Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Save winding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

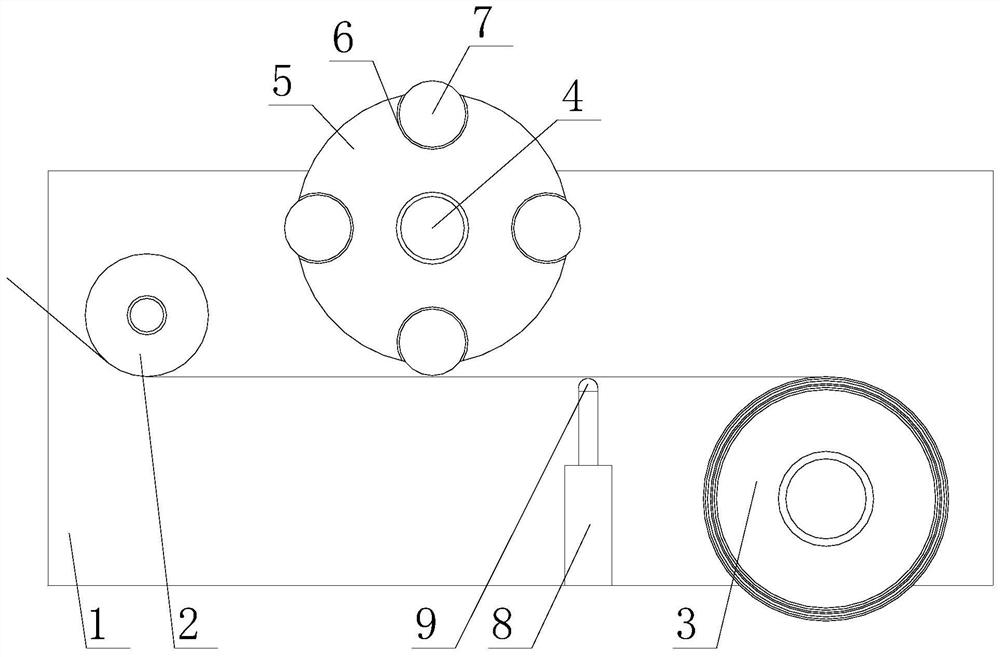

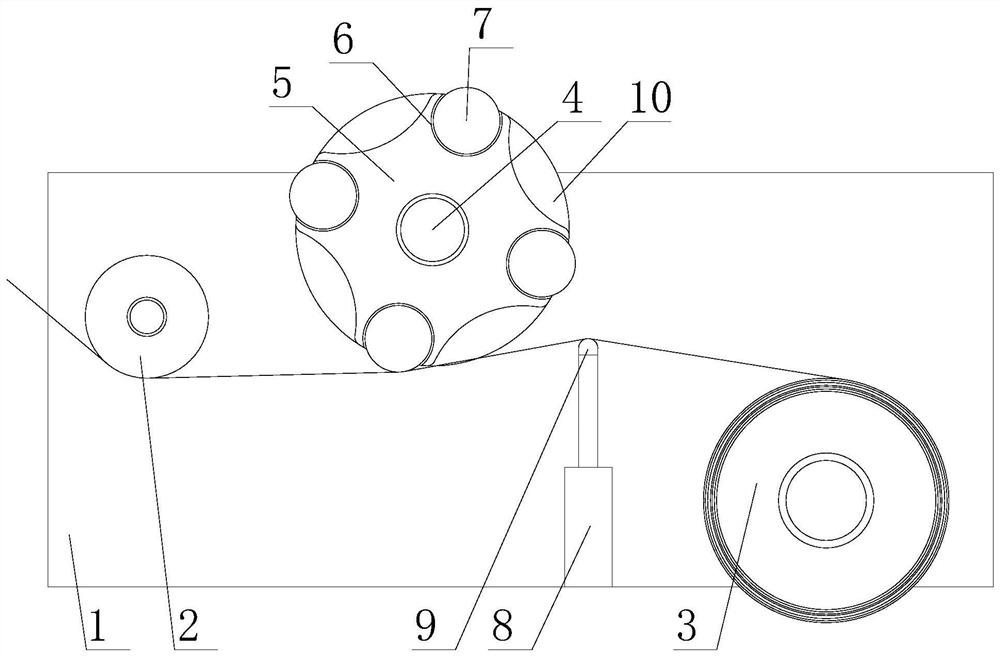

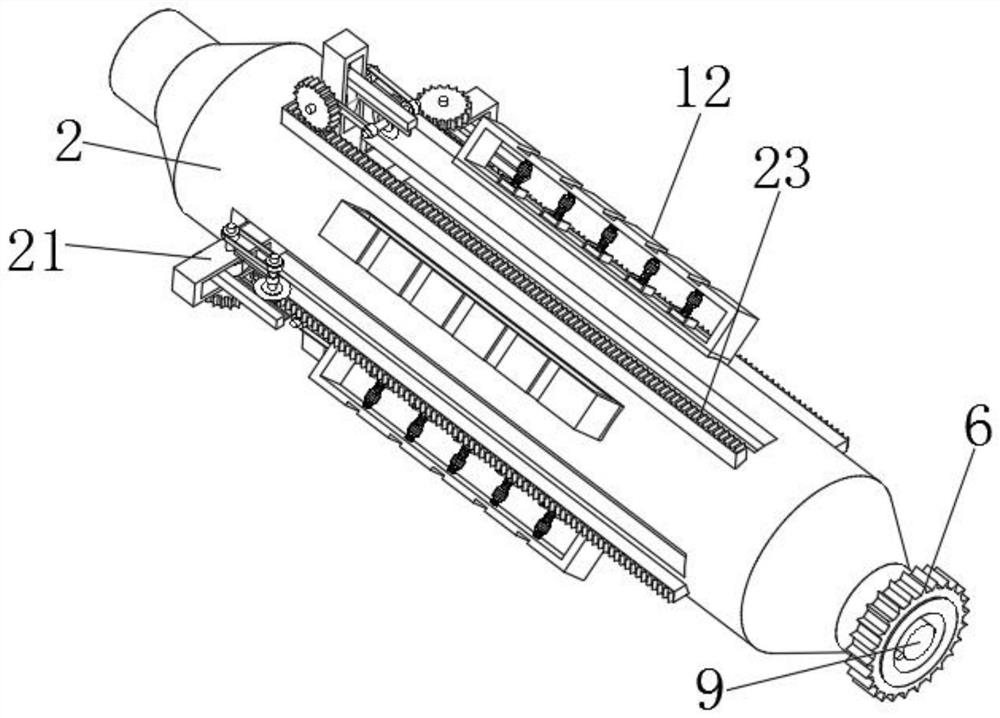

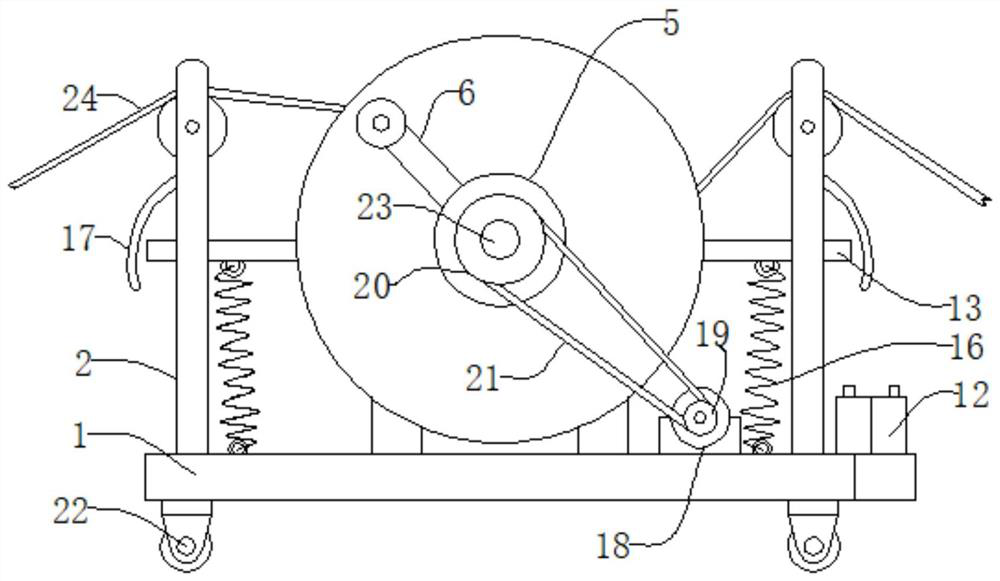

Automatic four-axis cast film winding machine

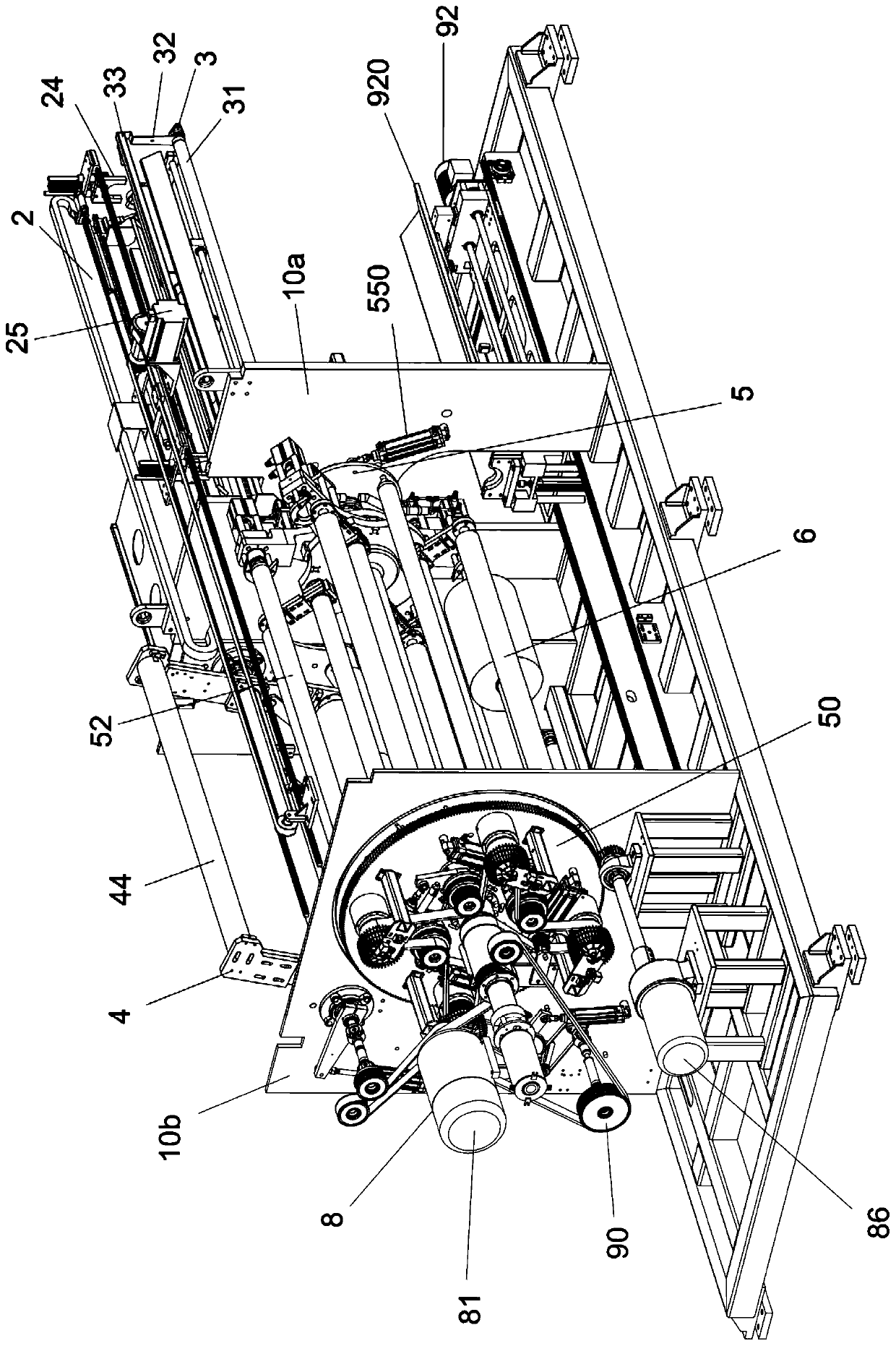

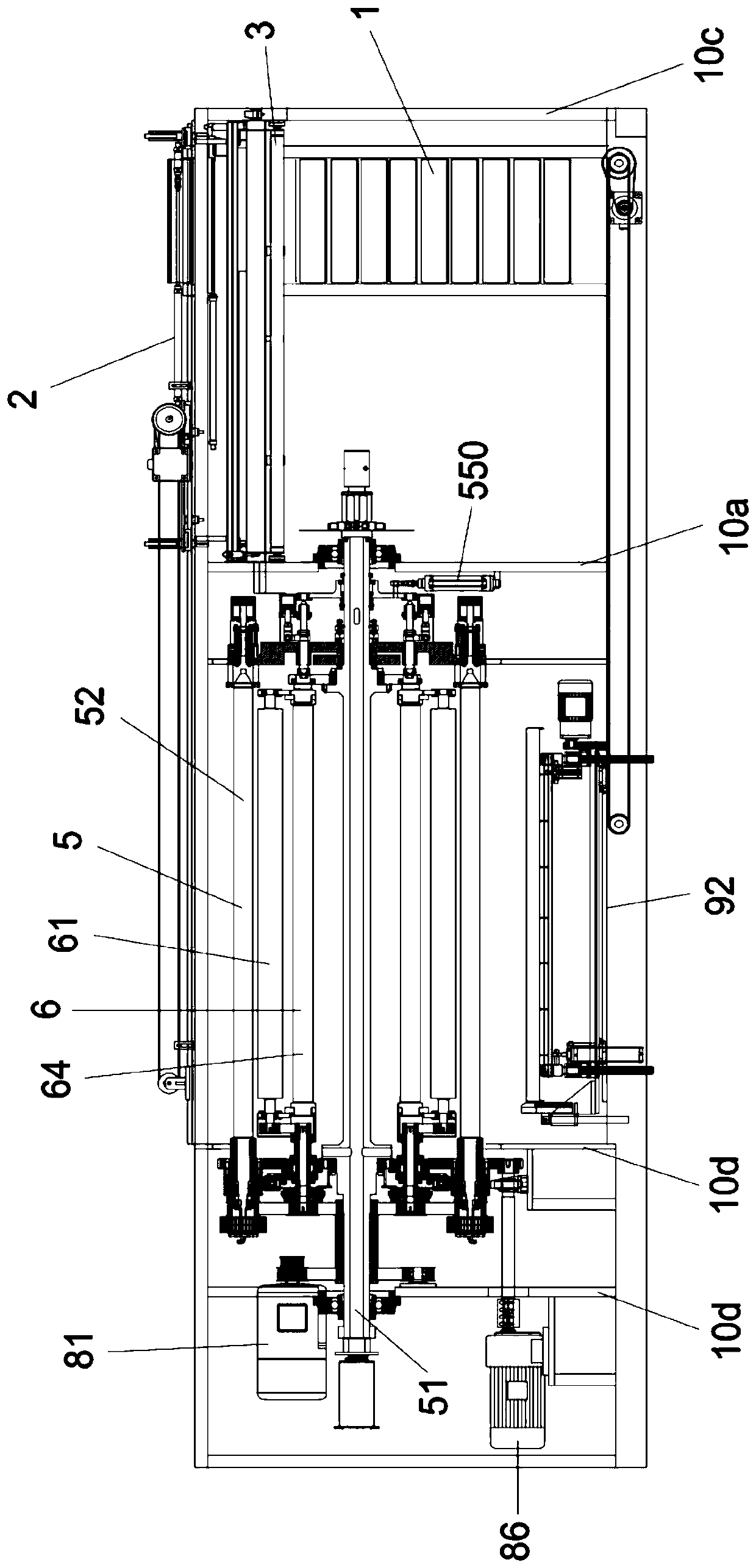

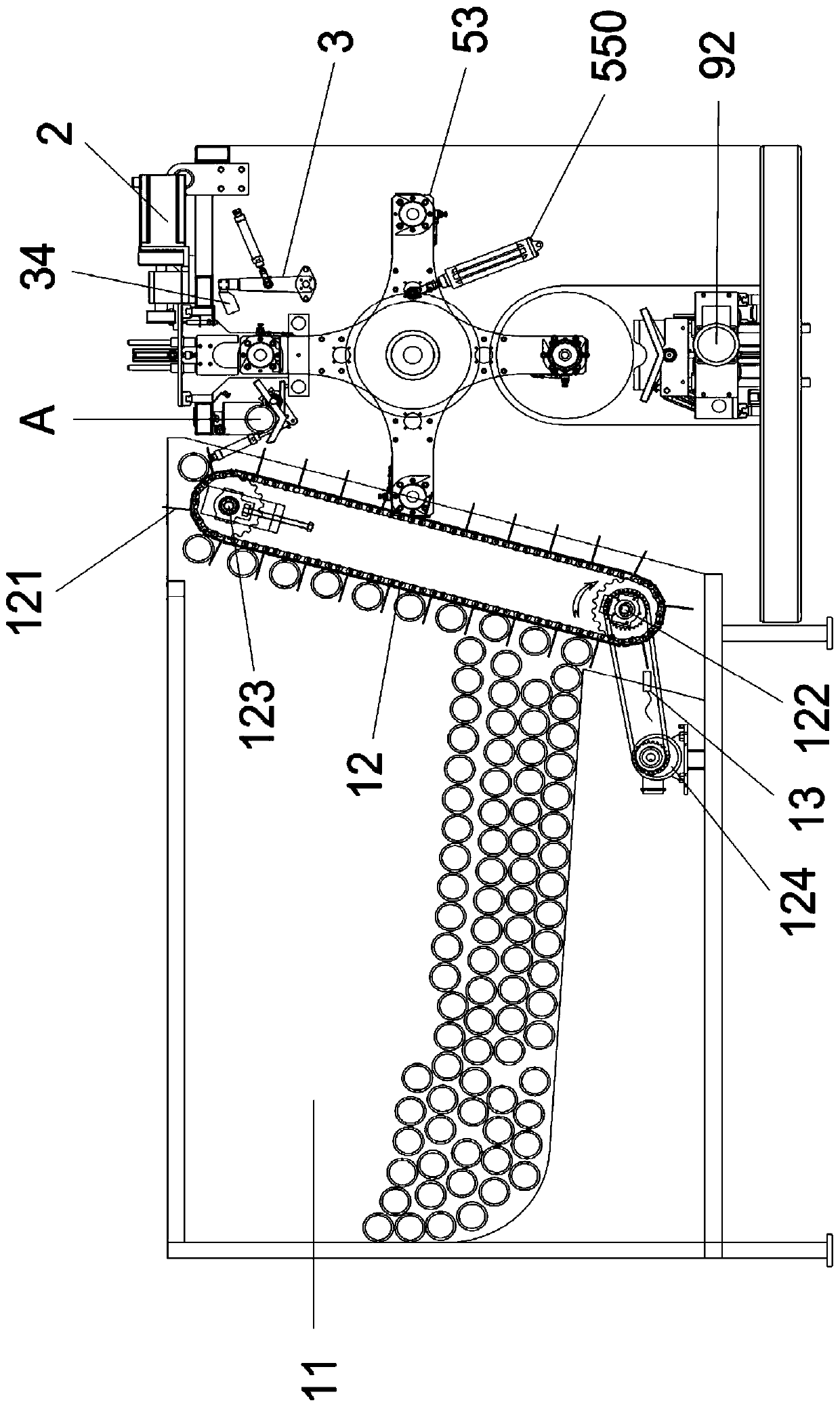

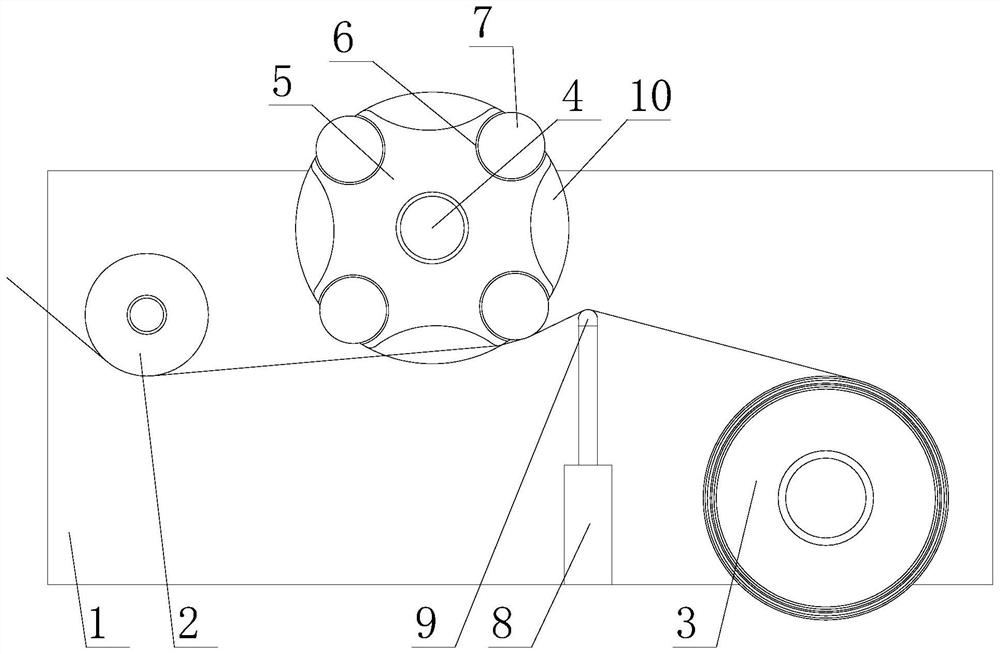

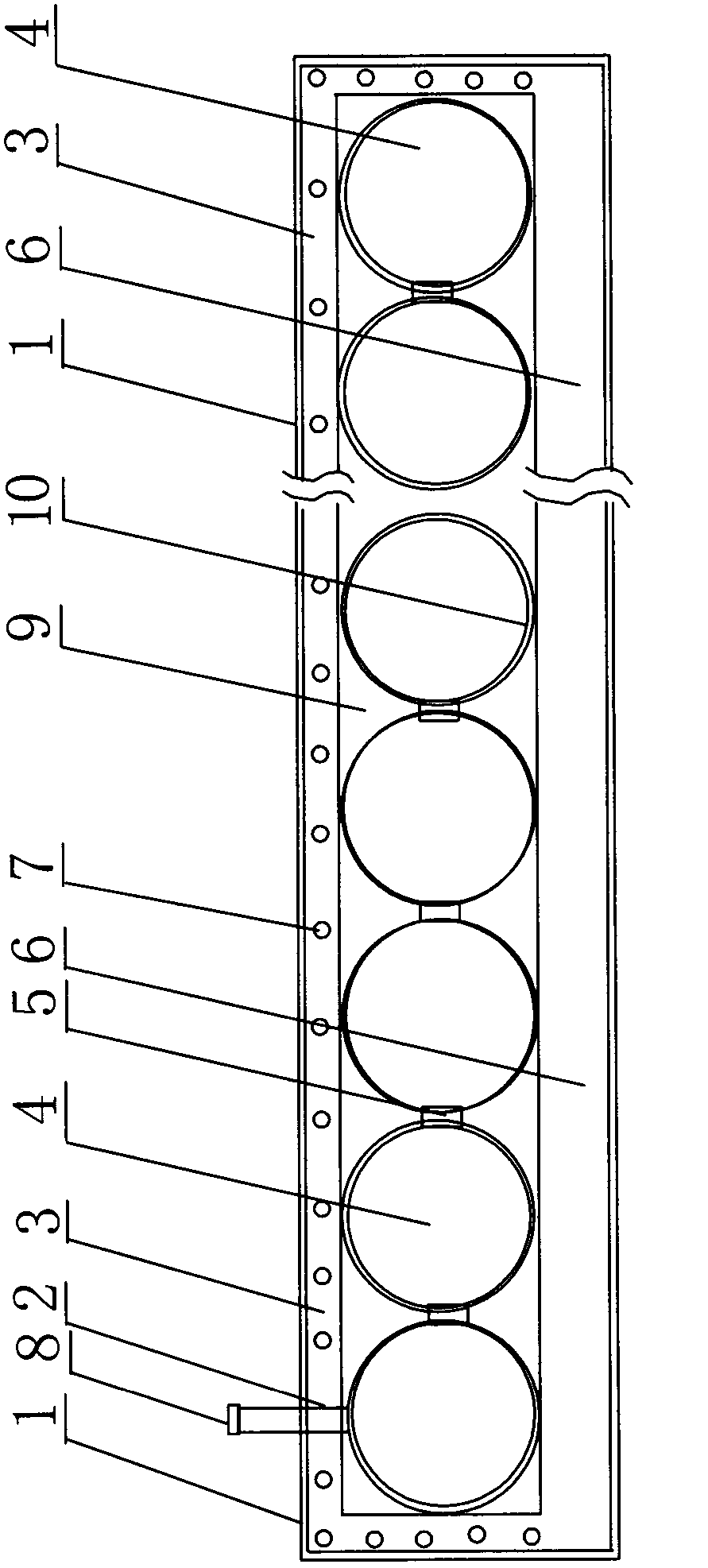

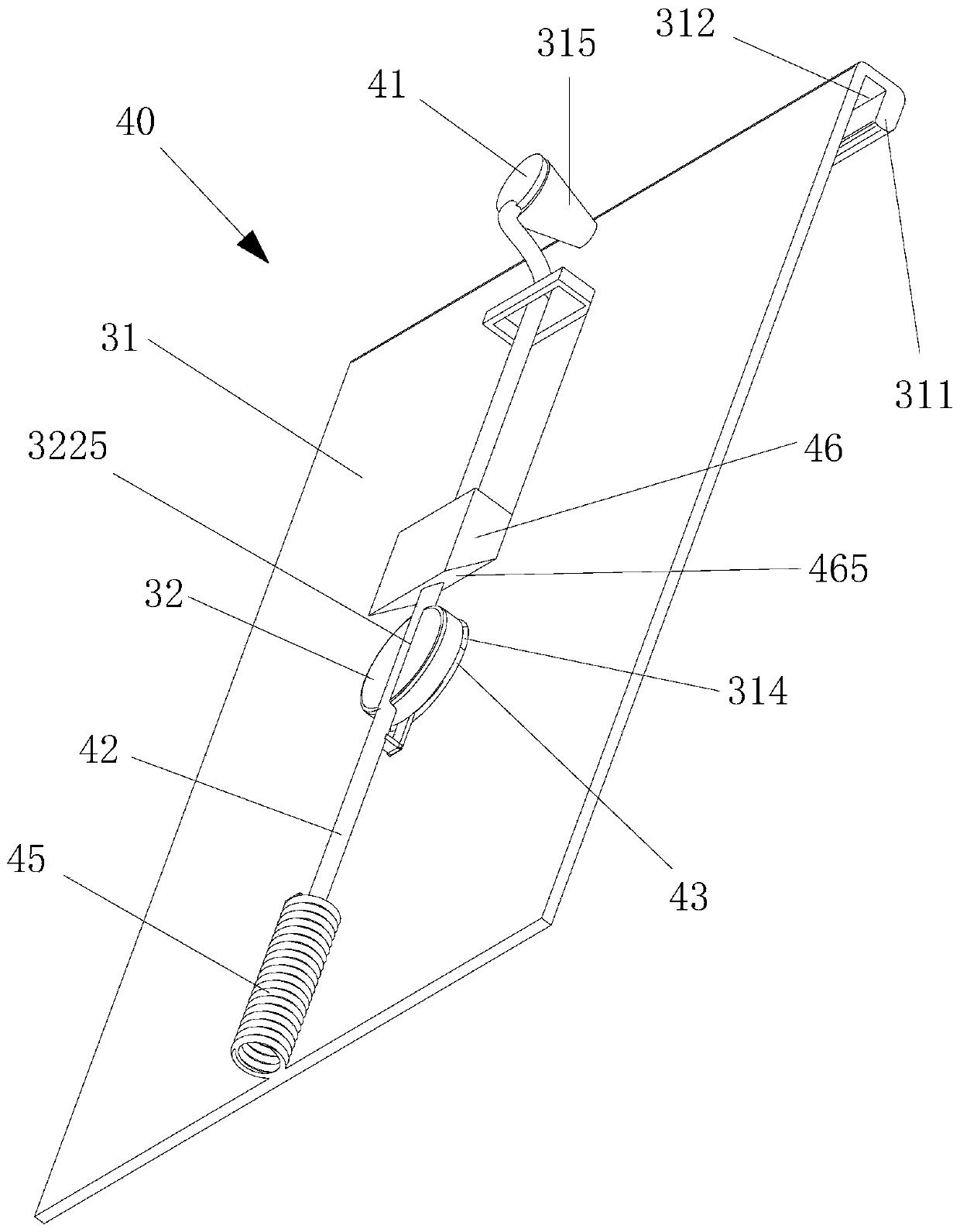

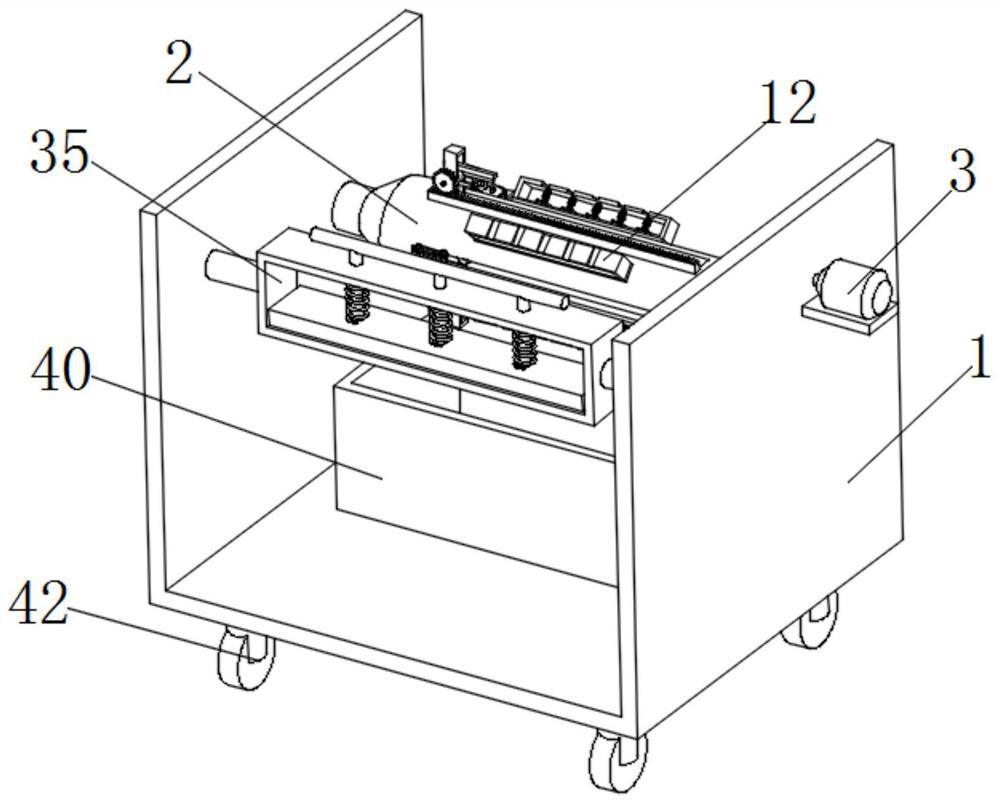

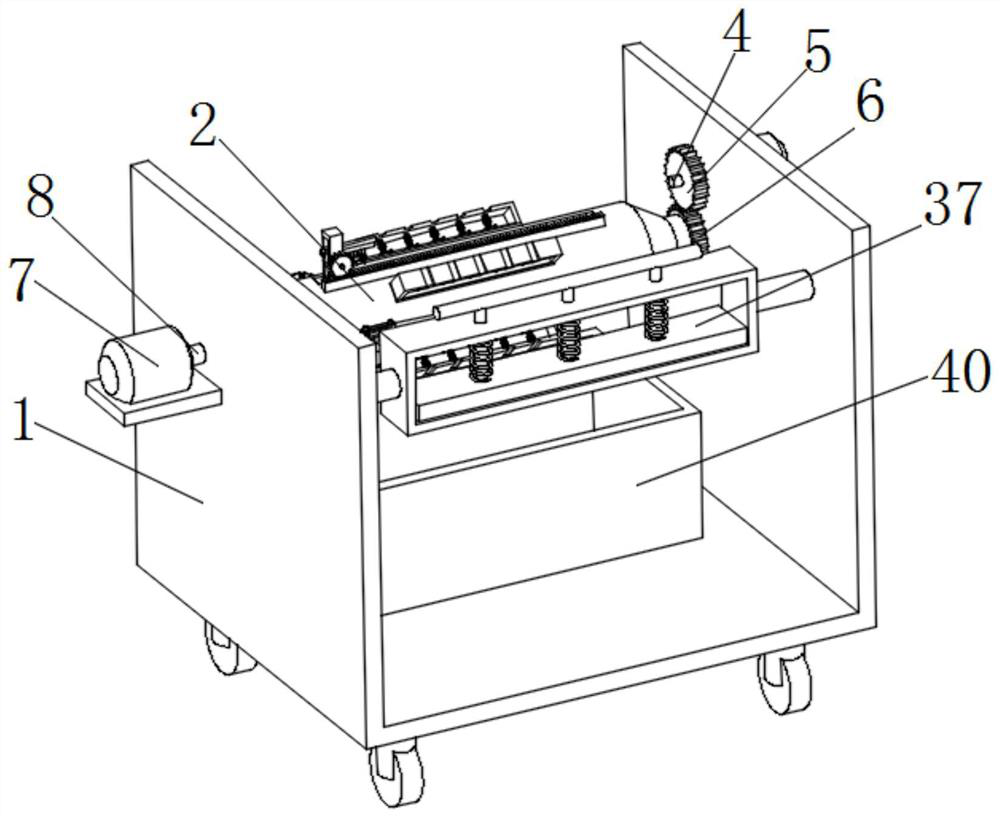

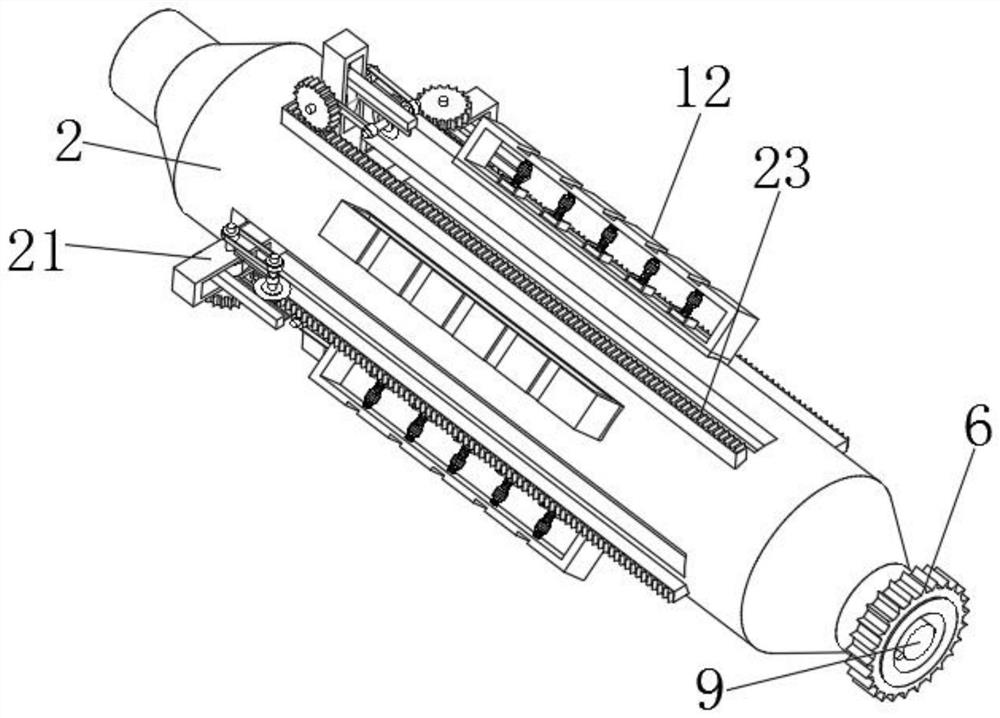

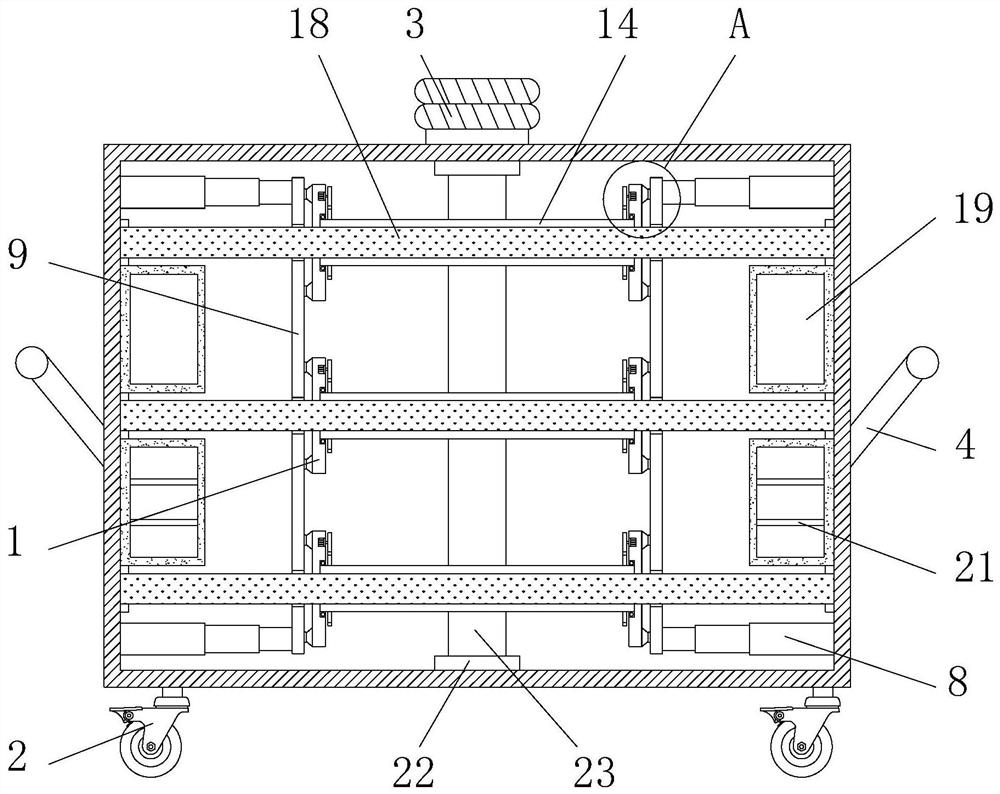

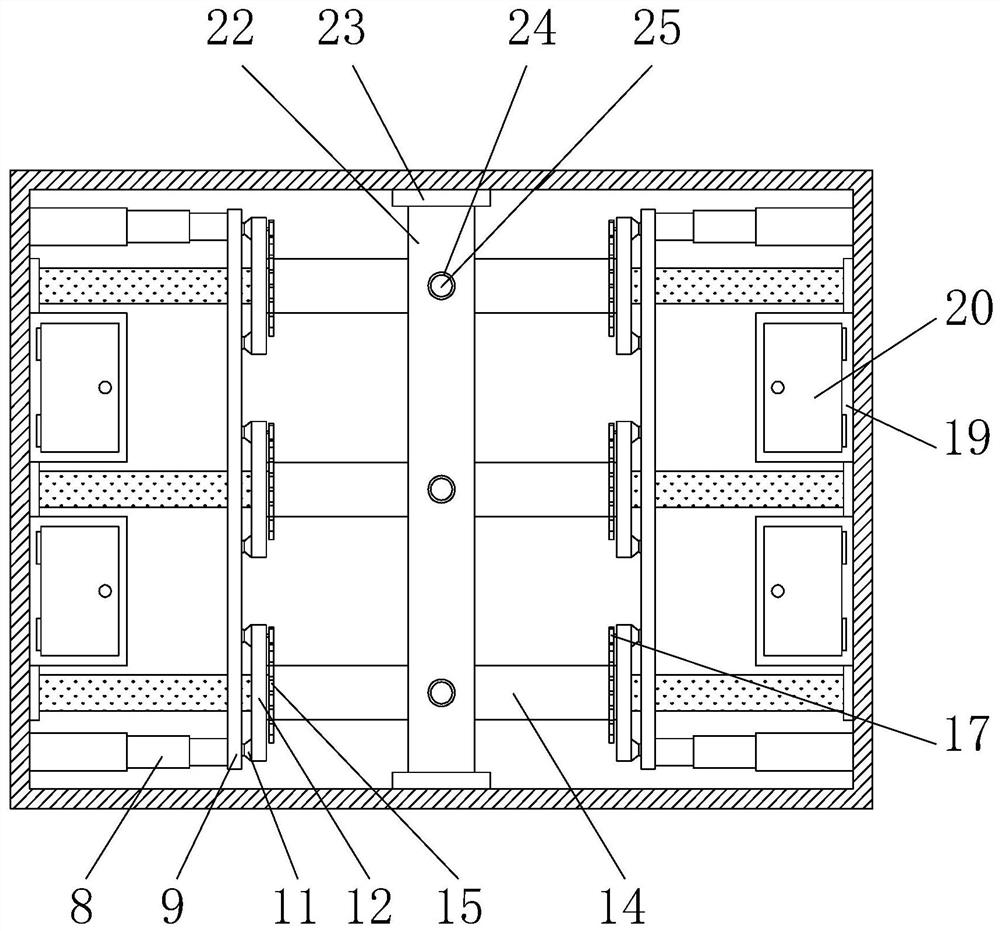

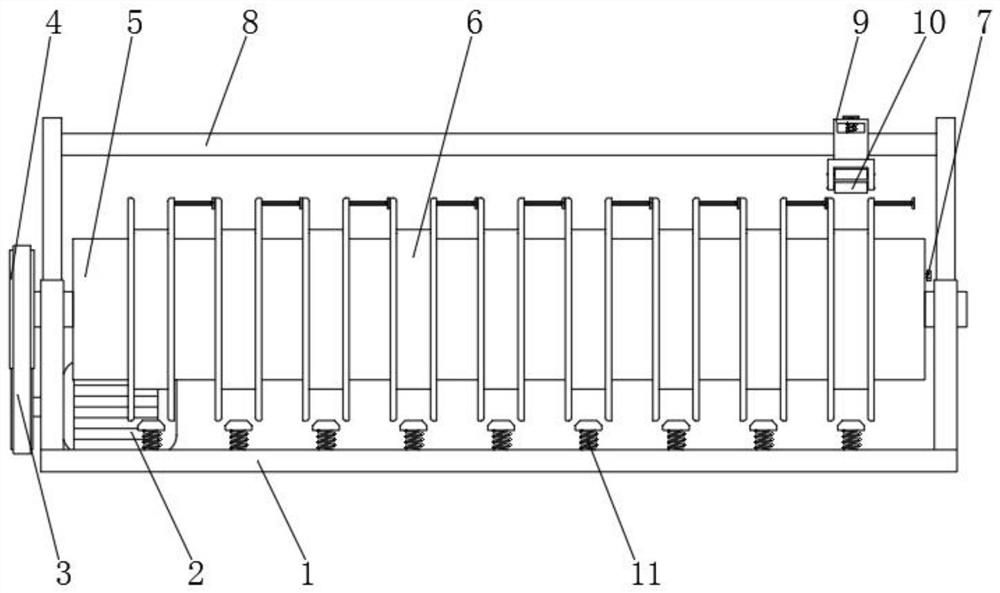

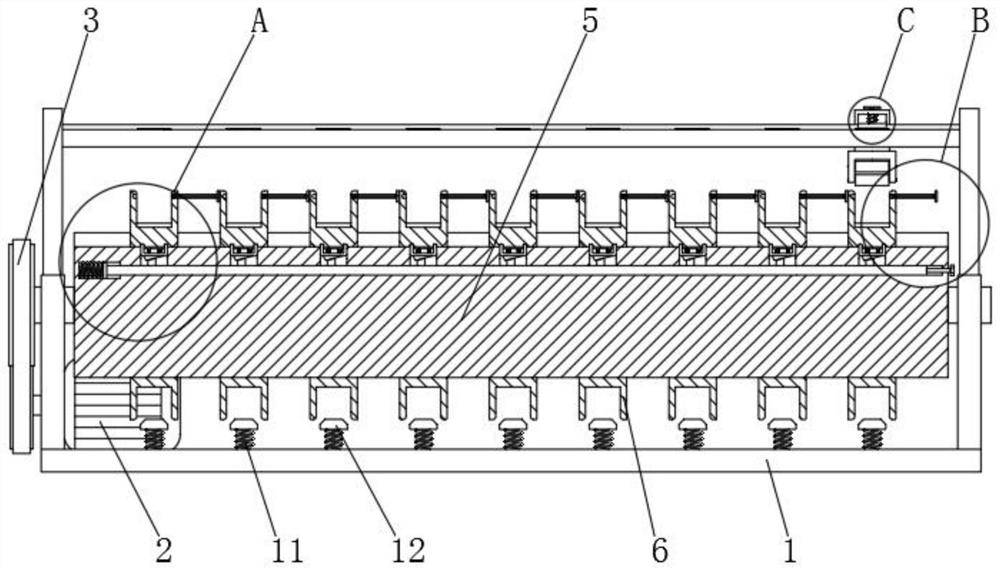

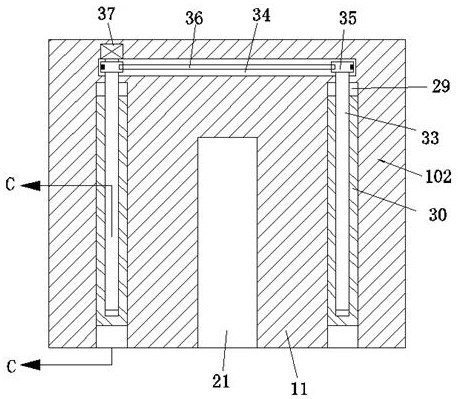

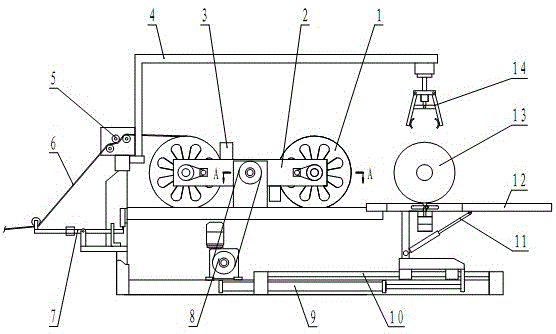

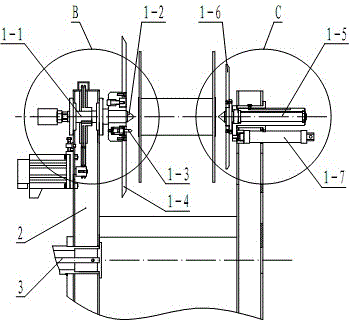

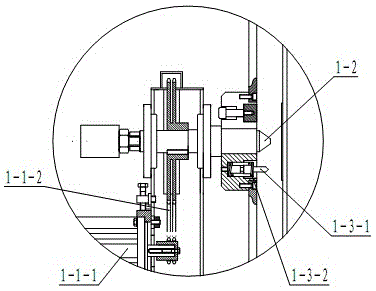

The invention provides an automatic four-axis cast film winding machine. The automatic four-axis cast film winding machine is provided with a plurality of expansion shafts, the expansion shafts at different positions can carry out tube sleeving, cast film winding, roll moving-out and standing for cooling down correspondingly, the expansion shafts are driven by a motor to change positions to realize function switching of the plurality of expansion shafts, so that not only the tube sleeving, cast film winding and roll moving-out processes of the expansion shafts can be separated to be independent to save the cast film winding time, but also the expansion shafts can be left to stand for cooling down after working so as to prolong the service lives of the expansion shafts and an expansion shaft installation assembly; and in the meanwhile, a paper tube conveying assembly and a paper tube sleeving assembly are independent from an expansion shaft winding structure, so that paper tubes can bearranged and subjected to tube sleeving while cast films are wound around the expansion shafts, and the winding working time is shortened. A defective product returning assembly of the winding machinecan move damaged paper tubes which cannot sleeve the expansion shafts out of the internal structure of a winding machine body, so that the internal structure of the machine body is stabilized and thestability and safety of the cast film winding process are ensured.

Owner:CHANGLONGXING SCI & TECH SHENZHEN CO LTD

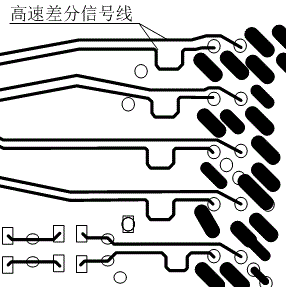

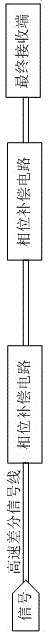

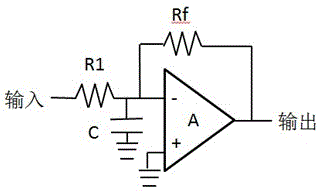

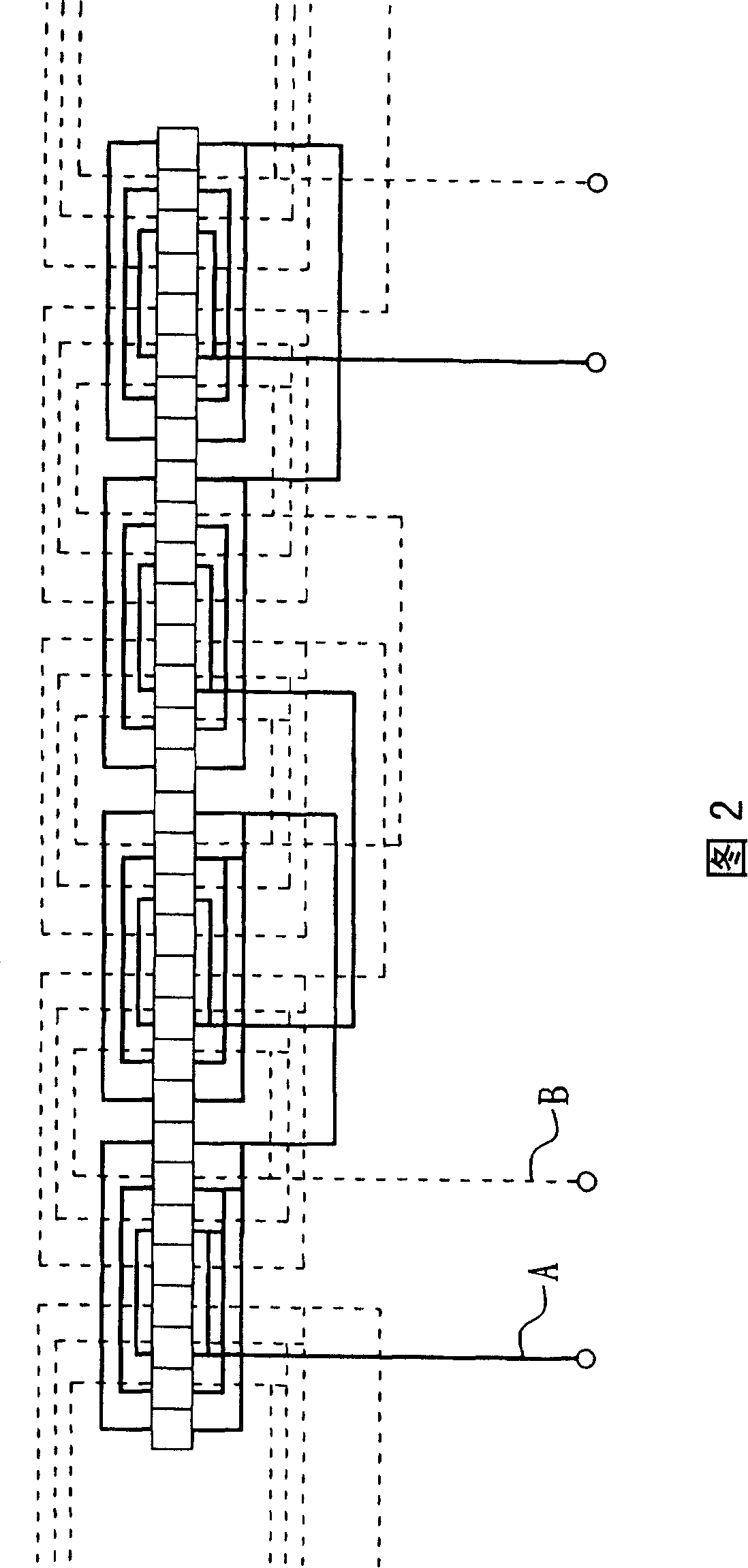

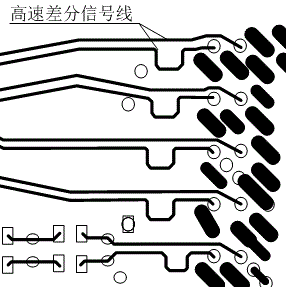

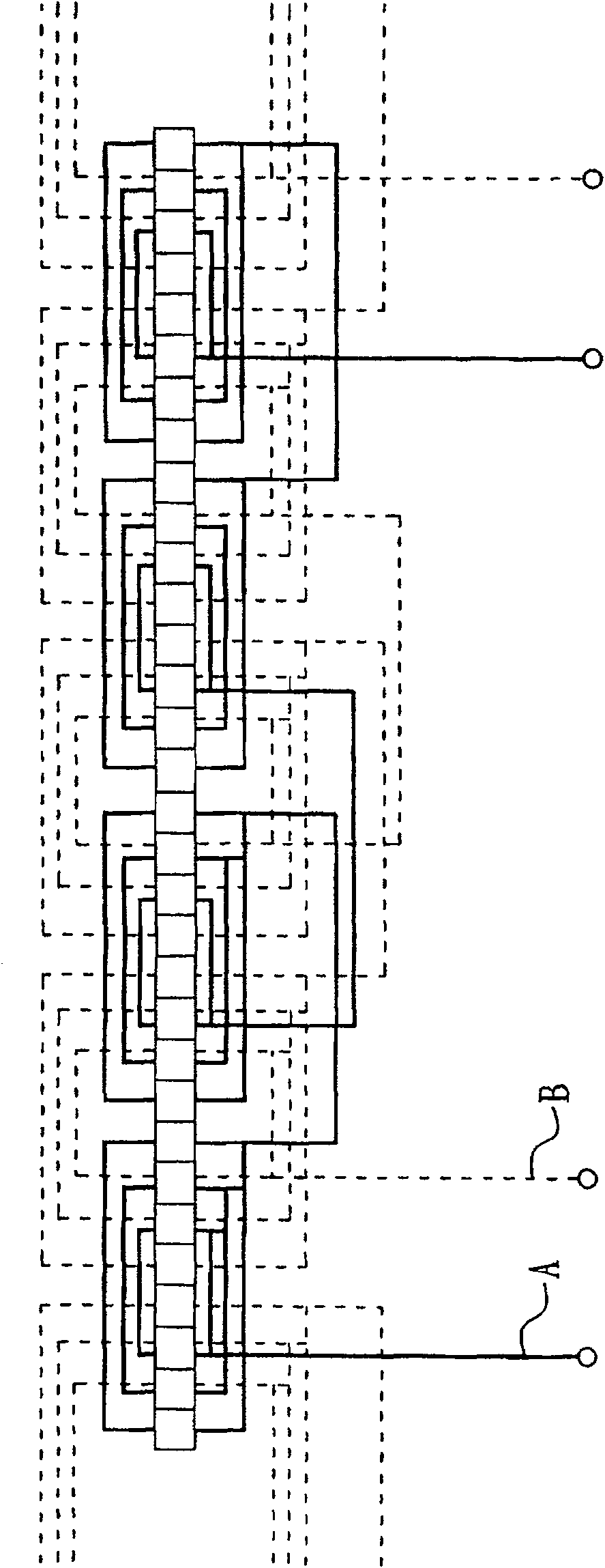

High-speed differential signal line equal length matching design method

InactiveCN105045960ASave winding timeReduce the accumulation of common mode noiseSpecial data processing applicationsSignal onConductor Coil

The present invention particularly relates to a high-speed differential signal line equal length matching design method. According to the high-speed differential signal line equal length matching design method, for high-speed differential signal lines resulting from layout cabling, a central region in which cabling lengths of the high-speed differential signal lines do not match is determined, and then a phase compensating circuit is connected in the central region in which cabling lengths of the high-speed differential signal lines do not match, so as to enable phases of signals on the high-speed differential signal lines to match, thereby avoiding unnecessary winding. According to the high-speed differential signal line equal length matching design method, the phase compensating circuit is added to the central region in which cabling lengths of the high-speed differential signal lines do not match, so as to implement phase compensation, thereby significantly reducing accumulation of common mode noise caused by a phase error of unnecessary equal length winding, saving cable layout space, greatly decreasing winding time of a designer, improving research and development efficiency, lowering time of product design and development and shortening the research and development period.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

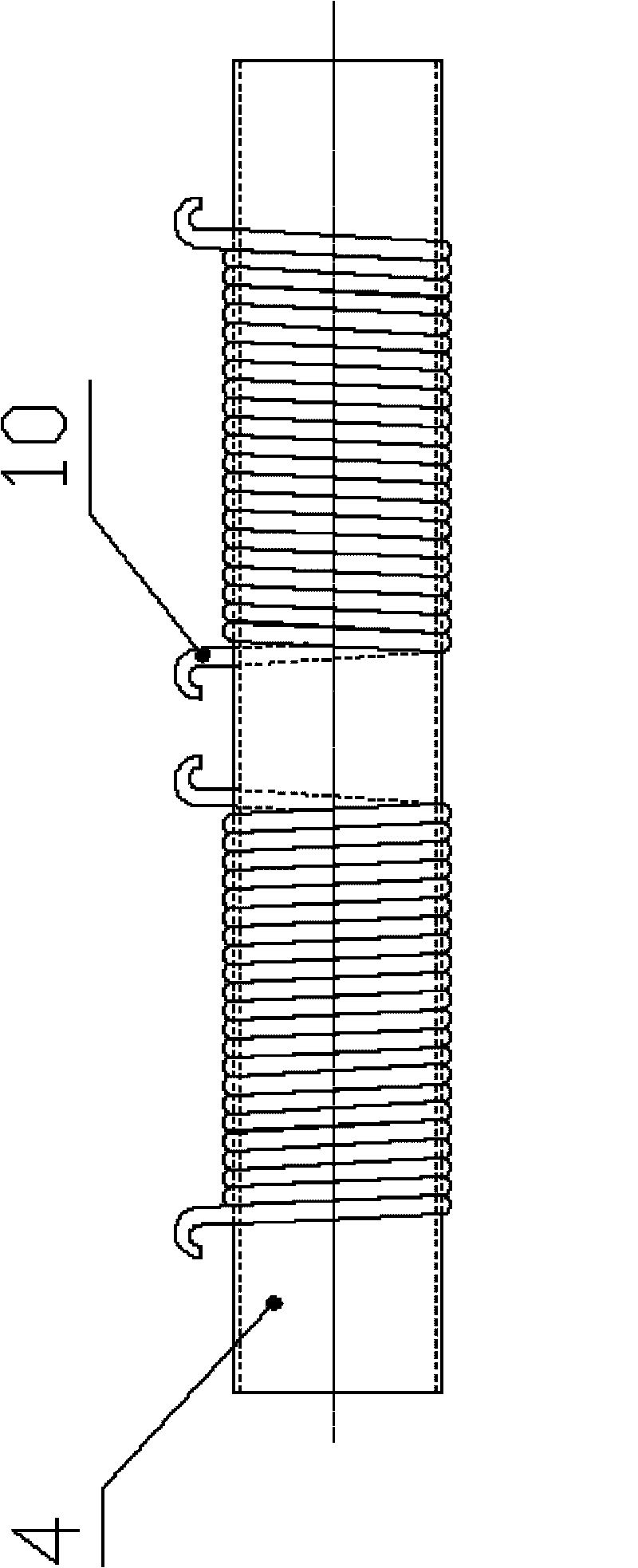

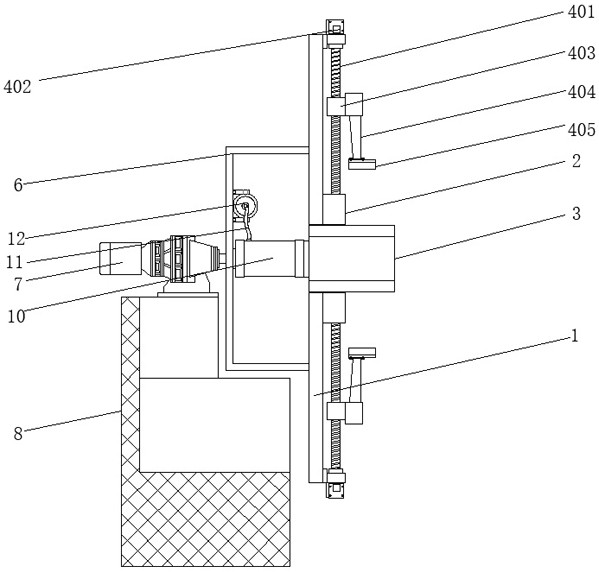

Device for winding coil by rectangular conducting wire

InactiveCN101702373AAxially arranged tightly and neatlyReduce labor intensityCoils manufactureWinding machineEngineering

The invention discloses a device for winding a coil by a rectangular conducting wire, which can enhance the winding quality of the rectangular conducting wire. The device for winding the coil by the rectangular conducting wire comprises a wire coil disk, a wire pressing device and a horizontal type wire winding machine which are sequentially arranged, wherein a coil framework is arranged on the horizontal type wire winding machine, and a positioning device which can penetrate and sleeve the rectangular conducting wire and enable the narrow side of the section of the rectangular conducting wire to be in a horizontal state is arranged between the wire pressing device and the horizontal type wire winding machine. The device has simple structure, very low cost and very convenient turning, lightens the labor strength of operators, reduces the number of the operators, lowers the winding difficulty, also shortens the winding time, ensures the tight and tidy axial arrangement and the tight radial winding of the coil after the winding is completed, ensures the winding quality and is especially suitable for popularization and use on a winding device which needs to wind the narrow side of the section of a conducting wire onto a coil framework; in addition, the rectangular conducting wire only needs to penetrate through the positioning device.

Owner:攀枝花钢城集团瑞泰电器有限公司

Rapid take-up device of fire hose

Owner:天津鑫源建设发展有限公司

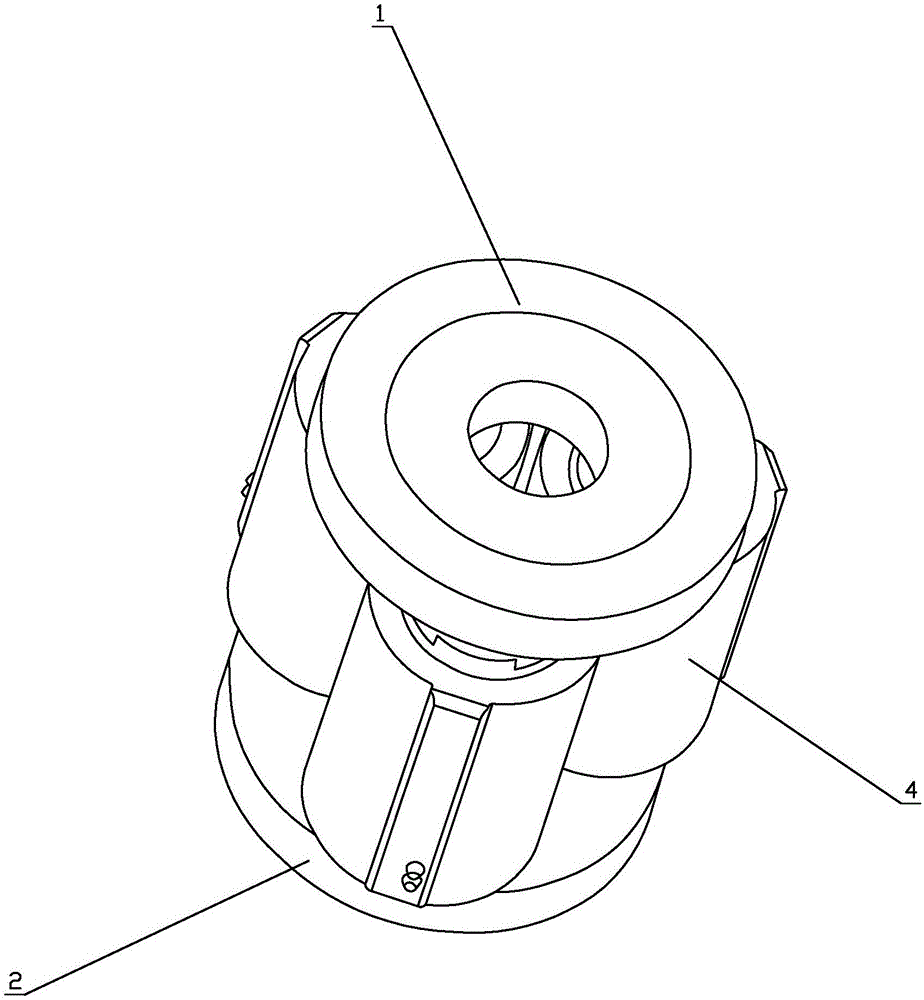

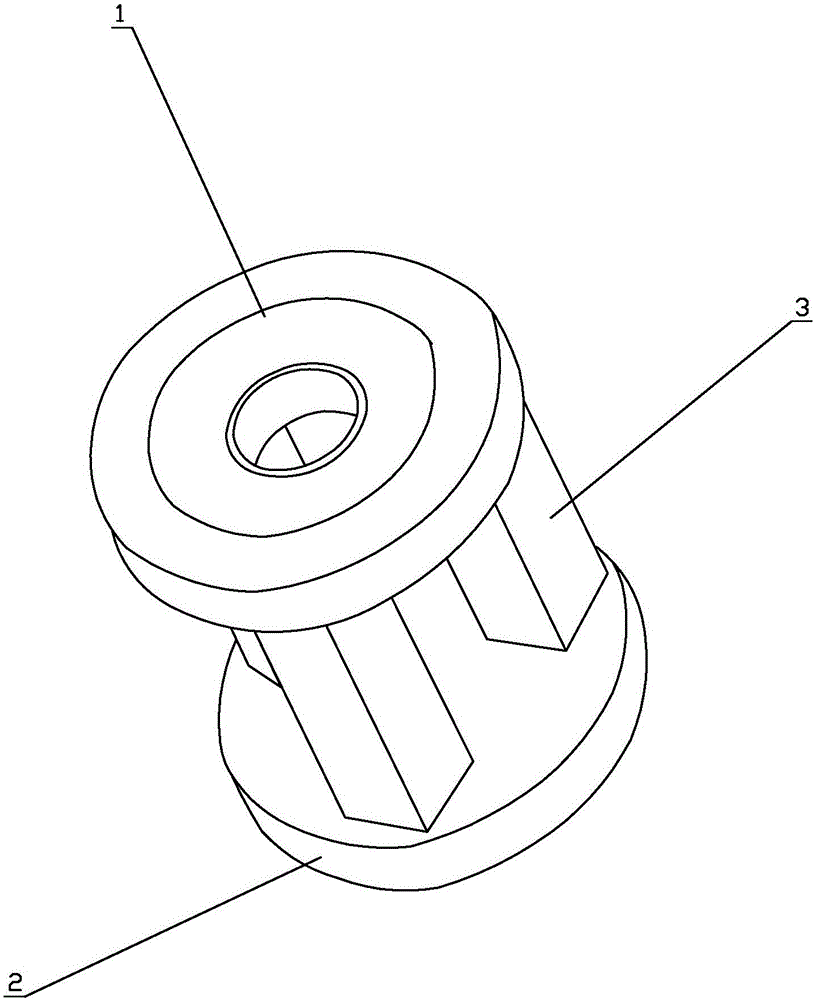

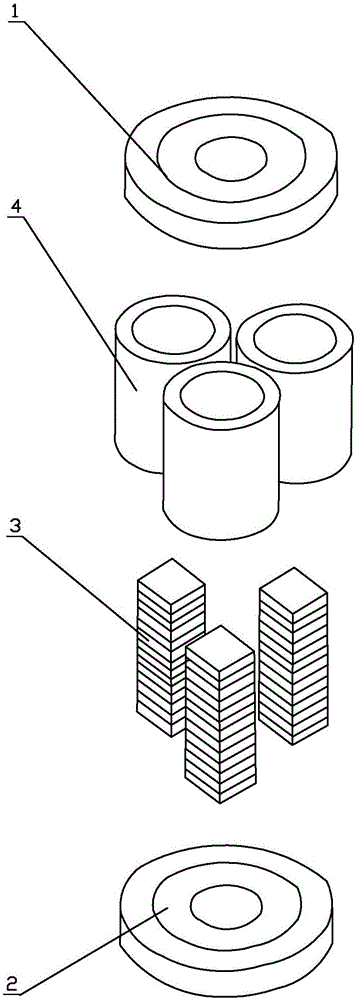

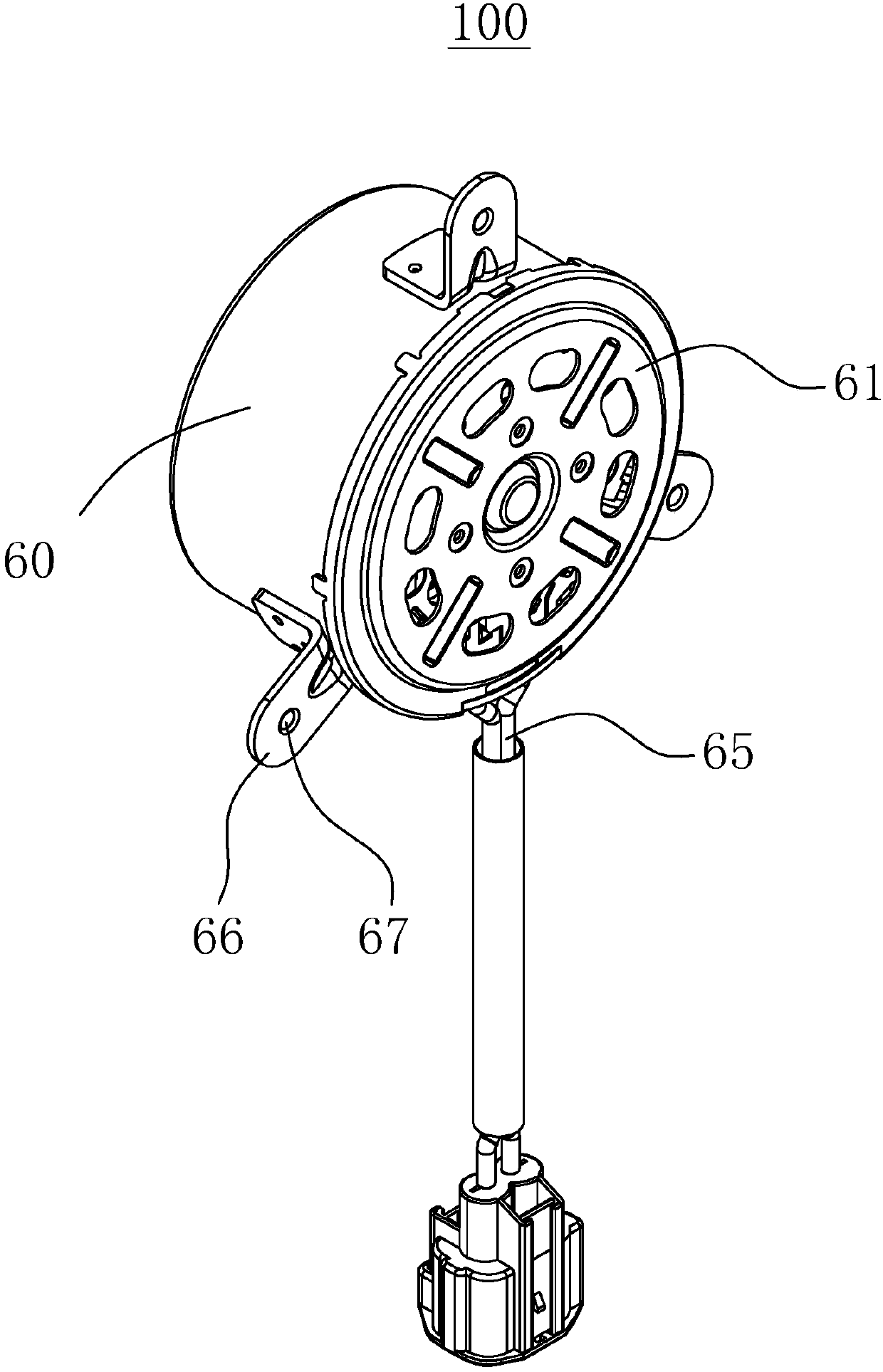

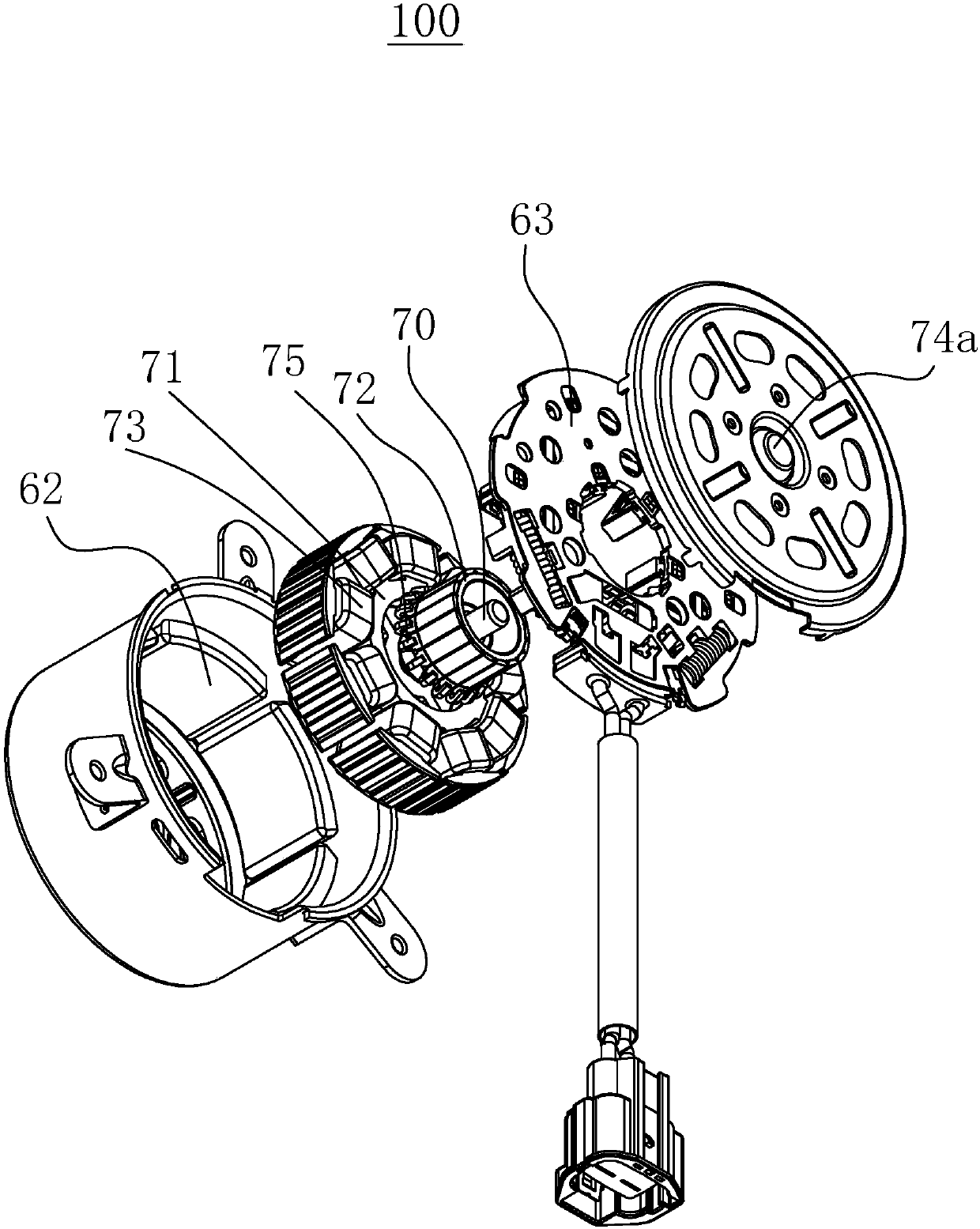

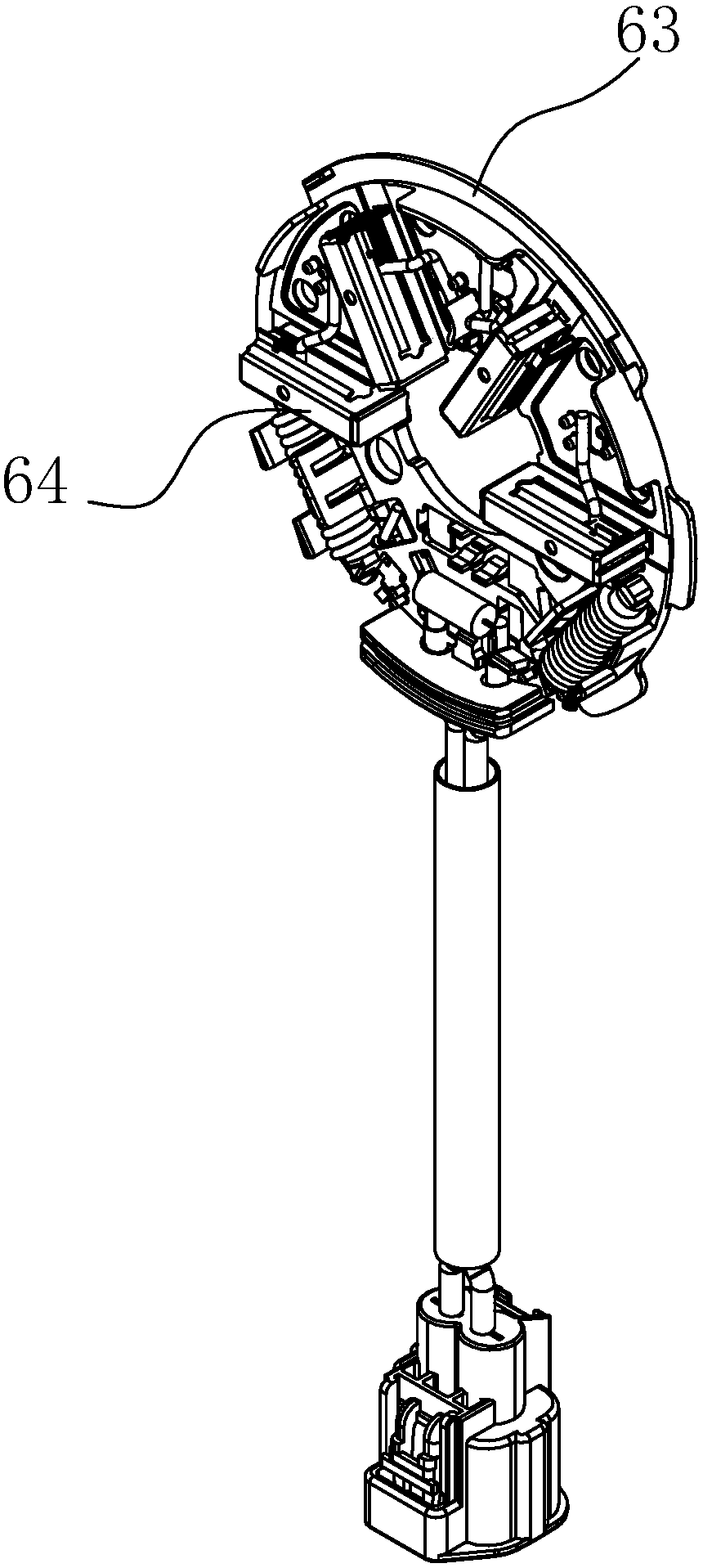

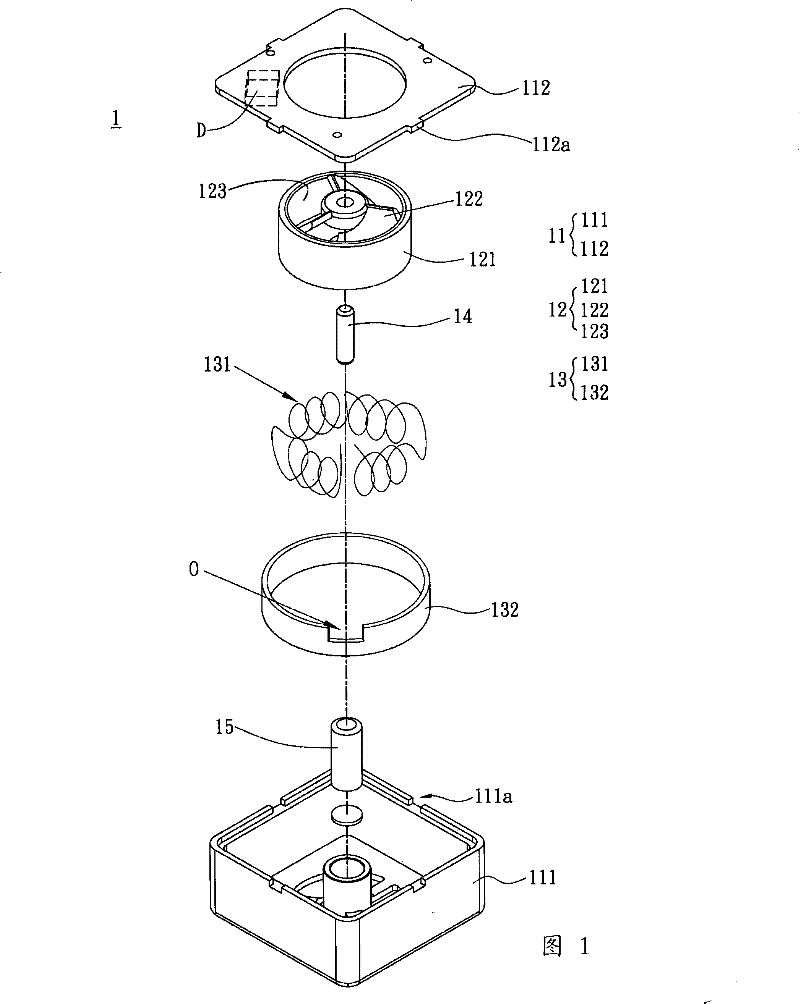

Fan and motor

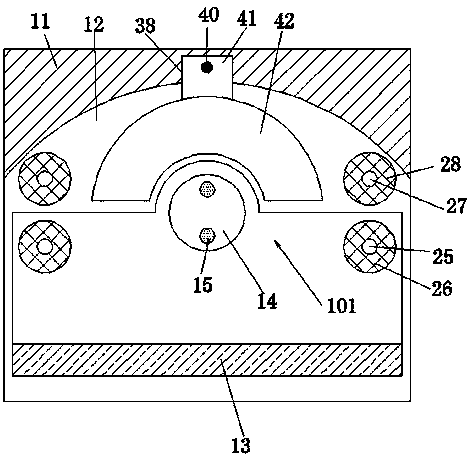

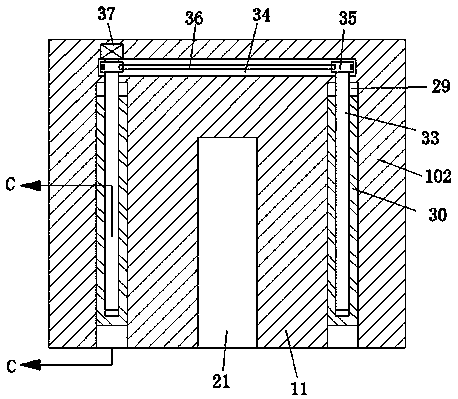

InactiveCN103107648AReduce manufacturing costIncrease the setting areaMechanical energy handlingPump installationsRotor magnetsMagnetic poles

The invention discloses a motor which comprises a rotor magnet ring, a stator iron core, a first silicon steel sheet, and a second silicon steel sheet. The stator iron core is arranged outside the rotor magnet ring. The first silicon steel sheet is ring-shaped, arranged on an upper side of the stator iron core and provided with at least one first magnetic pole. The second silicon steel sheet is ring-shaped, arranged on a lower side of the stator iron core and provided with at least one second magnetic pole. The first magnetic pole and the second magnetic pole are arranged in the projection direction in a staggered mode. The invention further discloses a fan with the motor.

Owner:DELTA ELECTRONICS INC

Motor

ActiveCN101192763AWinding method is simpleSave winding timeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineConductor Coil

The invention relates to a motor, in particular to a two-stator convolved in a radial winding way. The two-stator is staggered from a special angle of the motor and forms a specific structure through coaxial arrangement with rotors, so that stator loops can be convolved with relatively a small amount of materials and a simple winding way, and the purpose of saving winding time and material is achieved.

Owner:TECO ELECTRIC AND MACHINERY

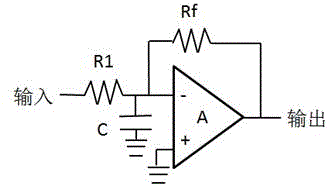

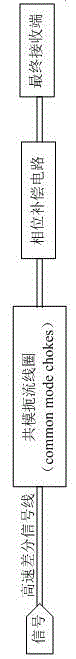

High-speed internet terminal matching design method

InactiveCN104978298ASave winding timeReduce equal length windingElectric digital data processingPhase compensationSignal lines

The invention particularly relates to a high-speed internet terminal matching design method. According to the high-speed internet terminal matching design method, the final receiving end of a high-speed differential signal line is connected with a common-mode choking coil and a phase compensation circuit; the high-speed differential signal line is first connected to the common-mode choking coil for inhibiting common-mode voltage, so that the common-mode voltage of the high-speed differential signal line is 0; then the high-speed differential signal line is connected to the phase compensation circuit for realizing phase compensation, so that the signal phases of the high-speed differential signal line are matched; and finally the high-speed differential signal line is connected to the final receiving end. According to the high-speed internet terminal matching design method, the common-mode choking coil is adopted for inhibiting the common-mode voltage, so that the common-mode voltage of the high-speed differential signal line is 0; the phase compensation circuit is adopted for realizing phase compensation, so that the signal phases of the high-speed differential signal line are matched; and therefore, unnecessary isometric windings are reduced, wire arrangement space is saved, the winding time of design personnel is greatly shortened, the product design and development time is shortened, and the research and development cycle is shortened.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Static electricity removing device for chemical fiber fabrics

InactiveCN111918468ASave winding timeImprove winding efficiencyElectrostatic chargesWebs handlingFiberElectric machinery

The invention provides a static electricity removing device for chemical fiber fabrics, and relates to the field of fabrics. The static electricity removing device comprises symmetrically arranged side plates, a guide cylinder and a winding cylinder, wherein an end shaft at one end of the winding cylinder is fixedly connected with a driving motor; a fixing shaft and a rotating drum rotationally connected with the fixing shaft, wherein the two ends of the fixing shaft are fixed to the side plates, and a plurality of containing grooves are formed in the side surface of the rotary drum along theaxial direction; and static electricity removing rods matched with the containing grooves. When chemical fiber fabric is wound on the winding drum, the static electricity removing rod in one containing groove makes contact with the chemical fiber fabric all the time to remove static electricity of the chemical fiber fabric, and when the static electricity removing effect of the static electricityremoving rod is reduced and the chemical fiber fabric cannot be effectively subjected to static electricity removing, the rotating drum is rapidly rotated, and the rotating direction of the rotating drum is opposite to the winding direction, and at the moment, the next new static electricity removing rod is in contact with the chemical fiber fabric, so that static electricity removing is continuously carried out on the chemical fiber fabric, the action of winding the chemical fiber fabric does not need to be stopped when the static electricity removing rod is replaced, the winding time is saved, and the winding efficiency is improved.

Owner:安徽杰达纺织科技有限公司

Heat insulating device of nitrogen charged air bag of crop greenhouse

InactiveCN102696436AHigh strengthProtect the safety of useClimate change adaptationGreenhouse cultivationEngineeringGreenhouse

The invention belongs to crop greenhouse production equipment, and in particular relates to a heat insulating device of a nitrogen charged air bag of a crop greenhouse. A mat covered on the top of a plastic crop greenhouse in the prior art, so that the defects of easiness to damage, short service life and high cost exist in the prior art. The outer surface of an outer layer (3) of the device provided by the invention is provided with a protective layer (1), an inner layer (9) is internally provided with air bags (4), and the inner layers of the air bags (4) are provided with air bag inner layer protective layers (10); a communicating pipe (5) is arranged between every two adjacent air bags (4); the upper part of the outer layer (3) is provided with an air bag charging pipe (2); the upper side, the left side and the right side of the outer layer (3) are provided with fixing rings (7); and the lower part of the outer layer (3) is provided with a bottom edge (6). The heat insulating device has the advantages of low cost, capability of saving time for rolling or unrolling the mat every day, rapidness in temperature rise and good heat insulation effect in winter, reduction of light saturation points, and light weakening, and is suitable for crop growth in summer, good in wind resistance and suitable for windy places.

Owner:安徽飞天农用生物科技有限公司 +2

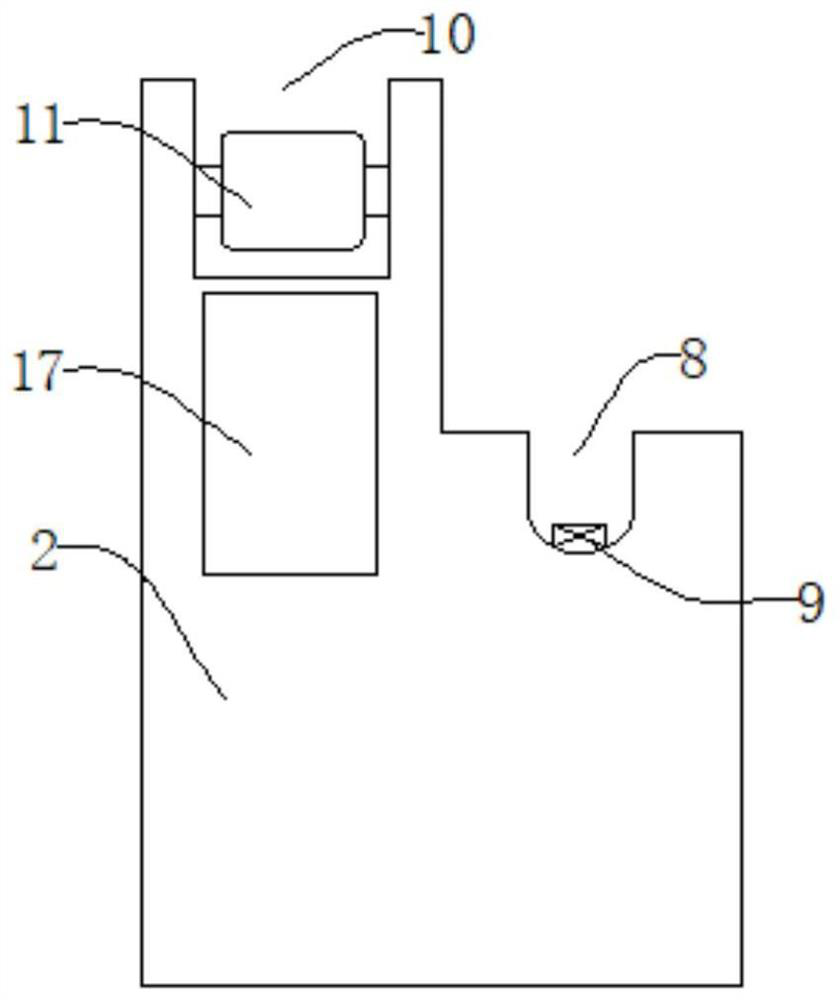

Mother and infant monitor for maternity department and application method of mother and infant monitor

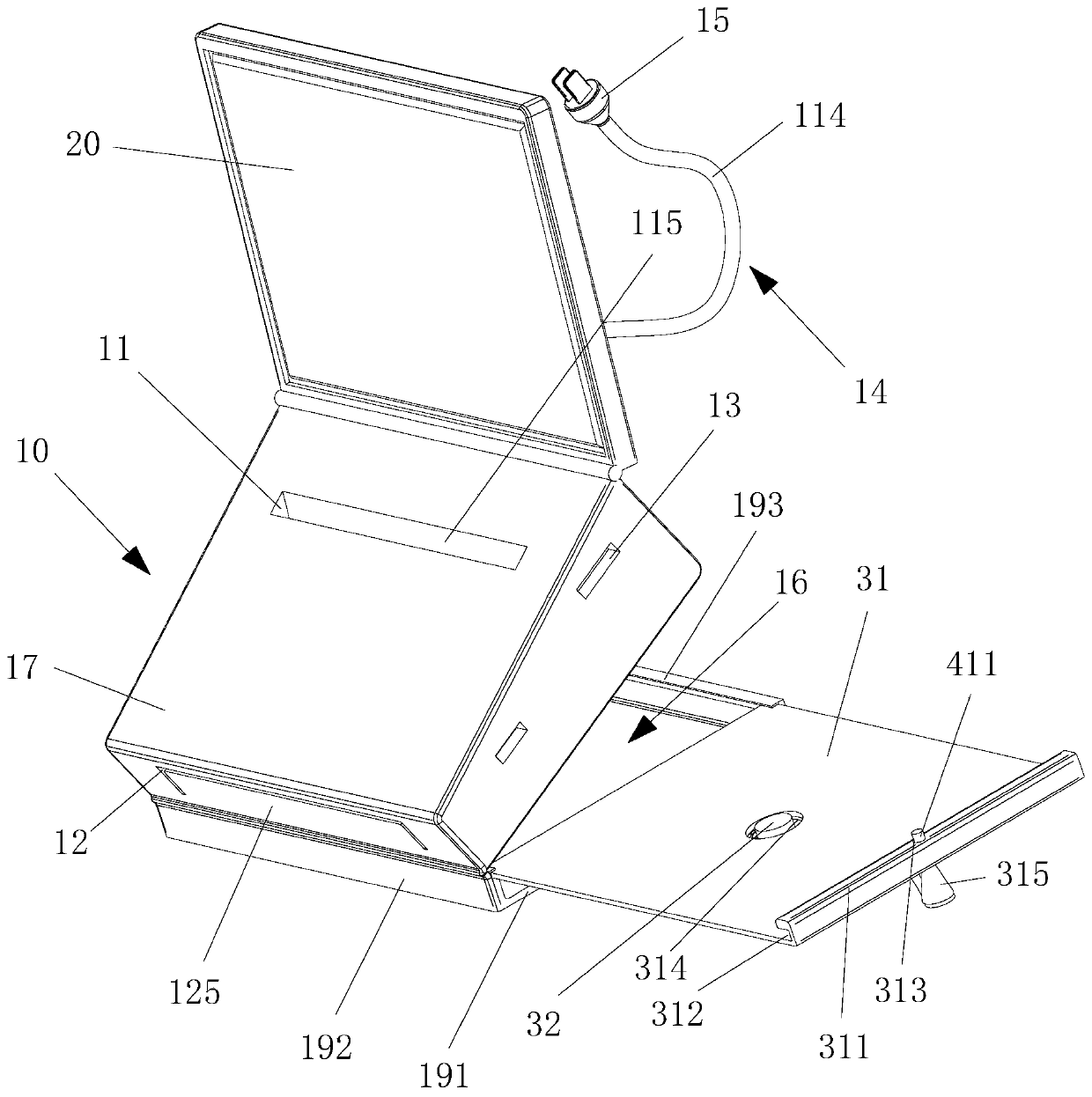

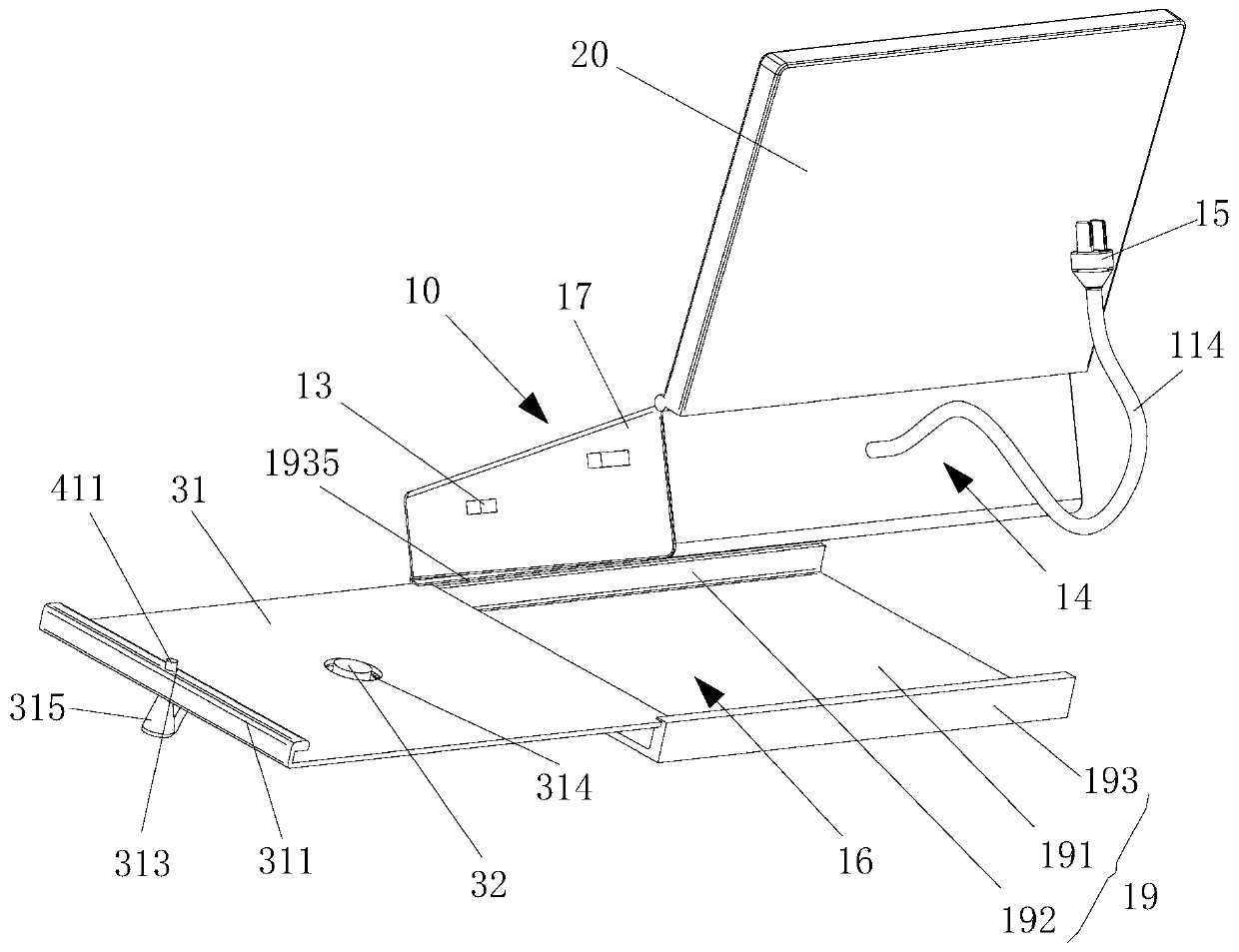

PendingCN110037802APrevent saggingSave winding timeSurgical furnitureEvaluation of blood vesselsEngineeringConductor Coil

The invention relates to a mother and infant monitor for maternity department. The mother and infant monitor for maternity department comprises a body, a display screen and a winding assembly, whereinthe display screen is rotatably arranged on one side of the body; an electrocardio monitoring module, a blood pressure monitoring module and a printing module are arranged in the body; a printing paper inlet is formed in the surface of the body; a printing paper outlet is formed in one side of the body; a USB interface is formed in one side of the body, and limb electrode clips and a measurementleather sheath are connected to the USB interface; the limb electrode clips and the measurement leather sheath are connected to the body through connecting strips; the winding assembly comprises a drawing plate and a flexible coiling piece; and the drawing plate is arranged at the bottom of the body in a sliding and inserting manner. The mother and infant monitor for maternity department disclosedby the invention is convenient to use. The invention also provides an application method of the mother and infant monitor for maternity department.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV

Efficient edge collecting machine for degradable plastic film production and degradable plastic film production process

The invention discloses an efficient edge collecting machine for degradable plastic film production, and relates to the technical field of degradable plastic film production equipment. The efficient edge collecting machine comprises a rack, wherein a winding drum is rotatably connected in the rack, a plurality of waste fixing parts which are evenly distributed are mounted on the side wall of the winding drum, mounting plates are fixedly connected to the two sides of the rack, a winding motor and a cutting motor are fixedly connected to the two mounting plates respectively, output shafts of the winding motor and the cutting motor are in driving connection with a first transmission shaft and a second transmission shaft respectively, and first rotating holes are formed in the inner walls of the two sides of the rack. According to the edge collecting machine, the waste fixing parts are used for fixing edge materials, the winding motor drives the winding drum to rotate to make the waste materials wound on fixing frames, and winding grooves can make the wound waste materials more orderly. Through the arrangement of the multiple waste fixing parts, the edge collecting machine can wind the multiple waste edge materials at the same time, so that the winding speed is increased, and the winding time is saved.

Owner:吴孟龙

Winding method of double coils of motor

InactiveCN102315731AClosely arrangedGuaranteed Radial WindingManufacturing dynamo-electric machinesDrive motorEngineering

A winding method of double coils of a motor is disclosed. The method relates to the motor coil and specifically relates to a winding technology field of the direct-driven-motor double coils. In the invention, firstly, a first group of coils is wound around a double layer winding frame; and then through a positioning commutation wheel, a second group of coils is wound around the double layer winding frame. In the invention, double coil winding can be achieved on the same double layer winding frame. The method is easy to be realized. Production efficiency can be effectively raised and precision of the coil winding can be raised. A resistor balance degree can be increased. A high temperature at which the coils can be damaged during a welding process can not appear so that reliability of a wind driven generator can be ensured.

Owner:江苏宝杰隆电磁线有限公司

Energy-saving type transformer and manufacturing method thereof

InactiveCN106298178AOptimized magnetic circuitReduce manufacturing costTransformers/inductances noise dampingTransformers/inductances magnetic coresChinese charactersTransformer

The invention provides an energy-saving type transformer and a manufacturing method thereof. The energy-saving type transformer comprises an iron core. The iron core is mainly composed of an upper iron yoke, a lower iron yoke and core columns. The energy-saving type transformer is characterized in that the three core columns are arranged and located between the upper iron yoke and the lower iron yoke; the three core columns are arranged in a shape like a Chinese character 'pin'; the intervals between the three core columns are equal. Seams are filled with high-permeability materials, a magnetic circuit is improved, and no-load losses and no-load currents of the iron core are reduced. The transformer formed by directly sewing the rolled core is treated through a seam special process, compared with a traditional linear laminated core transformer, materials can be saved, production efficiency can be improved, and the production cost can be reduced; due to the fact that the magnetic circuit can be improved through the iron core columns, noise is also relieved and obviously reduced while the no-load losses and the no-load currents are small. A transformer coil can be independently wound and then installed on the iron core, and production efficiency is improved. The economical energy-saving type transformer core is provided for the transformer industry.

Owner:顺特电气设备有限公司

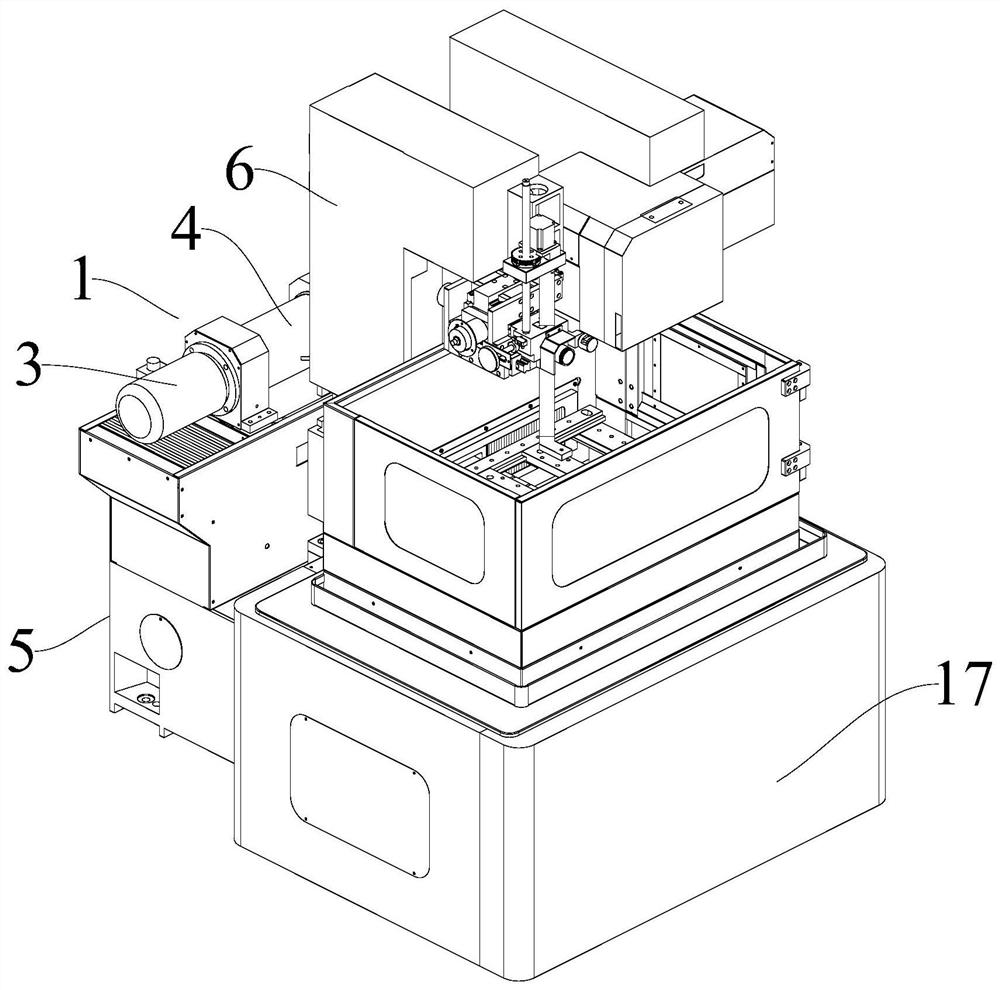

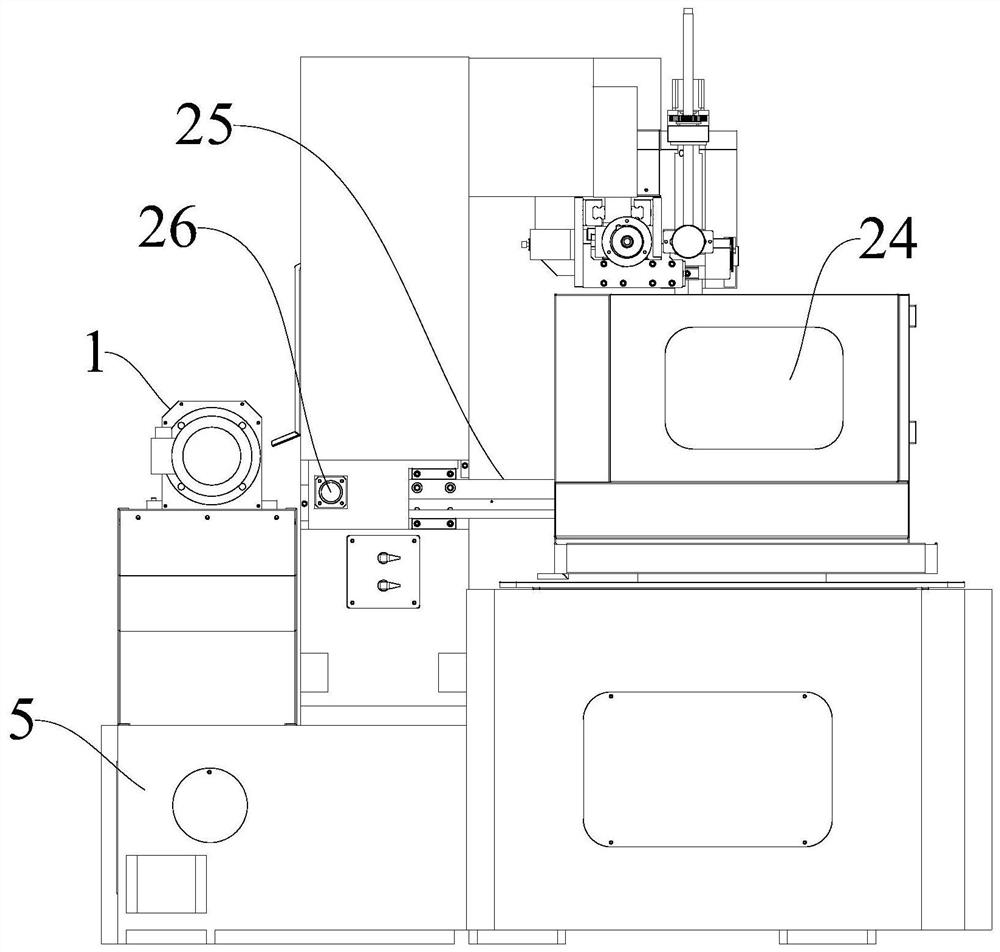

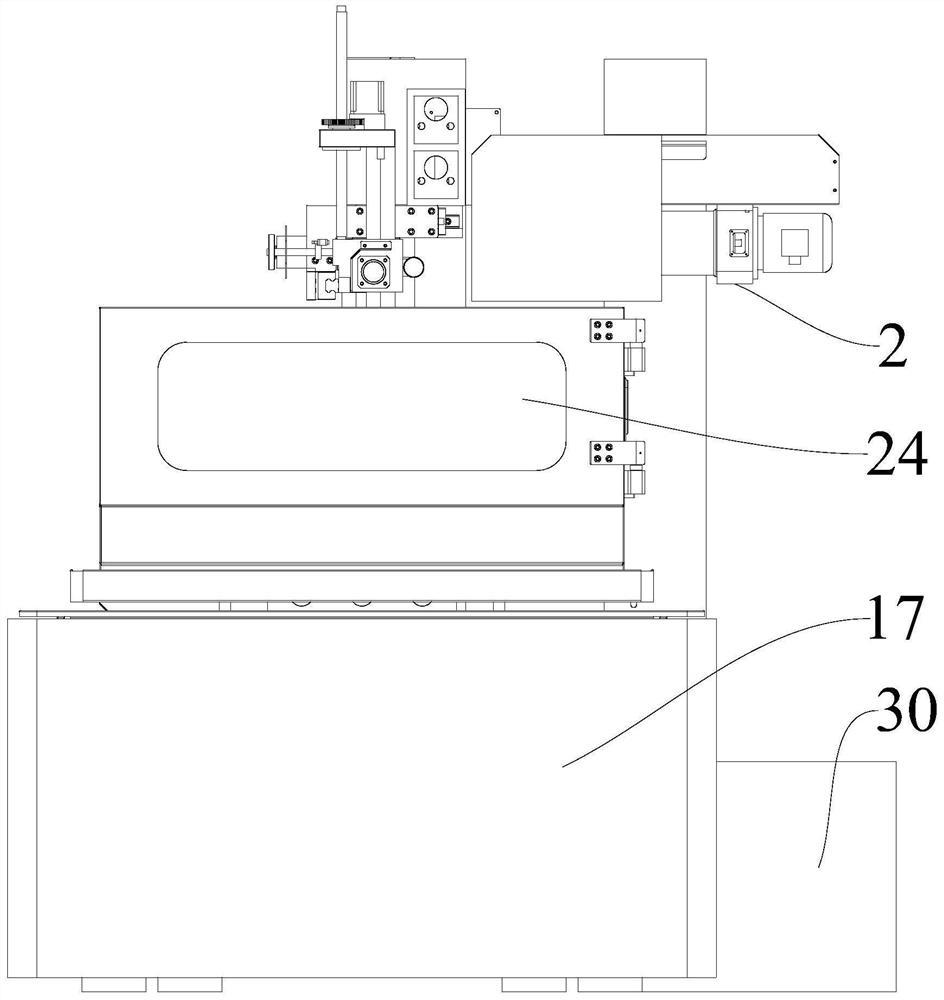

Medium-speed wire cutting machine capable of fast threading

PendingCN113070538ASave winding timeIncrease productivityElectrical-based machining electrodesWire cuttingMachine

The invention provides a medium-speed wire cutting machine capable of fast threading, and relates to the field of wire cutting machines. The machine comprises a machine body and a cutting wire; a first winding device is arranged on the rear side of the machine body; a second winding device is arranged on the front side of the machine body; one end of the cutting wire is connected with the first winding device, and the other end of the cutting wire is connected with the second winding device; and the machine body is further provided with a winding assembly used for transmission of the cutting wire. The first winding device is arranged on the rear side of the medium-speed wire cutting machine, the second winding device is arranged on the front side of the cutting piece, one end of the electrode wire is wound around the first winding device, the other end of the electrode wire is wound around the second winding device, and an operator enables the cutting wire to penetrate through a workpiece and then can directly wind around the second winding device, so that the winding time is shortened, and the production efficiency is improved.

Owner:王朝林

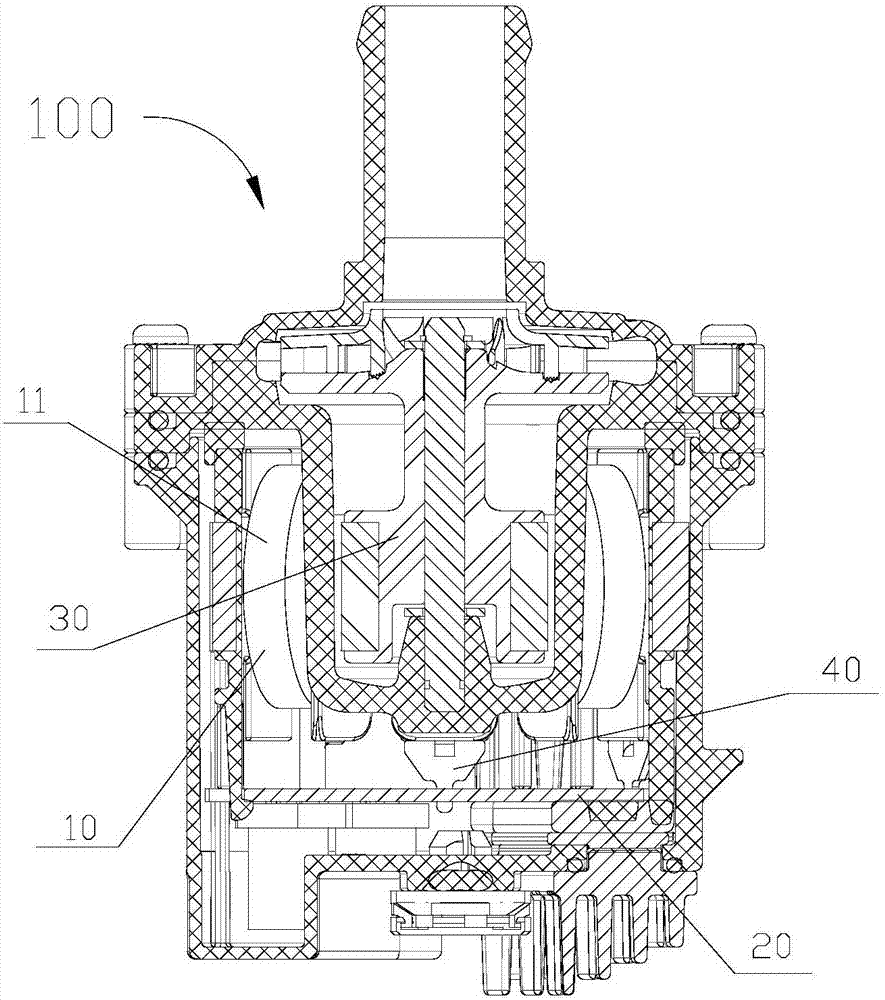

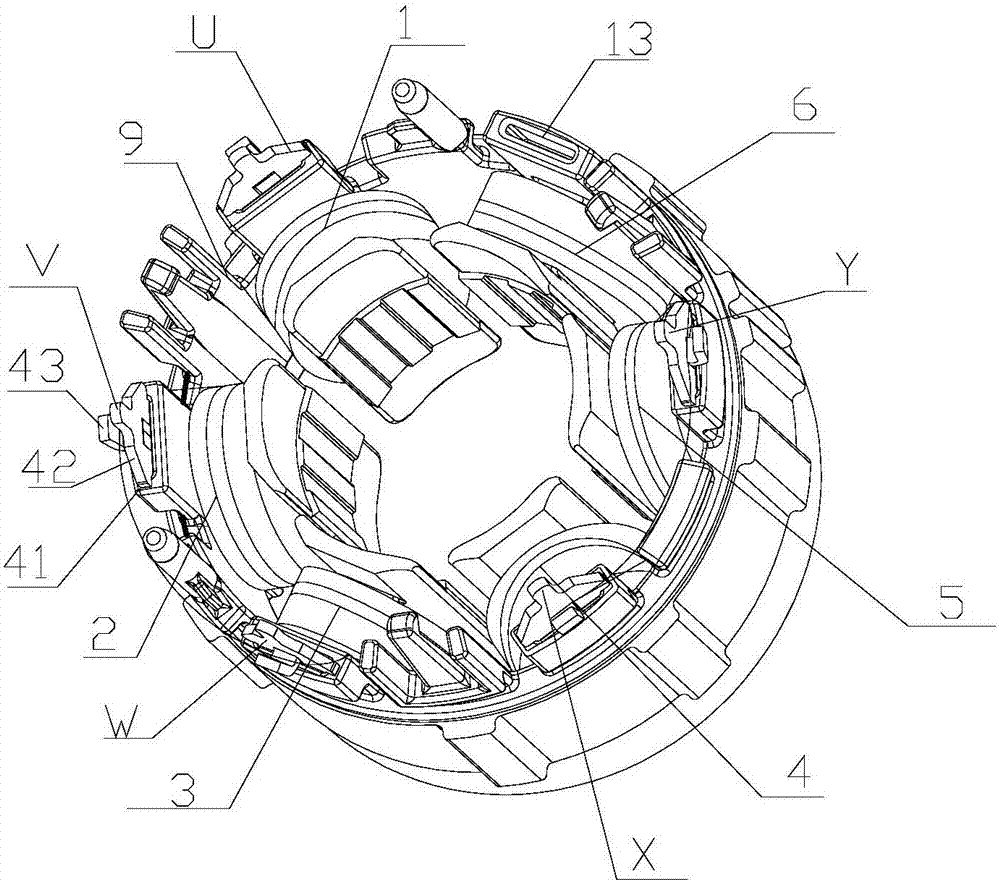

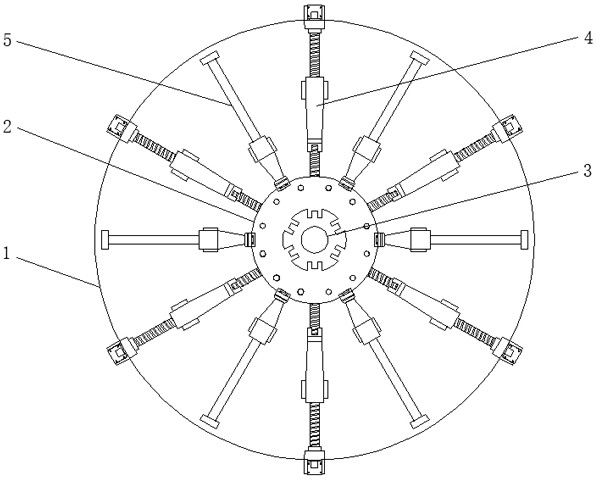

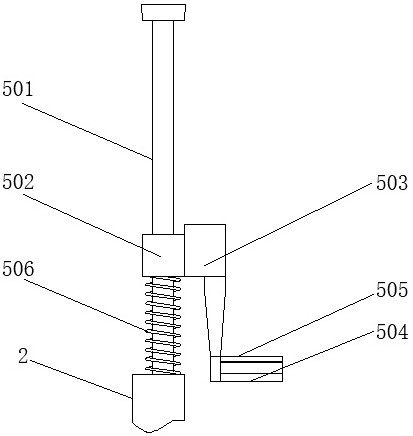

Fluid pump manufacturing method

InactiveCN107346928ASave winding timeImprove winding efficiencyManufacturing dynamo-electric machinesElectricityEngineering

The invention discloses a fluid pump manufacturing method. A fluid pump comprises an enameled wire and a stator assembly. The wire winding method of the stator assembly comprises the steps of: hooking the tail end of the enameled wire on a first terminal; winding the enameled wire on a wire winding frame to form a first coil; winding a fourth coil after the wire winding of the first coil is completed, wherein the wire winding direction of the fourth coil is the same as that of the first coil; completing the winding of a first group of coils after the wire winding of the fourth coil is completed; and winding a second group of coils or a third group of coils after the wire winding of the first group of coils is completed, wherein the enameled wire is electrically connected with a wiring terminal. The fluid pump manufacturing method can save the wire winding time, and improve the wire winding efficiency.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

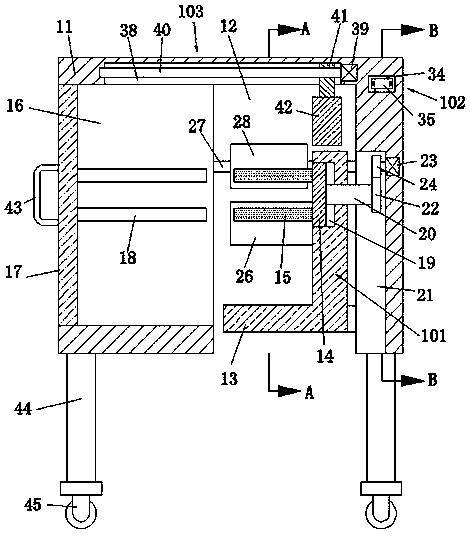

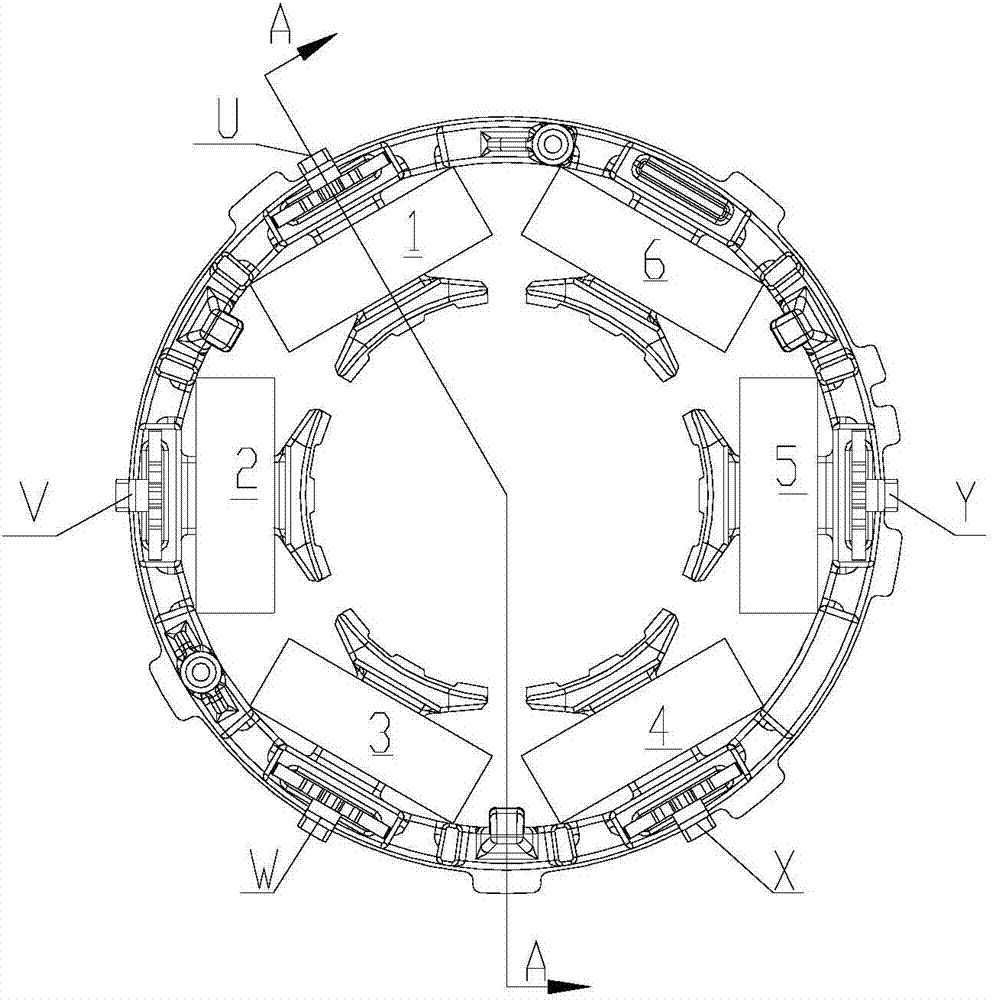

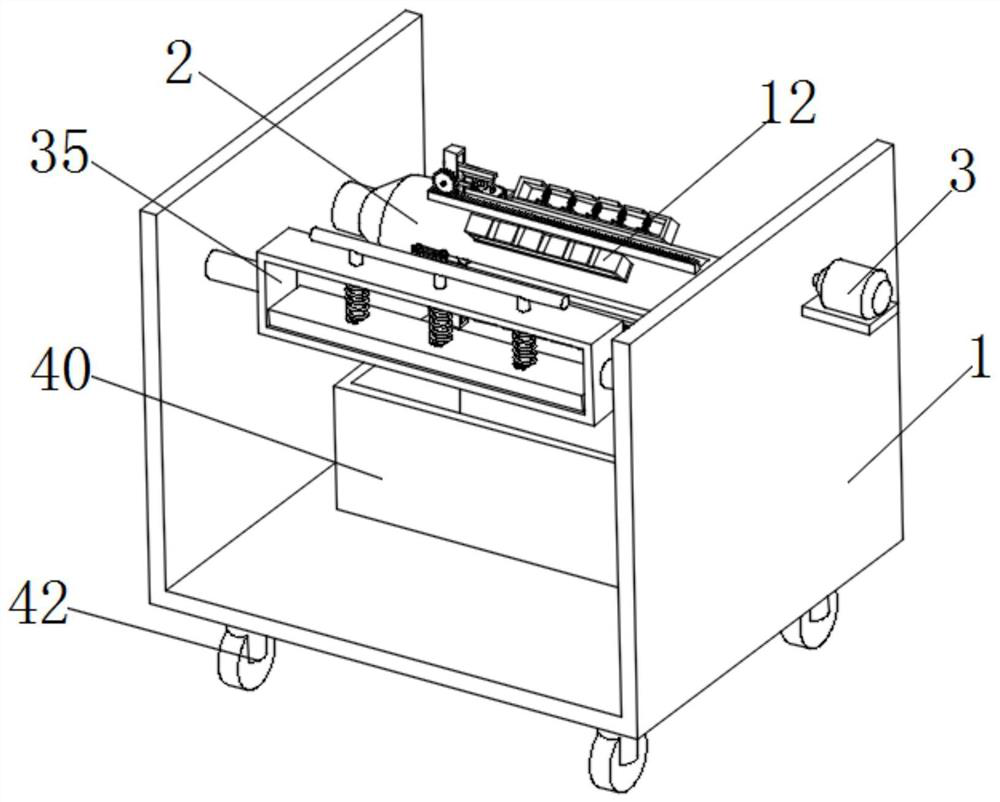

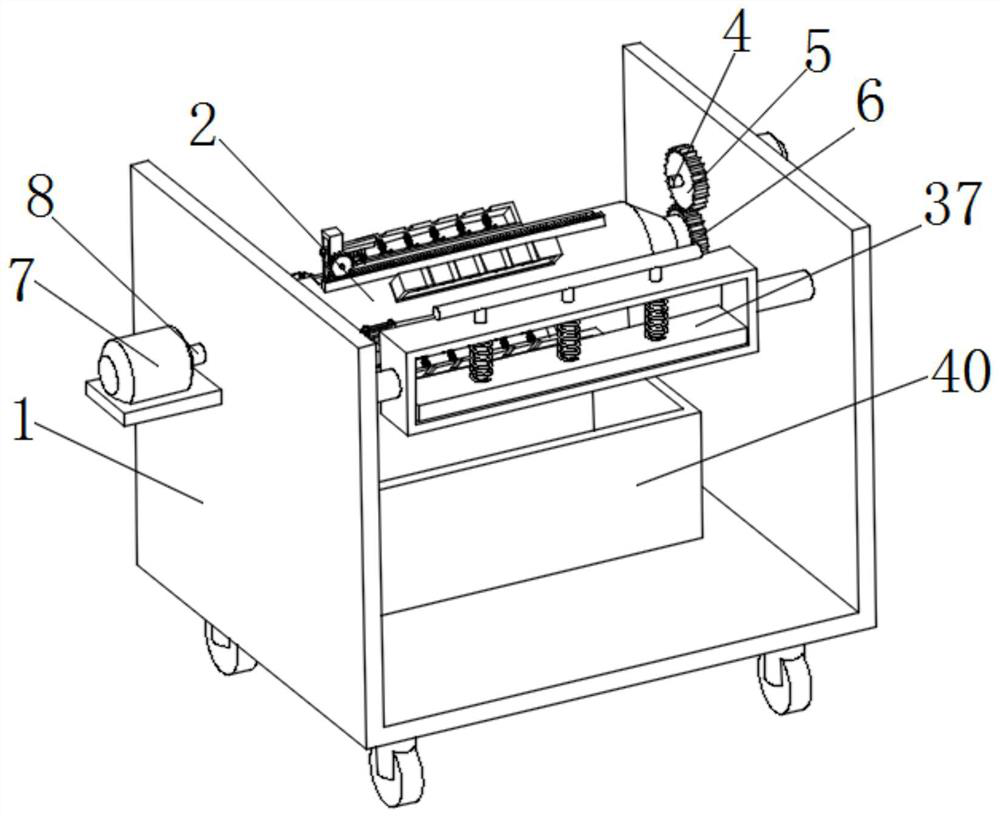

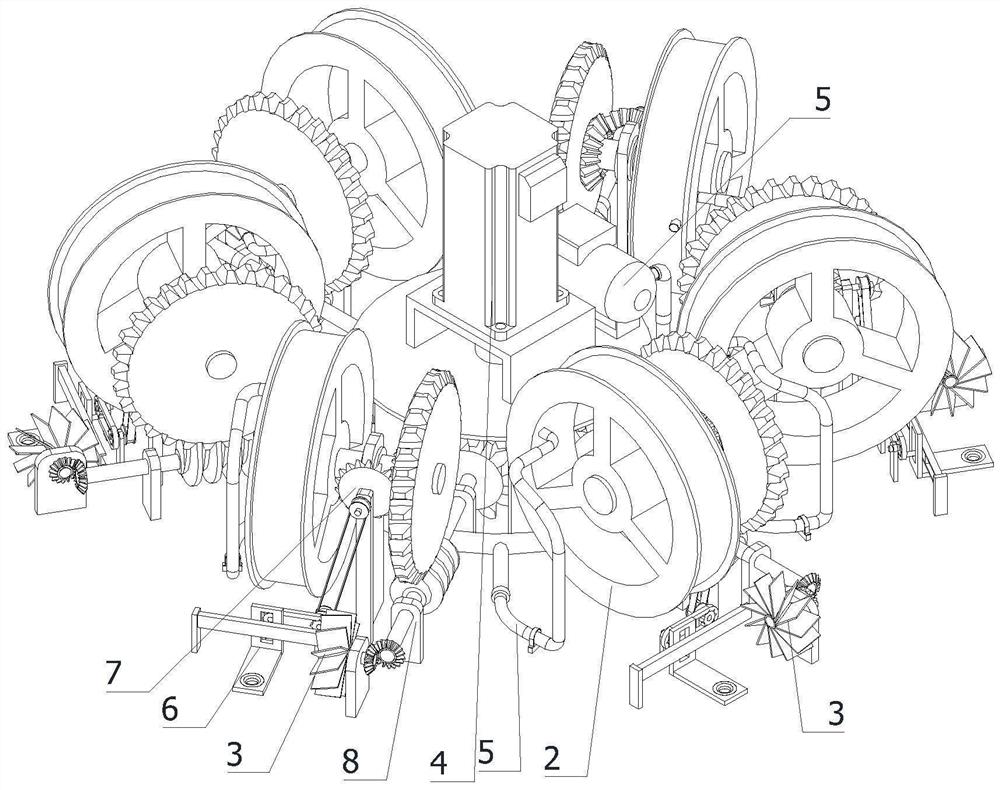

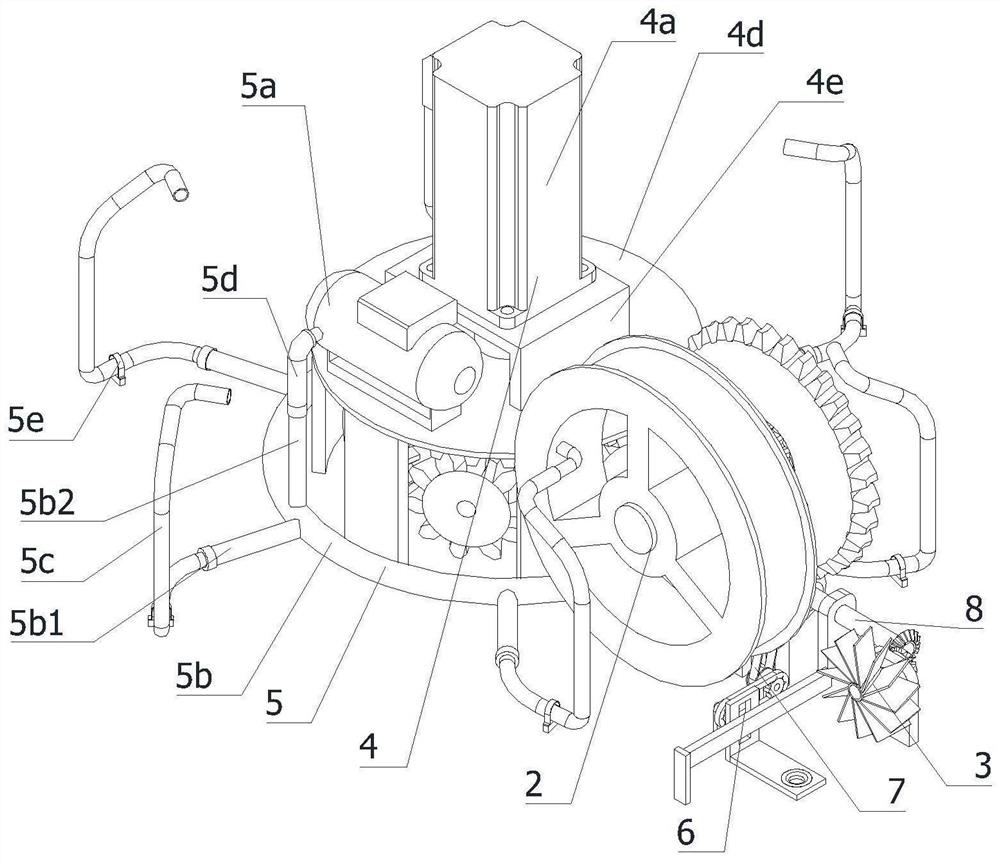

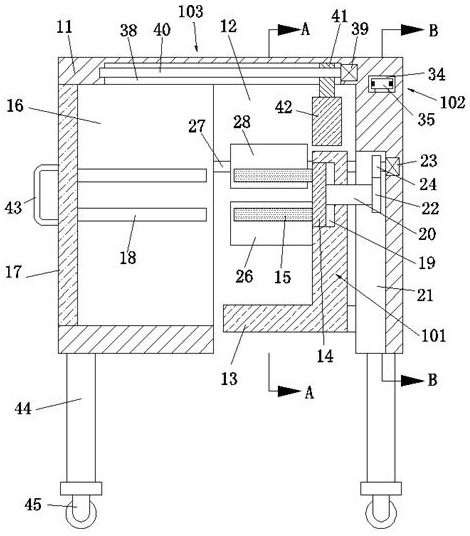

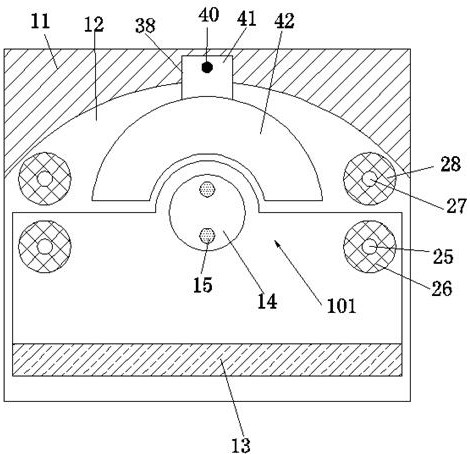

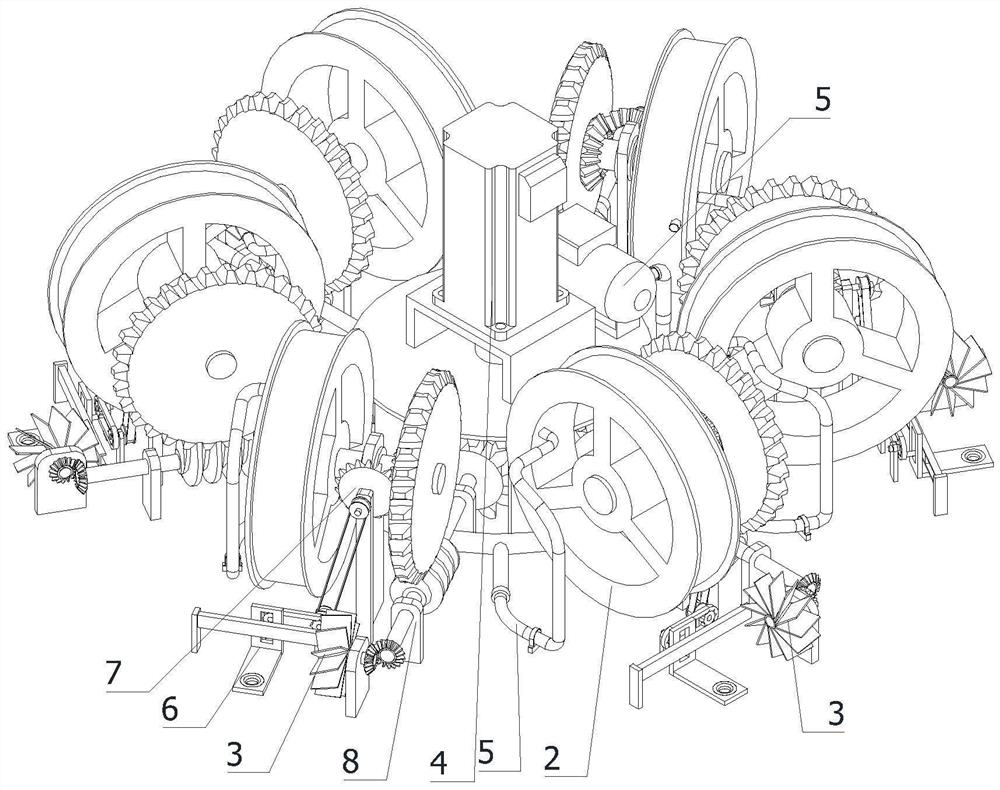

A quasi-sinusoidal coil pressing and forming equipment for a generator stator

ActiveCN111564306BEasy to change the pressure stateEasy to discharge and storeCoils manufactureCompression moldingElectric machine

The invention discloses a sine-like coil pressing and forming equipment for generator stator, which comprises a turntable and a pressing component. A round table is installed in the middle of the front of the turntable, and an ejector die is arranged in the middle of the front of the round table. The components are evenly installed on the outer edge of the round table, and a support component is arranged between the adjacent pressing components, a frame is fixed on the back of the turntable, and a stepper motor is connected to the left side of the frame. In the invention, a pressing component and a supporting component are arranged to divide the turntable into 6 parts, so as to form a quasi-sine-shaped coil, which is consistent with the existing motor stator coil structure, and is more convenient to use. The stepping motor can drive the turntable to rotate through the skeleton, Realizing the direct rotation and winding of the enameled wire on the support component, the overall winding can not only greatly save the winding time, improve the winding efficiency, but also effectively save the use of the enameled wire, thereby saving a certain production cost.

Owner:潍坊万隆电气股份有限公司

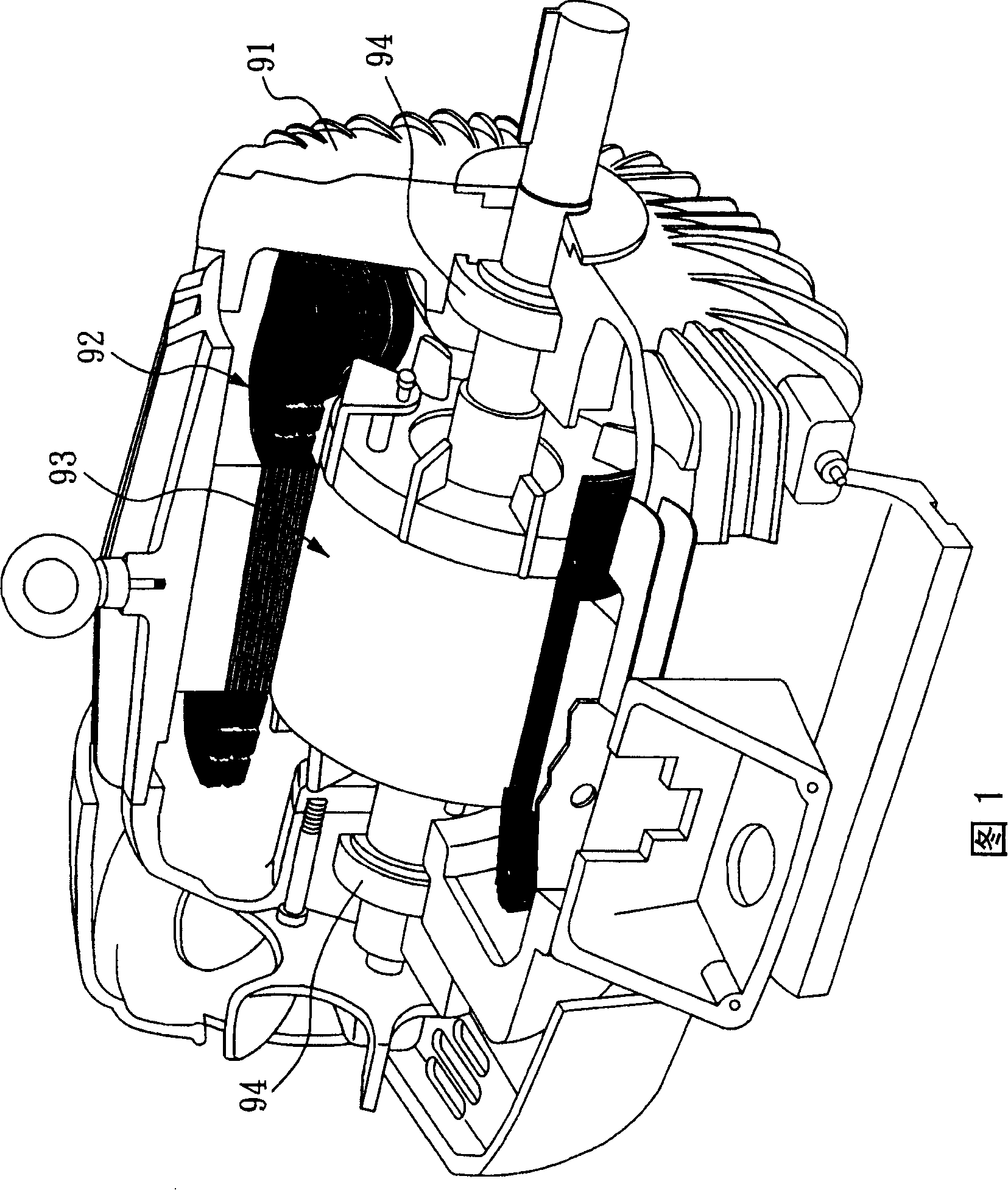

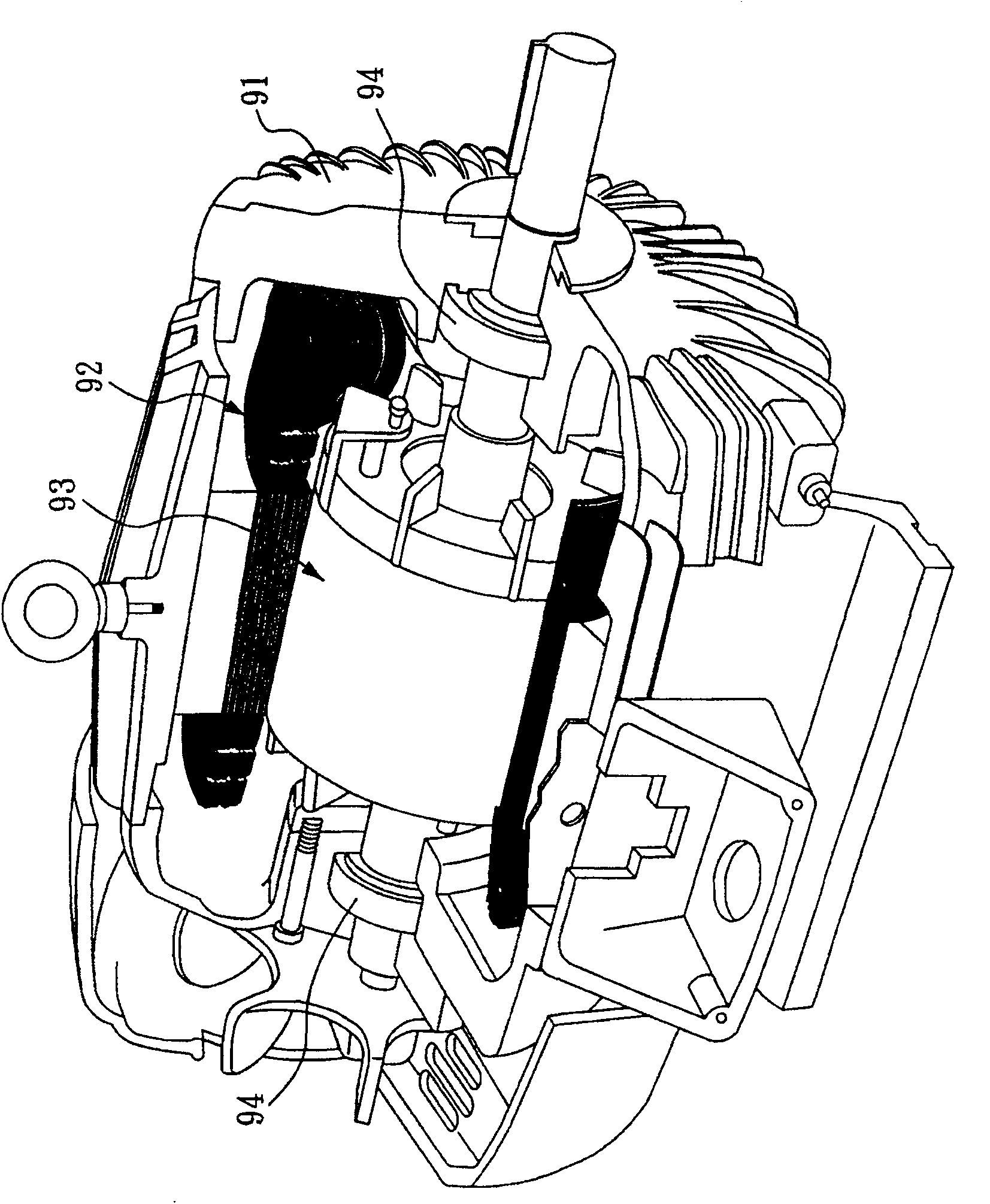

Cooling module and brush motor thereof

ActiveCN107872135ATotal turns reductionIncrease productivityMagnetic circuit rotating partsSalient polesConductor CoilMechanical engineering

The invention provides a brush motor including a stator and a rotor. The rotor includes a rotary shaft, a rotor magnetic core fixed to the rotary shaft and a commutator. The commutator includes an insulation base and a plurality of commutator bars fixed on the insulation base. The stator is provided with 2*P stator electrodes and the rotor has m teeth, wherein P is an integer greater than 1, m isgreater than 2P and smaller than 4P and 2m is the integral multiple of P. A rotor winding of the rotor is a centralized winding provided with m first elements and m second elements. Each tooth is coiled with one first element and one second element. The m first elements form a plurality of element sets. Each element set is provided with n first elements connected in series. Merely two ends of eachelement set are connected to a corresponding commutator bar. n is greater than or equal to 2 and is smaller than or equal to P. Two ends of each second element are connected to a corresponding commutator bar. By applying the invention, motor production efficiency can be improved and production efficiency can be reduced.

Owner:JOHNSON ELECTRIC SHENZHEN

Winding mechanism for preventing cable from being stacked and bent

InactiveCN113044674AWind evenlyEasy to wrapFilament handlingCoverings/external coatingsElectric machineGear wheel

The invention discloses a winding mechanism for preventing a cable from being stacked and bent. The winding mechanism comprises a cable winding box, the bottom of the cable winding box is fixedly connected with universal wheels, the top of the cable winding box is fixedly provided with folding rainproof cloth, and the side wall of the cable winding box is fixedly provided with a cart handle. According to the winding mechanism for preventing the cable from being stacked and bent, a motor is arranged to drive a driving gear to rotate, a driven gear meshed with the driving gear rotates along with the motor, a winding sleeve is driven to rotate, the cable is wound around the surface of the winding sleeve, meanwhile, an electric telescopic rod drives a connecting plate to move left and right, and therefore the winding sleeve is driven to slide along a center sliding rod, the other end of the cable is limited by a limiting hole, so that the cable can move left and right along with the winding sleeve to be evenly wound on the surface, local stacking is avoided, the cable winding mechanism has the effect of preventing stacking and bending, the situation of cable stacking is not prone to occurring when the cable is wound, the cable is not prone to being damaged by pressing and wound, and the protection effect on the cable is good.

Owner:刘宁琳

A high-efficiency trimming machine for degradable plastic film production and its production process

The invention discloses a high-efficiency trimming machine for degradable plastic film production, which relates to the technical field of degradable plastic film production equipment, including a frame, the inside of which is rotatably connected to a reel, and the side of the reel is A plurality of evenly distributed waste fixing parts are installed on the wall, and mounting plates are fixedly connected to both sides of the frame, and a winding motor and a cutting motor are respectively fixedly connected to the two mounting plates, and the winding motor A first transmission shaft and a second transmission shaft are drivingly connected to the output shaft of the cutting motor respectively, and first rotating holes are opened on the inner walls of both sides of the frame. In the present invention, the waste fixing part is used to fix the side material, and the winding motor drives the reel to rotate so that the waste is wound on the fixing frame. The winding groove can make the waste more tidy after being rolled. The edge machine can rewind multiple waste edge materials at the same time, thereby increasing the rewinding speed and saving rewinding time.

Owner:吴孟龙

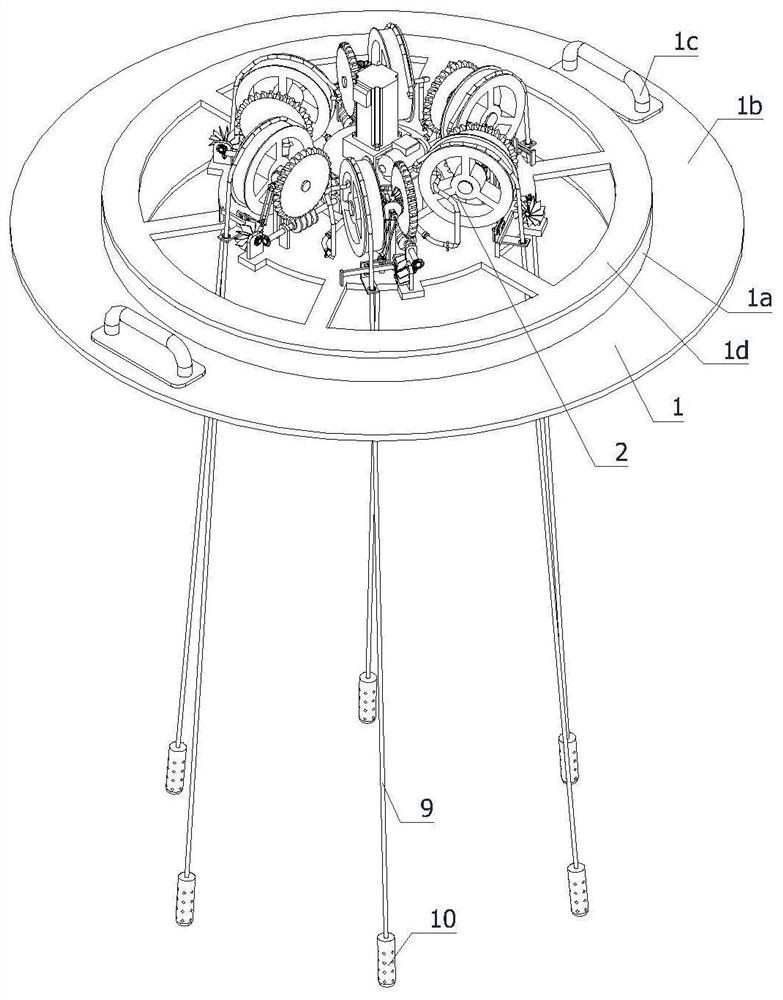

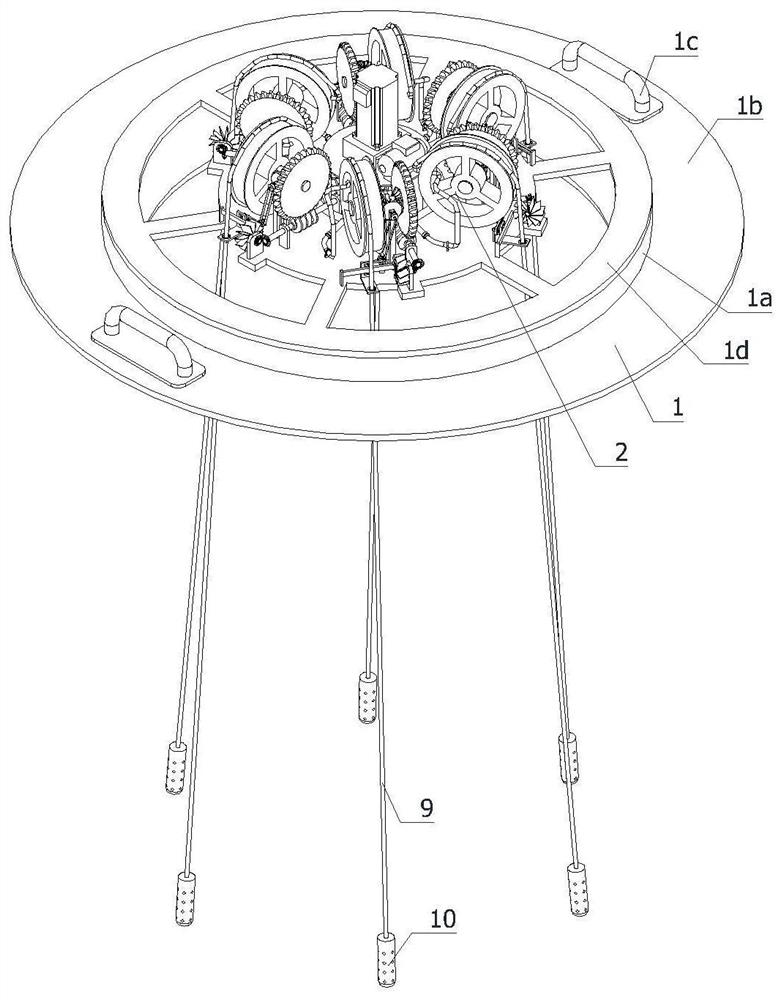

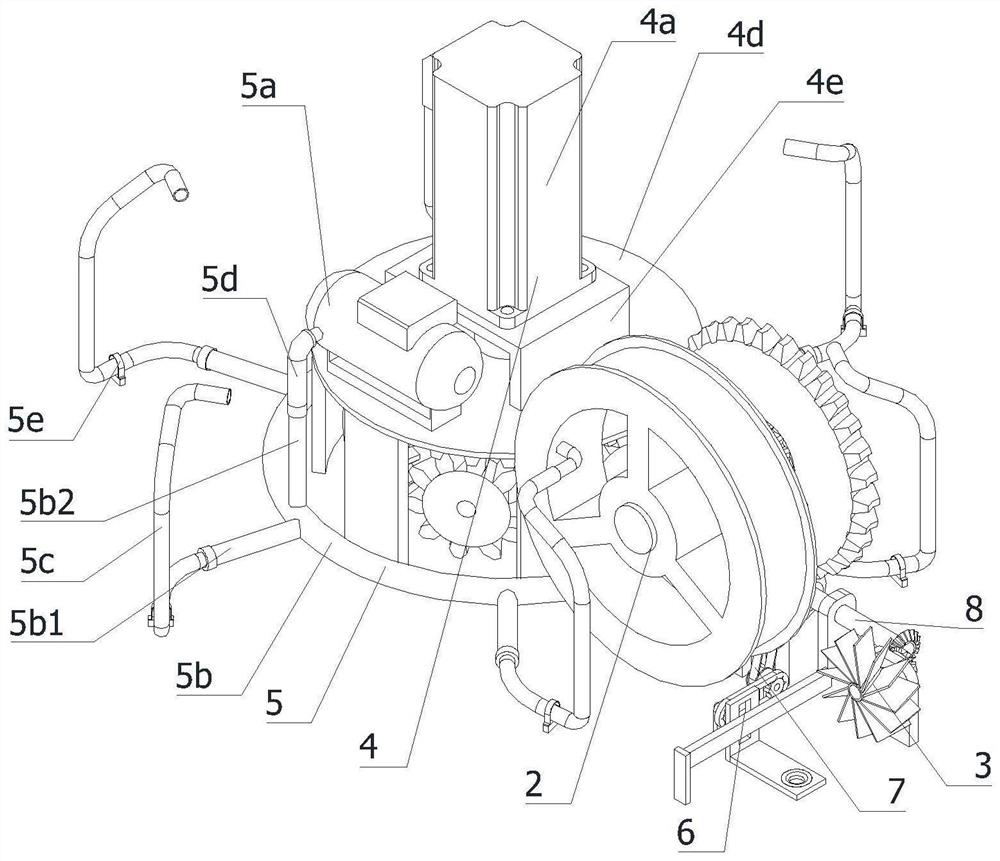

Working method of oxygen supply equipment convenient to install and store for fish culture

InactiveCN112352732ASave winding timeWinding evenlyFilament handlingPisciculture and aquariaEngineeringEnvironmental geology

The invention relates to the field of fish culture, in particular to a working method of oxygen supply equipment convenient to install and store for fish culture. The oxygen supply equipment comprisesa floating frame, a driving mechanism, an air supply mechanism, six winding frames, a water blowing mechanism, a left-right adjusting mechanism, a transmission mechanism, a multi-directional transmission assembly, a hose and an air outlet cylinder. According to the oxygen supply equipment convenient to install and store for fish culture, the multi-directional transmission assembly is driven by the driving mechanism to work, so that a third rotating shaft rotates to drive the winding frames, the water blowing mechanism, the transmission mechanism and the left-right adjusting mechanism to movesynchronously, winding, blow-drying and left-right moving are achieved at the same time, the procedures are prevented from being conducted step by step, the winding time of the hose is saved, uniformwinding of the hose is achieved, the situation that part of an oxygenation pipe cannot be completely wound up is avoided, the water blowing mechanism can blow-dry water on the outer surface of the hose, then the outer surface of the hose is prevented from being soaked in water and rotten, and the service life of the hose is prolonged.

Owner:ANHUI HUATENG AGRI TECH CO LTD

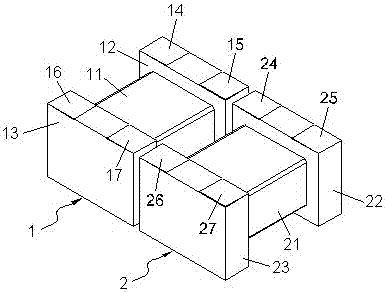

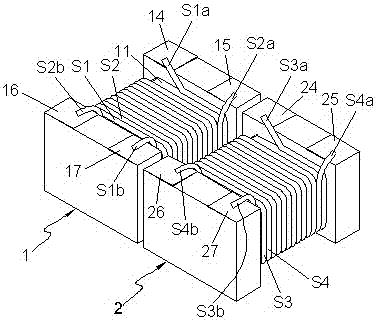

Transformer manufacturing method capable of increasing output

InactiveCN107123534AEasy to prepareThe preparation method is reasonableTransformers/inductances magnetic coresCoils manufactureMagnetic coreCenter tap

The invention relates to a transformer manufacturing method capable of increasing output. The method comprises the steps of material preparation; wherein a first magnetic core and a second magnetic core are provided; winding; wherein two winding machines are utilized simultaneously to wind the first magnetic core and the second magnetic core; center tapping; wherein the first magnetic core and the second magnetic core obtained after the winding step are combined and fixed, and part of terminal electrodes of different magnetic cores are connected with one another and in a short circuit to form a center tap of a transformer. Therefore, in the premise of the same winding mode, the first magnetic core and the second magnetic core of the transformer can carry out winding operation through the two winding machines simultaneously, so that half of winding time can be shortened, and thus the method can achieve the effects of improving production efficiency and increasing the output.

Owner:TAI TECH ADVANCED ELECTRONICS SI HONG

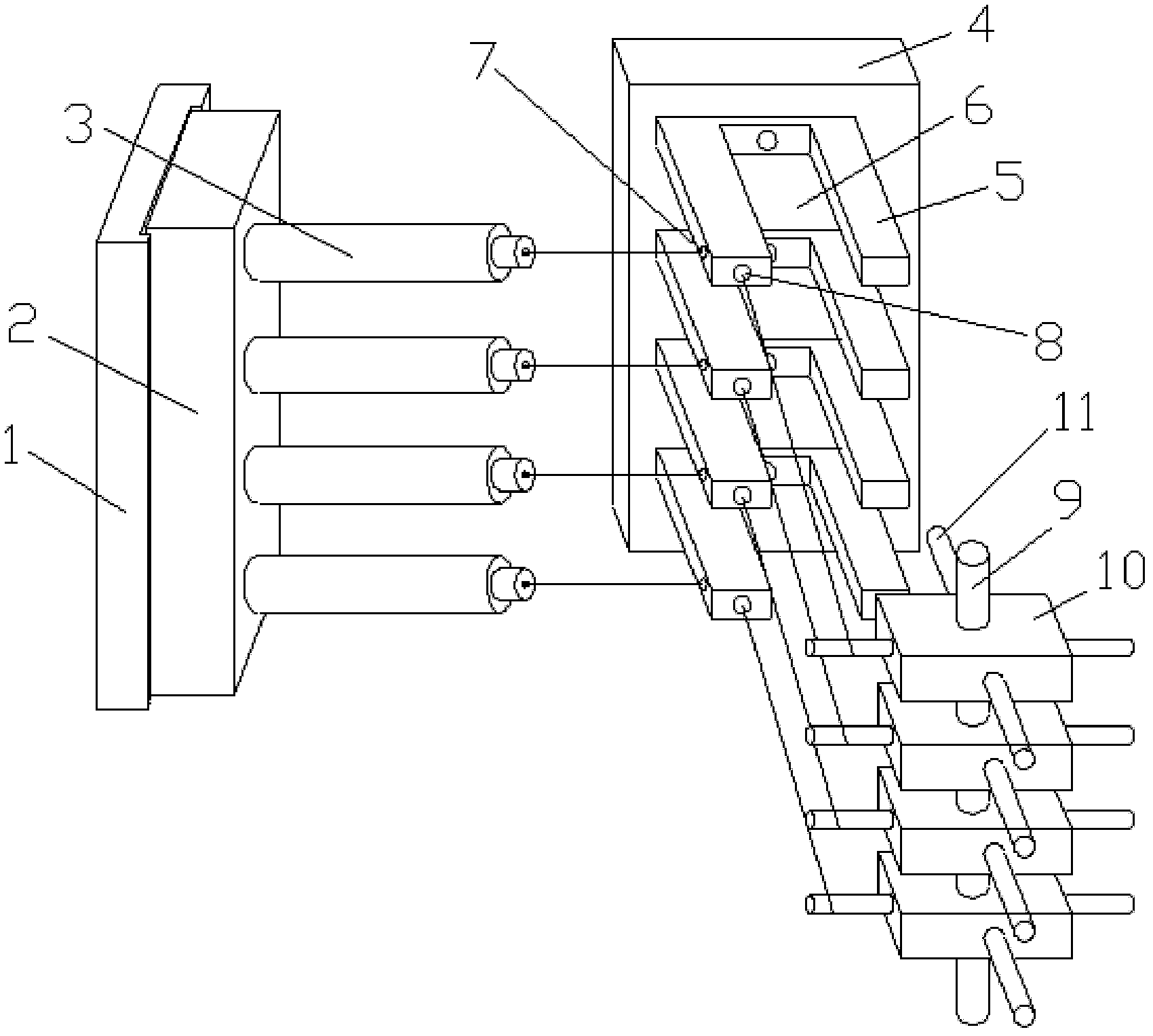

Coil winding device

InactiveCN102208850ASolve the problem of messy and unevenSimple structureManufacturing dynamo-electric machinesConductor CoilMechanical engineering

Owner:CHIZHOUSHI HONGGANG SCI & TECH ELECTRONICS CO LTD

Small-rolling-diameter high-speed full-automatic rolling device

The invention relates to the technical field of rolling machines, in particular to a small-rolling-diameter high-speed full-automatic rolling device. The problems that in the prior art, after rollingof a single rolling drum is completed, the single rolling drum needs to be taken down and replaced with a new rolling drum, one rolling drum is replaced once, the replacement time is long, and a largeamount of rolling time of equipment is consumed are solved. The small-rolling-diameter high-speed full-automatic rolling device comprises a mounting rack, a motor is arranged at the top of the mounting rack, a roller is rotationally connected to the top of the mounting rack, the surface of the roller is sleeved with multiple rolling discs distributed at equal distance, positioning mechanisms arearranged between the rolling discs and the roller, and a transmission wheel is arranged at one end of the roller. According to the device, after single rolling is completed, next-time rolling can be carried out again, one-time replacement is carried out after rolling is completed, the replacement time in the period is saved, and the rolling time is saved.

Owner:四川羽玺新材料股份有限公司

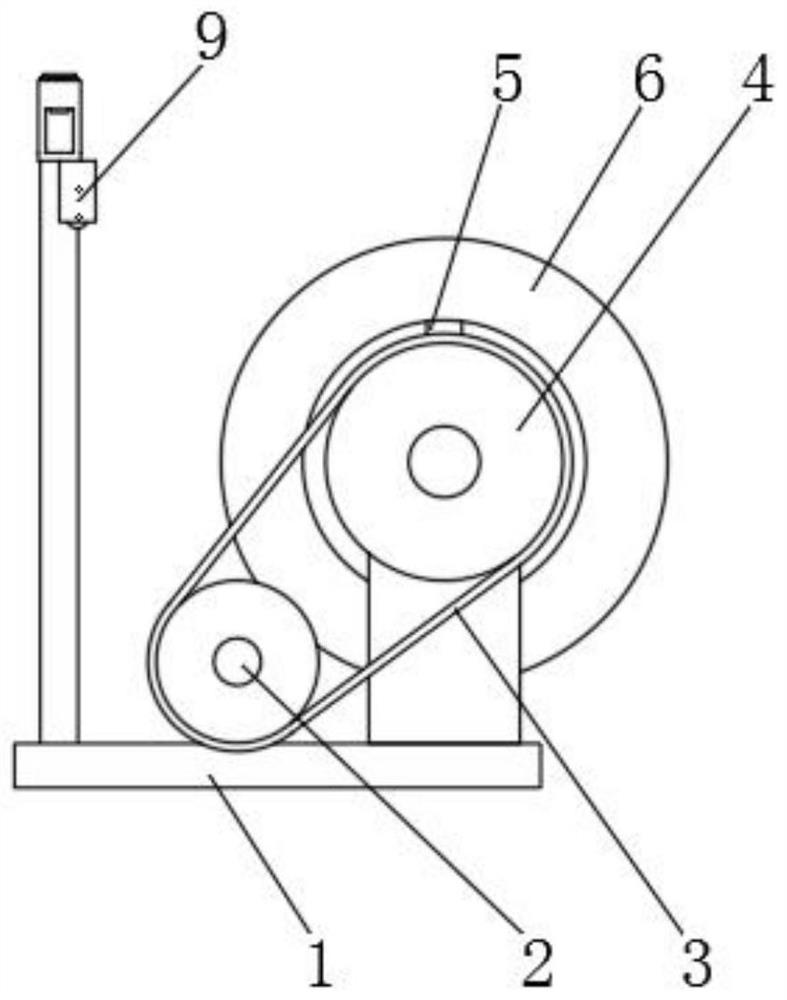

A fire belt fast hovering device and using method thereof

The invention discloses a firefighting belt fast coiling device. The device includes a pedestal; the two side on the upper part of the pedestal are fixedly connected to supporting plates; supports arefixedly connected to the upper part of the pedestal; the upper parts of the supports are connected to a first disc; the middle part of the first disc is rotatably connected to a rotating shaft; the two ends of the rotating shaft pass through the first disc, and extend to the outside of the first disc; a second disc is fixedly installed on the rear side of the rotating shaft; and the outside of the second disc is connected to a crank. The device can rapidly coil firefighting belts, so that the coiling time of fire fighters can be reduced; the device has two coiling ways, and an electric coiling way can reduce the physical output of the fire fighters when the fire fighters coil the firefighting belts; the function of starting a switch can be achieved by placing a limit cross rod in first opening grooves, so that a motor can be started; and the motor drives a driving belt pulley to drive the rotation of a driven belt pulley through a belt, so that the firefighting belts can be coiled.

Owner:淮北辰威科技有限公司

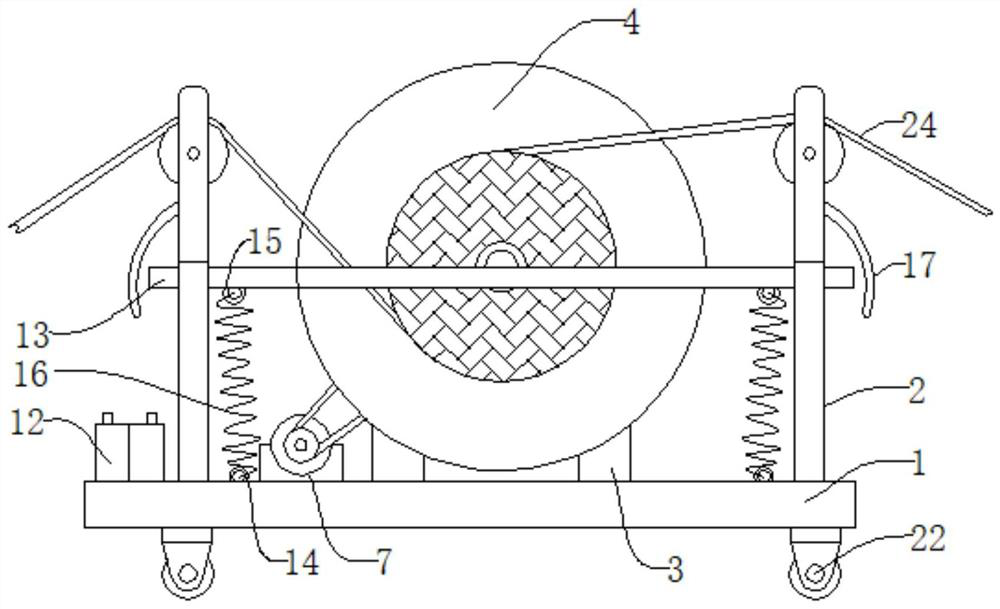

A quick rewinding device for a fire hose

ActiveCN110407004BSave winding timeWith storage functionWebs handlingMechanical engineeringFirewater

Owner:天津鑫源建设发展有限公司

An automatic rewinding equipment for plastic pipes

A plastic tube automatic rolling device comprises a main rack, a large rotating arm, a tube bank mechanism, a tension control mechanism, a tube cutting mechanism, a moving caliper assembly, a movable reel loading and unloading working table and a reel conveying mechanism, wherein the large rotating arm, the tube bank mechanism, the tension control mechanism, the tube cutting mechanism, the moving caliper assembly, the movable reel loading and unloading working table and the reel conveying mechanism are arranged on the main rack. The large rotating arm is driven by a motor and a transmission assembly. Two sets of reel assemblies are symmetrically arranged on the large rotating arm left and right, one set of reel assemblies are located on the rolling station, plastic tubes conveyed by a production line pass the tube bank mechanism and the tension control mechanism and then are wound on the reel assemblies, the other set of reel assemblies are located on the reel alternation station and matched with the moving caliper assembly, the movable reel loading and unloading working table and the reel conveying mechanism to finish reel alternation operation, and the two sets of reel assemblies are driven by the large rotating arm to be switched between the rolling station and the reel alternation station. By the adoption of the plastic tube automatic rolling device, labor intensity of operators is relieved, plastic tube rolling time is shortened, and working efficiency of the plastic tube production line is improved.

Owner:武志生

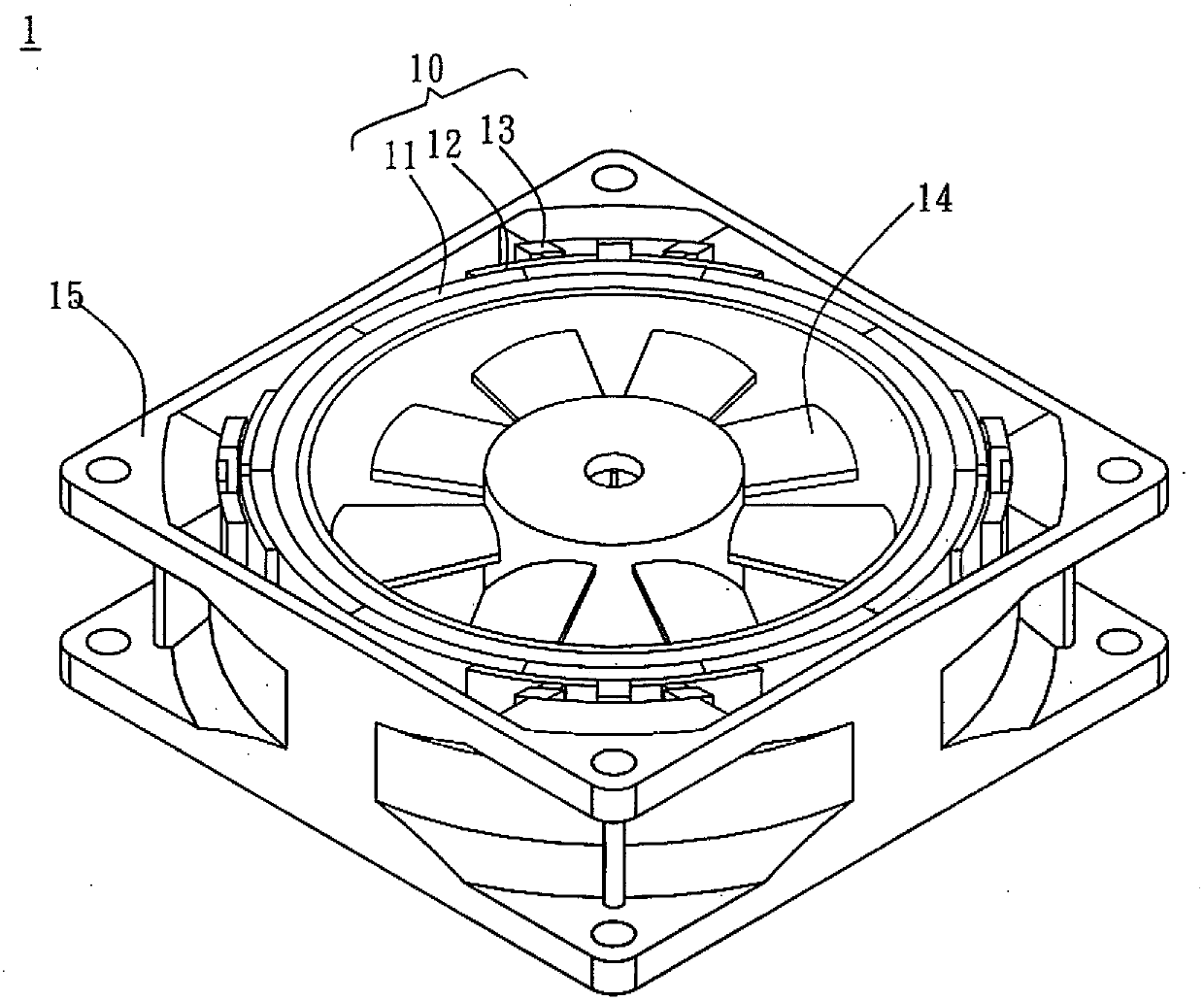

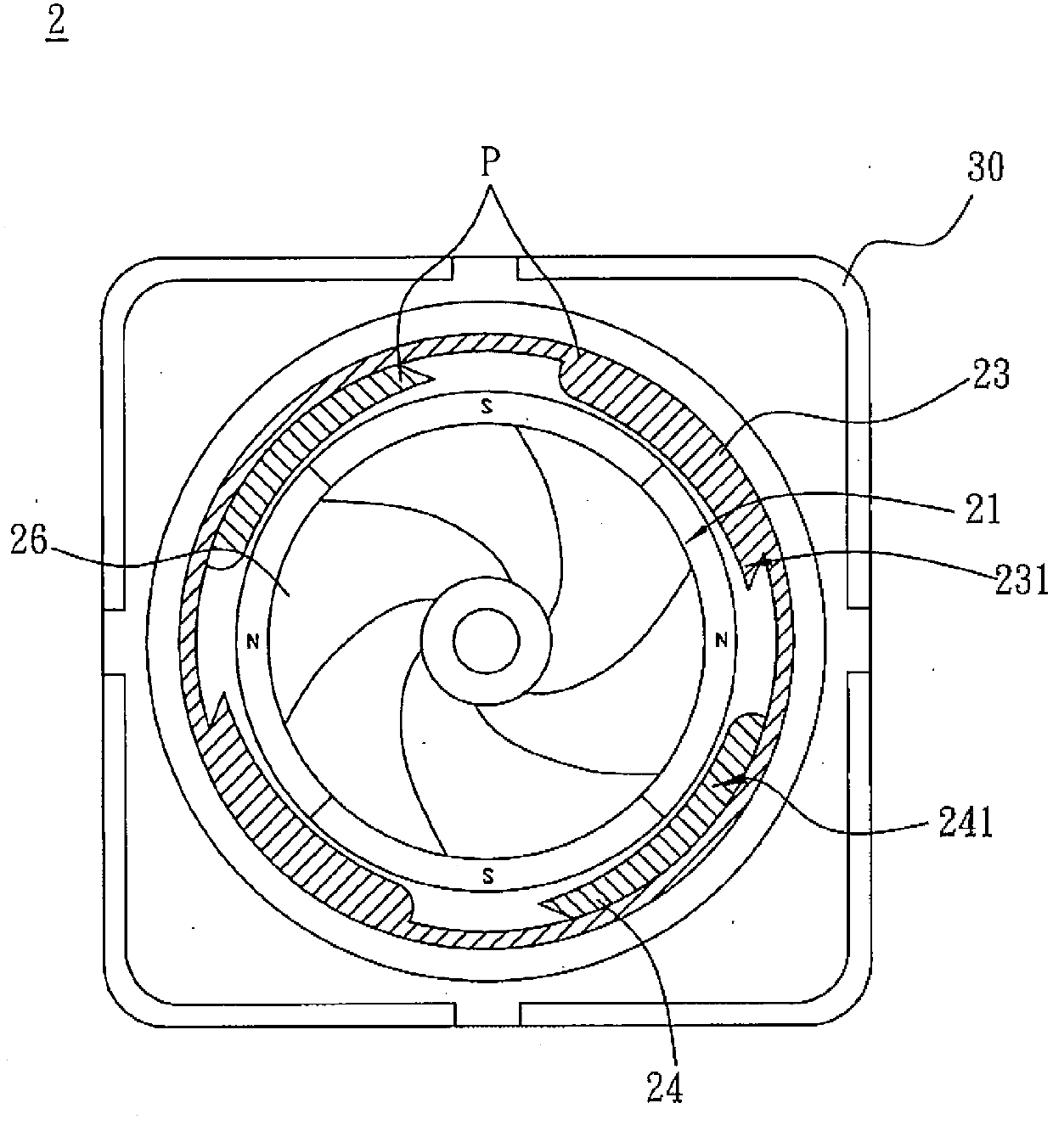

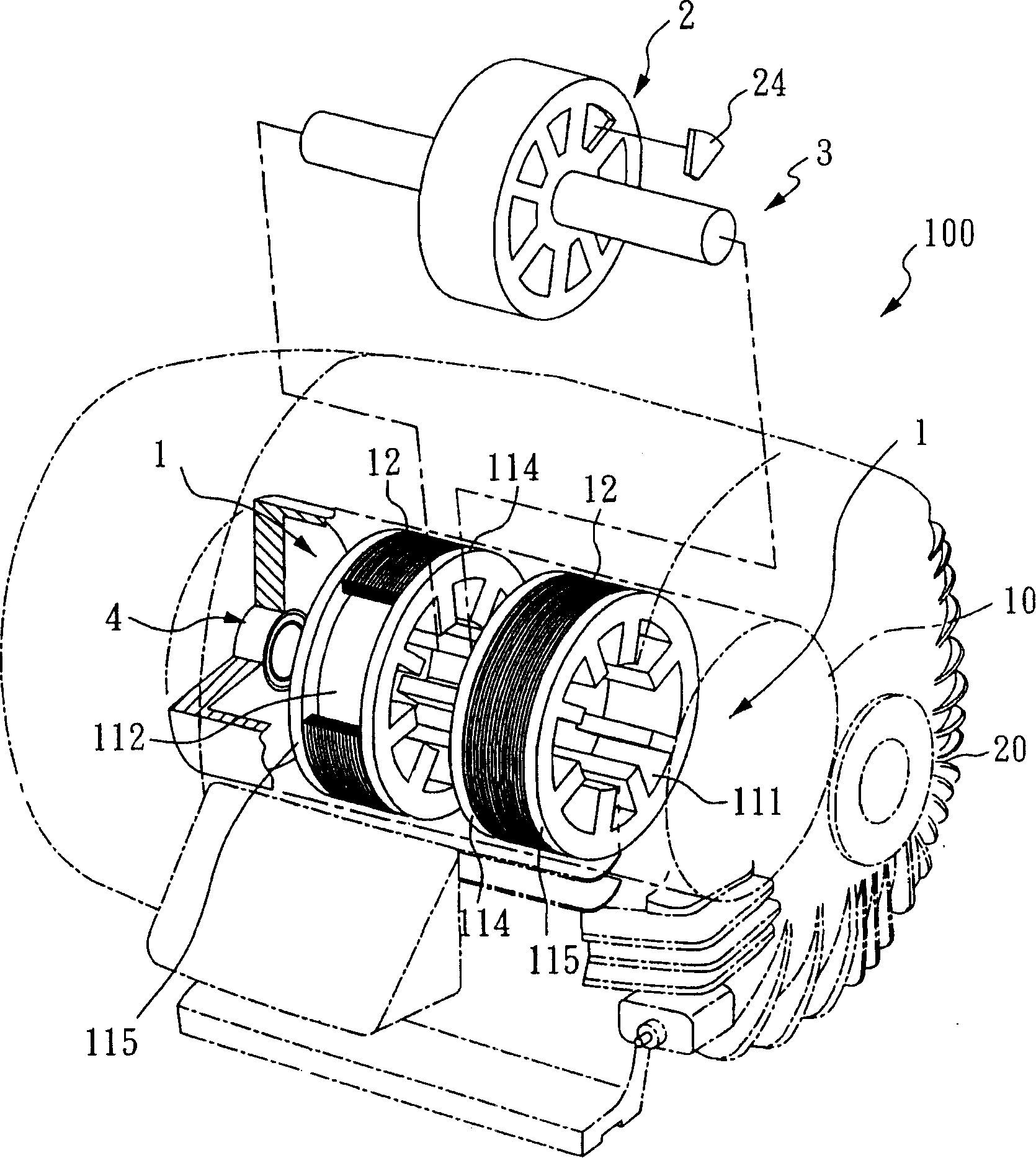

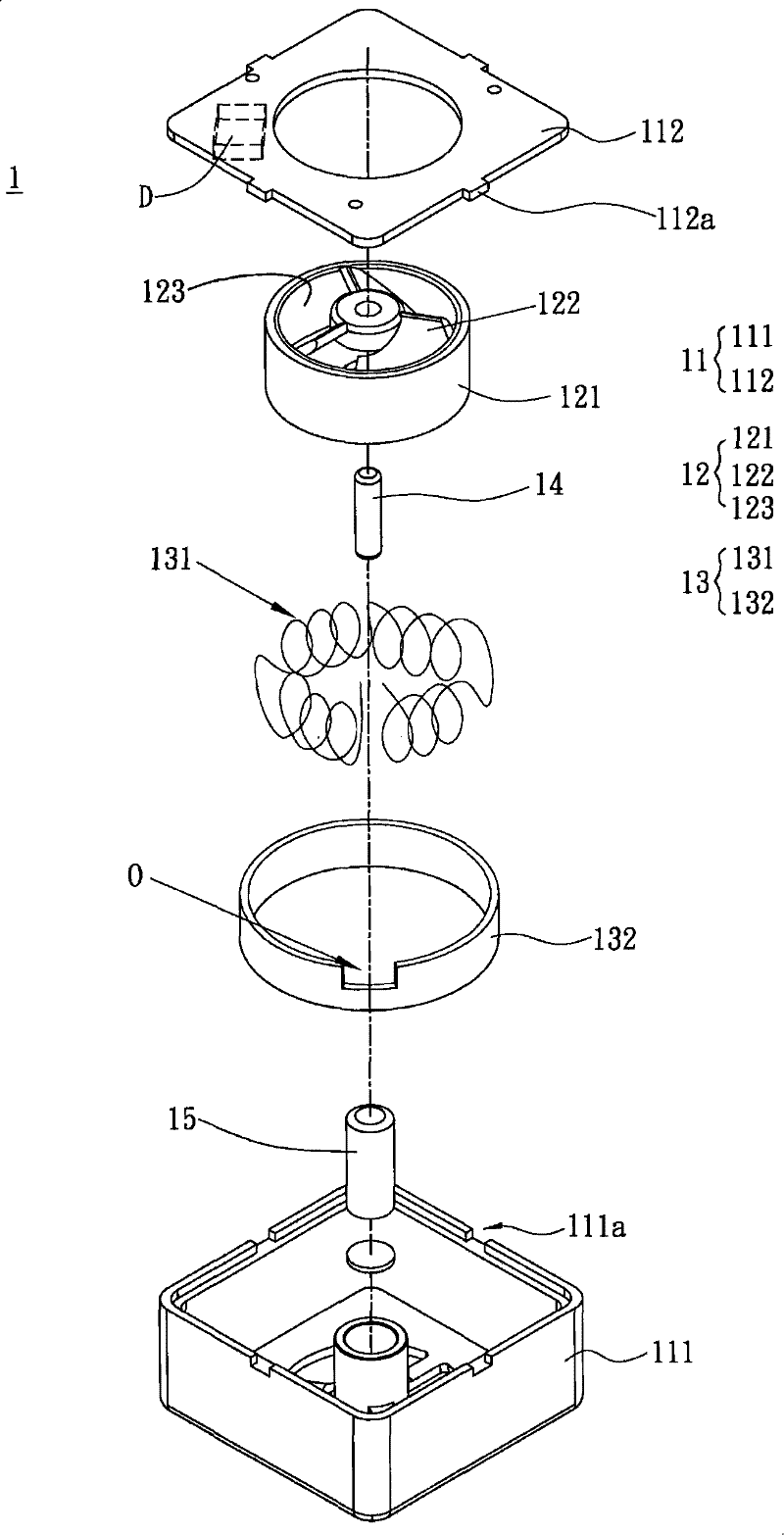

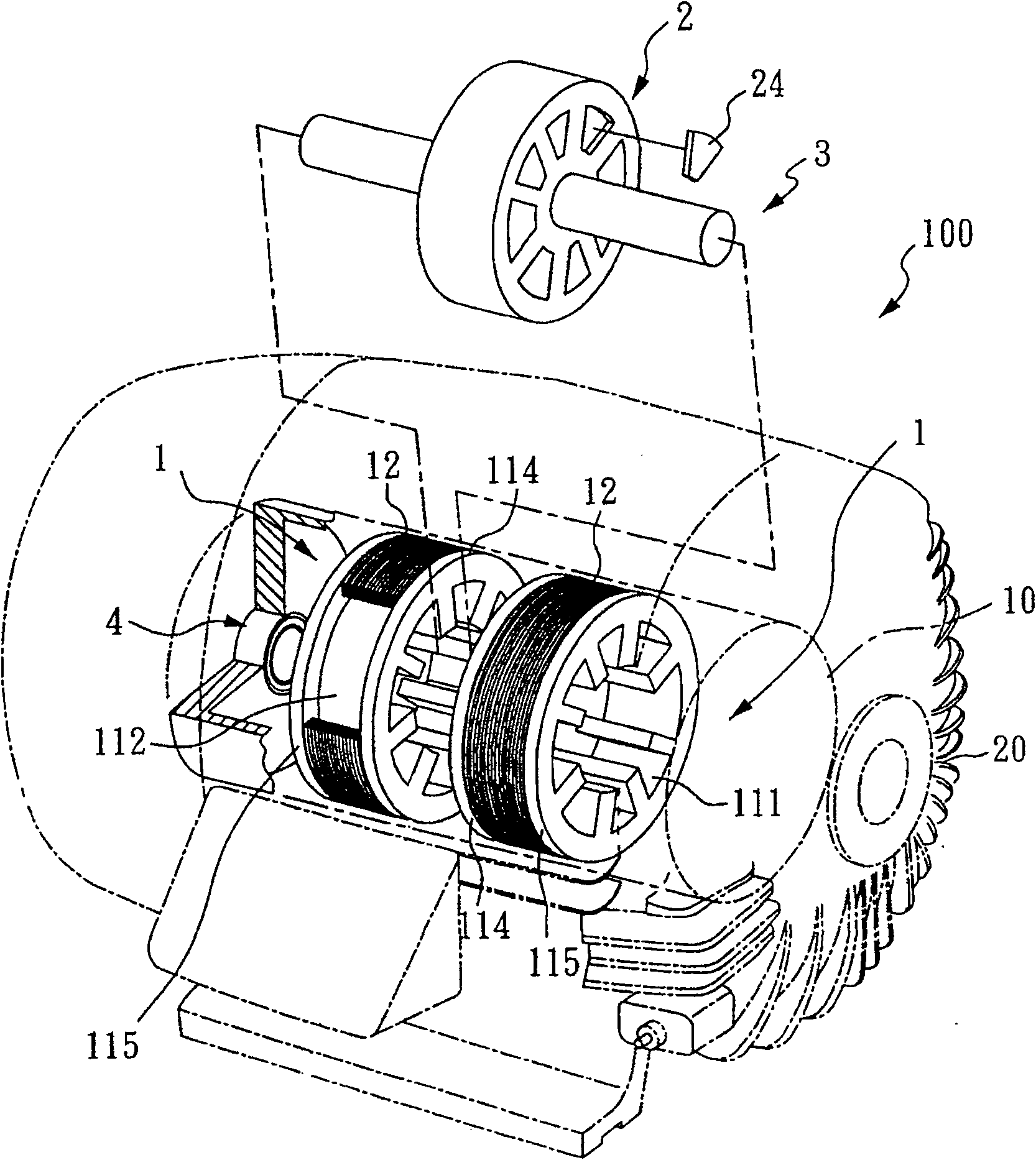

Fan and motor thereof

ActiveCN101582616BReduce manufacturing costIncrease the setting areaSynchronous machine detailsMagnetic circuit rotating partsEngineeringFan blade

The invention discloses a fan and a motor thereof. The fan comprises an interior rotor motor. The motor comprises a casing, a rotor group and a stator group, wherein the rotor group is provided with arotor. The rotor is provided with a fan blade arranged in the casing, the stator group corresponding to the rotor group is arranged in the casing and comprises a coil, and the coil is formed in sucha way that a continuous wire material surrounds the rotor after forming a flat helical structure along the circumferential direction of the rotation of the motor by taking the radial direction of themotor as a center in a helical winding mode.

Owner:DELTA ELECTRONICS INC

Oxygen supply equipment convenient to install and store for fish culture

The invention relates to the field of fish culture, in particular to oxygen supply equipment convenient to install and store for fish culture. The oxygen supply equipment comprises a floating frame, adriving mechanism, an air supply mechanism, six winding frames, a water blowing mechanism, a left-right adjusting mechanism, a transmission mechanism, a multidirectional transmission assembly, a hoseand an air outlet cylinder. According to the oxygen supply equipment convenient to install and store for fish culture, the multi-directional transmission assembly is driven by the driving mechanism to work, so that a third rotating shaft rotates to drive the winding frames, the water blowing mechanism, the transmission mechanism and the left-right adjusting mechanism to move synchronously, winding, blow-drying and left-right moving are achieved at the same time, the procedures are prevented from being conducted step by step, the winding time of the hose is saved, uniform winding of the hose is achieved, the situation that a part of an oxygenation pipe cannot be completely wound up is avoided, the water blowing mechanism can blow-dry water on the outer surface of the hose, then the outer surface of the hose is prevented from being soaked in water and rotten, and the service life of the hose is prolonged.

Owner:ANHUI HUATENG AGRI TECH CO LTD

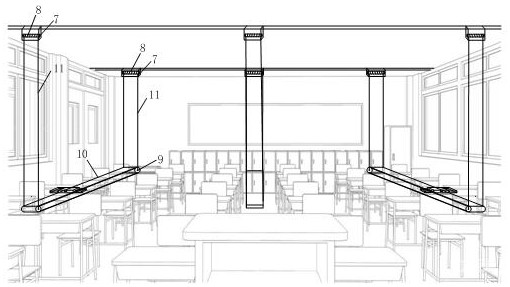

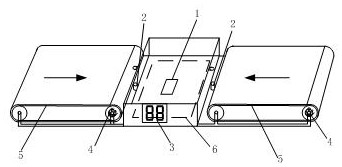

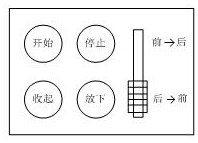

Student examination paper automatic collecting device and method

ActiveCN113148551AEasy to operateSave winding timeConveyorsCounting objects on conveyorsPhotoswitchElectric machinery

The invention discloses a student examination paper automatic collecting device and method. The device comprises a single-chip microcomputer, photoelectric switches, a nixie tube, motors, conveying belts, iron chains, roller shutters and a control panel. The single-chip microcomputer serves as a main controller. The photoelectric switches are used for counting examination paper. The nixie tube is used for displaying the count. One of the conveying belts is used for conveying the examination paper into the device, and the other is used for operating the device from front to back or from back to front. The device is hoisted by the iron chains. The roller shutters can wind and unwind the iron chains up and down. The motors control the conveying belts and the roller shutters to operate. The control panel is used for controlling the whole device. A release button in the control panel is pressed down to put down the device from a ceiling to be placed beside students, then a start button is pressed down, the students put the examination paper into the conveying belts, the examination paper is automatically taken back into the device and counted, an invigilation teacher presses a stop button when the process is finished, the examination paper is taken out of the device, and the numbers displayed on the nixie tubes of all the devices are accumulated. The device has the advantages of being high in examination paper collecting speed and accurate in examination paper counting.

Owner:SHAANXI UNIV OF SCI & TECH

Motor

ActiveCN100570989CWinding method is simpleSave winding timeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineConductor Coil

The invention relates to a motor, in particular to a two-stator convolved in a radial winding way. The two-stator is staggered from a special angle of the motor and forms a specific structure through coaxial arrangement with rotors, so that stator loops can be convolved with relatively a small amount of materials and a simple winding way, and the purpose of saving winding time and material is achieved.

Owner:TECO ELECTRIC AND MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com