Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Shorten teaching time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and a system for programming an industrial robot

ActiveUS20050149231A1Shorten teaching timeQuality improvementProgramme-controlled manipulatorComputer controlGraphicsAnalog robot

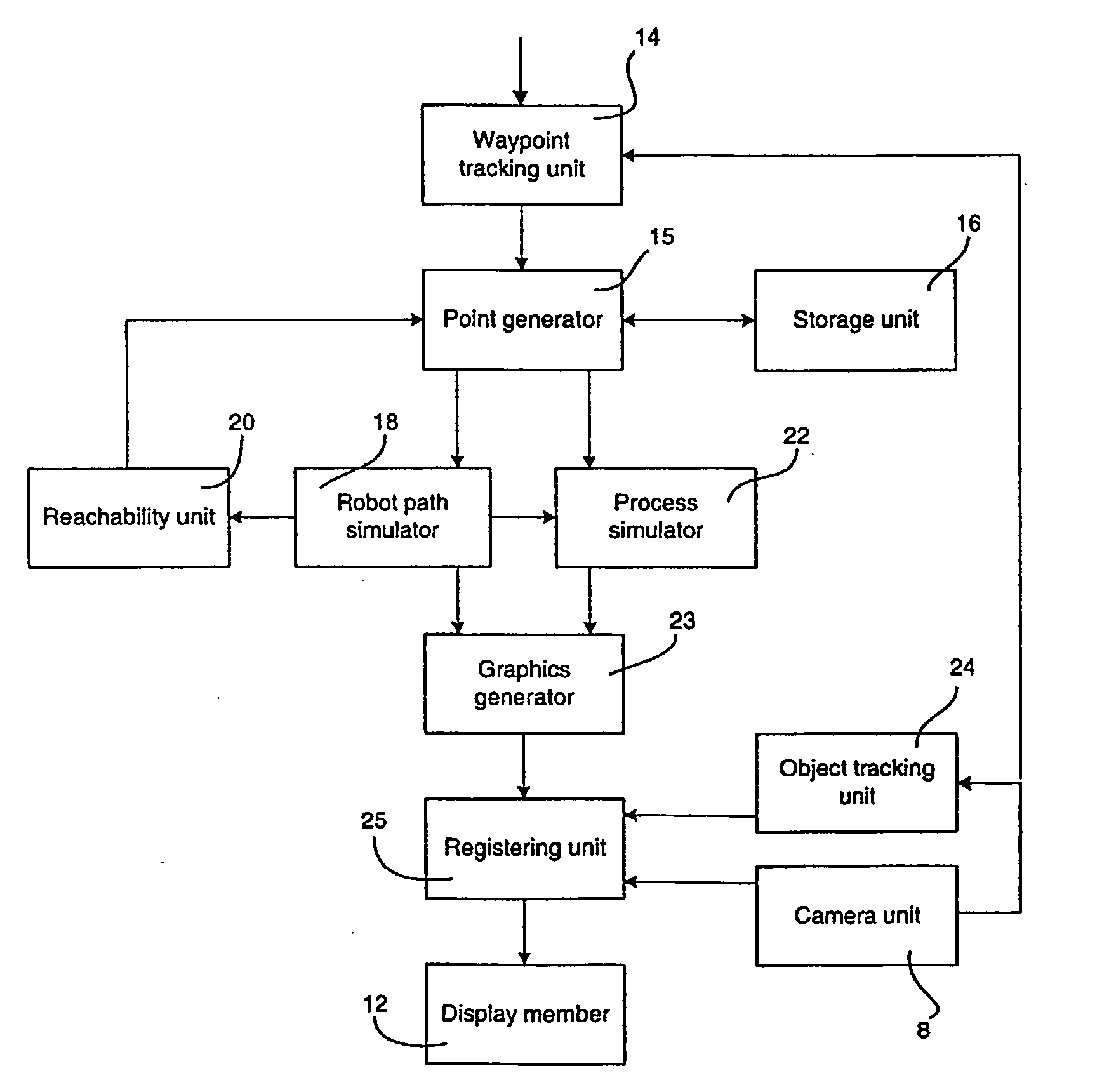

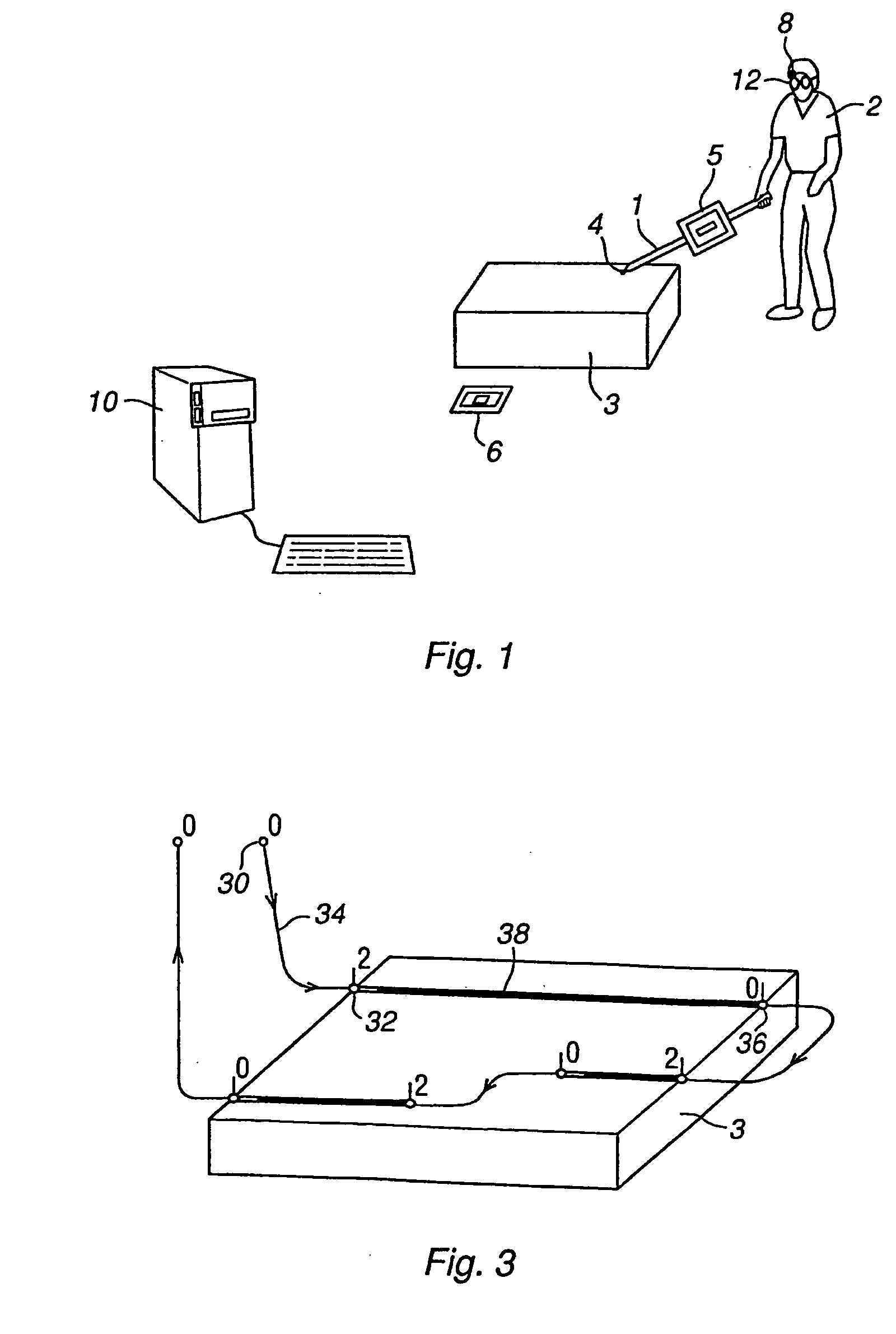

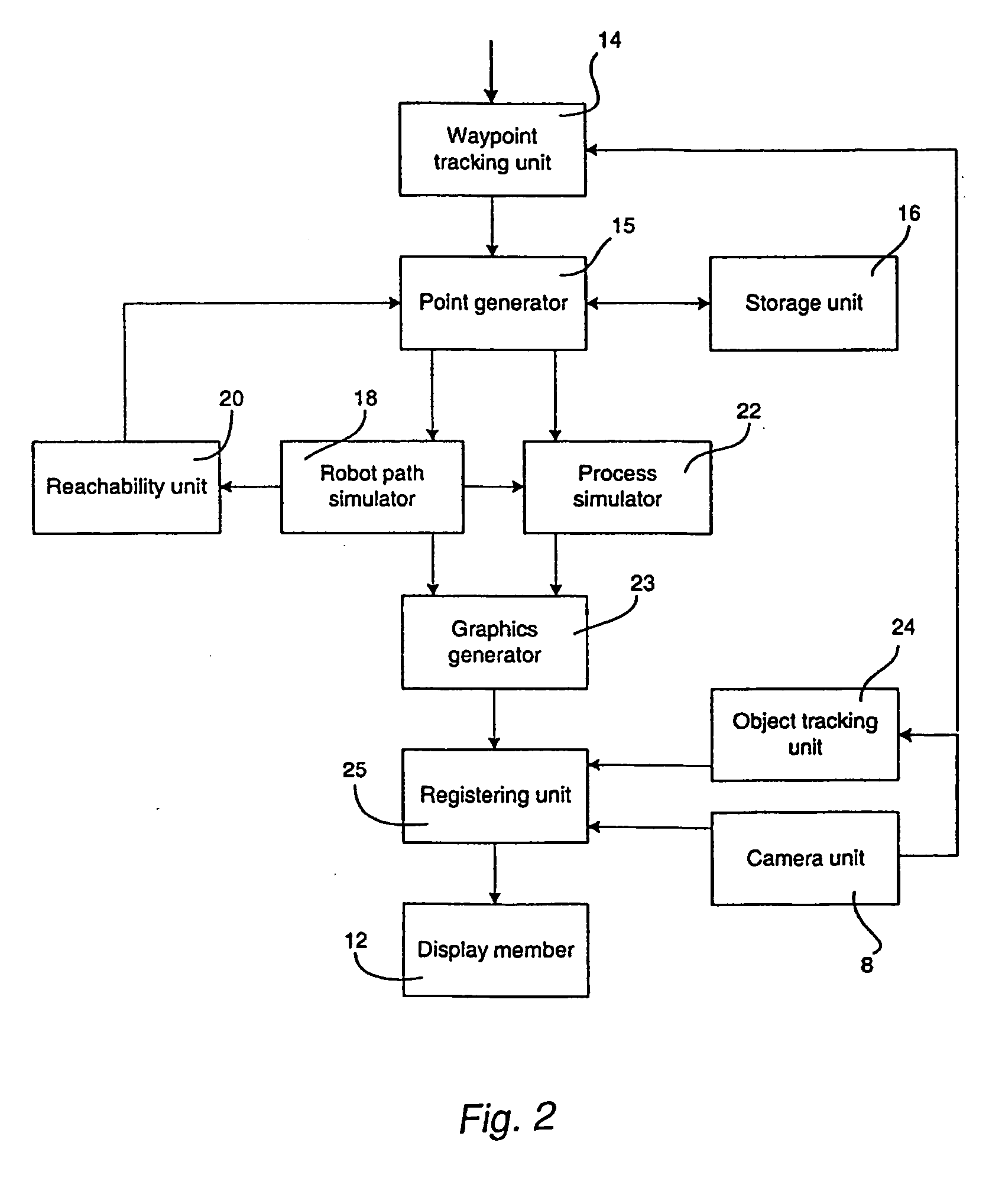

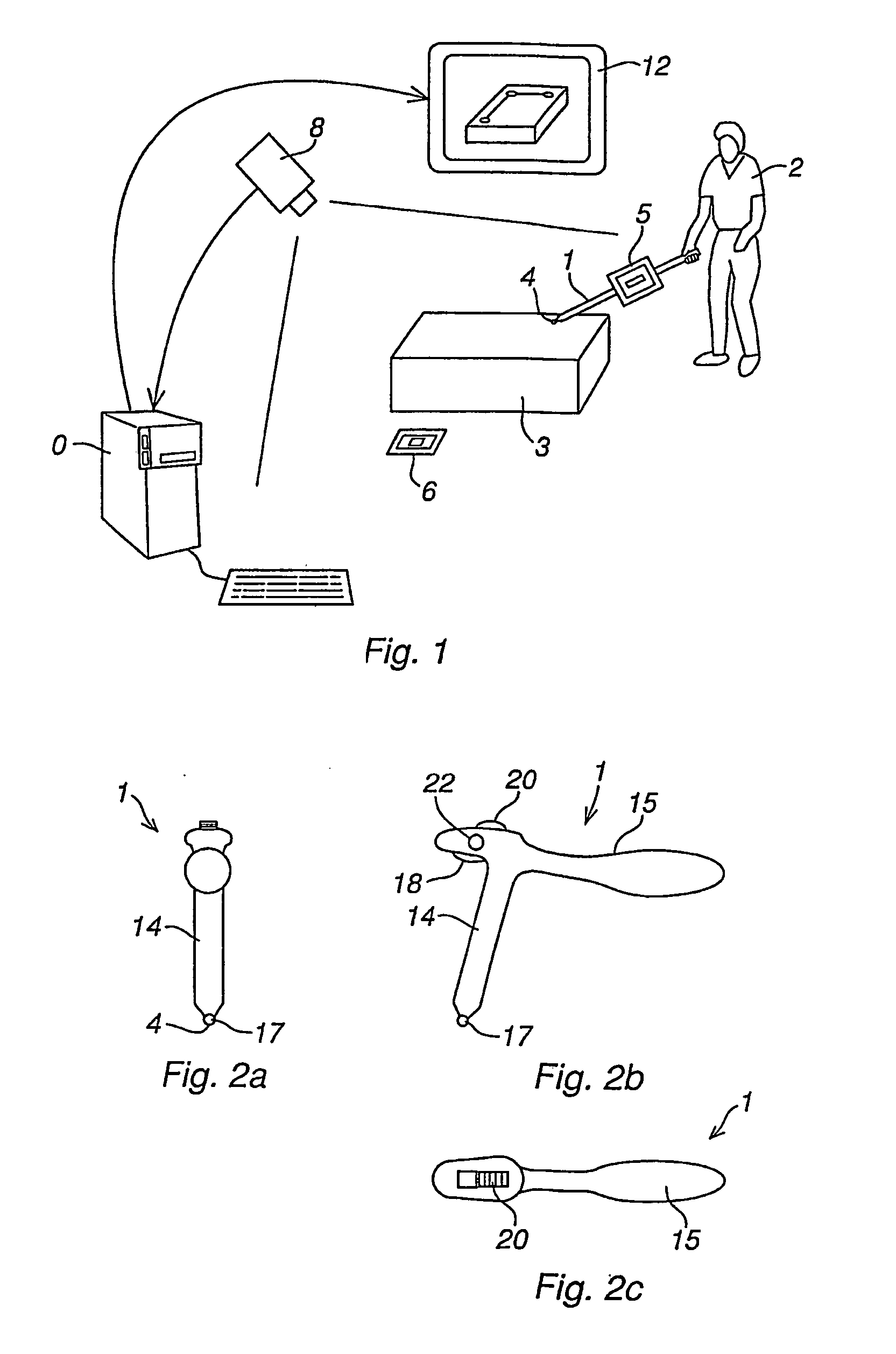

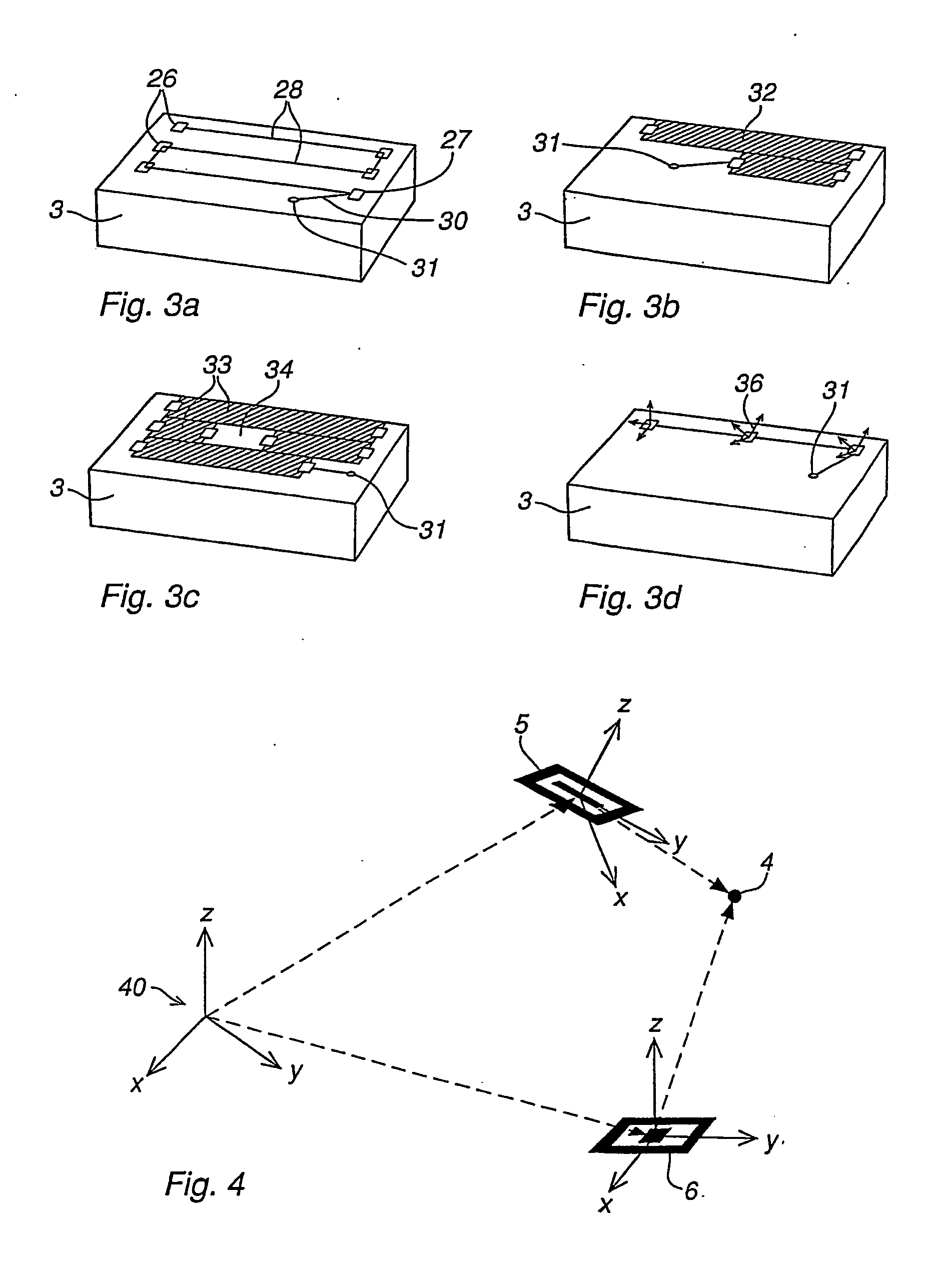

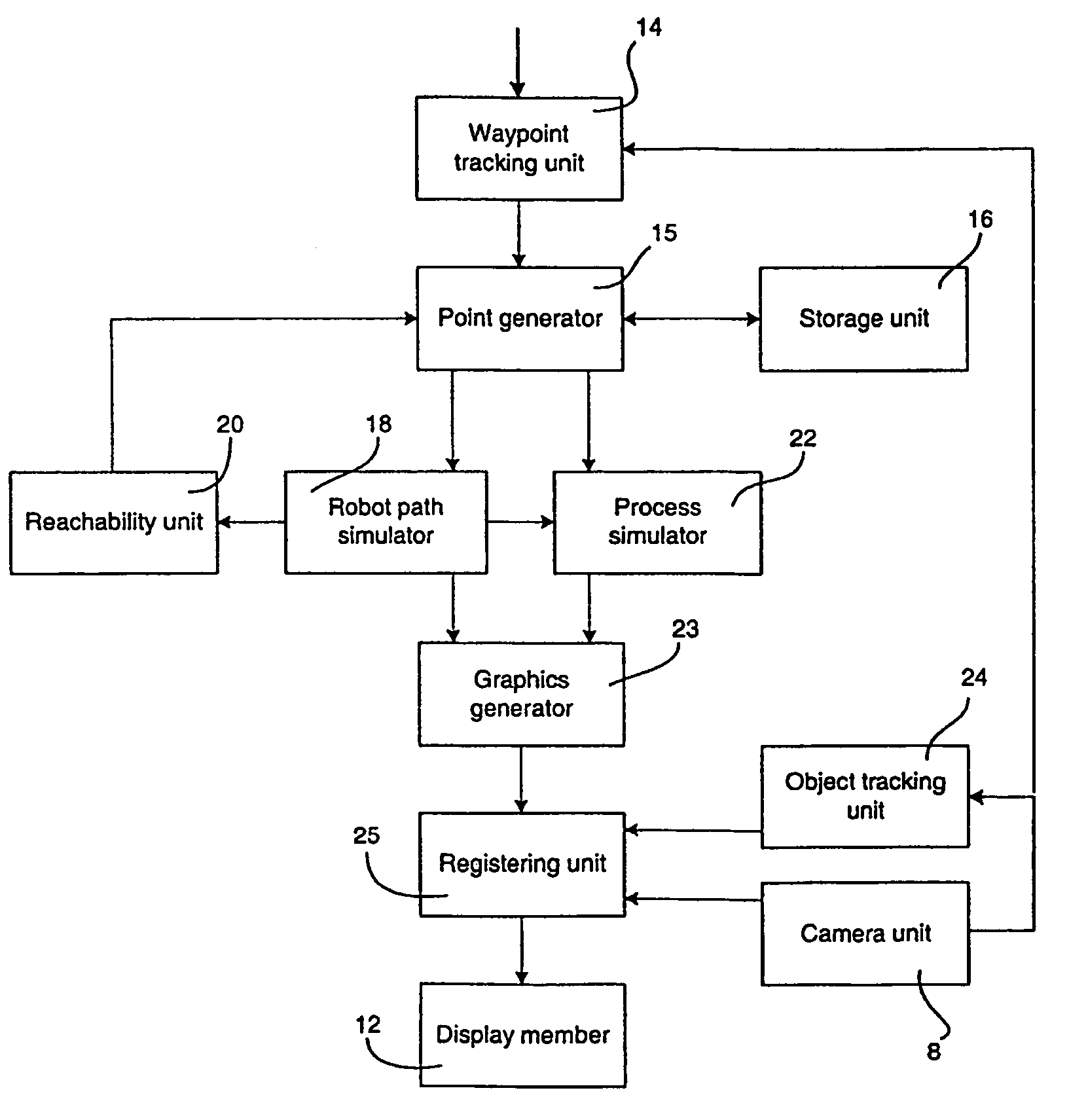

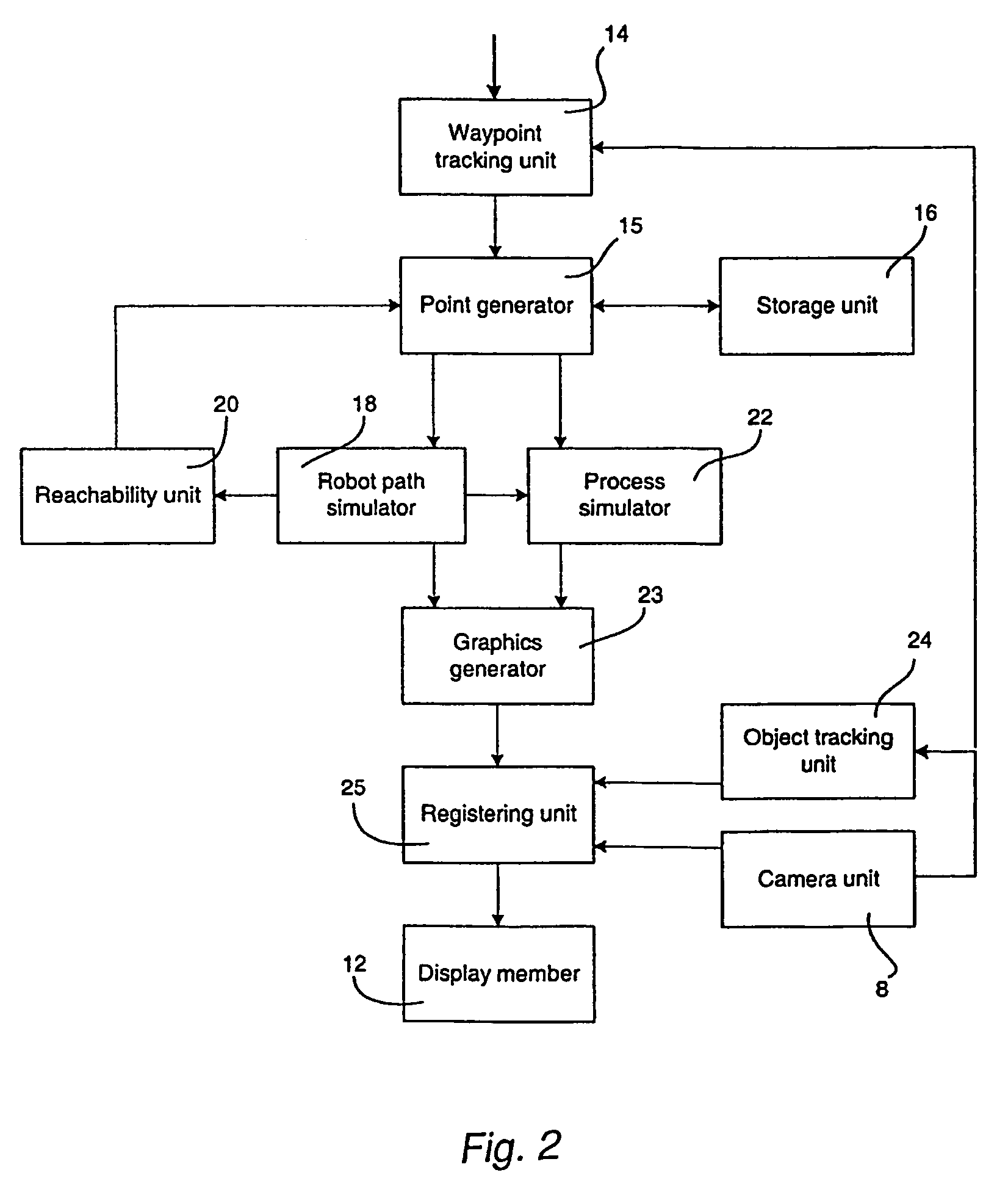

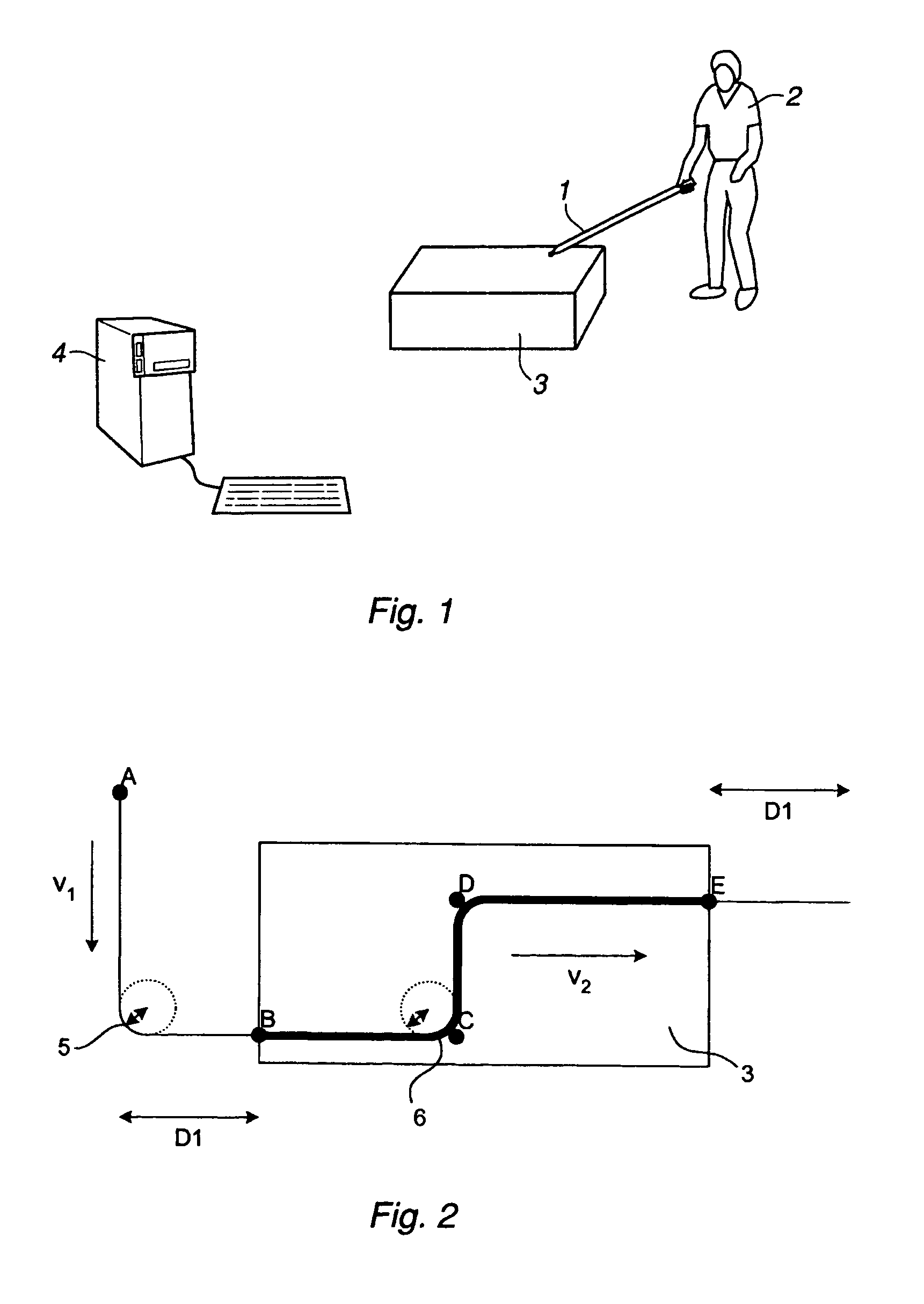

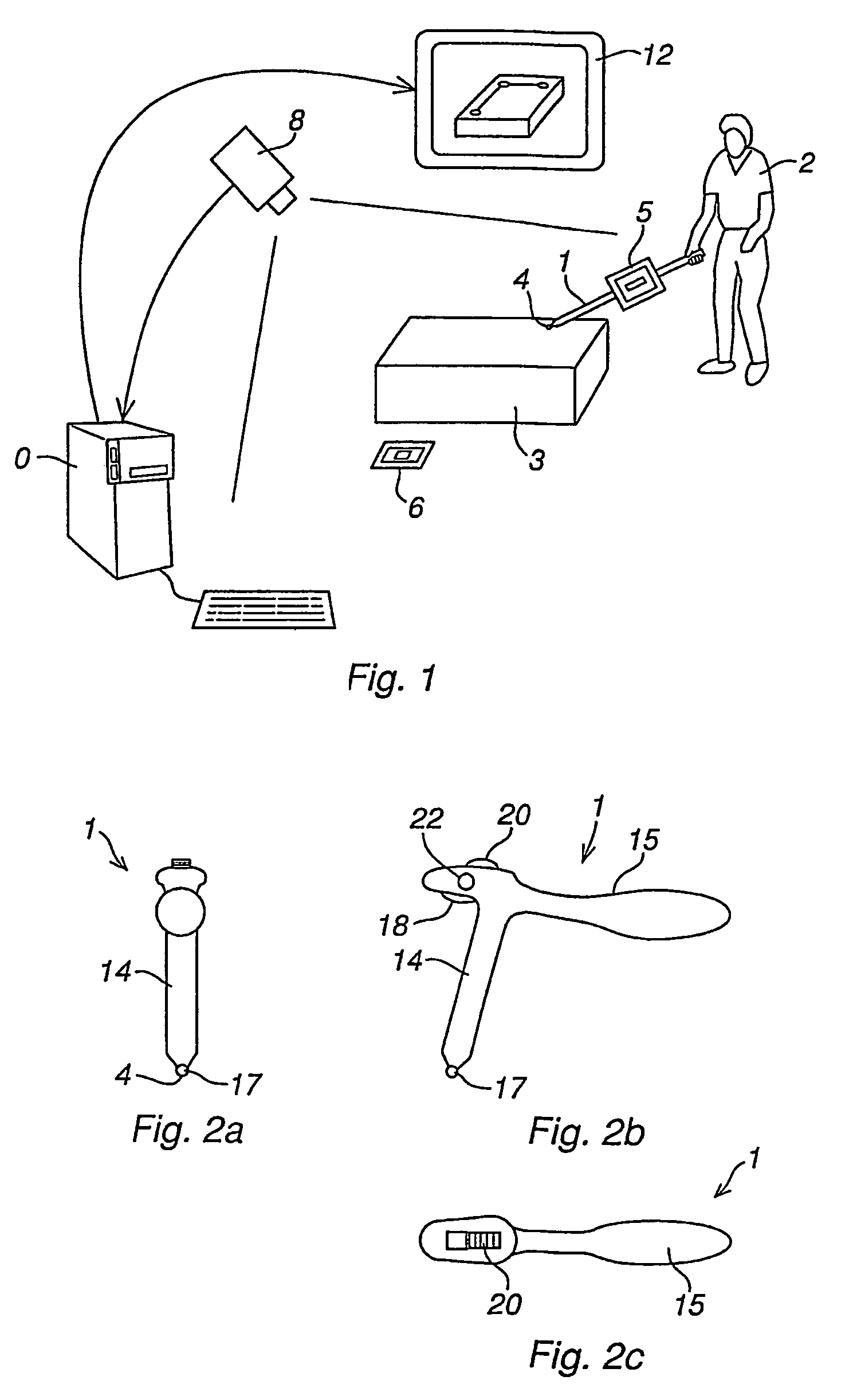

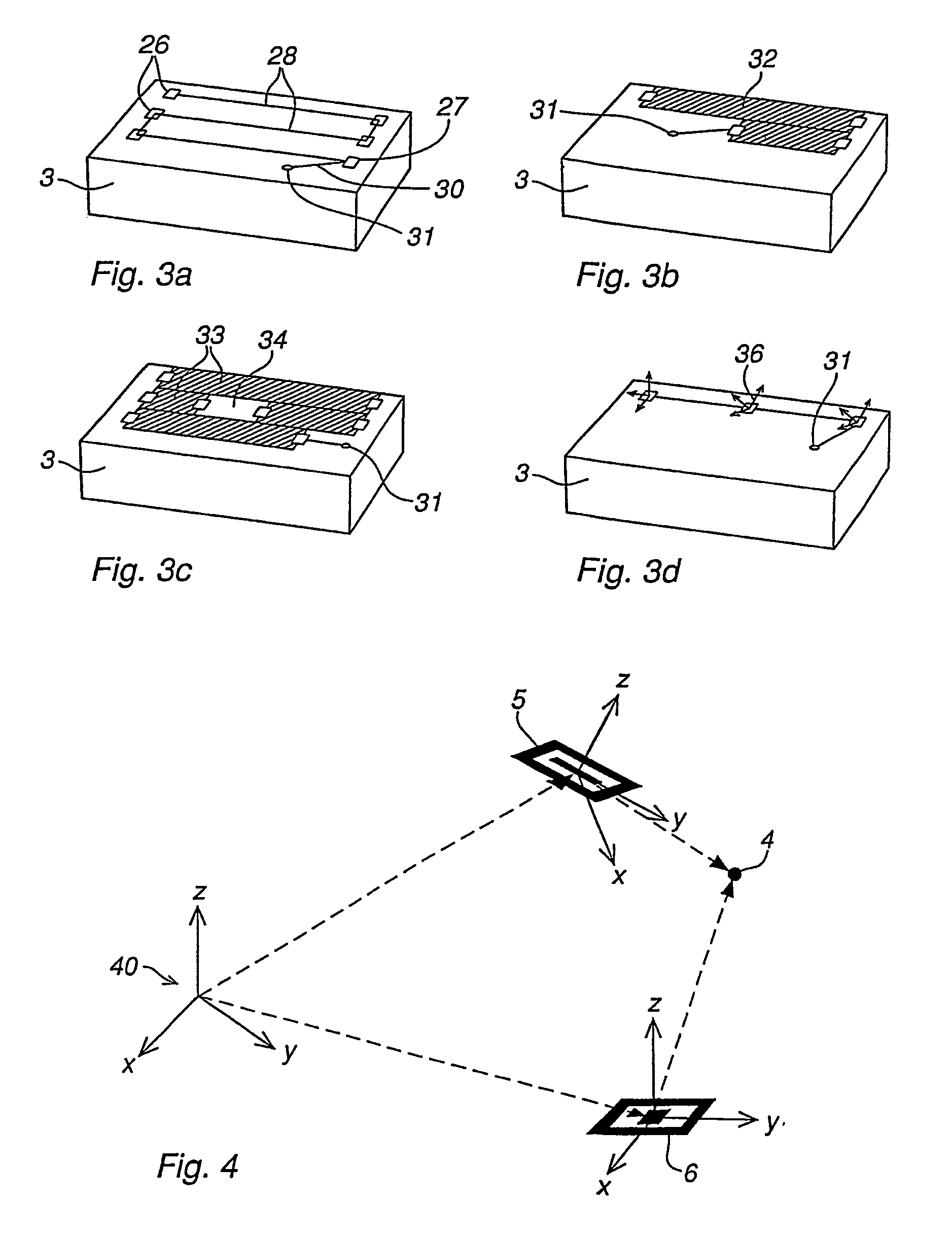

A method and a system for use in connection with programming of an industrial robot, the programming comprises teaching the robot a path having a number of waypoints located on or in the vicinity of an object to be processed by the robot. The system comprises: means for obtaining information about the waypoints of the path in relation to the object, a storage unit (16), for storing the obtained information, a simulation unit (18), simulating the robot path based on the obtained information about the waypoints and a model of the robot, a graphics generator (23), generating a graphical representation of the simulated robot path, and a display member (12) displaying a view comprising the object and said graphical representation of the robot path projected on the object.

Owner:ABB (SCHWEIZ) AG

Method and a system for programming an industrial robot

ActiveUS20050251290A1Pointed outShorten teaching timeProgramme-controlled manipulatorComputer controlGraphicsDisplay device

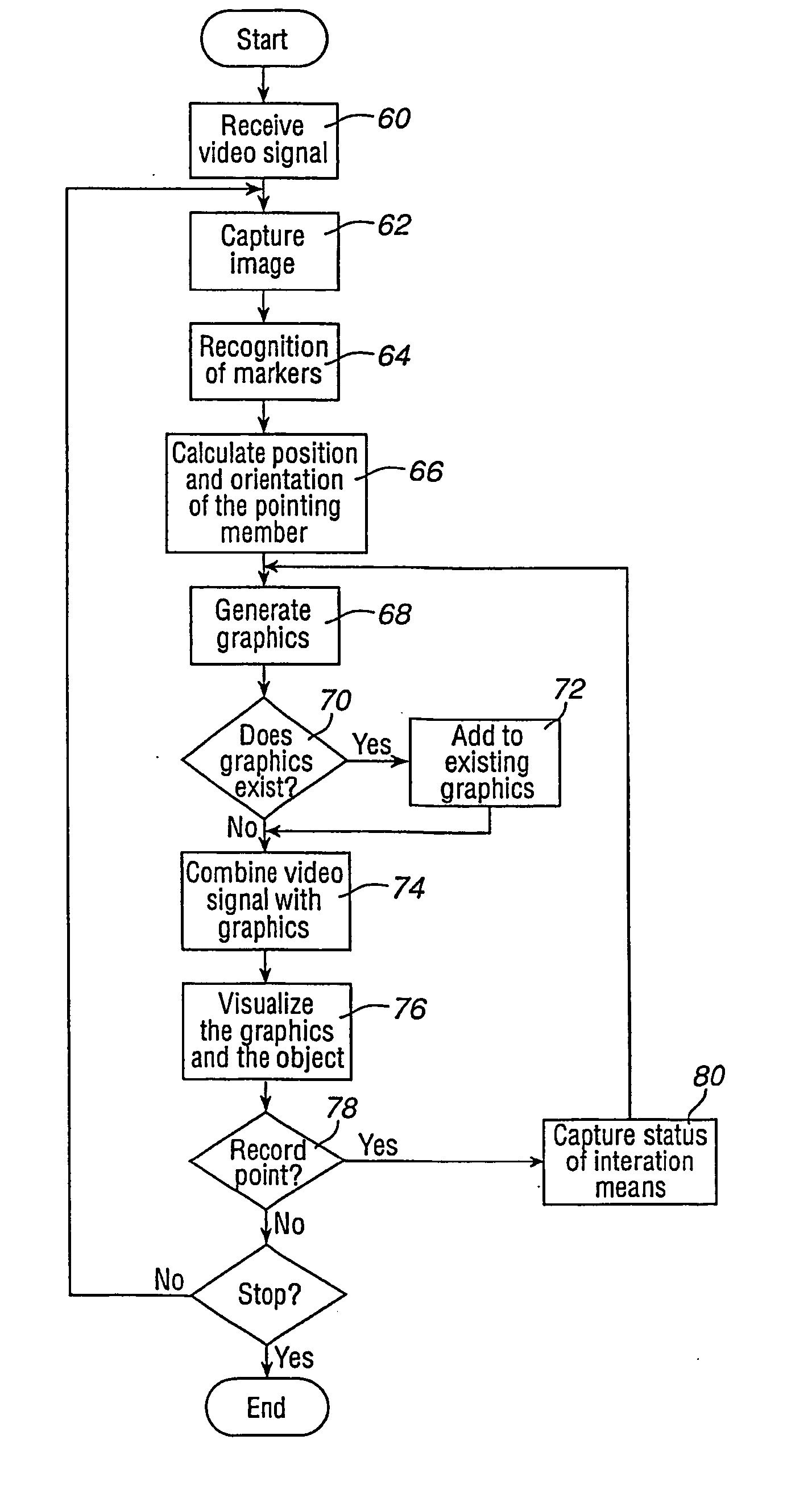

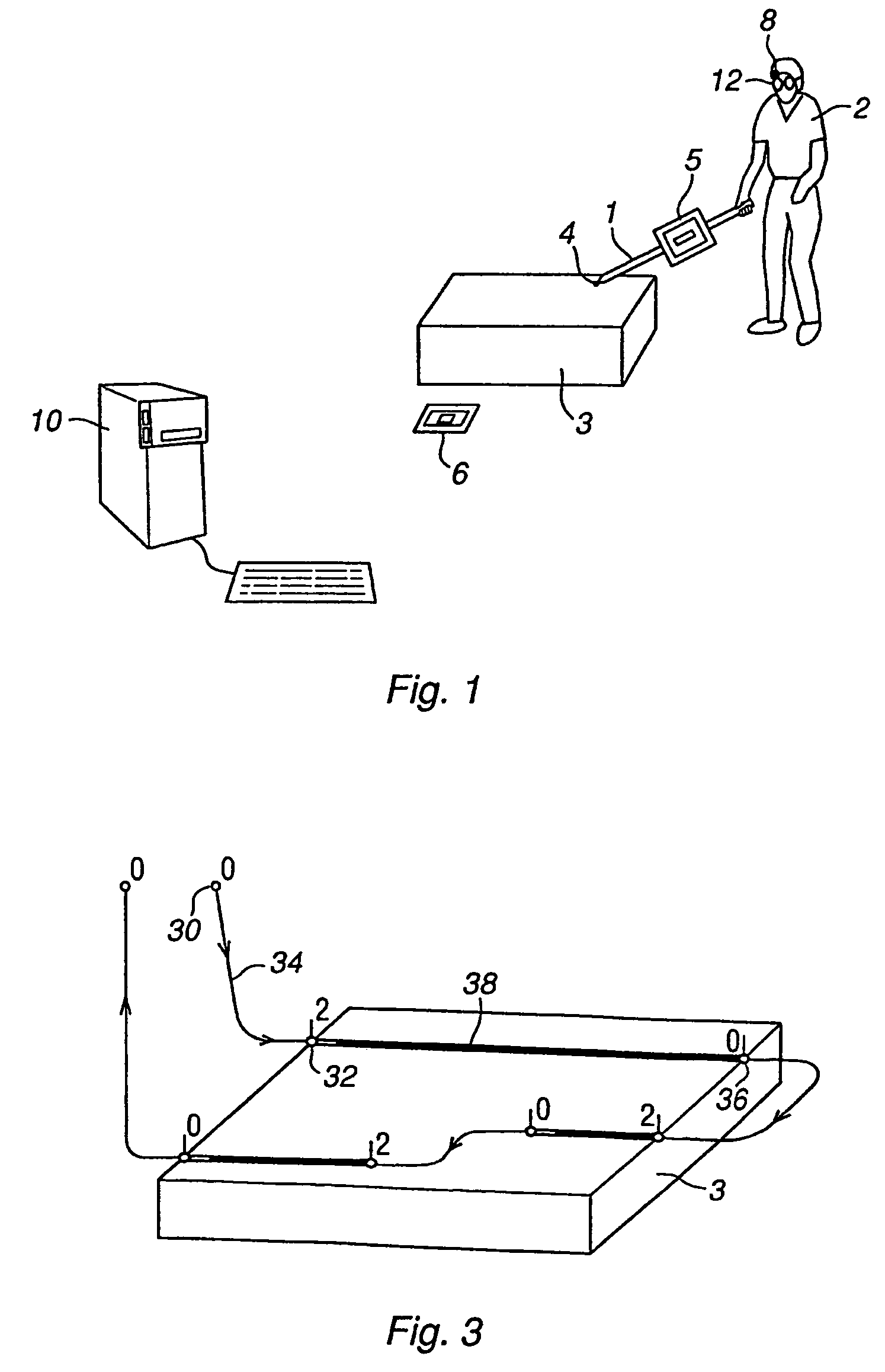

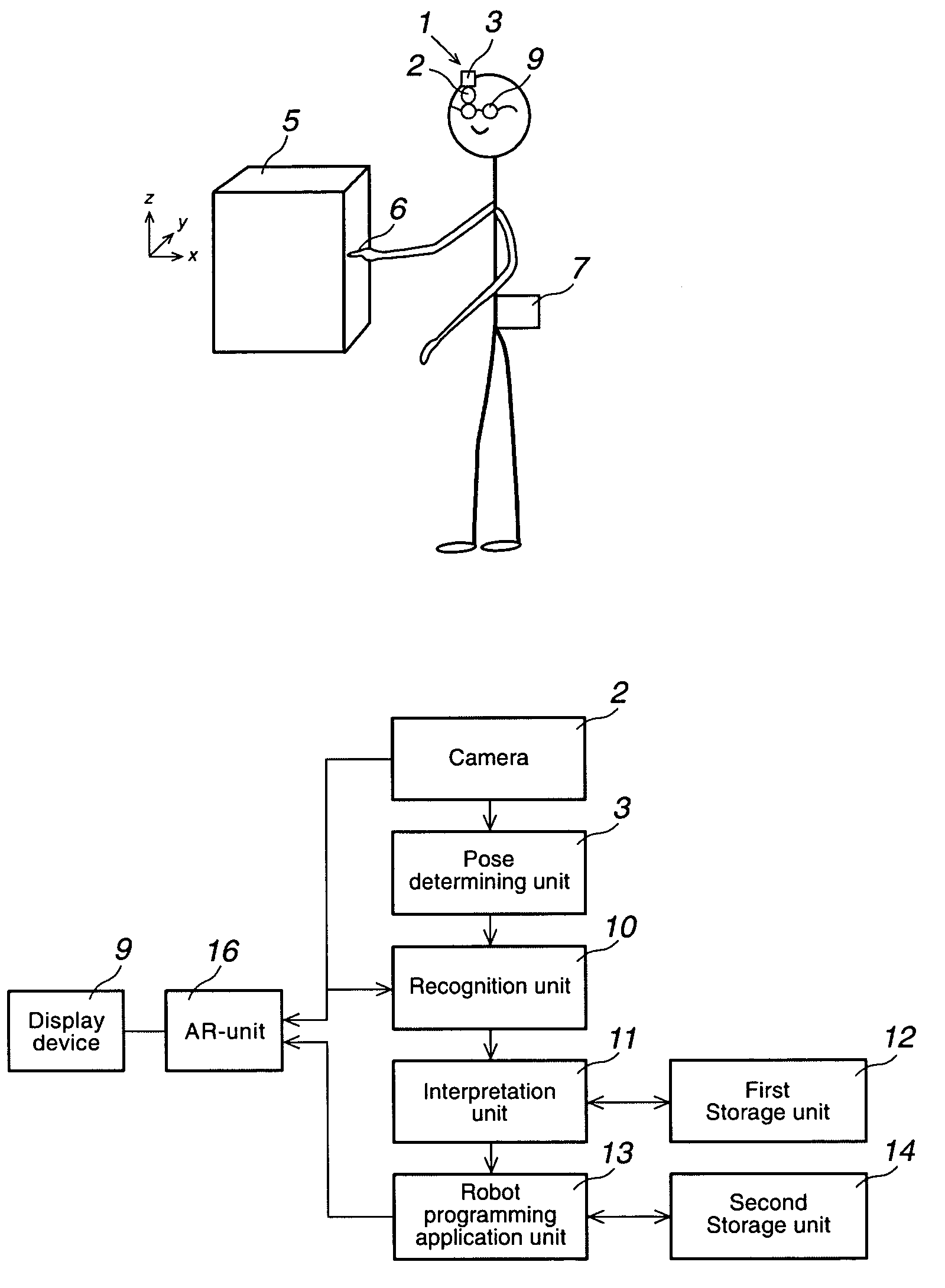

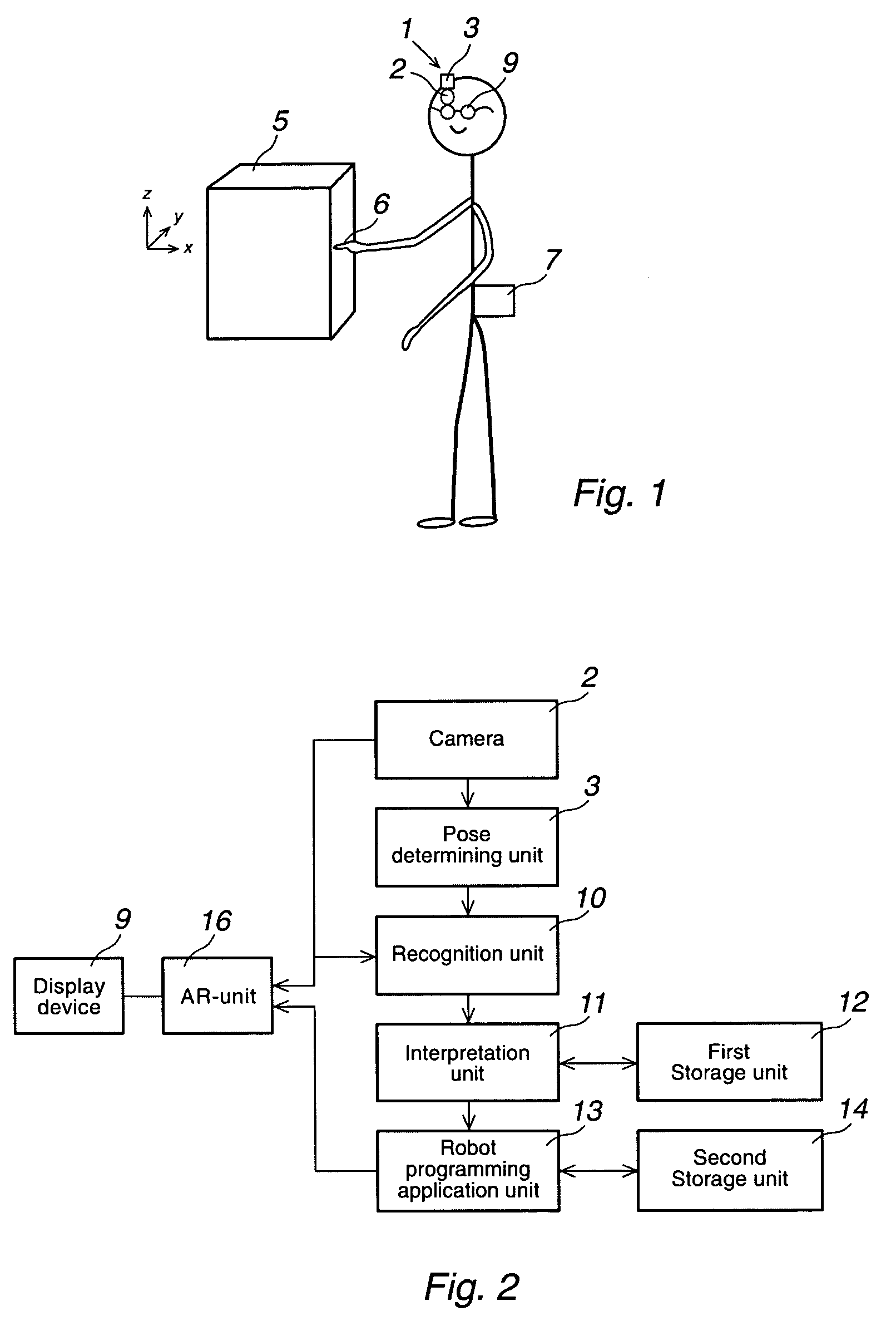

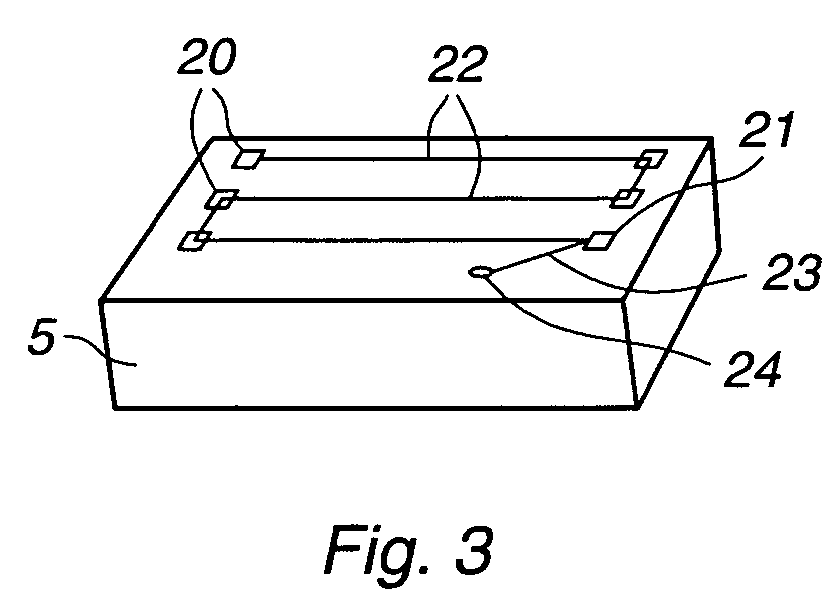

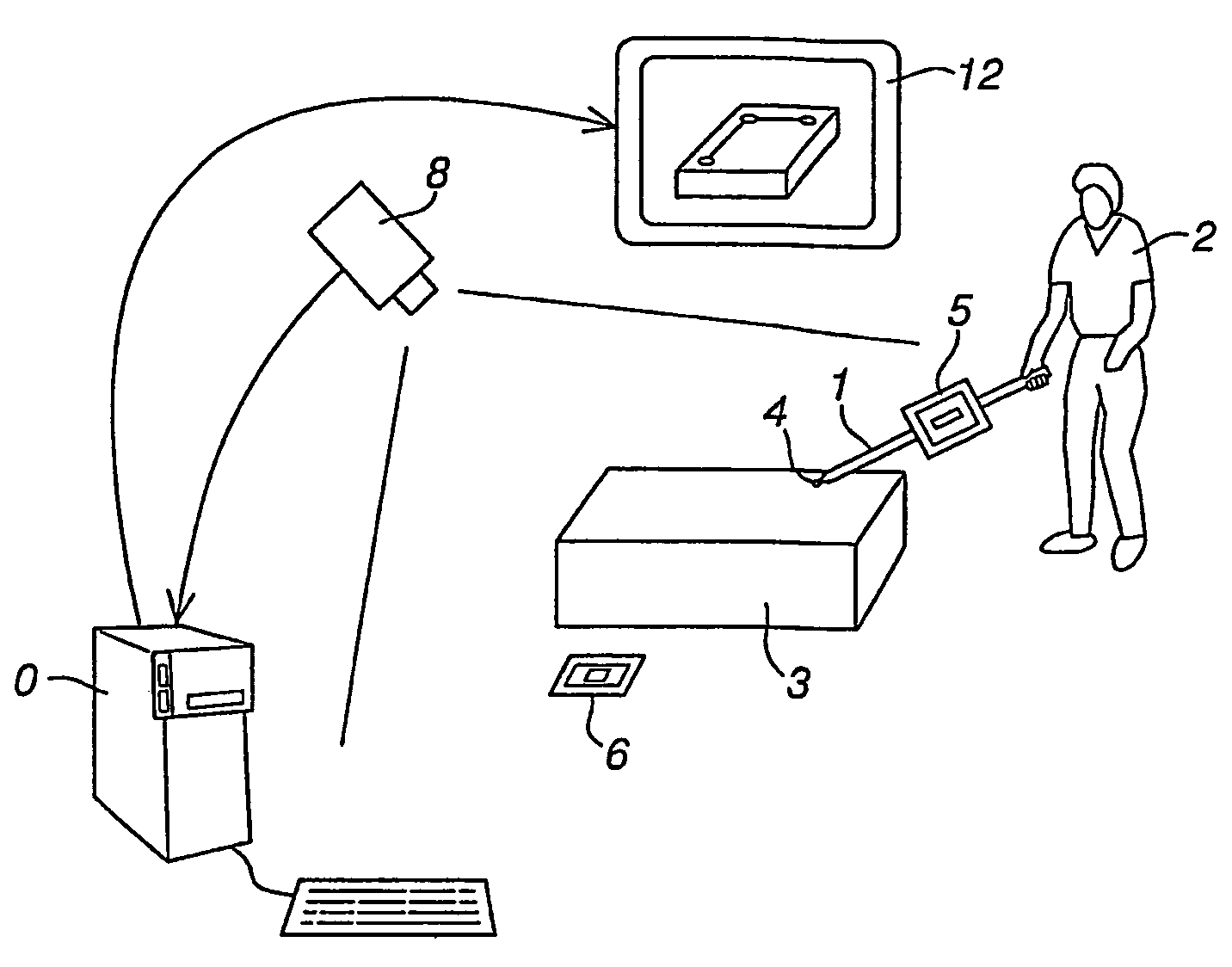

A method for programming an industrial robot. The robot is taught a path having waypoints located on or in the vicinity of an object. An image of the object is obtained. Information is obtained about the position of a pointer pointing at points. The position of the points relative to the object is determined. A point being pointed out is stored as a waypoint. A graphical representation is generated of the stored waypoint and the point being pointed out. A view is displayed including the object and the graphical representation. A system includes a pointer for pointing out points on or in the vicinity of the object, a position determiner determines the position of the points relative to the object, a camera delivers an image of the object and the pointer, a graphical generator generates graphics, a display displays a view including the object and graphical representation, and an activator.

Owner:ABB (SCHWEIZ) AG

Method and a system for programming an industrial robot

ActiveUS7236854B2Shorten teaching timeQuality improvementProgramme-controlled manipulatorComputer controlGraphicsAnalog robot

A method and a system for use in connection with programming of an industrial robot. The programming includes teaching the robot a path having a number of waypoints located on or in the vicinity of an object to be processed by the robot. The system includes elements for obtaining information about the waypoints of the path in relation to the object, a storage unit for storing the obtained information, a simulation unit for simulating the robot path based on the obtained information about the waypoints and a model of the robot, a graphics generator for generating a graphical representation of the simulated robot path, and a display member for displaying a view comprising the object and the graphical representation of the robot path projected on the object.

Owner:ABB (SCHWEIZ) AG

Method and a system for programming an industrial robot

ActiveUS7353082B2Shorten teaching timeQuality improvementProgramme-controlled manipulatorComputer controlCombined useControl engineering

A method and a system for use in connection with off-line programming of an industrial robot. The robot is taught a path having a number of waypoints located on or in the vicinity of at least one object to be processed by the robot. The system includes a tracking system unit adapted to provide information about the position of a part of the body of an operator pointing by the part at points on or in the vicinity of the object, a visual feed-back unit generating a visual feed-back to the operator of the position of the point being presently pointed at by the part of the body, in relation to the object, and a storage unit adapted for storing the position of the part of the body as a waypoint upon receiving a recording command.

Owner:ABB (SCHWEIZ) AG

Method and a system for programming an industrial robot

ActiveUS7209801B2Easy and intuitive to useShorten teaching timeProgramme-controlled manipulatorComputer controlAlgorithmComputer vision

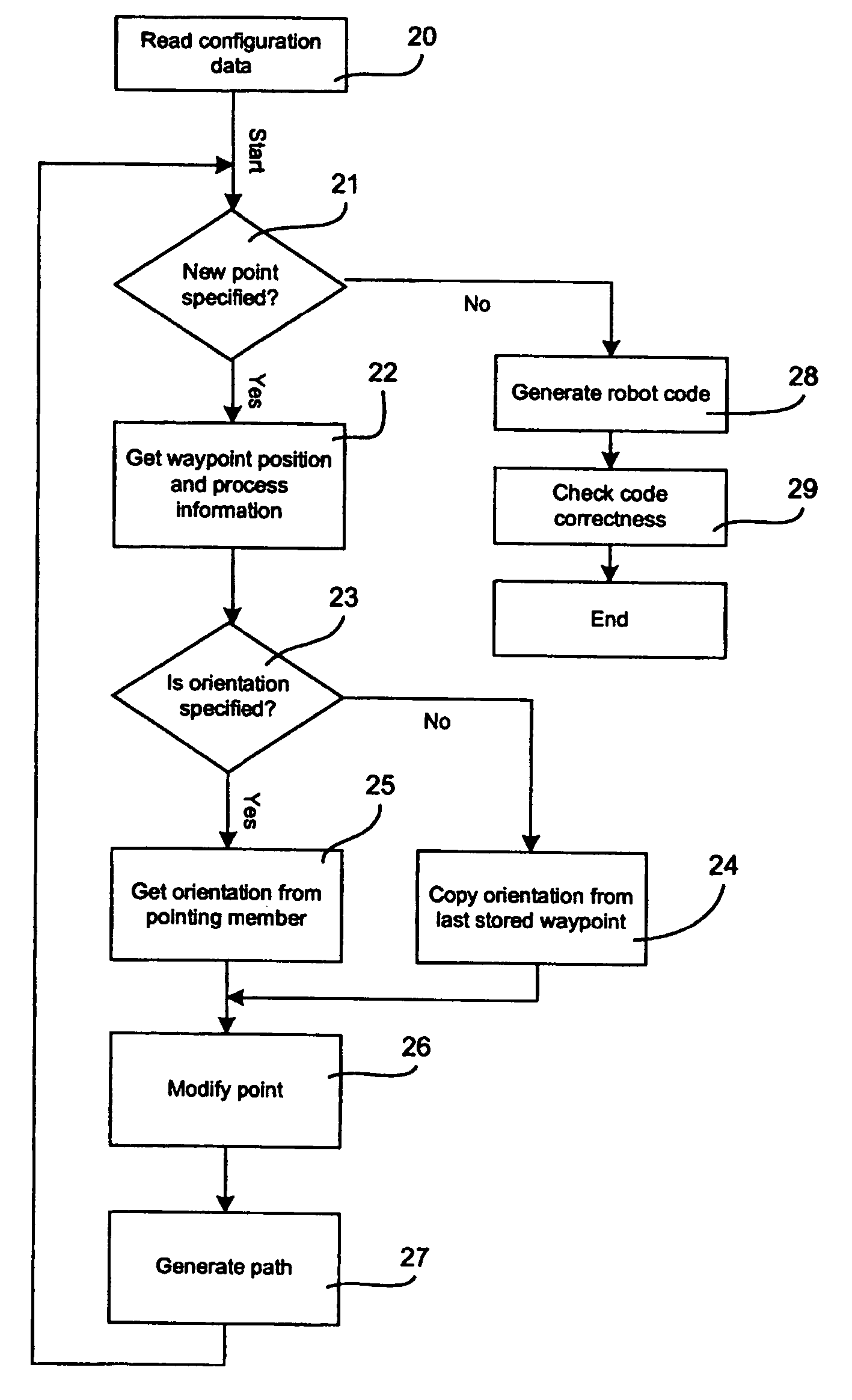

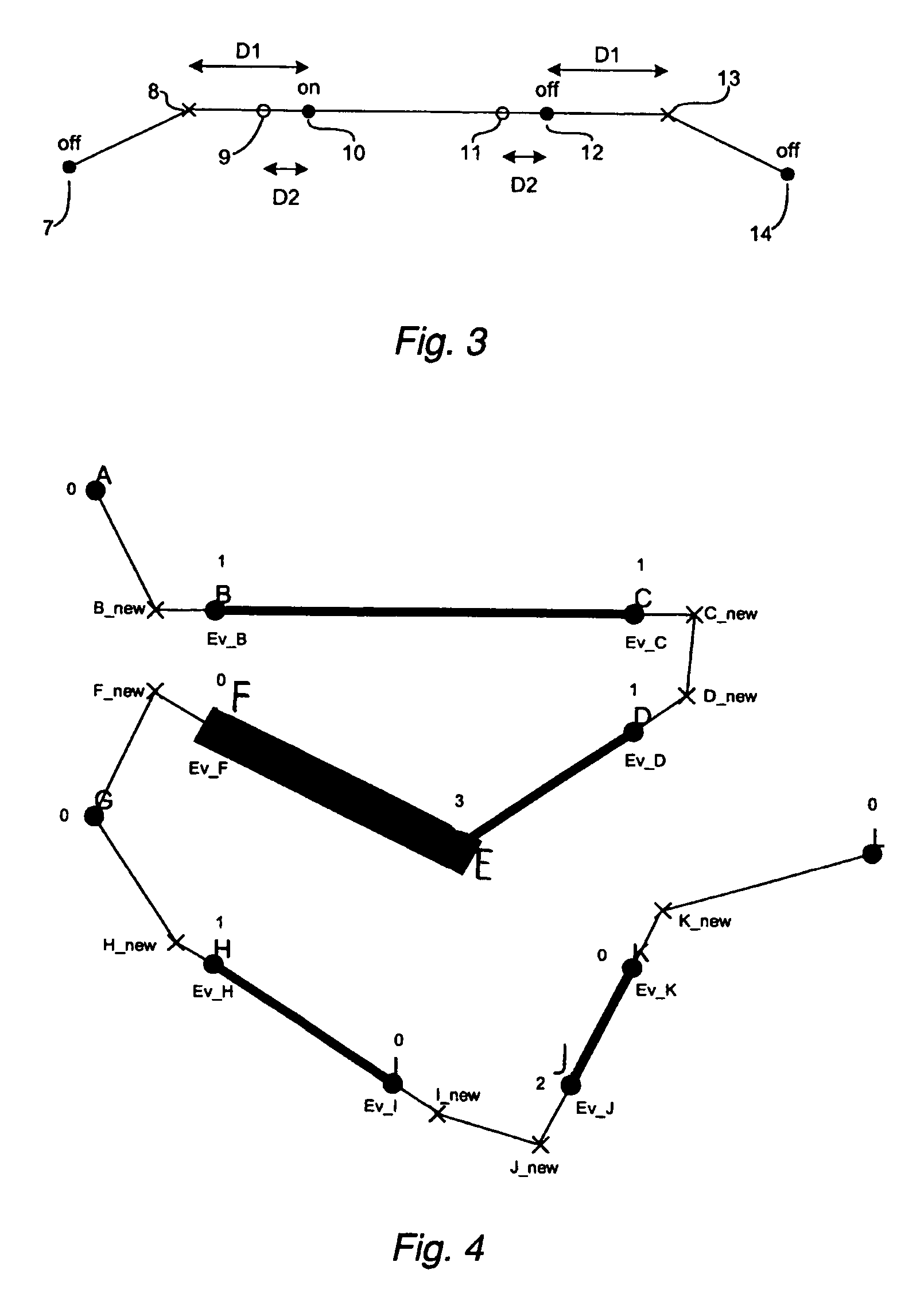

A method for programming an industrial robot having a tool. The method includes obtaining configuration data for the tool and for the robot path and information about the position and orientation of the object in relation to the robot, obtaining a sequence of waypoints, which defines the process in relation to the object, obtaining at least one distance for adjusting the position of a waypoint, deciding whether an obtained waypoint should be modified or not, based on the obtained information about the waypoints, generating a modified sequence of waypoints by modifying the waypoints in the obtained sequence of waypoints, based on the decision, the obtained distance and the obtained information about the waypoints and generating the actual robot path based on the modified sequence of waypoints and the obtained configuration data.

Owner:ABB (SCHWEIZ) AG

Method and a system for programming an industrial robot

InactiveUS7353081B2Shorten teaching timeQuality improvementProgramme-controlled manipulatorComputer controlGraphicsDisplay device

A method for programming an industrial robot. The robot is taught a path having waypoints located on or in the vicinity of an object. An image of the object is obtained. Information is obtained about the position of a pointer pointing at points. The position of the points relative to the object is determined. A point being pointed out is stored as a waypoint. A graphical representation is generated of the stored waypoint and the point being pointed out. A view is displayed including the object and the graphical representation. A system includes a pointer for pointing out points on or in the vicinity of the object, a position determiner determines the position of the points relative to the object, a camera delivers an image of the object and the pointer, a graphical generator generates graphics, a display displays a view including the object and graphical representation, and an activator.

Owner:ABB (SCHWEIZ) AG

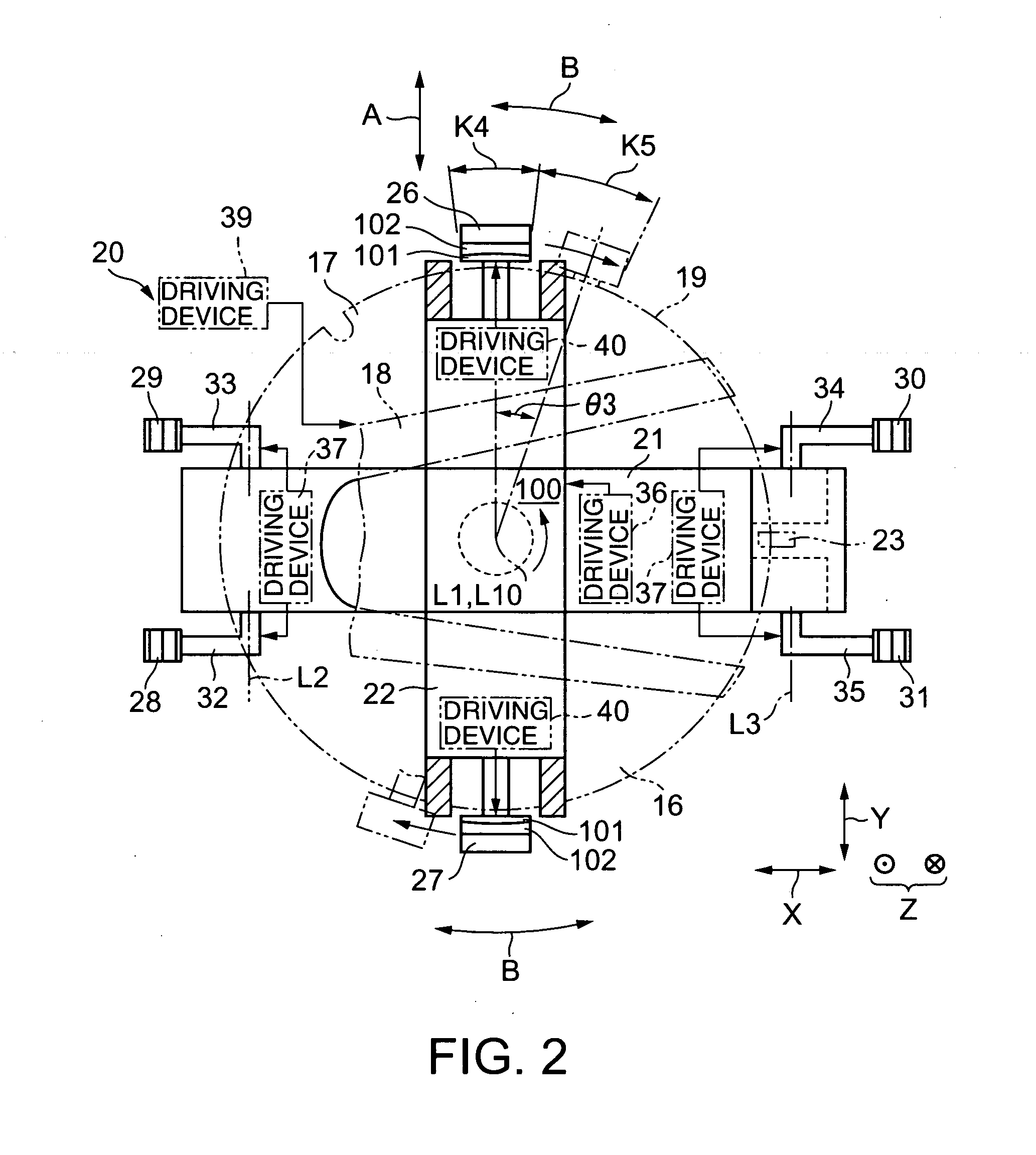

Edge-holding aligner

ActiveUS20050110974A1Shorten teaching timeCorrect position deviationSemiconductor/solid-state device manufacturingPhotographic printingEngineeringElectrical and Electronics engineering

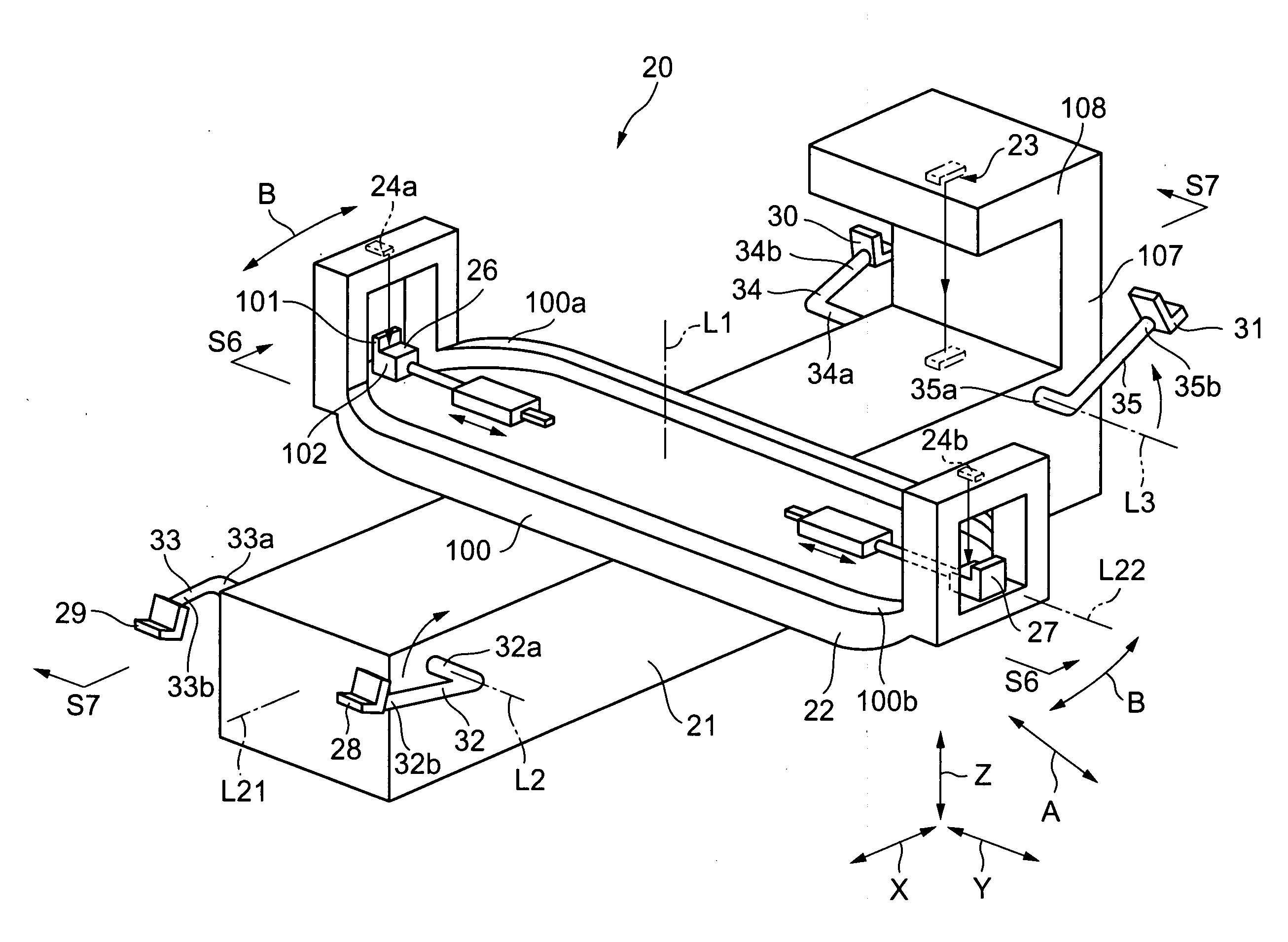

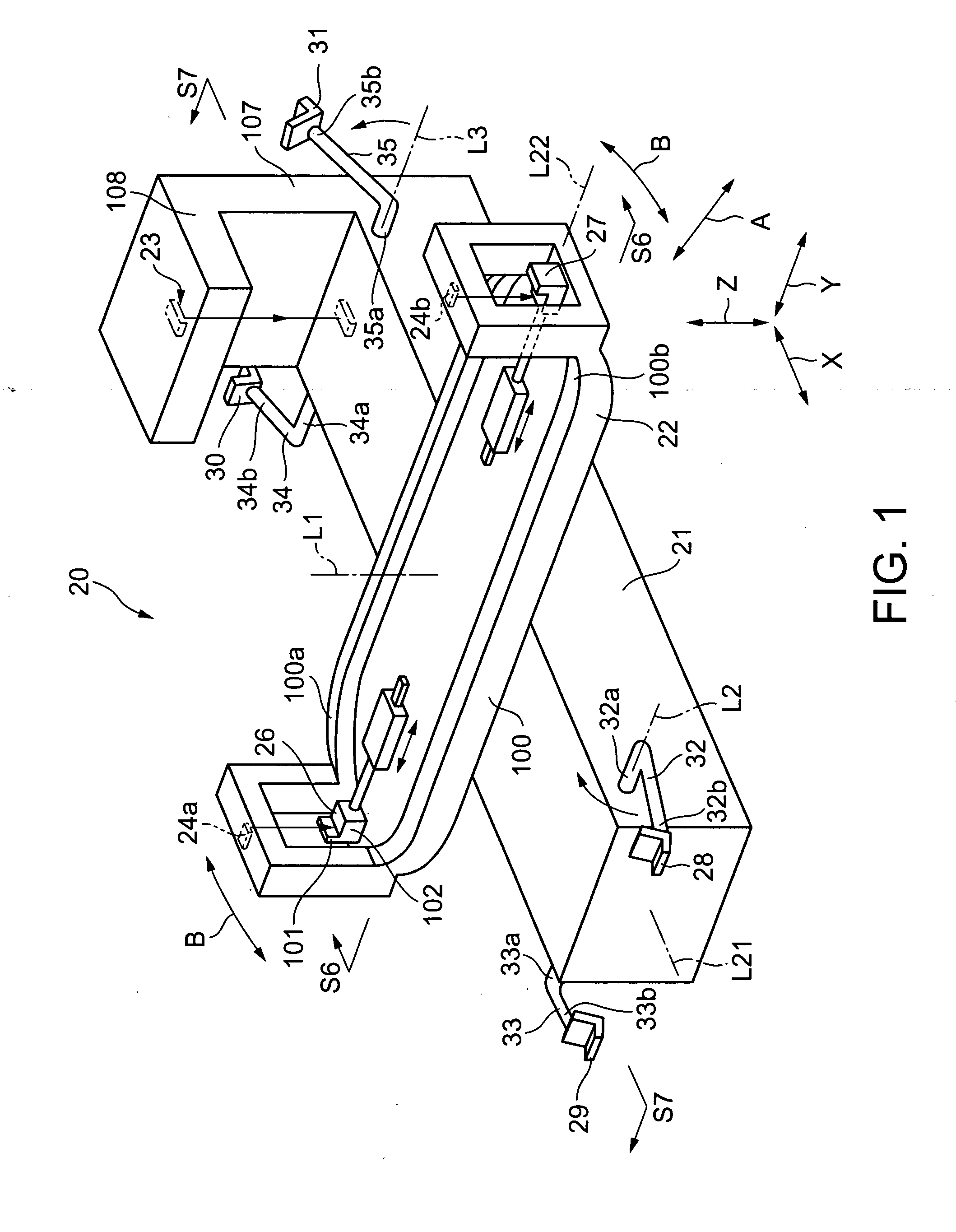

The angular position of a notch 17 is determined on the basis of data provided by second notch detectors 24a and 24b and an encoder 25. A controller 38 turns a rotational arm 22 for angular displacement such that holders 26 and 27 are displaced in a circumferential direction B from the notch 17, and then the holders 26 and 27 hold a wafer 19. Since the holders 26 and 27 are in touch with edges in which the notch 17 is not formed, the first notch detector 23 is able to detect the notch 17 without difficulty. Thus the position of the wafer 19 relative to the rotational arm 22 does not need to be changed several times depending on positions at which the holders 26 and 27 hold the wafer 19, which is necessary in the prior technology. The aligner 20 touches parts, not including the notch 17, of the wafer 19 and is capable of adjusting the position of the wafer 19 in a short time.

Owner:KAWASAKI HEAVY IND LTD

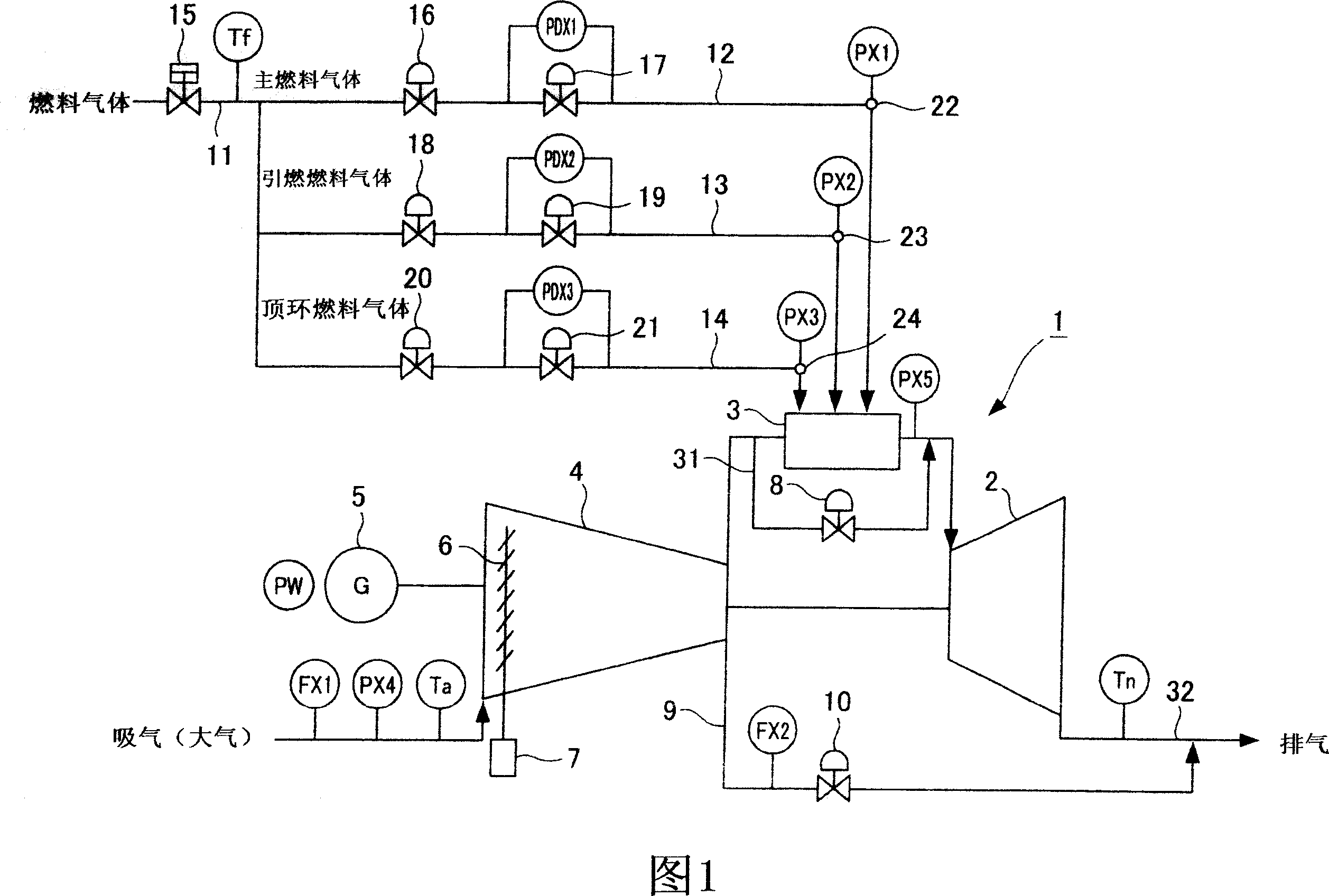

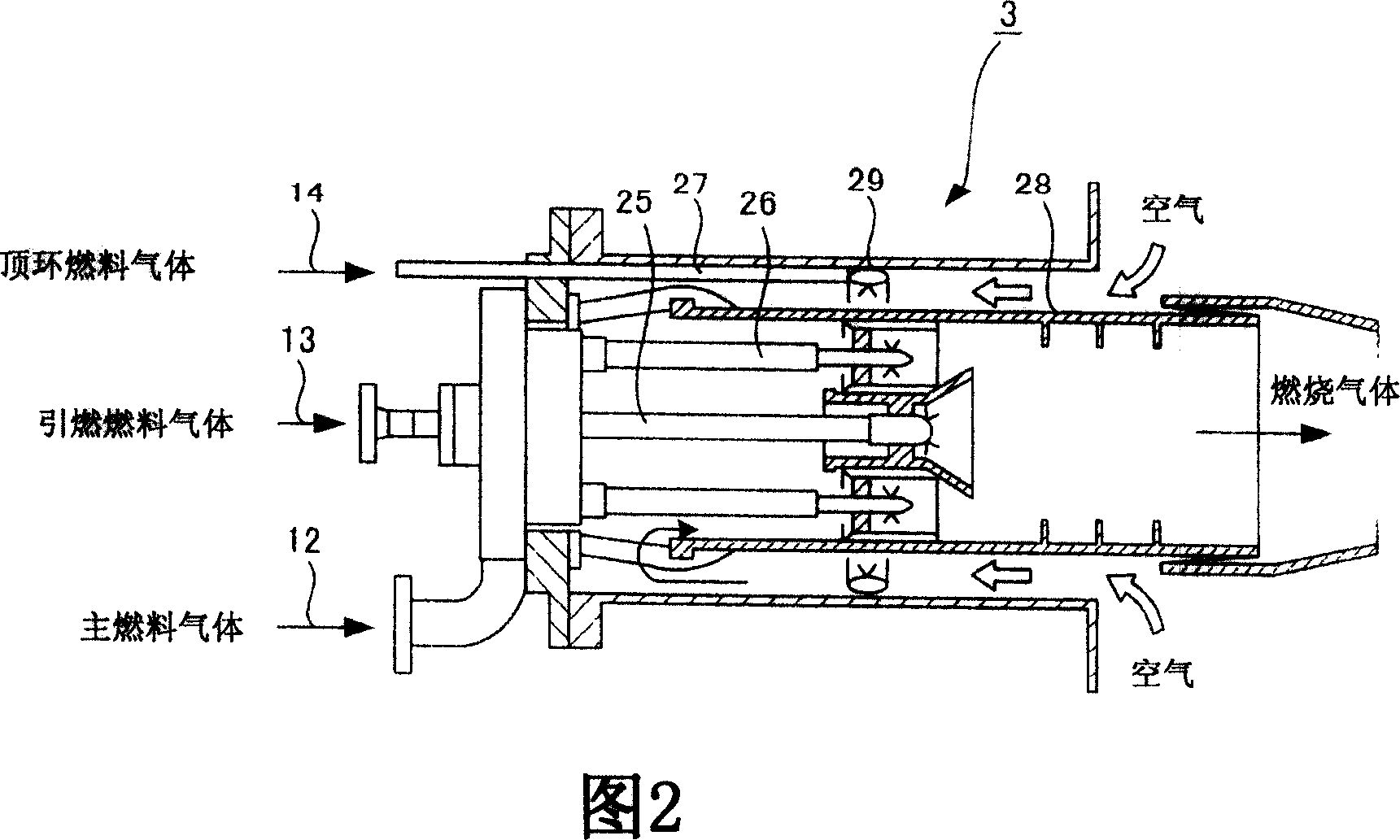

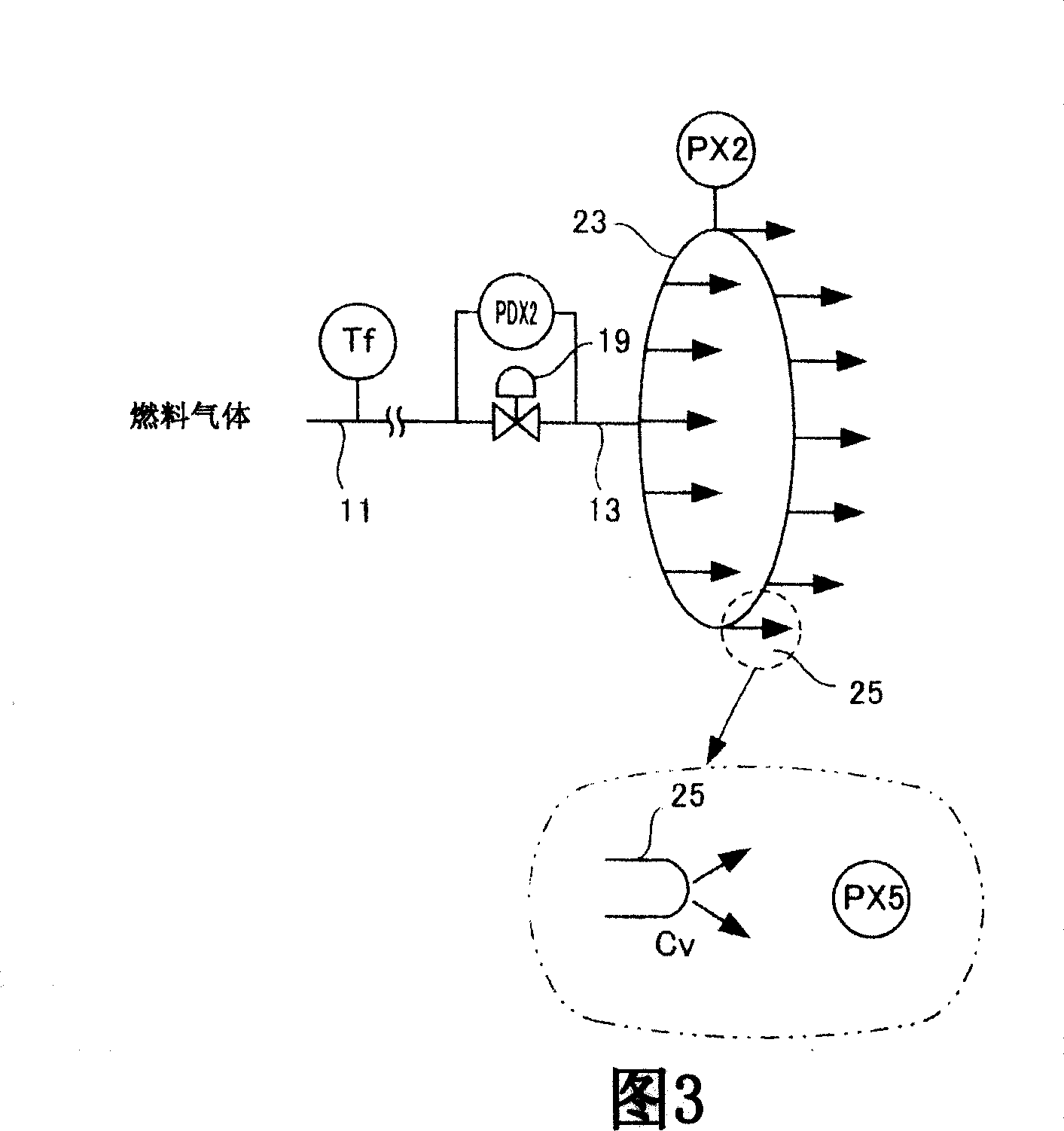

Gas turbine output learning circuit and combustion control device for gas turbine

ActiveCN101079199AHigh outputQuick correctionGas turbine plantsCombustion signal processingTemperature controlCombustion

Owner:MITSUBISHI POWER LTD

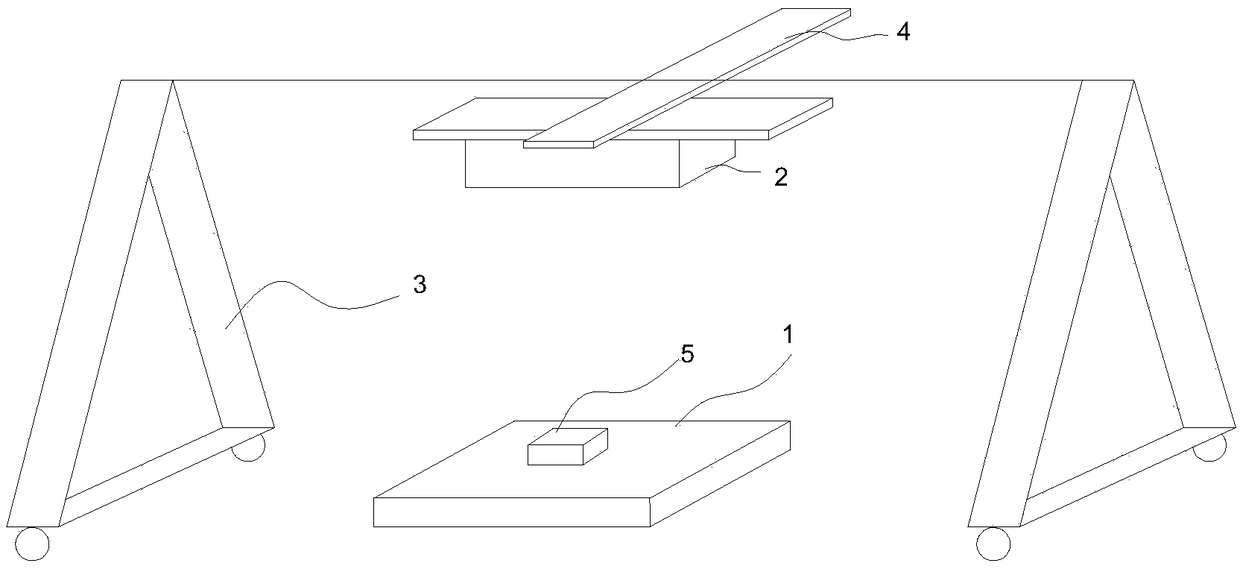

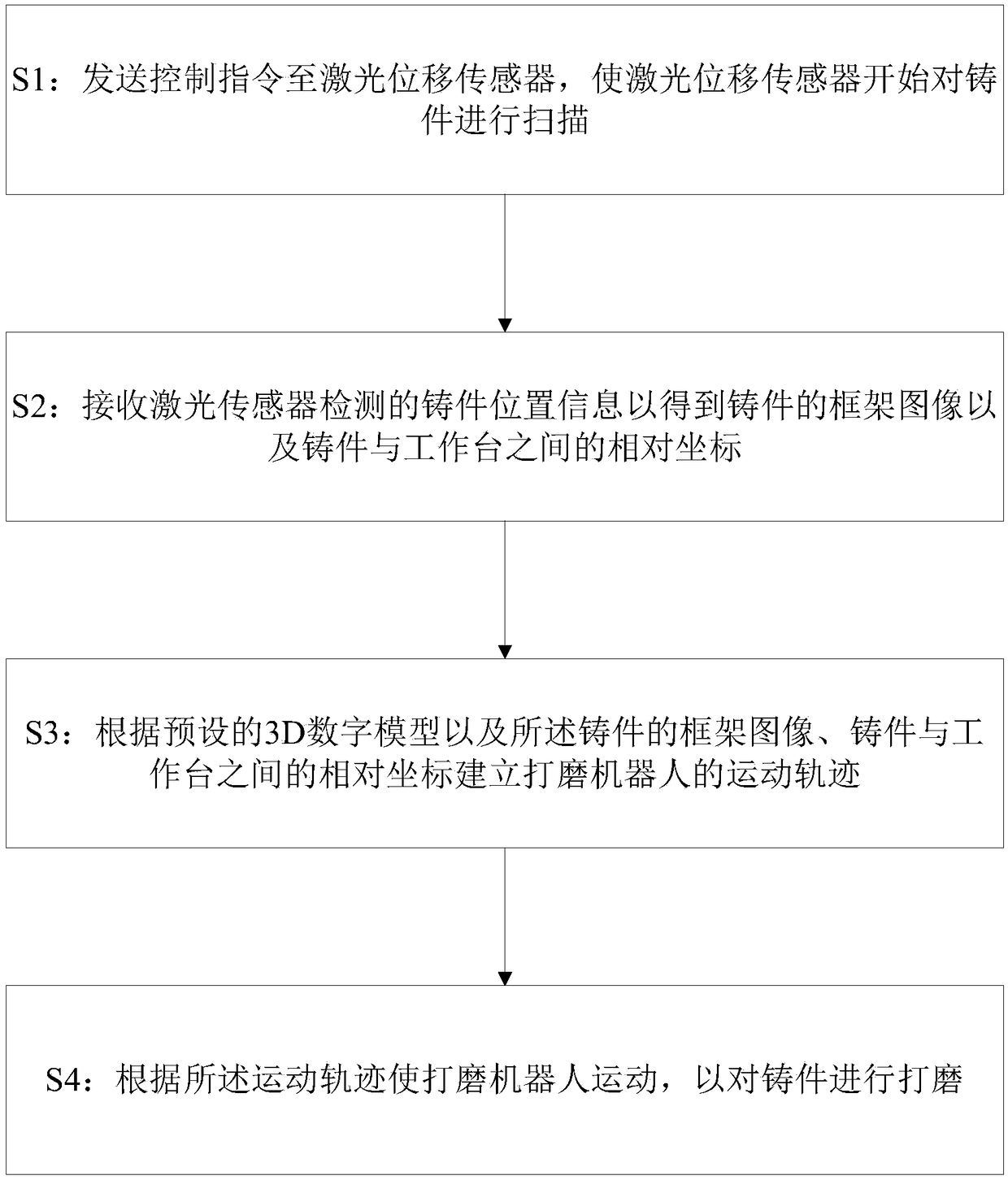

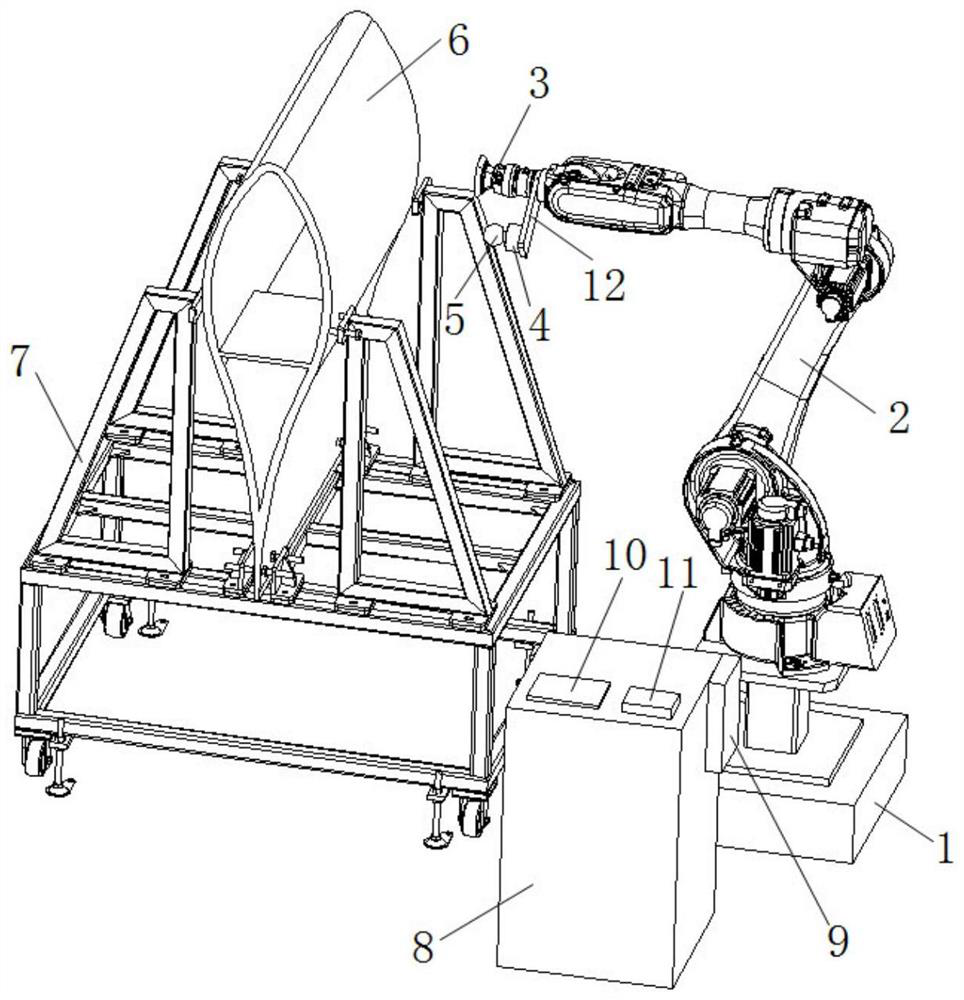

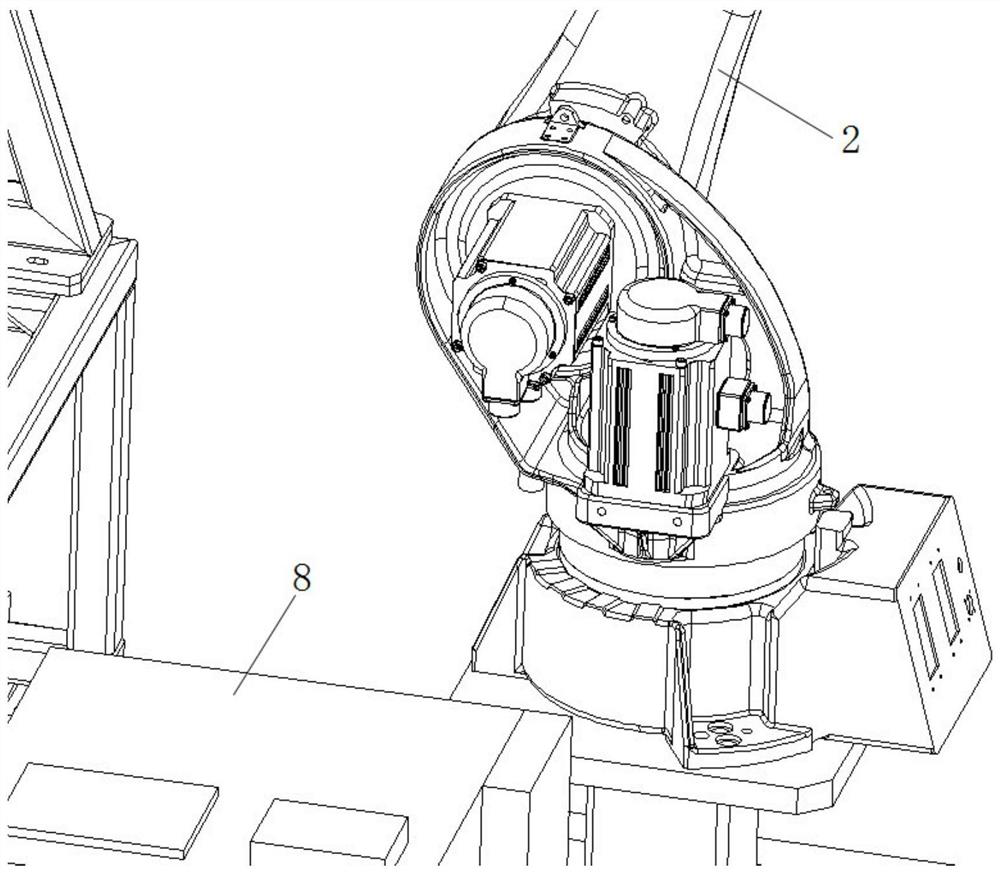

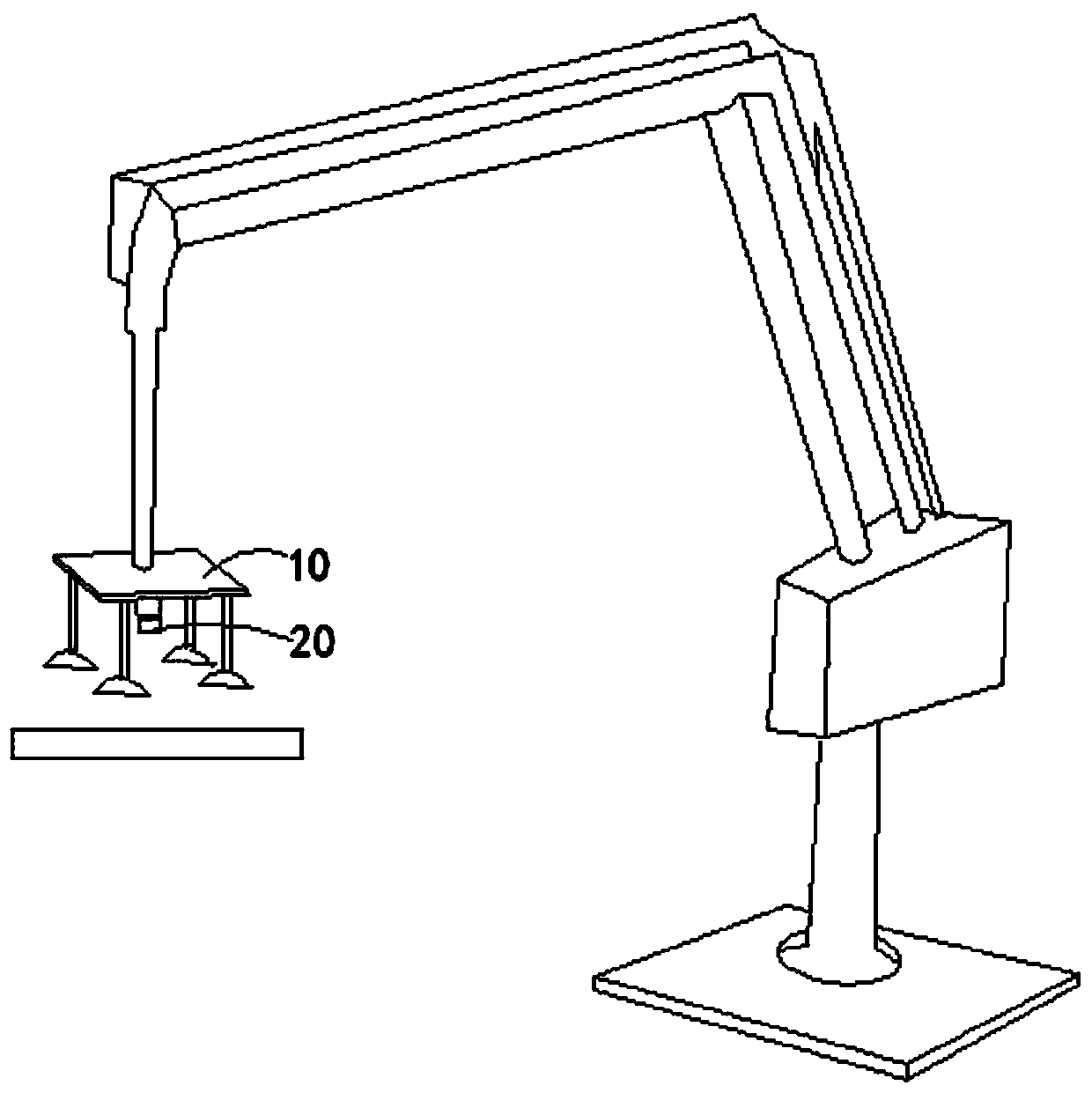

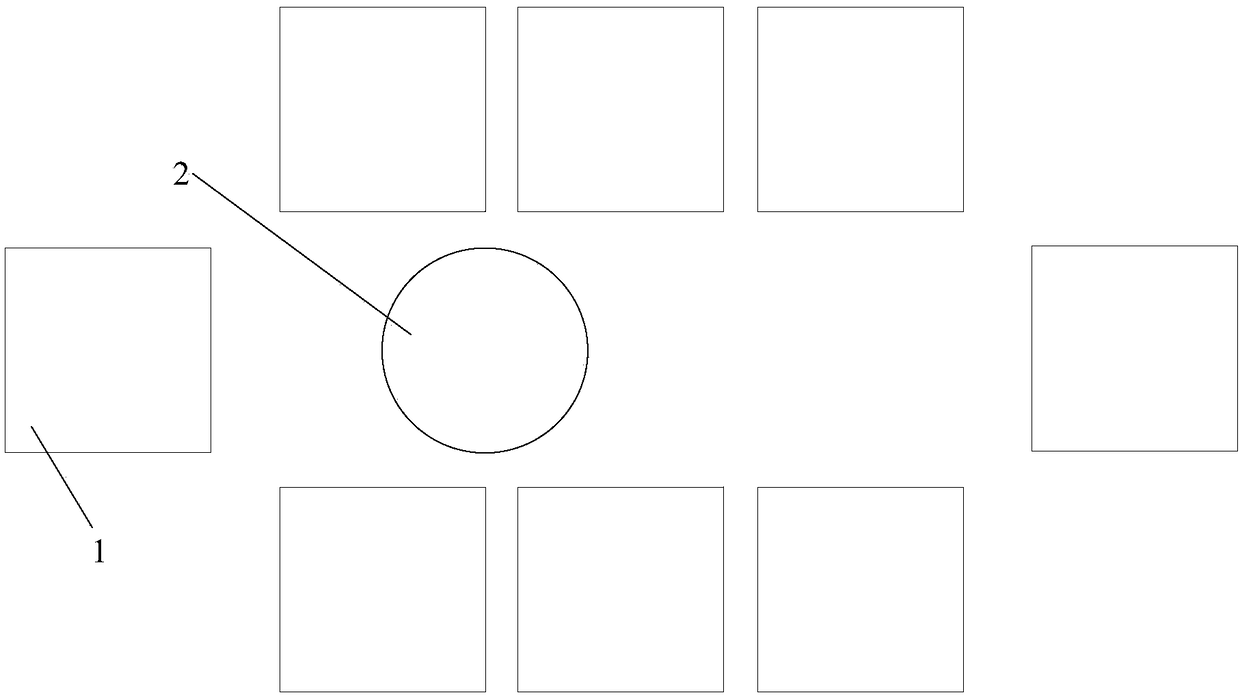

Polishing robot system with movement locus self-learning function and control method

InactiveCN108637850ALow technical requirementsShorten teaching timeGrinding carriagesGrinding feed controlRobotic systemsEngineering

The invention discloses a polishing robot system with a movement locus self-learning function. The polishing robot system comprises a worktable, a laser displacement sensor, a fixed mount, a moving track, an upper computer and a polishing robot, wherein the moving track is mounted on the fixed mount; the laser displacement sensor is mounted on the moving track; the worktable is used for bearing acasting to be scanned; the laser displacement sensor and the polishing robot are connected with the upper computer; and the laser displacement sensor is located above the casting. The polishing robotutilizes the laser displacement sensor to scan the whole casting right above to obtain border images of the casting and relative coordinates of the casting to the worktable, and moves with reference to a movement locus constructed by a 3D digital model, so that the teaching time is greatly shortened, technical demands on teaching personnel are greatly lowered, the precision reaches 0.5-1.0 mm, theplacement position of the casting does not need to be unchanged, the effects of quick mounting and clamping and accurate positioning are achieved, and time saving and high efficiency are realized.

Owner:广州神力机器人科技有限公司

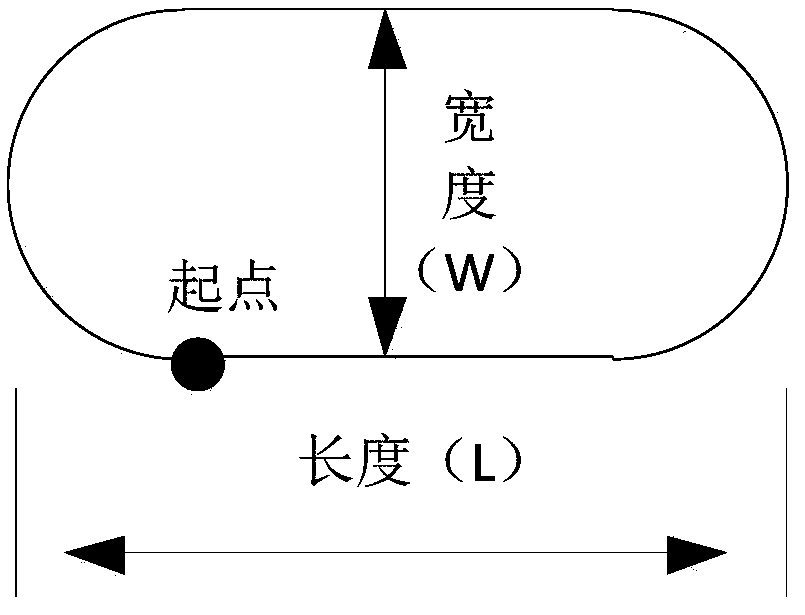

A desktop dispensing teaching method and device

The embodiment of the invention provides a desktop dispensing teaching method and device, belonging to the field of industrial automation. The desktop dispensing teaching method comprises the following steps: determining the product shape corresponding to the product to be taught; acquiring a teaching type matching the product shape from a plurality of preset teaching types; determining coordinates of the teaching type; acquiring dispensing process parameters corresponding to the teaching type; determining a motion trajectory of each axis according to the coordinates and the dispensing processparameters. Thus, the operator can greatly reduce the teaching time when teaching the common graphics such as rounded rectangle, runway, ellipse, helix, rectangular coating, circular coating, multi-line, continuous curve and the like, thereby effectively increasing the workload of the operator and improving the work efficiency.

Owner:SHENZHEN LEAD CNC SYST

Robot motion trajectory planning system, method and device

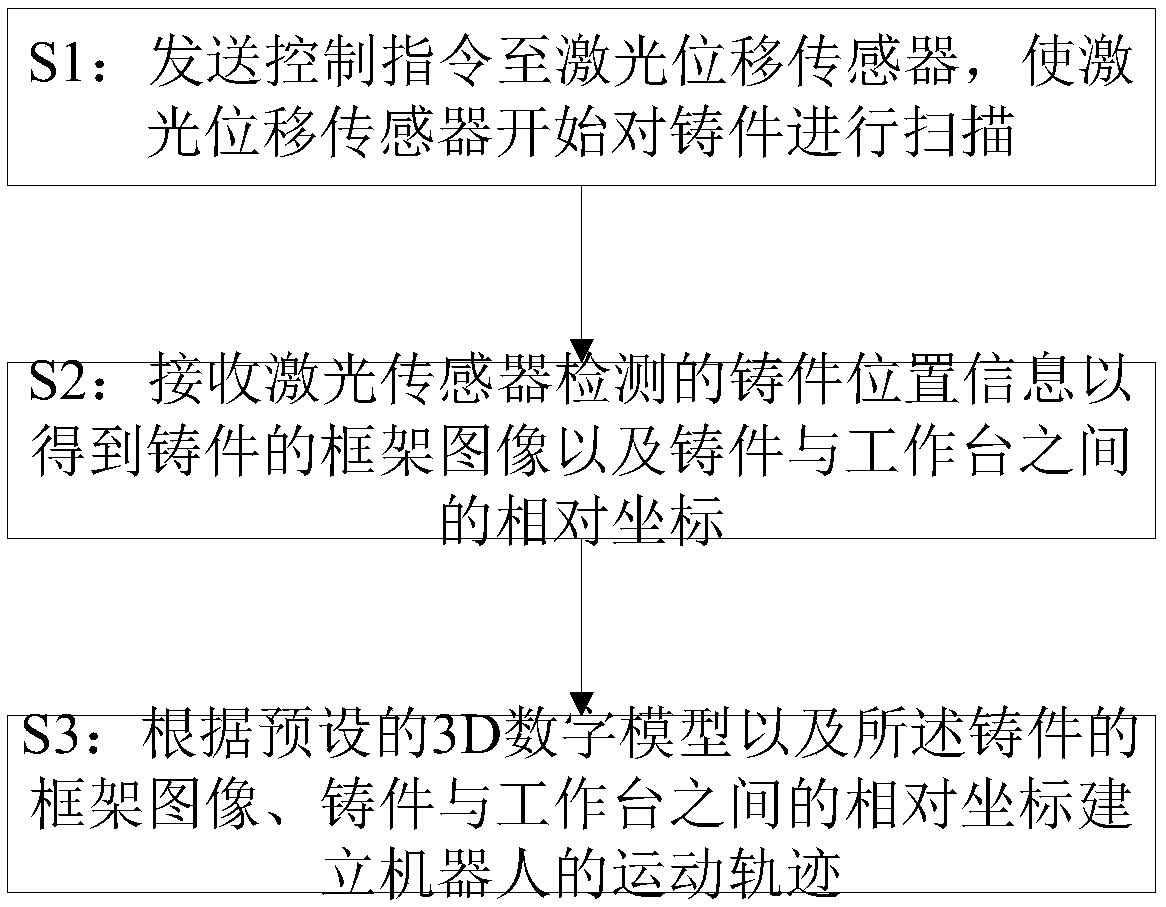

InactiveCN108789412ALow technical requirementsShorten teaching timeProgramme-controlled manipulatorFixed frameEngineering

The invention discloses a robot motion trajectory planning system. The system comprises a worktable, a laser displacement sensor, a fixed frame and a movable rail; the movable rail is mounted on the fixed frame; the laser displacement sensor is mounted on the movable rail; the worktable is used for bearing castings to be scanned; and the laser displacement sensor is positioned above the castings,and is used for moving in X-axis and Y-axis directions under driving by the movable rail to scan the castings. The laser displacement sensor scans the whole castings from the upper side, and a motiontrajectory is built according to obtained frame images of the castings, relative coordinates of the castings relative to the worktable and 3D digital models, so that the demonstration time is greatlyshortened, the technical requirements on demonstration staff are greatly reduced, and the precision reaches 0.5-1.0 mm; and the placing positions of the castings have no need to be fixed, so that theeffects of quick clamping and precise positioning can be achieved, the time is saved, and the efficiency is high.

Owner:广州神力机器人科技有限公司

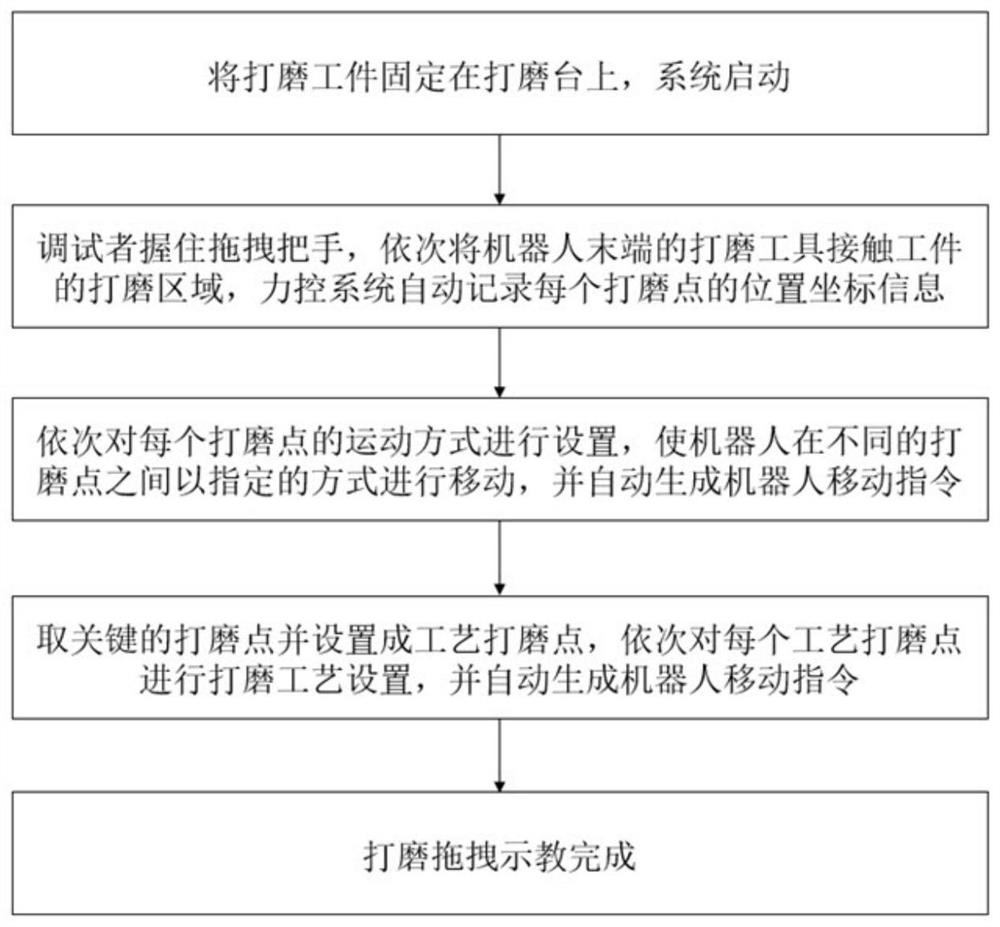

Dragging teaching method based on force control robot polishing and implementation device thereof

PendingCN112123344AEasy to holdCreate simple and flexibleProgramme-controlled manipulatorGrinding carriagesControl systemPolishing

The invention relates to a dragging teaching method based on force control robot polishing and an implementation device thereof in the technical field of force control robot automatic polishing. The dragging teaching method based on force control robot polishing comprises the following steps: a work-piece to be polished is fixed on a polishing table, and a system is started; a debugger holds a dragging handle by hand and makes polishing tools at the tail end of the robot be contact with the polishing area of the work-piece to be polished in sequence, and a force control system automatically records the position coordinate information of each polishing point; the motion mode of each polishing point is set in sequence, so that the robot moves among different polishing points in a specified mode, and a robot moving instruction is automatically generated; and the polishing points at a designated positions are taken and set as process polishing points, polishing process setting is performedon each process polishing point in sequence, and the robot moving instruction is automatically generated. According to the invention, selection of the polishing teaching points is more free, the number of the polishing teaching points is smaller, establishment of a robot polishing path is simpler and more flexible, and a large amount of teaching time is saved; and due to the fact that the polishing process can be automatically generated, the polishing stability is improved, and the polishing quality is greatly improved.

Owner:佳奕筱安(上海)机器人科技有限公司

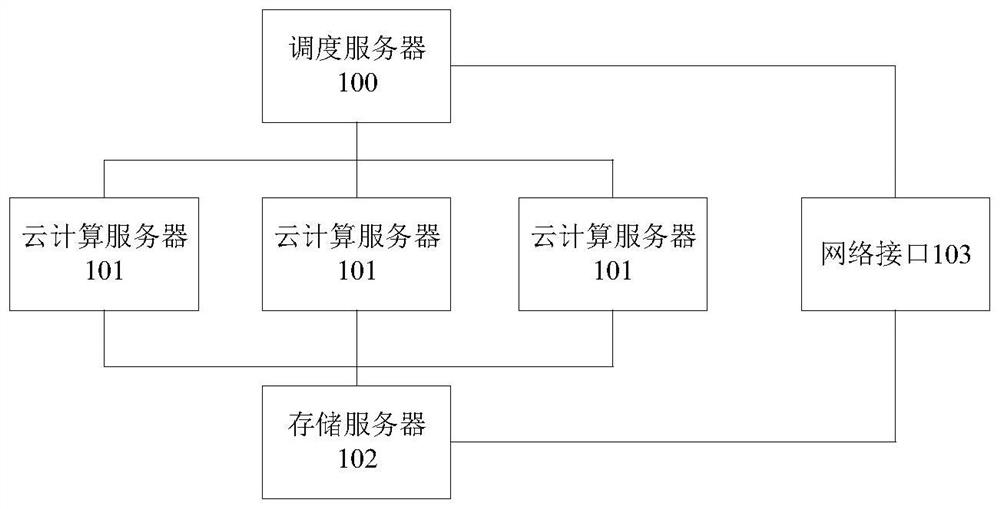

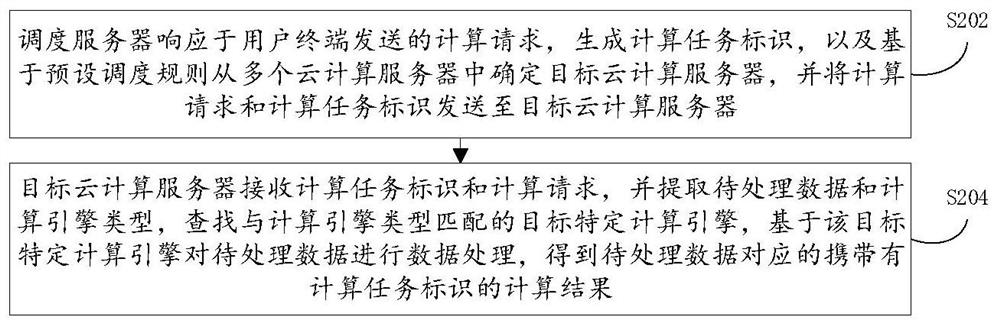

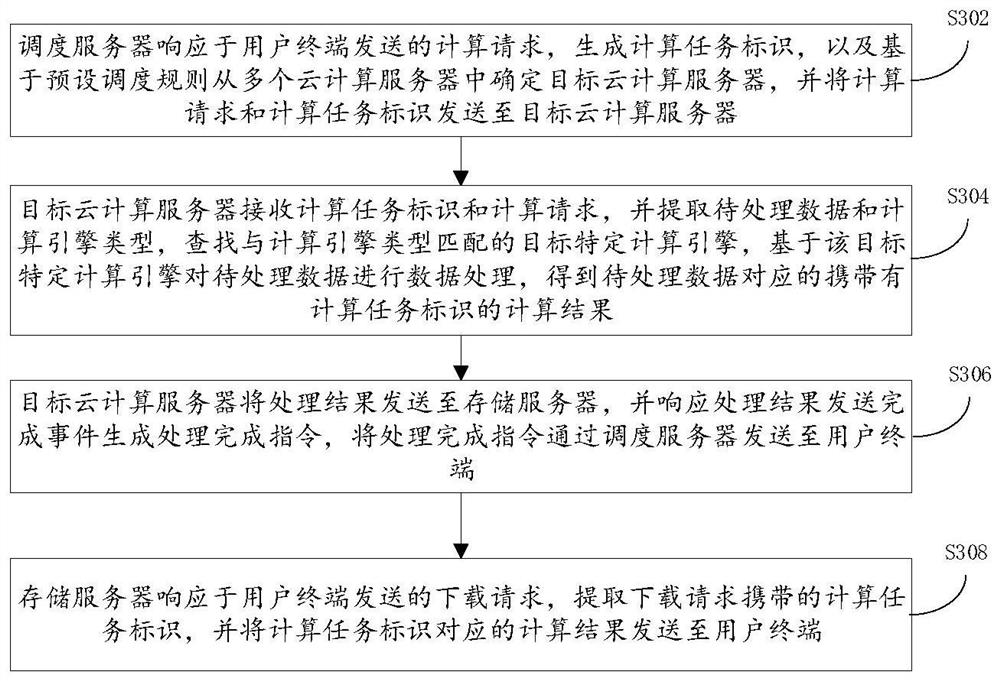

Data processing system and method and electronic equipment

InactiveCN112861346AImprove computing speedSave spaceProgram initiation/switchingResource allocationData processing systemEngineering

The embodiment of the invention provides a data processing system and method and electronic equipment, the system comprises a scheduling server and a plurality of cloud computing servers communicating with the scheduling server, and each cloud computing server pre-stores a plurality of specific computing engines and a specific computing engine type corresponding to each specific computing engine; and on this basis, when the scheduling server responds to a calculation request sent by a user terminal, a calculation task identifier is generated, a target cloud calculation server is determined from a plurality of cloud calculation servers based on a preset scheduling rule, and the target cloud calculation server performs data processing on the to-be-processed data to obtain a calculation result. According to the method, the computing engine is installed on the cloud computing server, the computing engine does not need to be installed in a laboratory computer, the hard disk space is saved, the installation time is saved, and the computing rate of the cloud computing server is higher than that of the laboratory computer, so the computing rate of simulation computing is increased, and the teaching duration is shortened.

Owner:北京润尼尔科技股份有限公司

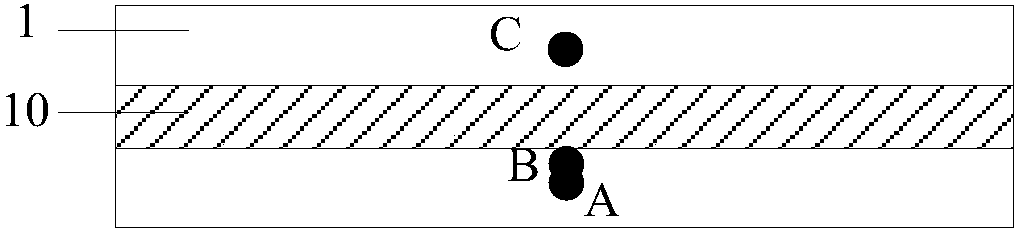

Visual teaching method of robot based on vision system

PendingCN111283685AImprove teaching accuracyImprove work efficiencyProgramme-controlled manipulatorRobot handComputer graphics (images)

The invention relates to a visual teaching method of a robot based on a vision system. The method comprises the following steps that an image collection device is mounted on the tail end of a mechanical arm; an image processor adjusts the vision angle range of the image collection device through an image provided by the image collection device; the mechanical arm moves to the position above a workpiece to be machined, and is aligned with the position to be mounted, the image collection device carries out photo taking, and the position is recorded as a position A; the mechanical arm moves to the position above a part to be mounted and carries out grabbing, the image collection device carries out photo taking, and the position is recorded as a position B; and the image processor works out the motion track relation between the position A and the position B, through the motion track relation, the mechanical arm is controlled to move, the part to be mounted is accurately mounted in the workpiece to be machined, and teaching is finished. According to the visual teaching method of the robot based on the vision system, the vision system is adopted for serving a teaching auxiliary system, the teaching precision is greatly improved, the teaching time is reduced, work intensity is reduced, and work efficiency is improved.

Owner:广州市斯睿特智能科技有限公司

Demonstrating method of robot, demonstrating device of robot and robot system

ActiveCN108127668ASimplify the teaching processShorten teaching timeProgramme-controlled manipulatorConveyor partsRobotic systemsSimulation

The embodiment of the invention provides a demonstrating method of a robot, a demonstrating device of the robot and a robot system, and relates to the technical field of robots. The problem in the prior art that when the robot is demonstrated, the demonstrating process is complicated can be solved. The demonstrating method comprises the steps of according to identifications of loading equipment ofan object to be carried, obtaining equipment information corresponding to the identifications of the loading equipment of the object to be carried, wherein the equipment information comprises the position of a demonstrating point needed by carrying the loading equipment of the object to be carried relative to a reference point on the loading equipment of the object to be carried; obtaining demonstrating coordinates of the reference point obtained in the process of demonstrating the reference point; according to the position of the reference coordinate of the reference point and the demonstrating point relative to the reference point on the loading equipment of the object to be carried, obtaining demonstrating coordinates of the demonstrating point. The demonstrating method of the robot isused for demonstrating the robot.

Owner:合肥欣奕华智能机器股份有限公司

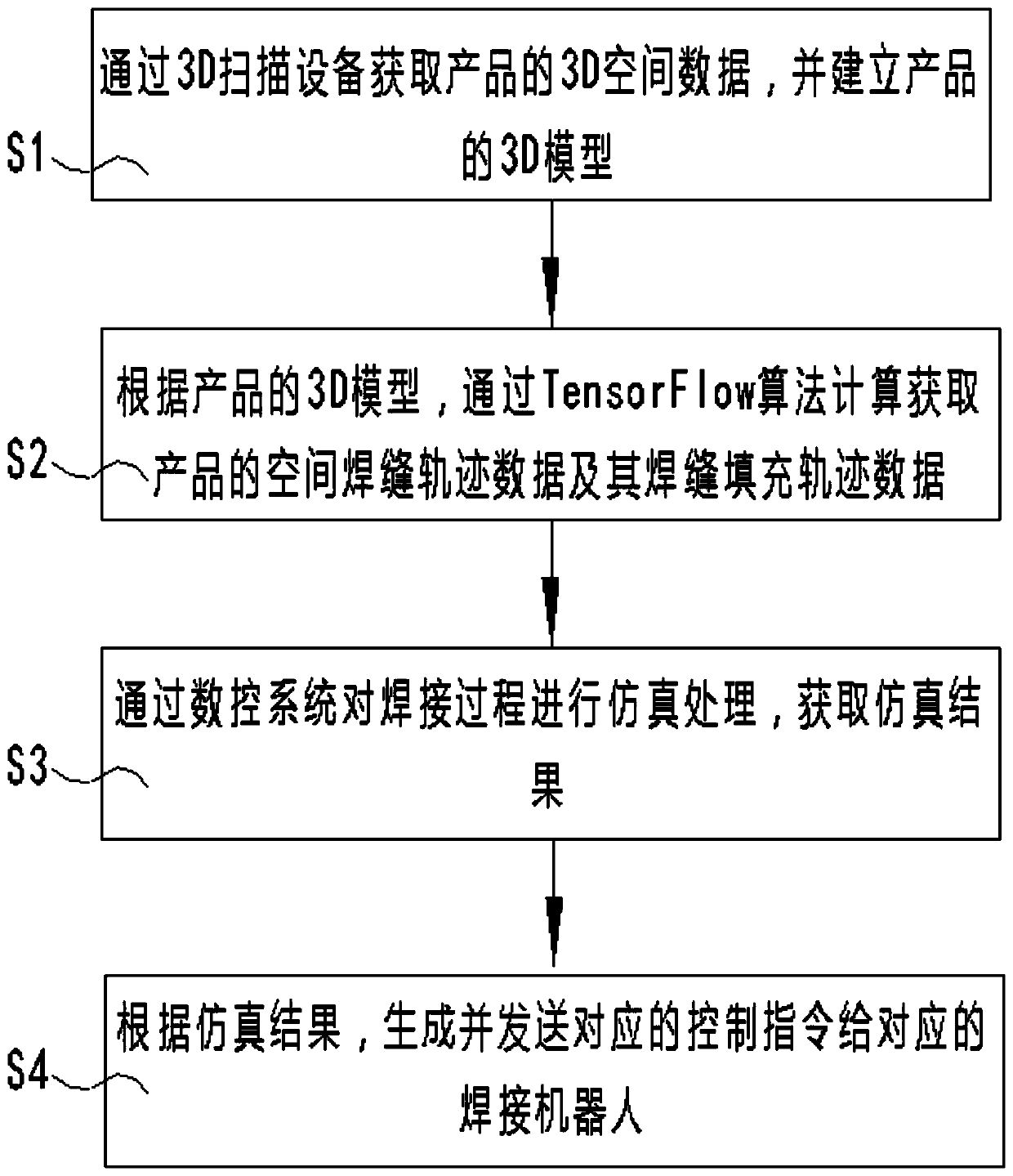

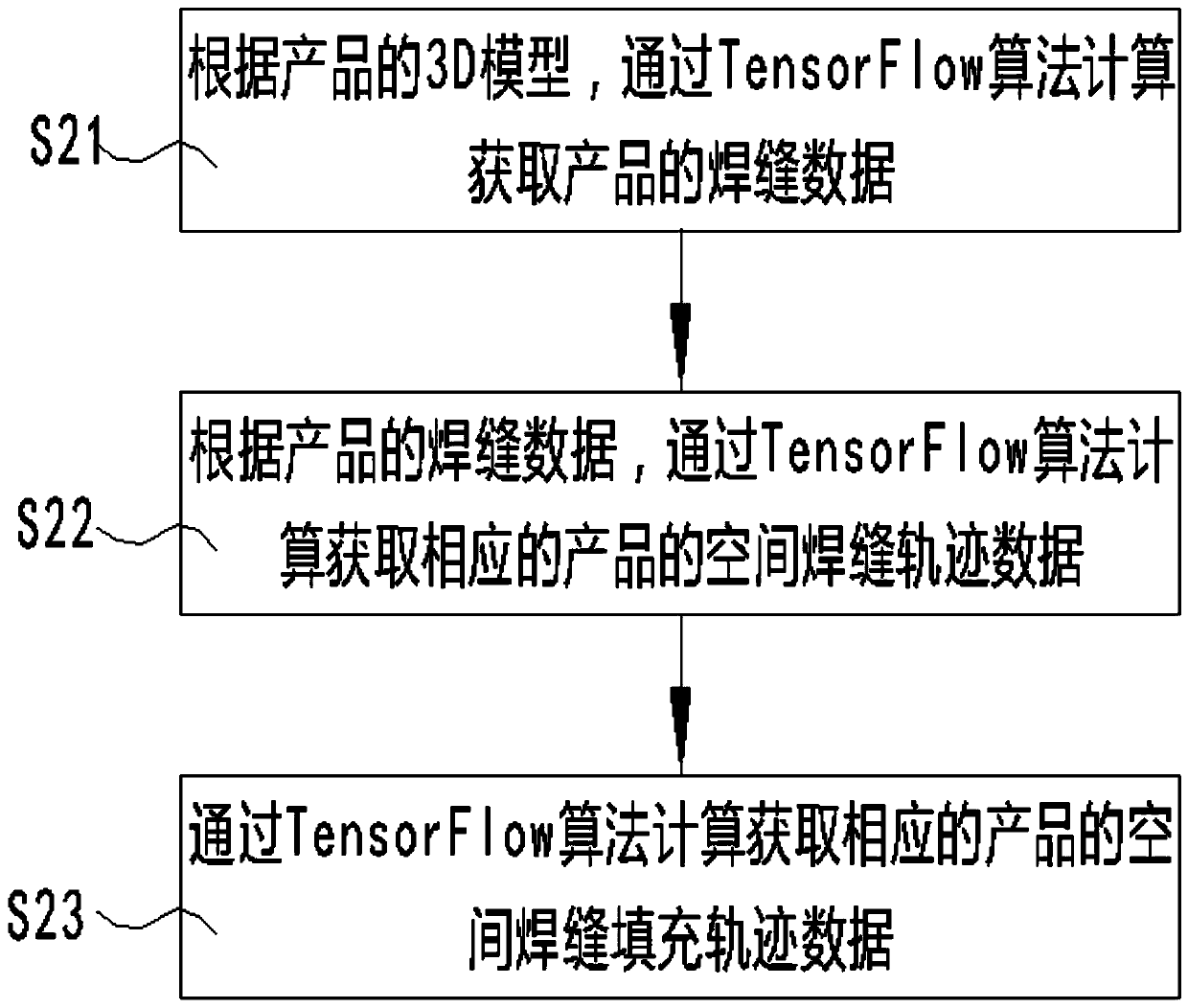

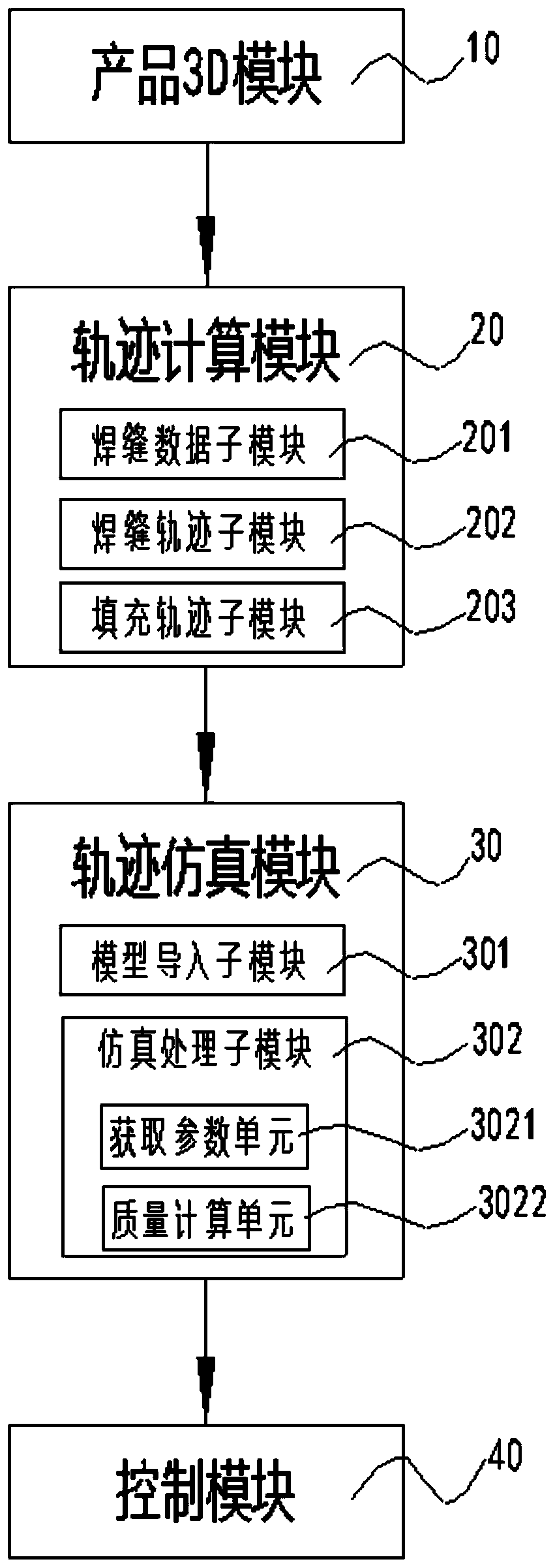

Welding track processing method and system based on 3D scanning and TensorFlow algorithm

ActiveCN111037549AShorten teaching timeIncrease productivityProgramme-controlled manipulatorManufacturing computing systemsEngineeringWeld seam

The invention discloses a welding track processing method based on 3D scanning and TensorFlow algorithm. The welding track processing method comprises the following steps that 3D spatial data of a product are acquired through 3D scanning equipment,a 3D model of the product is established; according to the 3D model of the product, space welding seam track data and welding seam filling track data of the product are calculated and obtained through a TensorFlow algorithm; according to the 3D model of the product and the calculated product space welding seam track data and welding seam filling track data, simulation processing is carried out on the welding process through a numerical control system, a simulation result is obtained; and according to the simulation result, a corresponding control instruction is generated and sent to a corresponding welding robot. The invention further discloses a welding track processing system based on the 3D scanning and TensorFlow algorithm. According tothe welding track processing method based on the 3D scanning and TensorFlow algorithm, the 3D data of the product are obtained through the 3D scanning equipment, the welding seam track is obtained through the TensorFlow algorithm, then the welding track of the welding robot can be rapidly generated, and the control instruction of the welding robot can be generated, so that the teaching time is shortened, and the production efficiency is improved.

Owner:重庆顺泰铁塔制造有限公司

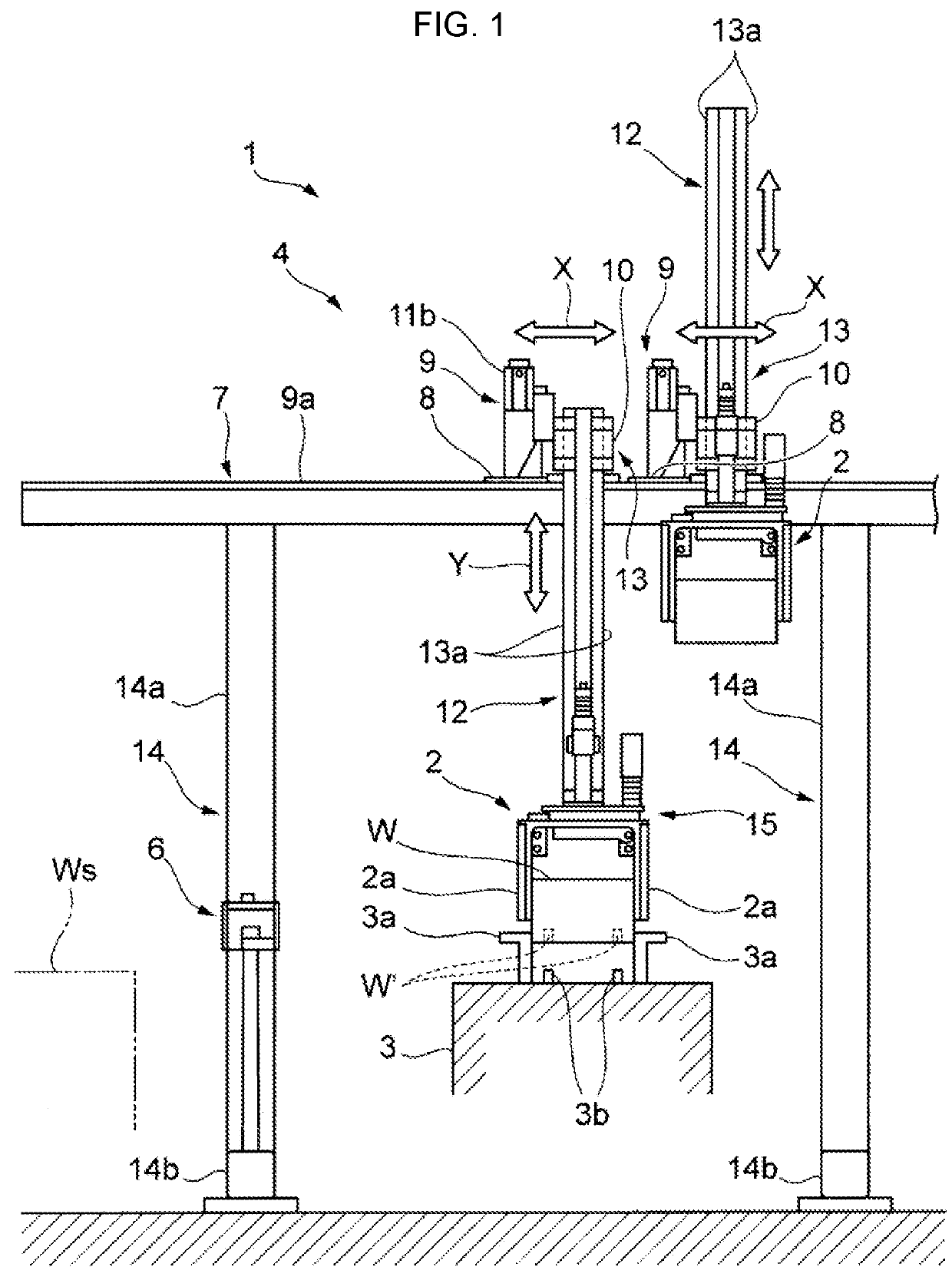

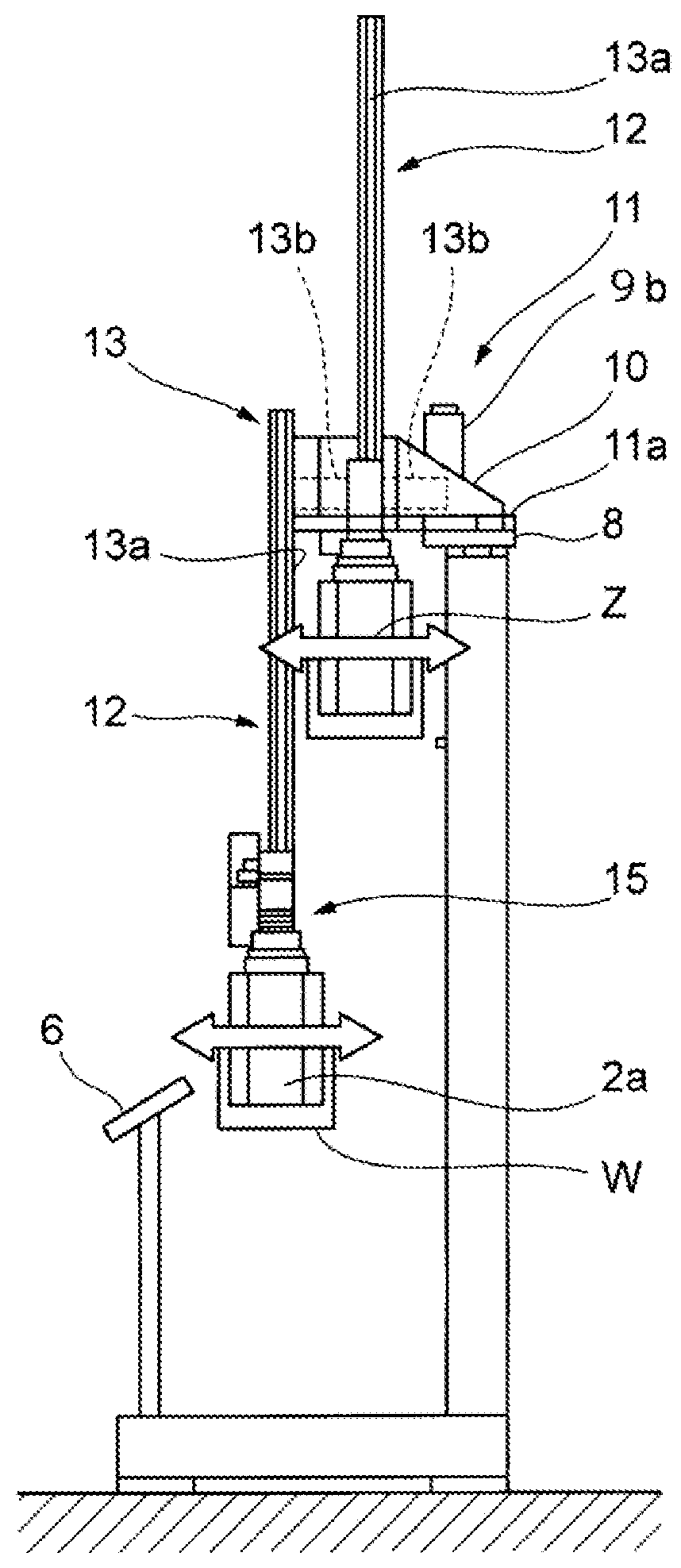

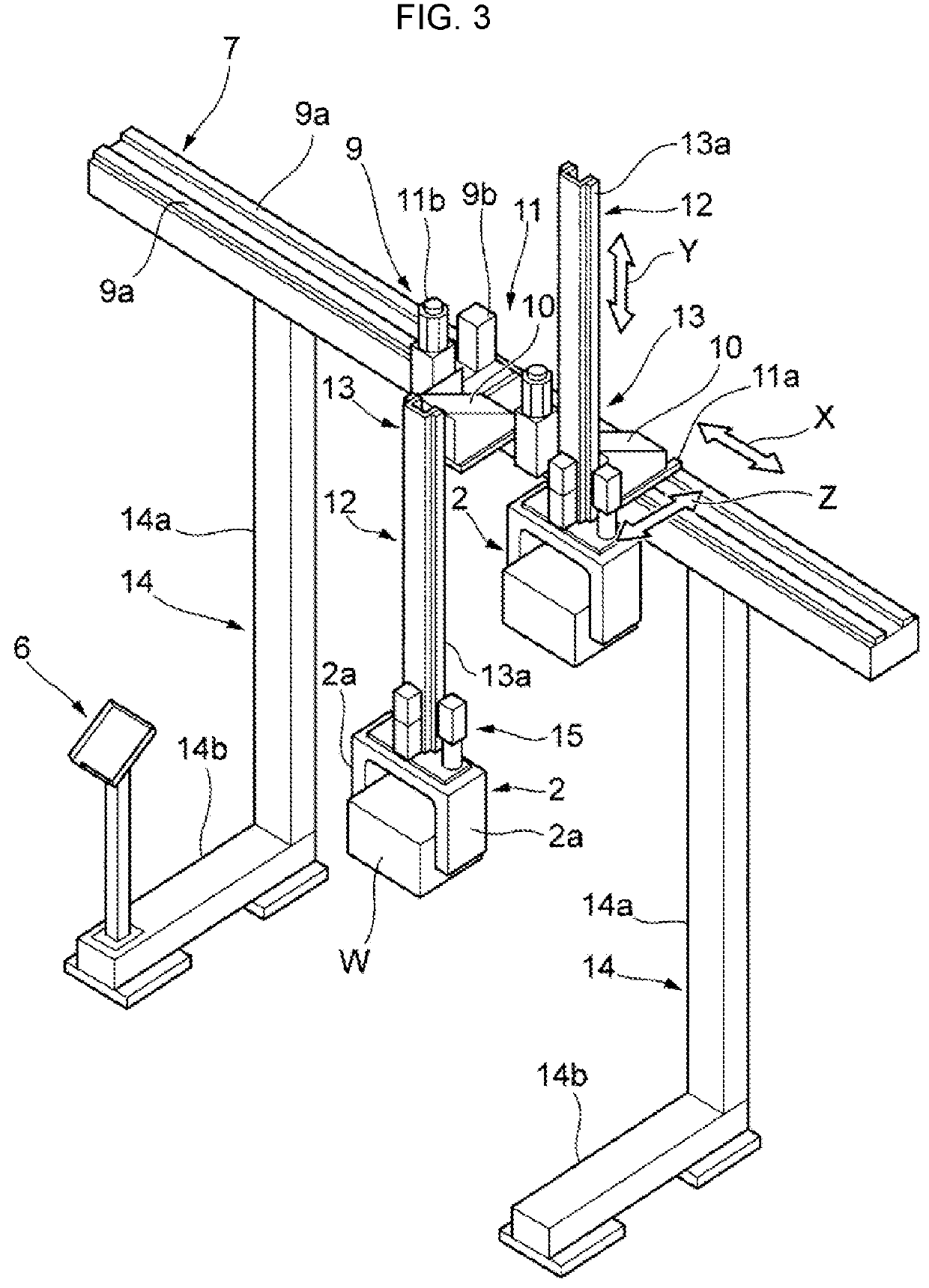

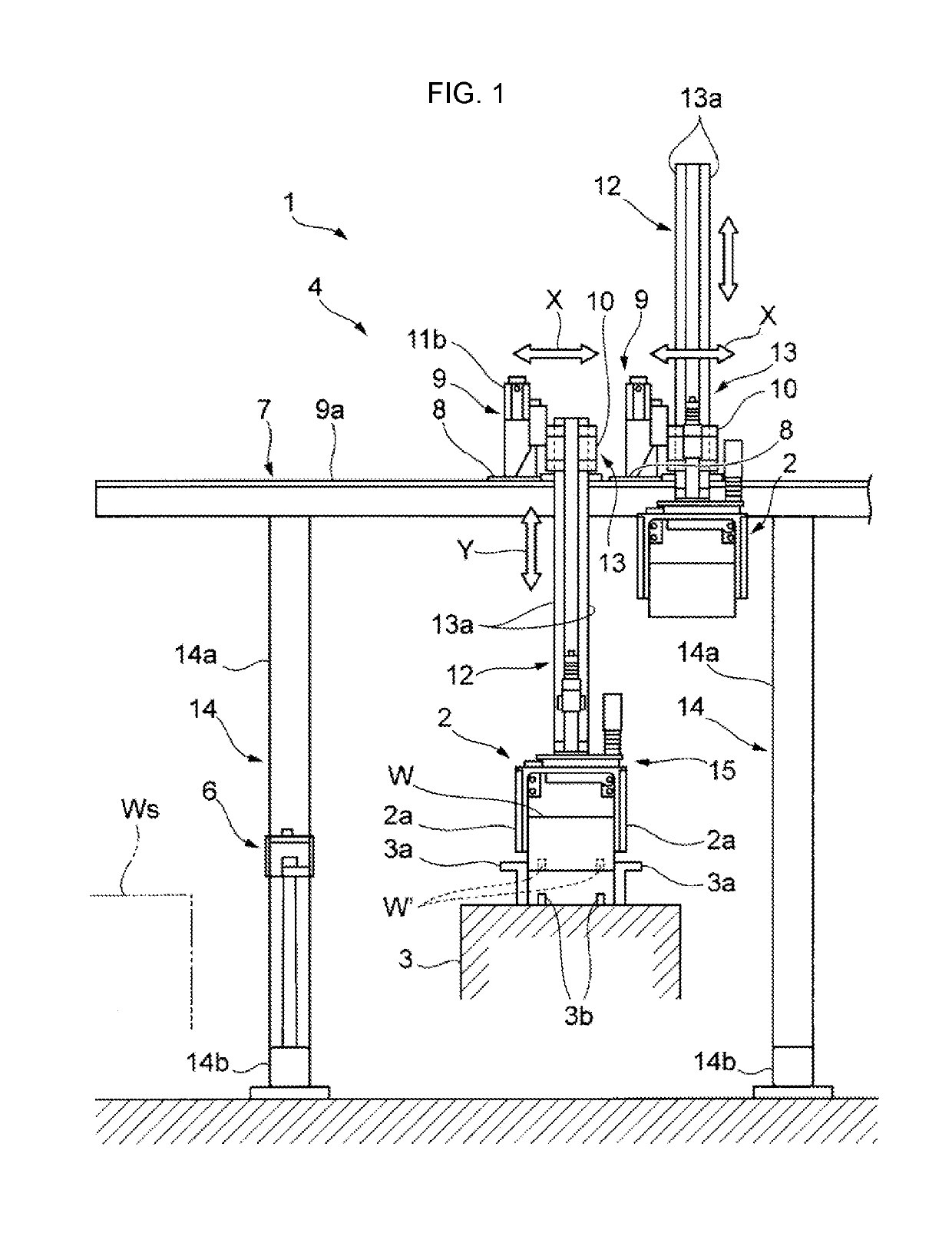

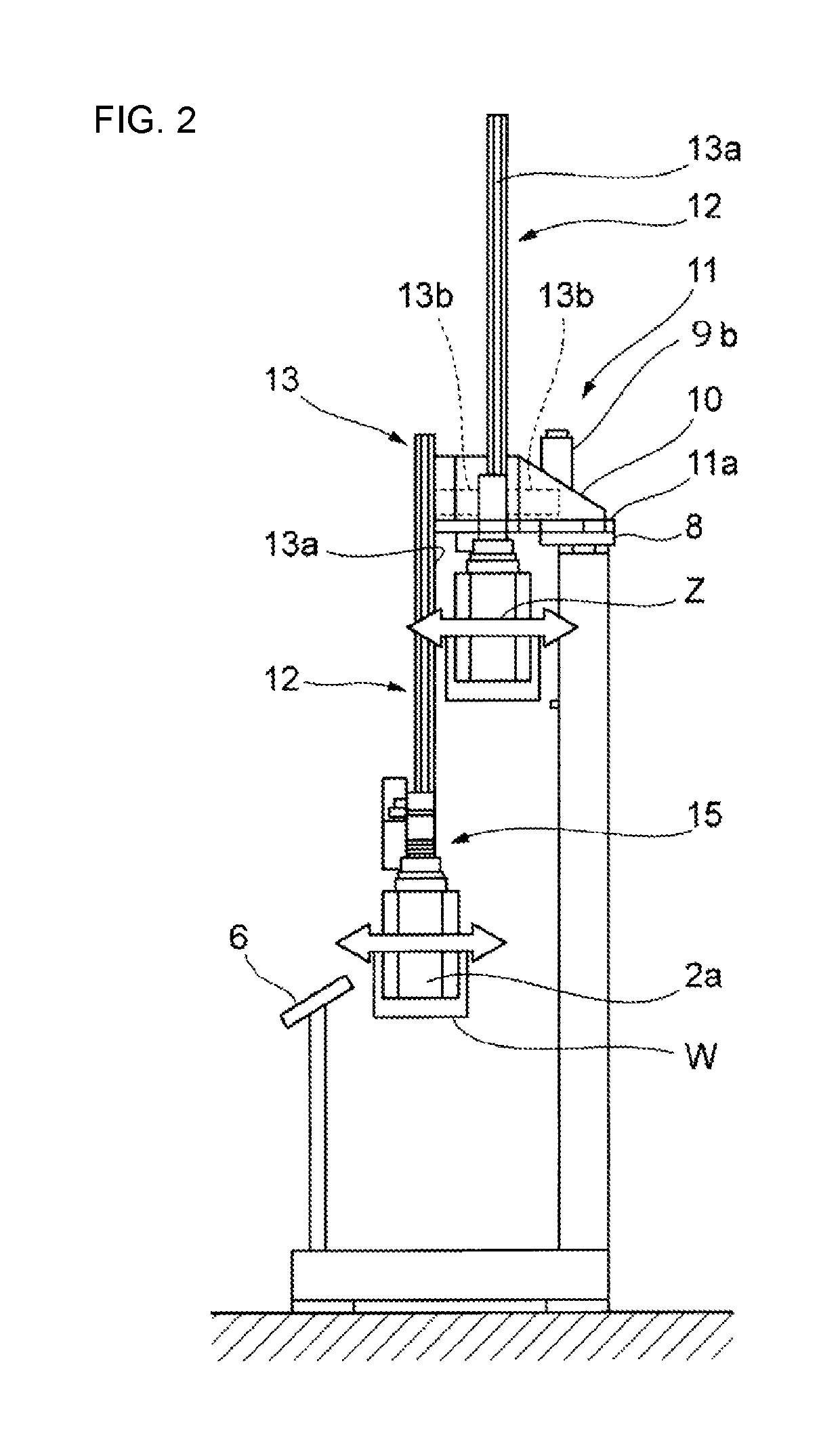

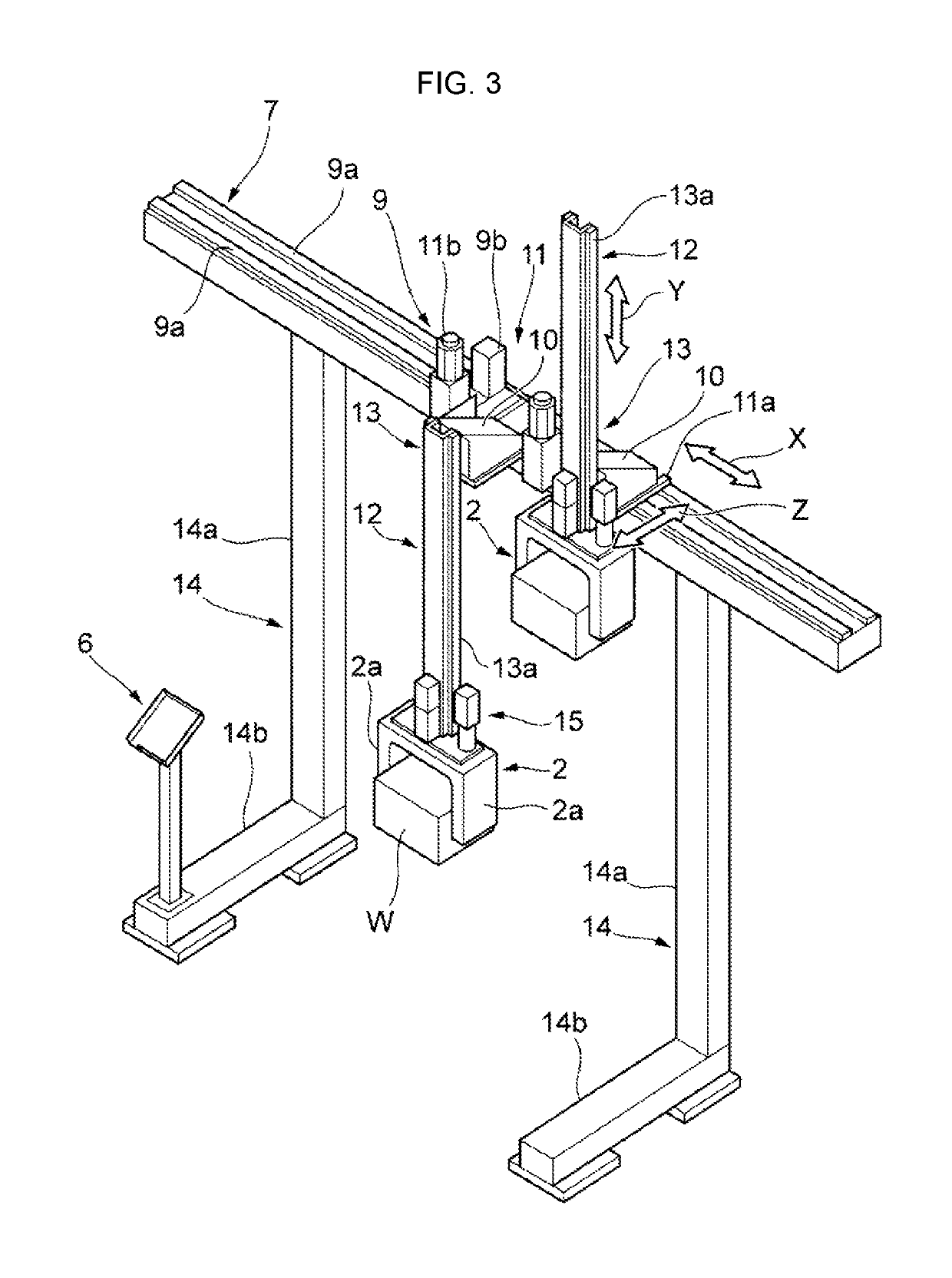

Workpiece loader device

ActiveUS20180104781A1Simplify workShorten teaching timeProgramme controlProgramme-controlled manipulatorLoader

In a workpiece loader device, a loader mechanism is configured to move a loader hand directly held by operator's hands to a desired position. A loader mechanism control part stores position coordinates as workpiece receiving position coordinates when the loader hand is moved by operator's hands to the workpiece receiving position and a completion of moving is confirmed.

Owner:DMG MORI SEIKI CO LTD

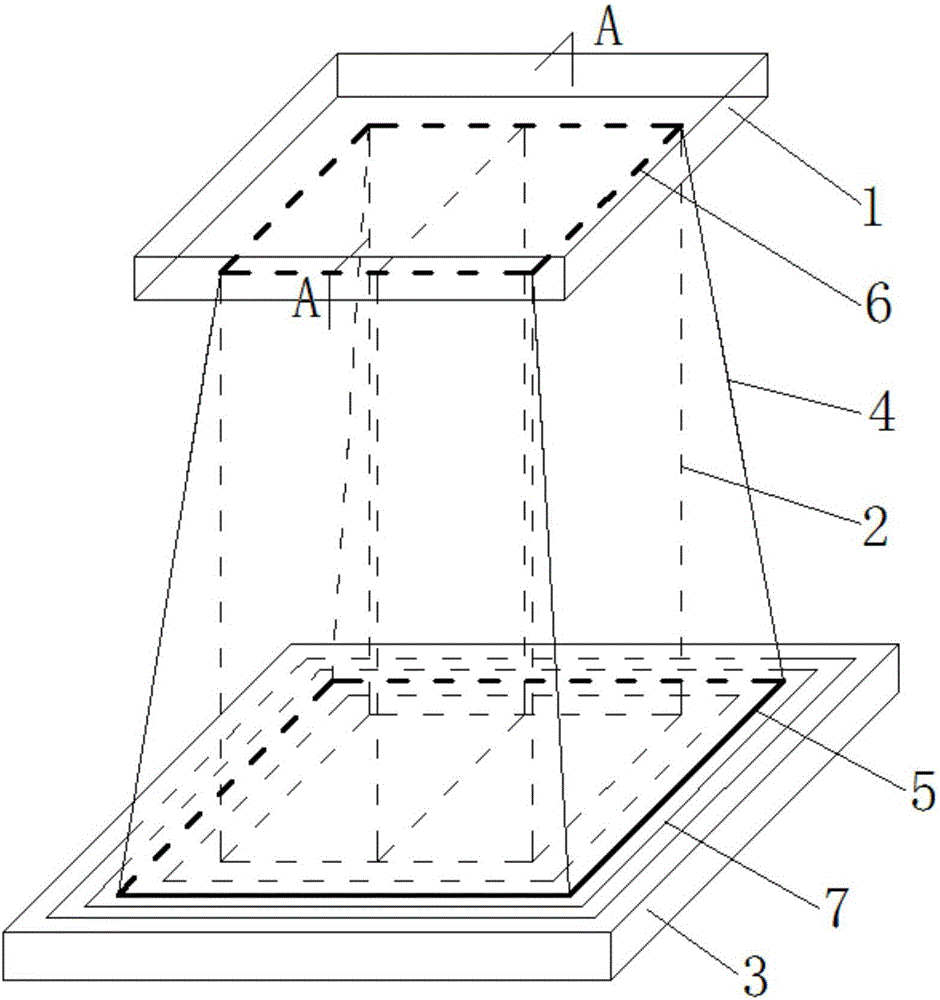

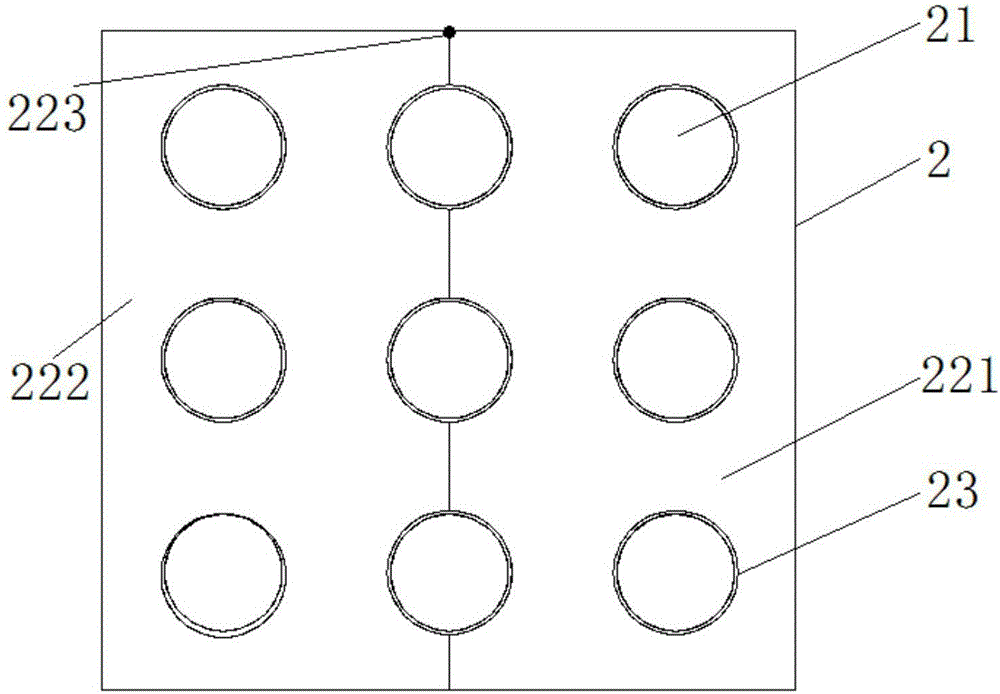

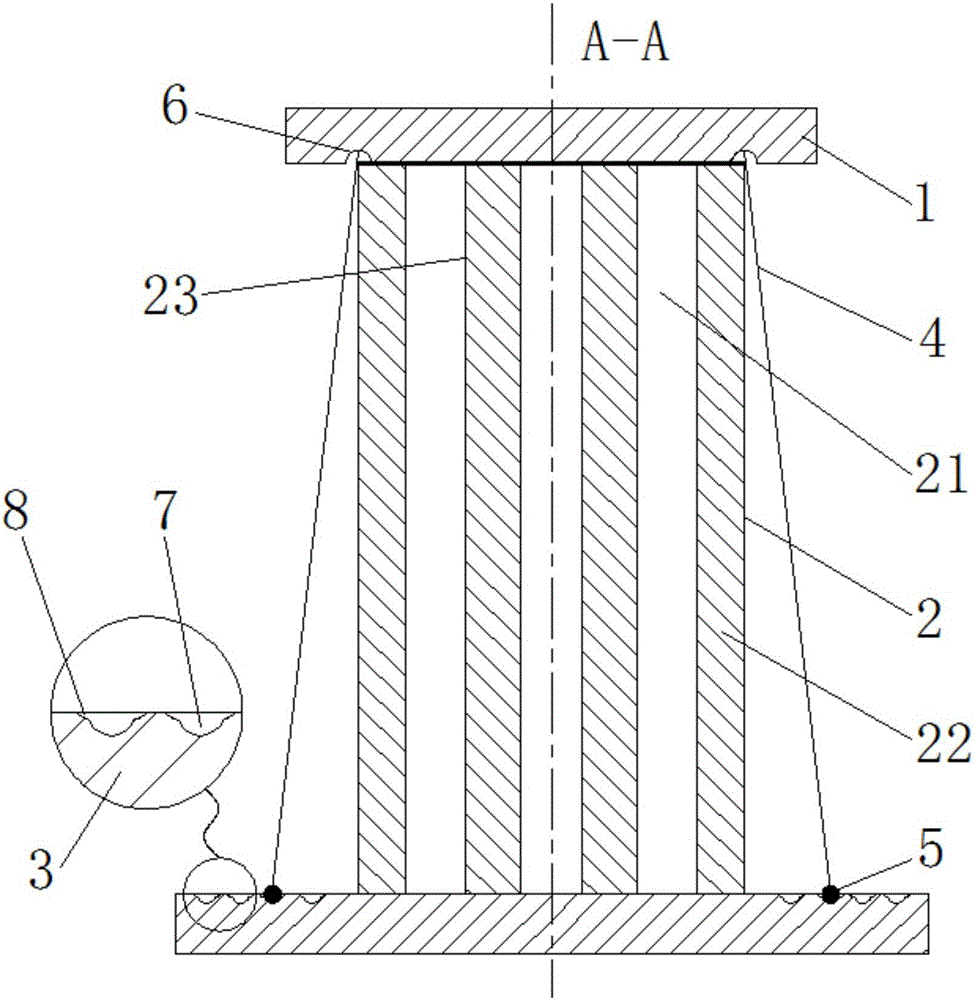

Teaching aid for calculating bearing capacity of pile group foundation according to physical deep foundation method

The invention provides a teaching aid for calculating bearing capacity of pile group foundation according to physical deep foundation method. The teaching aid comprises a bearing platform, a foundation soil plate, a foundation model and four stress diffusion assemblies. The foundation model is a cuboid. The bearing platform and the foundation soil plate are respectively fixed on the top surface and the bottom surface of the foundation model. The lower surface of the bearing platform is provided with four mounting troughs. The positions of the four mounting troughs correspond with four top sides of the foundation model. Each stress diffusion assembly comprises a reel and a reel surface. The reel surface is trapezoidal. The upper bottom side of each reel surface is fixed in the mounting trough, and the lower bottom side is fixedly connected with the reel. The dimension of the reel is smaller than that of the mounting trough. The foundation soil plate is provided with reel fixing positions. The teaching aid simulates stress diffusion of a physical deep foundation through four stress diffusion assemblies. The reel surface is a stress diffusion surface in which an angle between each side at the top of a pile side and the horizontal direction is alpha. The force bearing condition of the pile group foundation is simulated through a physical model, thereby facilitating understanding by the student, improving teaching effect and shortening teaching time.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

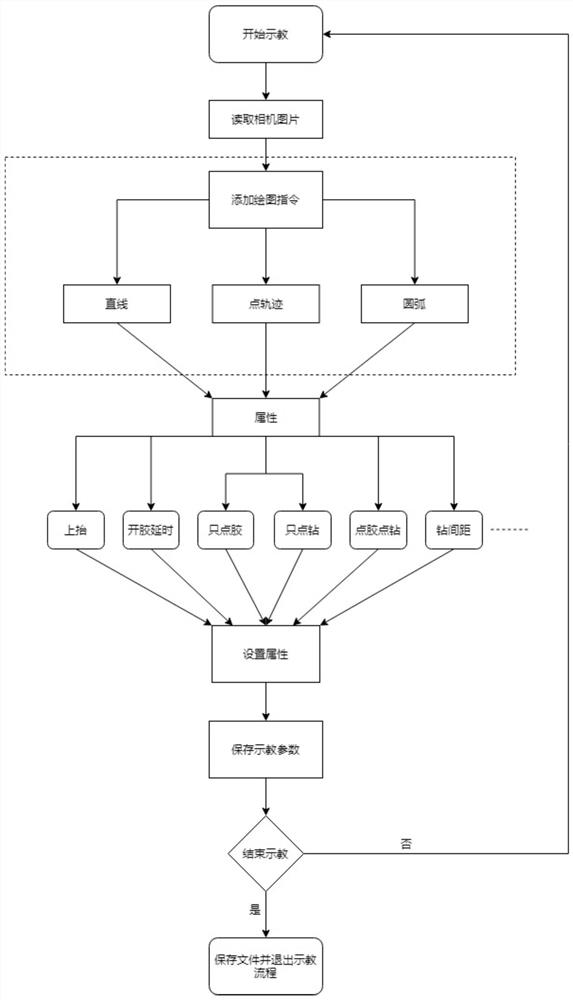

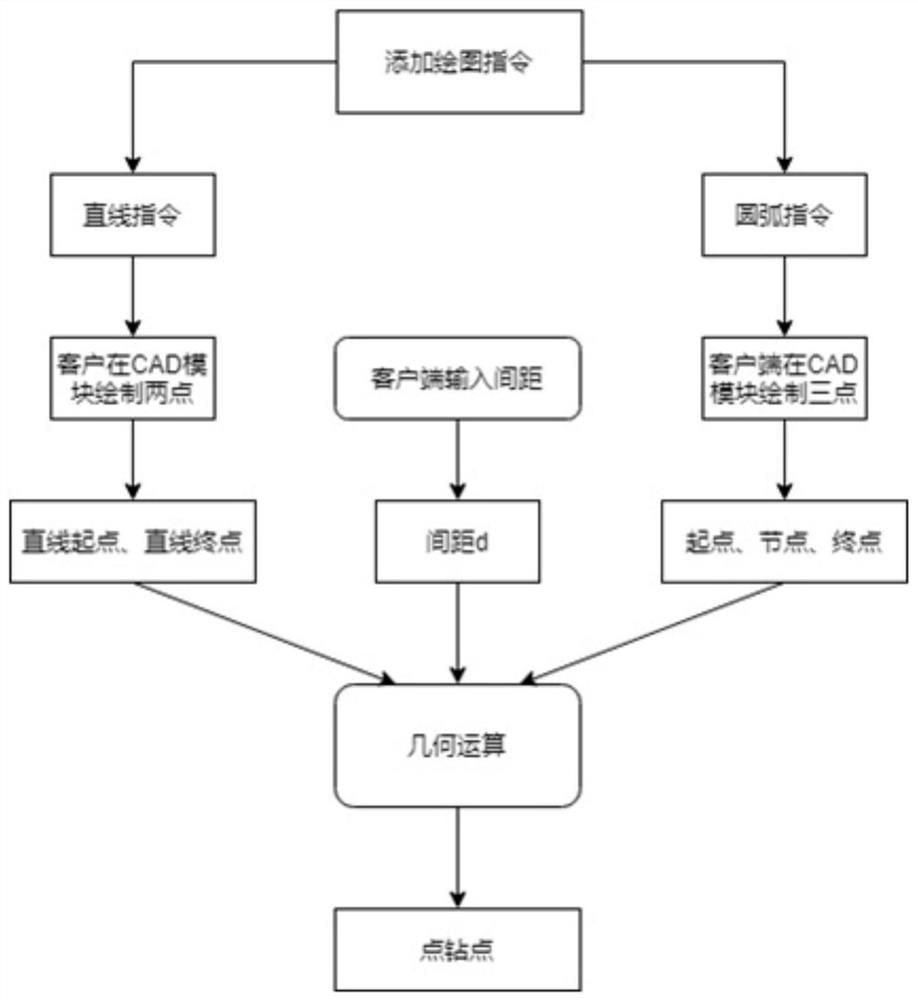

Method for generating drilling point demonstration by point drilling machine according to track

PendingCN112765697AShorten teaching timeEasy to operateGeometric CADDesign optimisation/simulationComputer Aided DesignImaging processing

The invention provides a method for generating drilling point teaching according to a track by a point drilling machine. The method comprises the following steps of: 1, creating a curve drawing instruction in a CAD (Computer Aided Design) module of point drilling software; 2, adding a curve drawing instruction; enabling a CAD module of the software interface to draw a curve track according to the contour of the position to be subjected to spot drilling in the workpiece picture, and obtaining image coordinate data of the corresponding point location on the curve track; 3, returning image coordinate data to an image processing module of the software by using a CAD (Computer Aided Design) module, converting the image coordinate data into mechanical coordinate data, and transmitting the mechanical coordinate data to a motion control module of the software; 4, inputting the drilling distance d; 5, carrying out geometric operation through the data interaction process in the motion control module according to the mechanical coordinate data in the step 3 and the step 4, and forming coordinates of all point positions; 6, setting the attribute of each point location; and 7, and finishing teaching. The method has the characteristics that the operation is simple and quick, the teaching time of a customer is greatly shortened, and the production efficiency and the product quality are improved.

Owner:深圳市旗众智能科技有限公司

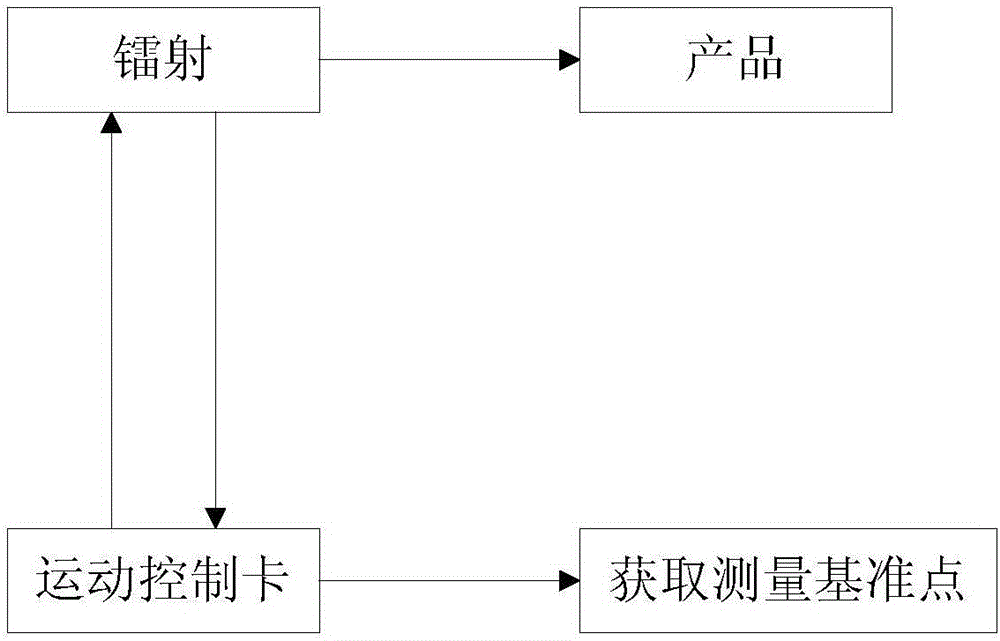

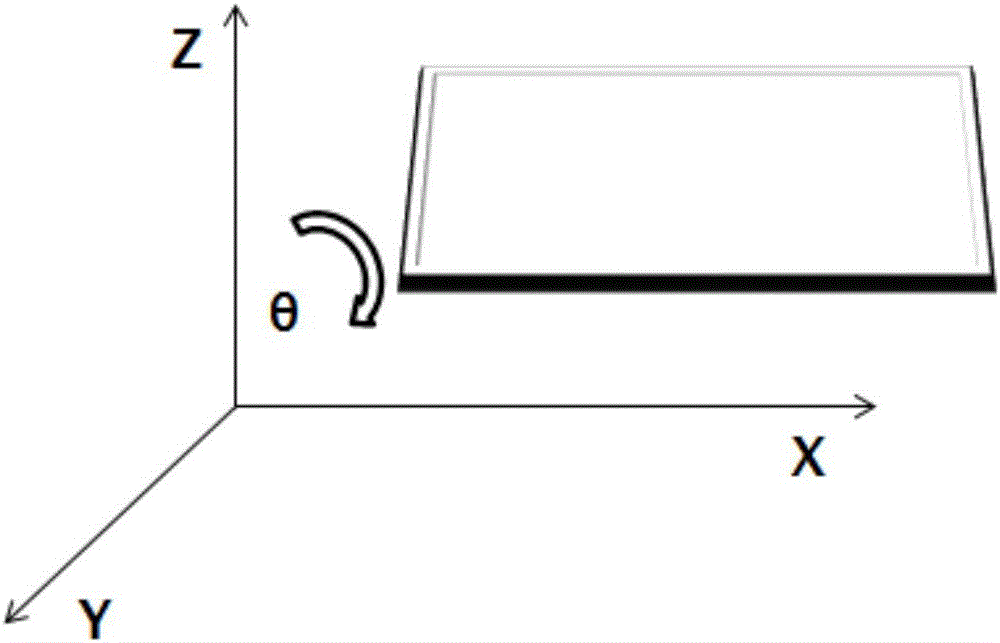

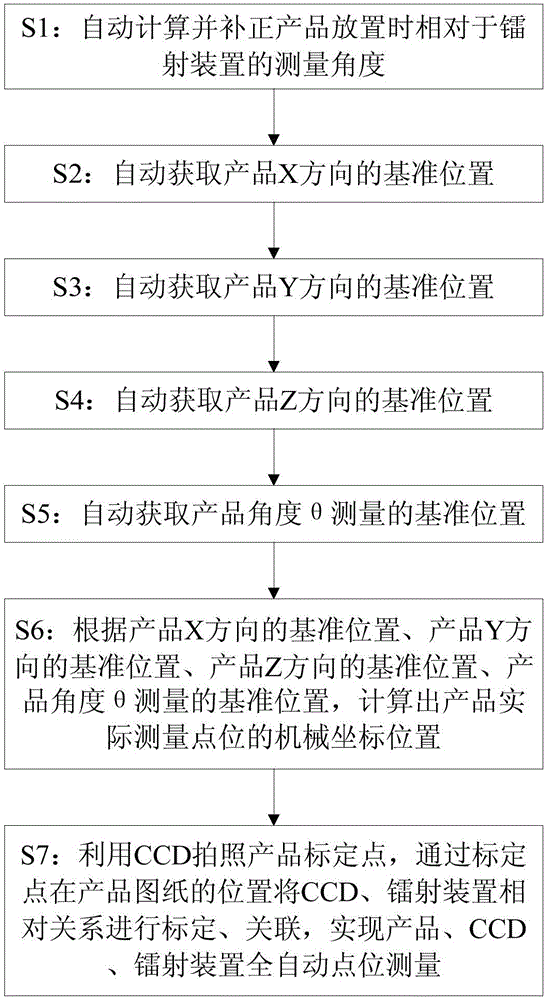

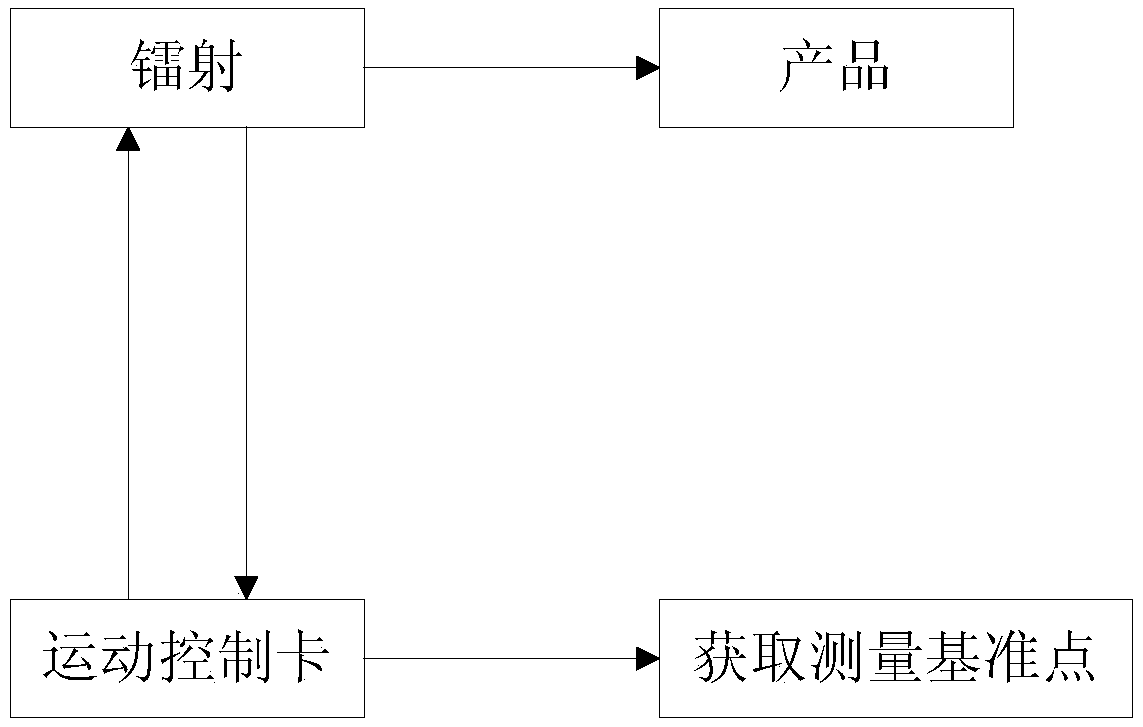

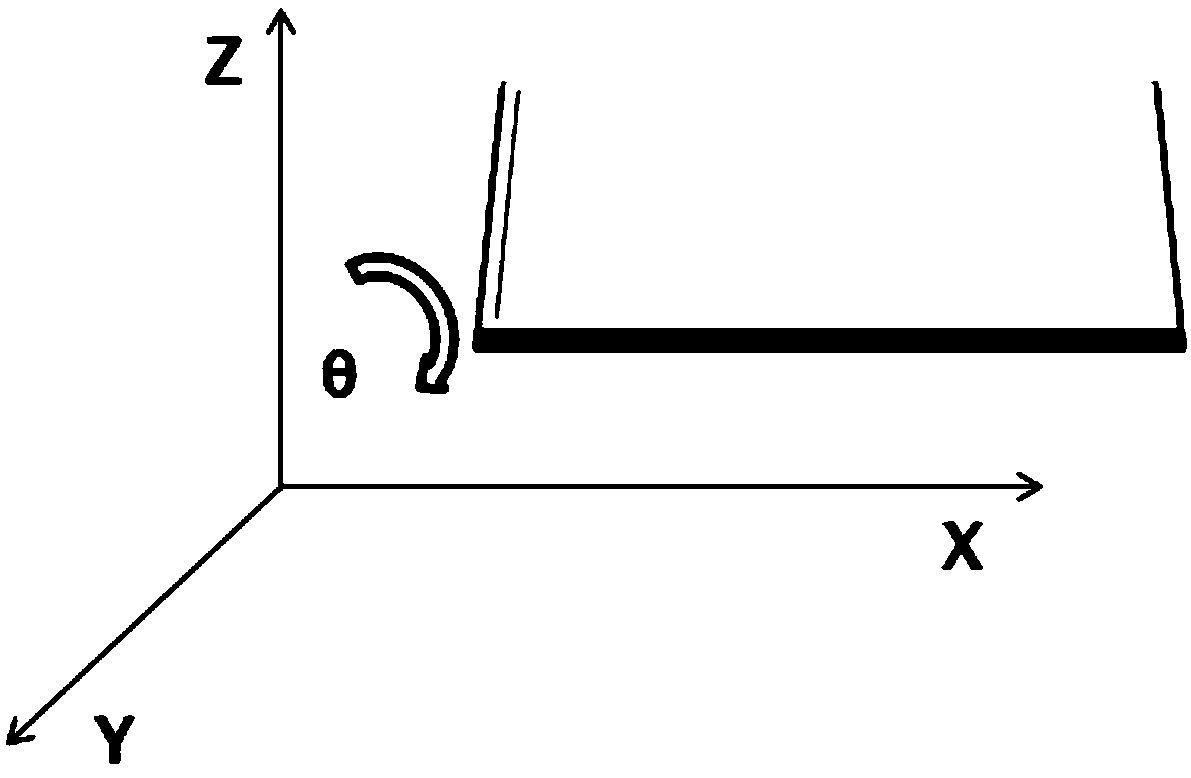

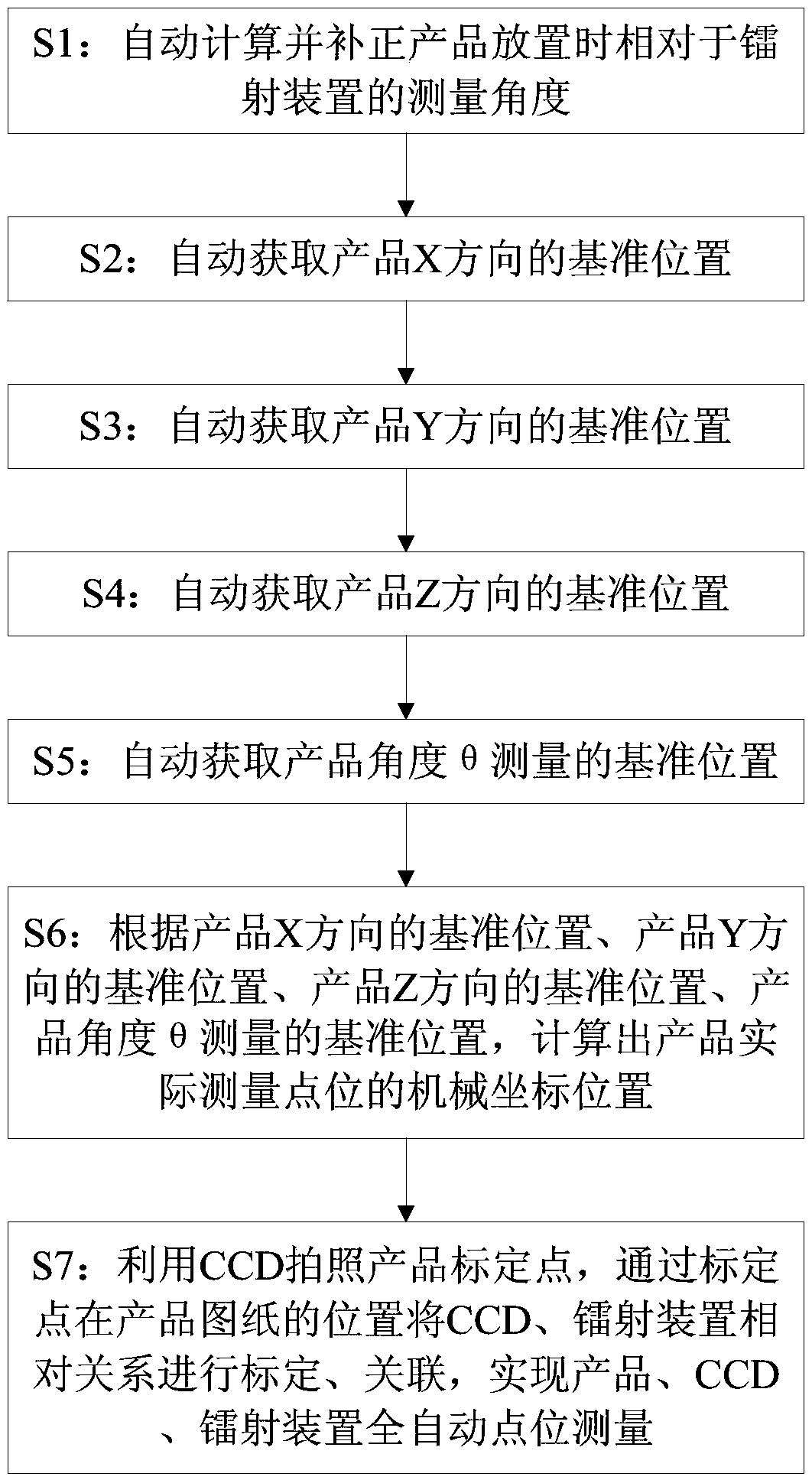

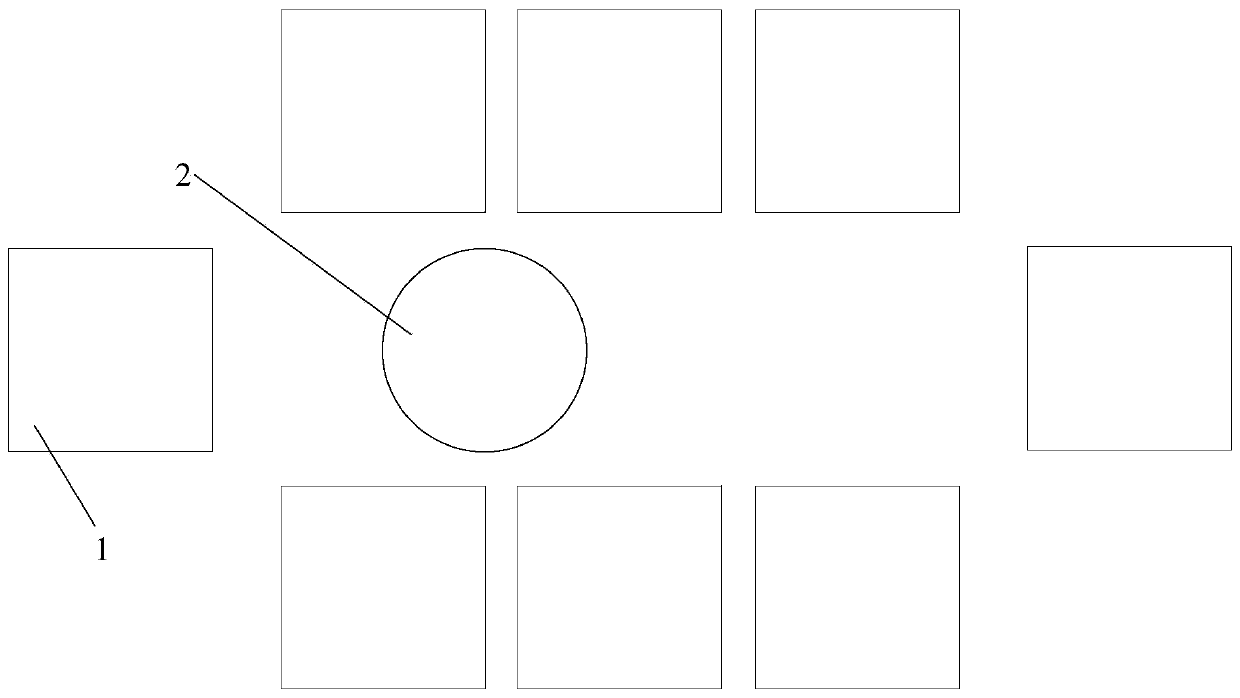

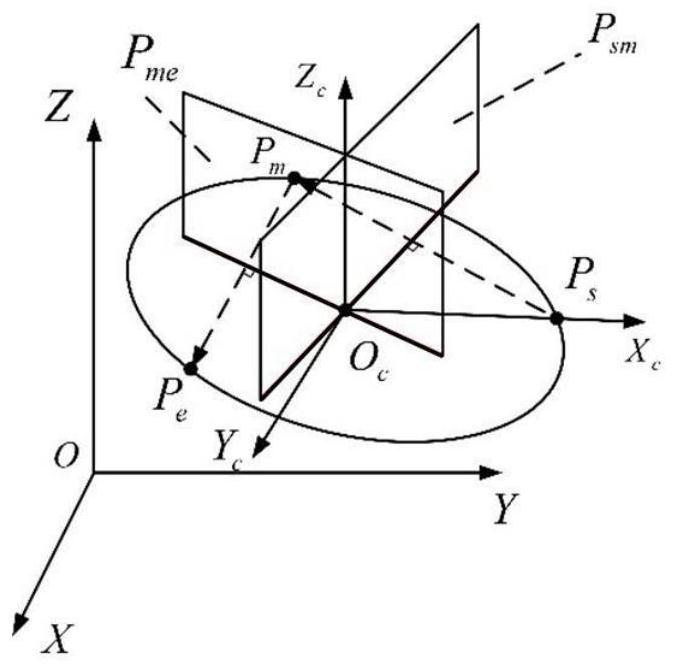

Automatic product measuring point location calculating system and method based on laser-guided measurement

ActiveCN106441090ARealize automatic calculationShorten teaching timeUsing optical meansAngular degreesCoordinate-measuring machine

The invention discloses an automatic regular product three-dimensional measuring point location calculating system and method based on 2D laser-guided measurement. Automatic measuring point location calculation can be achieved, and the teaching time of test point locations is greatly shortened. The mode that the test point locations are taught manually is changed to the mode that calculation is automatically conducted through software, the measuring point location accuracy is improved, and errors generated in manual teaching are eliminated through software calculation. According to the system and method, the test location accuracy and repeatability can reach 0.03 mm, the measuring precision is effectively improved to 0.02 mm from 0.03 mm, and test point location sharing among devices can be achieved; the reference significance is achieved on three-dimensional test devices such as a tri-coordinate measuring machine, and the appropriate test angle can be regulated while the X-direction, Y-direction and Z-direction three-dimensional locations of a product are positioned.

Owner:BOZHON PRECISION IND TECH CO LTD

A system and method for automatic calculation of product measurement points based on laser-guided measurement

ActiveCN106441090BRealize automatic calculationShorten teaching timeUsing optical meansMeasurement pointAngular degrees

The invention discloses an automatic regular product three-dimensional measuring point location calculating system and method based on 2D laser-guided measurement. Automatic measuring point location calculation can be achieved, and the teaching time of test point locations is greatly shortened. The mode that the test point locations are taught manually is changed to the mode that calculation is automatically conducted through software, the measuring point location accuracy is improved, and errors generated in manual teaching are eliminated through software calculation. According to the system and method, the test location accuracy and repeatability can reach 0.03 mm, the measuring precision is effectively improved to 0.02 mm from 0.03 mm, and test point location sharing among devices can be achieved; the reference significance is achieved on three-dimensional test devices such as a tri-coordinate measuring machine, and the appropriate test angle can be regulated while the X-direction, Y-direction and Z-direction three-dimensional locations of a product are positioned.

Owner:BOZHON PRECISION IND TECH CO LTD

A robot teaching method, a robot teaching device and a robot system

ActiveCN108127668BSimplify the teaching processShorten teaching timeProgramme-controlled manipulatorConveyor partsRobotic systemsSimulation

The embodiment of the invention provides a demonstrating method of a robot, a demonstrating device of the robot and a robot system, and relates to the technical field of robots. The problem in the prior art that when the robot is demonstrated, the demonstrating process is complicated can be solved. The demonstrating method comprises the steps of according to identifications of loading equipment ofan object to be carried, obtaining equipment information corresponding to the identifications of the loading equipment of the object to be carried, wherein the equipment information comprises the position of a demonstrating point needed by carrying the loading equipment of the object to be carried relative to a reference point on the loading equipment of the object to be carried; obtaining demonstrating coordinates of the reference point obtained in the process of demonstrating the reference point; according to the position of the reference coordinate of the reference point and the demonstrating point relative to the reference point on the loading equipment of the object to be carried, obtaining demonstrating coordinates of the demonstrating point. The demonstrating method of the robot isused for demonstrating the robot.

Owner:合肥欣奕华智能机器股份有限公司

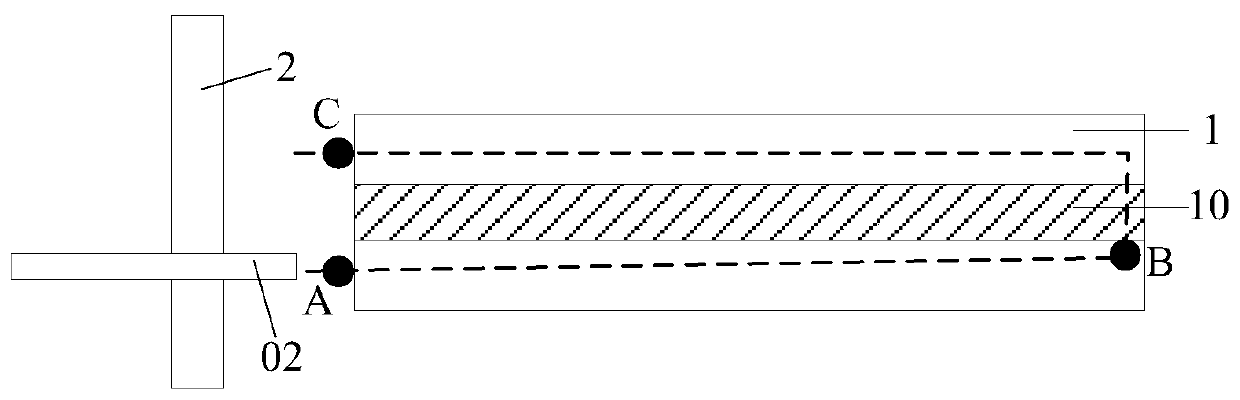

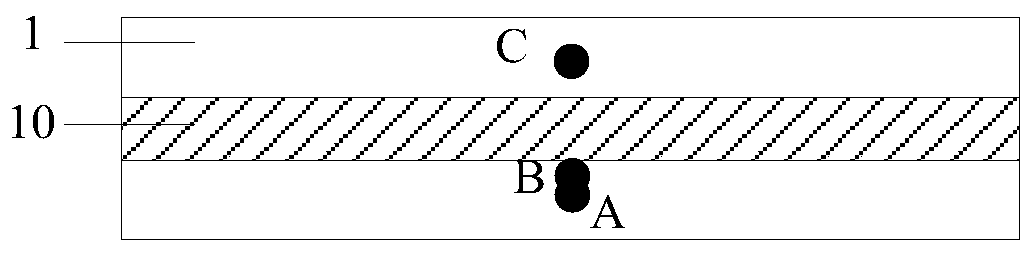

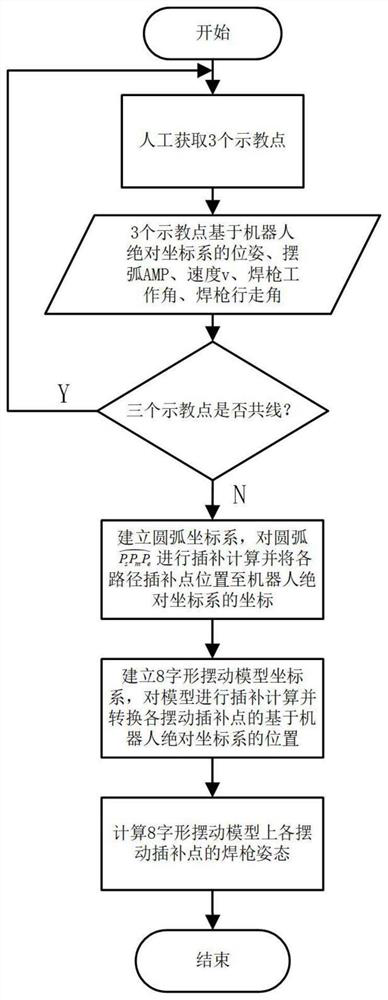

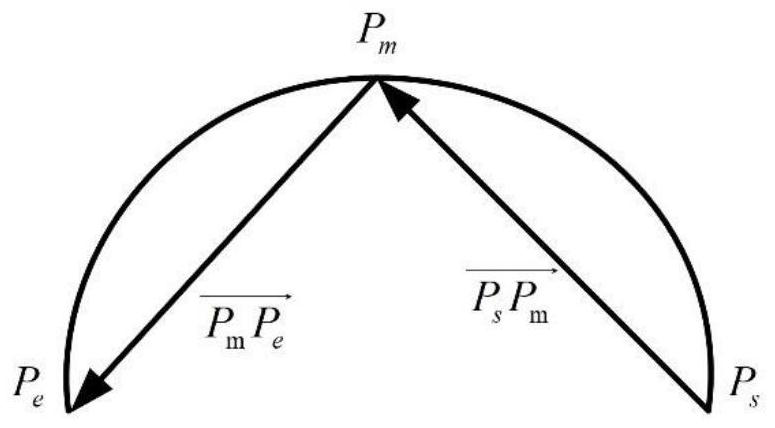

Arc 8-shaped swing arc path planning algorithm capable of quickly adjusting posture of welding gun

ActiveCN113199476AShorten teaching timeAchieve regulationProgramme-controlled manipulatorWelding/cutting auxillary devicesAlgorithmControl engineering

The invention discloses an arc 8-shaped swing arc path planning algorithm capable of quickly adjusting a posture of a welding gun. The planning algorithm comprises the following steps of: carrying out position teaching on an arc welding seam according to any welding gun posture, and adding a welding gun working angle to adjust the posture of a welding gun to obtain a welding surface; calculating an offset vector from path interpolation points to the welding surface according to a geometrical relationship between the welding surface and the workpiece; calling an arc 8-shaped swing arc path generation algorithm to obtain position information of each swing interpolation point on a swing model based on a robot absolute coordinate system according to parameters such as a welding gun swing amplitude and a robot tail end linear speed; and establishing a welding gun coordinate system, adding a welding gun walking angle to adjust the welding gun posture, and calculating a welding gun posture change matrix to obtain the posture value of each swing interpolation point in the robot welding process. According to the method, new path planning for quickly adjusting the posture of the welding gun can be realized, and the teaching efficiency and the welding quality of an industrial robot are improved.

Owner:GUANGXI UNIV +1

Workpiece loader device

ActiveUS10300572B2Simplify workShorten teaching timeProgramme-controlled manipulatorComputer controlEngineeringMechanical engineering

Owner:DMG MORI CO LTD

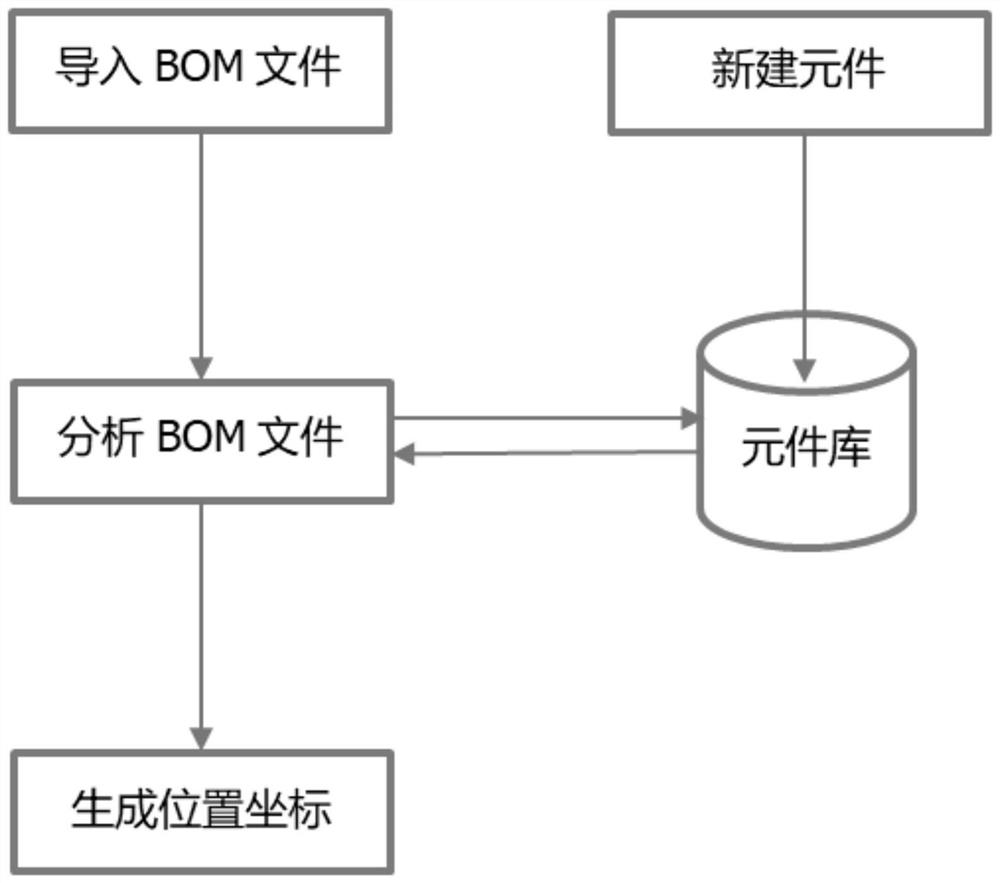

SMT (Surface Mount Technology) red glue dispensing teaching method and system and storage medium

PendingCN114429093AShorten teaching timeCAD circuit designSpecial data processing applicationsProcess engineeringSystems engineering

The invention provides an SMT (Surface Mount Technology) red glue dispensing teaching method and system and a storage medium. The SMT red glue dispensing teaching method comprises the following steps: an element library establishment step: establishing an element library according to all element types; an importing step: importing a BOM file of the current PCB; and an analysis step: analyzing the BOM file, and searching corresponding template information from the element library to generate a dispensing position coordinate of the whole PCB. The method has the beneficial effects that under the condition that the number of components on the PCB is large, the component library is established, the BOM file is imported to generate the dispensing position on the PCB, the teaching time is shortened by 90% or above, and a debugging machine with higher efficiency is achieved.

Owner:深圳德森精密设备有限公司

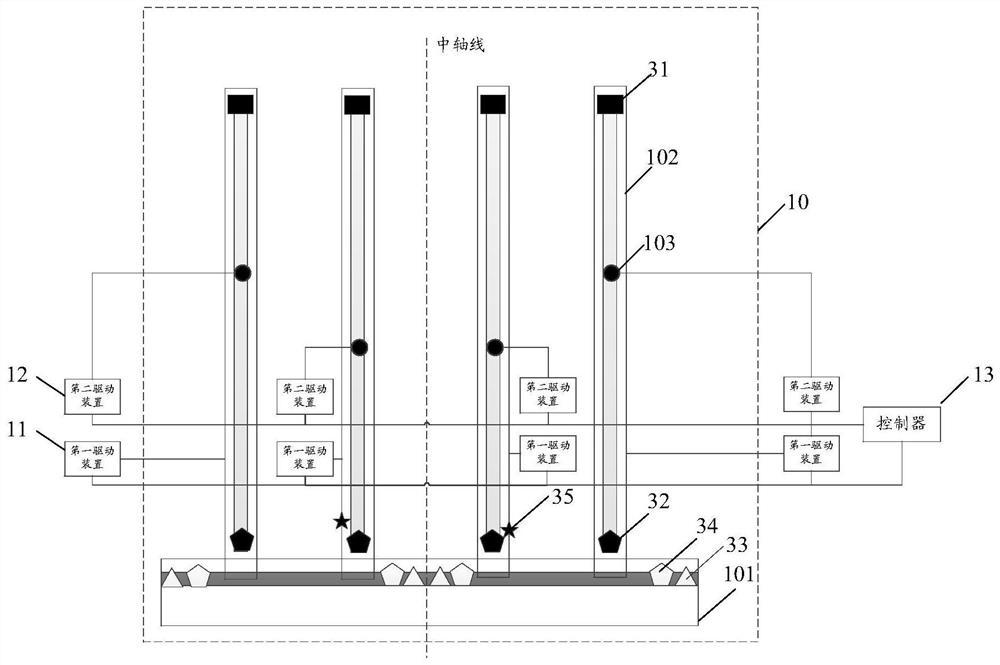

Carrying robot, carrying control method, device and equipment thereof and medium

ActiveCN112894795AIncrease profitHigh degree of automationProgramme-controlled manipulatorHand partsControl engineering

The invention provides a carrying robot and a carrying control method, device and equipment thereof and a medium, capale of increasing the utilization rate of the carrying robot and the automation degree and saving the teaching time. The carrying robot comprises a hand, a first driving device, a second driving device and a controller, wherein the hand comprises a root and a plurality of fingers, the plurality of fingers are parallel and arranged in a first direction, each finger is installed on the root, can move in the first direction and is provided with a first sensor used for positioning a carried object, and each first sensor can move in a second direction; the first driving device is connected with the fingers and used for driving the plurality of fingers to move in the first direction; the second driving device is connected with the first sensor and used for driving the first sensors to move in the second direction; and the controller is connected with the first driving device and the second driving device and used for controlling the first driving device to adjust the positions of the fingers and controlling the second driving device to adjust the positions of the first sensors on the fingers respectively according to the received size of the carried object.

Owner:合肥欣奕华智能机器股份有限公司

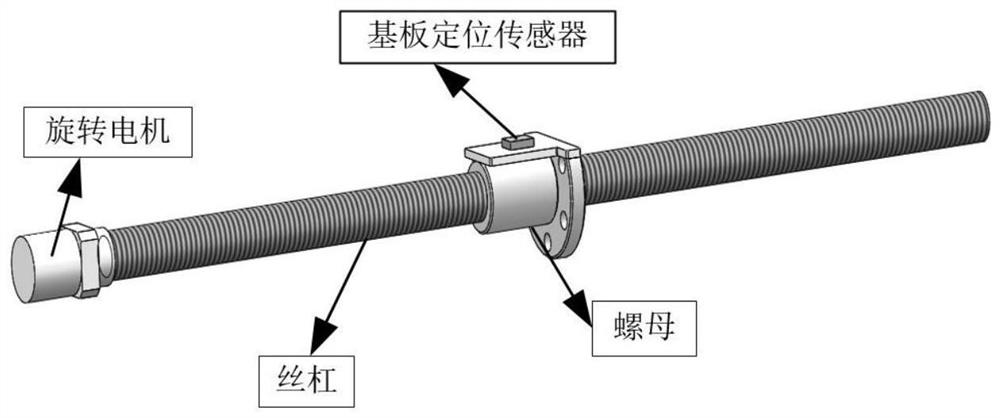

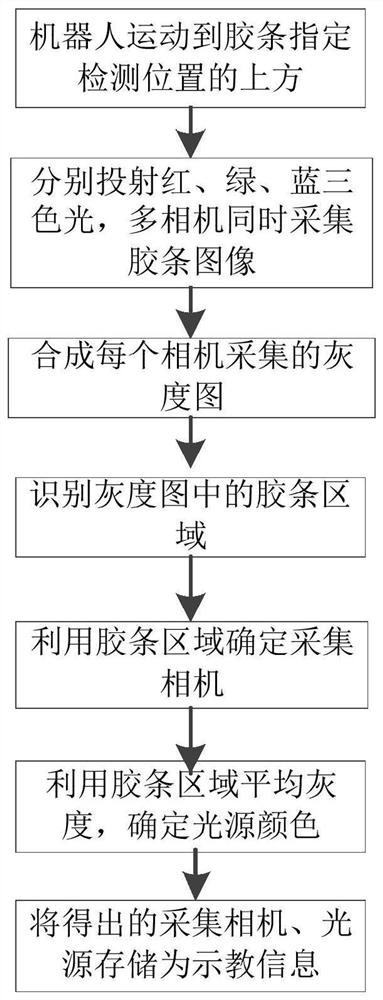

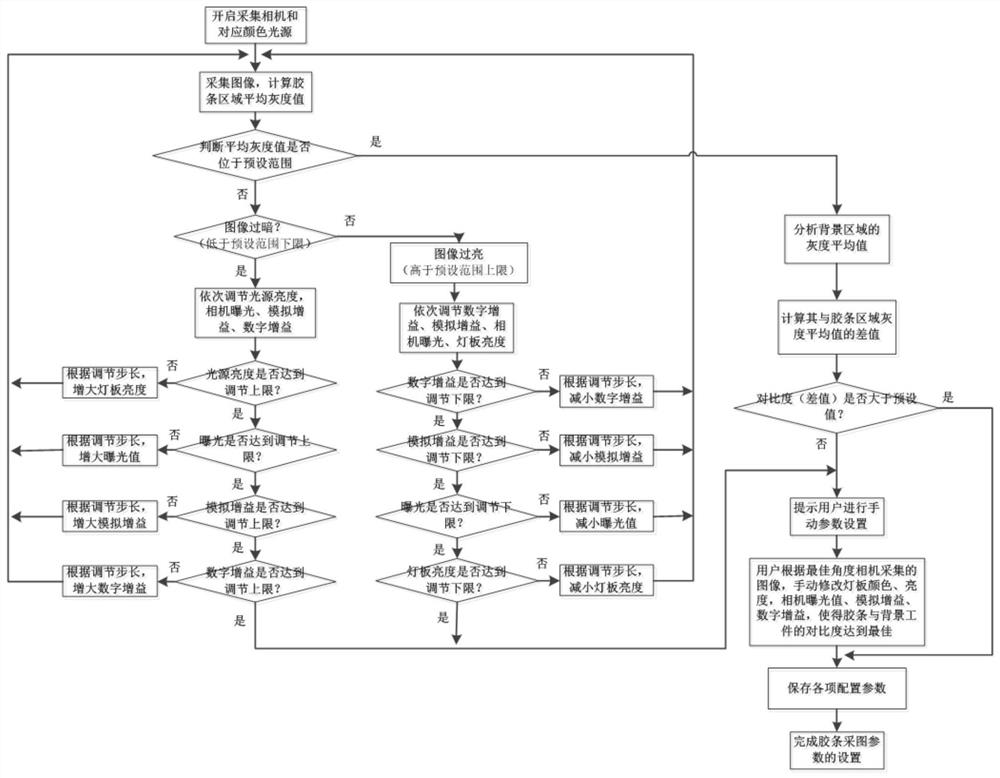

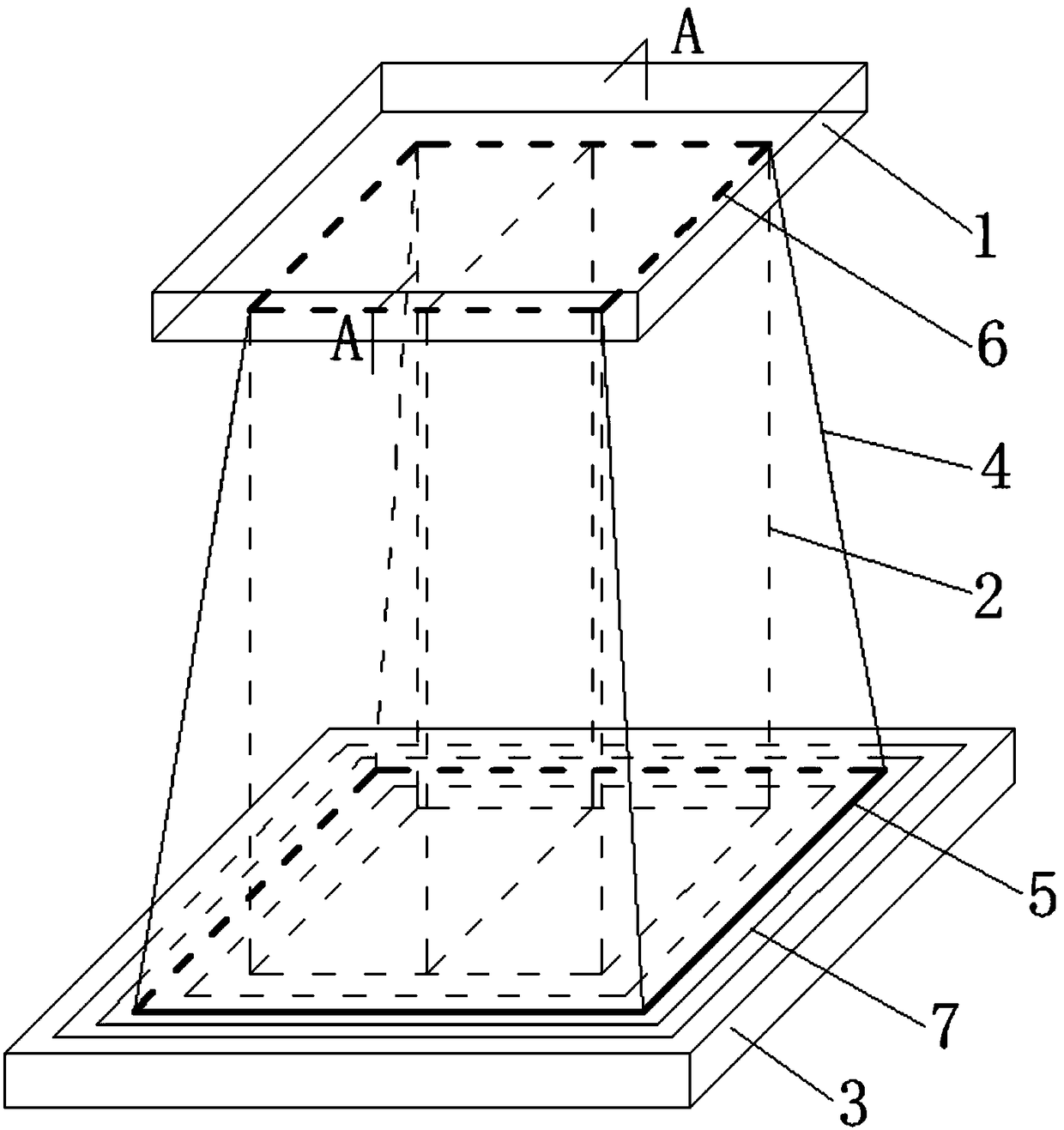

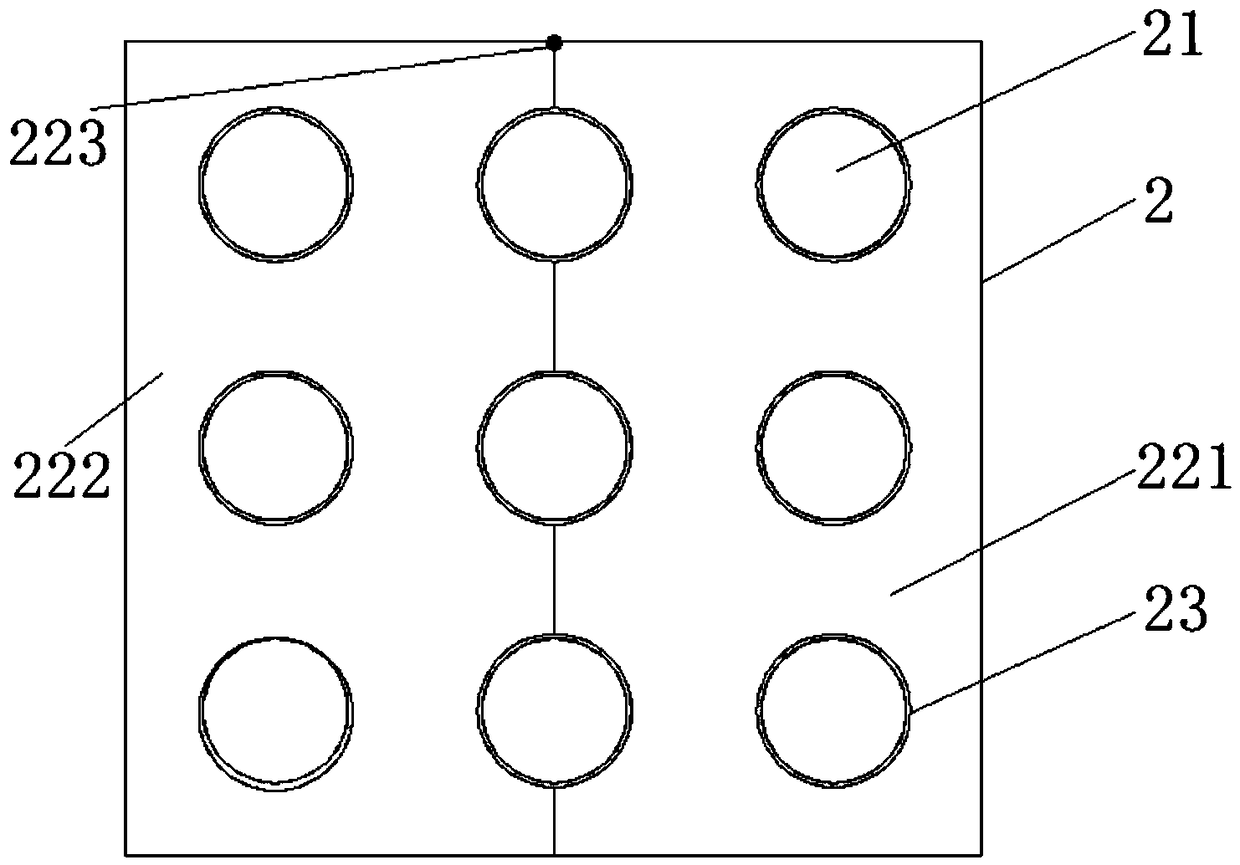

Automatic teaching method of glued sensor

ActiveCN110646431BFree from subjective interferenceImprove accuracyImage enhancementImage analysisComputer graphics (images)Engineering

The invention discloses an automatic teaching method for a glue coating sensor. At the position where the glue strip is to be detected, a light source projects red, green and blue light rays to the glue strip, and the corresponding grayscale image is synthesized by using the images in the three colors. And get the glue strip area; according to the integrity of the glue strip area and the position in the image, determine the camera with the best shooting angle, record it as the acquisition camera; store the acquisition camera at each detection position as the camera teaching information; Use the average grayscale of the glue strip area to judge the color of the light source; store the color information of the light source at each detection position as the teaching information of the light source; this method can also perform automatic parameter teaching, only the operator needs to set the initial parameters of the camera and the light source. After setting, the computer can be used to complete the subsequent teaching process, so that the image can achieve better contrast and improve the teaching efficiency.

Owner:易思维(杭州)科技有限公司

A Teaching Aid for Calculating the Bearing Capacity of Pile Group Foundations Using Solid Deep Foundation Method

ActiveCN105976695BEasy to understandImprove teaching effectEducational modelsPhysical modelFixed position

The invention provides a teaching aid for calculating bearing capacity of pile group foundation according to physical deep foundation method. The teaching aid comprises a bearing platform, a foundation soil plate, a foundation model and four stress diffusion assemblies. The foundation model is a cuboid. The bearing platform and the foundation soil plate are respectively fixed on the top surface and the bottom surface of the foundation model. The lower surface of the bearing platform is provided with four mounting troughs. The positions of the four mounting troughs correspond with four top sides of the foundation model. Each stress diffusion assembly comprises a reel and a reel surface. The reel surface is trapezoidal. The upper bottom side of each reel surface is fixed in the mounting trough, and the lower bottom side is fixedly connected with the reel. The dimension of the reel is smaller than that of the mounting trough. The foundation soil plate is provided with reel fixing positions. The teaching aid simulates stress diffusion of a physical deep foundation through four stress diffusion assemblies. The reel surface is a stress diffusion surface in which an angle between each side at the top of a pile side and the horizontal direction is alpha. The force bearing condition of the pile group foundation is simulated through a physical model, thereby facilitating understanding by the student, improving teaching effect and shortening teaching time.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

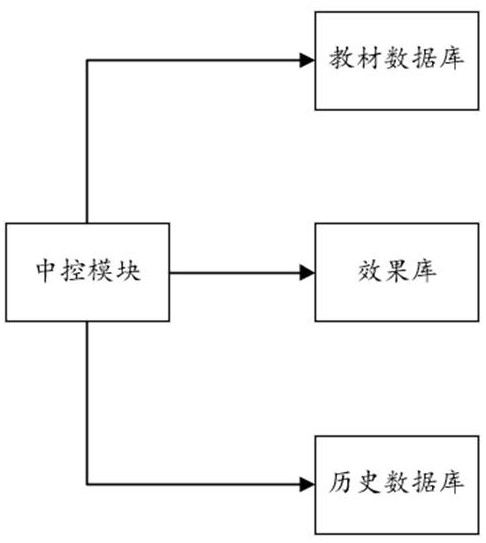

A platform for providing digital teaching materials for teachers to prepare lessons

ActiveCN114036445BMeet coursework needsShorten teaching timeData processing applicationsWebsite content managementDigital textbookKnowledge management

The present invention relates to a platform for providing digital teaching materials for teachers to prepare lessons, including a teaching material database, an effect database, a historical database, a central control module, and the central control module is respectively connected to the teaching material database, the effect database, and the historical database , the central control module adjusts the teaching duration of the teaching knowledge points according to the historical learning effects and historical teaching data stored in the effect library and the historical database, and according to the determined teaching duration, the teaching material database provides corresponding teaching content, and the number of exercises for teaching explanations. The present invention adjusts the upcoming teaching time by storing the historical teaching time and the corresponding teaching effect, so that the teaching time can be shortened as much as possible under the premise of meeting the students' academic needs, and the sufficient time can be arranged by the students themselves, which is reasonable The length of teaching and teaching hours is planned.

Owner:广东省出版集团数字出版有限公司

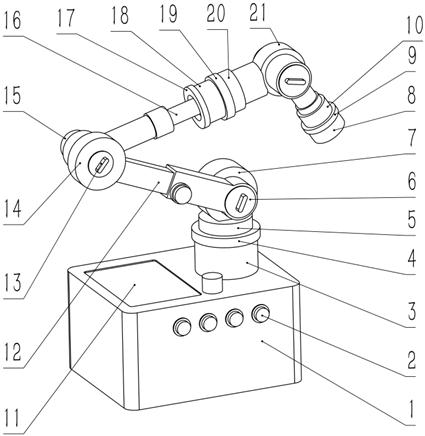

Teaching method of industrial robot

PendingCN112847380AQuick implementation of single axisQuickly realize multi-axis linkageProgramme-controlled manipulatorControl engineeringLinkage (mechanical)

The invention discloses a teaching method of an industrial robot. An unpowered mechanical arm type teaching device with damping adjustment devices is designed according to equal-ratio scaling of lengths of all mechanical arms of the industrial robot, an angle sensor, an electronic fine tuning device, a damper and the damping adjustment device are arranged at each joint of the unpowered mechanical arm type teaching device, the positions of all arms of a teaching device are freely moved through two hands, the angle sensors at all joints are driven to give angle data, the industrial robot is driven to reach a position or a track designed by an operator, the joint linkage of a part which is desired to be driven is freely controlled by limiting the movement speed or opening and closing of the joints through the damping adjustment devices, and teaching operation of the industrial robot is quickly realized. According to the teaching method of the industrial robot, single-axis or multi-axis linkage can be rapidly realized, and complex motion trail operation teaching can be rapidly realized; the unpowered mechanical arm type teaching device can be used independently and can further be used in cooperation with a panel type teaching device, and the compatibility is higher; and the operation method is simple and convenient, the use is fast, and the teaching time is greatly shortened.

Owner:SUZHOU ANHUI SAIERWODE INTERNET OF THINGS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com