Fluid pump manufacturing method

A manufacturing method and a fluid pump technology, which are applied in the field of pump device manufacturing, can solve problems such as increasing the winding time of a stator assembly, and achieve the effects of saving the winding time and improving the winding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0021] The fluid pump 100 is applied in an automobile heat management system, and the fluid pump 100 provides flow power for the working medium of the automobile heat management system.

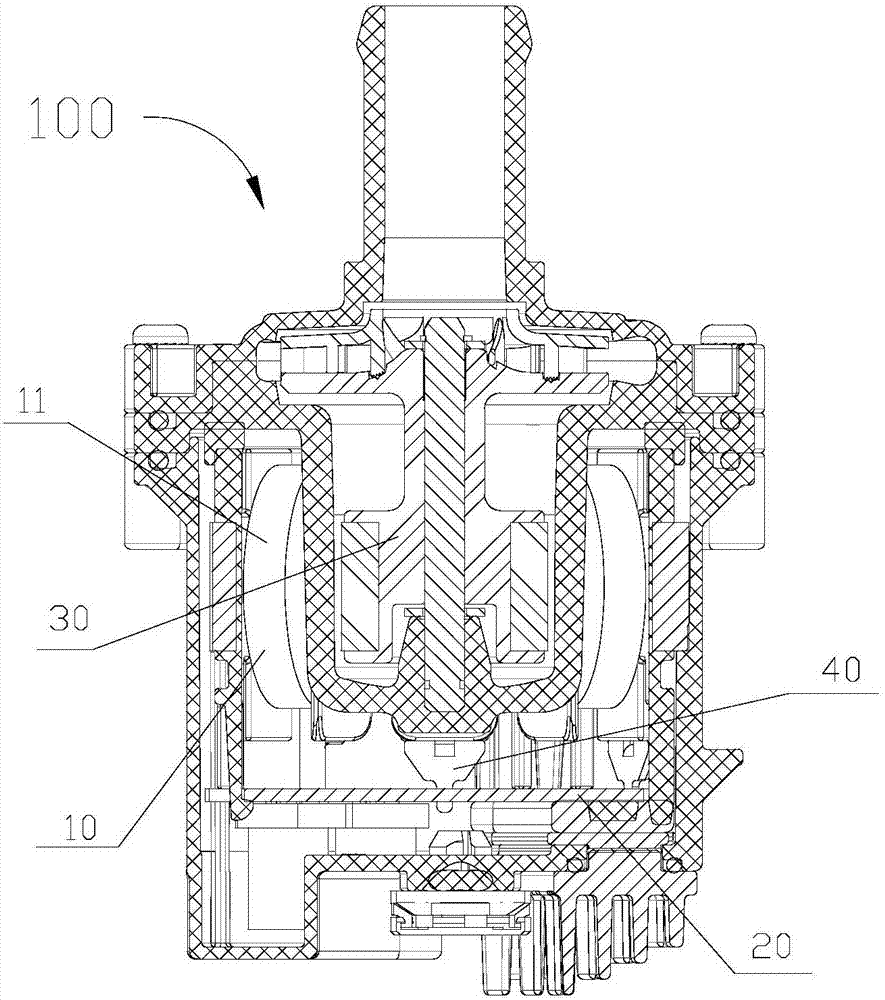

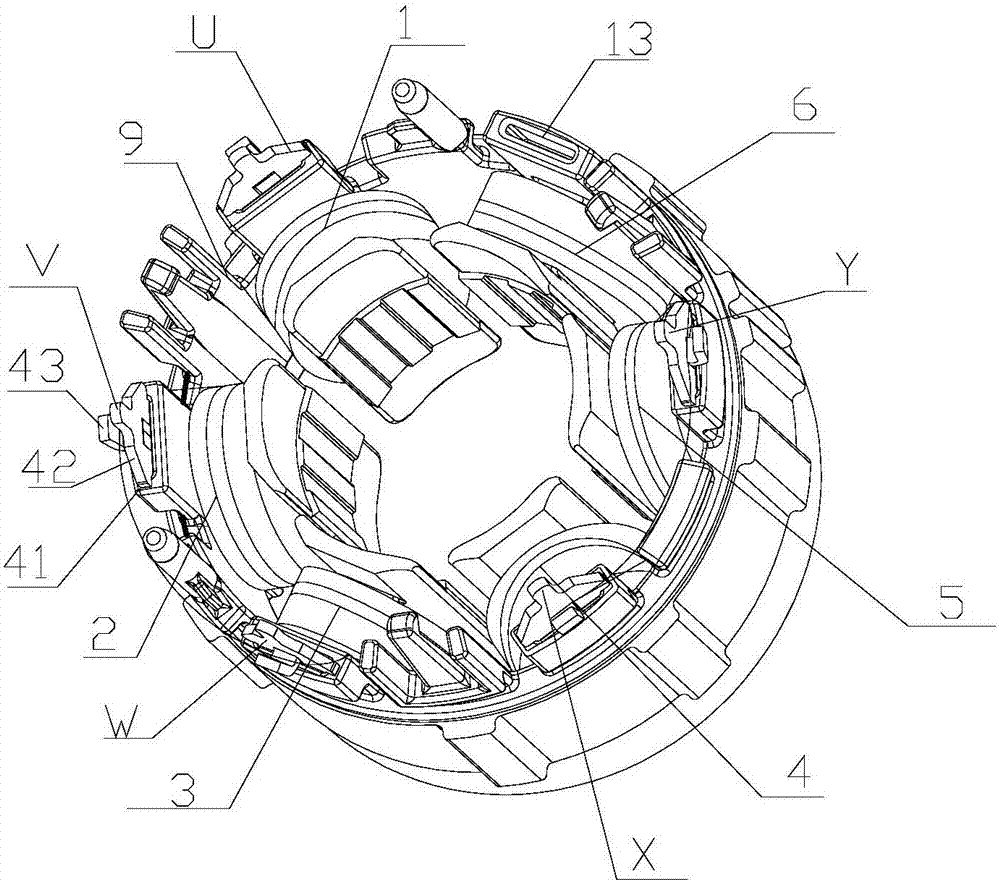

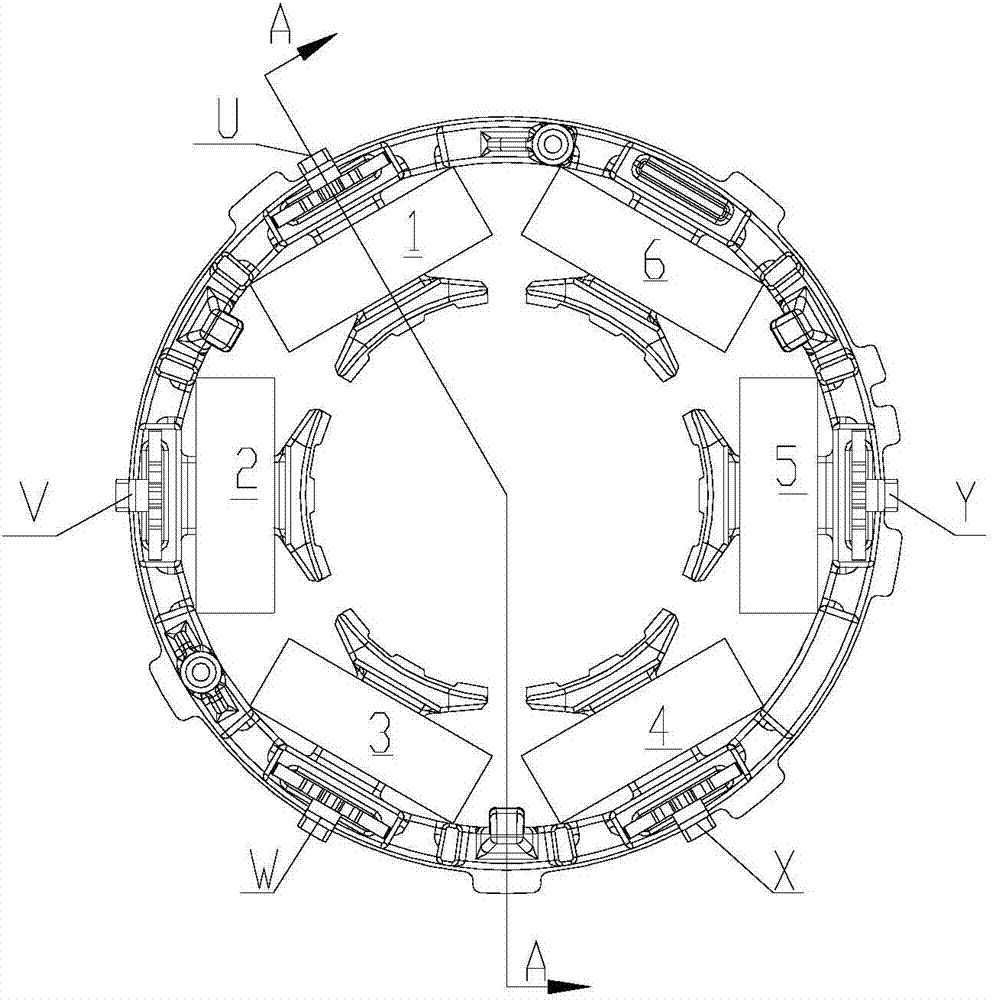

[0022] see in conjunction Figure 1 to Figure 6 , the fluid pump 100 includes a stator assembly 10, a printed circuit board 20, and a rotor assembly 30, the rotor assembly 30 includes four magnetic poles, the stator assembly 10 includes six tooth poles, the fluid pump 100 includes a three-phase motor, and the three-phase motor includes a stator assembly 10 And the rotor assembly 30, the stator assembly 10 includes the coil 11, the winding frame 12 and the terminal 40, the coil 40 and the printed circuit board 20 are electrically connected through the terminal 40, and the printed circuit board 20 is controlled by the set program or the set circuit through the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com