Fan and motor thereof

A motor and casing technology, applied in the field of coil setting of fans and their inner rotor motors, can solve the problems of difficult start, reduce fan air volume, magnetic flux leakage, etc., reduce production and manufacturing costs, improve motor efficiency, and simplify winding way effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A fan and its motor according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

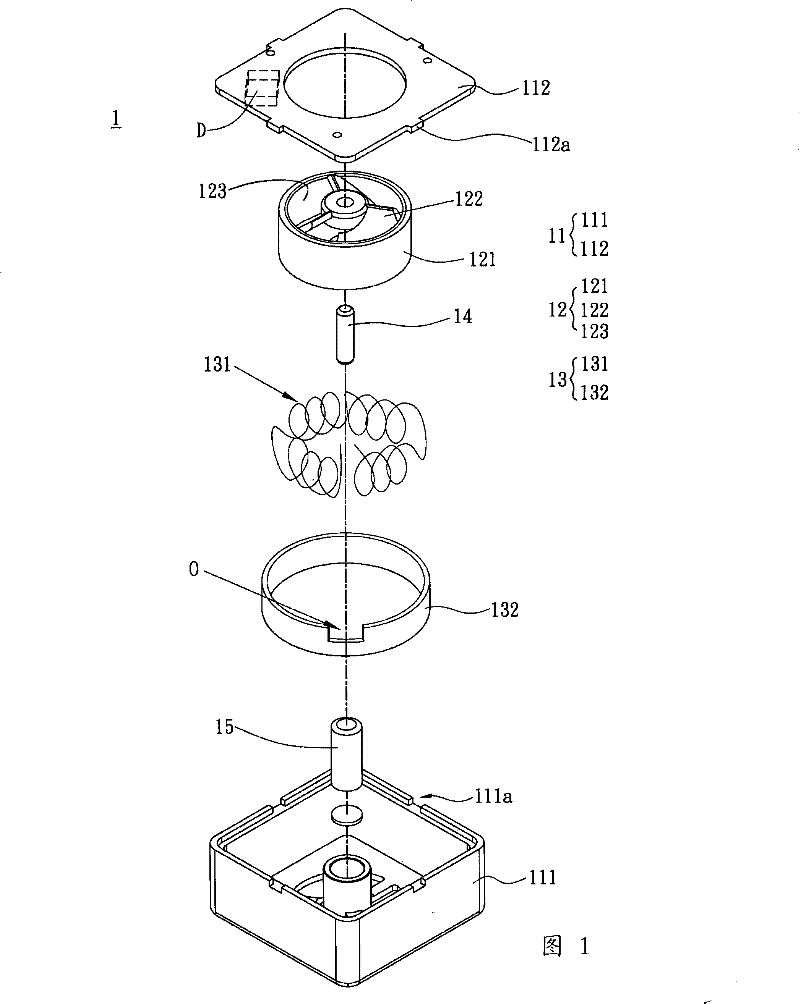

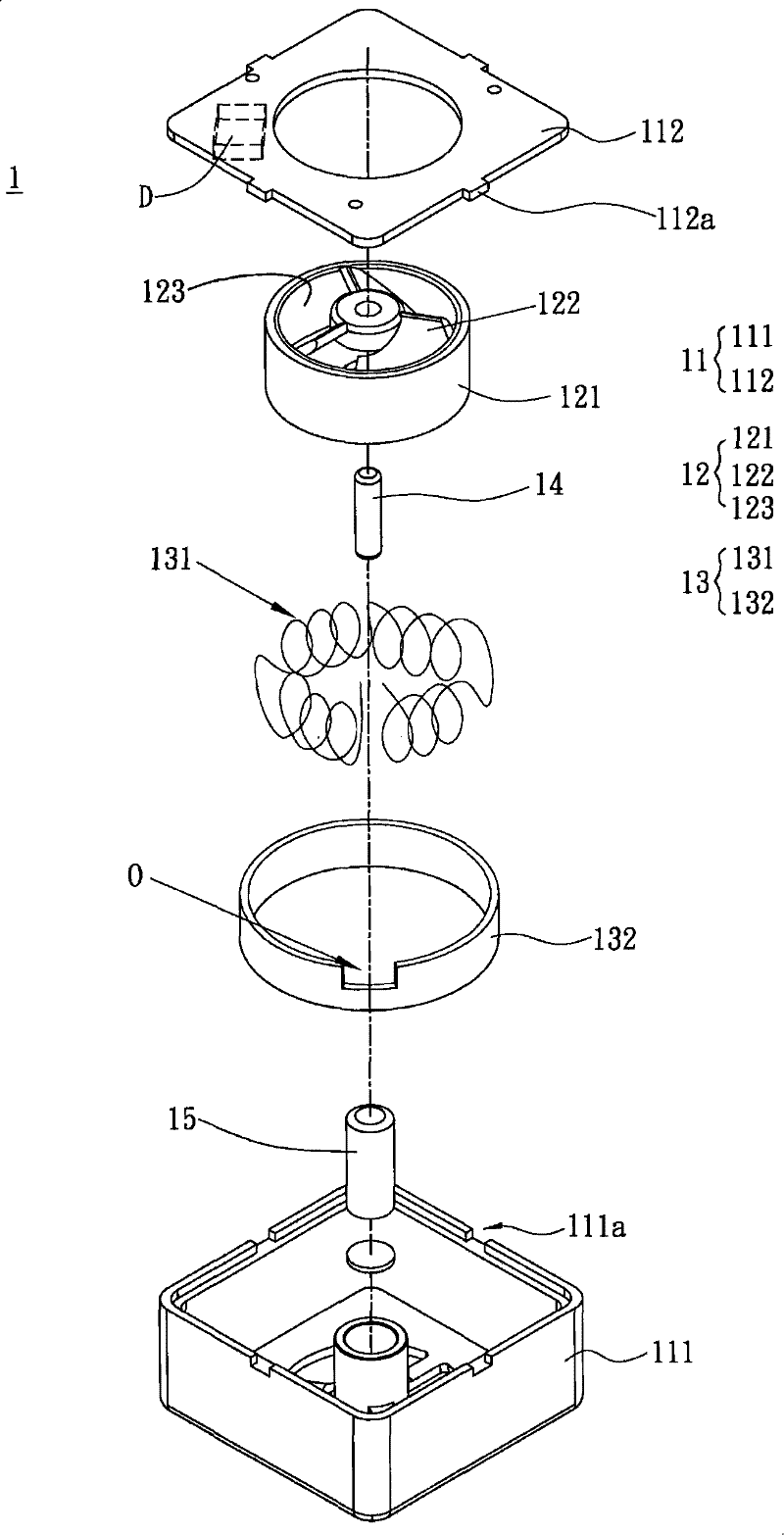

[0022] Please refer to figure 1 As shown, a fan 1 of the present invention includes an inner rotor motor, and the inner rotor motor includes a casing 11 , a rotor assembly 12 and a stator assembly 13 . The rotor set 12 has a rotor 121, the rotor has a fan blade 122 accommodated in the casing 11, and another magnetic element is sleeved on the rotor 121, the rotor 121 can also be directly made of magnetic materials, so that it can save As a demagnetizing element, a first magnetically conductive element 123 is arranged on the inner ring of the rotor 121 to provide a closed magnetic circuit. The stator group 13 is accommodated in the housing 11 corresponding to the rotor group 12. The stator group 13 includes A coil 131 , the coil 131 is formed by a continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com