Large-caliber PVDF pipe bend forming process

A molding process and large-diameter technology, applied in the field of large-diameter PVDF pipe bend forming process, can solve problems such as waste of resources, high scrap rate, rupture, etc., and achieve the effect of solving springback, eliminating internal stress and maintaining size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

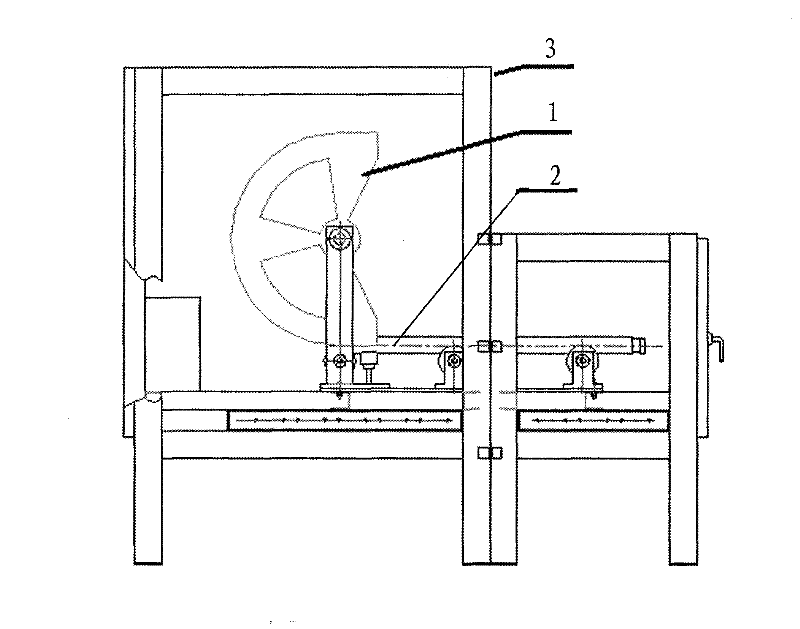

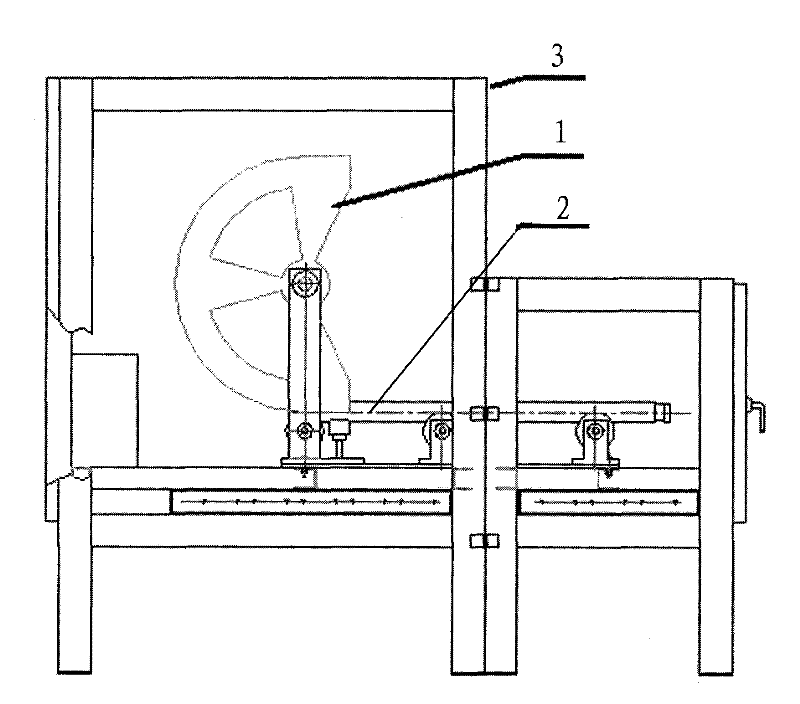

[0022] refer to figure 1 , PVDF pipe elbow forming process, including the following steps:

[0023] (1) Blanking: blanking according to the process requirements and drilling demoulding process holes on the pipe material;

[0024] (2) Heating: After heating the drying oven to a certain temperature, put the PVDF pipe material and flexible filler into the oven to heat for a certain period of time, and turn the PVDF pipe material 90° at regular intervals;

[0025] (3) Continuous heating: After the heating time is up, put the flexible filling body into the PVDF pipe material and heat it for a certain period of time, and turn the PVDF pipe material with the flexible filling body 90° at regular intervals, and at the same time turn the forming mold 1 is installed in the automatic bending equipment 2, and the forming mold 1 is heated by an oven 3;

[0026] (4) Bending forming: after the heating time of the PVDF pipe material with flexible filler is up, the automatic bending equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com