Universal clamping tool for two-sided milling machine milling bolt groove

A technology for clamping tooling and milling machines, applied in the field of milling processing, can solve the problems of cumbersome positioning, pressing, installation and disassembly, low processing efficiency, and difficult to guarantee processing accuracy, and achieves the same product identity, high work efficiency, and guaranteed processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

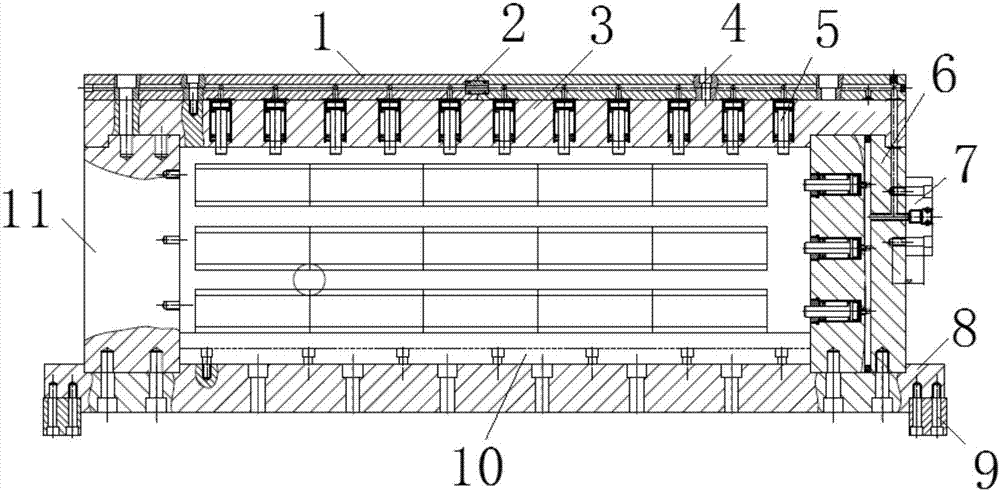

[0022] Such as figure 1 As shown, the double-sided milling machine uses a universal clamping tool for milling pin slots, including a bottom plate 8, a side column, a cylinder cover plate 1, a cylinder integrated plate 3, and a set of piston assemblies 5 for clamping the product to be processed.

[0023] The side columns are a pair arranged side by side, respectively arranged on the end of the bottom plate, divided into side columns I6 and side columns II11. The bottom end of the side column is arranged on the bottom plate 8, and the cylinder integrated plate 3 is arranged on the top of the side column. Positioning, reliable positioning, guaranteed structural strength, and good clamping stability.

[0024] A group of piston assemblies 5 are set in the cylinder integrated plate 3, and the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com