Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Resolve rebound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

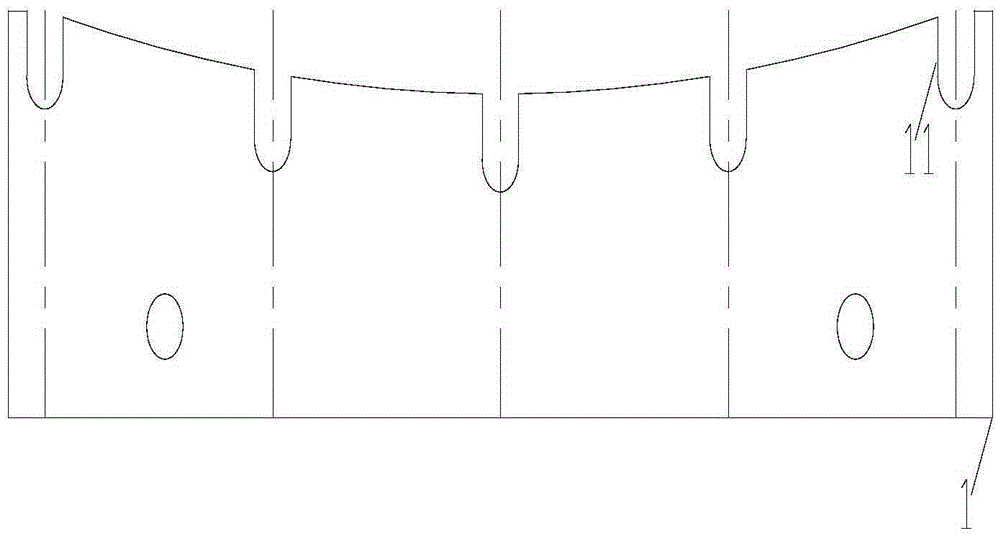

Resilience control method for moulding top surface of car roof

ActiveCN101549380ASmall sizeEffectively meet size requirementsShaping toolsVehicle componentsSkylightEngineering

The invention relates to a resilience control method for the moulding top surface of a car roof. The method is used in the process of punching and forming a set of moulds of a full car roof and a skylight car roof, and includes the step of respectively punching a full car roof workpiece and a skylight car roof workpiece by selecting the common mould by N steps of working procedures, N is an integer larger than zero, the moulding surface of a mould core of the common mould is a first compensation moulding surface, and the shape of the first compensation moulding surface is identical with the shape of a punched moulding surface in any working procedure in the N steps of working procedures of punching the full car roof workpiece and the skylight car roof workpiece before resilience; and after the N steps of punching working procedures are accomplished, at least one mould core and one stripper plate of the mould are replaced, a new mould core and a new stripper plate are used for punching the skylight car roof workpiece by M steps of working procedures after replacement, M is an integer larger than zero, and the resilience volume of the skylight car roof workpiece is different from the resilience volume in the N steps of punching working procedures.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

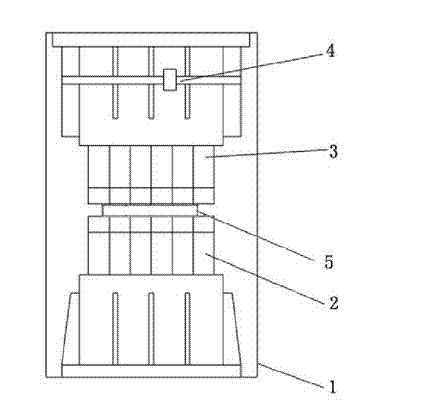

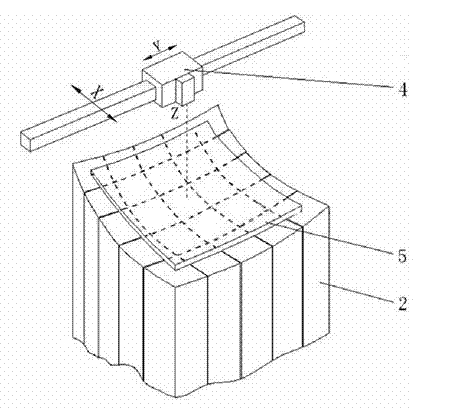

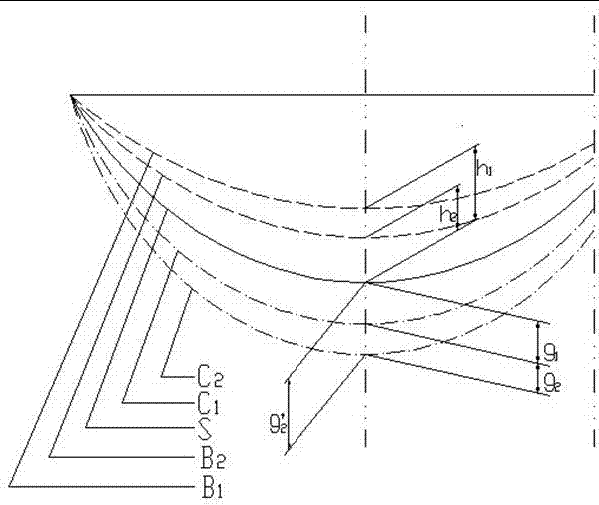

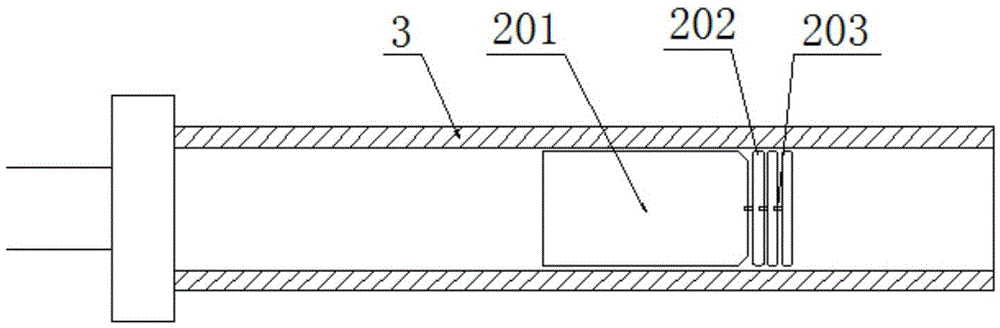

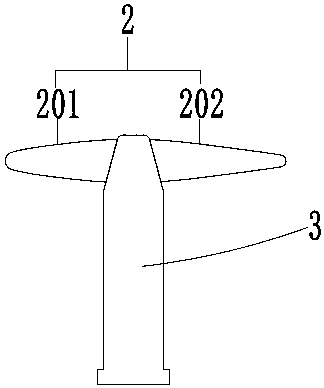

Method and device for forming plates through gradual approximation bending

InactiveCN102500672ASolve the problem of bending springbackResolve reboundMetal working apparatusNumerical controlMeasuring instrument

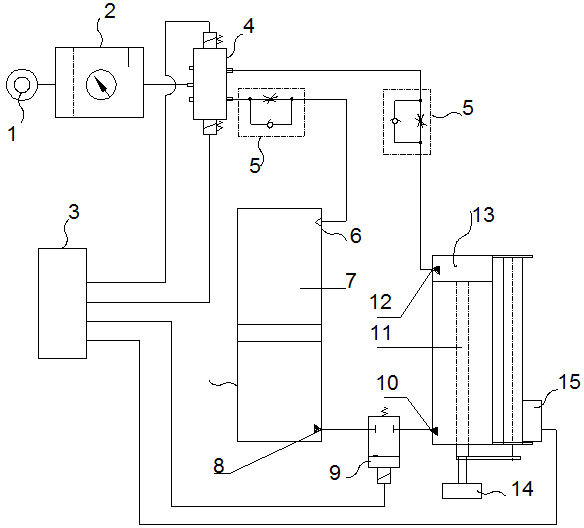

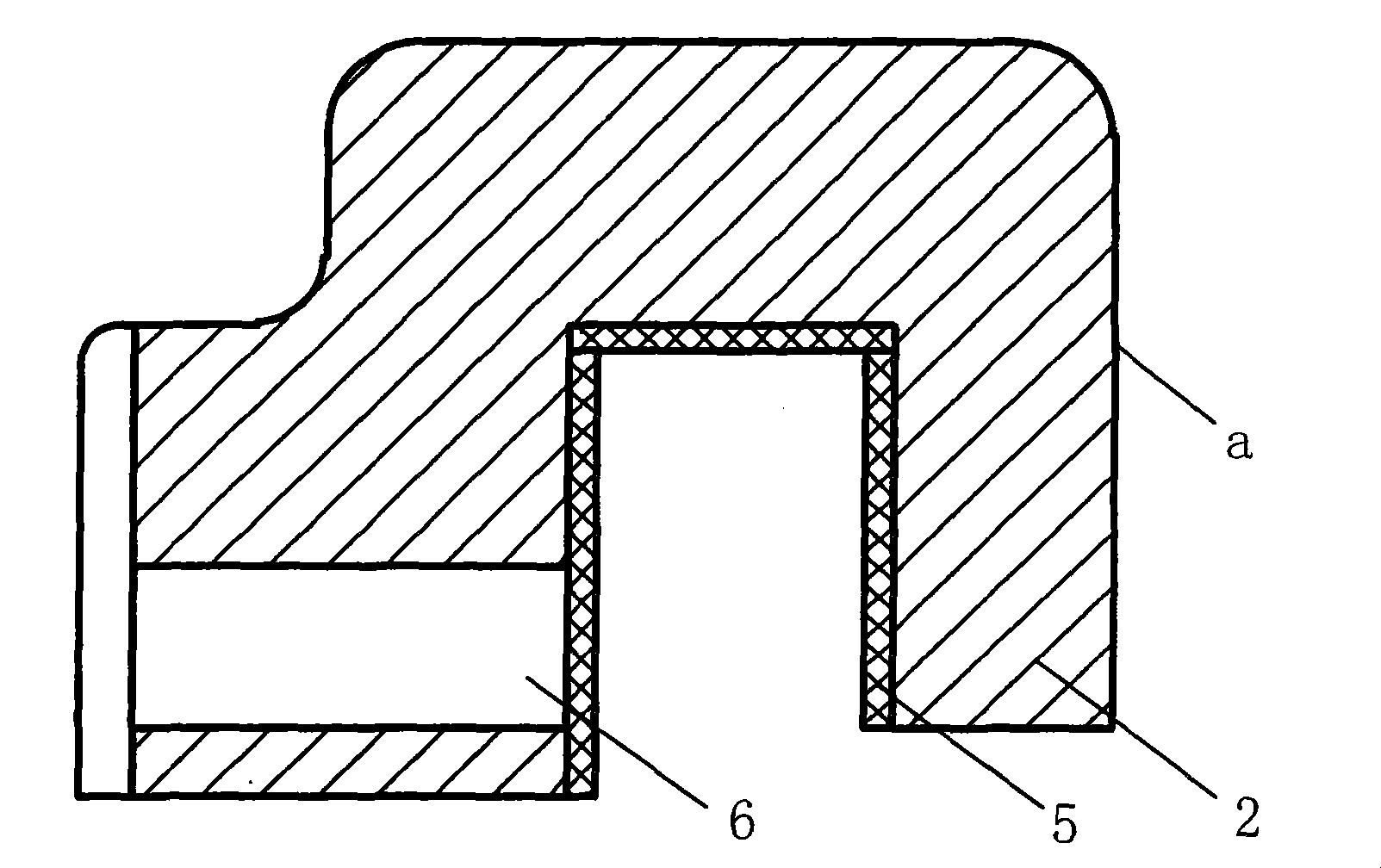

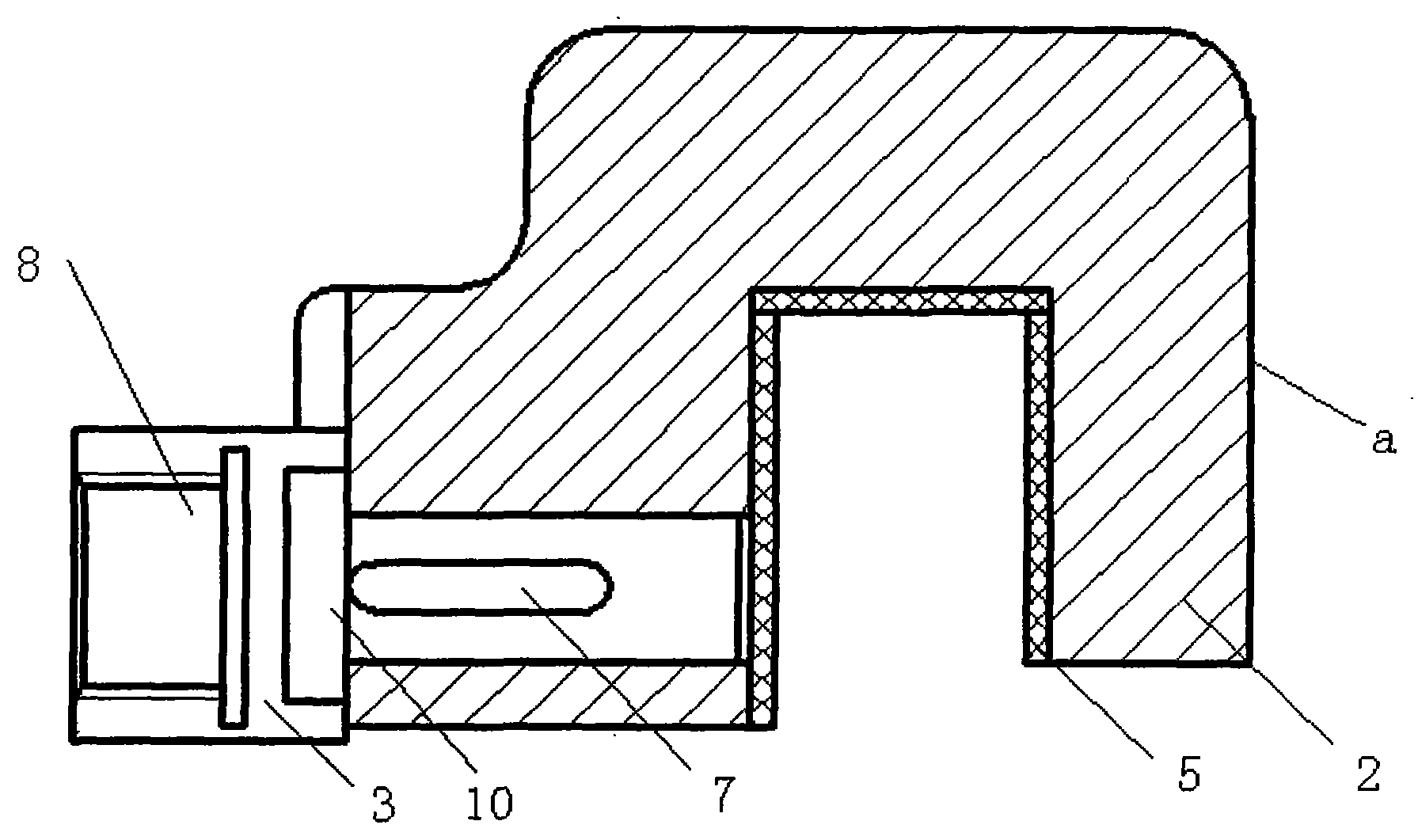

The invention discloses a method and a device for forming plates through gradual approximation bending on a three-dimensional numerical control plate bending machine (1). The method comprises the following steps of: performing targeted iteration gradual approximation bending by utilizing a resilience rule of a plate (5), comparing a shape of an actually formed curved surface B of the plate (5) subjected to pressing resilience with a shape of a theoretical target curved surface S through online measurement, and setting an approximation bending pressing curved surface C for limited approximation pressing according to an error offset value h after resilience. By the device, an online laser three-dimensional coordinate measuring instrument (4) connected with a computer is arranged on the three-dimensional numerical control plate bending machine (1). Complex mechanical calculation is not needed, the problem of bending resilience of a ship plate can be rapidly solved on line in real time, as long as the approximation bending pressing is performed for 1 to 3 times generally, the requirement on machining accuracy can be met, the problem of resilience of a numerically controlled bent plate is rapidly and effectively solved, the forming accuracy of a three-dimensional curved surface ship plate is guaranteed, and the method and the device have simple and rapid effects.

Owner:SHANDONG SURELY MACHINERY CO LTD

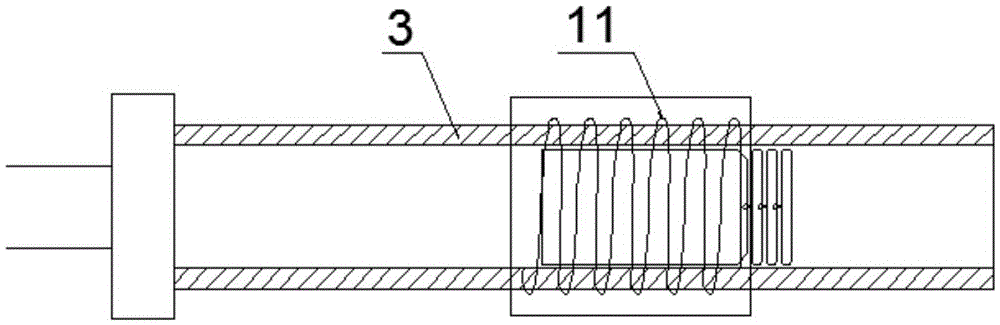

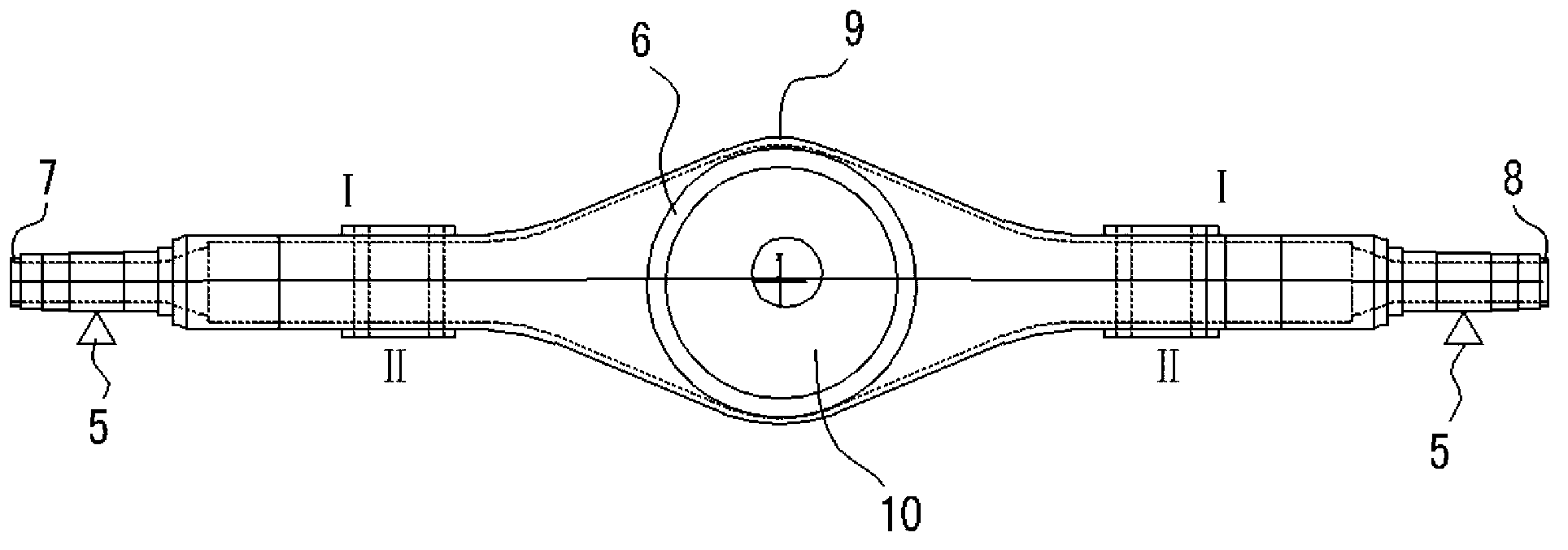

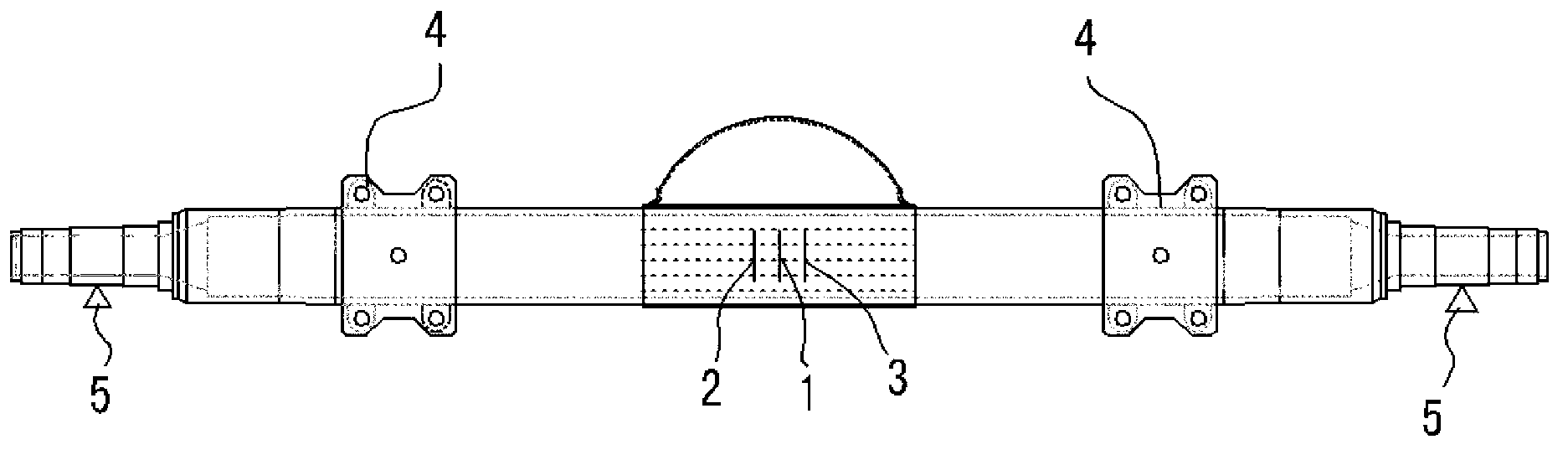

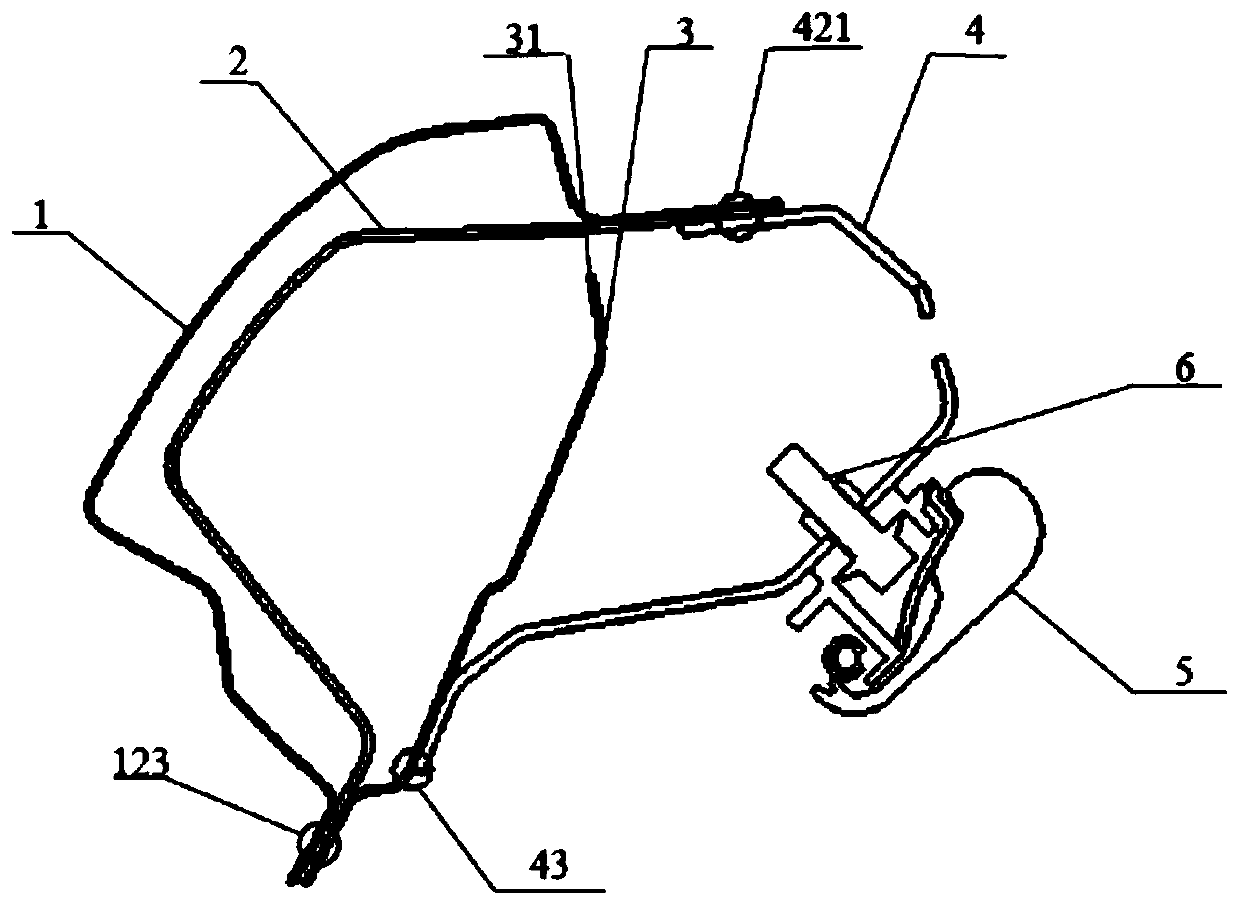

Solid solution-bending-aging forming device and method for vehicle body aluminum alloy pipe

The invention discloses a solid solution-bending-aging forming device and method for a vehicle body aluminum alloy pipe. The device comprises a heating mechanism and a bending mechanism. The heating mechanism comprises an induction coil and a high-frequency power source. The induction coil is arranged on the periphery of a bent part of the pipe in a sleeving mode and connected with the high-frequency power source. The bending mechanism comprises a bending die, a fixed clamp block, a crease-resistant block, movable clamp blocks and a rigid / flexible core die. The bent part of the pipe is placed on the bending die. One end of the pipe is clamped on the bending die through the fixed clamp block and the crease-resistant block, and the other end of the pipe is clamped by the movable clamp blocks. The rigid / flexible core die is arranged in the pipe. The fixed clamp block, the crease-resistant block and the movable clamp block are designed in a split mode, and the bending die is designed in an insert mode, so that water channels are processed conveniently and replacement after abrasion is convenient. The bending die, the fixed clamp block, the crease-resistant block and the movable clamp blocks are all internally provided with serpentine channels used for introducing cooling water. The solid solution-bending-aging forming device and method for the vehicle body aluminum alloy pipe can significantly improve the strength, the hardness and the forming precision of aluminum alloy pipes, and the springback problem of the pipes after bending and quenching is effectively solved.

Owner:WUHAN UNIV OF TECH

Method for straightening flame of large-deformation automobile drive axle housing

ActiveCN103008402ASimple measurement toolConvenient measuring toolMetal working apparatusFixed bearingEngineering

The invention discloses a method for straightening the flame of a large-deformation automobile drive axle housing. The method is characterized in that a deformed axle housing is put on a detection platform to measure the axle housing deformation; sand is fully filled in an inner cavity of the deformed axle housing, the deformed axle housing is sealed and is then put on a 'V'-shaped piece fixed bearing, the other parts of the deformed axle housing are kept suspended in the air, the back side of a working surface of the deformed axle housing is put upwards, and loading application force points for assisting the straightening are positioned on two end positions, at which an axle housing spring seat assembly is installed; and heating wires which have the same length and width and are symmetrically distributed are marked on the axle housing along the longitudinal direction sequentially, acetylene flame is used to move from one ends to the other ends of the heating wires to heat, after each heating is completed, water is adopted to cool the axle housing, and flame heating and loading force applying are repeatedly carried out until the axle housing deformation reaches the tolerance allowed range of the axle housing design. By the method, the material shaping reserve consumption can be effectively avoided, and accordingly, the reutilization ratio of the large-deformation drive axle housing is increased.

Owner:HEFEI UNIV OF TECH

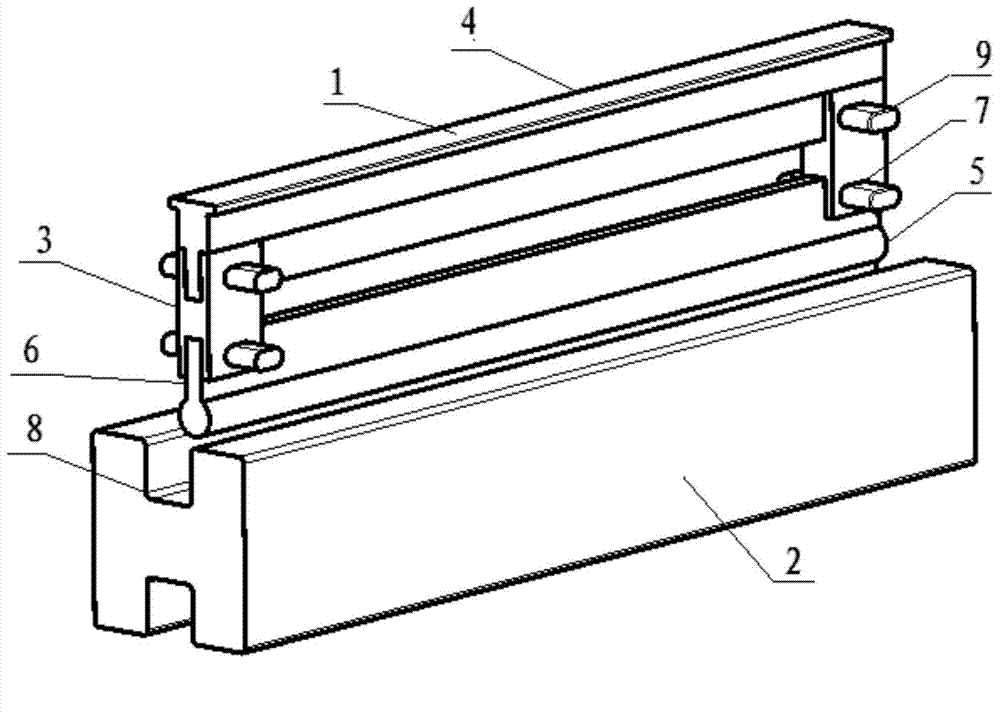

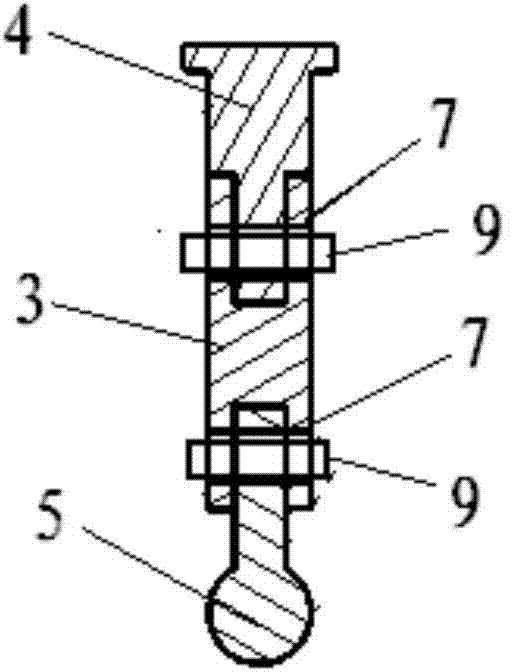

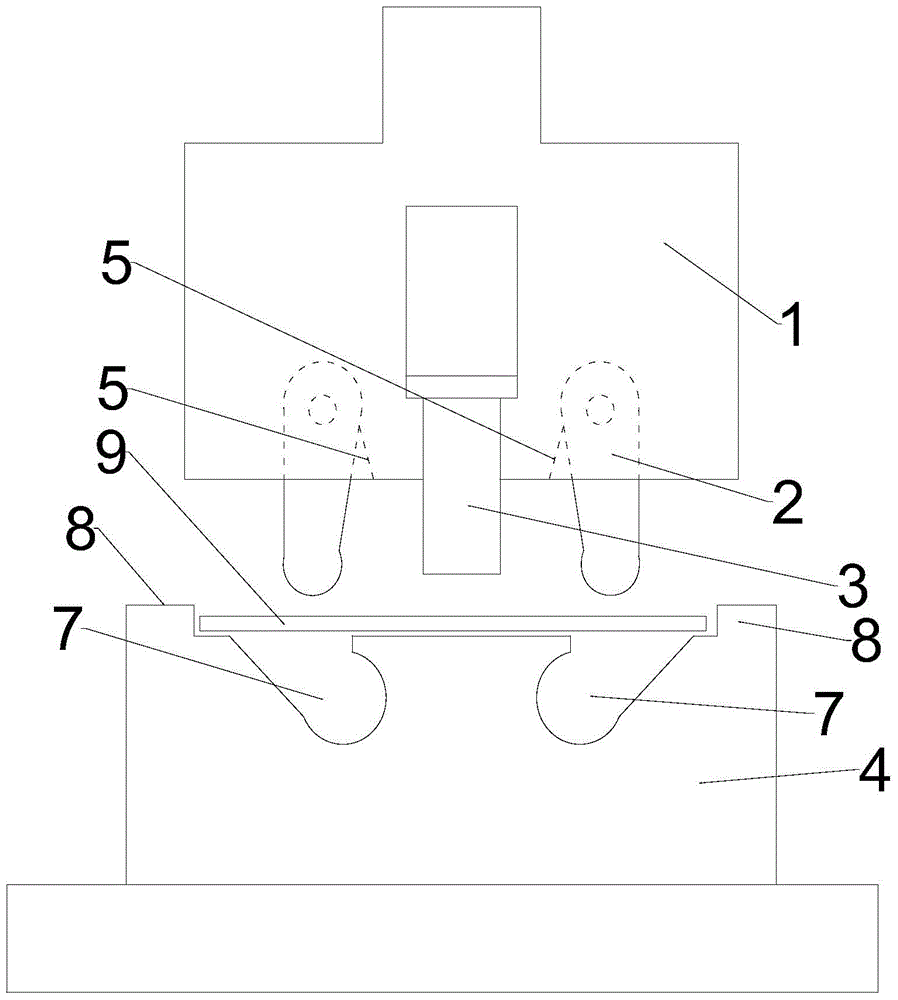

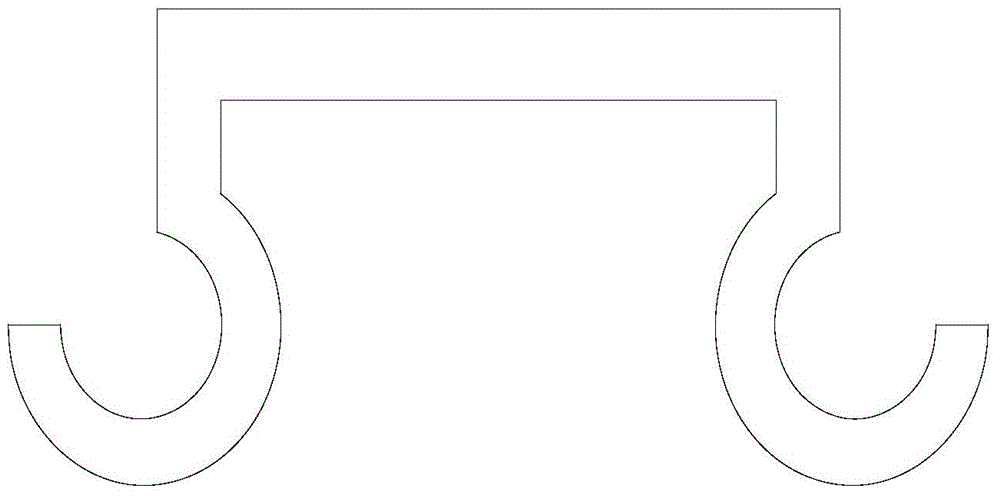

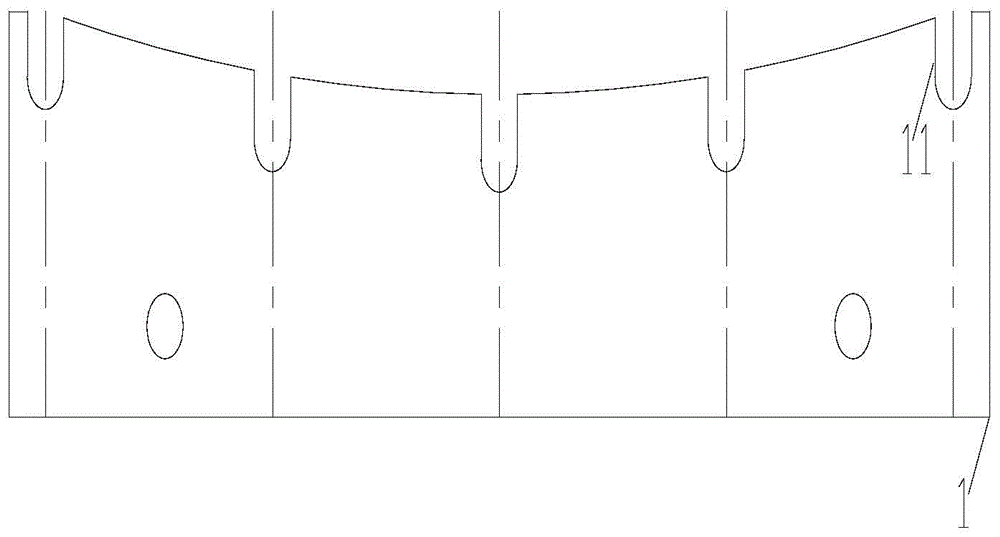

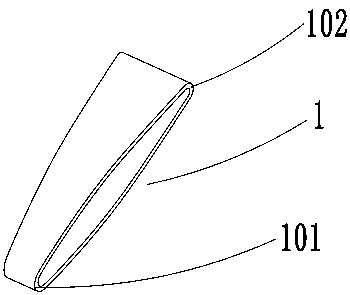

Bending mould of forming straight circular tube and incremental forming method

InactiveCN104741460AResolve reboundOvercome the problem of uneven springbackShaping toolsMaterials scienceComposite structure

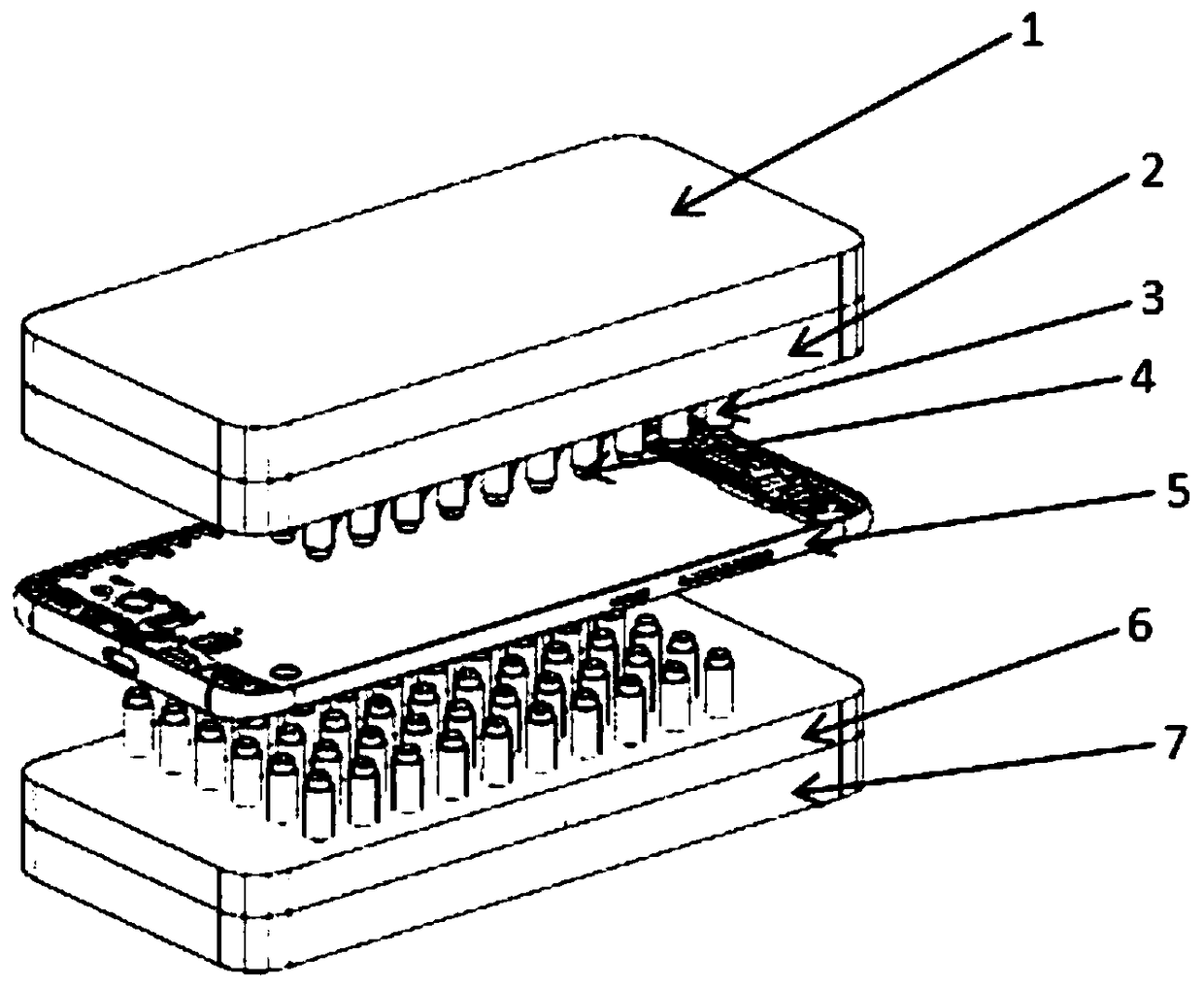

Provided are a bending mould of a forming straight circular tube and an incremental forming method. The mould comprises an upper mould body and a lower mould body. The upper mould body is of a composite structure and is composed of a mould handle and a forming male mould, the mould handle is of a strip-shaped structure with a T-shaped section, the two ends of the mould handle are provided with connecting holes, the forming male mould is of a strip-shaped structure with a hammer-shaped section, the two ends of the forming male mould are provided with connecting holes corresponding to the mould handle, and the mould handle is connected with the forming male mould through connecting blocks with upper and lower connecting holes and connecting pins. The lower mould body is in the shape of a cuboid with grooves, and the grooves are corresponding to the position of the forming male mould.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

Positioning control mechanism of vertical load for double-acting cylinder

InactiveCN102606562ASolve the speed problemPrecise positioning controlServomotorsFluid-pressure actuator componentsElectrical controlVertical load

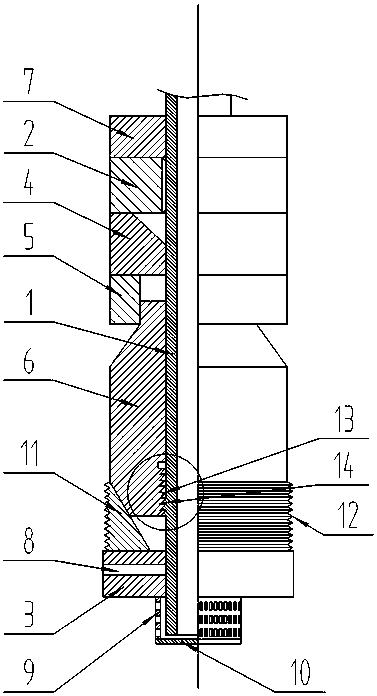

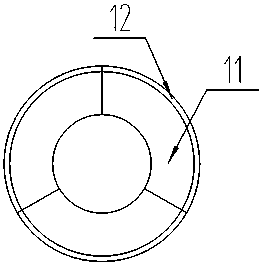

The invention aims at providing a positioning control mechanism of a vertical load for a double-acting cylinder (13). A three-position five-way electromagnetic valve for air supply (4) is connected to an air inlet and outlet opening (6) of an air-liquid converter (7) and an air inlet and outlet opening (12) of a double-acting cylinder, and a stopping electromagnetic valve (9) is connected between a liquid inlet and outlet opening (8) of the air-liquid converter and a liquid inlet and outlet opening (10) of the double-acting cylinder. The control mechanism is provided with a position sensor (15) for detecting the position of a cylinder piston and an electrical control system (3), wherein the electrical control system (3) controls the opening and the closing of the electromagnetic valves according to the piston position (11) detected by the position sensor (15), and stably moves the cylinder piston to the target position, so that the cylinder piston is stopped and kept at the stopping position.

Owner:王凡

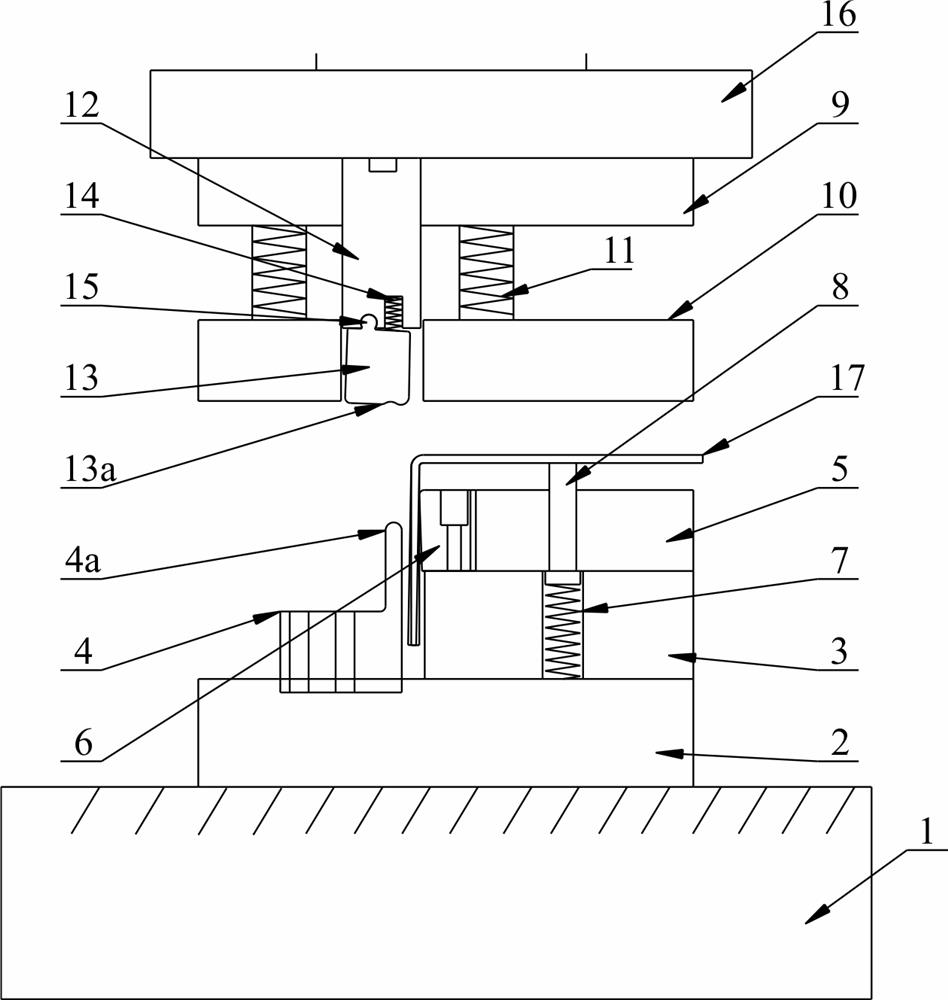

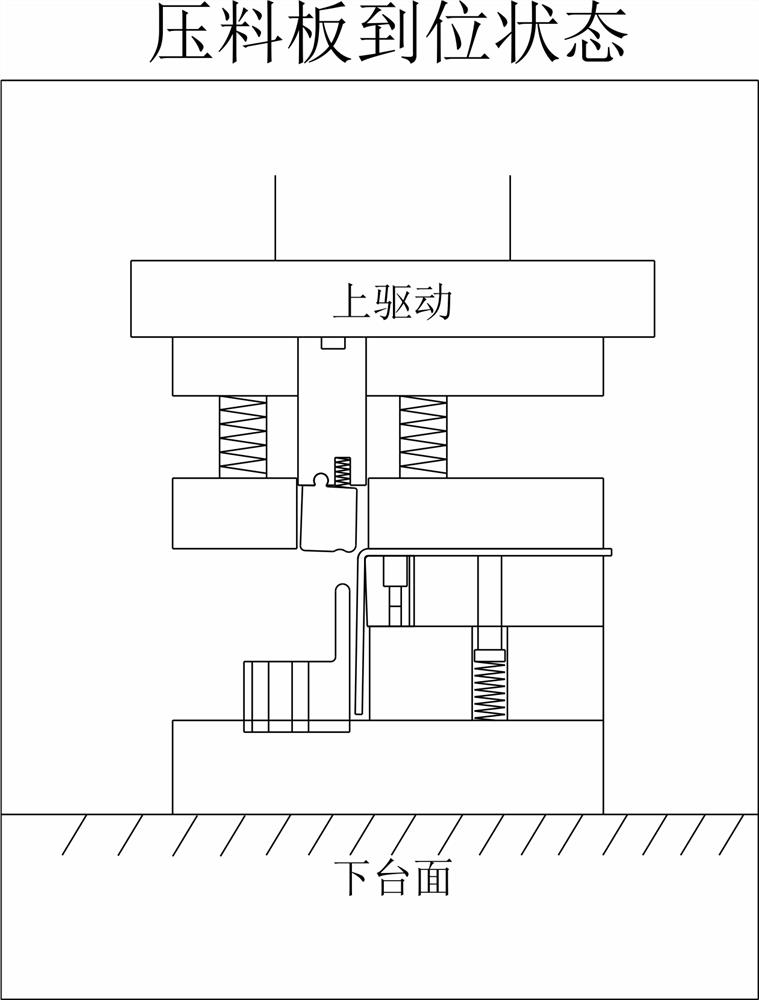

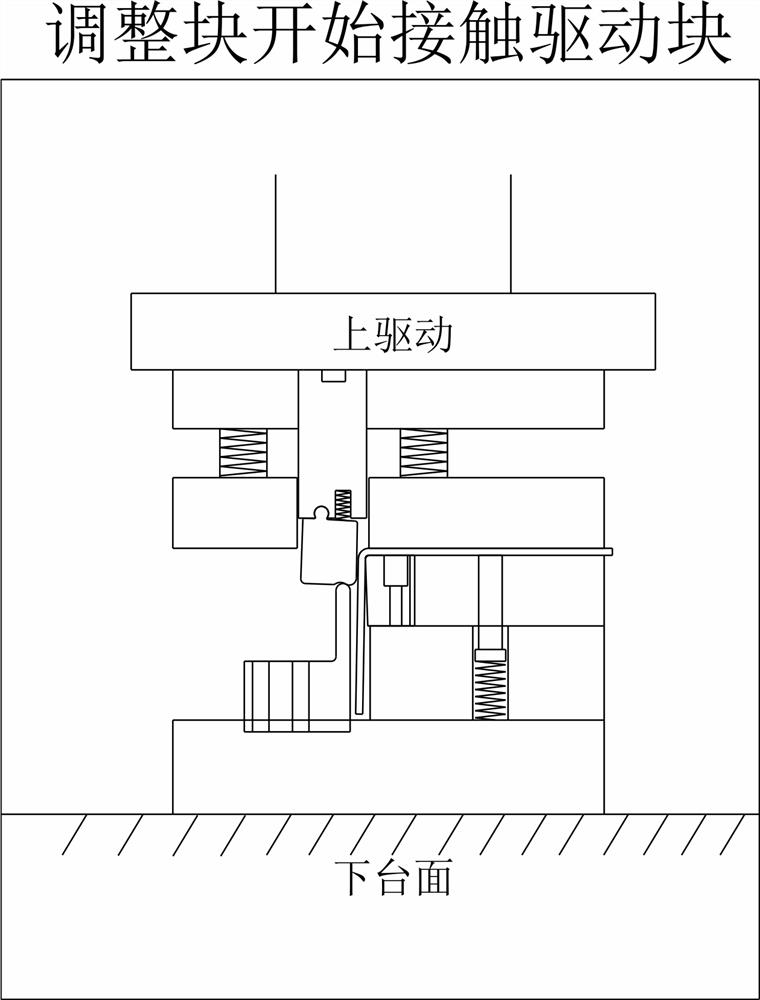

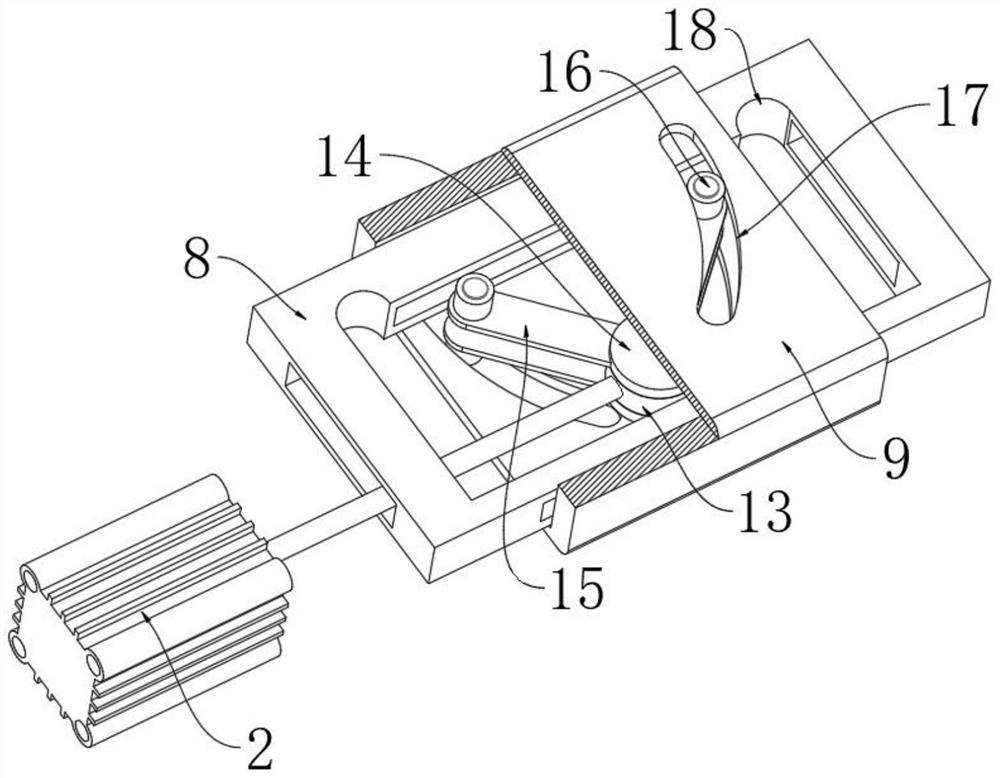

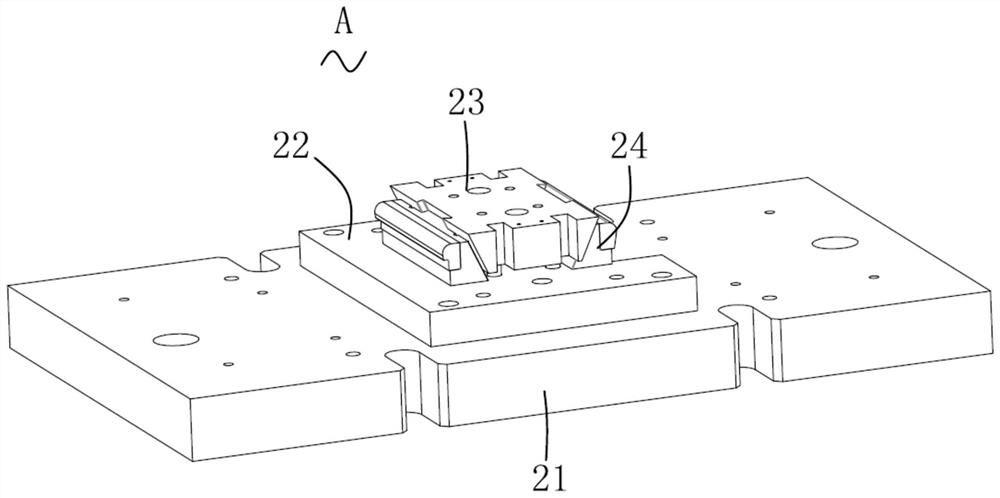

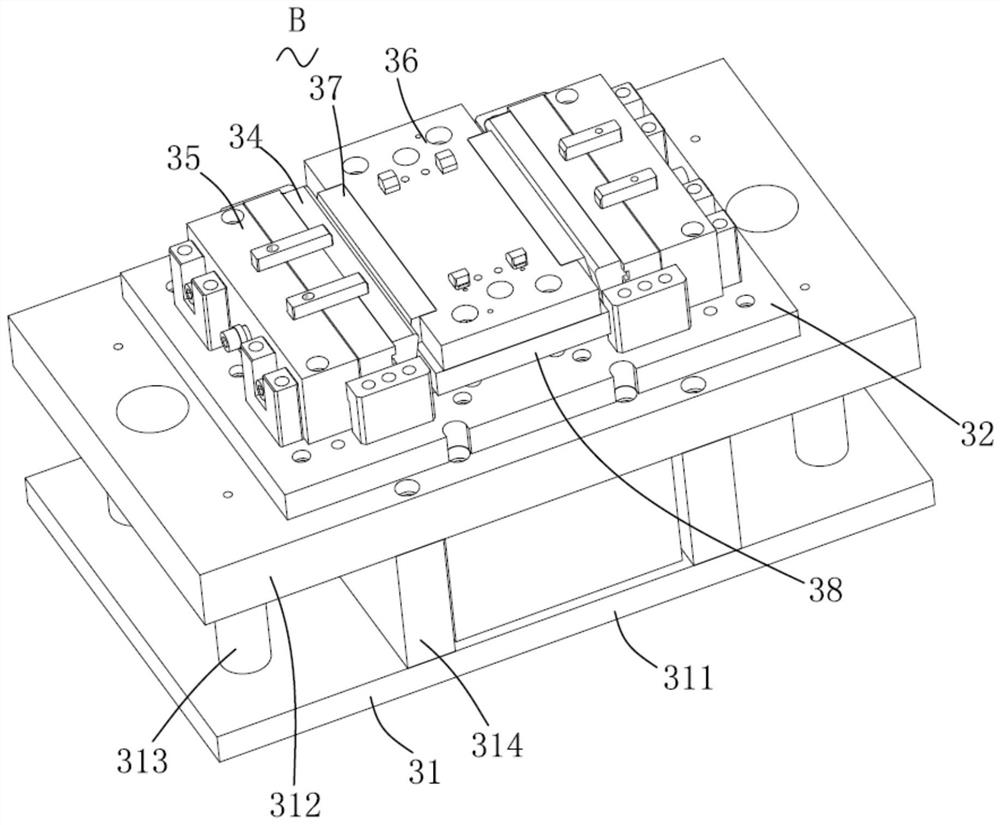

Quick adjusting device for bending springback of stamping die

The invention discloses a quick adjusting device for bending springback of a stamping die. The quick adjusting device for bending springback of the stamping die comprises a lower table top assembly and an upper punch assembly, wherein the lower table top assembly comprises a lower die plate installed on a lower table top, a lower die adjusting block and an adjusting driving block; the adjusting driving block is arranged beside the lower die adjusting block; the upper punch assembly comprises a material pressing plate and a bending assembly which are installed at an upper drive bottom; the material pressing plate is connected to the upper drive bottom through a spring; the bending assembly comprises an adjusting fixing base; a channel allowing the adjusting fixing base to penetrate through is formed in the material pressing plate; the bottom of the adjusting fixing base is connected with a bending adjusting block jointly matched with the adjusting drive block and the lower die adjusting block; the side face of the bending adjusting block is a bending molded surface; the top face of the bending adjusting block is hinged to the bottom of the adjusting fixing base through a rotating shaft; and the bending adjusting block abuts against the bending adjusting block from the bottom through the adjusting driving block to drive the bending adjusting block to rotate so as to extrude a product. According to the quick adjusting device for bending springback of the stamping die provided by the invention, the springback amount of a stamped part can be controlled more effectively and accurately.

Owner:JIANGSU SCHUERHOLZ PRECISION METAL FORMING CO LTD

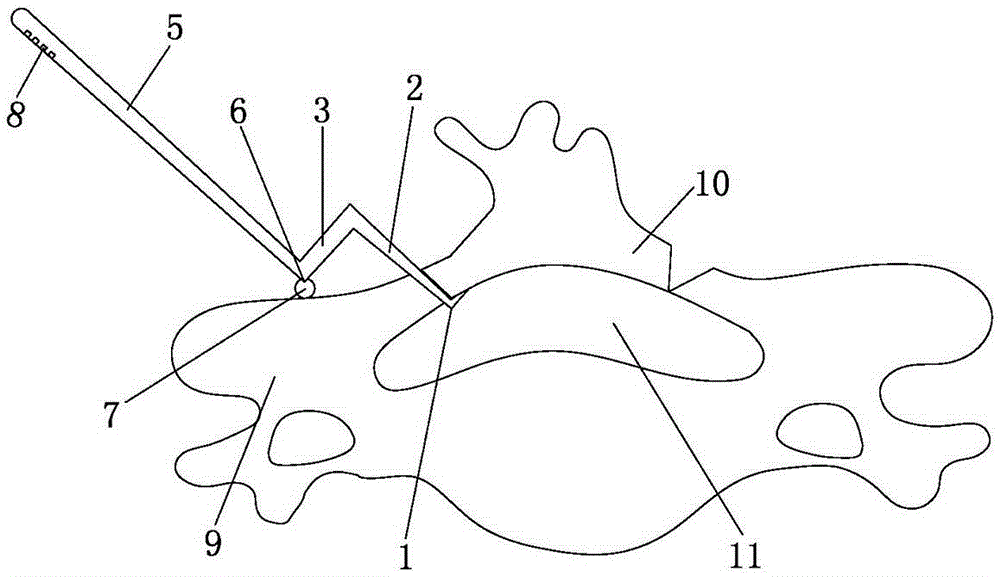

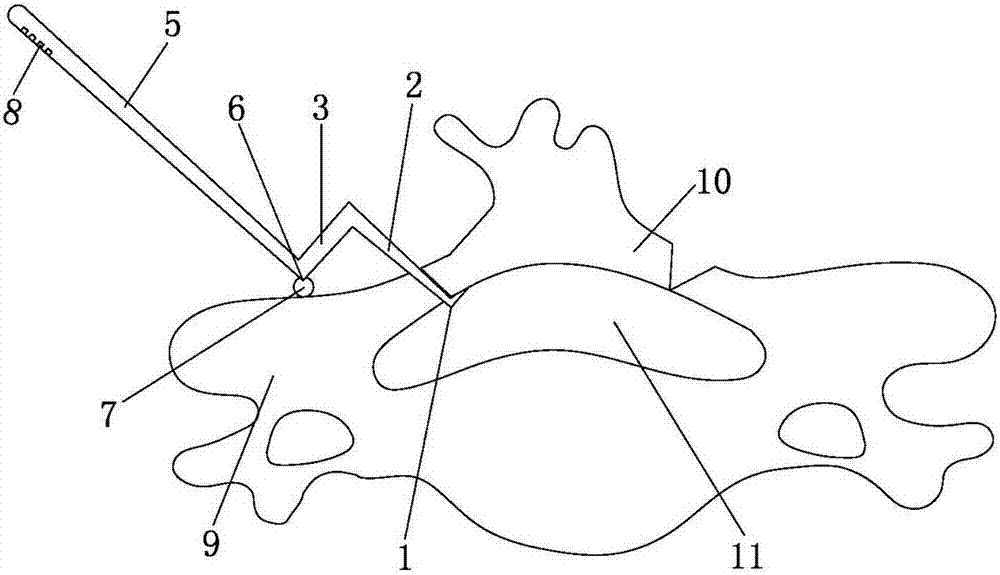

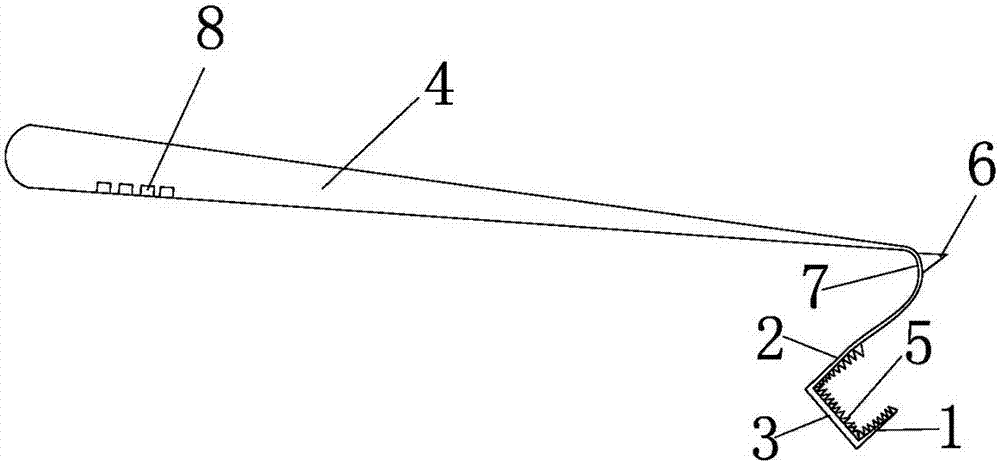

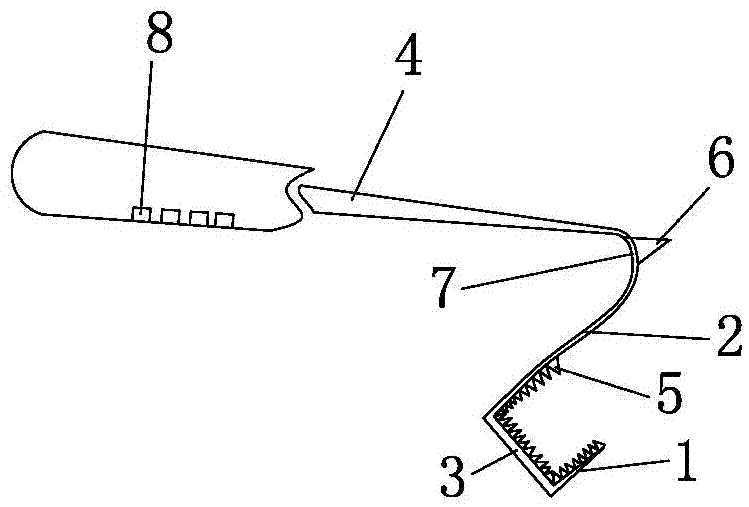

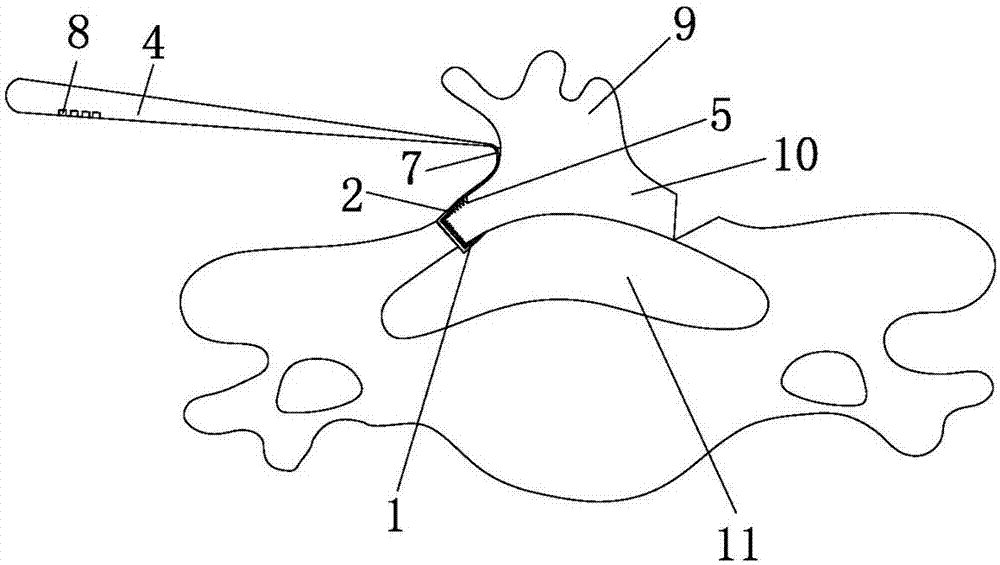

Opener for vertebral plate

The invention relates to an opener for a vertebral plate, and effectively solves the problems in a cervical posterior operation of inconvenience in use, difficulty in operation and poor effect in an operation of pushing a door opening side and opening the vertebral plate and occurrence of a dangerous accident caused by easiness in springback when the vertebral plate is opened. The opener is characterized in that the front part is L-shaped; a bending position of the front part is used as a first vertex; the rear end of a long edge of the front part is obliquely connected with the upper end of a connecting section; the connecting section and a short edge of the front part are mutually, oppositely and respectively arranged at two sides of the long edge of the front part; the lower end of the connecting section is obliquely connected with a handle; the handle and the long edge of the front part are mutually, oppositely and respectively arranged at two sides of the connecting section; the central lines of the front part, the connecting section and the handle are located in the same plane; a connecting position between the connecting section and the handle is used as a second vertex. The opener for the vertebral plate, disclosed by the invention, has the advantages that the structure is simple, the use is convenient, the operation is easy, the working efficiency is high, the springback problem caused when the vertebral plate is opened is solved, and the operation safety is increased.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Bending die with swing male dies

Owner:CHANGZHOU YONGAN SECURITY SERVICE

Electromagnetic repulsion mechanism built through angle steel

ActiveCN107978482AEven by forceLife-span-reducing effectsHigh-tension/heavy-dress switchesAir-break switchesEpoxyEngineering

The invention discloses an electromagnetic repulsion mechanism built through angle steel. The electromagnetic repulsion mechanism is characterized in that a permanent magnet mechanism is arranged at the left side of an angle steel frame; a plurality of vacuum contacts are arranged at the right side of the angle steel frame; a rotating angle steel mechanism is arranged at the upper end of the anglesteel frame; a movable iron plate is arranged at the left side of the rotating angle steel mechanism; the permanent magnet mechanism is arranged at the lower part of the movable iron plate; a plurality of movable conducting rods are arranged at the right side of the rotating angle steel mechanism; the lower end of each movable conducting rod is opposite to one vacuum contact; a plurality of repulsion mechanisms are arranged on the angle steel frame; and each repulsion mechanism is located between the plurality of movable conducting rods and the plurality of vacuum contacts. An original repulsion mechanism is improved, so that repulsion coil epoxy boards of the repulsion mechanism are uniform in stress, springback when the movable conducting rods and the vacuum contacts are opened and closed is avoided and the influence on the life of the vacuum contacts is reduced; and meanwhile, the electromagnetic repulsion mechanism has the characteristics of being high in strength, good in reliability and beneficial to assembly.

Owner:SHANGHAI ELECTRICGROUP CORP

Self-locking bending machine and machining process thereof

PendingCN114505376AAvoid damageAvoid injuryShaping safety devicesGlass productionStructural engineeringMachine

The invention discloses a self-locking bending machine and a machining process thereof, and relates to the technical field of plate machining, the self-locking bending machine comprises a mounting assembly, the mounting assembly comprises a workbench and an outer frame, the outer frame is located above the workbench, and the outer frame and the workbench are fixedly connected through a supporting rod; the two sets of air cylinders are symmetrically arranged on the inner top of the outer frame; and the self-locking assembly comprises two rectangular frames fixedly arranged in the outer frame, and the rectangular frames are sleeved with movable shells in a sliding mode. When the air cylinder moves to the minimum distance or the maximum distance, the mounting shafts can be pushed to enable the mounting plates to rotate, so that the pressing shafts and the rolling wheels enter the limiting openings, one of the mounting plates is in a horizontal state, the movable shell is in a self-locking state, and the situation that a material plate rebounds and a cutter falls off due to damage of the air cylinder is effectively prevented.

Owner:ANHUI SANXIN HEAVY IND MACHINERY MFG

U shaped riveted joint and riveting gun joint

The invention discloses a U-shaped rivet joint, which is characterized in that the rivet joint takes a shape of an inverted U-shaped structure, a bayonet is arranged downwards, the lower end of the tail of the rivet joint is provided with a connecting hole, and the side wall which is axially opposite to the connecting hole is provided with a screwed hole. The invention also discloses a connector used for connecting the U-shaped rivet joint and a rivetter, which is characterized in that the connector takes a shape of a column-table structure, the head of the connector is a column which is provided with a key slot and in transition fit with the connecting hole on the U-shaped rivet joint in a transition way, the tail of the connector is a round table which has one concave station respectively at the left side and the right side which are matched with two bosses at the tail of the U-shaped rivet joint, and the radial center of the round table is provided with a screwed hole. As the bayonet of the U-shaped rivet joint can escape from the non-open part, the riveting of the non-open part can be realized; the U-shaped rivet joint and the connector adopt the transition fit connection, as the two can move relatively, the rebound problem of the rivet joint can be solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Large-caliber PVDF pipe bend forming process

The invention discloses a large-diameter PVDF pipe elbow forming process. It includes the steps of blanking, heating, continuous heating, bending, cooling and reclaiming. The invention adopts a constant temperature method to heat the PVDF pipe material in a continuous rolling manner, so that the inside and outside of the pipe are heated fully and evenly. By controlling the temperature of the pipe to be heated and softened, the bending method of the filler is used when the pipe is bent, which effectively controls the distortion of the cross-sectional shape of the pipe when it is bent. Defects such as wrinkling and large cross-sectional thickness error; and through effective control of the ambient temperature, the heating temperature of the pipe, the preheating temperature of the mold and the filler, the size of the pipe after bending and forming is kept consistent; in addition, after bending and forming The bent pipe is kept in the mold for heat preservation process. Through the control of temperature and time, the internal stress is eliminated, and the springback problem of the pipe can be effectively solved, so that high-quality PVDF bent pipe can be manufactured, which is suitable for various occasions.

Owner:岳阳高澜节能装备制造有限公司

Middle frame shaping equipment and middle frame shaping method for electronic product

Owner:DONGGUAN HUAJING POWDER METALLURGY

Bridge plug with sand production prevention function for fracturing and using method thereof

ActiveCN111577199AReduce erosion damageSolve the problem of borehole sand pluggingFluid removalSealing/packingLine tubingExplosive material

The invention relates to the field of downhole pressure dividing tools for fracturing oil and gas fields, and particularly relates to a bridge plug with a sand production prevention function for fracturing and a using method thereof. The bridge plug comprises a center pipe, a seat sealing push cylinder, a base, a ball seat, a sealing rubber cylinder, a seat sealing cylinder, a locking part and anexplosive, wherein the outside of the center pipe is sequentially sleeved with the base, the locking part, the seat sealing push cylinder, the sealing rubber cylinder, the ball seat, the seat sealingcylinder and the explosive from bottom to top, the explosive, the seat sealing cylinder, the ball seat and the sealing rubber cylinder are in contact with each other, the lower end of the seat sealingpush cylinder is in contact with the locking part and is located in the locking part, the top end of the seat sealing push cylinder is located in the sealing rubber cylinder, and the inner circumferential surfaces of the explosive, the seat sealing cylinder, the ball seat, the sealing rubber cylinder and the seat sealing push cylinder are in clearance fit with the center pipe. According to the bridge plug, the problems of high-speed erosion damage of returned solid substance to a wellhead, an oil extraction pipeline and a gas pipeline and blockage of the inner diameter of a bridge plug by thereturned solid substance and the like are effectively solved, and the bridge plug capable of preventing blockage is achieved.

Owner:PETROCHINA CO LTD

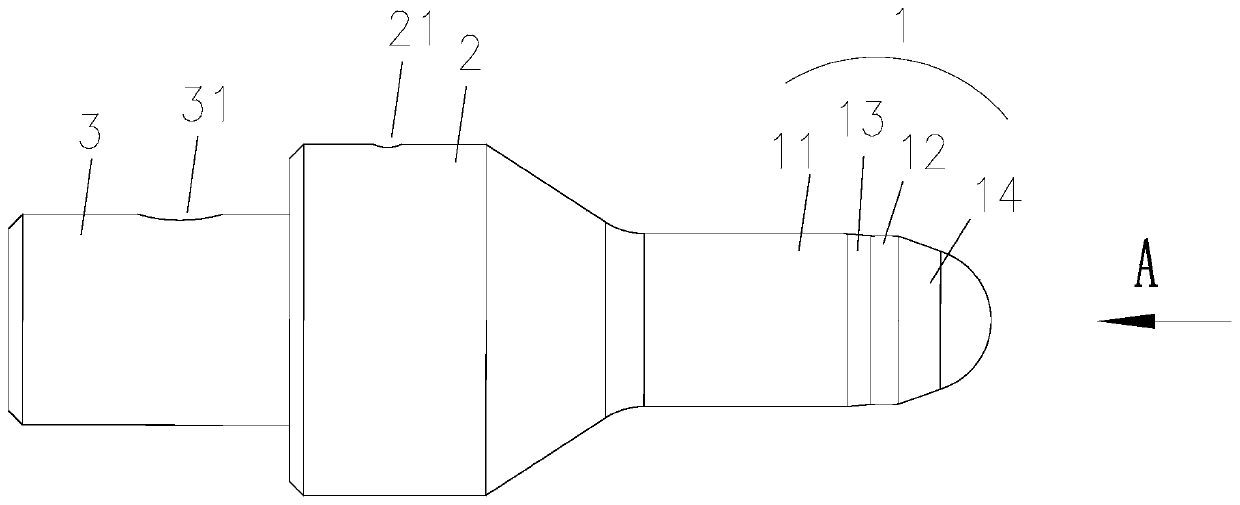

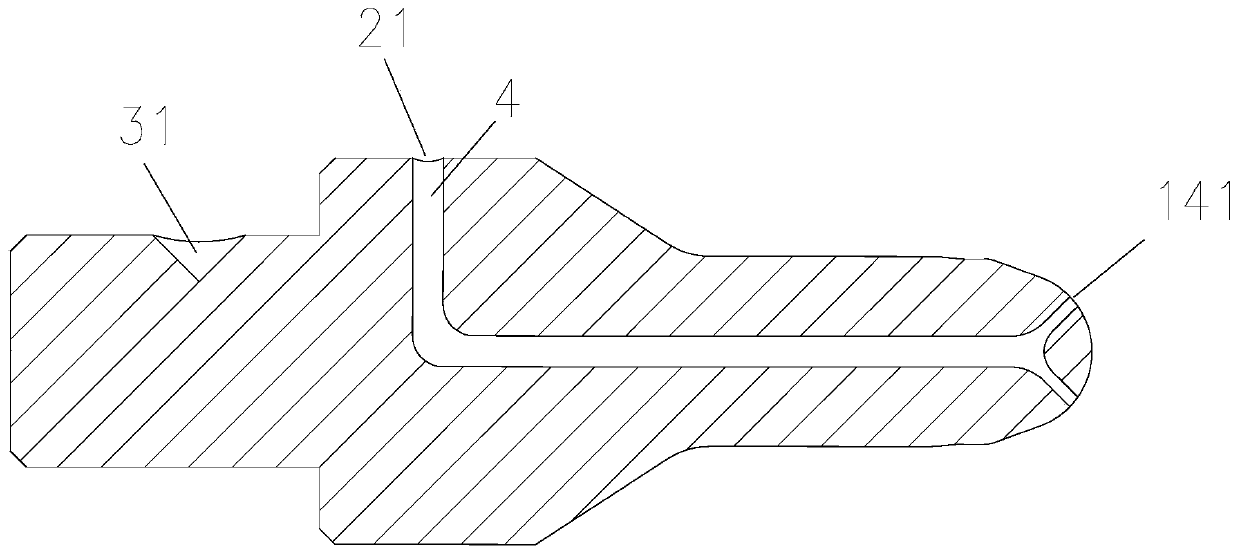

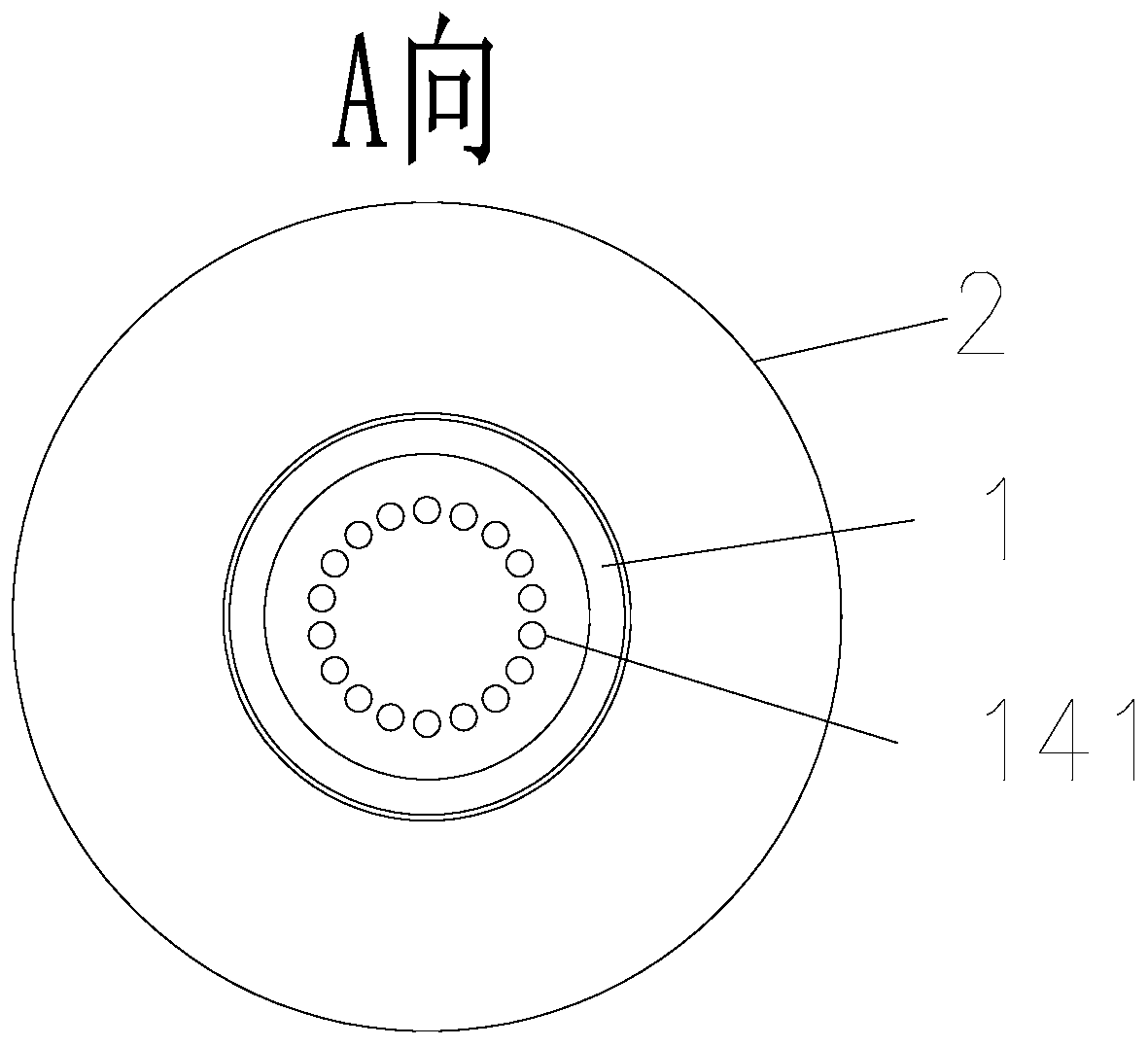

Pipeline part flaring punch die and pipeline forming equipment

PendingCN111250610AResolve reboundAvoid solder pluggingShaping toolsStructural engineeringMechanical engineering

The invention belongs to the field of pipeline processing, and particularly relates to a pipeline part flaring punch die. The pipeline part flaring punch die comprises a die front section, wherein thedie front section is provided with a flaring part and an insertion part; a locking part is arranged between the flaring part and the insertion part; the size of the flaring part is larger than the internal size of a pipeline, and the size of the locking part is smaller than the internal size of the pipeline; and the pipeline sequentially passes through the insertion part, the locking part and theflaring part in the pipeline flaring process, and is subjected to flaring operation through the flaring part. The assembly consistency and positioning accuracy of assembly of the pipeline flared by the flaring die and a normal pipeline are effectively improved.

Owner:GREE ELECTRICAL APPLIANCE SHIJIAZHUANG +1

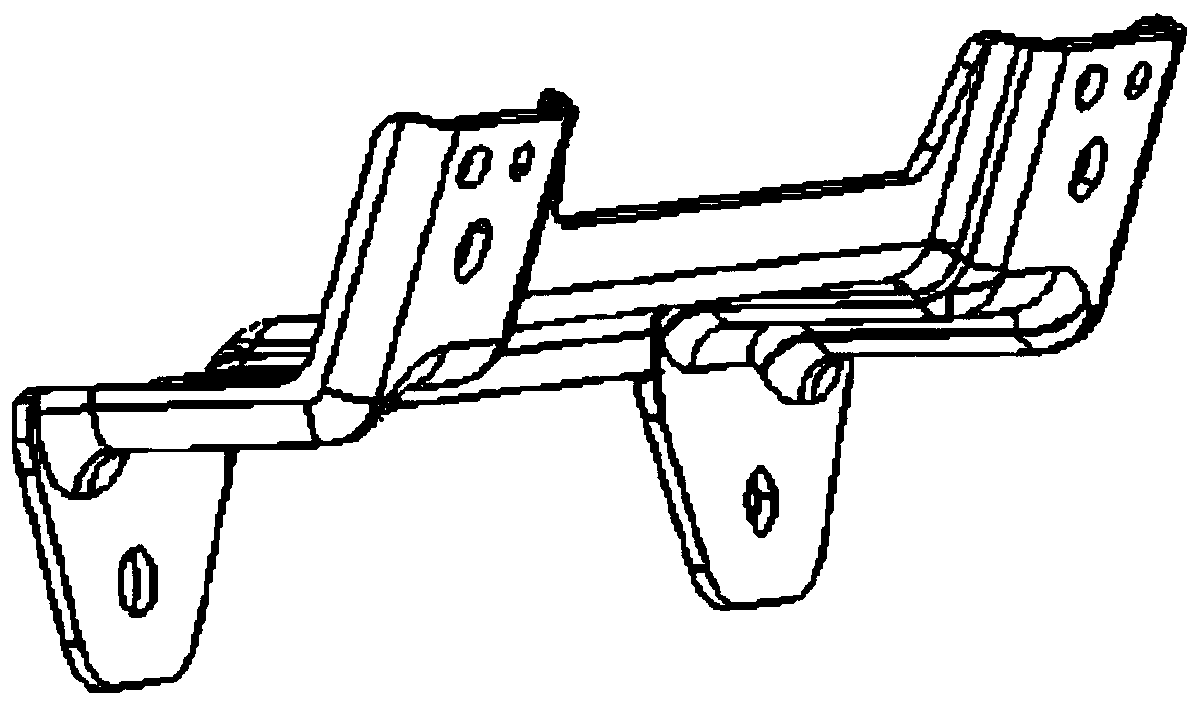

Passenger car passenger armrest bracket mounting structure and mounting method thereof

InactiveCN110979129AReduce failureResolve reboundVehicle arrangementsStructural engineeringCar passenger

The invention discloses a passenger car passenger armrest support mounting structure and a mounting method thereof. The mounting structure comprises a side wall outer plate, a side wall edge beam reinforcing plate, a side wall inner plate, a passenger armrest support and a passenger armrest. The lower parts of the side wall outer plate, the side wall edge beam reinforcing plate and the side wall inner plate are welded together through a first welding spot. The passenger armrest support, the side wall edge beam reinforcing plate and the side wall outer plate are welded together through a secondwelding spot. The passenger armrest support and the side wall inner plate are welded together through a third welding spot. The passenger armrest is fixedly connected to the passenger armrest supportthrough bolts. The passenger armrest support mounting structure is simple in structure, good in rigidity and capable of improving the rigidity of passenger armrest support mounting points on a largescale.

Owner:江苏开沃汽车有限公司

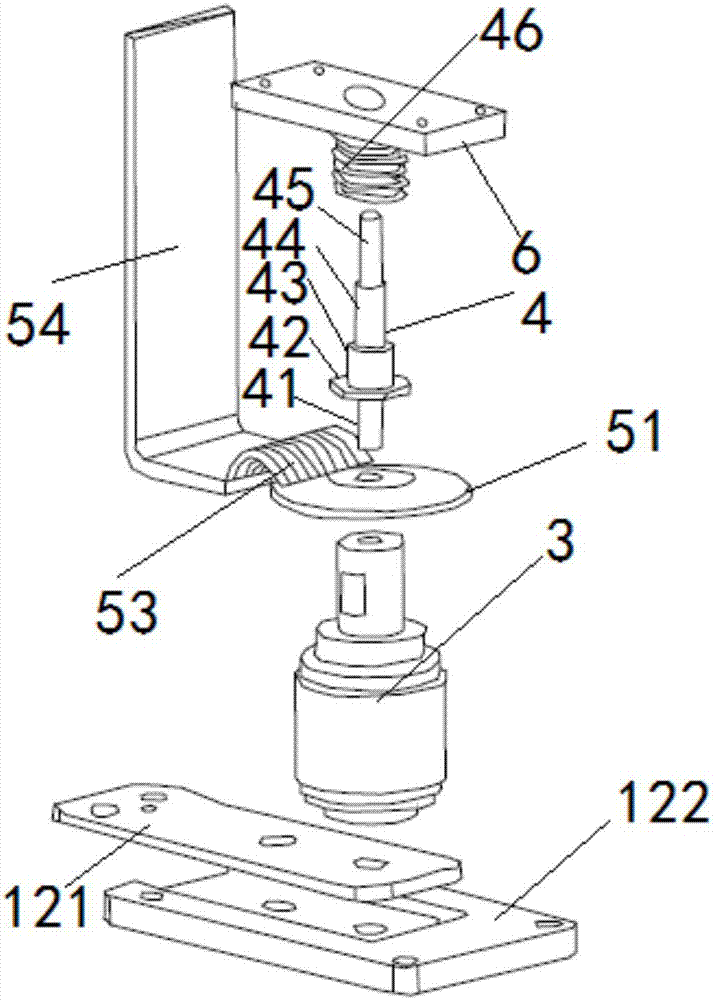

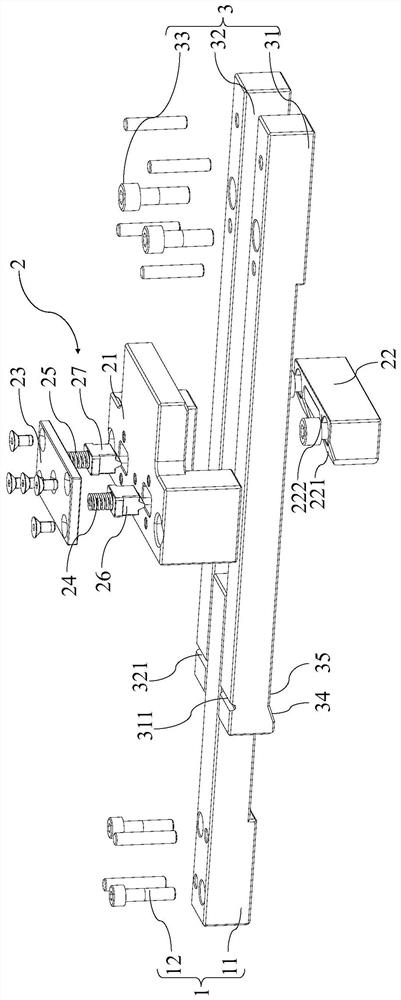

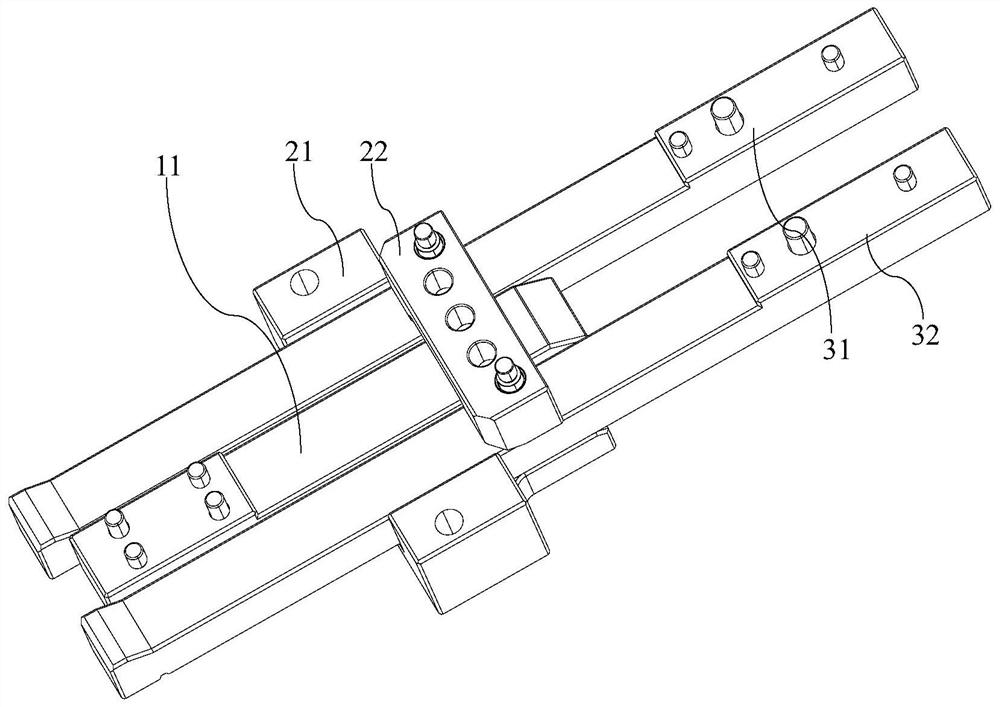

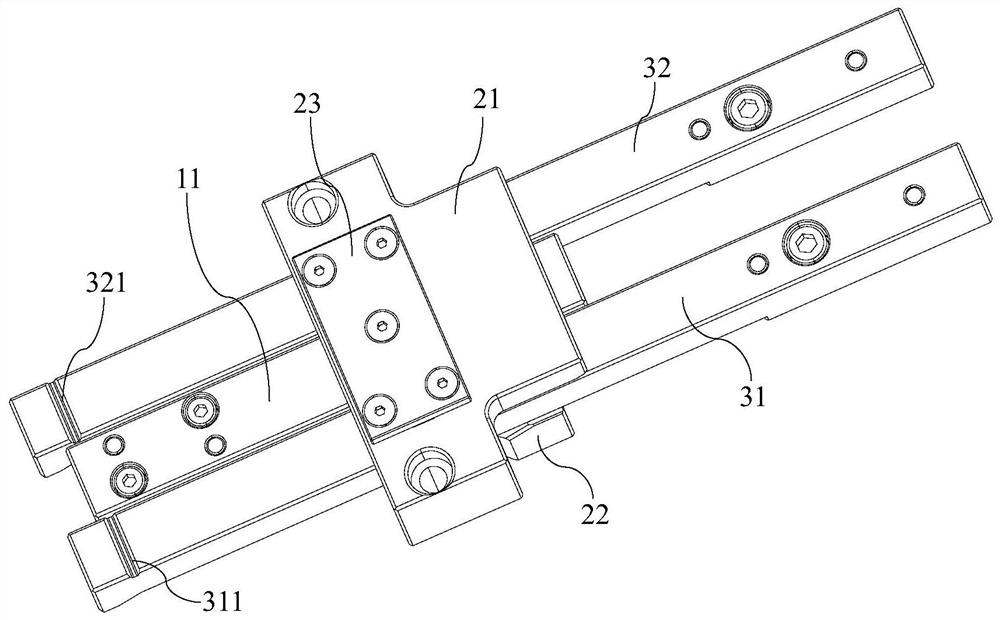

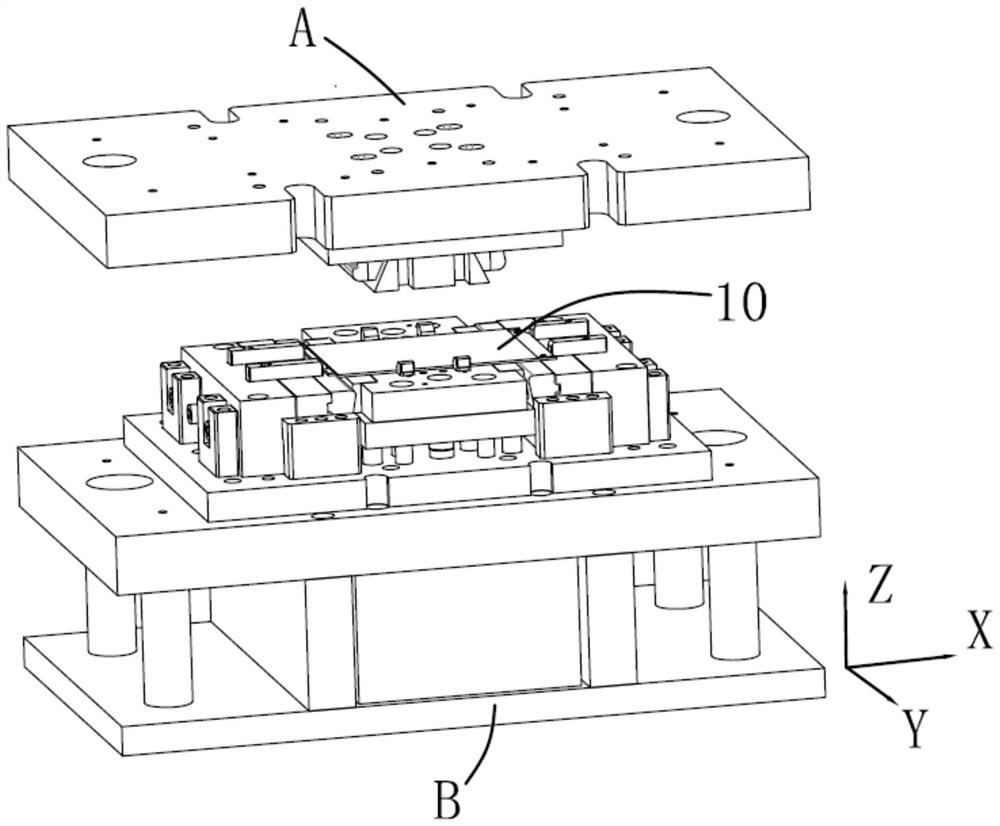

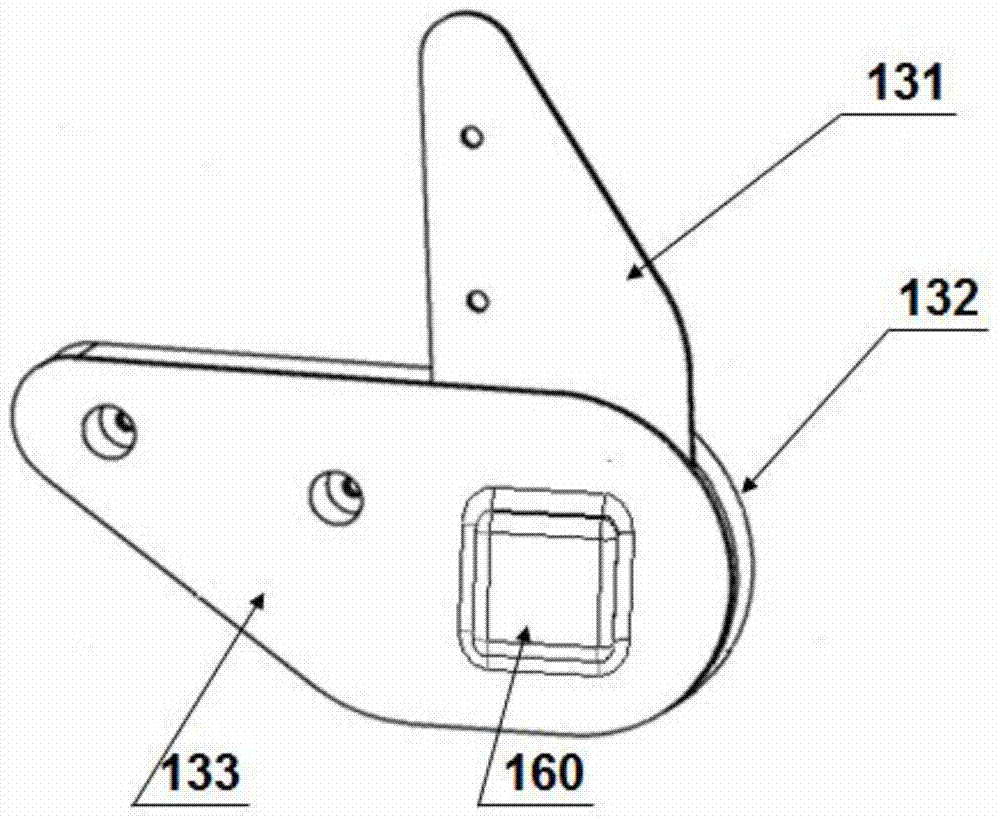

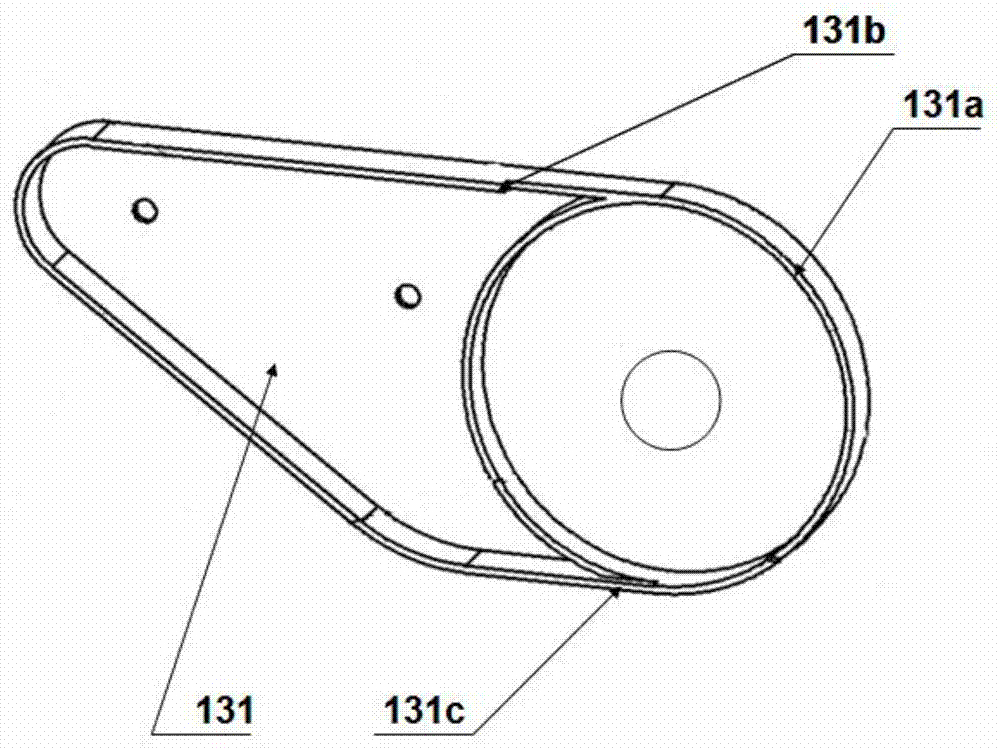

Mold positioning device and die

The invention belongs to the technical field of machining equipment, and particularly relates to a mold positioning device and a mold. The mold positioning device comprises a male mold fixing module, a female mold fixing module and a female mold fixing plate fixing module, the male mold fixing module is used for being connected with a male mold, and the female mold fixing module is used for being connected with a female mold; and the female mold fixing plate fixing module is used for being connected with a female mold fixing plate, the male mold fixing module is in contact connection with the female mold fixing module, and the female mold fixing module is arranged to be switched between a limiting state and a sliding state. According to the mold positioning device disclosed by the embodiment of the invention, the female mold fixing module and the female mold fixing plate fixing module are in limiting fit, so that product damage caused by the fact that a female mold rebounds to steal a main parting surface is avoided, and the quality of an injection product is ensured. Besides, the position of the female mold relative to a shifting plate is fixed, so that the gap between the female mold and the shifting plate is not changed, a manipulator can accurately enter the space between the female mold and the shifting plate to take out a rake, and the manipulator cannot be damaged due to interference.

Owner:GOERTEK INC

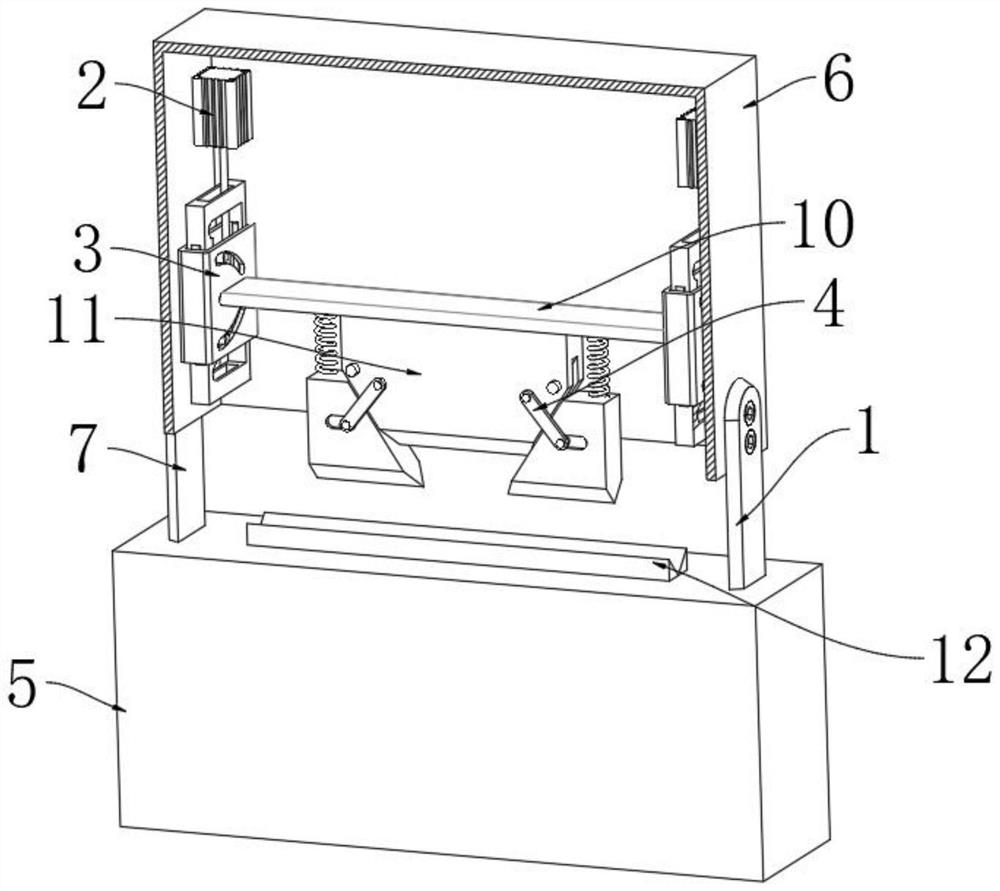

Traceless bending equipment

PendingCN112718951AAvoid bendingResolve reboundShaping toolsMetal-working feeding devicesEngineeringStructural engineering

The invention relates to traceless bending equipment. The equipment comprises an upper die and a lower die which are used for bending a metal plate; the upper die comprises an upper die plate, a sliding block seat and sliding blocks, the sliding block seat is fixed below the upper die plate in an up-down movable mode, the sliding blocks are arranged on the two transverse sides of the sliding block seat, bending punches are formed on the two transverse sides of each sliding block, and the sliding block seat moves up and down to drive the sliding blocks to move in the transverse direction; and the lower die comprises a base, a lower die plate fixed to the base, a precursor block arranged on the lower die plate and capable of moving up and down, a forming block arranged on the transverse outer side of the precursor block, a baffle fixed to the lower die plate and located on the transverse outer side of the forming block, and an elastic piece of which one end abuts against the baffle and which provides transverse elastic force for the forming block, a matching inclined surface is arranged on the transverse outer side of the precursor block, and the forming block is provided with a forming inclined surface corresponding to the matching inclined surface. Traceless bending can be achieved, and springback after bending is avoided.

Owner:NEW AMERIOCEAN TECH CO LTD

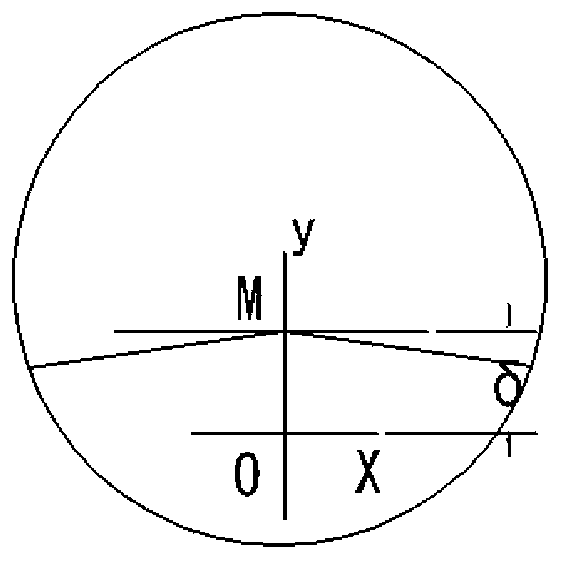

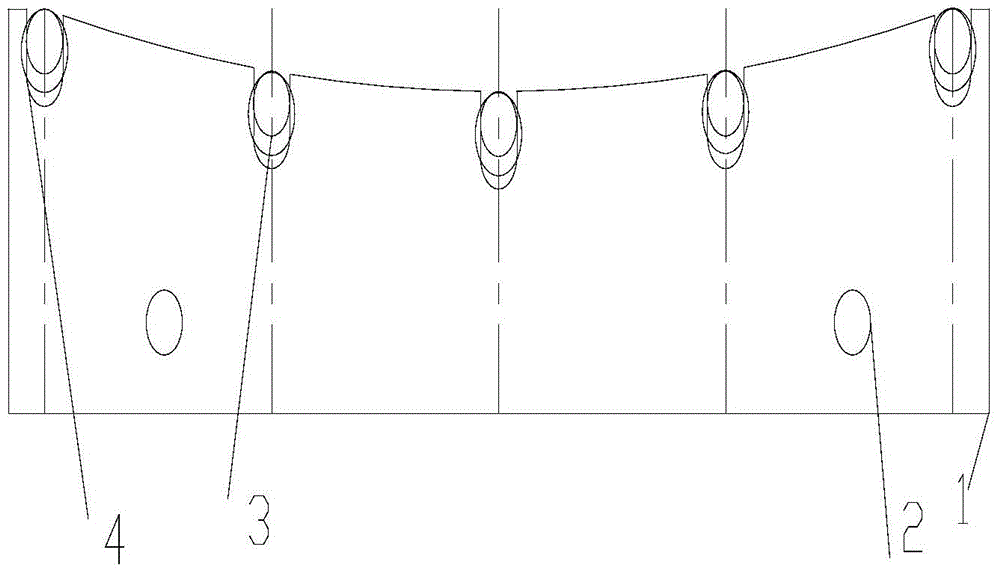

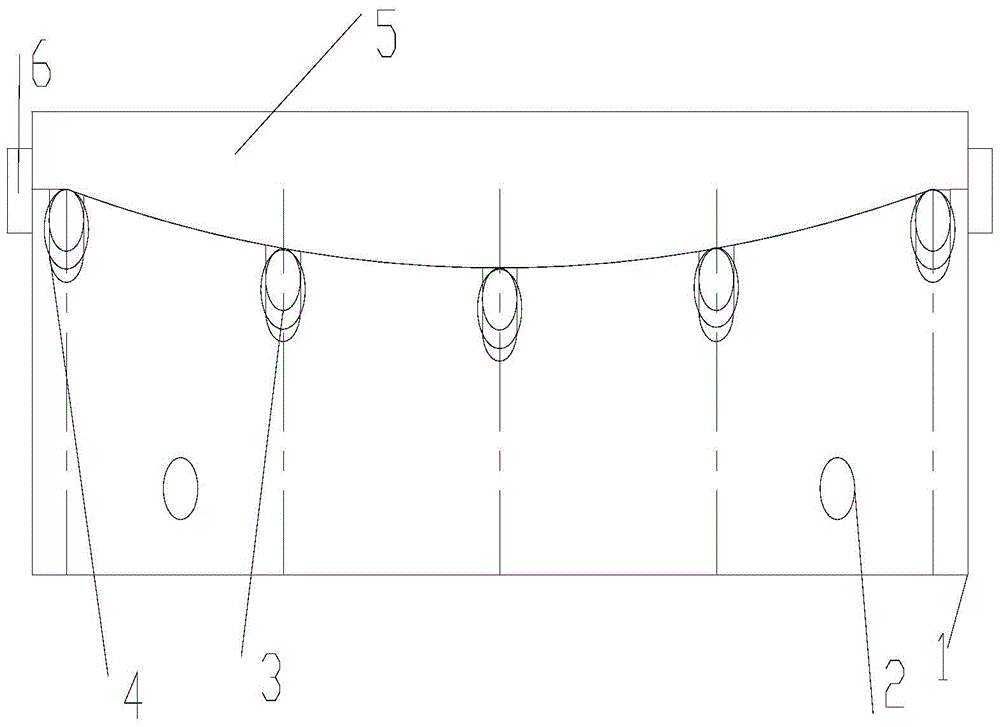

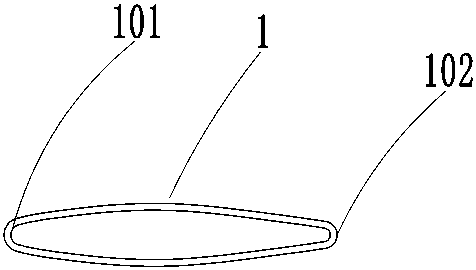

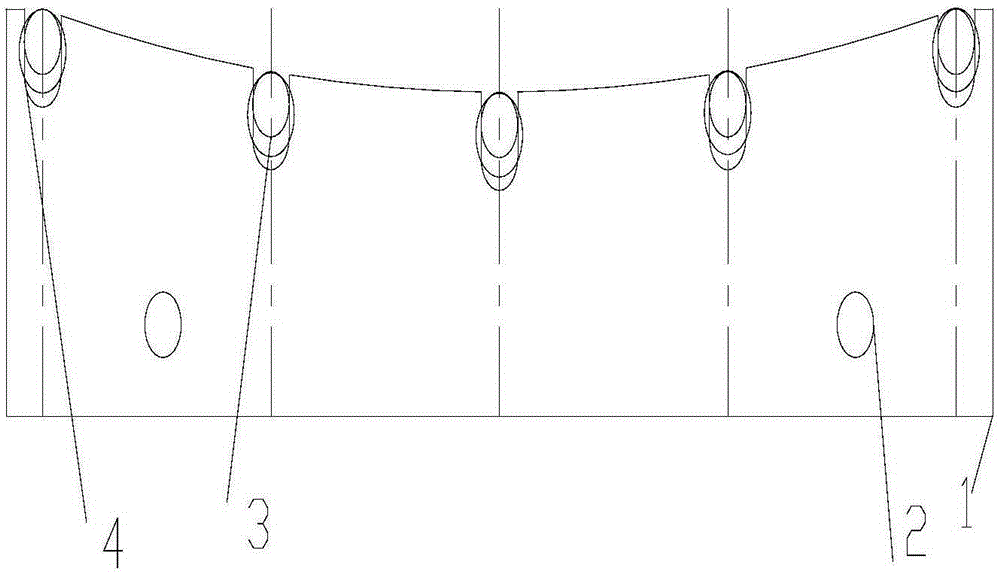

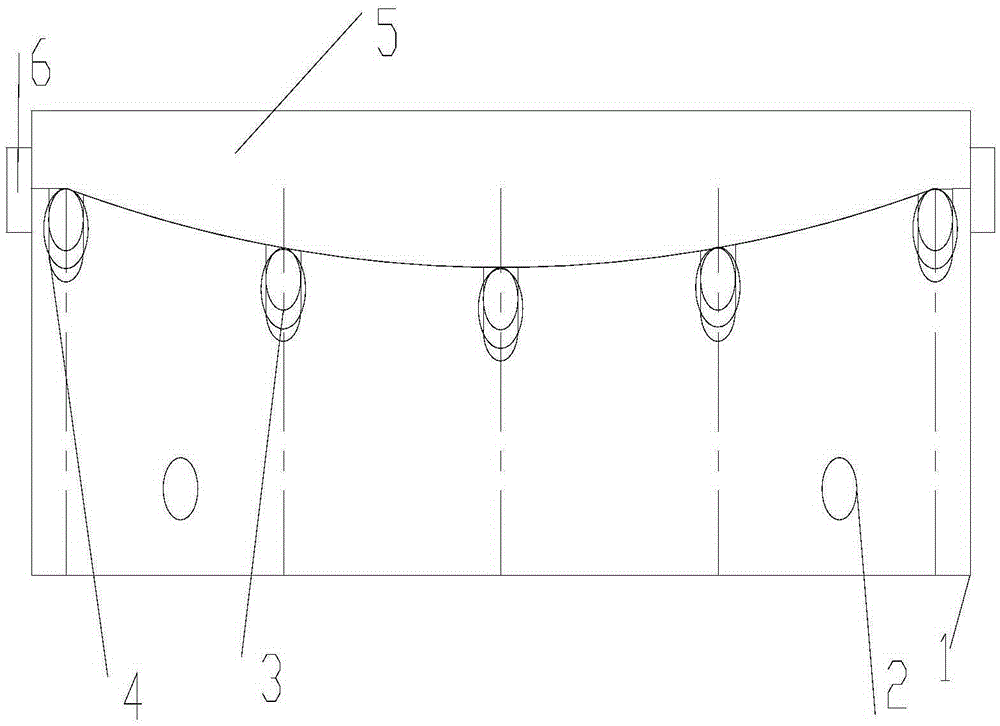

Parabolic mirror hot-bending forming mold for trough-type solar concentrating heat collector and manufacturing method

ActiveCN105299919BLow costSimple structureSolar heating energySolar heat devicesEngineeringEnergy consumption

Owner:SOUTHEAST UNIV

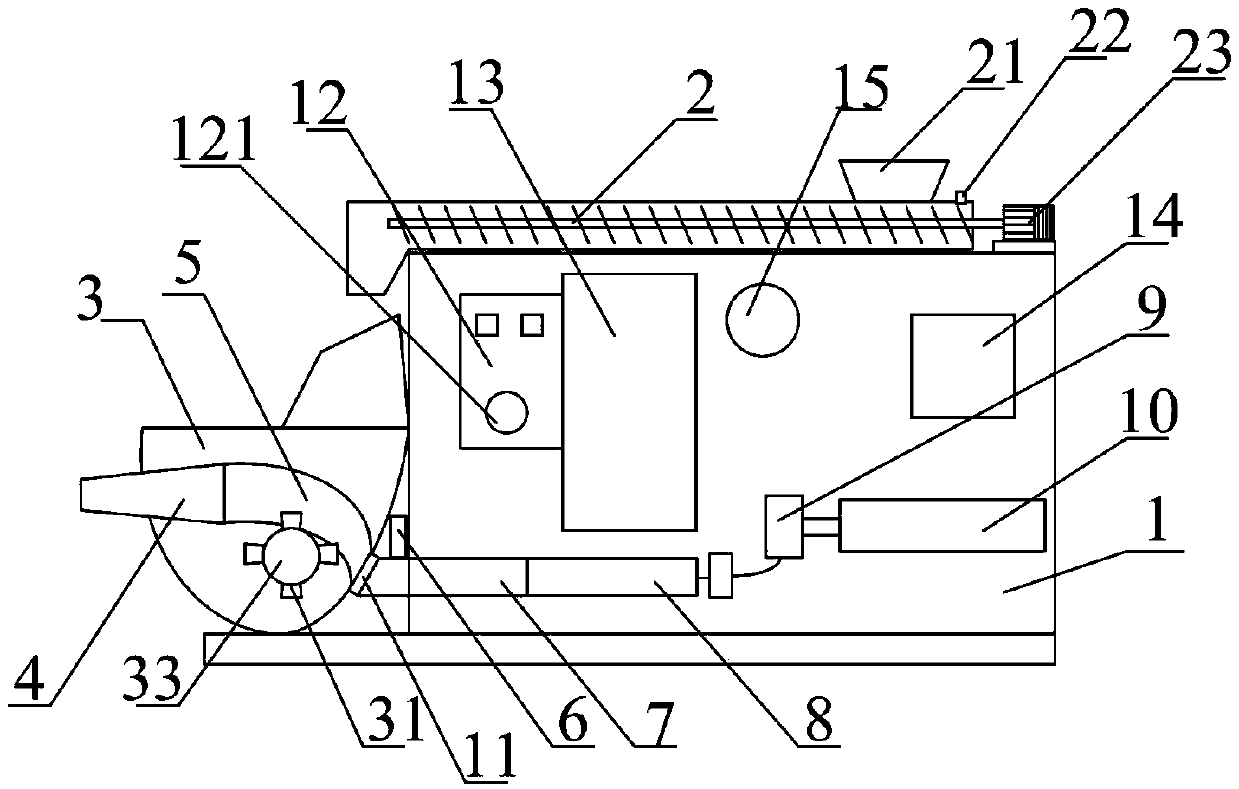

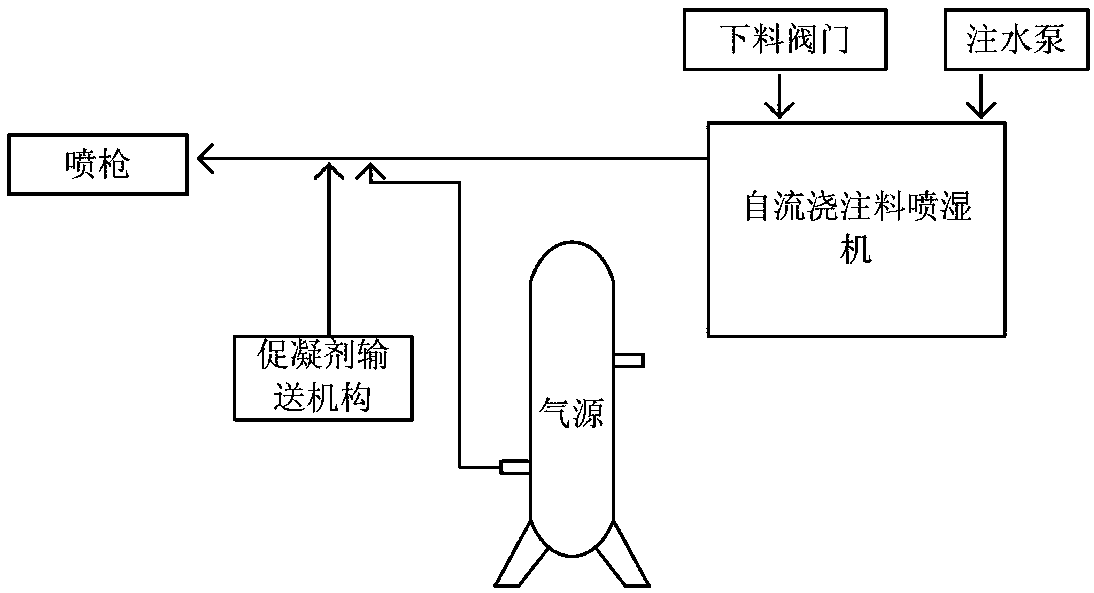

A self-flowing pouring material spraying machine and a spraying method based on the spraying machine

ActiveCN107152153BResolve reboundSave resourcesCovering/liningsCement mixing apparatusWorking environmentEngineering

The invention provides a self-flow castable wet-spraying machine and a wet-spraying method based on the wet-spraying machine. According to the distance from a construction site to the wet-spraying machine, a conveying pressure is adjusted; a blanking valve is adjusted to determine blanking quantity, and a water injection pump is started to determine water injection amount; a secondary stirring motor is firstly started, then a primary stirring motor is started, and materials are put and stirred; an air source pressure is adjusted to reach 0.5 MPa, and a coagulant conveying mechanism normally operates; after the materials are fed into a secondary stirring feeding hopper, the materials are further confirmed, a conveying button is turned on after no error is confirmed through checking, and a material pumping unit begins to work and convey materials. The wet-spraying process is compared with a dry-spraying process, the material rebounding problem in dry spraying is solved, resources are saved, and a site construction environment is obviously improved. By comparing the wet-spraying process with the dry-spraying process, formwork links are saved, the mechanization and automation degree of production is remarkably improved, labors are liberated from a 'dirty, hard, tiring and dangerous' working environment, and the construction time is greatly shortened.

Owner:山东同得利集团有限公司

A kind of child intelligent seat and control method

The invention discloses a child intelligent seat and a control method. The seat comprises a backrest, a base, pressure sensors, a weight sensor, angle regulating devices, a servo motor and a controller, wherein the pressure sensors are used for detecting pressure applied to the chair back by the human body, and the weight sensor is used for detecting the weight of the human body; each angle regulating device comprises an upper piece and a lower piece, one end of each upper piece is connected with the backrest, one end of each lower piece is connected with the base, an inner circular boss at the other end of each upper piece and an outer circular boss at the other end of each lower piece are in rotation connection, and the inner side of each angle regulating device is arranged at the joint of the base and the backrest; the center of each inner circular boss is provided with an inner gear; a rotating shaft of the servo motor is meshed with the corresponding inner gear so as to drive the corresponding upper piece to rotate, and the servo motor is arranged on the outer side of the corresponding upper piece; the controller is used for controlling the servo motor to be started and closed, and the controller is connected with a sensor set and the servo motor. According to the seat, the angle required to be regulated is judged according to the pressure and the height of children, and an angle regulating device is intelligently sensed and controlled to regulate the seat to be required angle.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

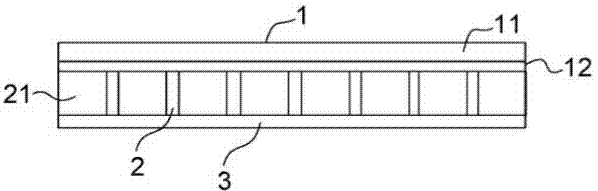

Three-layer composite floor and manufacturing method thereof

ActiveCN107338939AHigh surface flatnessImprove flatnessLamination ancillary operationsWood compressionHigh densityTransition layer

The invention provides a three-layer composite floor. The three-layer composite floor sequentially comprises a surface plate, core plates and a bottom plate from top to bottom. The surface plate at least comprises a high-density layer and a transition layer from top to bottom. The average density, on the thickness cross section, of the high-density layer is 0.65-0.75 g / cm<3>, and the density, on the thickness cross section, of the transition layer is gradually decreased from the side close to the high-density layer to the side close to the core plates. The high-density heavy layer and the transition layer are naturally connected in a same material mode. The three-layer composite floor has the characteristics that surface smoothness is good, the product stability is good, and surface wave traces are not prone to occurring.

Owner:ZHEJIANG SHIYOU TIMBER

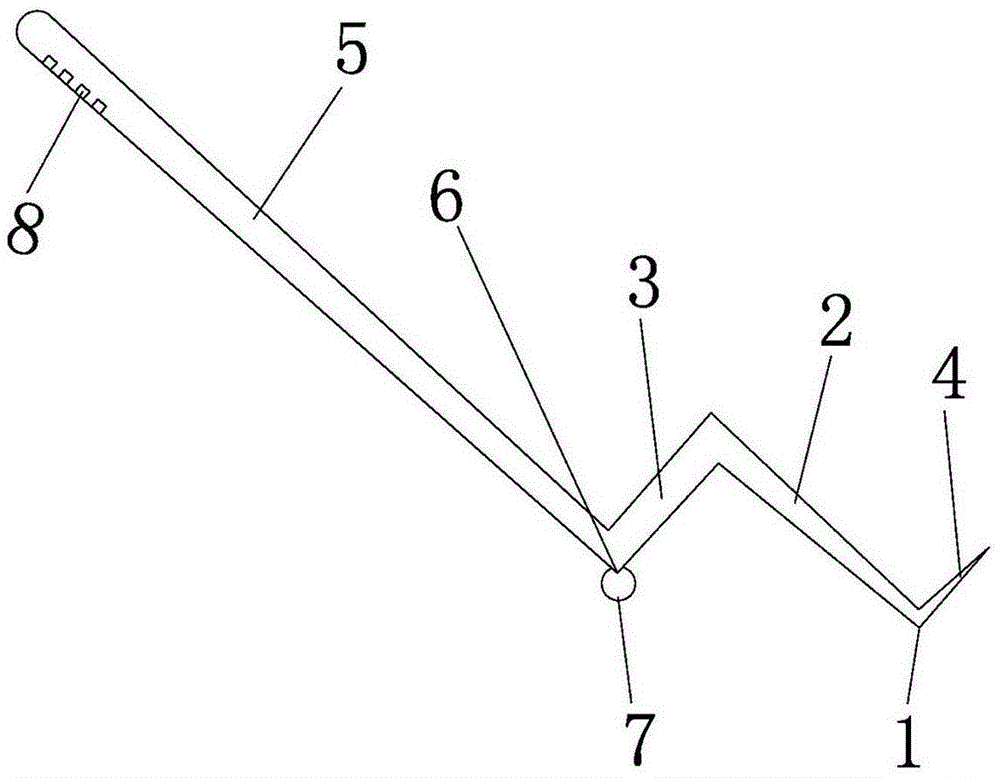

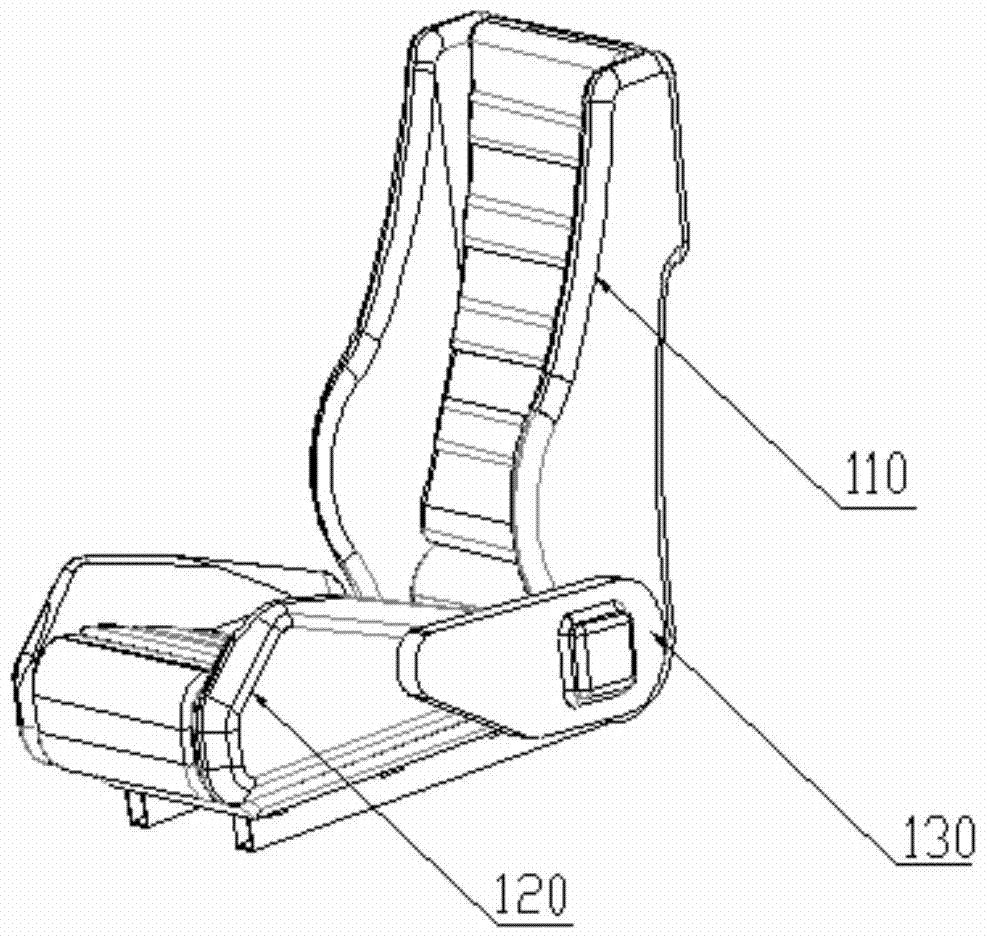

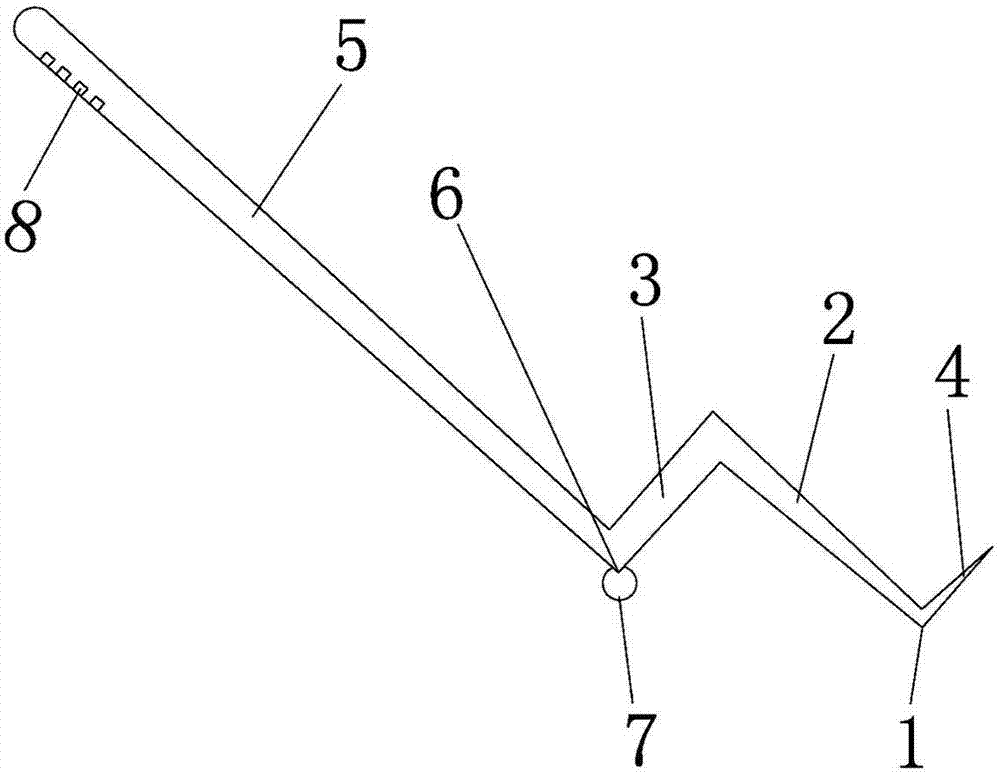

Lifters for Laminae

The invention relates to an opener for a vertebral plate, and effectively solves the problems in a cervical posterior operation of inconvenience in use, difficulty in operation and poor effect in an operation of pushing a door opening side and opening the vertebral plate and occurrence of a dangerous accident caused by easiness in springback when the vertebral plate is opened. The opener is characterized in that the front part is L-shaped; a bending position of the front part is used as a first vertex; the rear end of a long edge of the front part is obliquely connected with the upper end of a connecting section; the connecting section and a short edge of the front part are mutually, oppositely and respectively arranged at two sides of the long edge of the front part; the lower end of the connecting section is obliquely connected with a handle; the handle and the long edge of the front part are mutually, oppositely and respectively arranged at two sides of the connecting section; the central lines of the front part, the connecting section and the handle are located in the same plane; a connecting position between the connecting section and the handle is used as a second vertex. The opener for the vertebral plate, disclosed by the invention, has the advantages that the structure is simple, the use is convenient, the operation is easy, the working efficiency is high, the springback problem caused when the vertebral plate is opened is solved, and the operation safety is increased.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Small diameter pvdf pipe bend forming process

The invention discloses a small diameter PVDF pipe elbow forming process. Including blanking, heating, continuous heating, bending and cooling steps. The invention adopts a constant temperature method to heat the PVDF pipe material, so that the inside and outside of the pipe are fully and evenly heated. By controlling the temperature of the pipe to be heated and softened, the pipe is bent by one-time extrusion molding with filler bending, which effectively controls the cross-sectional shape of the pipe when it is bent. Distortion, wrinkling, and large errors in cross-section thickness; and through effective control of the ambient temperature, the heating temperature of the pipe, and the preheating temperature of the mold and filler, the size of the pipe after bending and forming can be kept consistent; in addition, the bending made After molding, the bent pipe is kept in the mold for natural cooling. Through the control of temperature and time, the internal stress is eliminated, and the springback problem of the pipe can be effectively solved, so that high-quality PVDF bent pipe can be manufactured, which is suitable for various occasions. application.

Owner:岳阳高澜节能装备制造有限公司

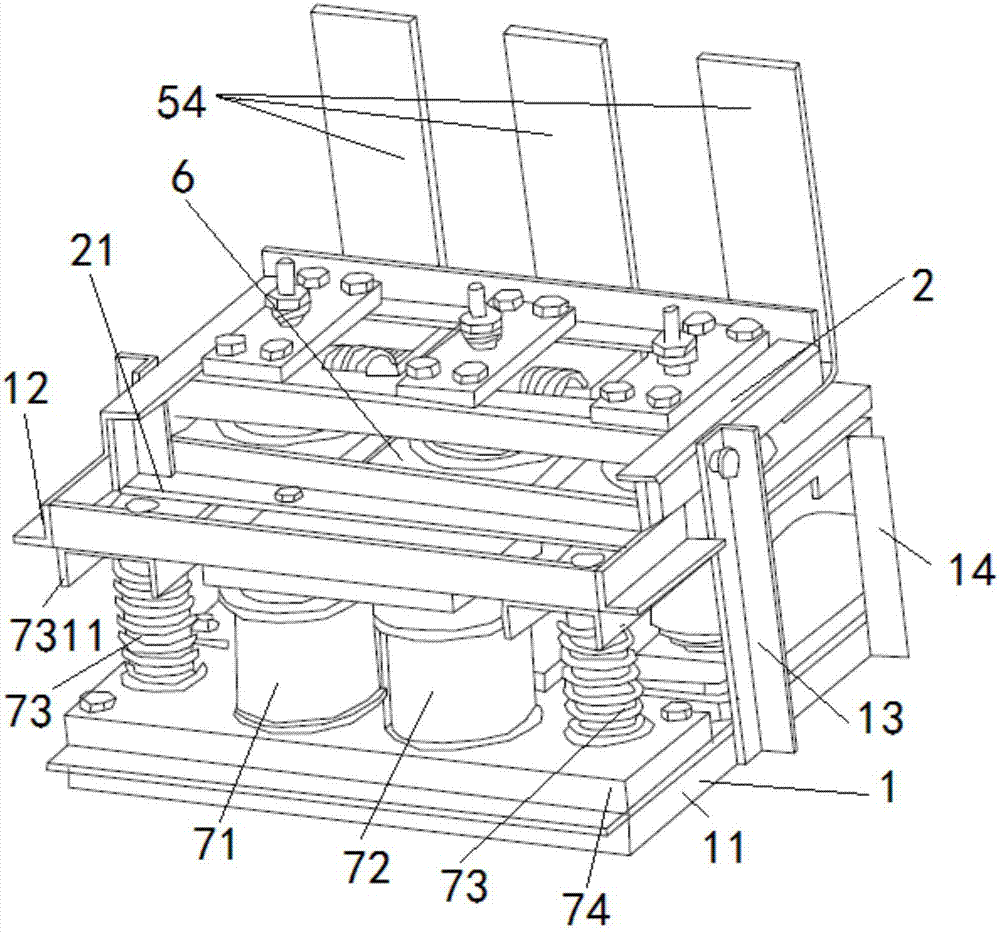

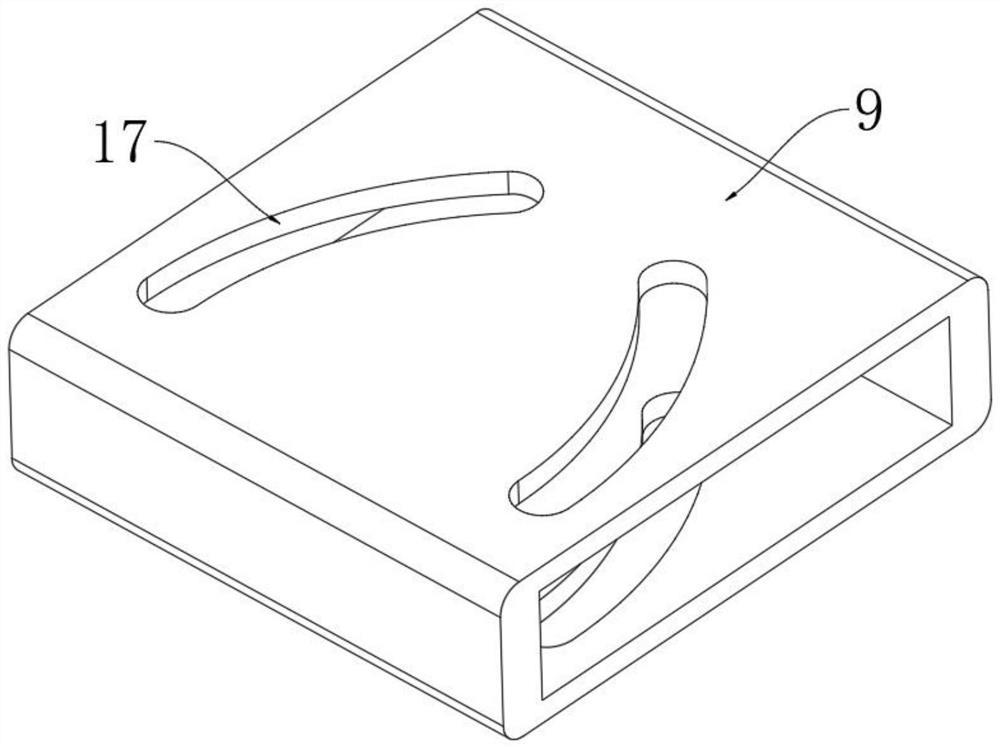

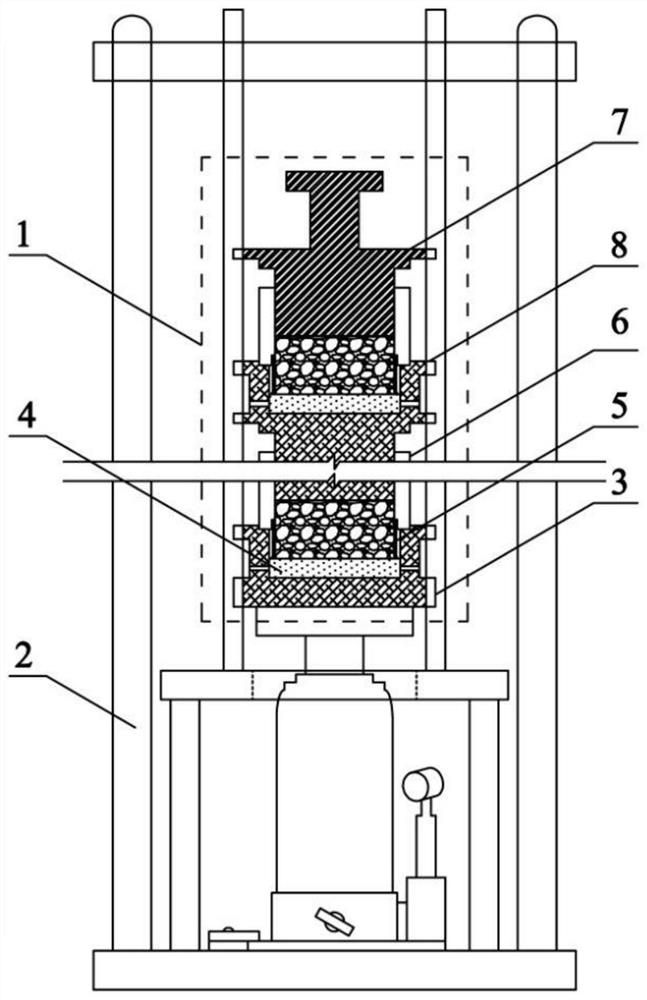

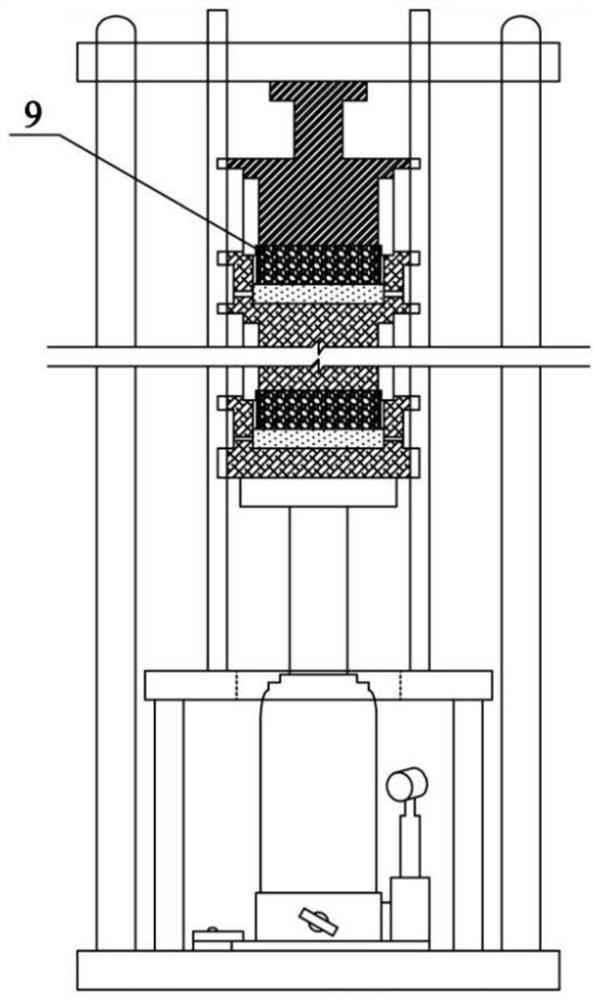

Combined multi-connected sample preparation instrument of remolded soil cutting ring sample and sample preparation method

PendingCN113008641AWidely used valueResolve reboundPreparing sample for investigationPhysical chemistryEngineering

The invention relates to a combined multi-connected sample preparation instrument of a remolded soil cutting ring sample and a sample preparation method. The combined multi-connected sample preparation instrument comprises a sample pressing device and a pressurizing device, and the sample pressing device comprises a base, a cutting ring, an extension cylinder, a sample pressing piston and a combined body. A sampling groove, an exhaust hole and other parts are arranged on the base. During use, a permeable stone is placed at the upper part of the base, so that gas contained in a loose soil sample can be effectively discharged. The extension cylinder comprises an upper hoop cylinder and a lower positioning ring, the inner diameter of the hoop cylinder is the same as that of the cutting ring, the inner diameter of the positioning ring is matched with the outer diameter of the cutting ring, and the extension cylinder is matched with the cutting ring for use, so that disturbance to a sample can be effectively reduced; the combined body is formed by combining the base and the sample pressing piston, simultaneous preparation of a plurality of samples can be achieved, and the sample preparation efficiency is improved. According to the invention, the defects of non-uniform remolded soil sample preparation, difficulty in demolding and sampling, sample rebound, incapability of performing subsequent test operation and the like at present are overcome, and a plurality of standard homogeneous cutting ring samples suitable for various indoor soil tests can be accurately, simply and quickly prepared at the same time.

Owner:LUOYANG INST OF SCI & TECH

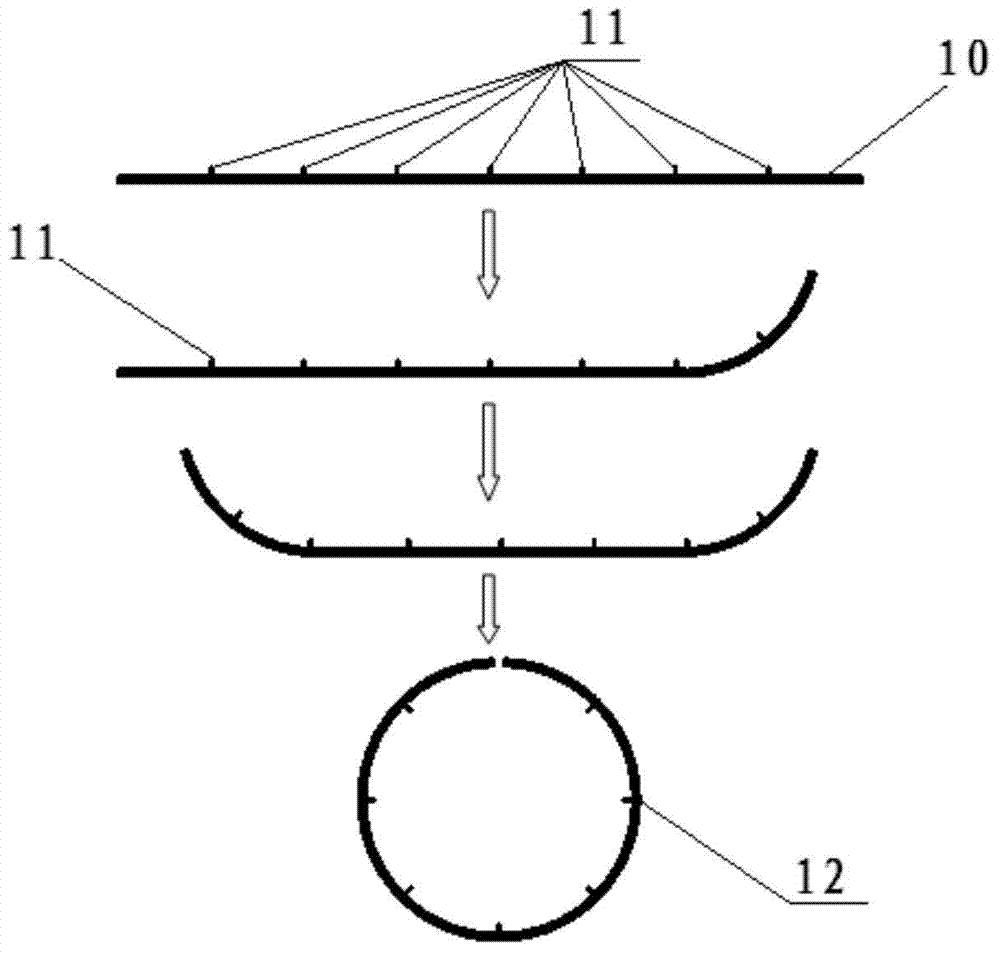

Forming method of flat pipe fitting

The invention relates to the technical field of pipe fitting forming, in particular to a forming method of a flat pipe fitting. The forming method comprises the following steps that A, edge rolling isconducted, wherein a plate is bent and rolled, the two ends of the plate are welded, and the plate forms a closed ring body through a welding seam; B, radial forming is conducted, wherein a mold corematched with the preset shape of the pipe fitting is added into the welded closed ring body, then the side wall of the pipe fitting is pressed to make the radial section of the pipe fitting achieve apreset shape, and the welding seam is made to avoid the inflection point position of the closed ring body on the radial section in the process; and C, axial forming is conducted, wherein after the radial section of the pipe fitting is formed, the front end and the rear end of the pipe fitting are cut correspondingly to make the pipe fitting achieve a preset shape in the axial direction. Accordingto the forming method, the plate is connected into the closed ring body through the welding seam, the grinding amount is greatly reduced, the mold core is added into the pipe fitting, the interior and the exterior of the pipe fitting are formed simultaneously, the problem of part springback is solved, the workload of manual shape correction is reduced, the pipe fitting forming effect is better, the quality guarantee of products is enhanced while the production efficiency is improved, and mass production of the flat pipe fitting is achieved.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

Mold for hot bending and forming trough type solar concentrating collector parabolic mirrors and manufacturing method thereof

ActiveCN105299919ALow costSimple structureSolar heating energySolar heat devicesEngineeringEnergy consumption

The invention discloses a mold for hot bending and forming trough type solar concentrating collector parabolic mirrors and a manufacturing method thereof. The mold comprises a plurality of support plates and a support plate fixing device, wherein the plurality of support plates form a trough-shaped space fixing structure through the support plate fixing device; the support plates are sunk part structures obtained by cutting a whole steel plate according to a parabolic mirror molded line; a plurality of open slots are formed in cutting end faces of molded line sides of the support plates; corresponding formed steel pipes are arranged in the open slots corresponding to the adjacent support plates; the formed steel pipes are fixedly arranged tangent to end openings of the open slots through a steel pipe fixing device. The mold is simple in structure, reasonable in design and simple to manufacture, and is capable of effectively reducing production energy consumption and efficiently hot bending and forming glass of trough type parabolic mirrors.

Owner:SOUTHEAST UNIV

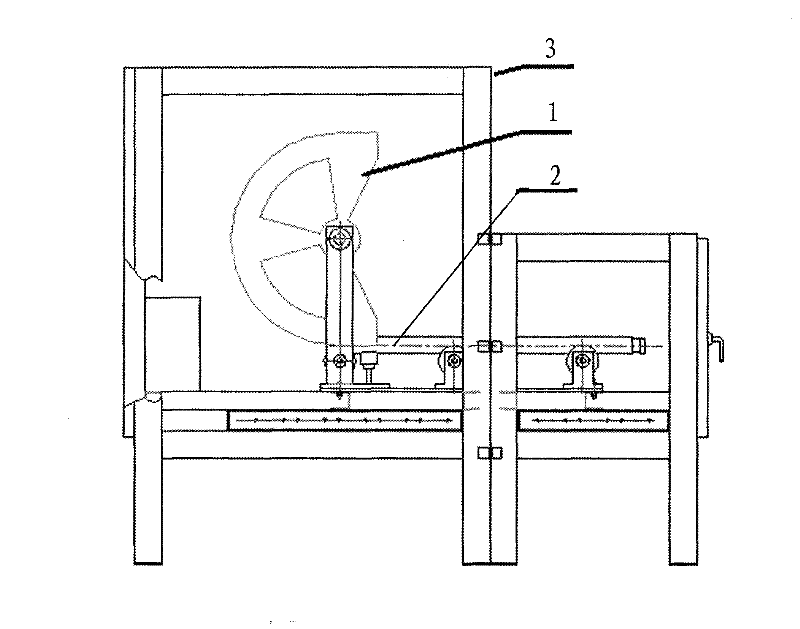

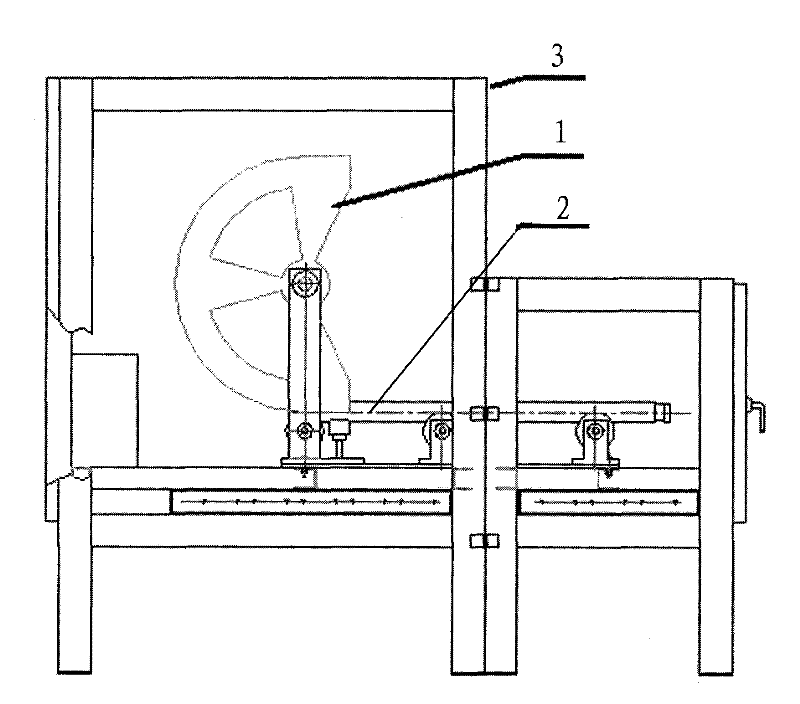

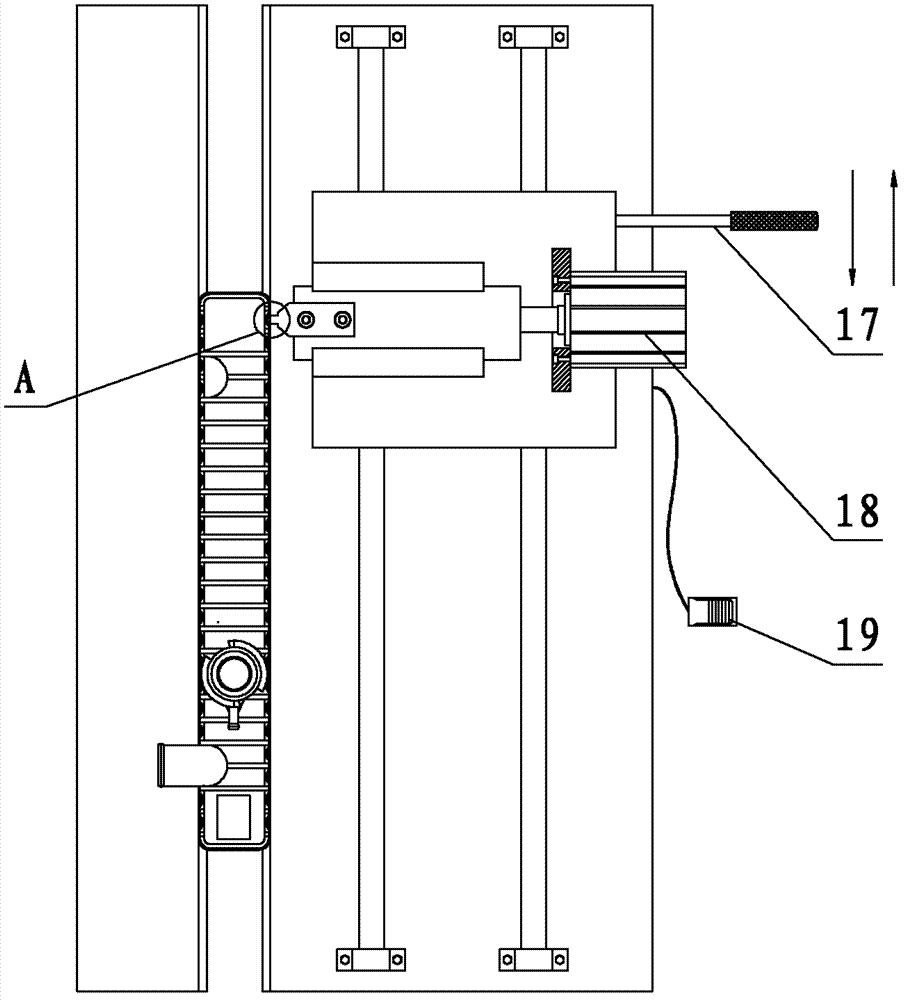

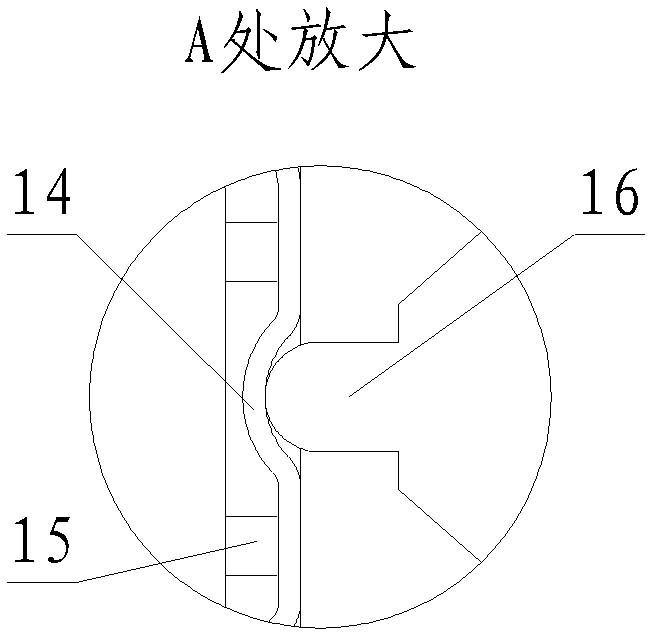

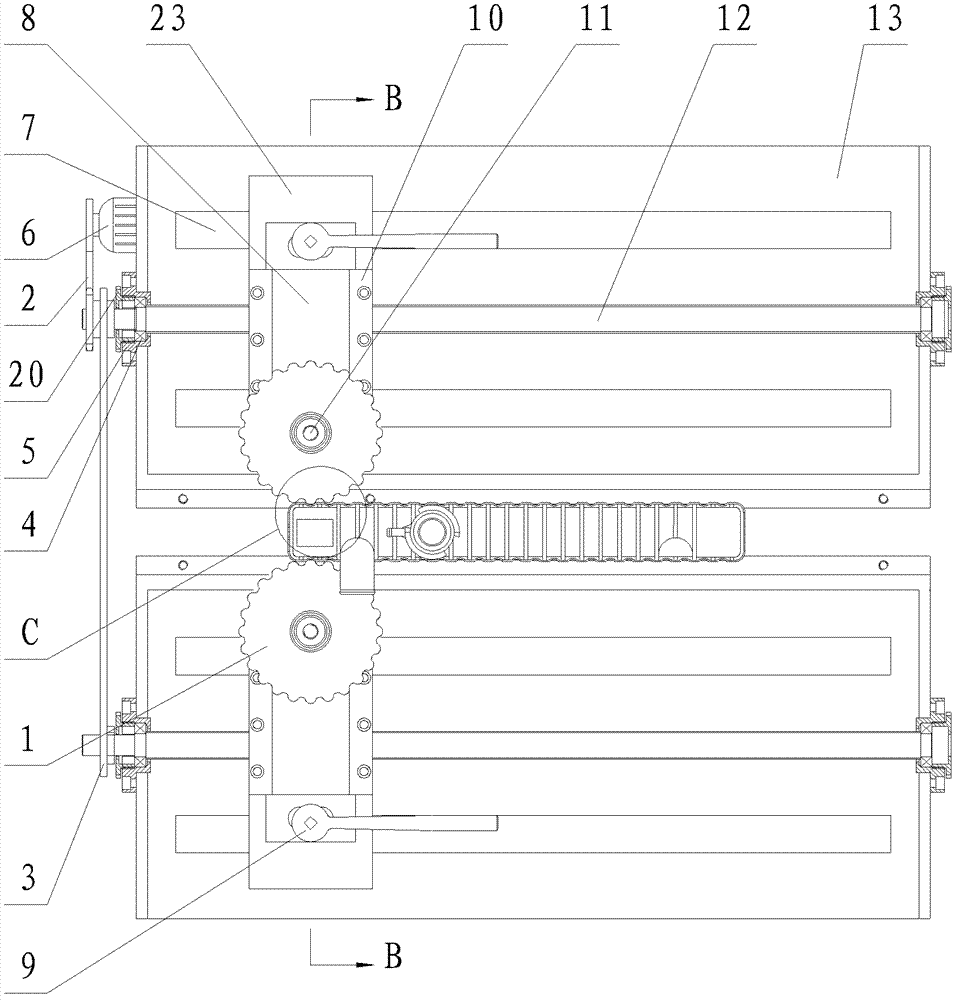

Roller press for installing radiator water chamber of combustion engine

ActiveCN103170824BImprove work efficiencyThe pressing position is accurateMetal working apparatusCombustionReciprocating motion

The invention relates to installation equipment for a radiator water chamber of a combustion engine, in particular to a roller press for installing the radiator water chamber of the combustion engine. The roller press comprises two case bodies which are arranged side by side. Longitudinal guide rails are arranged in each case body. The longitudinal guide rails in each case body are connected with a longitudinal sliding plate in a slidable mode. A transverse sliding plate is arranged on each longitudinal sliding plate. One end of each transverse sliding plate is connected with a rolling wheel. The other end of each transverse sliding plate is connected with a cam mechanism which is used for driving the transverse sliding plate to feed in the transverse direction. The longitudinal sliding plates do reciprocating motion along the longitudinal guide rails through driving mechanisms which are connected with the bottoms of the longitudinal sliding plates. The driving mechanisms in the two case bodies are connected through a second chain wheel and chain transmission mechanism. Any driving mechanism is connected with a motor through a first chain wheel and chain transmission mechanism. A main slice to be pressed and the water chamber to be pressed are arranged between the two case bodies and are formed by the rolling wheels on the two case bodies through rolling. The rolling wheels of the roller press can run automatically, can automatically complete press fitting to the main slice and the water chamber, can automatically stop after rolling is completed, and can work in a reciprocating mode. The roller press is free from empty running strokes and high in working efficiency.

Owner:沈阳华铁异型材有限公司

Lamina lifter

InactiveCN105615977BImprove securityResolve reboundOsteosynthesis devicesPediatricsPosterior surgery

The invention relates to a lamina lifter, which effectively solves the problem that the rongeur is inconvenient to use, difficult to operate, and poor in effect during the operation of opening the door and opening the lamina in posterior cervical surgery, and the lamina tends to rebound when it is lifted , leading to the problem of dangerous accidents, the hook body has a free end and a connecting end, the length of the free end of the hook body is less than the length of the connecting end, the top of the hook body is flat, the connecting end of the hook body and the handle are connected in a V shape, V-shaped The opening and the opening of the hook body are in opposite directions, and the free ends of the handle and the hook body are respectively placed on both sides of the connecting end of the hook body. The problem of springback when opened avoids the occurrence of medical accidents and improves the safety of surgery.

Owner:郑文迪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com