Medium-speed wire cutting machine capable of fast threading

A technology of cutting machine and wire, which is applied in the field of medium-feeding wire cutting machine, and can solve the problems of low production efficiency and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

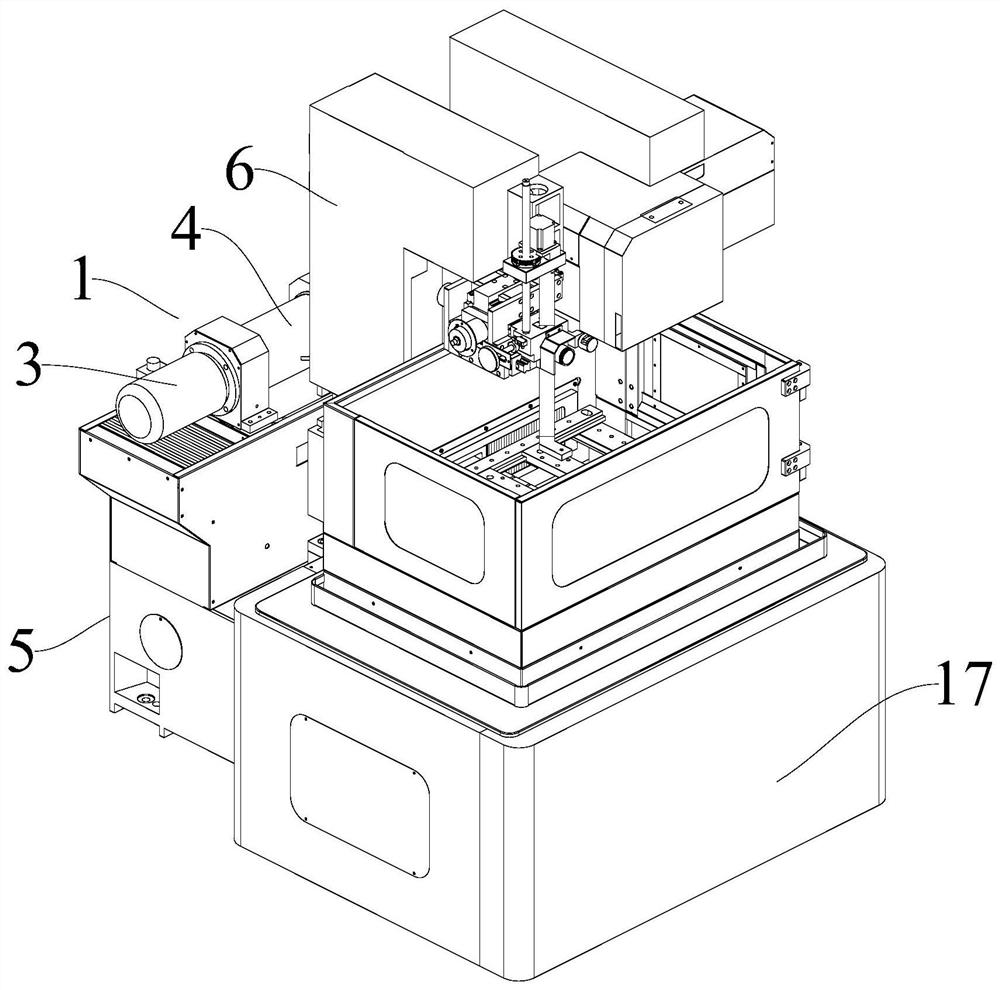

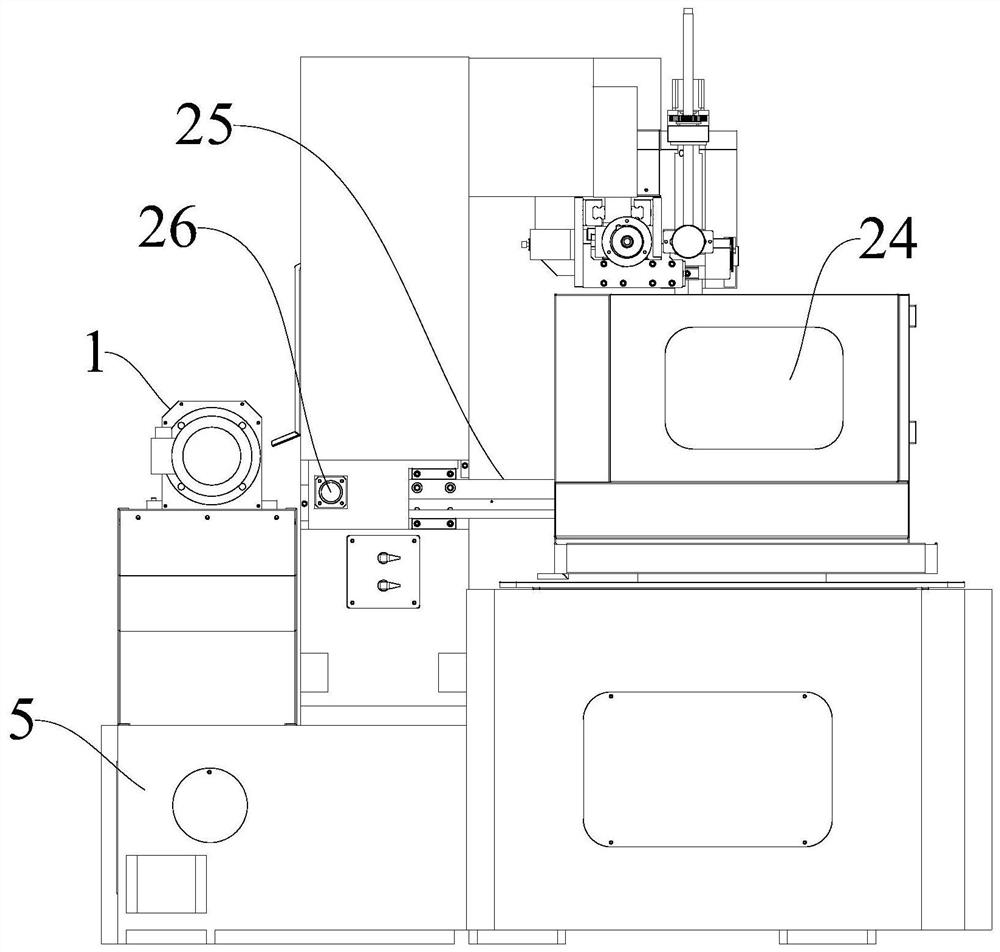

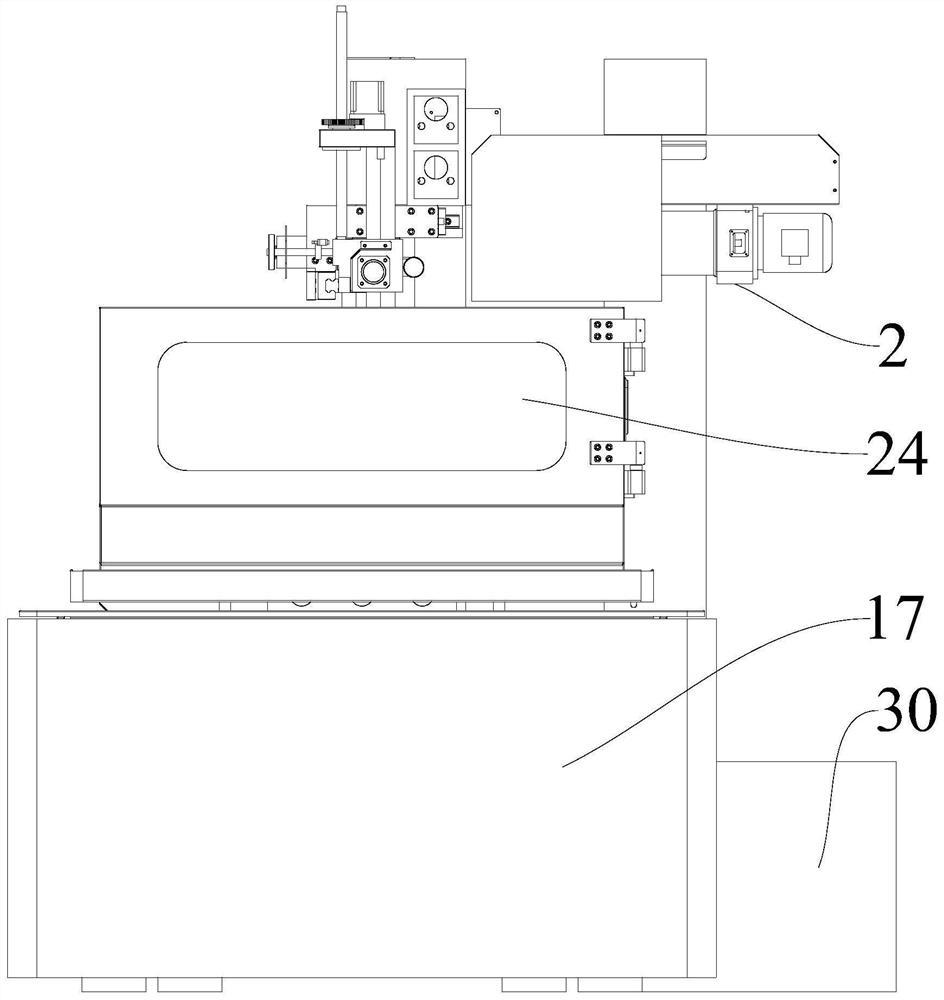

[0041] Please refer to Figure 1-13 , a wire-feeding wire cutting machine with fast threading, comprising a body and a cutting wire; the rear side of the body is provided with a first winding device 1, and the front side of the body is provided with a second winding device 2; one end of the cutting wire is connected to the first winding The device 1 is connected, and the other end of the cutting wire is connected with the second winding device 2; the machine body is also provided with a winding assembly for cutting wire transmission.

[0042] In this embodiment, both ends of the cutting wire are respectively connected to the first winding device 1 and the second winding device 2, the first winding device 1 can be used as a wire releasing device, and the second winding device 2 can be used as a wire taking device. The first winding device 1 and the second winding device 2 are all provided with the synchronous motor 3 of the bobbin 4 and the rotation of the driving bobbin 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com