Roller press for installing radiator water chamber of combustion engine

A radiator and internal combustion engine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inaccurate press-fitting position and low production efficiency, achieve high work efficiency, firm rolling quality, and overcome edge backlash The effect of playing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

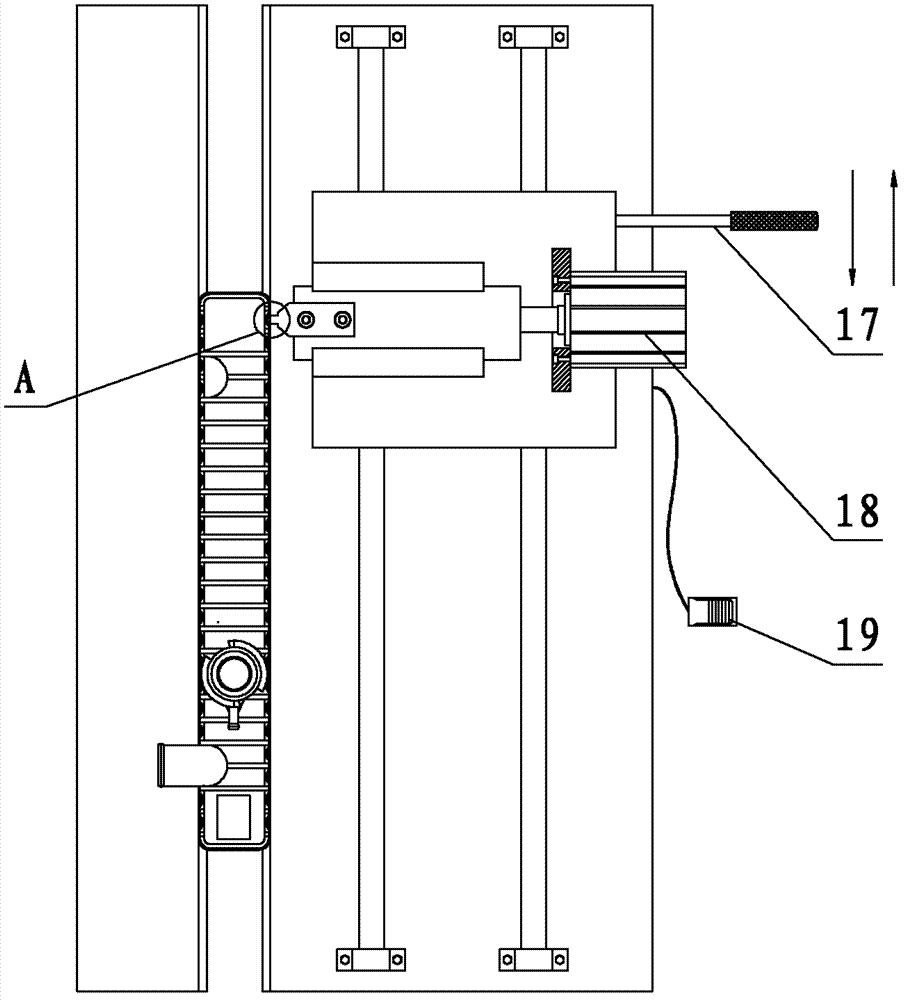

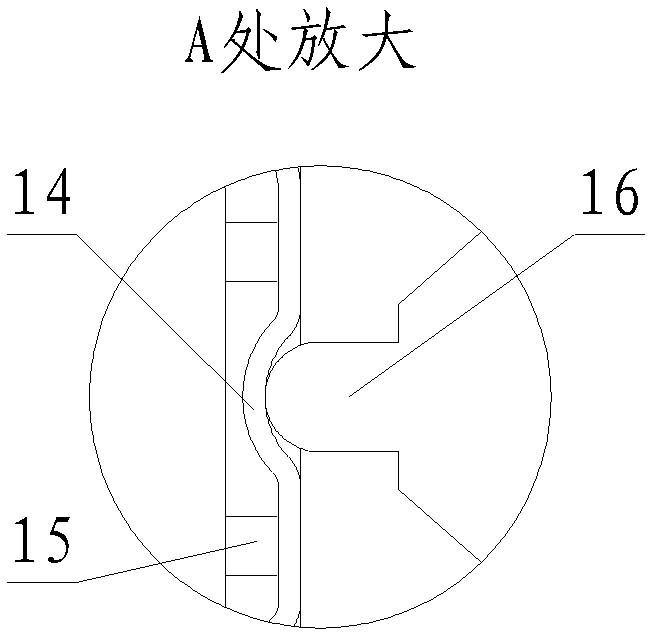

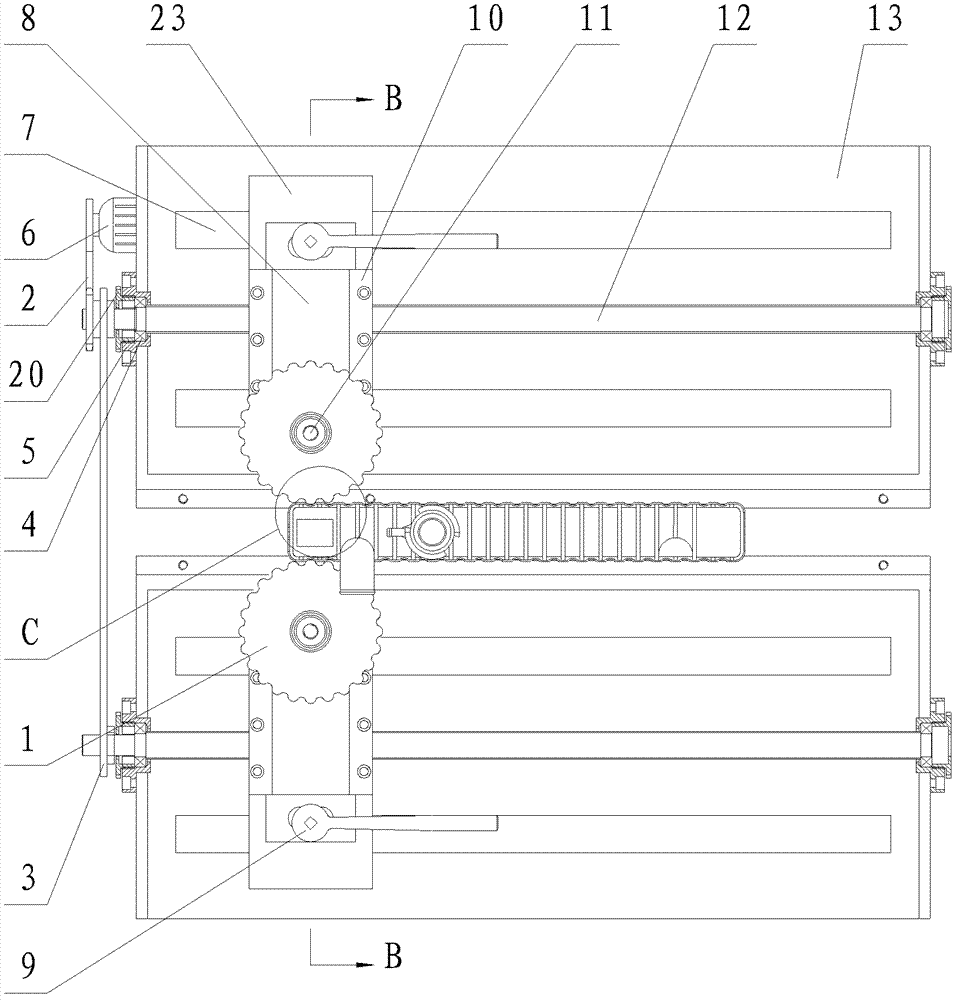

[0022] like image 3 , Figure 4 , Figure 8 As shown, the present invention has two box bodies 13 arranged side by side, the components installed in each box body 13 are the same, a support plate 27 is arranged between the two box bodies 13, the main piece 14 to be press-fitted and the water The chamber 15 is located on top of this pallet 27 .

[0023] Taking a box body 13 as an example, there are two supports 21 in the box body 13 , each support 21 is provided with a longitudinal guide rail 7 respectively, and the two longitudinal guide rails 7 are of equal height and parallel to each other. Both ends of the lower surface of the longitudinal sliding plate 23 are respectively provided with longitudinal sliding blocks 22 slidably connected with the longitudinal guide rails 7 , and a driving mechanism for driving the longitudinal sliding plates 23 to slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com