Middle frame shaping equipment and middle frame shaping method for electronic product

A technology of electronic products and equipment, which is applied in the field of electronic product frame shaping equipment and shaping, can solve the problems of complex thermal shaping process, affecting product performance, and low processing efficiency, so as to save processing cost and product production cost, and improve Frame shaping yield and the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

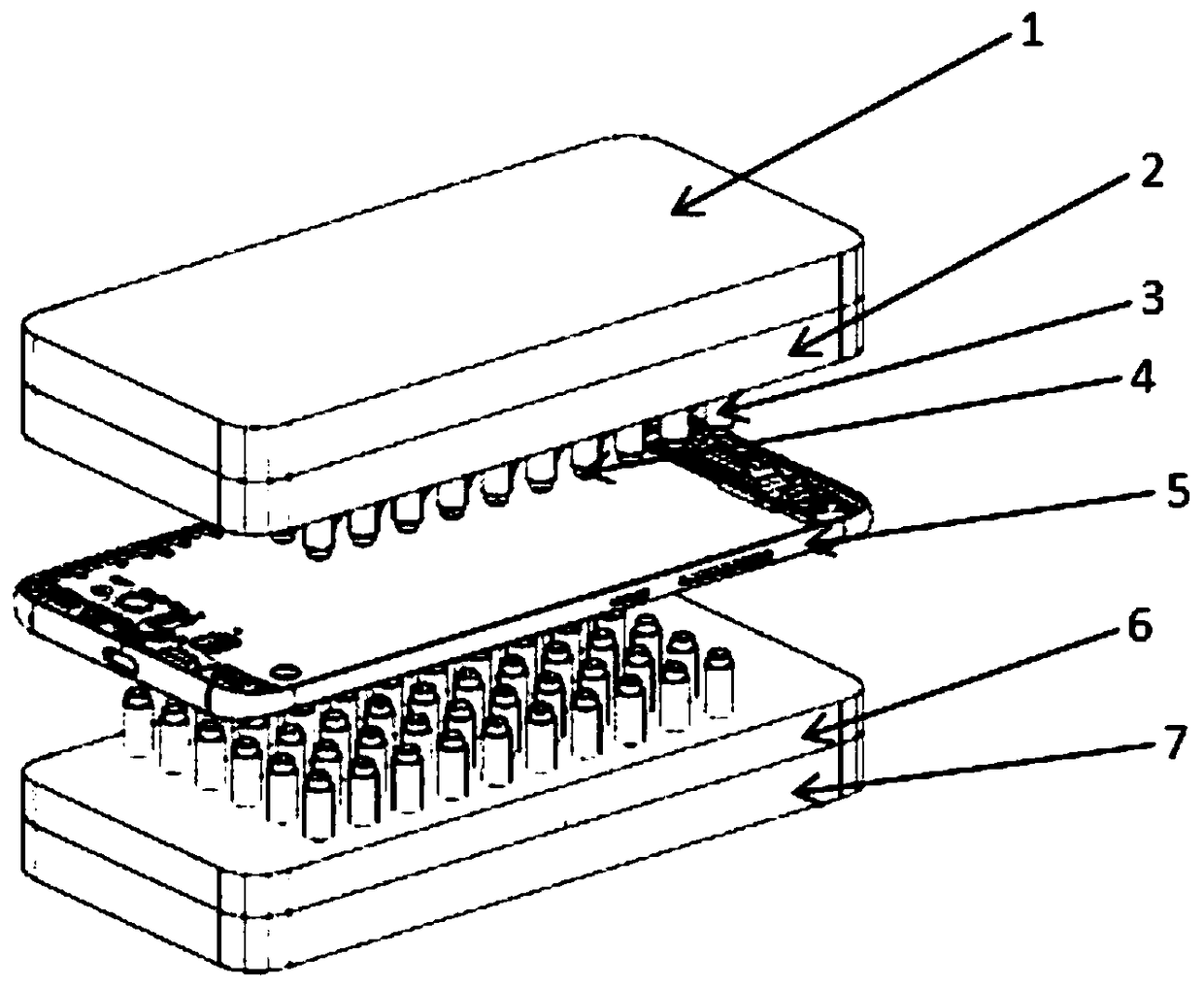

Image

Examples

example 1

[0060] 1. Install the needle array pressurized heat preservation plastic fixture on the four-column hydraulic press.

[0061] 2. According to the traditional method, adjust the jig and adjust the pressing position of the hydraulic press.

[0062] 3. Connect the electric heating device to the orthopedic fixture, and preheat the pressure needle, the preheating temperature is 200°C.

[0063] 4. Place the middle frame blank of the mobile phone on the lower needle array jig.

[0064] 5. Start the hydraulic press, and the upper and lower molds of the shaping jig are pressed and shaped. When pressing, the holding pressure is 18MPa, and the holding time is 1.5s.

[0065] 6. Open the mold, take out the shaped mobile phone middle frame, cool at room temperature for 5 minutes, and enter the next process.

[0066] After testing, the yield rate of the product is 92%

example 2

[0068] 1. Install the needle array pressurized heat preservation plastic fixture on the four-column hydraulic press.

[0069] 2. According to the traditional method, adjust the jig and adjust the pressing position of the hydraulic press.

[0070] 3. Connect the electric heating device to the orthopedic fixture, and preheat the pressure needle, the preheating temperature is 220°C.

[0071] 4. Place the middle frame blank of the mobile phone on the lower needle array jig.

[0072] 5. Start the hydraulic press, and the upper and lower molds of the shaping jig are pressed and shaped. When pressing, the holding pressure is 18MPa, and the holding time is 2s.

[0073] 6. Open the mold, take out the shaped mobile phone middle frame, cool at room temperature for 10 minutes, and enter the next process.

[0074] After testing, the yield rate of the product is 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com