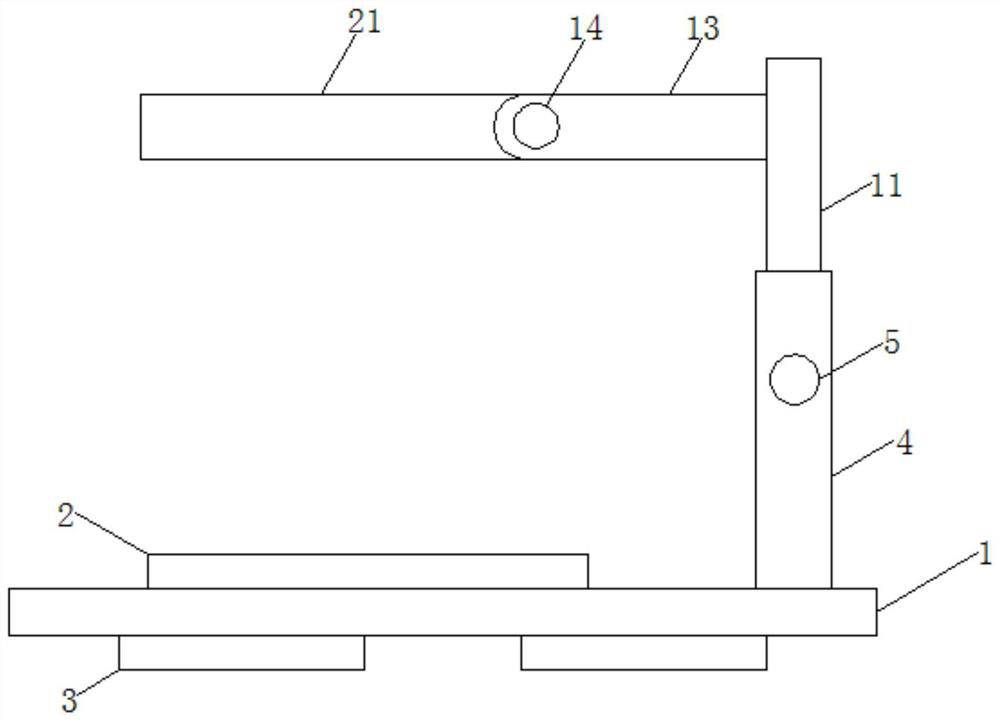

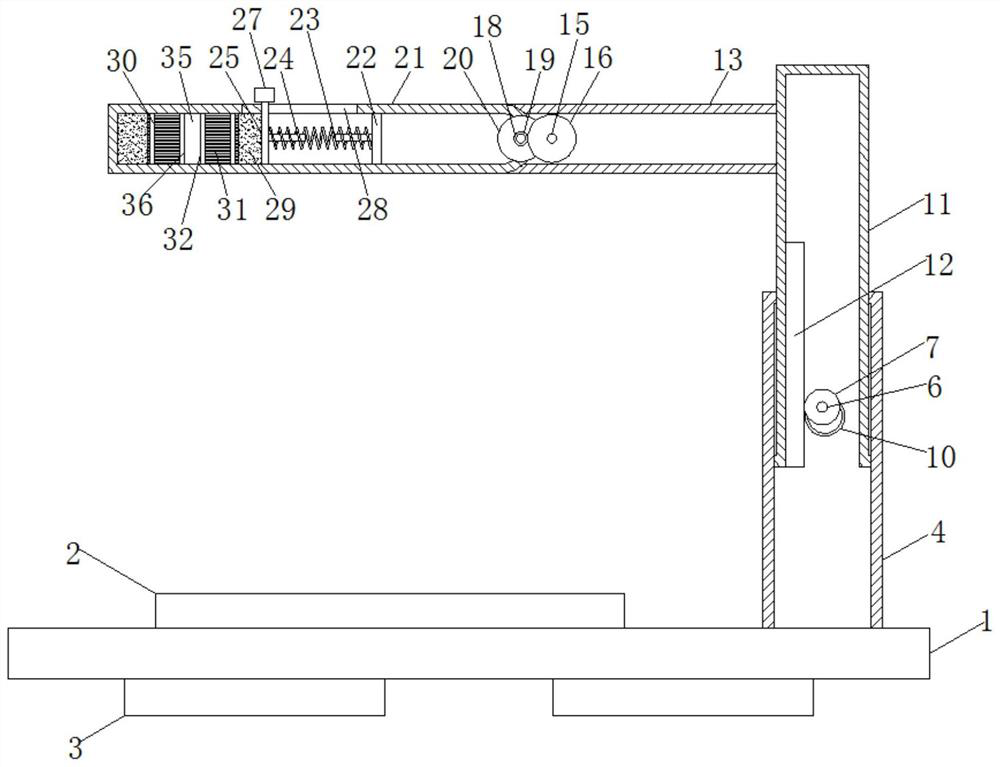

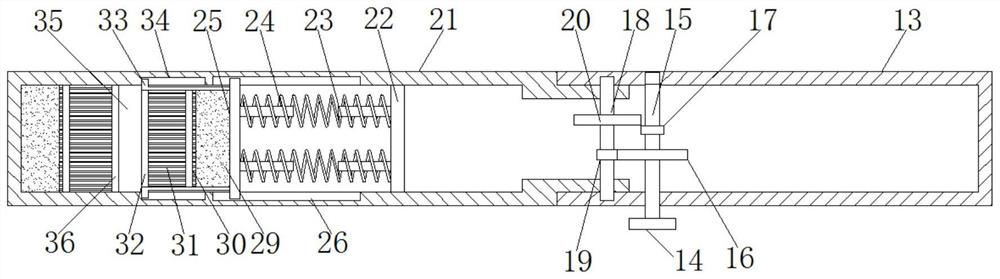

Robot component intelligent boring and milling machining center compressing device

PendingCN112935887ALittle elasticityAvoid affecting the control effectPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to the technical field of numerical control machining center equipment, in particular to a robot component intelligent boring and milling machining center compressing device. The robot component intelligent boring and milling machining center compressing device comprises a support and a pressing plate, wherein the pressing plate is installed on the side face of the support in a sliding mode, fixing holes matched with a workpiece are formed in the pressing plate, and the robot component intelligent boring and milling machining center compressing device further comprises a balance assembly used for balancing the gravity of the pressing plate and an energy storage assembly and a piston rod assembly which comprise a first cylinder body, a second cylinder body and an oil tank. According to the robot component intelligent boring and milling machining center compressing device, a closed oil way is formed through communication of a backflow oil pipe, an output oil pipe and an overflow oil pipe, when the robot component intelligent boring and milling machining center compressing device is used, the balance assembly pulls the pressing plate to keep the pressing plate in a normally-lifted state, a spring of the energy storage assembly is compressed to store energy through the pressure of the workpiece on a workbench, the tension of the pressing plate is adjusted through the piston rod assembly, lifting and pressing actions of the pressing plate can be completed only by controlling three control valves on the oil way, the device does not need extra power, work is reliable, workpiece clamping operations are simple and convenient, and clamping efficiency is high.

Owner:CHANGZHOU INST OF LIGHT IND TECH

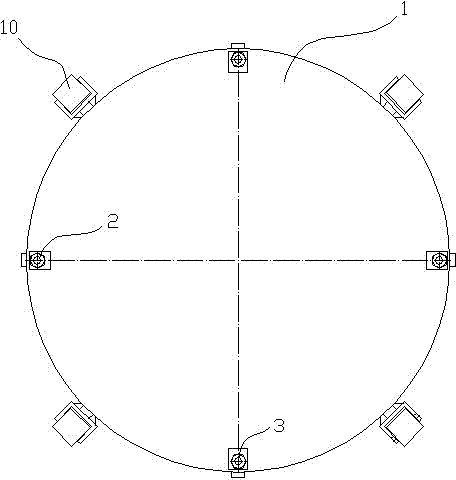

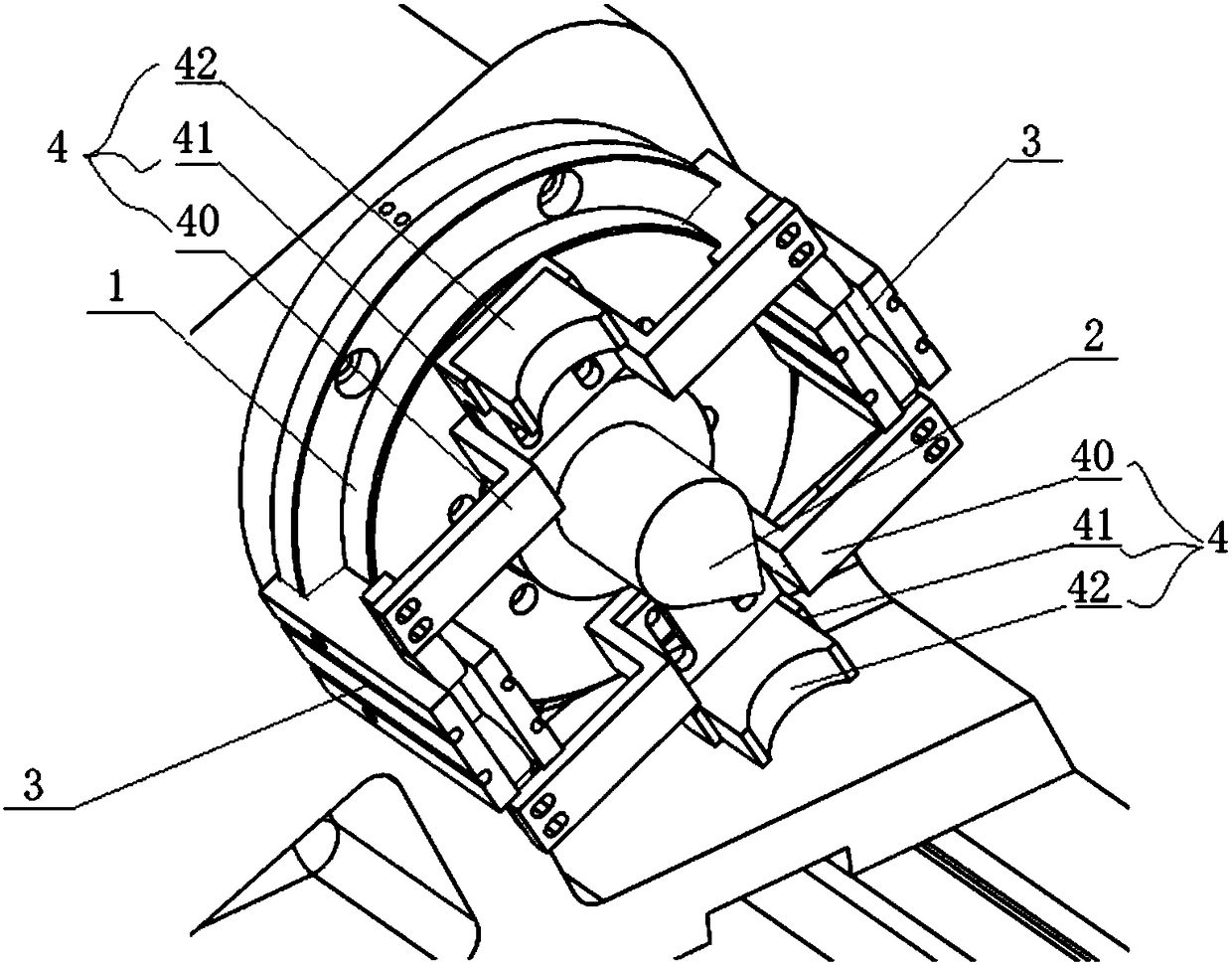

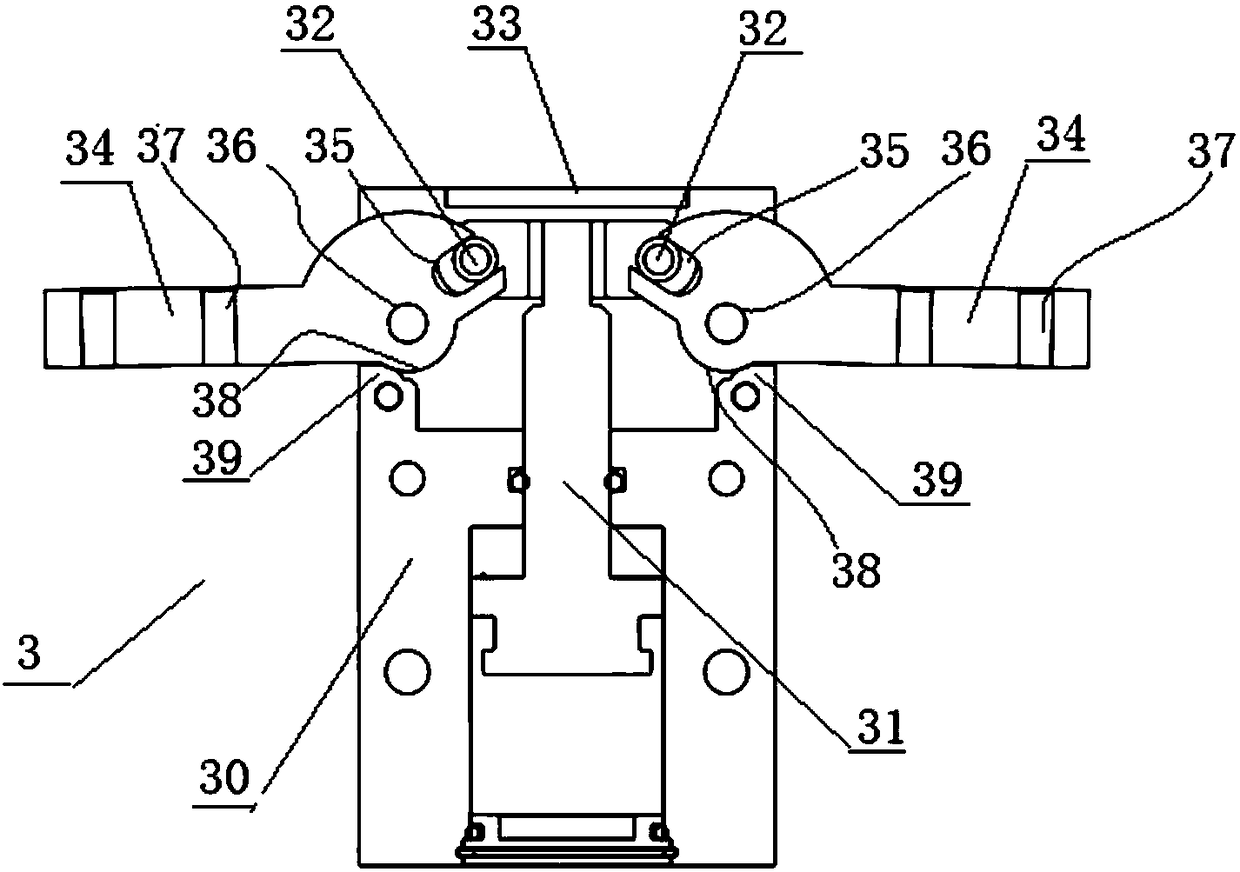

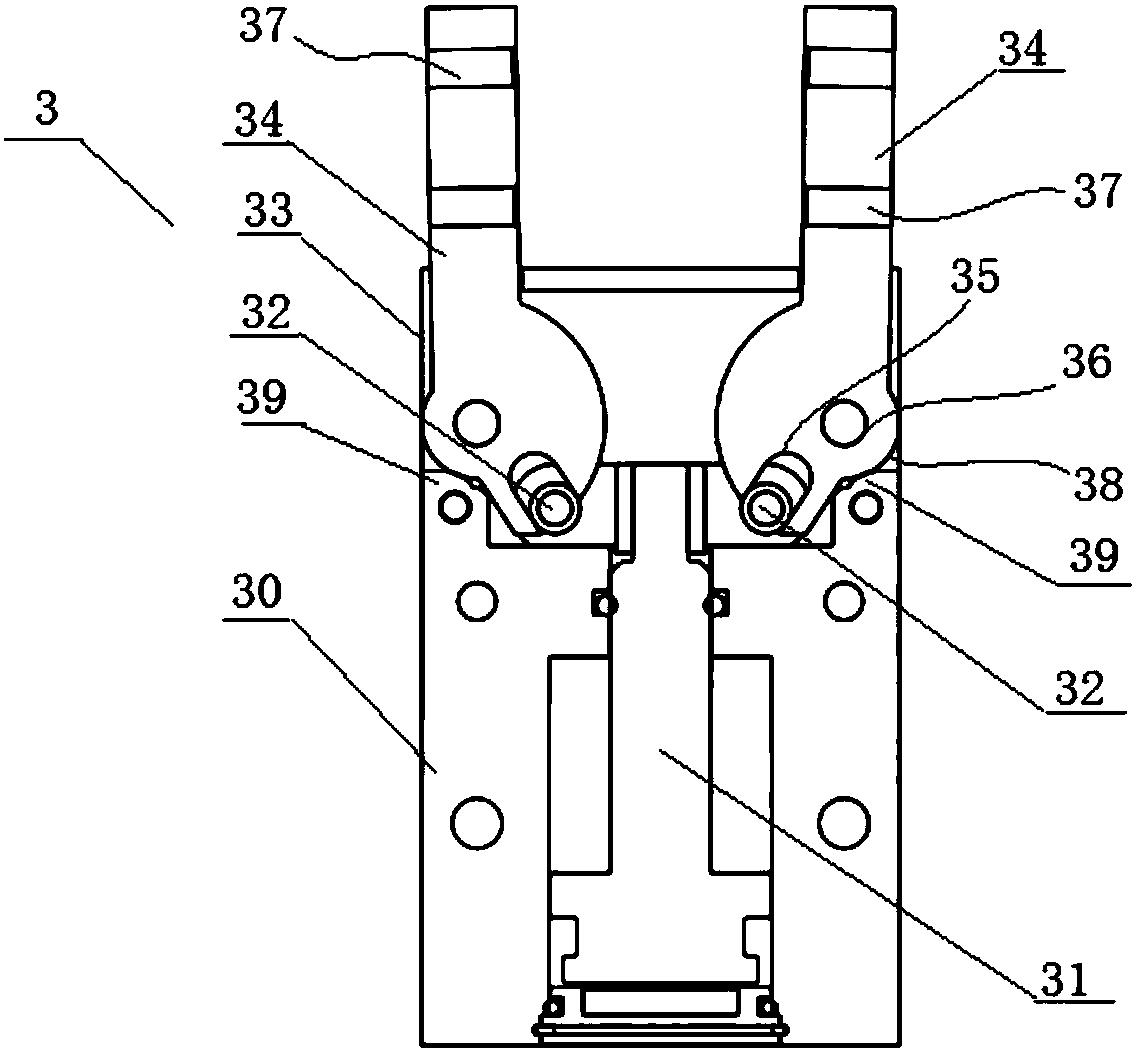

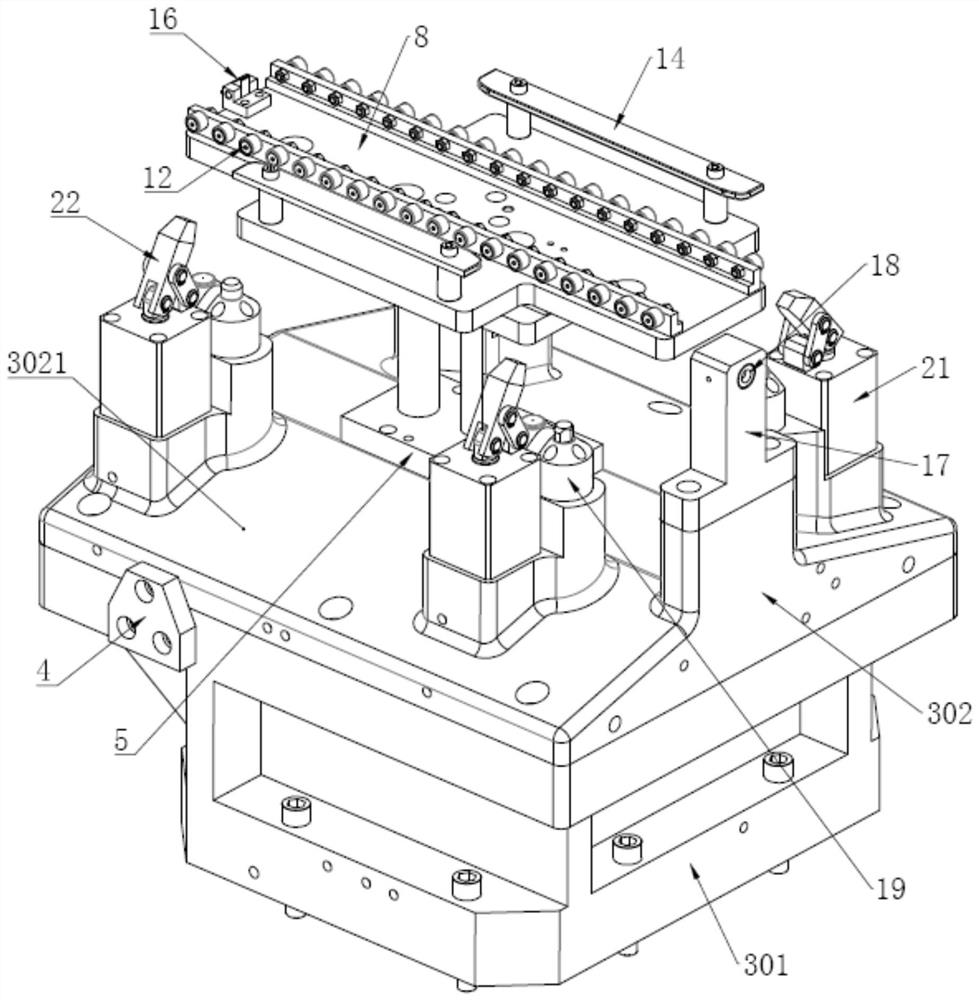

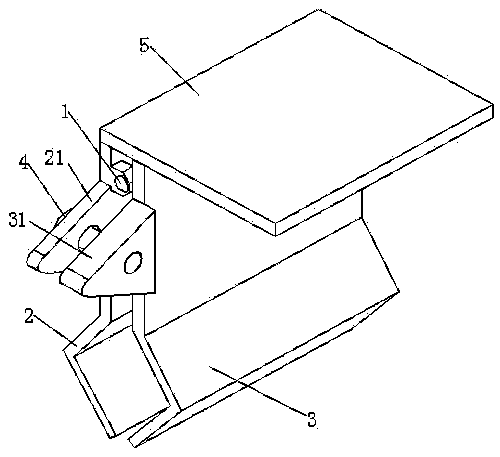

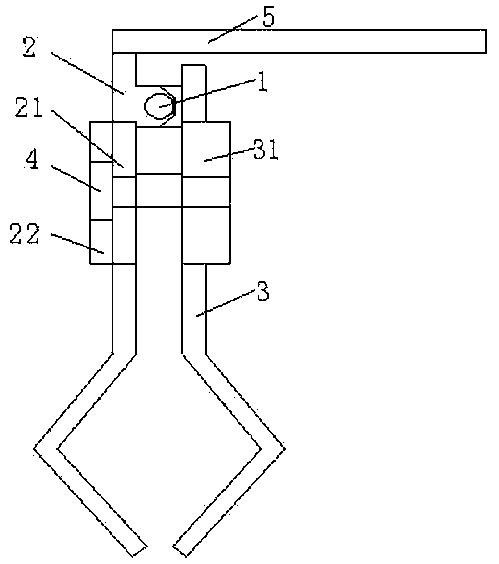

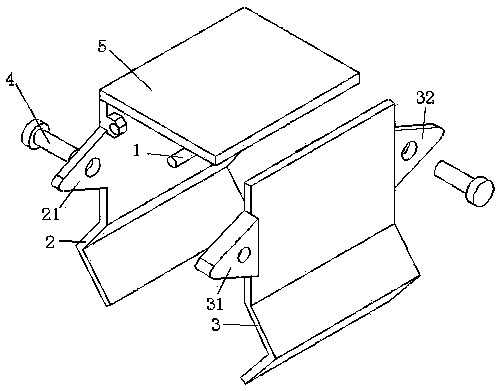

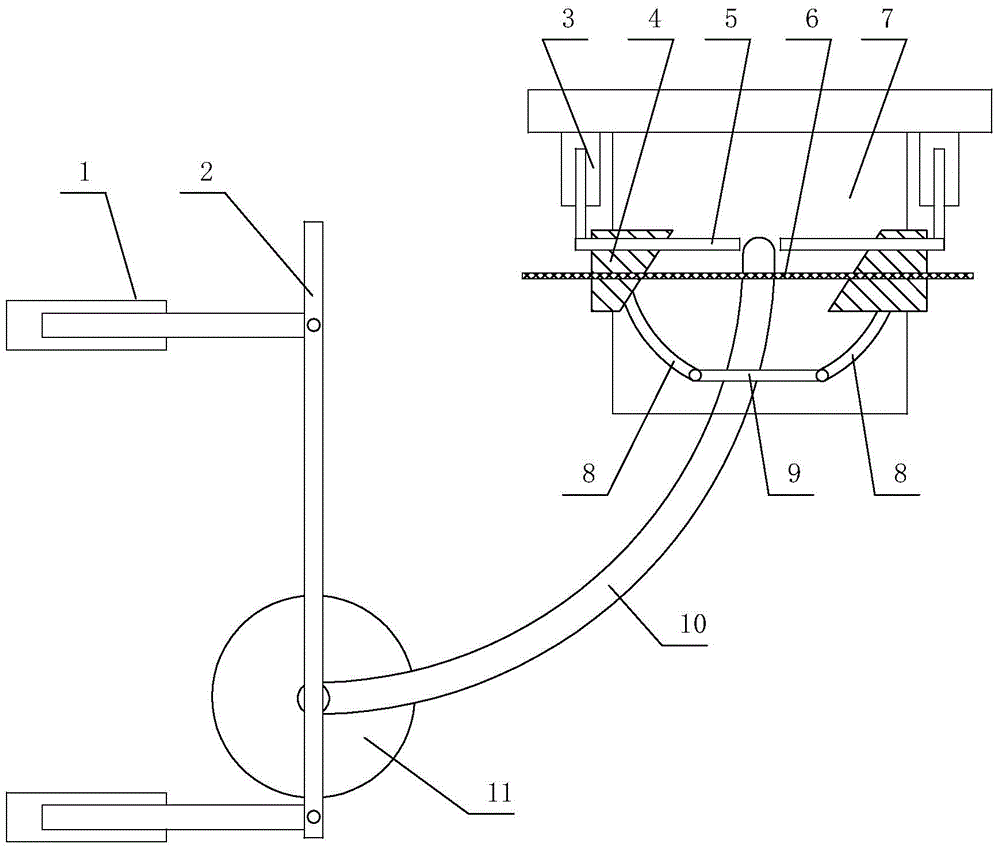

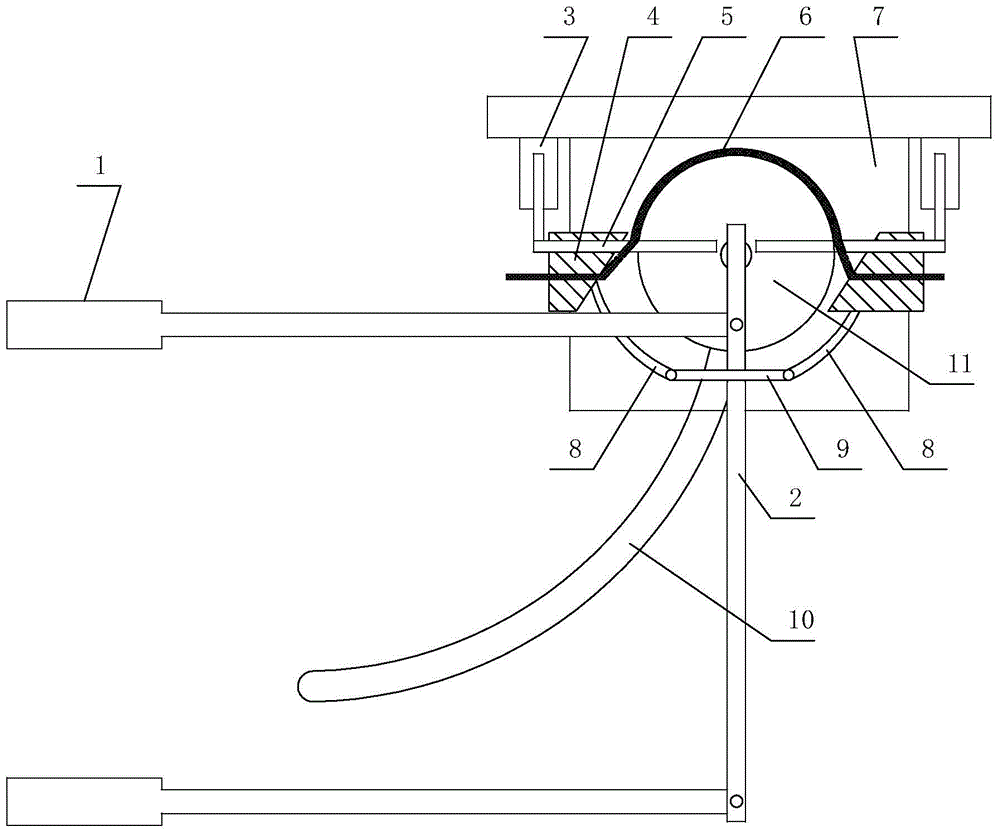

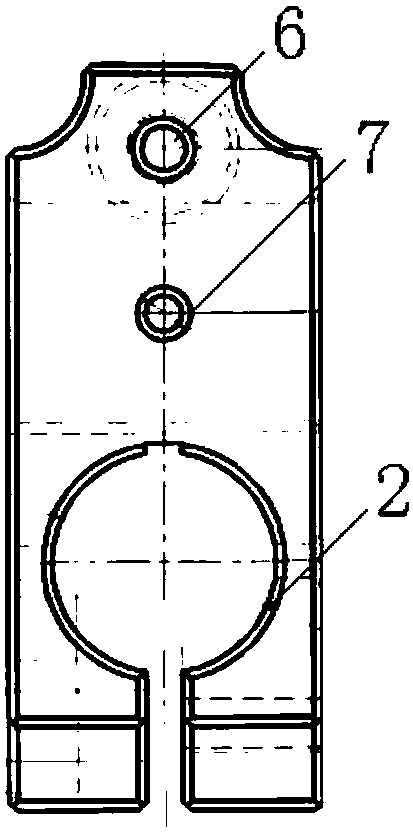

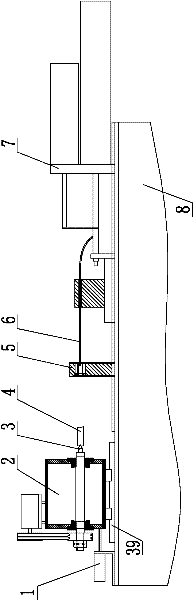

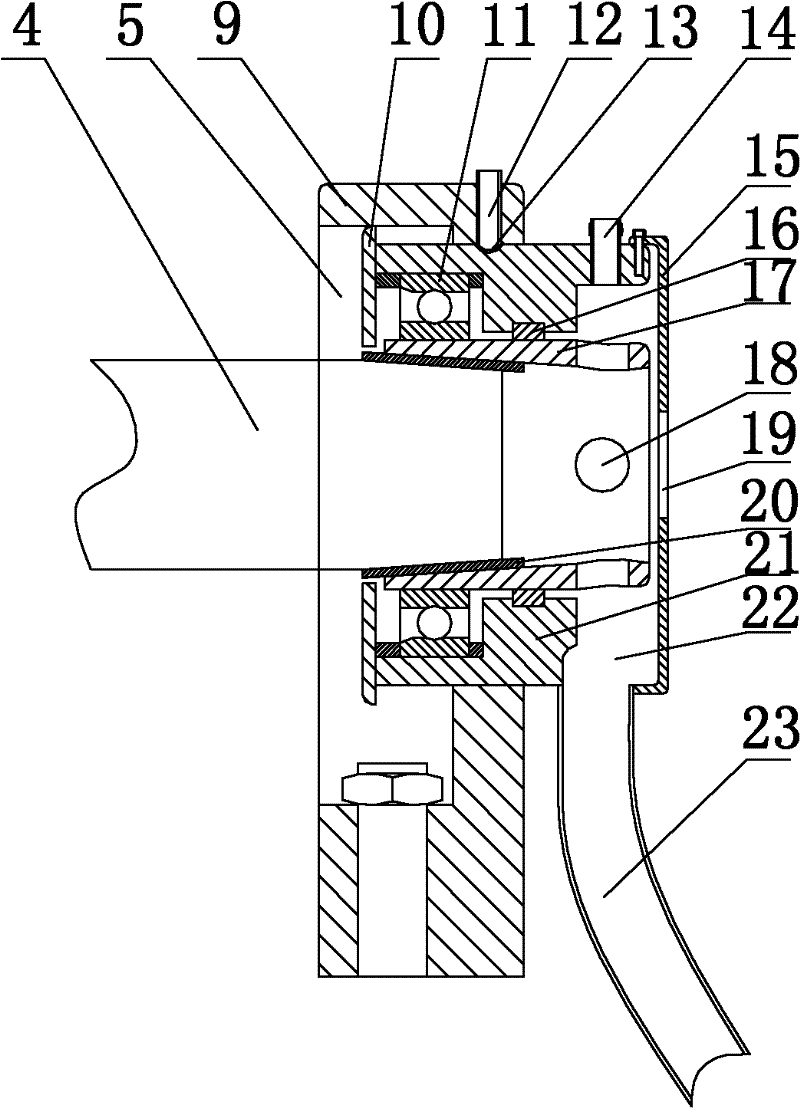

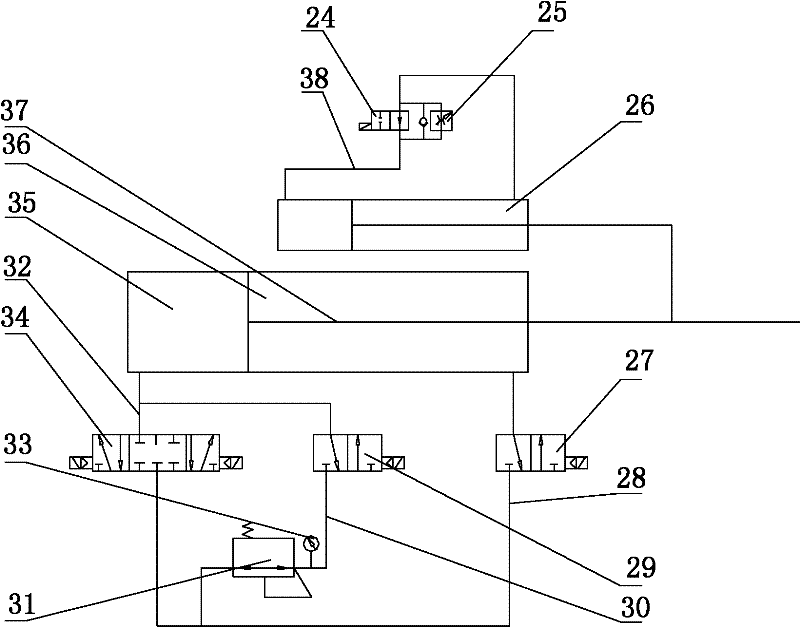

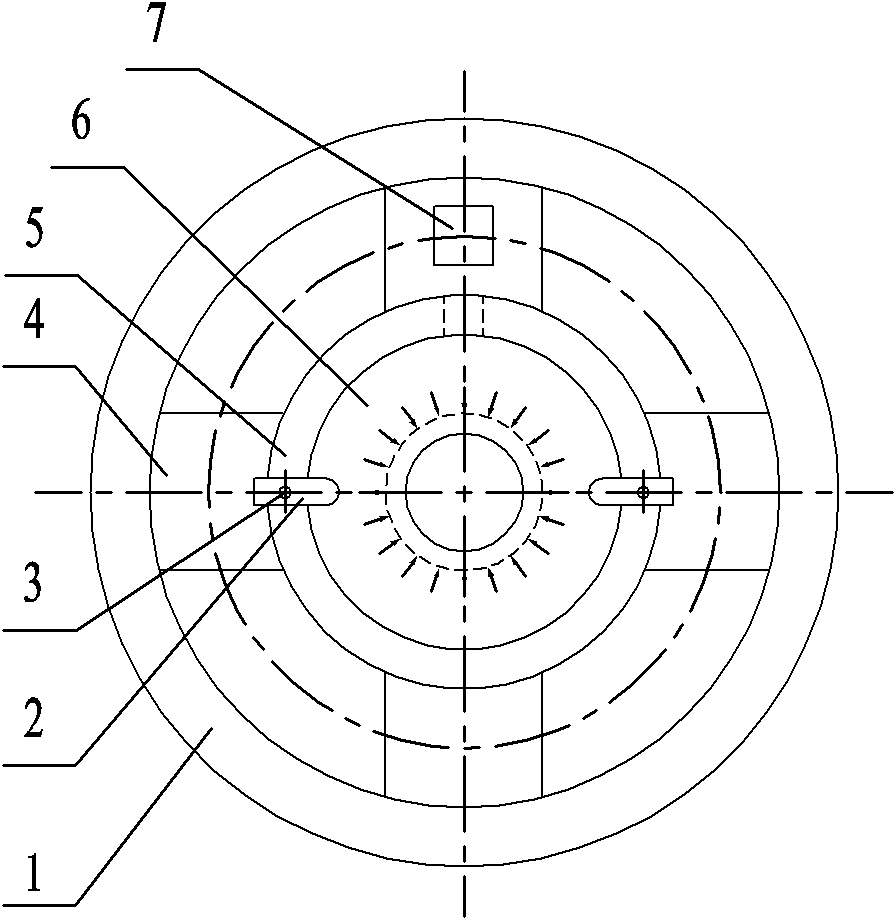

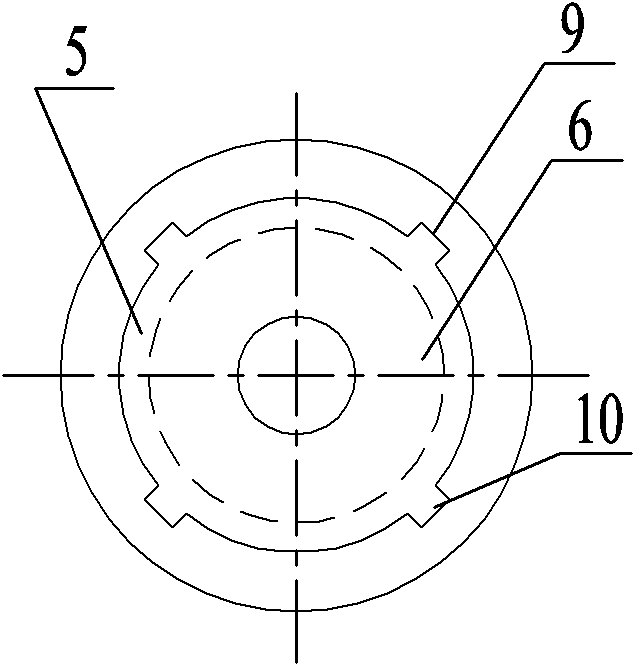

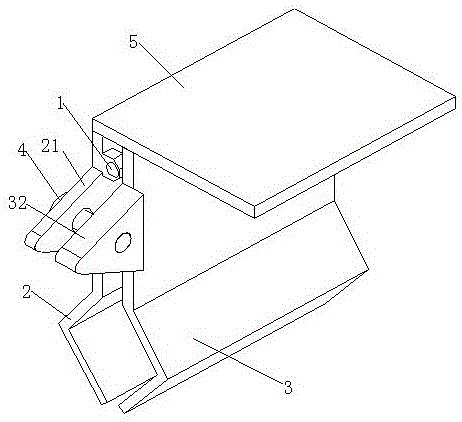

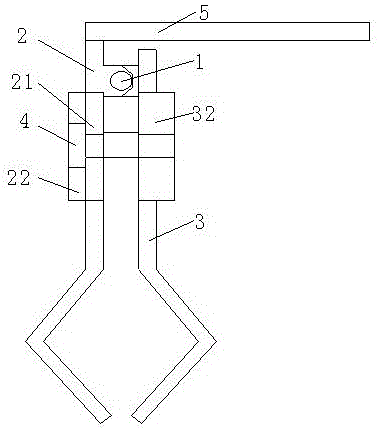

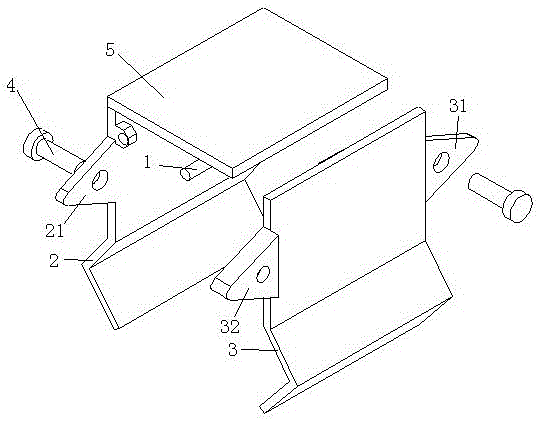

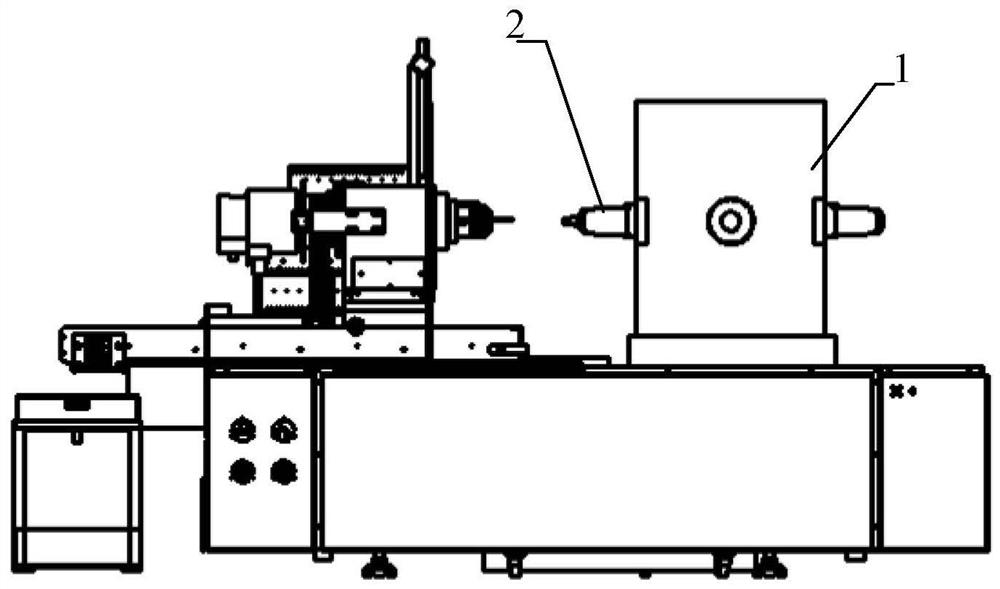

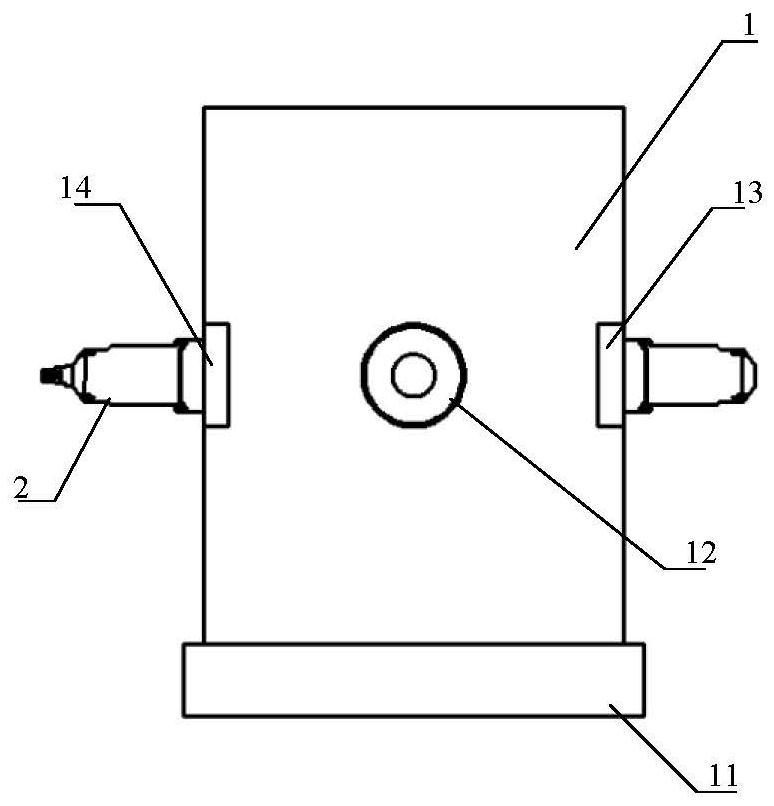

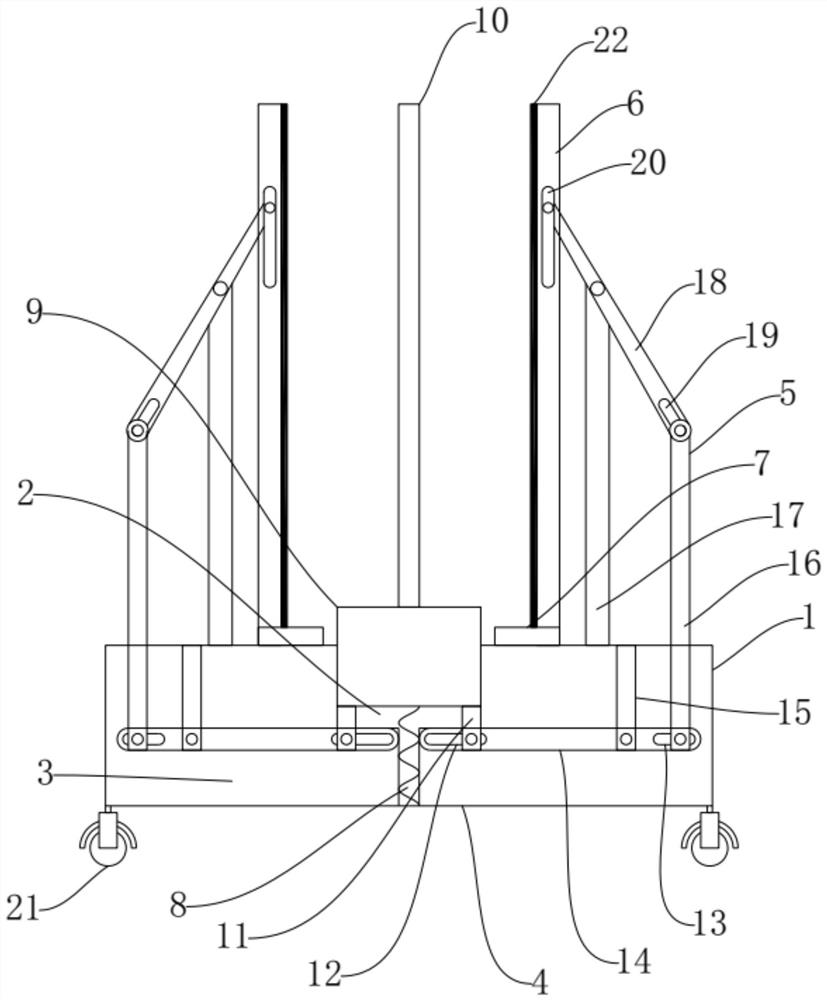

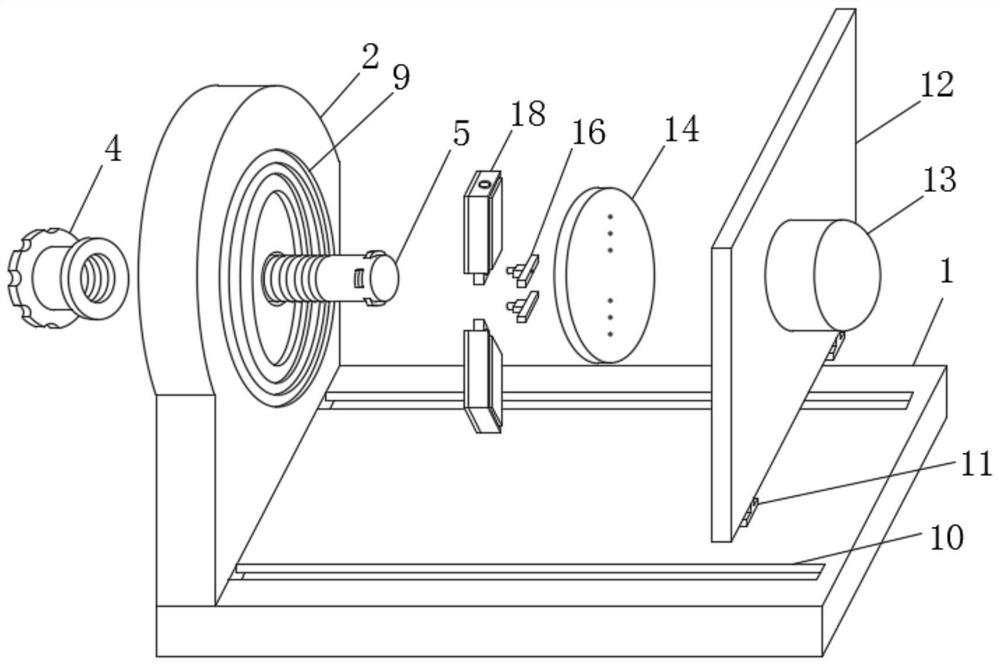

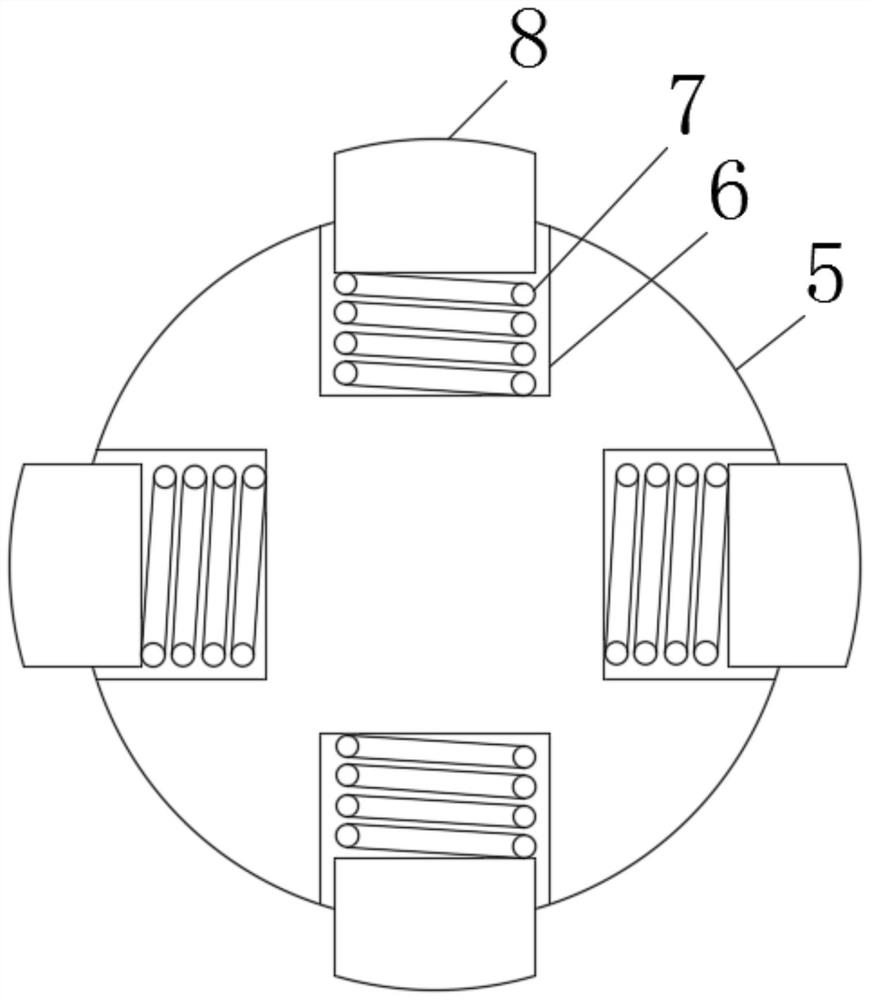

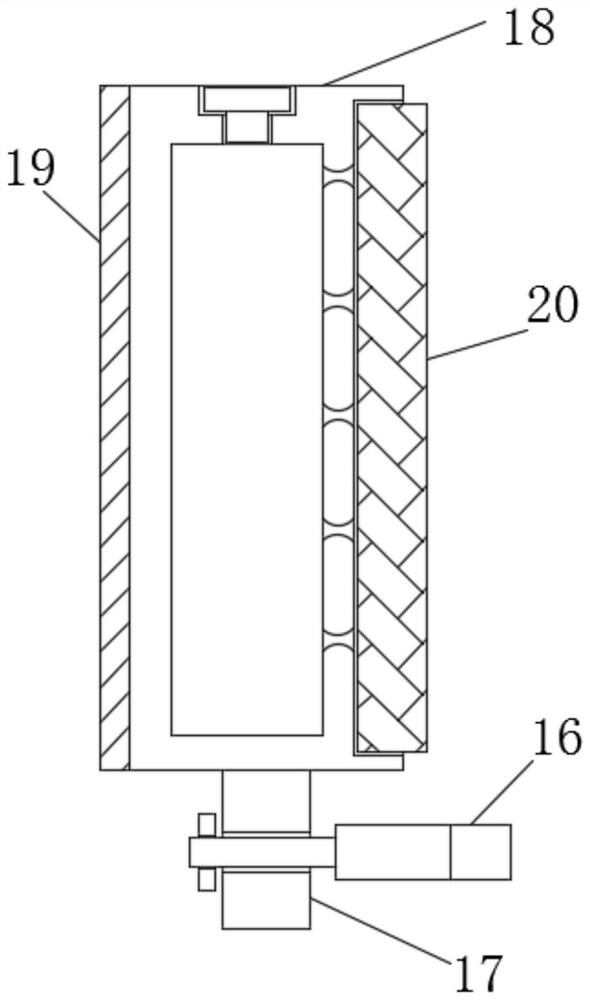

Shaft workpiece propping and clamping device

InactiveCN108356574ASimple and convenient clamping operationReliable clampingWork clamping meansPositioning apparatusTailstockMachine tool

The invention relates to a shaft workpiece propping and clamping device which comprises a stepped disc seat and a propping tip, wherein the disc seat is fixedly connected onto a machine tool spindle box or tail sea; the propping tip extends out of the center of the disc seat. The shaft workpiece propping and clamping device is characterized in that a hydraulic overturning and clamping mechanism isfixedly connected with the edge of the disc seat, and comprises two sets of hydraulic driving components as well as two pairs of overturning and clamping components; the hydraulic driving componentsare of the same structure and symmetrically arranged on the edge of the disc seat; and the overturning and clamping components are correspondingly connected with the hydraulic driving components. Theshaft workpiece propping and clamping device provided by the invention has not only the clamping function of a conventional machine tool spindle box but also the propping function of a conventional machine tool tail seat; a shaft workpiece can be stably and reliably clamped; the simple and convenient clamping operation can be achieved; all parts of the shaft workpiece can be machined through one-time clamping; and the machining efficiency and the machining precision can be improved.

Owner:重庆恒博机械制造有限公司

Oil channel hole machining device for air cylinder cover assembly line production

PendingCN112548141AEasy clamping and operationAchieve precisionMetal working apparatusPositioning apparatusAssembly lineDrill bushing

The invention belongs to the technical field of air cylinder cover machining equipment, and provides an oil channel hole machining device for air cylinder cover assembly line production. The oil channel hole machining device comprises a mounting base, wherein a drilling device is arranged on the mounting base, and a tool base is fixedly arranged on a workbench of the mounting base; a lifting connecting plate driven by a driving device is arranged on the tool base, a supporting plate is rotationally arranged on the lifting connecting plate, and a rotary positioning mechanism is arranged betweenthe supporting plate and the lifting connecting plate; a sliding way used for achieving conveying of an air cylinder cover, a guide plate used for sliding guide and a material blocking plate used forpre-positioning are arranged on the supporting plate; a drill bushing is arranged at the end, close to the drilling device, of the tool base, and the drill bushing corresponds to a drilling tool of the drilling device; and a plurality of positioning pins, a supporting table and a clamping mechanism are further arranged on the tool base. The oil channel hole machining device can be matched with upstream and downstream machining procedures to achieve integrated line production, clamping operation is easy and convenient, time and labor are saved, positioning and clamping of the air cylinder cover are accurate and firm, and the machining quality and the production efficiency of the air cylinder cover are greatly improved.

Owner:潍坊思博精工科技有限公司

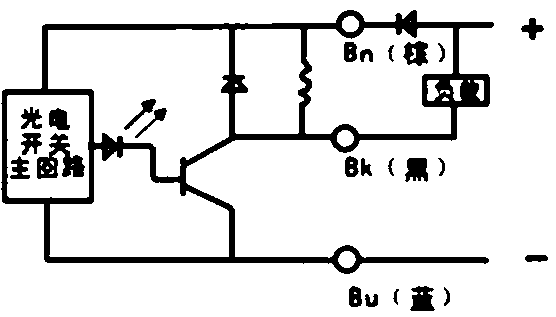

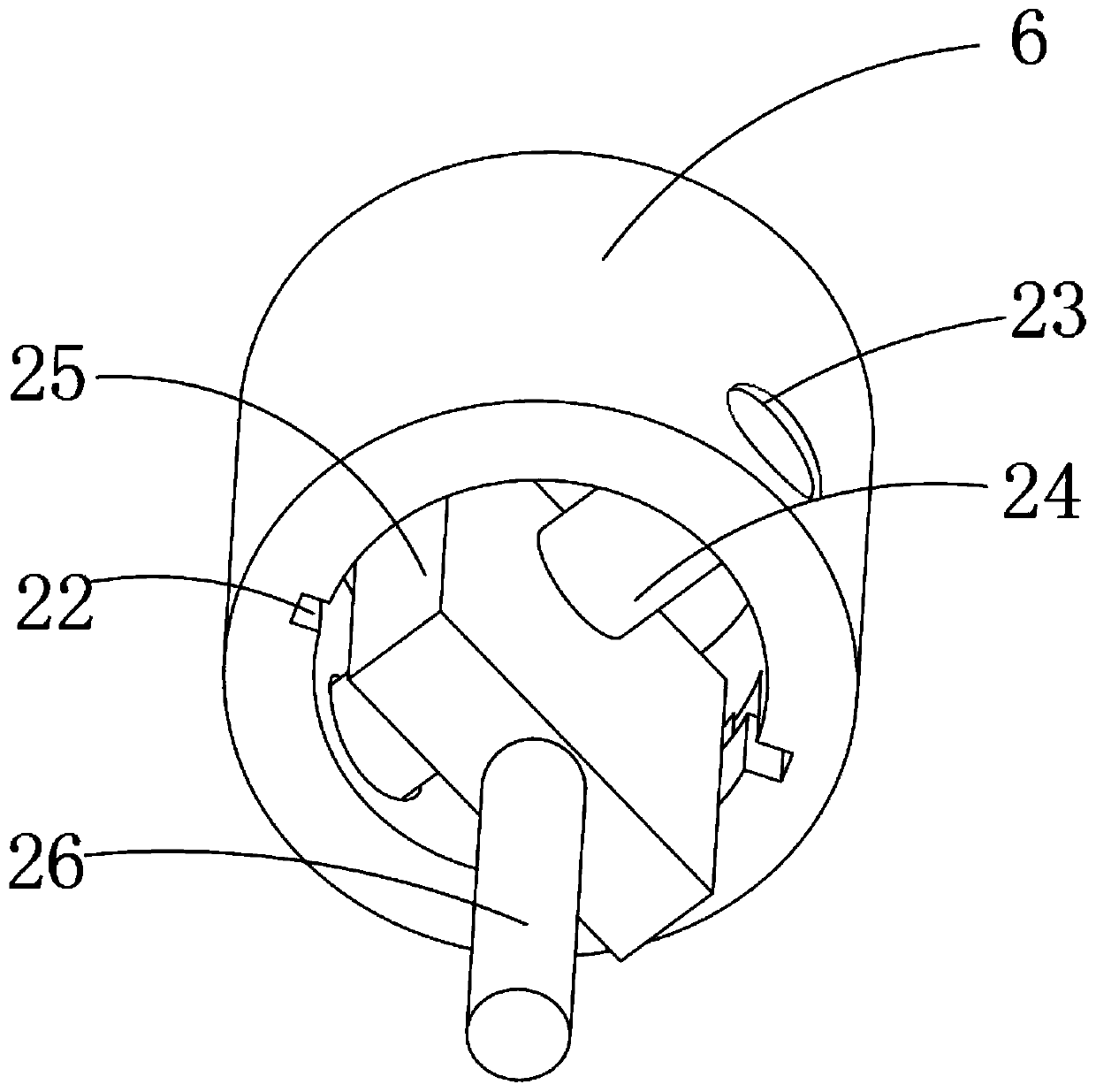

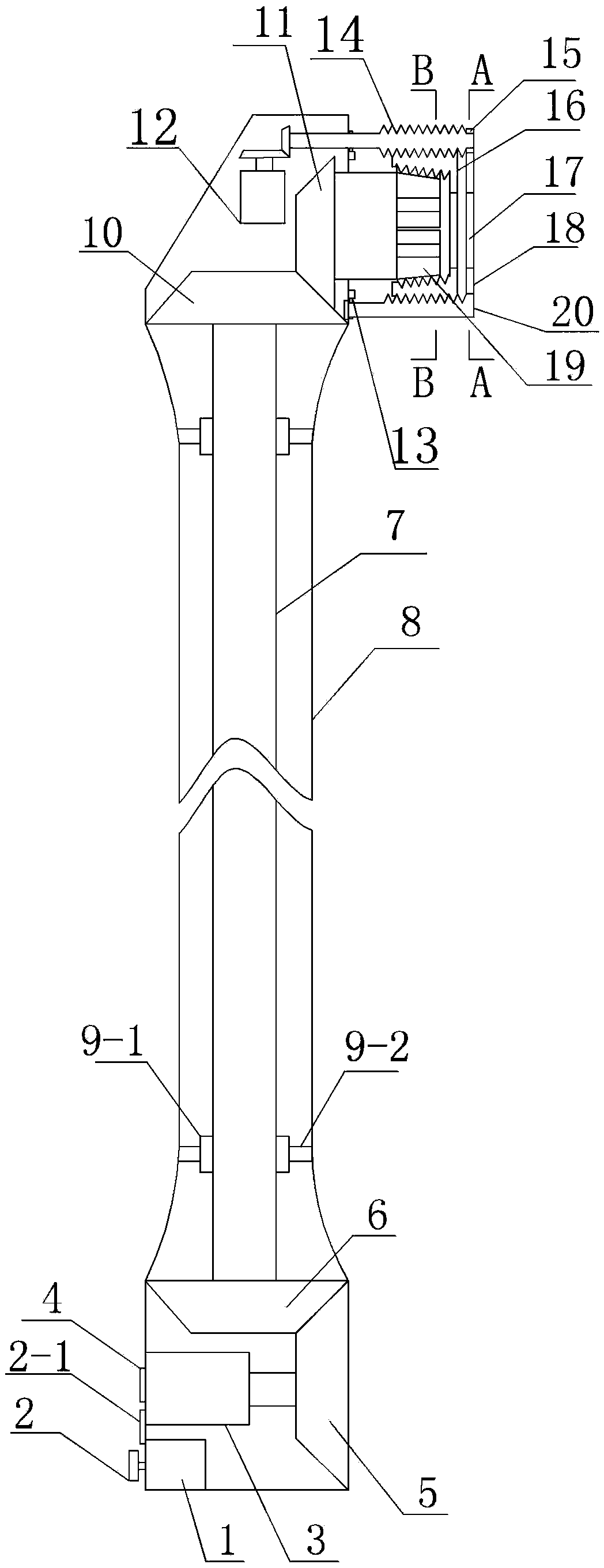

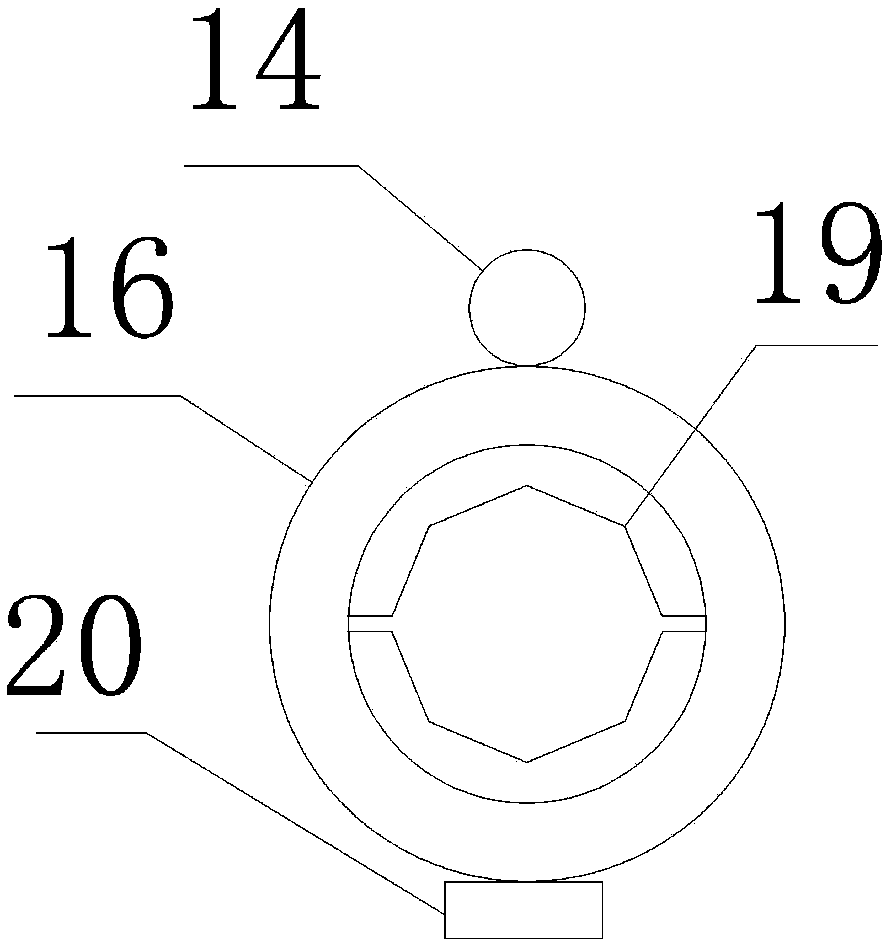

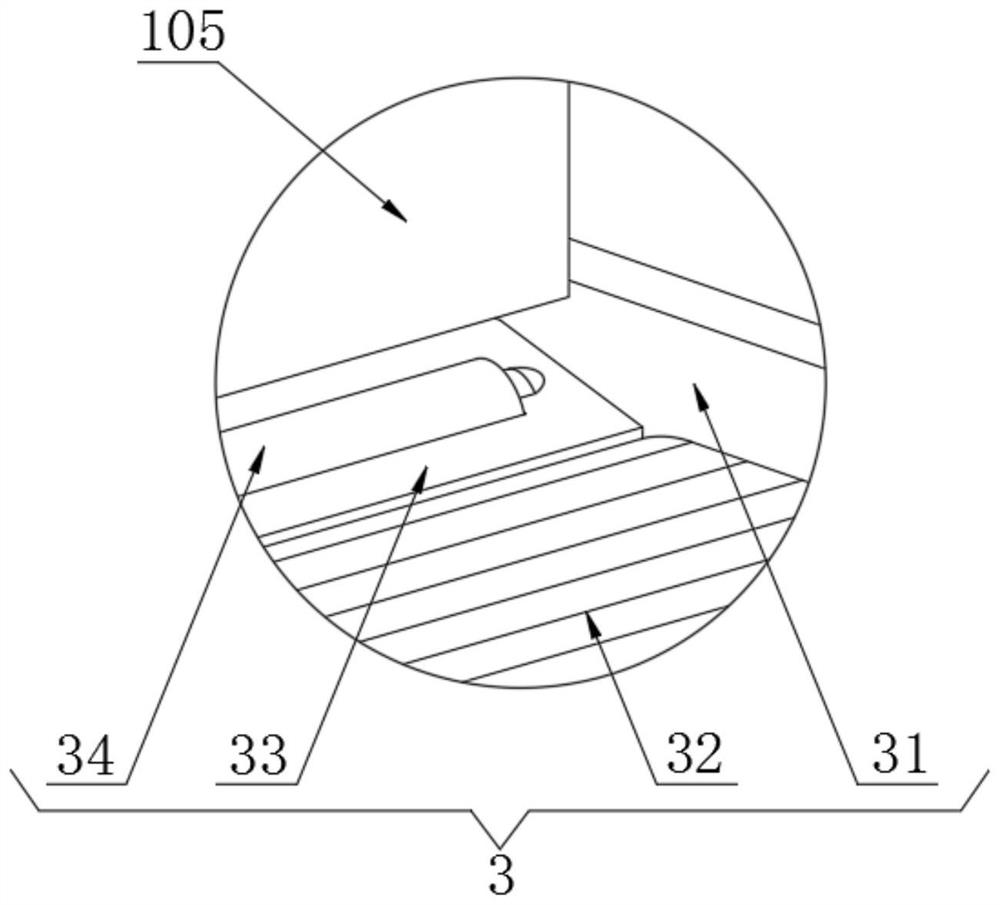

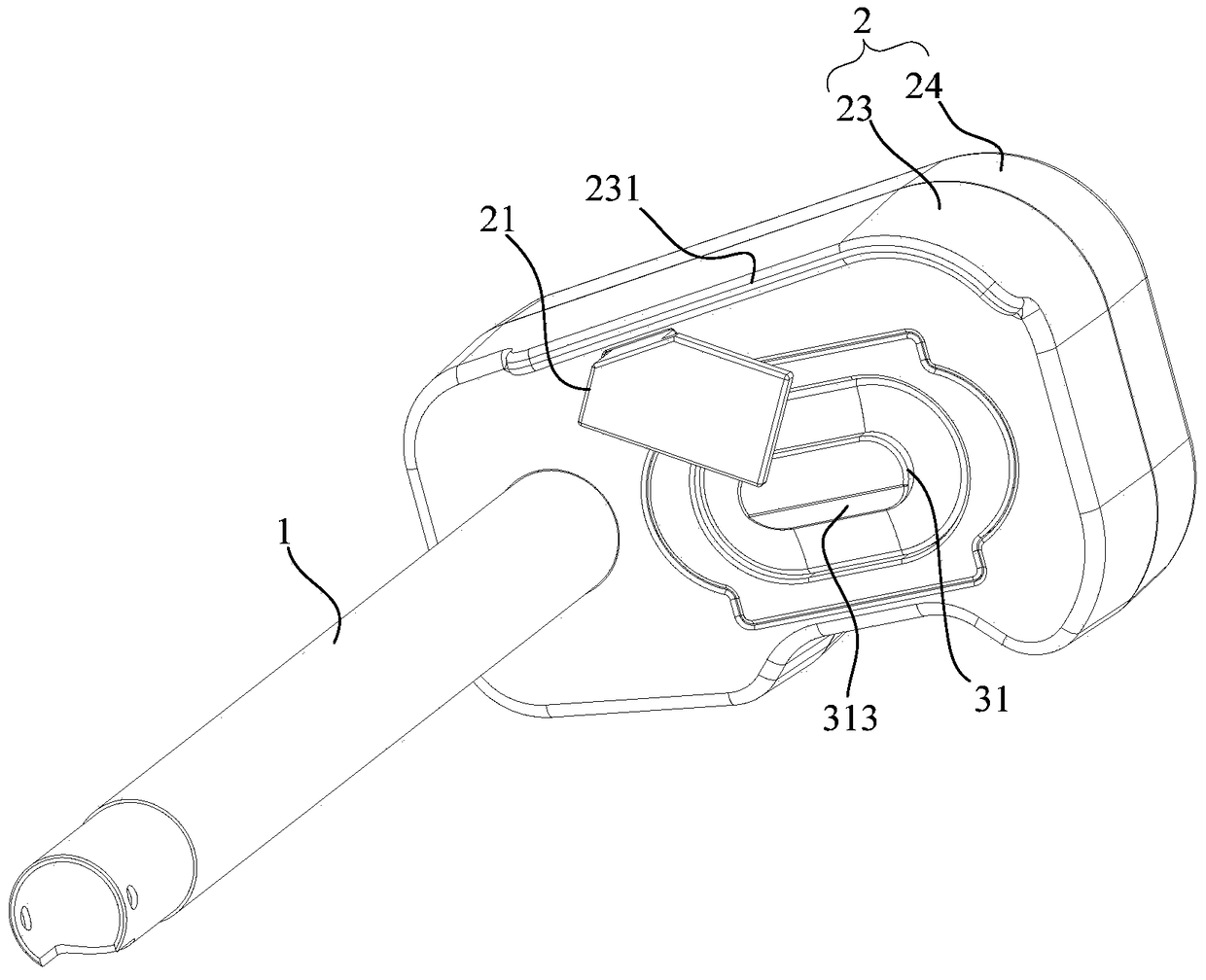

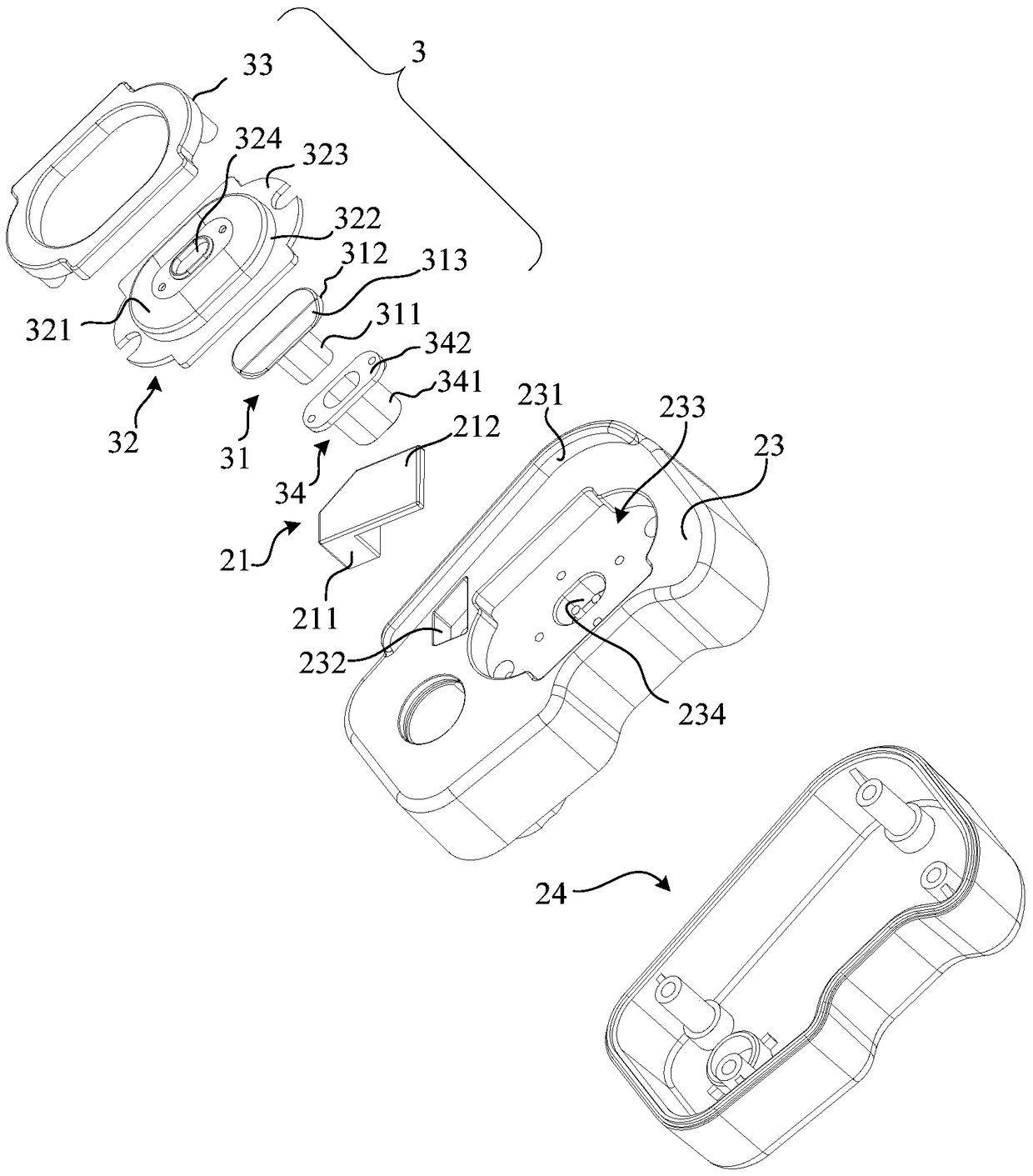

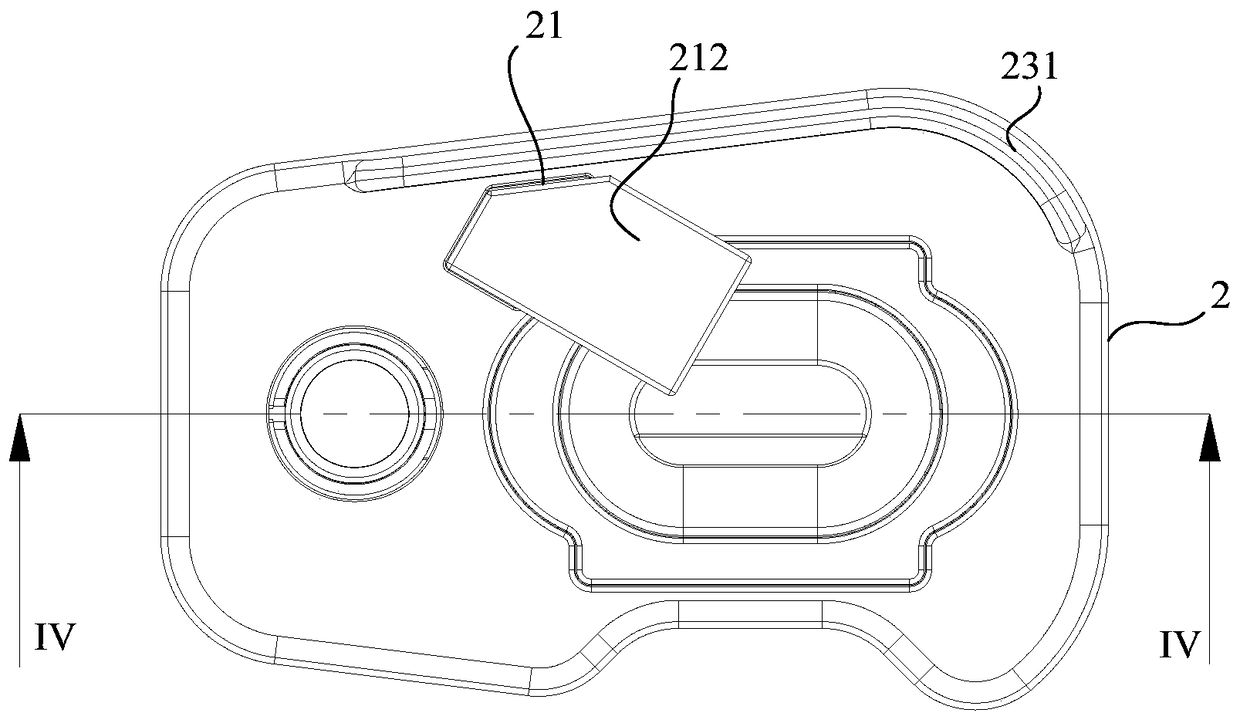

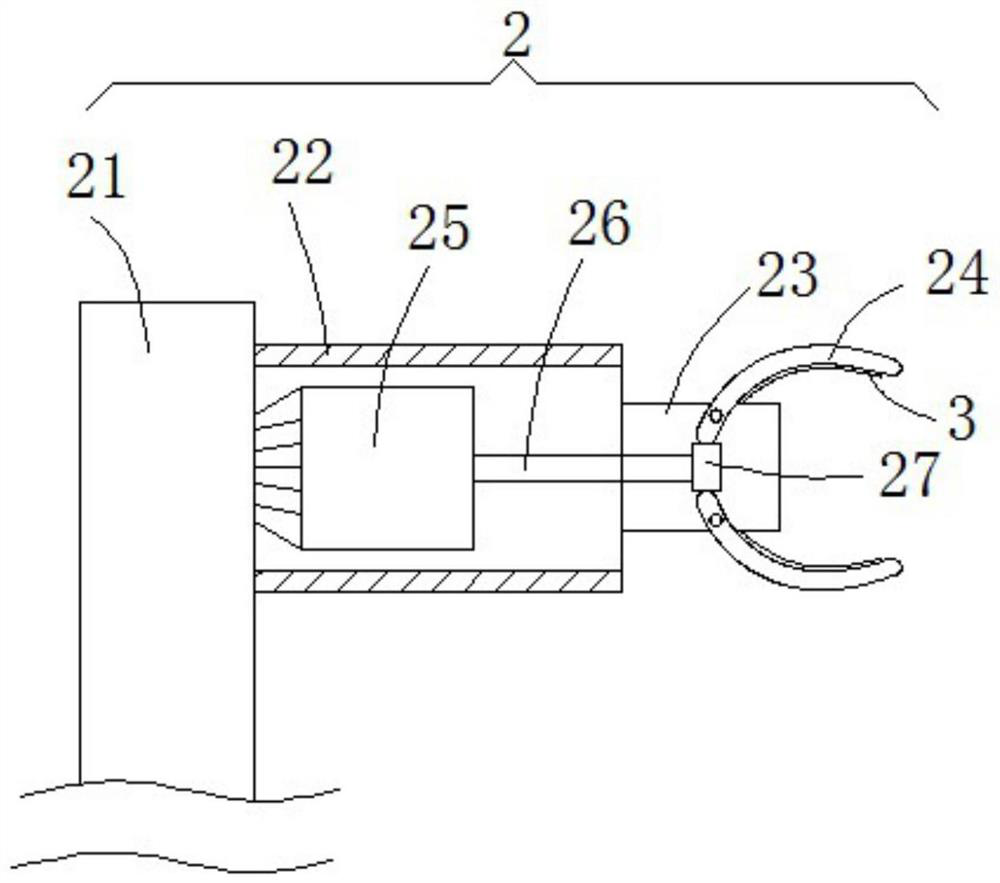

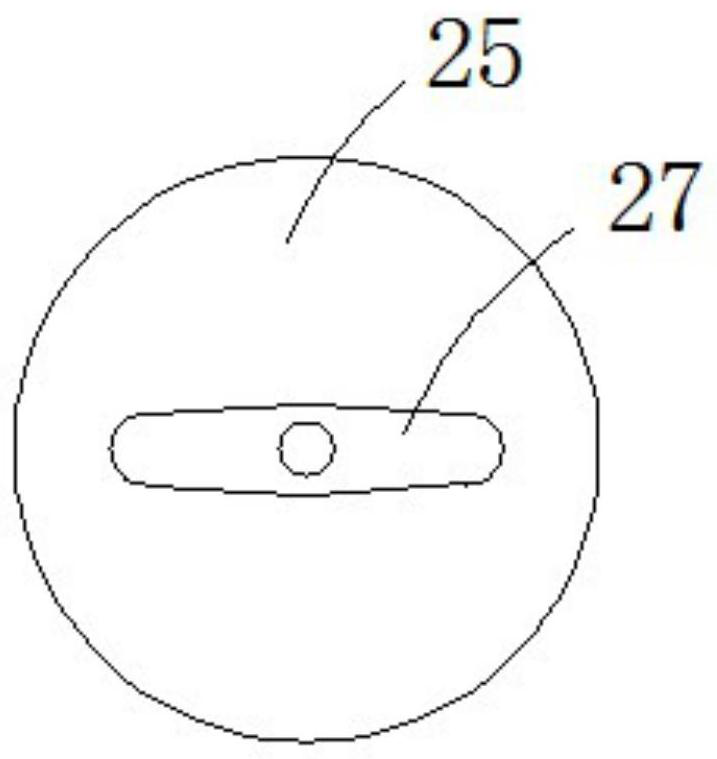

Spanner for high-voltage hot-line work

PendingCN108789253AChange sizeEasy and convenient clamping operationSpannersWrenchesControl systemEngineering

The invention relates to the technical field of high-voltage hot-line maintenance machinery and particularly relates to a spanner for high-voltage hot-line work. The spanner comprises an insulating housing, a control system, a driving component, a transmission component, a clamping component and a regulating component, wherein the control system, the driving component, the transmission component,the clamping component and the regulating component are installed inside the housing; the control system and the driving component are installed at one end of the housing; the clamping component and the regulating component are installed at the other end of the housing; one end of the clamping component is a driving end and the other end is a clamping end; the driving component is connected with the driving end of the clamping component through the transmission component which is positioned at the middle part of the housing and is used for providing power for the clamping component; the regulating component is installed at the clamping end of the clamping component; and the control system is connected with the regulating component and is used for controlling the clamping force of the clamping component through the regulating component. According to the spanner provided by the invention, the clamping component is used for clamping a to-be-overhauled component so as to realize simple andconvenient clamping operation; in cooperation with the regulating component, the spanner is applicable to circuit elements which are different in size and shape; meanwhile the clamping force is changed; and the operation process is simplified.

Owner:BENXI POWER SUPPLY COMPANY OF STATE GRID LIAONINGELECTRIC POWER SUPPLY +1

A roof clamp for easy installation

InactiveCN106401080BAvoid restrictionsImprove work efficiencyRoof covering using slabs/sheetsSoftware engineeringEngineering

Owner:四川省科拓梦无人机科技有限公司

Binding devices for steel pipes

InactiveCN104843217BEasy to transportSmall footprintBundling machine detailsEngineeringBinding force

The invention discloses a binding device for a steel pipe. The device comprises a clamping device (11), a conveying device, a binding device and a rope twisting device. The clamping device (11) is in sliding connection with the conveying device, the binding device is connected with the conveying device through a conveying track, and the rope twisting device is disconnected or connected with the binding device. The binding device comprises a base plate (7), two groups of binding assemblies located on two sides of the steel pipe and two groups of driving assemblies used for driving the two groups of binding assemblies to draw close or deviate from each other. By means of the structure, on one hand, the bound steel pipes are still subjected to constraint force, the problem that the steel pipes are loose and roll away is resolved; on the other hand, the bound steel pipes are very stable in a package box and are convenient to transport.

Owner:郑惠文

An automatic line clamping adapter block

Owner:CHERY AUTOMOBILE CO LTD

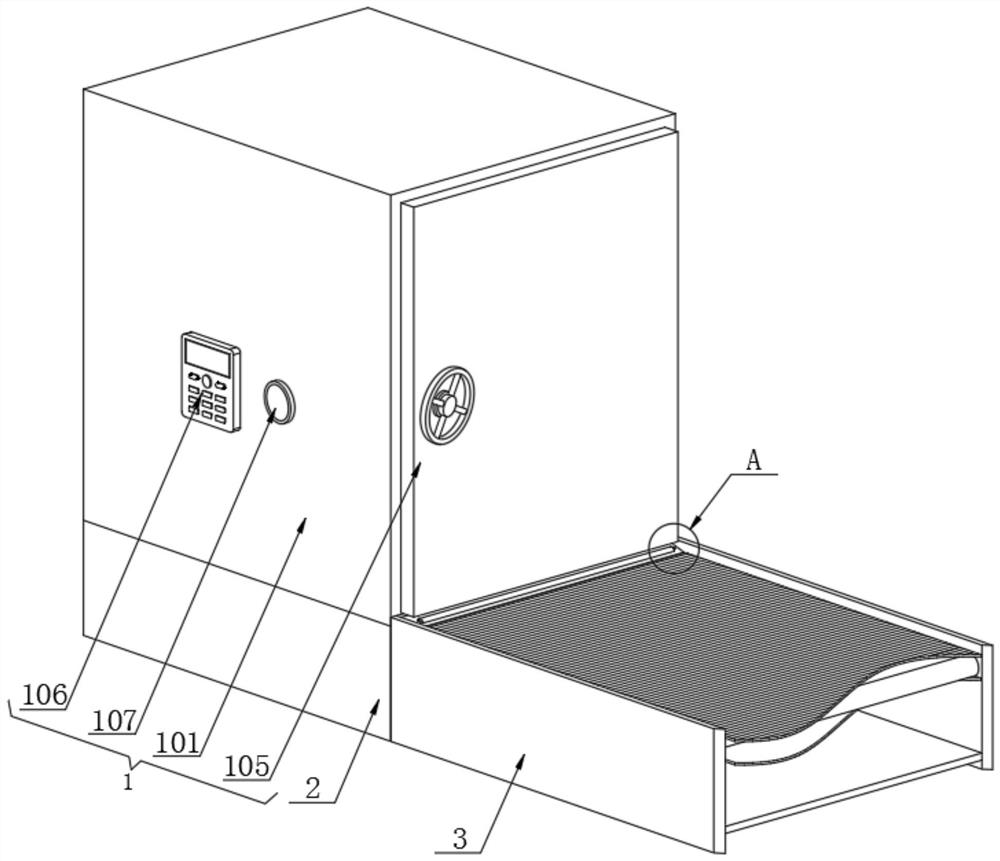

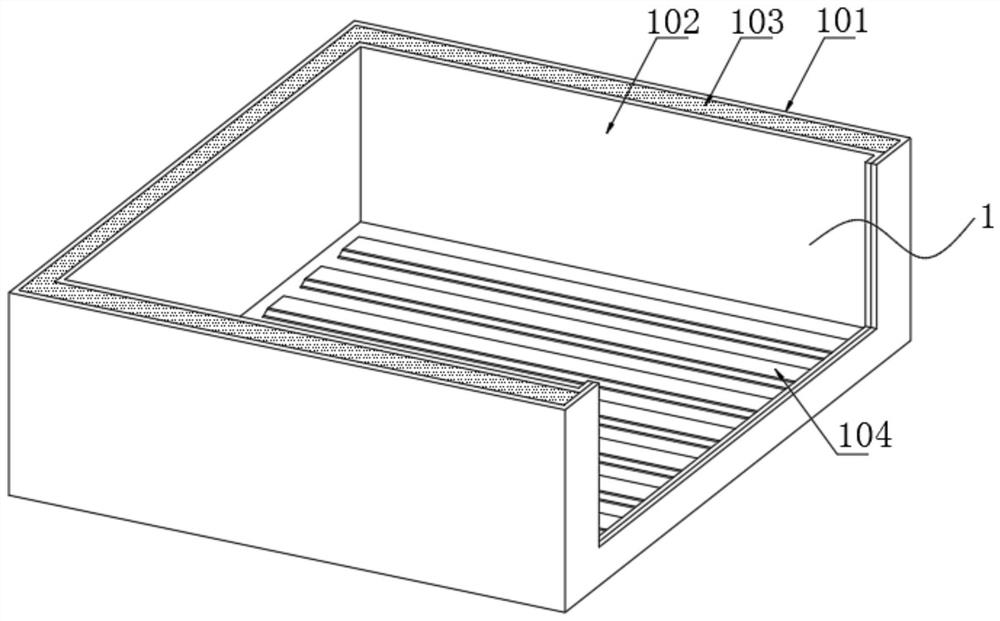

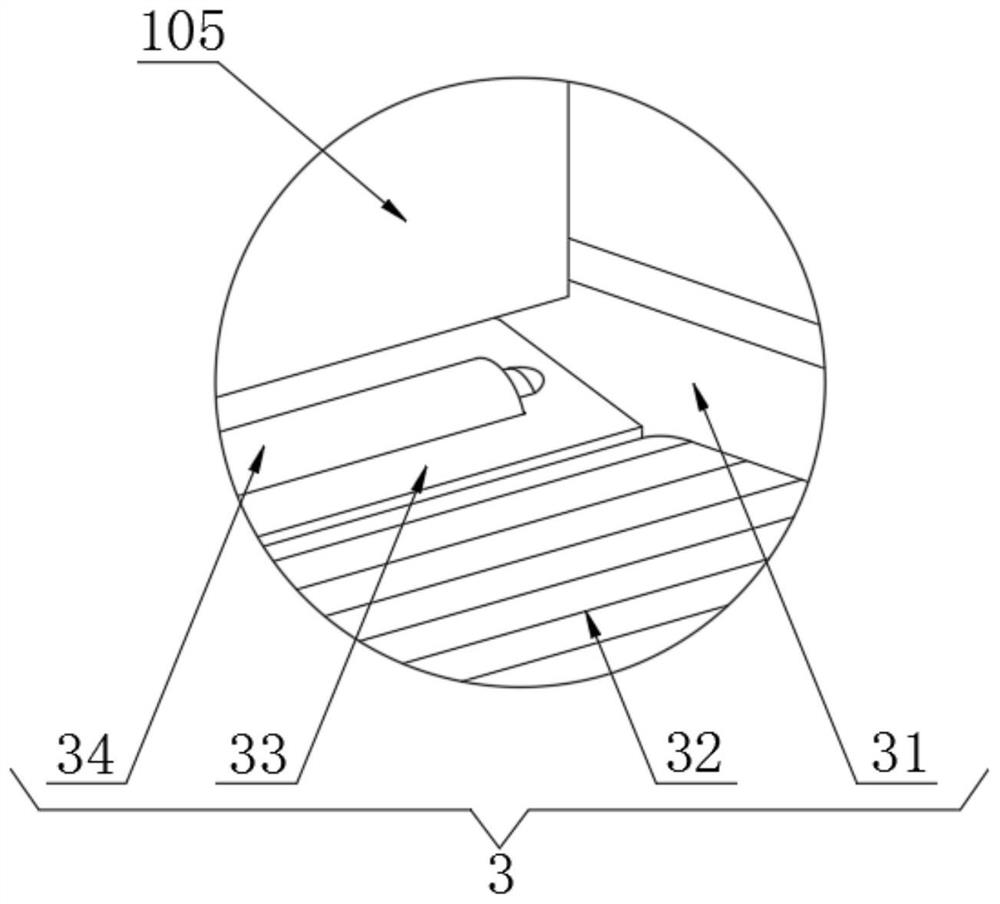

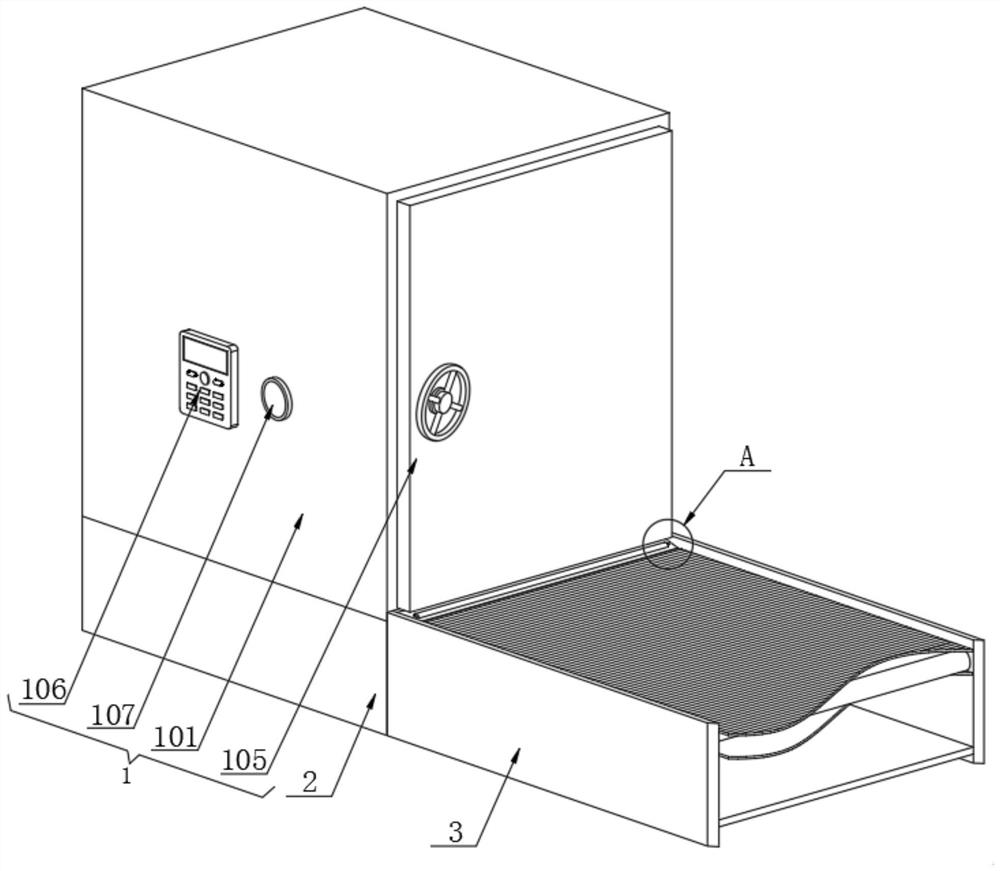

Flame-retardant plate flame-retardant processing technology based on macromolecular flame retardant

InactiveCN113844065AMultiple efficiencyImprove flame retardant effectFlat articlesProcess engineeringFire retardant

The invention discloses a flame-retardant plate flame-retardant processing technology based on a macromolecular flame retardant, and relates to the technical field of plate processing. A high-pressure explosion-proof box is included, a machine box is fixedly connected with the bottom of the high-pressure explosion-proof box, and a feeding mechanism is fixedly connected with the right side of the machine box. According to the flame-retardant plate flame-retardant processing technology based on the macromolecular flame retardant, a pressure pump is arranged to be matched with related pipelines, the high-pressure explosion-proof box can be pressurized, internal air is promoted to circularly flow, heating is carried out in the process, the flame-retardant plate can be uniformly heated and dried, the probability of explosion of the flame-retardant plate can be reduced through pressurization, then the atomized flame retardant is sprayed into the high-pressure explosion-proof box, and the fully dried flame-retardant plate can quickly absorb the flame retardant; and meanwhile, part of steam is mixed in the atomized flame retardant, the fumigation effect can be achieved, the flame retardant can penetrate into the flame-retardant plate more deeply in cooperation with the pressurization effect, and compared with simple soaking, more flame retardants can be absorbed, and the efficiency is higher.

Owner:于焕

Deep hole processing equipment

ActiveCN101862838BReduced risk of breakageFeed speed reducedTailstocks/centresAuxillary equipmentAxial displacementEngineering

Owner:MIANYANG BRILLIANCE RUIAN AUTOMOTIVE COMPONENTS

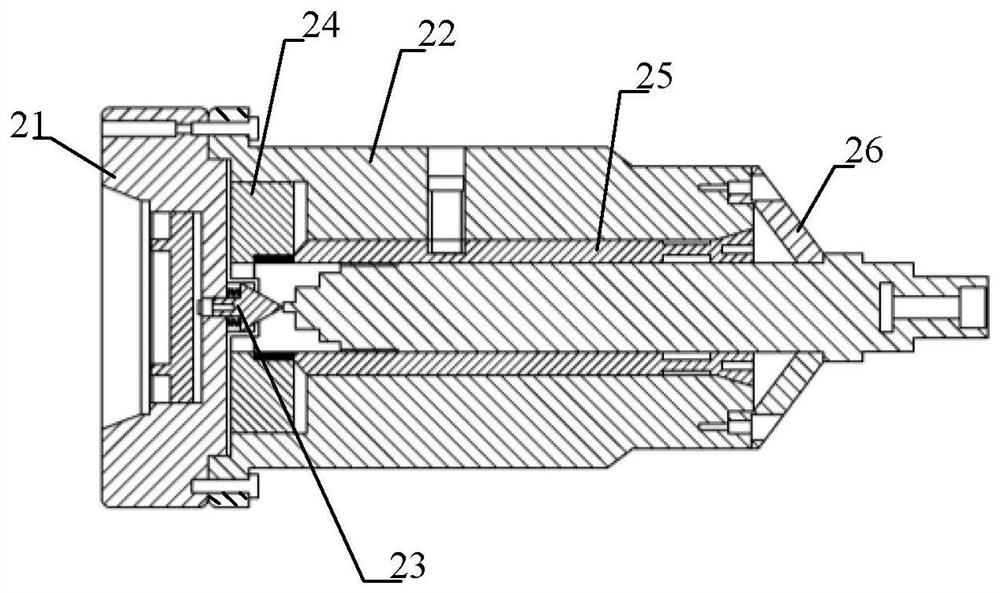

Airbag clamping device with function of feeding back intervention operation resistance

ActiveCN102671280BSimple and convenient clamping operationThe intervention process is safe and effectiveSurgeryCatheterEngineeringAirbag

The invention provides an airbag clamping device with a function of feeding back intervention operation resistance. The airbag clamping device comprises an airbag, an airbag casing pipe, an air pump, a pressure measuring chamber, an air pipe and an air pressure sensor, wherein the airbag and the an airbag casing pipe are connected without circular relative rotation; the two sides of one end of the airbag casing pipe are respectively provided with a baffle plate; the air pump is connected with the pressure measuring chamber, the air pipe and the airbag successively; and the air pressure sensoris arranged in the air pressure measuring chamber. According to the airbag clamping device, the clamping function of a conduit is realized by aerating the airbag; the airbag is in tight contact with the conduit at the peripheral direction of the conduit; the appearance of the conduit is kept; and the conduit is prevented from being damaged. The aerating pressure is detected by using the air pressure sensor so as to modulate the aeration quantity, control the size of an inner chamber of the airbag and adapt to the clamping function of the conduits in different diameters. A foil gauge is arranged on an elastic spoke plate between the airbag casing pipe and an outer casing pipe, so that the measurement of a pushing force and a twisting force is realized by using the deformation of the foil gauge. The airbag clamping device is capable of not only realizing both the measurements of two orthogonal direction feedback forces, but also ensuring the measurement result to be accurate due to a smaller inertia.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

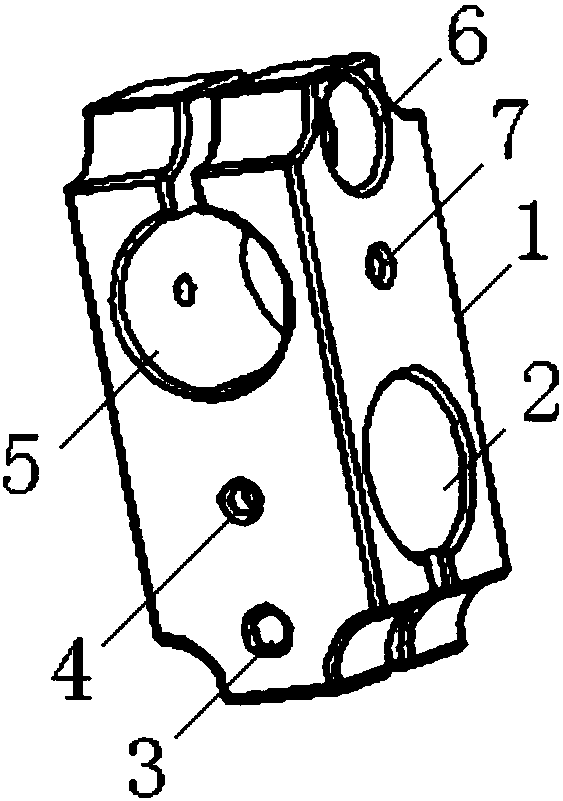

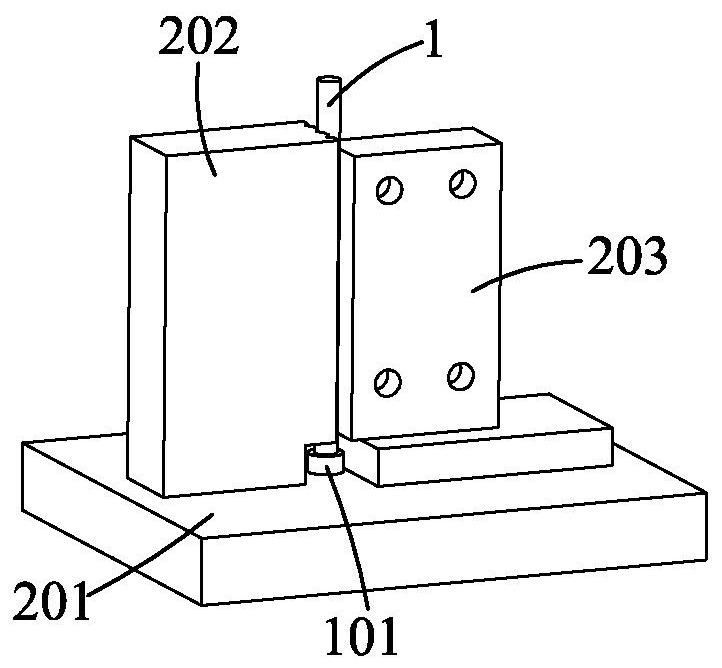

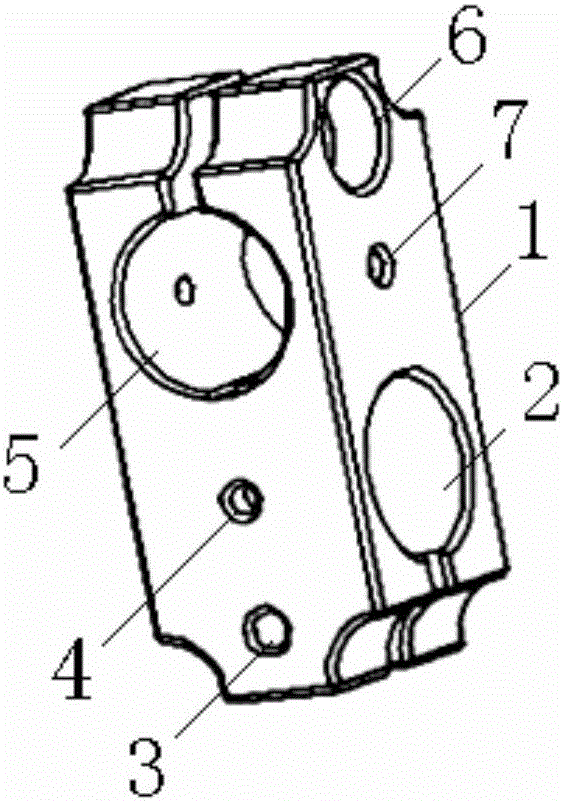

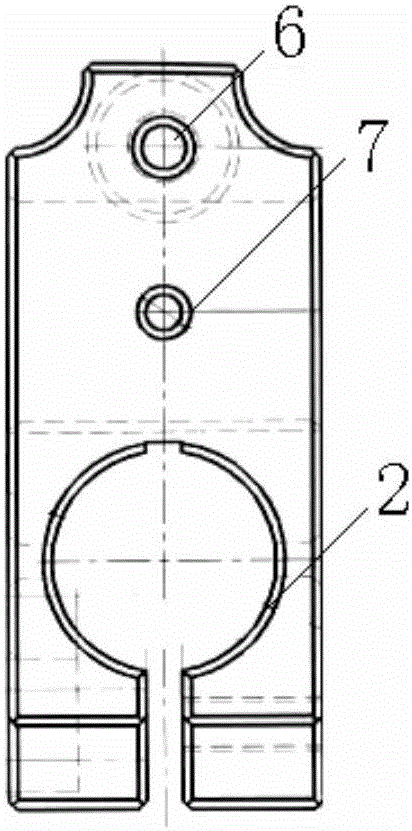

Angle pin pull rod height grinding jig

PendingCN113579994ASimple and convenient clamping operationImprove work efficiencyLapping machinesWork carriersPhysicsGrinding

The invention provides an angle pin pull rod height grinding jig. The angle pin pull rod height grinding jig comprises a body, a pressing plate and a locking structure; the body is provided with a first plane and a second plane perpendicular to the first plane; a plurality of limiting grooves are formed in the second plane in a sunken mode, and the limiting grooves are all perpendicular to the first plane; the body is further provided with a containing space, the containing space is sunken relative to the second plane, and the containing space is located between the first plane and the limiting groove; the pressing plate is provided with a third plane; and the locking structure is used for fixing the pressing plate and the body. The angle pin pull rod height grinding jig has the beneficial effects that the angle pin pull rod height grinding jig can clamp a plurality of angle pin pull rods at a time, the clamping operation is simple and convenient, and the working efficiency is improved.

Owner:SUZHOU MITAC PRECISION TECH

Roof clamp convenient to install

InactiveCN106401080AAvoid restrictionsImprove work efficiencyRoof covering using slabs/sheetsEngineeringHinge angle

Owner:四川省科拓梦无人机科技有限公司

Clamping adapter block for automatic line

Owner:CHERY AUTOMOBILE CO LTD

Shaft finish machining clamp and shaft machining machine tool

PendingCN114227331AWon't wear outSimple and convenient clamping operationPositioning apparatusMetal-working holdersStructural engineeringMachine tool

The invention discloses a shaft finish machining clamp. The shaft finish machining clamp comprises a base, a shell, a connecting sleeve, an expansion sleeve and a supporting cover. A base mounting cavity, a connecting sleeve mounting cavity and an expansion sleeve mounting cavity are sequentially formed in one end of the shell, the expansion sleeve is contained in the expansion sleeve mounting cavity, and the connecting sleeve is mounted in the connecting sleeve mounting cavity; one end of the expansion sleeve is connected with the connecting sleeve in a matched mode, the other end of the expansion sleeve is arranged on a port of the other end of the shell, and the supporting cover is fixed to the port of the other end of the shell. The base is fixed in the base mounting cavity, and one end of the base is connected with the connecting sleeve. According to the shaft finish machining clamp, a workpiece is fixed through the expansion sleeve, the movable center is arranged in the shaft finish machining clamp for centering, the clamp conducts positioning through the maximum outer circle of the workpiece, clamping operation is easy and convenient, the workpiece cannot be abraded in the clamping process, centering positioning of the workpiece is completed in the clamping process, and production efficiency is improved.

Owner:GUANGZHOU ROVMA AUTO PARTS

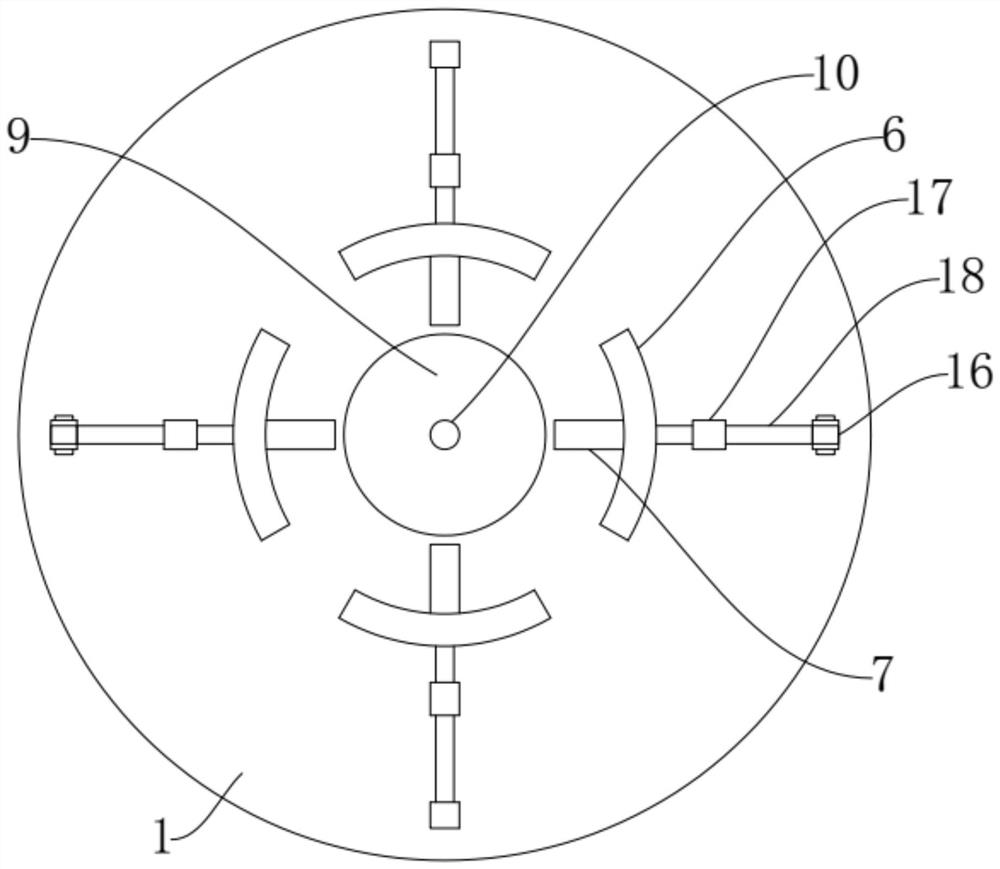

Transformer winding dry constant voltage device

InactiveCN111554507BSimple and convenient clamping operationAchieve clampingCoils manufactureClassical mechanicsMechanical engineering

The invention discloses a transformer winding drying constant pressure device, which includes a base, a platform lifting hole, a transmission cavity, a first lever device, a second lever device, an extrusion plate, an extrusion chute, a return spring, a winding platform and a winding shaft. The base is arranged in a circular shape, the platform lifting hole is set in the center of the base, the transmission cavity is set in the base, the return spring is vertically set in the center of the transmission cavity, and the winding platform is set in the platform lifting hole , the winding shaft is set on the winding platform, the extrusion chute is fixed on the upper wall of the base, the extrusion plate is slidably set on the extrusion chute, and the first lever device is set on the transmission space In the cavity, the second lever device is arranged above the base and outside the extrusion plate. The invention belongs to the technical field of transformer production, and specifically provides a transformer winding drying constant voltage device with tight clamping, continuous and constant clamping force, simple operation, high safety, high practicability, easy movement and low cost.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

Precise guide rail part machining tool convenient to clamp

InactiveCN112025348AEasy clampingEasy to fixLarge fixed membersPositioning apparatusEngineeringScrew thread

The invention relates to the technical field of machining tools, and discloses a precise guide rail part machining tool convenient to clamp. The precise guide rail part machining tool comprises a workbench; the four corners of the lower surface of the workbench are each fixedly connected with a supporting leg; a first clamping plate is fixedly connected to the sidewall of the upper side of the workbench; a fixed plate is fixedly connected to the sidewall of the upper side of the workbench; the fixed plate is located on the right side of the first clamping plate; a fixing hole is formed in thesidewall of the right side of the fixed plate; a threaded sleeve is fixedly connected inside the fixing hole; an adjusting screw rod is connected inside the threaded sleeve by screw threads; the two ends of the adjusting screw rod both extend out of the fixing hole; the left end of the adjusting screw rod is sleeved with a sleeve; and the inner wall of the sleeve is rotationally connected with theadjusting screw rod through a bearing. The precise guide rail part machining tool disclosed by the invention is simple and convenient in clamping operation, effectively improves the use convenience and effectively prevents the problem that waste fragments are easily accumulated on an existing tool.

Owner:马鞍山铭成科技信息咨询有限公司

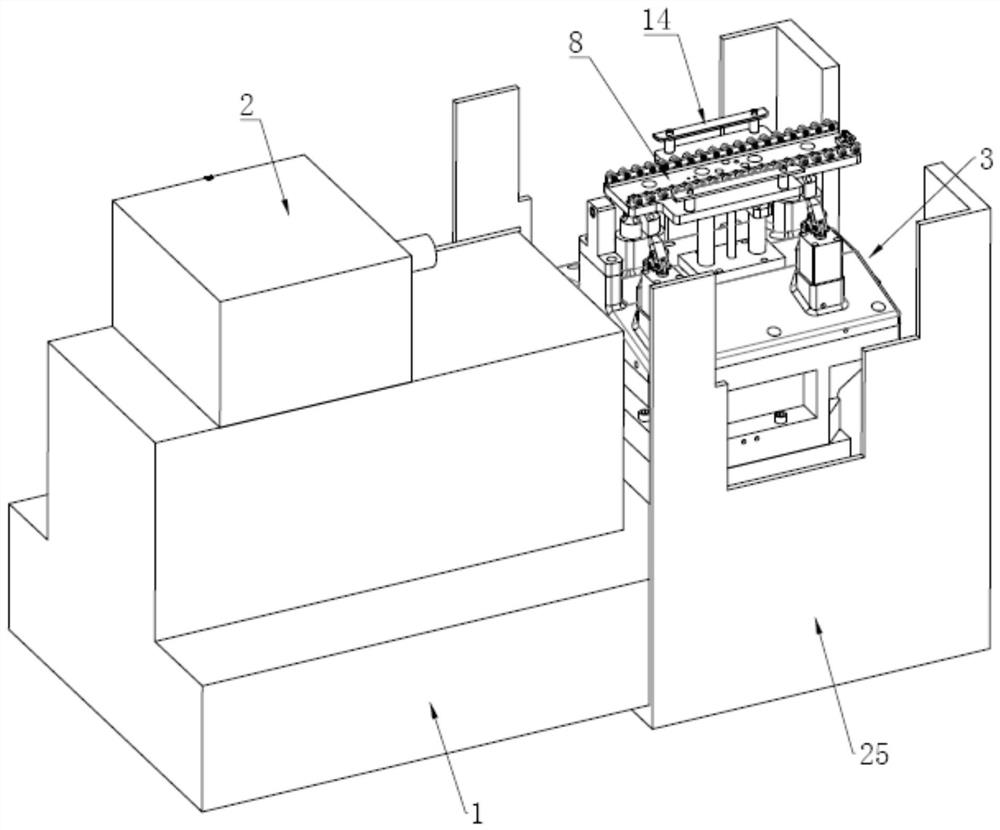

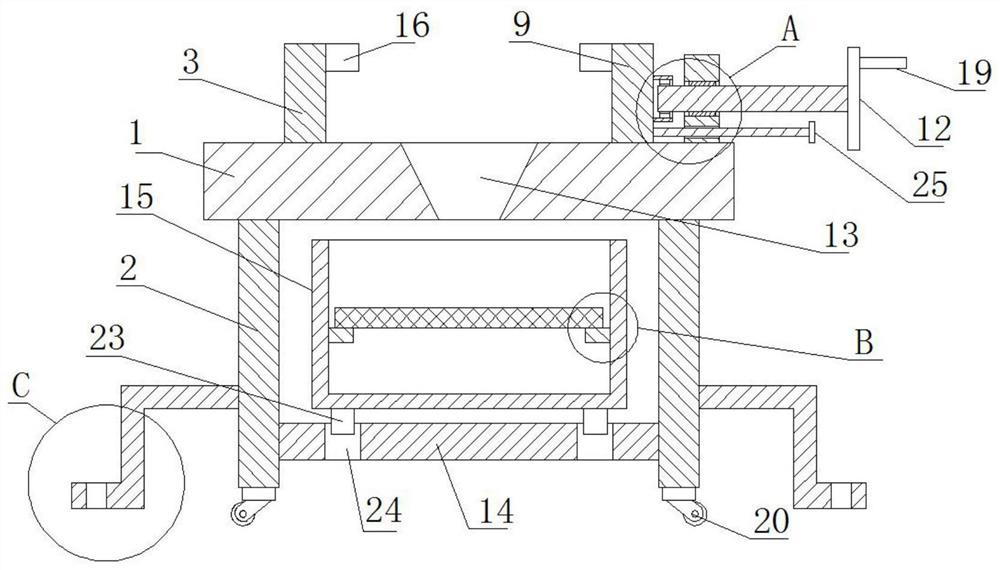

An autonomous grinding and polishing robot and control system for welding seams of large mechanical parts

ActiveCN113927396BSimple and convenient clamping operationEnsure safetyEdge grinding machinesGrinding carriagesControl systemProcess engineering

The invention discloses a welding seam autonomous grinding and polishing robot and control system for large-scale mechanism parts, which relate to the technical field of industrial robots and include a workpiece table, a clamping assembly, a transmission assembly, a grinding and polishing assembly, a screw lifting assembly and a protection assembly; the screw The lifting assembly is arranged on the side of the workpiece table, and the clamping assembly, the grinding and polishing assembly and the protection assembly are sequentially arranged above the workpiece table; the clamping assembly is based on the transmission assembly and the screw The lifting assembly is connected, and the grinding and polishing assembly and the protection assembly are fixed on the screw lifting assembly. The grinding and polishing robot drives the clamping component through the screw lifting component and the transmission component to carry out the clamping operation. The clamping operation is simple and convenient, and the spark waste generated during processing is blocked by the protective component to ensure the safety of processing. By setting the CPU The component controls the operation of the internal driving parts to complete the grinding and polishing of the workpiece, with convenient operation and good safety performance.

Owner:FOSHAN LONGSHEN ROBOT

Clamp for electrical discharge machining

InactiveCN111618387AOperation saves time and effortImprove work efficiencyElectrical-based auxillary apparatusDrive shaftCoupling

The invention discloses a clamp for electrical discharge machining. First sliding blocks are connected to the inner walls of first sliding grooves in a sliding mode, springs are arranged in the firstsliding grooves, extrusion plates are fixedly installed at the tops of the first sliding blocks through screws, a liquid storage tank is clamped and fixed between the two extrusion plates, first threaded rods are rotationally installed in second sliding grooves, one ends of the first threaded rods are in transmission connection with driving shafts of servo motors through couplers, the first threaded rods are in threaded connection with threaded sleeves, lifting plates are welded to one sides of the threaded sleeves, bearing plates are arranged on the upper surfaces of the two lifting plates, the tops of second sliding blocks are fixedly provided with clamping plates through screws, and second threaded rods penetrate through the two clamping plates and are in threaded connection with the clamping plates. The clamp has the advantages that the liquid storage tank can be conveniently and quickly fixed, the height of the bearing plates can be adjusted according to requirements, machined parts can be conveniently and quickly clamped and fixed, and the clamp is simple and convenient to operate.

Owner:HUNAN AUTOMOTIVE ENG VOCATIONAL COLLEGE

A saw blade surface treatment device with a positioning structure

ActiveCN109623605BEasy to handleReduce labor forceLiquid surface applicatorsGrinding machinesStructural engineeringMechanical engineering

Owner:ZHEJIANG NADIC CNC EQUIP CO LTD

Flame-retardant processing technology of flame-retardant plate based on macromolecular flame retardant

InactiveCN114347519APenetrate fastDeep penetrationFlat articlesPhysical chemistryProcess engineering

The invention discloses a flame-retardant processing technology for a flame-retardant plate based on a macromolecular flame retardant, and relates to the technical field of plate processing. The flame-retardant processing technology comprises a high-pressure explosion-proof box, the bottom of the high-pressure explosion-proof box is fixedly connected with a machine box, and the right side of the machine box is fixedly connected with a feeding mechanism. According to the flame-retardant processing technology for the flame-retardant plate based on the macromolecular flame retardant, the pressure pump is arranged to be matched with related pipelines, the high-pressure explosion-proof box can be pressurized, internal air is promoted to circularly flow, heating is conducted in the process, the flame-retardant plate can be uniformly heated and dried, the probability of explosion of the flame-retardant plate can be reduced through pressurization, and the flame-retardant effect of the flame-retardant plate is improved. The flame-retardant plate is fully dried, then the atomized flame retardant is sprayed into the high-pressure explosion-proof box, the fully dried flame-retardant plate can quickly absorb the flame retardant, meanwhile, part of steam is mixed in the atomized flame retardant, the fumigation effect can be achieved, the flame retardant can penetrate into the flame-retardant plate more deeply in cooperation with the pressurization effect, and compared with simple soaking, the flame-retardant effect is better, and the service life of the flame-retardant plate is prolonged. And more flame retardants can be absorbed, and the efficiency is higher.

Owner:于焕

Clamping and pushing device for syringe pump and syringe pump

Owner:深圳莫微医疗技术有限公司

Lead and tin plating method for lubricating oil separation sleeve and lubricating oil separation sleeve

The invention discloses a lead and tin plating method for a lubricating oil separation sleeve and the lubricating oil separation sleeve. The lead and tin plating method comprises the steps that S1, according to the end face size and an inner cavity structure of the lubricating oil separation sleeve, a cover plate used for covering the end face of the lubricating oil separation sleeve is designed, a through groove is formed in a central axis of the cover plate, an electric connecting piece used for penetrating through the cover plate and reaching the middle portion of an inner cavity of the lubricating oil separation sleeve is arranged in the through groove, and a lead-tin anode is arranged at the end, which is arranged in the inner cavity of the lubricating oil separation sleeve, of the electric connecting piece; S2, the lubricating oil separation sleeve is subjected to wax dipping, a wax layer on an electroplating face is removed, one end of a cathode wire is connected with the lubricating oil separation sleeve subjected to wax dipping, and the other end of the cathode wire is connected with a cathode; and S3, the cover plate covers the lubricating oil separation sleeve, the lead-tin anode is located in the center of the inner cavity of the lubricating oil separation sleeve, then lead-tin plating treatment is carried out, a wax layer is removed, and the lubricating oil separation sleeve containing a lead-tin plating layer is obtained. The plug-in inner anode is designed, so that the lead-tin anode is located in the center of the inner cavity of the lubricating oil separation sleeve; and electric field lines are uniformly distributed, so that the thickness of the plating layer is uniform.

Owner:CHINA HANGFA SOUTH IND CO LTD

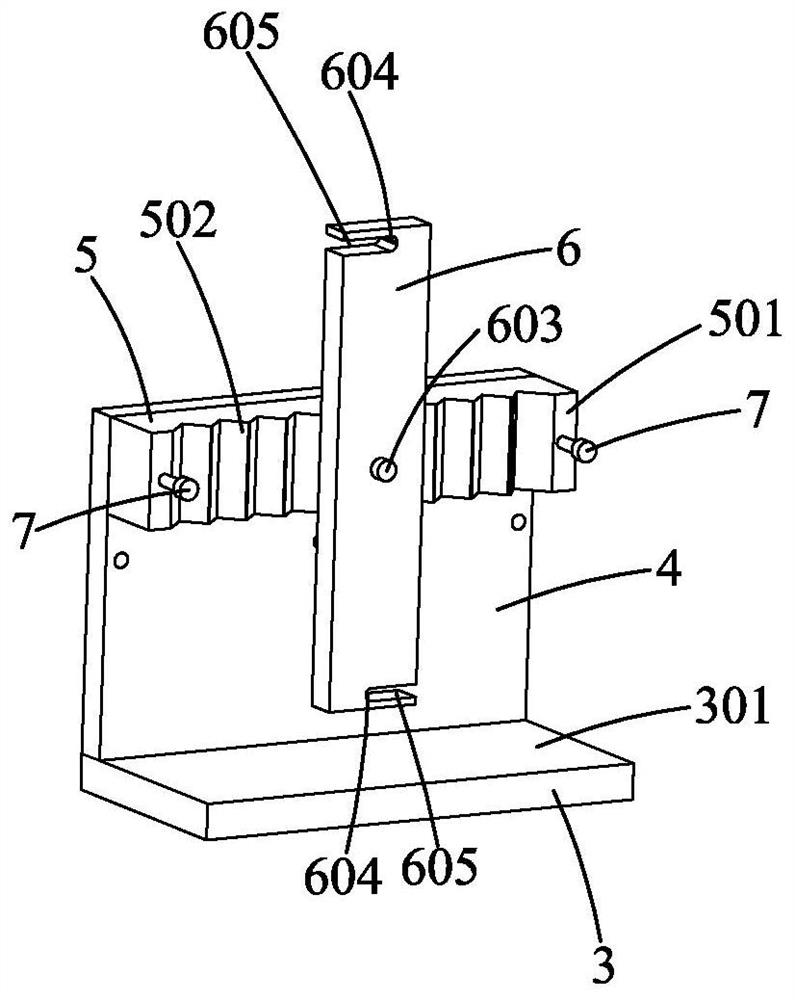

Universal clamping tool for two-sided milling machine milling bolt groove

PendingCN107350862AReasonable structural designCompact structurePositioning apparatusMetal-working holdersEngineeringStructural engineering

The invention discloses a universal clamping tool for a two-sided milling machine milling bolt groove. The universal clamping tool comprises a bottom plate and further comprises side stand columns, a cylinder body integration plate and a set of piston assemblies which are used for clamping products to be machined. The bottom ends of the side stand columns are arranged on the bottom plate, the cylinder body integration plate is arranged at the top ends of the side stand columns, and the set of piston assemblies are arranged in the cylinder integration plate. The universal clamping tool is reasonable in structural design, compact in tool structure, high in universality and capable of machining the multiple products through one-time clamping and high in working efficiency, the clamping operation is easy and convenient, the working intensity of an operator is lowered, the machining precision can be guaranteed, the identity of the products is easily guaranteed, and the product percent of pass is increased.

Owner:FANER INTELLIGENT TECH GRP CO LTD

Multifunctional clamping device for genetic engineering

InactiveCN111617818AWith quick adjustmentWith fine-tuningSupporting apparatusGear wheelGenetic engineering

The invention relates to the technical field of genetic engineering devices. The invention discloses a multifunctional clamping device for genetic engineering. The multifunctional clamping device includes a base, and a workbench is arranged on the surface of the base. Foot pads are arranged on the lower portion of the base. A supporting rod is arranged on the surface of the base; a regulator I isarranged on the surface of the supporting rod; the surface of the regulator I is fixedly connected with a rotating rod I; the surface of the rotating rod I is fixedly connected with a first gear; thesurface of the rotating rod I is fixedly connected with a second gear; a rack is matched with the first gear and a third gear for use; the second gear is matched with the third gear for use; the device can achieve the lifting function, meanwhile, the functions of quick adjustment and fine adjustment are achieved, a first driving gear and a first driven gear are used in cooperation, a second driving gear and a second driven gear are used in cooperation, the device can achieve vertical angle adjustment, and meanwhile the functions of quick adjustment and fine adjustment are achieved.

Owner:杭州乐垚生物科技有限公司

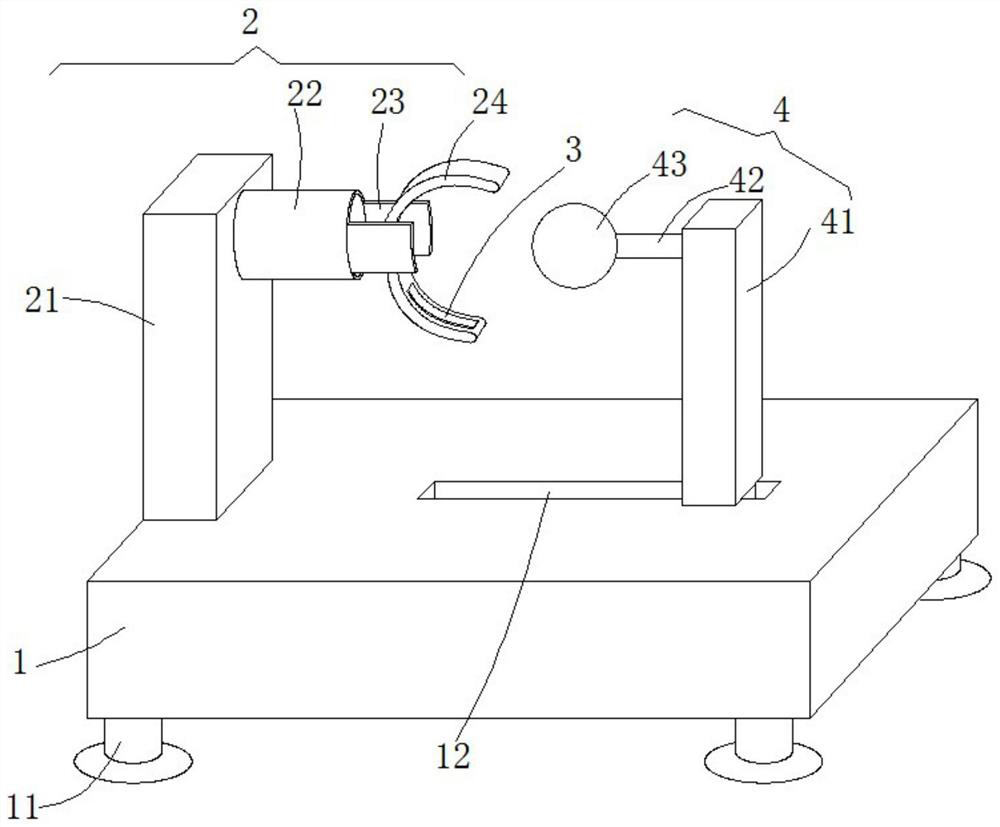

A clamping device and clamping method for automotive rubber bushings with automatic stress measurement

ActiveCN112109012BEasy clampingFacilitates stress detection operationsWork holdersApparatus for force/torque/work measurementMechanical engineeringElectrical and Electronics engineering

The invention discloses an automobile rubber bushing clamping device and clamping method for automatically measuring stress, comprising a base, a clamping mechanism and a jacking mechanism, and the clamping mechanism includes a column, a mounting sleeve, and two arc-shaped extension plates and two arc-shaped clamping plates, the column of the clamping mechanism is vertically welded to the middle position on the left side of the top surface of the base, and the middle position of the top surface of the base is provided with an inverted T-shaped chute on the right side of the column, and the jacking mechanism includes: The moving column, the connecting rod and the jacking ball are provided with an inverted T-shaped slider on the bottom surface of the moving column. The invention is convenient for quickly clamping the automobile bushing, and the clamping operation is simple and convenient, without causing damage to the automobile rubber bushing, and is convenient for carrying out the stress detection operation on the bushing, and the shaking phenomenon is not easy to occur during the detection process.

Owner:安徽誉林汽车部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com