A self-flowing pouring material spraying machine and a spraying method based on the spraying machine

A wet spraying machine and castable technology, which is applied to chemical instruments and methods, cement mixing devices, covering/lining, etc., can solve problems such as low work efficiency, waste of materials, and poor environment on the job site, and save formwork links, Shorten the construction time and improve the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

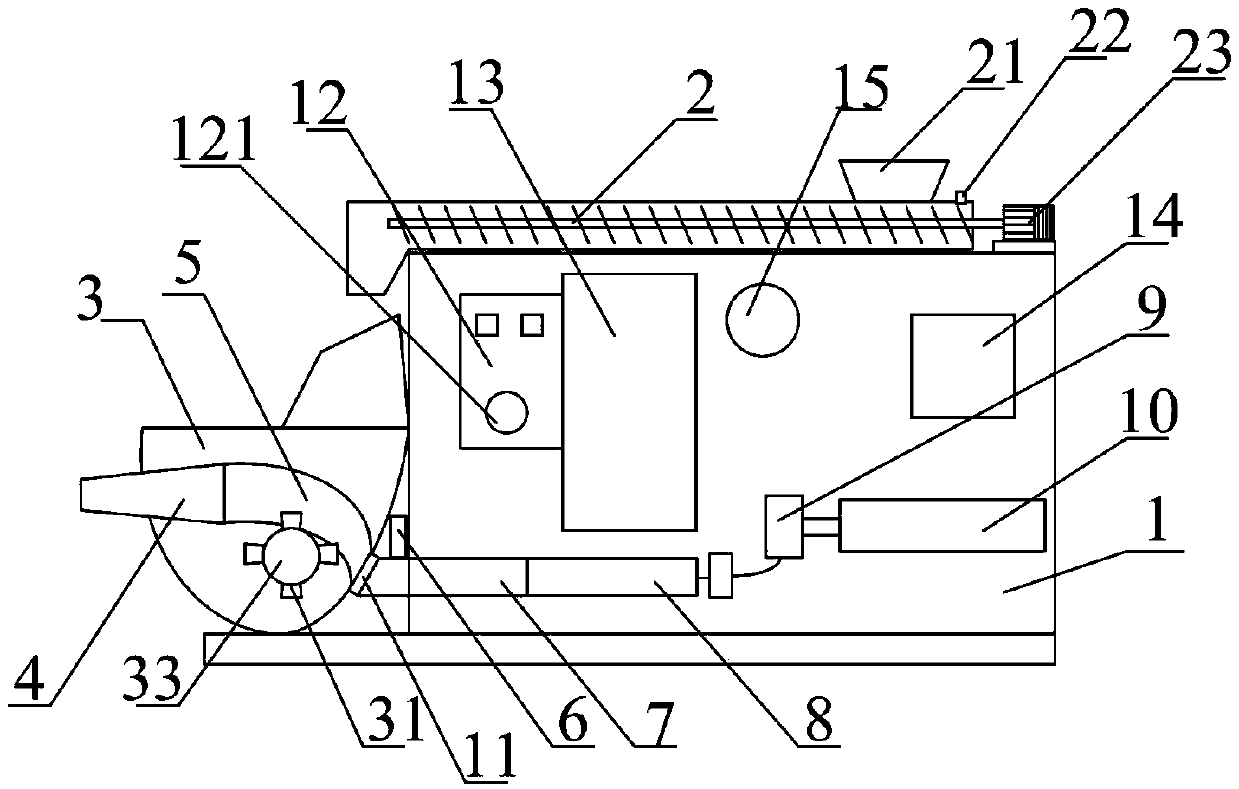

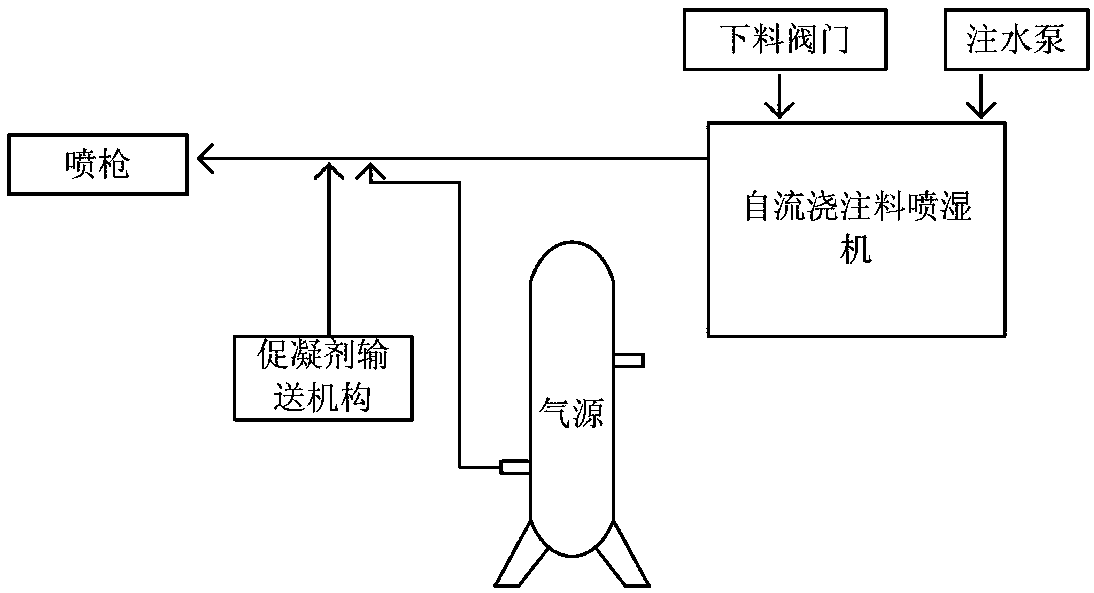

[0023] as attached figure 1 To attach figure 2 shown

[0024] The invention provides a self-flowing pouring material spraying machine and a spraying method based on the spraying machine. A self-flowing castable spraying machine includes a functional box 1, a primary mixing conveyor 2, a secondary mixing hopper 3, and a discharge Port 4, rotary feeding pipe 5, rotary hydraulic cylinder 6, material storage pipe group 7, material pumping unit 8, high-pressure oil pump 9, pumping motor 10 and hydraulic rotary pump 11, the outlet 4 passes through the rotary feeding pipe 5 and the rotary hydraulic cylinder 6 are connected to the material storage tube group 7; the rotary feeding tube 5 and the rotary hydraulic cylinder 6 are arranged inside the secondary mixing feeding hopper 3; one end of the hydraulic rotary pump 11 is connected to the rotary hydraulic cylinder 6 , the other end is connected to the high-pressure oil pump 9; one end of the material pumping unit 8 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com