Energy-saving type transformer and manufacturing method thereof

A manufacturing method and transformer technology, which is applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor magnetic core, transformer/inductor parts, etc., can solve the requirements of high technological level, inconvenient transformer assembly and maintenance, and low efficiency and other issues, to achieve the effect of reducing the waste of iron core materials and energy consumption, the utilization rate of materials is close, and the production cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

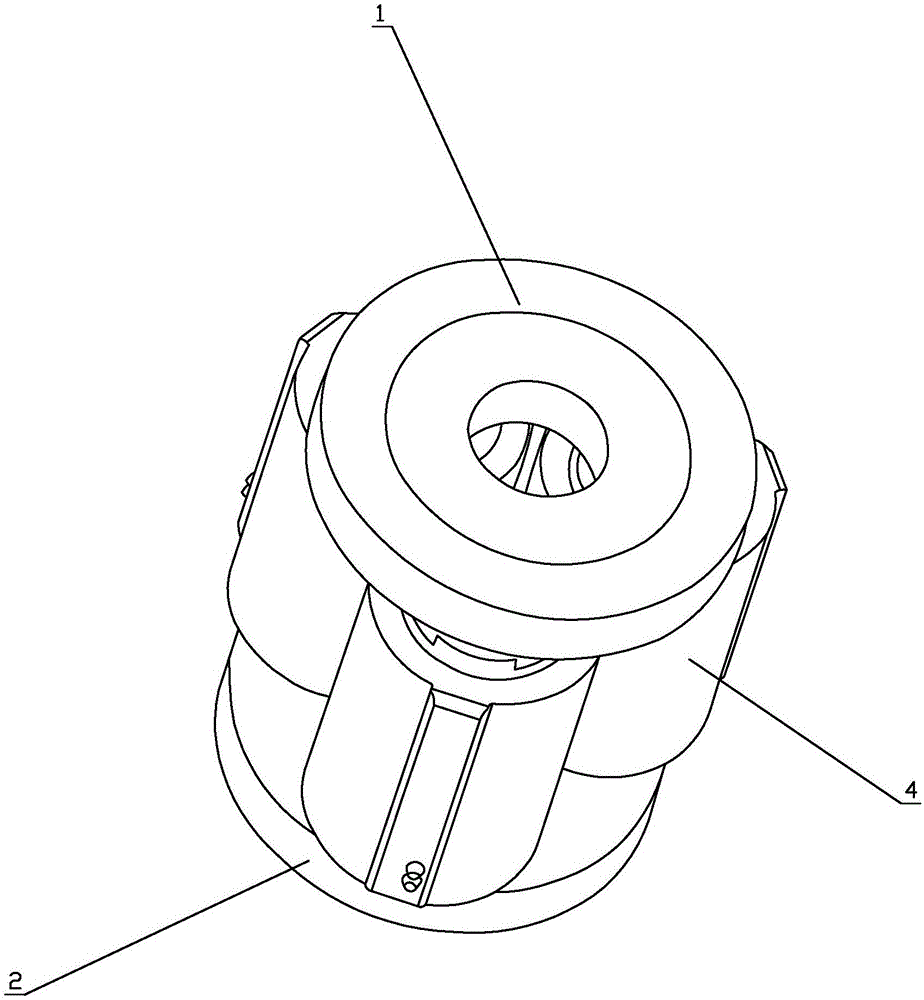

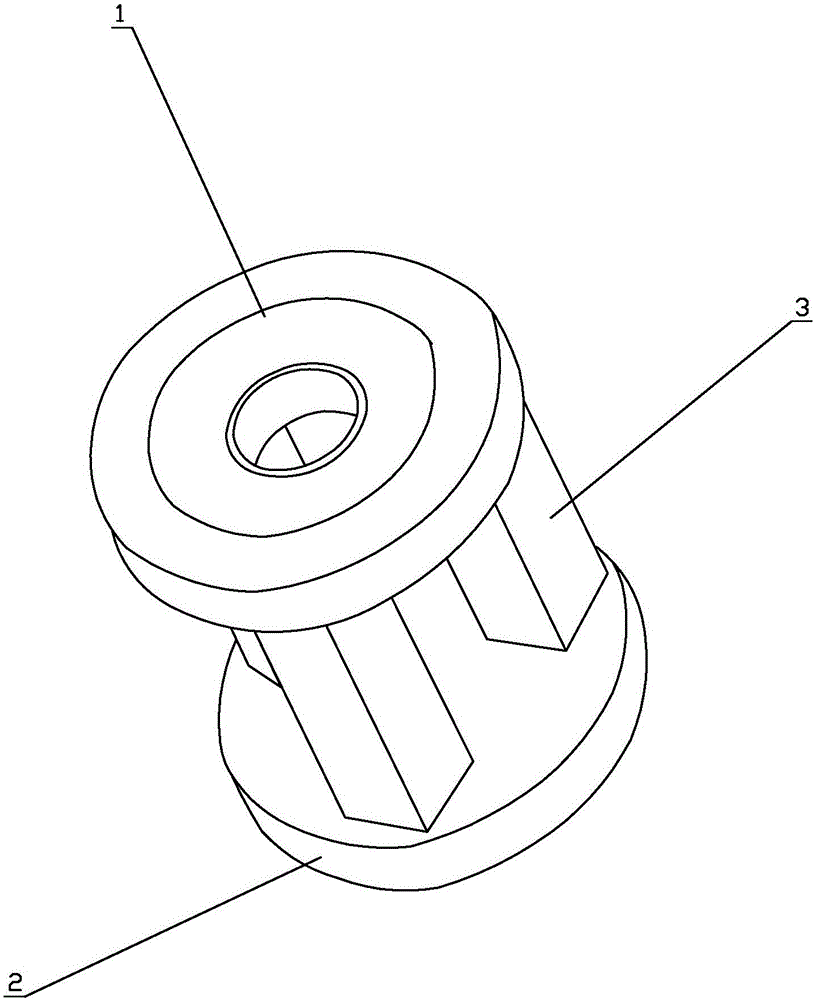

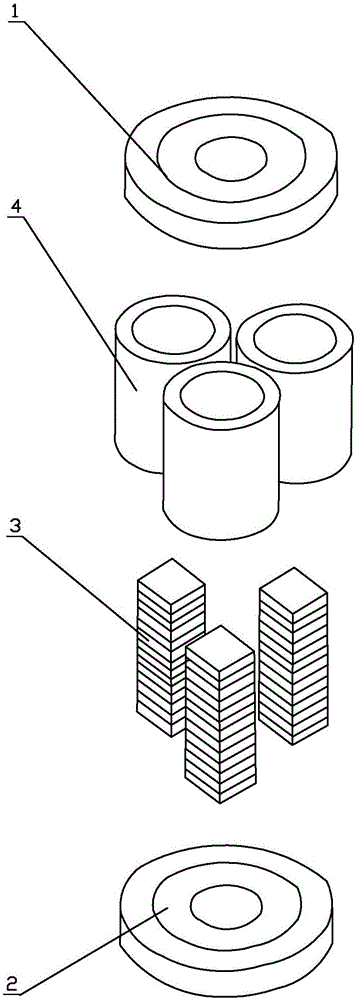

[0029] see Figure 1-Figure 3 , an energy-saving transformer, including a core and a coil 4; the core is mainly composed of an upper iron yoke 1, a lower iron yoke 2 and a core column 3, and there are three core columns 3, and are located between the upper iron yoke 1 and the lower iron yoke 2 The three pillars are arranged in a character shape; the distance between the three pillars is equal.

[0030] There are direct seams between the upper iron yoke 1, the lower iron yoke 2 and the core column 3, and are filled with high magnetic permeability materials.

[0031] The cross-sectional area of the magnetic flux of the upper iron yoke 1 and the lower iron yoke 2 is smaller than the cross-sectional area of the core post 3 .

[0032] The upper and lower iron yokes and the core column are directly seamed and bonded by a special process to achieve a ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com