Polishing robot system with movement locus self-learning function and control method

A technology of robot system and motion trajectory, which is applied in the control of workpiece feed motion, automatic grinding control device, grinding frame, etc., can solve the problem of high technical requirements for operators of grinding robots, and achieve shortened teaching time, The effect of reducing technical requirements and quick clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

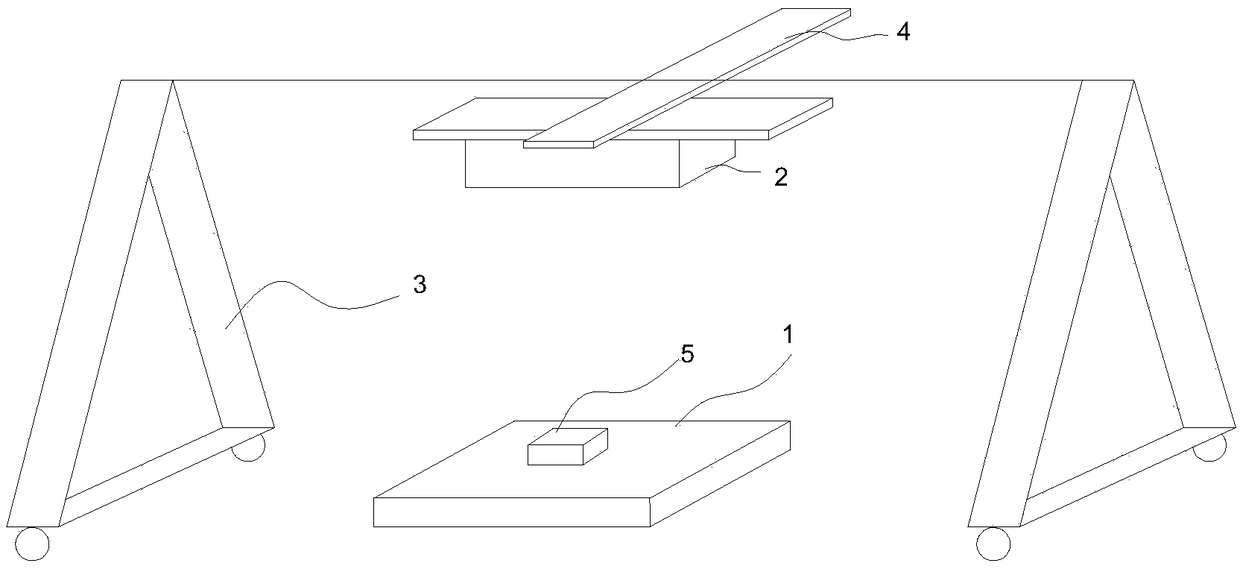

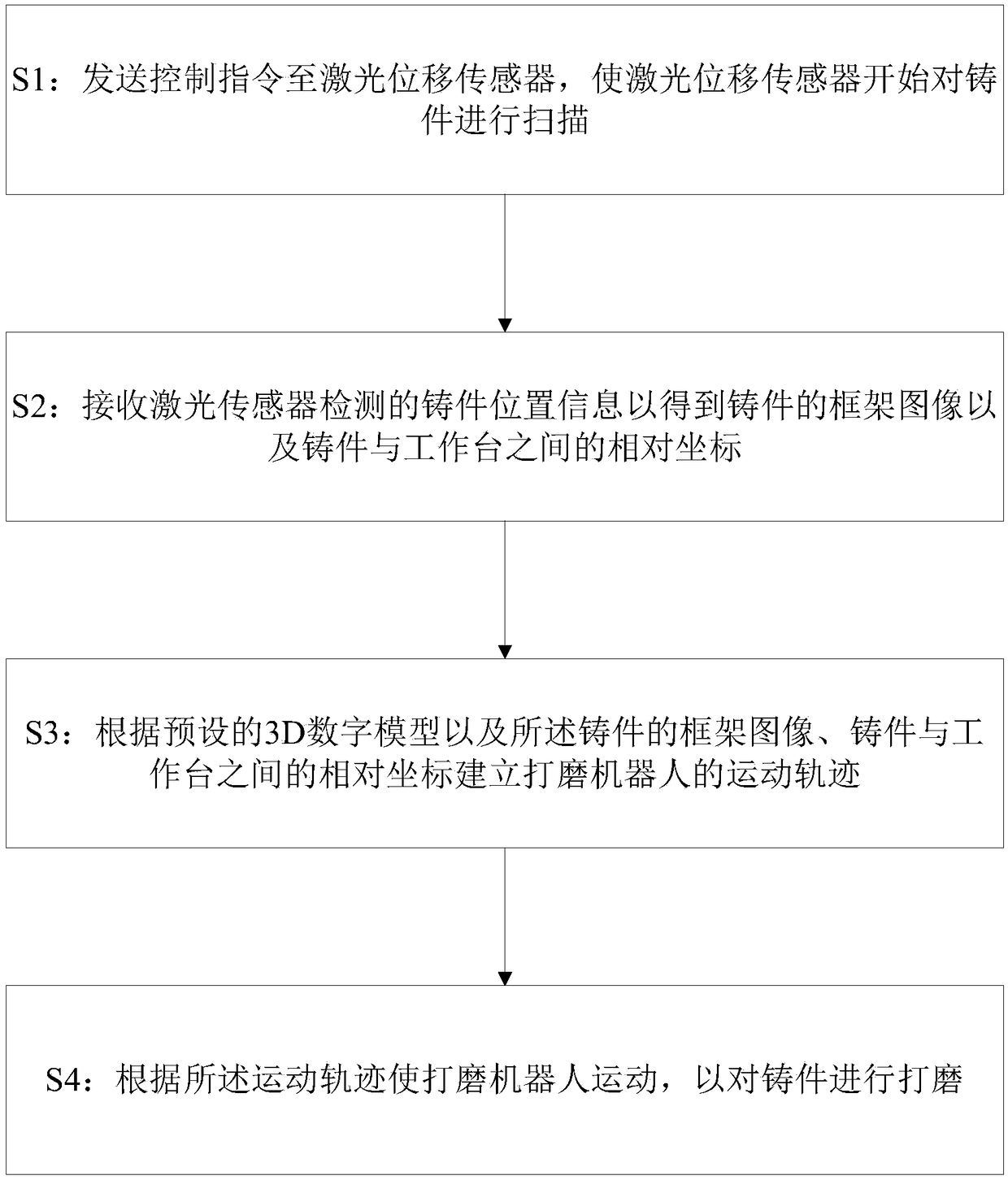

[0024] Such as figure 1 As shown, the present invention discloses a grinding robot system with self-learning motion trajectory. In order to solve the problems of time-consuming trajectory planning and inaccurate positioning of traditional casting grinding robots, the system includes a workbench 1, a laser displacement sensor 2, a fixed frame 3, a moving Track 4, upper computer and grinding robot, the moving track 4 is installed on the fixed frame 3, the laser displacement sensor 2 is installed on the moving track 4, the workbench 1 is used to hold the casting 5 to be scanned, the laser displacement sensor 2 Located above the casting 5, the laser displacement sensor 2 is used to move along the X-axis and Y-axis under the drive of the moving track 4, so as to scan the casting 5 directly above to form a frame image of the casting 5 and obtain the casting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com