A clamping device and clamping method for automotive rubber bushings with automatic stress measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

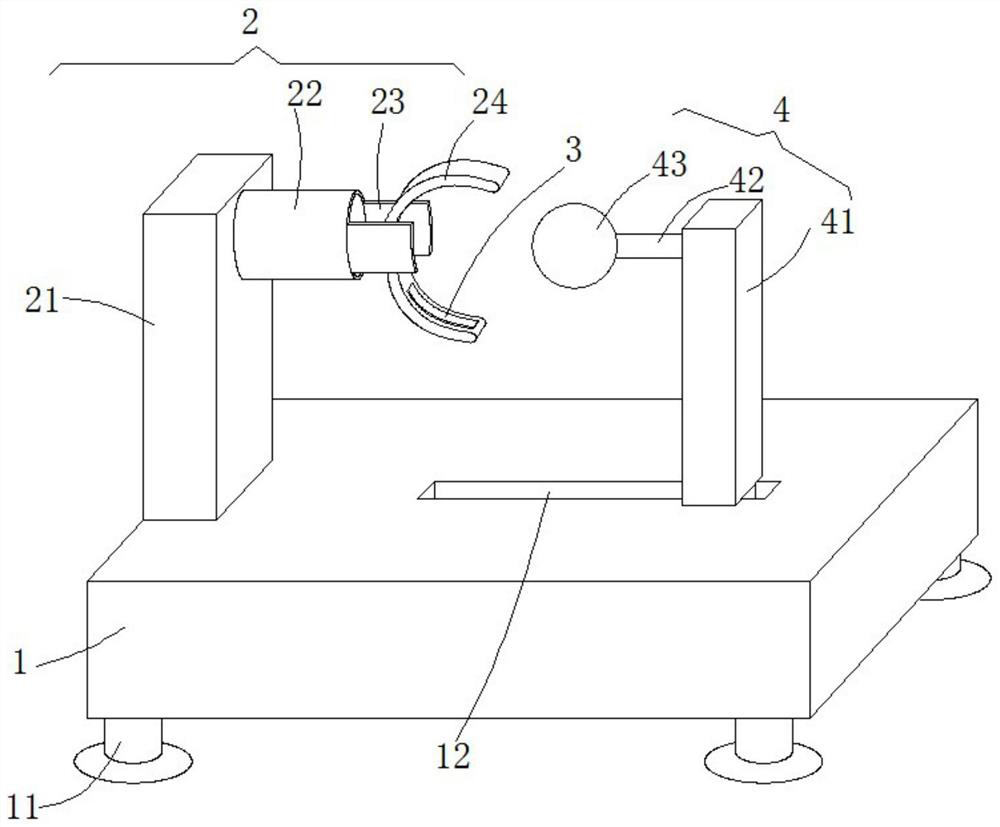

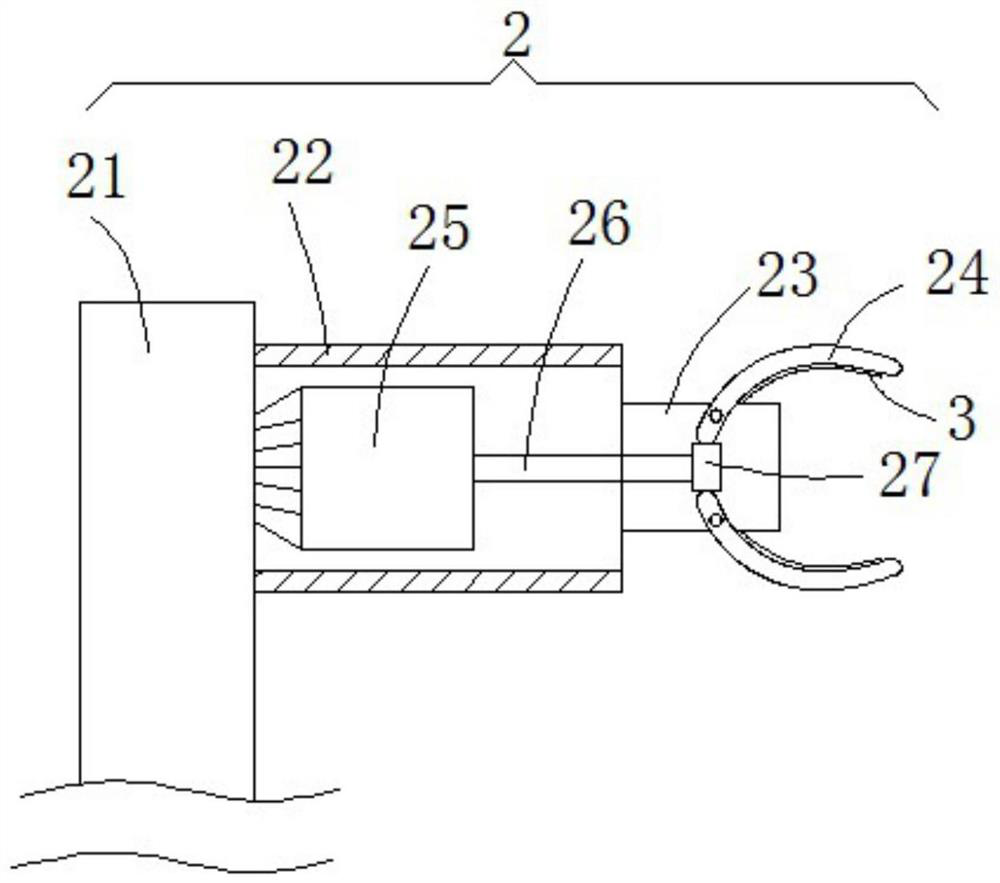

[0027] see Figure 1-4 , the present embodiment provides a clamping device and a clamping method for an automotive rubber bush that automatically measures stress, including a base 1, a clamping mechanism 2 and a jacking mechanism 4, and the clamping mechanism 2 includes a column 21, a mounting sleeve 22. Two arc-shaped extension plates 23 and two arc-shaped clamping plates 24. The column 21 of the clamping mechanism 2 is welded vertically to the middle position on the left side of the top surface of the base 1. 21 The inverted T-shaped chute 12 on the right side, the jacking mechanism 4 includes a moving column 41, a connecting rod 42 and a jacking ball 43, the bottom end surface of the moving column 41 is provided with an inverted T-shaped slide block 44, and the moving column 41 passes through the inverted T. The sliding block 44 is slidingly engaged with the inner cavity of the inverted T-shaped chute 12 of the base 1 .

[0028] The four corners of the bottom surface of th...

Embodiment 2

[0035] see Figure 1-4 , further improvements have been made on the basis of Example 1:

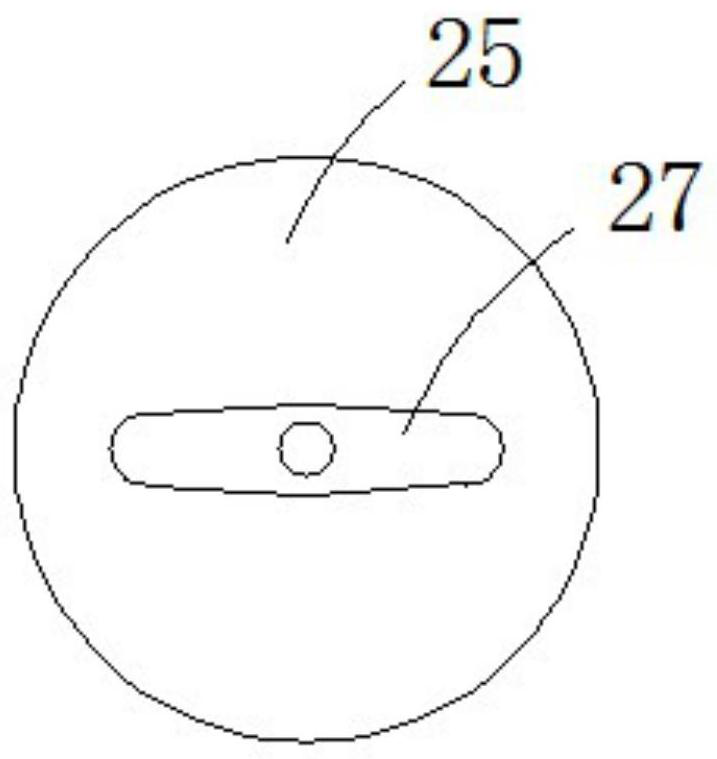

[0036] The hinged position of each arc clamping plate 24 is 1 / 5 of the length of the entire arc clamping plate 24 from the left end of each arc clamping plate 24, so that the arc clamping plate 24 leaves enough length to come It is convenient to rotate the two arc-shaped clamping plates 24 synchronously around the pin shaft by rotating the top block 27 .

[0037] The left ends of the two arc-shaped clamping plates 24 are all embedded with iron metal blocks, and the outer wall of the rotating top block 27 is embedded with magnet blocks. The magnet blocks are mutually adsorbed with the upper and lower iron metal blocks. The two iron metal blocks are adsorbed to each other, so that the left ends of the upper and lower arc clamping plates 24 are always rotated and attached to the upper and lower sides of the outer wall of the rotating top block 27, so that the right ends of the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com