Bending mould of forming straight circular tube and incremental forming method

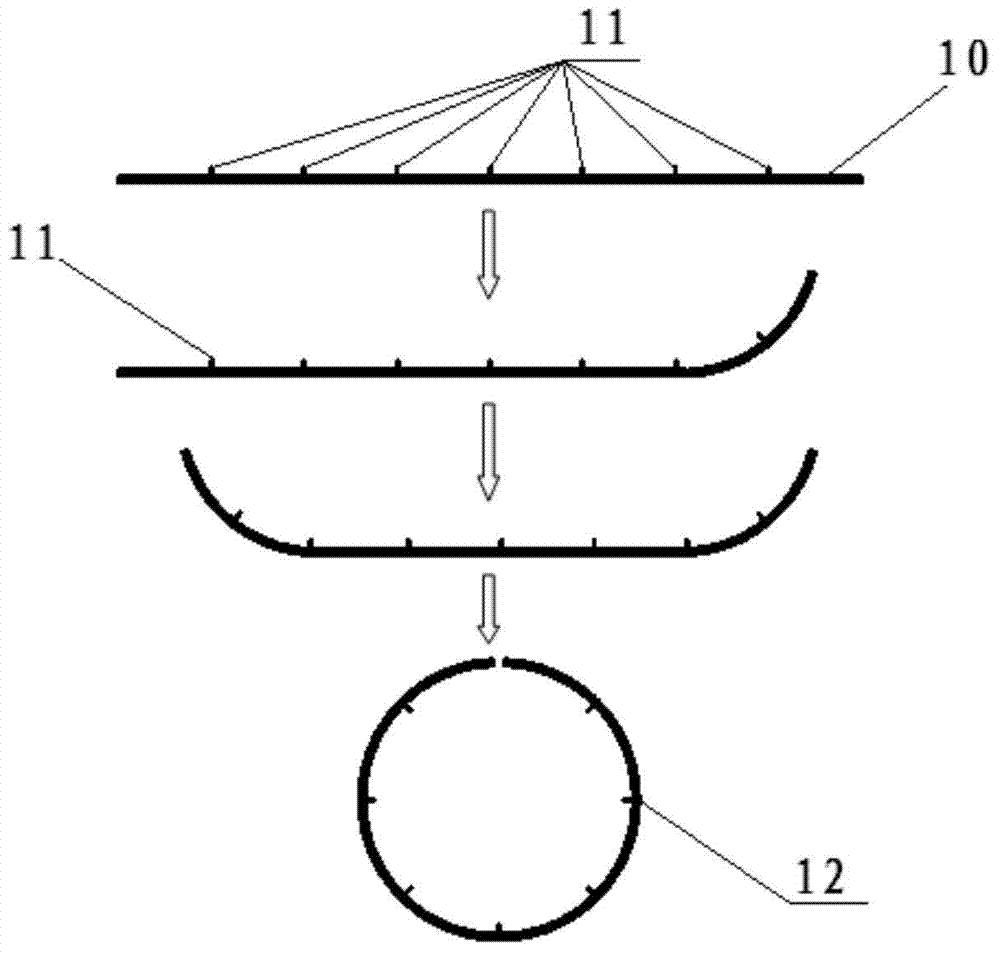

A round pipe and mold technology, which is applied in the fields of high strength and high resilience titanium alloy to be continuously bent into straight round pipes in multiple steps at room temperature, combined bending molds and progressive forming, and sheet metal bending forming, can solve the problem of Insufficient deformation of the material, inability to overcome springback, uneven deformation, etc., to achieve the effect of solving bending interference, simple and reasonable structure, and easy promotion and realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

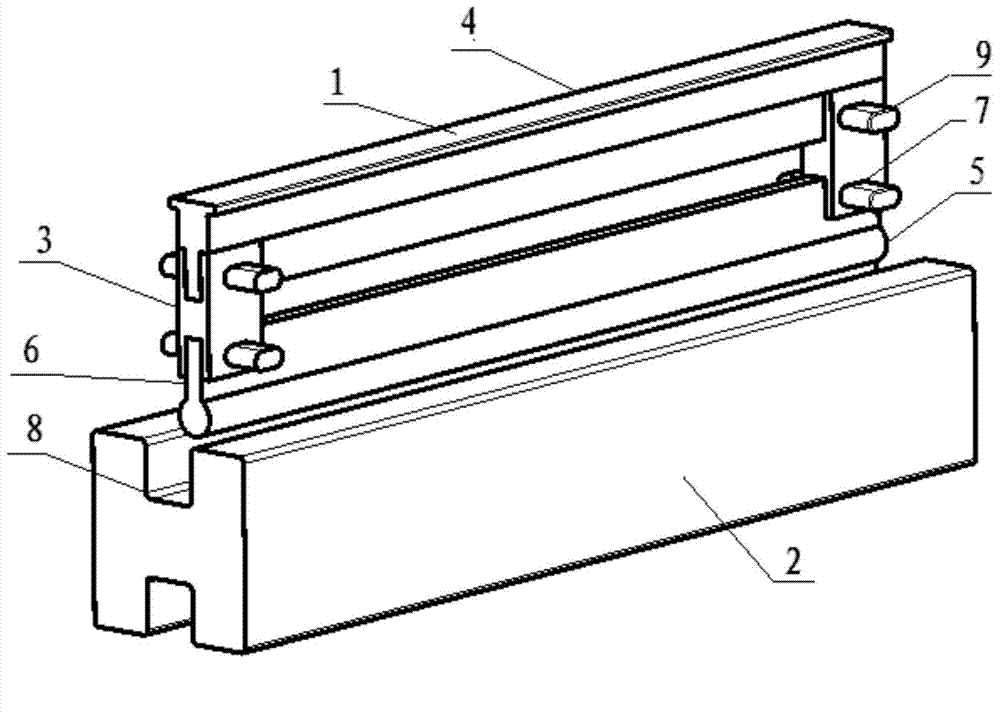

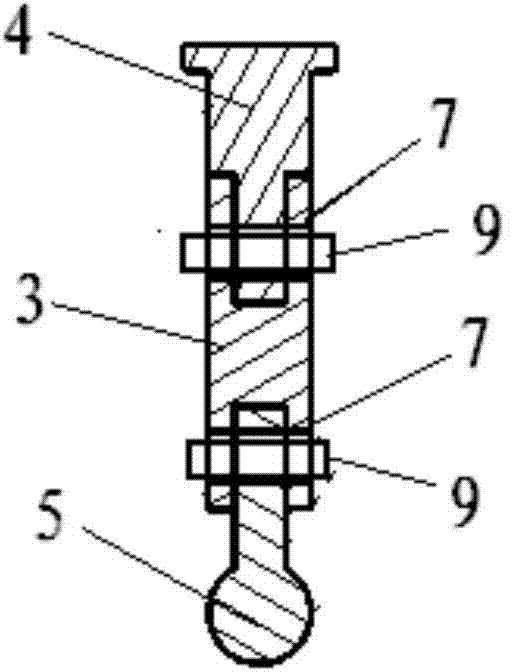

[0019] Referring to the accompanying drawings, a bending die for forming straight round pipe parts, the die contains an upper die 1 and a lower die 2, the upper die 1 is a combined structure, composed of a die handle 4 and a forming punch 5, the die The handle 4 is a strip structure with a T-shaped cross-section. The two ends of the mold handle 5 are provided with connecting holes 7. The forming punch 5 is a strip structure with a hammer-shaped cross-section. The connecting hole 7 corresponding to the die handle, the die handle 4 and the forming punch 5 are connected through the connecting block 3 with the upper and lower connecting holes 7 and the connecting pin 9, and the cross section of the connecting block 3 is an H-shaped structure with upper and lower mounting grooves , the two ends of the upper mold and the lower mold are respectively plugged into the upper and lower installation grooves of the connecting block, and then connected through the connecting holes with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com