Bending die with swing male dies

A technology for swinging punches and bending dies, applied in the field of bending dies, can solve the problems of easy springback of bending parts, low work efficiency, complex structure, etc., and achieve the effects of convenient operation, high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

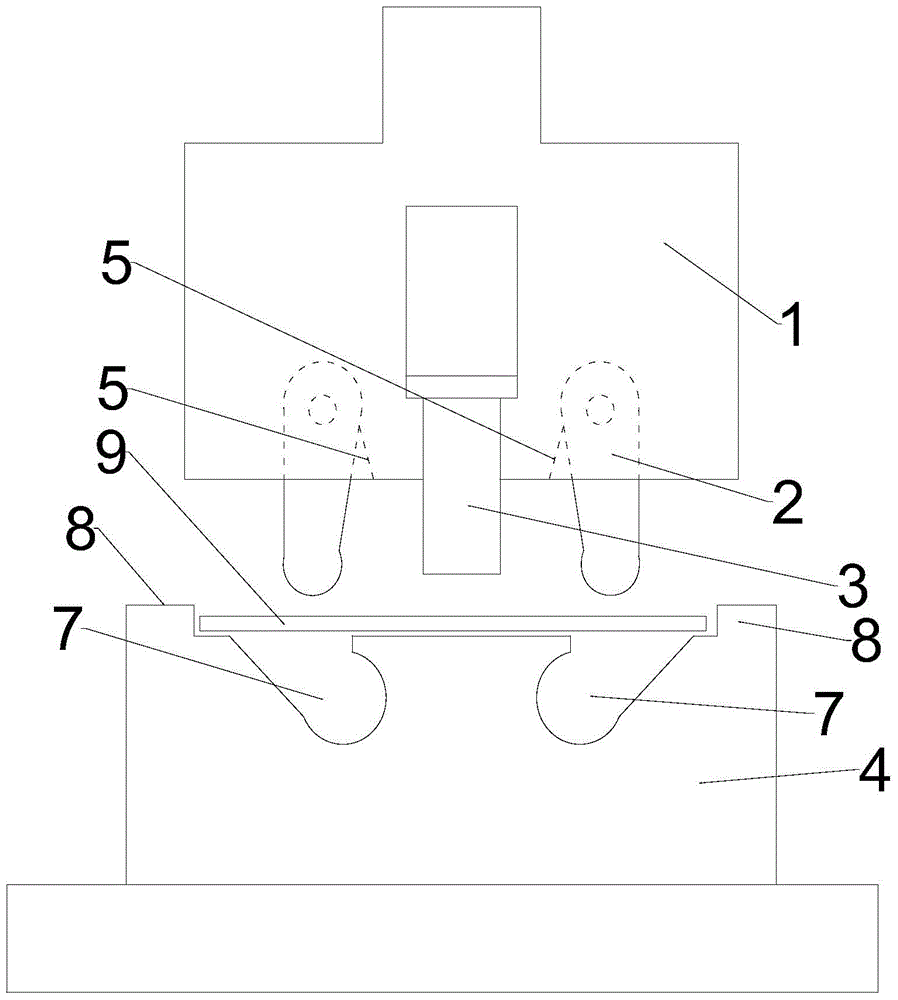

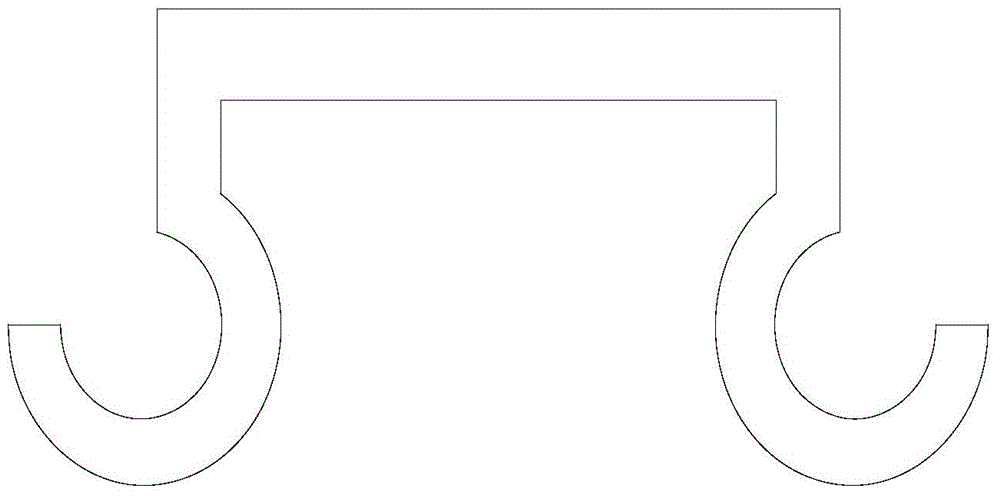

[0013] Depend on figure 1 It can be seen that a bending die with a swing punch of the present invention comprises an upper die 1, a swing punch 2, a ejector 3 and a die 4, the ejector 3 is a cylinder, and the ejector 3 is fixed on On the lower surface of the upper die 1, the upper die 1 is provided with two punch grooves 5, and a swing punch 2 is arranged in each punch groove 5, and the two swing punches 2 are arranged oppositely. The die 4 is provided with two grooves 7 corresponding to the swing punch 2 , and a boss 8 is respectively arranged on both sides of the die 4 .

[0014] When working, the blank 9 is positioned by the boss on the die, the upper mold presses the blank, the swing punch extends into the groove, the swing punch swings left and right under the action of the groove, and finally it is bent and formed , After removing the upper mold, use tweezers to shape it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com