Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce the number of piles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

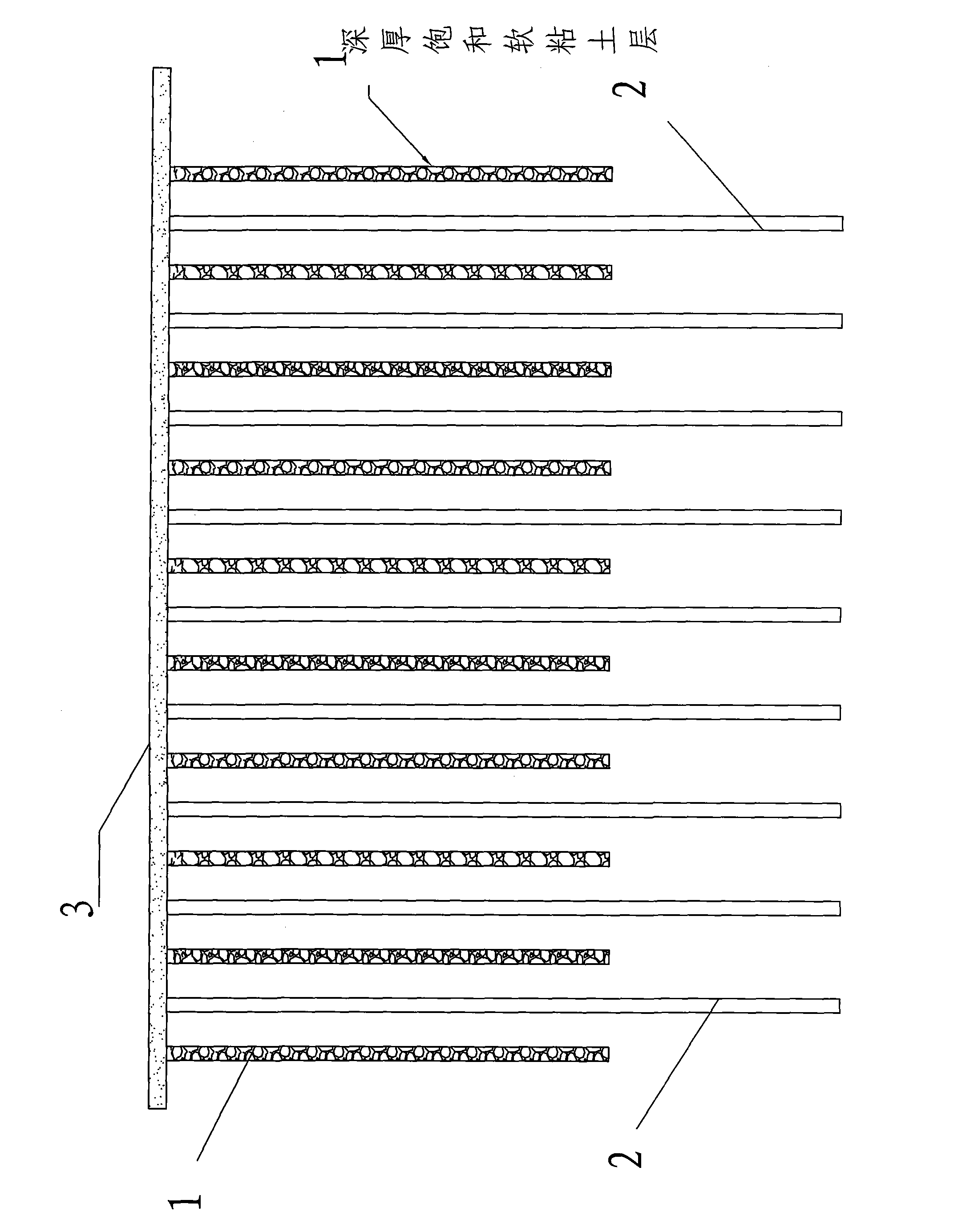

Method for treating spiral oil-extruding filling pile composite foundation in stratum containing soft clay

InactiveCN101634143AIncrease drainage rateAccelerated consolidationBulkheads/pilesSoil preservationSoft clayUltimate tensile strength

The invention relates to a construction method of a spiral oil-extruding filling pile composite foundation in the stratum containing soft clay, which comprises the following steps: determining the structural size, the position and the number of spiral oil-extruding filling piles; manufacturing and constructing a vertical drainage well in the middle part of the design positions of every two adjacent spiral oil-extruding filling piles; manufacturing and constructing each spiral oil-extruding filling pile according to the design position in the middle part between every two finished vertical drainage wells; and then paving drain liner layers on the foundation surface. The invention aims at providing a method for treating the spiral oil-extruding filling pile composite foundation in the stratum containing the soft clay, which avoids the negative oil-extruding effect of the spiral oil-extruding filling piles, improves the drain speed of saturated clay around piles, improves the strength of soil bodies around the piles and under the piles, substantially reduces the settlement after construction, improves the effectiveness and the use range of the spiral oil-extruding filling piles, increases the space length between the piles, reduces the pile number, saves the engineering investment, and accelerates the construction progress.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

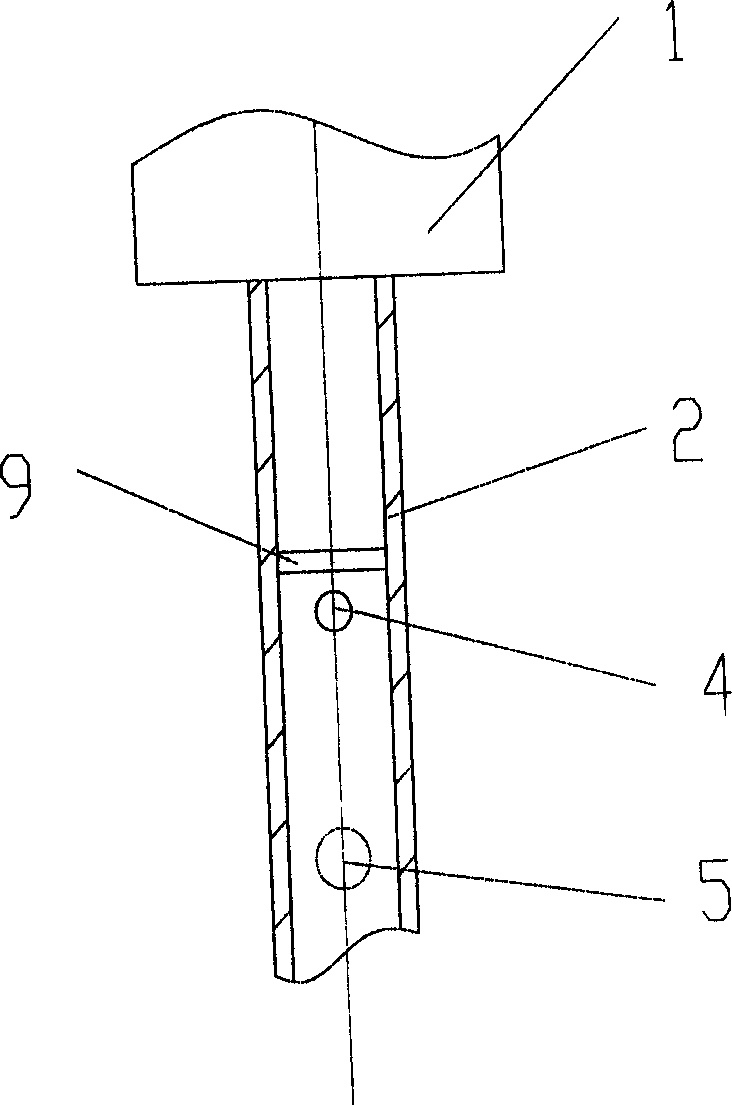

Method of vibration and extrusion for cast-in-place concrete in pile hole and its vibration rod device

InactiveCN1657710AReduce the impactLow powerBuilding material handlingBulkheads/pilesSteel tubeBearing capacity

A method for pouring concrete into pile hole and compressing and its vibrator are disclosed; including the following steps: (1) according to the work mode of concrete pile to choose the type of vibrator, use shape steel or steel pipe as the structural force-passing element; when there is mud staying in the upper part, use steel pipe; (2) pour concrete into the pile hole; (3) insert the vibrator into the concrete to vibrate and stress. The method suits for CFG pile dry work pouring pile method, wet work circulative pouring method and digging-drilling method etc.

Owner:北京市机械施工集团有限公司

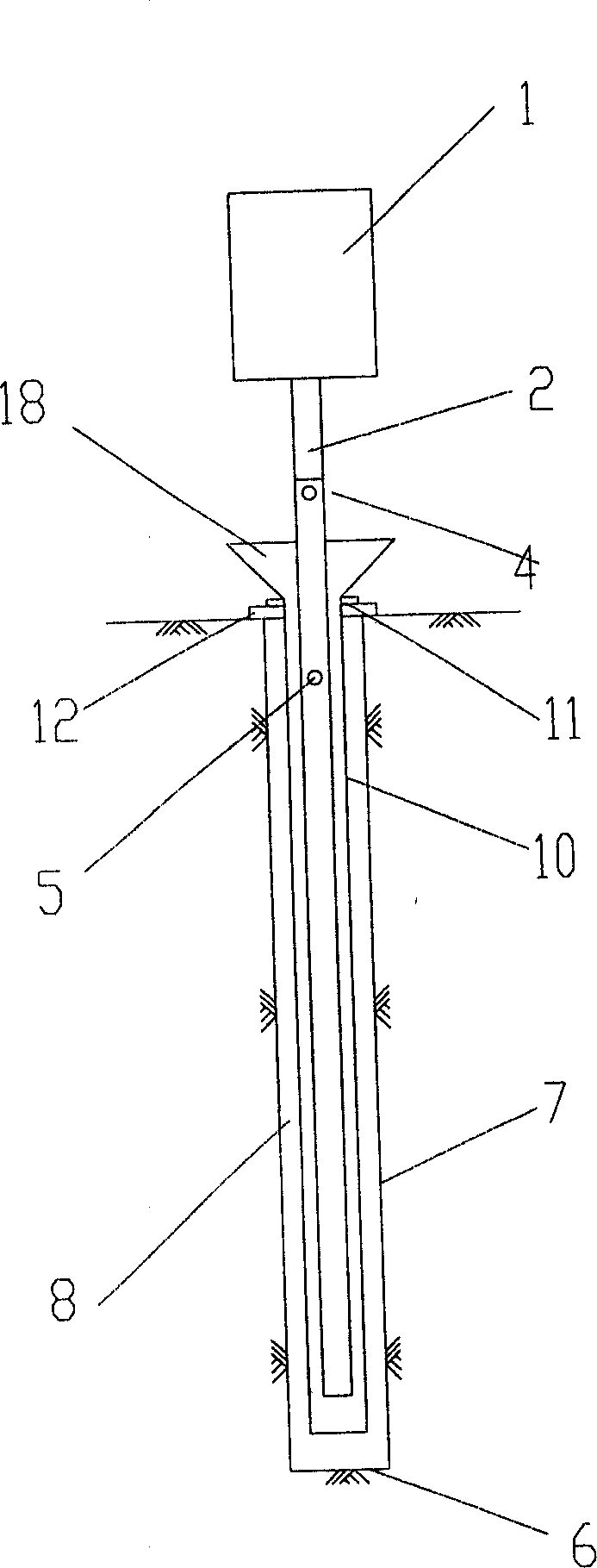

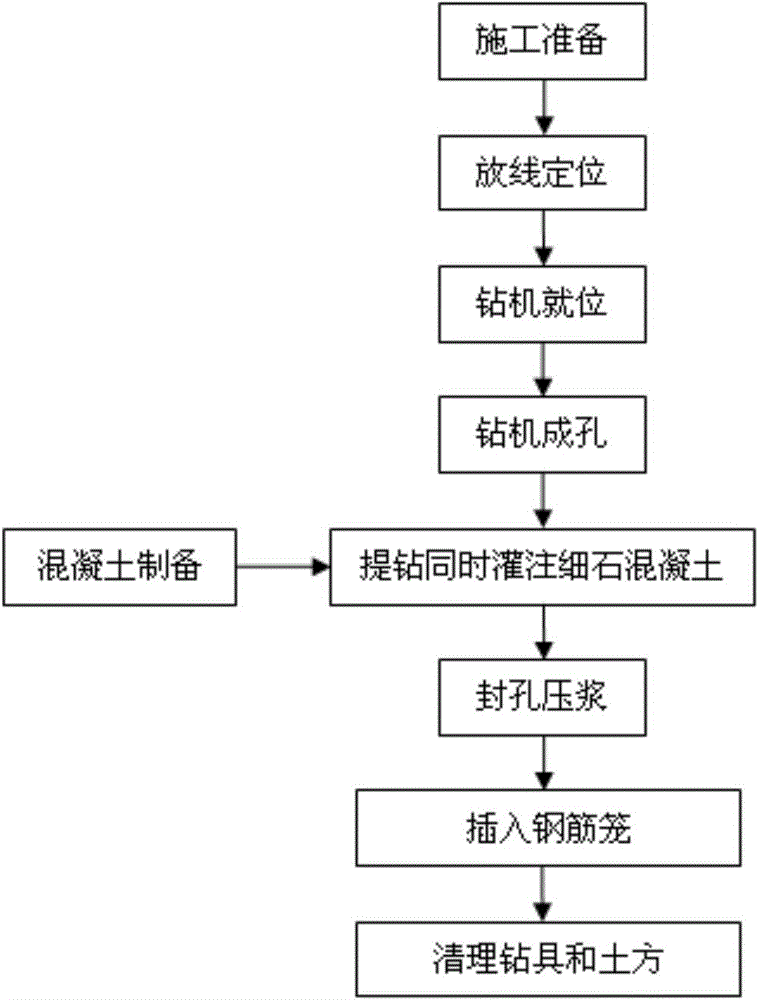

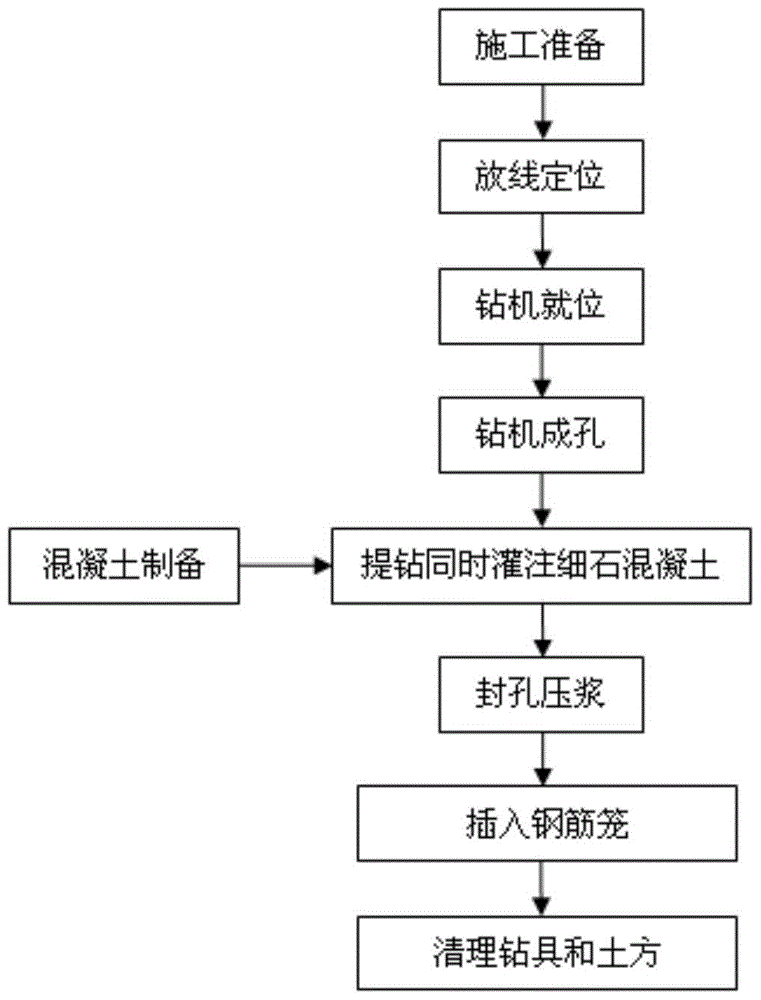

Method for constructing long auger bored cast-with-pressure concrete uplift pile

ActiveCN104631438AImprove pullout resistanceIncrease contact areaBulkheads/pilesStructural engineeringEngineering

The invention discloses a method for constructing a long auger bored cast-with-pressure concrete uplift pile. The method for constructing the long auger bored cast-with-pressure concrete uplift pile comprises the steps that the preparation for construction is made, paying-off for positioning is conducted, a drilling machine is prepared to work, a hole is formed by the drilling machine, drill lifting and fine aggregate concrete pouring are conducted at the same time, the hole is sealed and grouting is conducted, a steel reinforcement cage is inserted, and drilling tools and an earthwork are cleaned. The method for constructing the long auger bored cast-with-pressure concrete uplift pile has the advantages that concrete is pressed in a soil body and is located on the bottom and the side wall of the pile according to the specific grouting technique, the concrete and the soil body are glued into a whole, and in this way, the contact area between a pile body and the soil body is increased; compared with a traditional uplift pile, the uplift performance of the long auger bored cast-with-pressure concrete uplift pile is improved remarkably.

Owner:ANHUI TONGJI CONSTR GRP

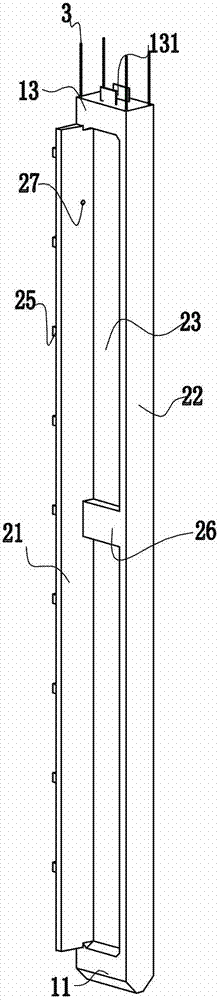

Deep-hole inverted-T-shaped pile based high-rise earthquake-resistant building structure

InactiveCN102720218AImprove carrying capacityReduce the number of pilesProtective foundationBulkheads/pilesEarthquake resistantDeep hole

The invention discloses a deep-hole inverted-T-shaped pile based high-rise earthquake-resistant building structure, which is characterized in that a whole-plate foundation is supported by a lower cast-in-place pile, underground and aboveground buildings are sequentially constructed on the whole-plate foundation, the cast-in-place pile is a deep-hole inverted-T-shaped pile, and a pile-base shock-insulating pad is arranged between a pile leg and a foundation. According to the invention, the construction is performed based on the deep-hole inverted-T-shaped pile, so that the bearing capacity of a single bearing pile is effectively improved, and the number of the pile and the construction cost can be significantly reduced. According to the invention, the bottom of the inverted-T-shaped pile is provided with the pile-base shock-insulating pad, and a basic shock-insulating pad is arranged below the whole-plate foundation, so that the vibration of earthquakes is absorbed by using a soft cushion pad below a rigid structure, therefore, an earthquake-resistant effect can be effectively achieved, the earthquake-resistant capacity of a building can be improved, and the life safety of residents in disasters can be ensured.

Owner:李国忠

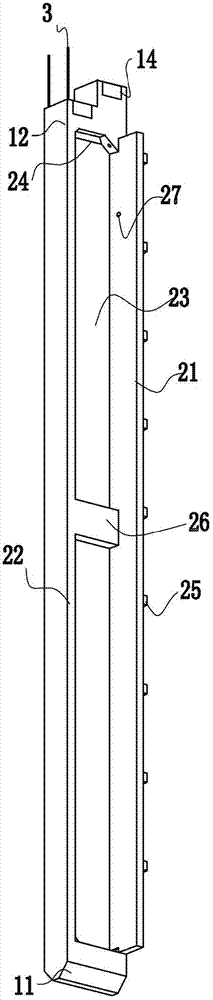

Pre-tensioned pre-stressing fender post

The invention provides a pre-tensioned pre-stressing fender post, comprising a post end head and a post body. The pre-tensioned pre-stressing fender post is characterized in that the post body is an H-shaped cross section of which the upper flange is wider than the lower flange; and pre-tensioned pre-stressing wires or steel wires are embedded in the upper flange and the lower flange. A main rib entirely uses the pre-tensioned pre-stressing wires or steel wires, so that a step of constructing steel ribs can be basically eliminated. The amount of the steel ribs can be further reduced, and the manufacturing cost is reduced.

Owner:杨众 +1

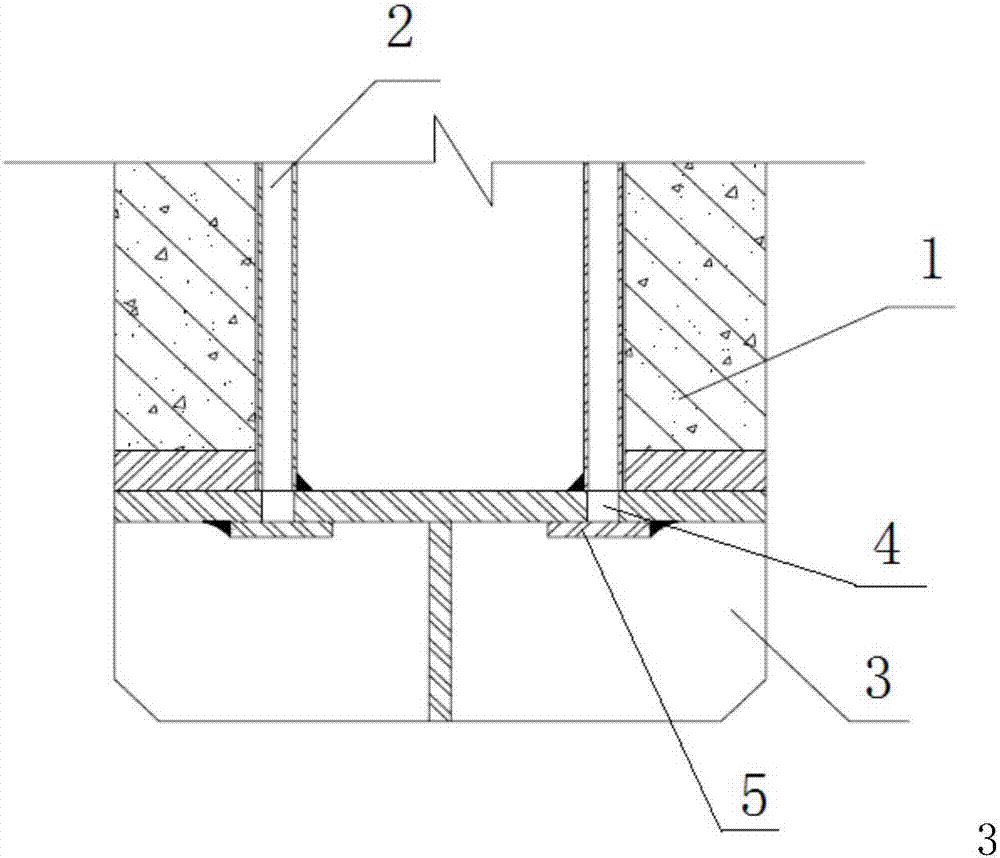

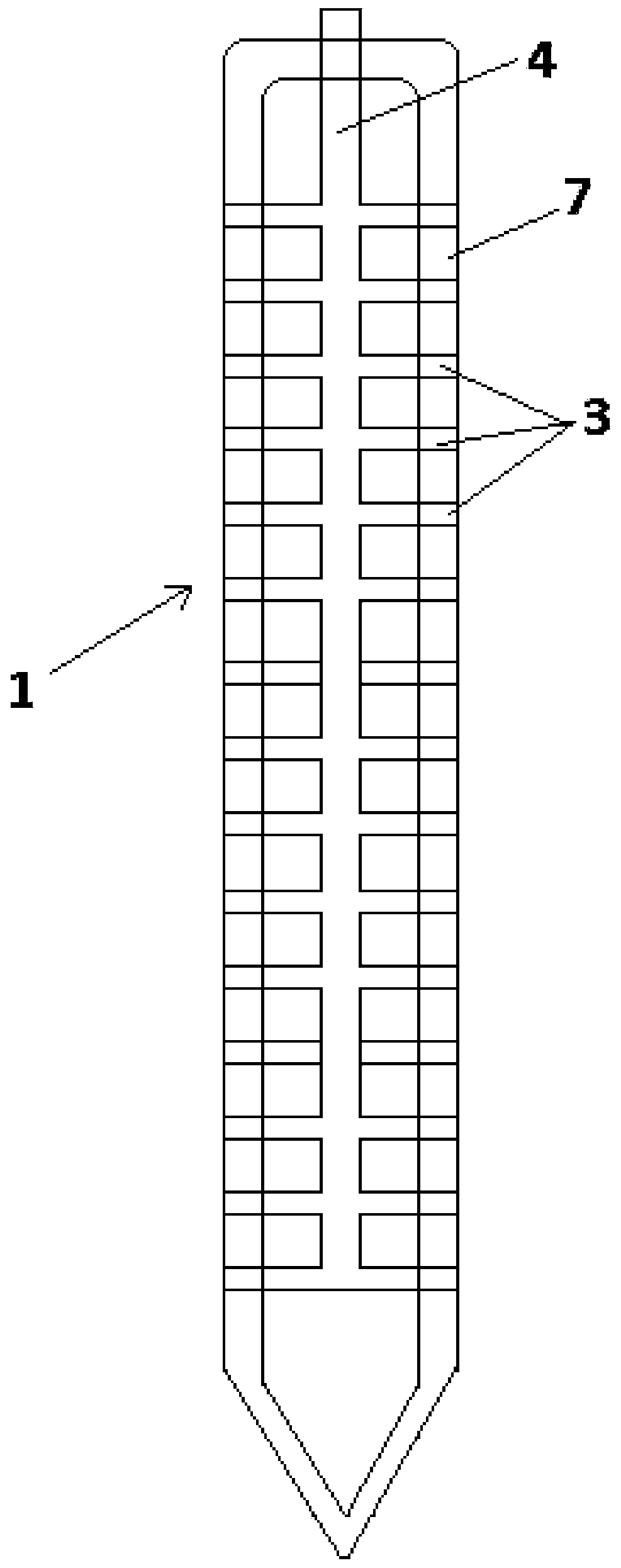

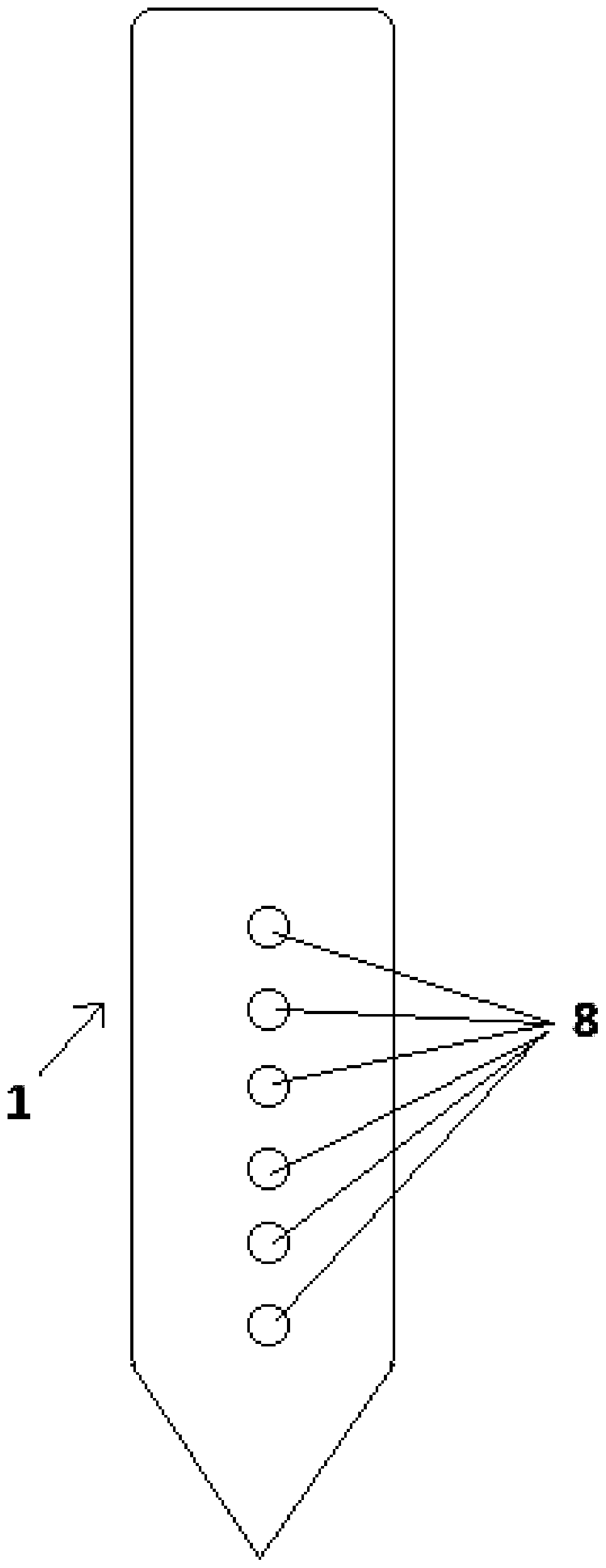

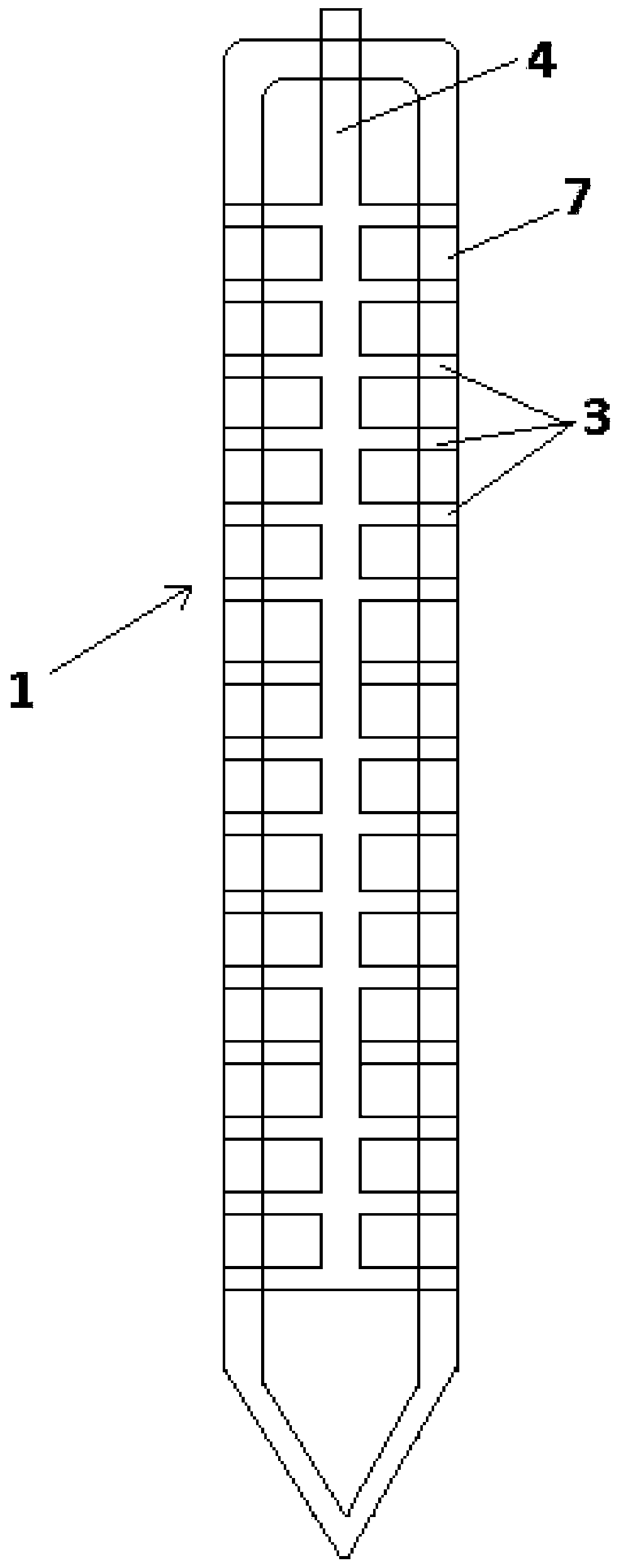

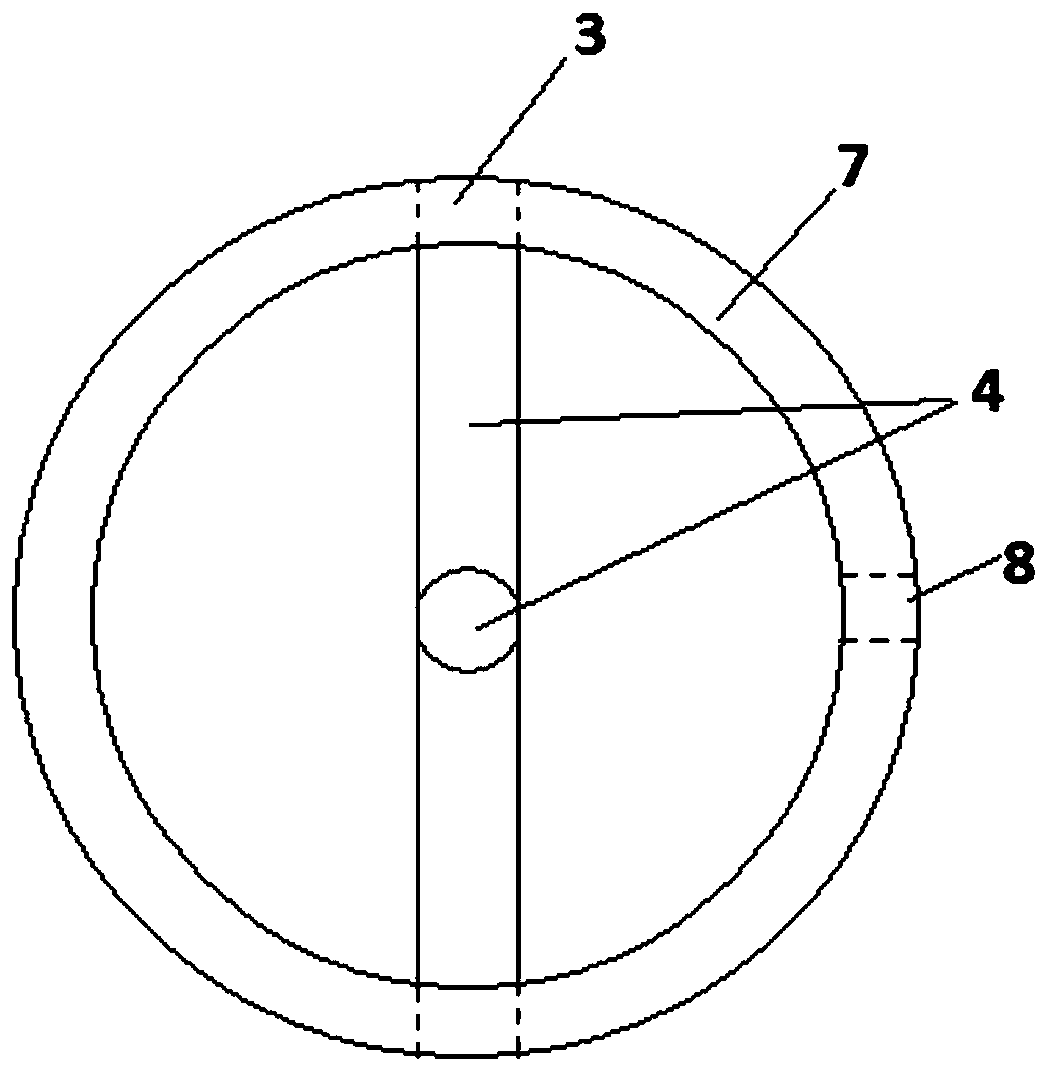

Pipe pile with post-pressure-grouting grouting pipes and construction method of pipe pile

ActiveCN107237319AImprove bearing capacityImprove the modulus of compressionBulkheads/pilesSlurrySpot welding

The invention provides a pipe pile with post-pressure-grouting grouting pipes. The pipe pile comprises a pipe pile body, the grouting pipes which are arranged in the pipe pile body and symmetrically arranged with the axis of the pipe pile body as the center and a steel pile point arranged at the lower end of the pipe pile body. Slurry discharge holes are formed in the positions, corresponding to the pouring pipes, on the steel pile point. Blocking plates which are used for covering the slurry discharge holes and can be jacked up by the grouting pressure are welded to the positions corresponding to the slurry discharge holes in a spot welding manner. The two grouting pipes are vertically arranged. The pipe pile body is formed by the multiple-joint butt joint. Each grouting pipe comprises multiple sections matched with the sections, corresponding to the grouting pipe, of the pipe pile in length. The portions, close to the joints of the pipe pile body, of the sections of the grouting pipes are connected through pipe joints. By the adoption of the pipe pile with the post-pressure-grouting grouting pipes, the single-pile bearing force of the prefabricated concrete pipe pile is improved effectively, the modulus of compression of foundation soil is increased, the settlement of a building is reduced, the pile length is reduced, the number of piles is reduced, the stability of the building is guaranteed, and the building cost is saved.

Owner:MCC TIANGONG GROUP

Core-grouted static pressure anchor rod pile

The invention relates to a core-grouted static pressure anchor rod pile forming device, which comprises a standard pile section and a bottom pile section, wherein a hard plastic pipe is embedded in the center of the cross section of the standard pile section; the bottom end of the hard plastic pipe is connected with a straight-through hollow chamber, and the four corners of the top end thereof are respectively provided with an anchor rod hole; the four corners of the bottom end of the standard pile section are respectively provided with a connecting hole; the connecting holes correspond to the axial positions of the anchor rod holes; a bottom hard plastic pipe is embedded in the center of the cross section of the bottom pile section; the bottom end of the bottom hard plastic pipe is in threaded connection with a hard plastic casing pipe; the four corners of the top surface of the bottom pile section are respectively provide with a bottom anchor rod hole; the bottom anchor rod holes correspond to the axial positions of the anchor rod holes; reinforcing steel bars the upper parts of which are provided with nuts are anchored into the bottom anchor rod holes; the nuts and the connecting holes are configured; a plurality of lower outlet pipes are communicated in the circumferential direction of the hard plastic casing pipe; and a plurality of upper outlet pipes are communicated in the circumferential direction of the straight-through hollow chamber. The invention has the advantages that firstly, the value of the pile bearing capacity can be increased, and thereby, the number of piles can be decreased so as to reduce construction cost, and the quality is reliable; secondly, the influence of compaction soil on adjacent buildings can be reduced so as to protect the surrounding construction environment.

Owner:孔超

Combined cofferdam under complex geological condition and construction method thereof

The invention discloses a combined cofferdam under the complex geological condition and a construction method thereof. The combined cofferdam is characterized in that a concrete antiskid pile section and a locking steel pipe pile section are arranged in the whole cofferdam by sections; and a front end concrete antiskid pile and a tail concrete antiskid pile in the concrete antiskid pile section are respectively connected with a tail locking steel pipe pile and a front end locking steel pipe pile in the locking steel pipe pile section to form the whole sealed cofferdam. The cofferdam under the complex geological condition has clear structural stress, firm structure, good water stopping effect and simpler construction method and can effectively protect basic construction quality.

Owner:THE FIRST CIVIL ENG CO LTD OF CREC SHANGHAI GRP

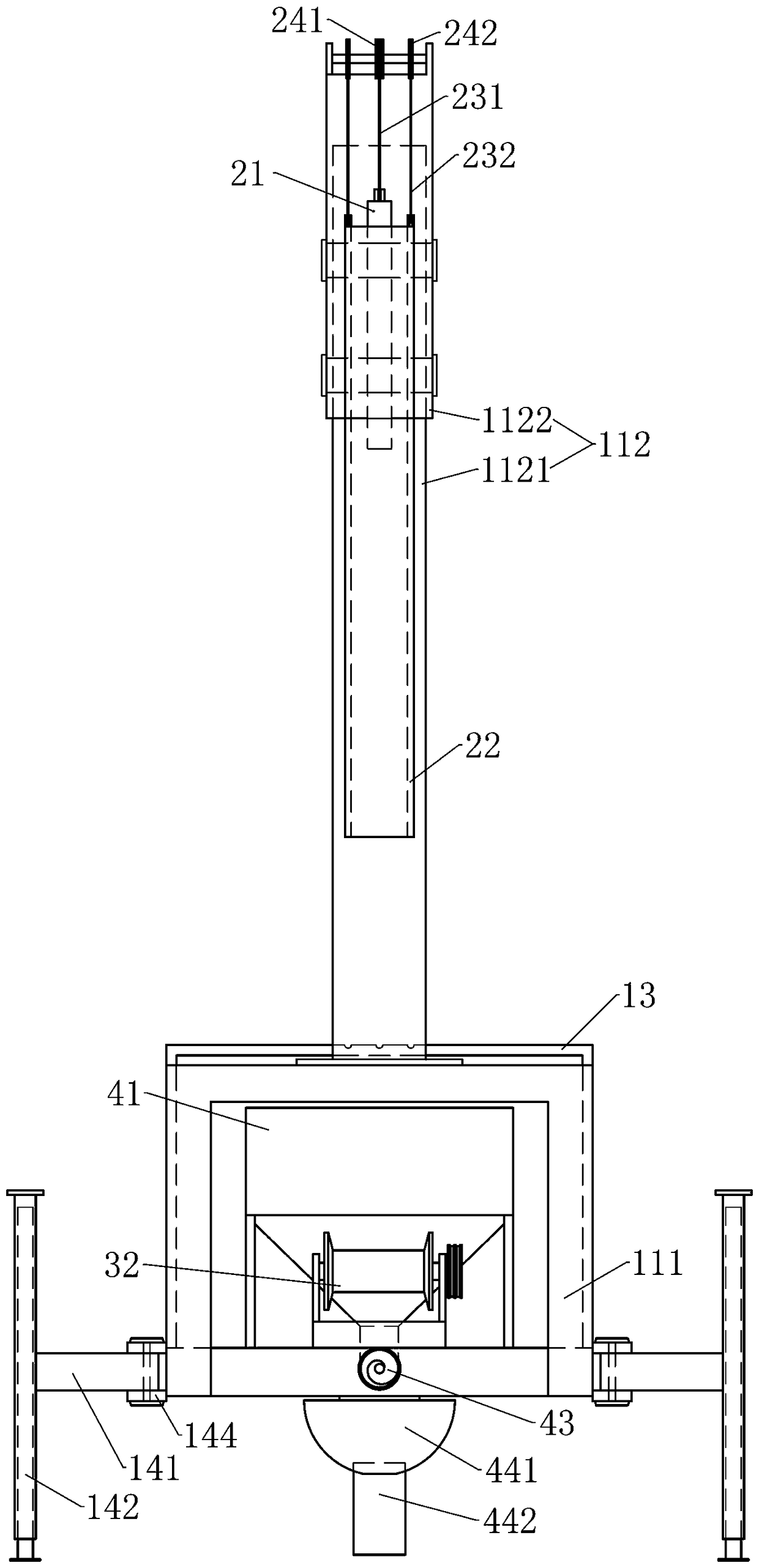

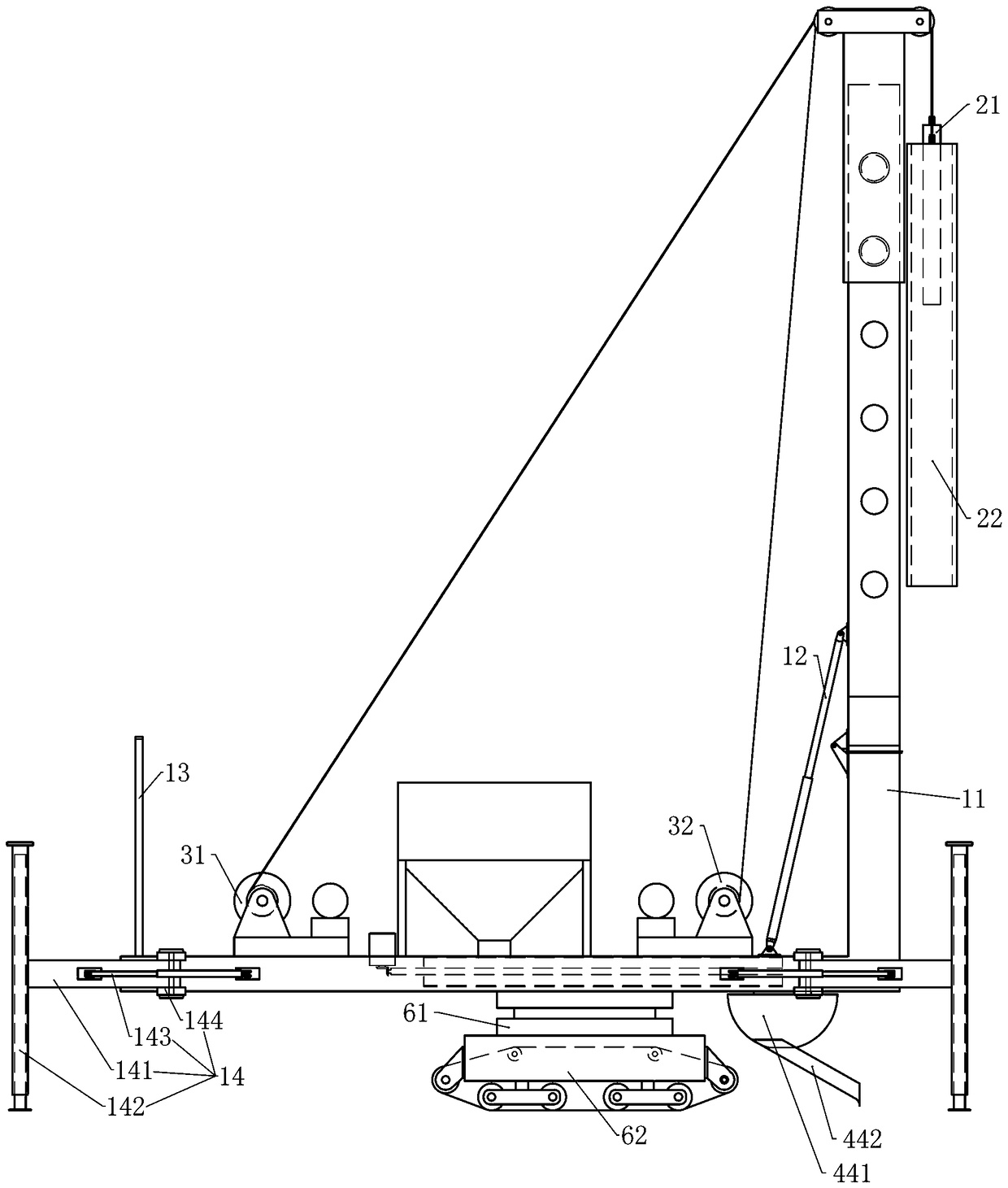

Automatic filling and compacting equipment and construction method for compaction pile foundation treatment

PendingCN108729435AQuality improvementThe filling is fully and evenly tampedSoil preservationEngineeringElectric control

The invention discloses automatic filling and compacting equipment. The automatic filling and compacting equipment comprises a structure platform, a compacting assembly, a feeding mechanism and an electric control device, a vertical frame is arranged on the structure platform, the compacting assembly comprises a compacting hammer and a protection casing outside the compacting hammer; and the automatic filling and compacting equipment is characterized in that the feeding mechanism comprises a power unit with a speed change function, the feeding mechanism is arranged at a corresponding positionon the structure platform so as to enable materials discharged from a discharge port of the feeding mechanism to enter a compaction pile hole, and the electric control device is provided with a controller used for coordinating a first winch and the power unit so as to enable the quantity of the materials filled into the compaction pile hole by the feeding mechanism to be linked with the hammeringfrequency of the compacting hammer. The construction method for the compaction pile foundation treatment adopts the automatic filling and compacting equipment so as to carry out compaction pile construction. According to the automatic filling and compacting equipment, filling and compacting can be sufficient and uniform, and the produced compaction pile is stable and excellent in quality.

Owner:中航旭日(北京)岩土工程技术有限公司 +2

Foundation pit supporting composite retaining wall and construction method thereof

InactiveCN109914429ASimple construction operationShort construction periodArtificial islandsExcavationsEngineeringRetaining wall

The invention provides a foundation pit supporting composite retaining wall. The foundation pit supporting composite retaining wall comprises a plurality of pipe piles arranged in the circumferentialdirection, and a cement soil retaining wall part positioned between two adjacent pipe piles and connected with the pipe piles to form a circumferentially closed retaining wall, wherein a grouting structure corresponding to the cement soil retaining wall part is arranged on the pipe wall of the pipe pile. The foundation pit composite cement soil retaining wall is simple in structure, simple in overall construction operation, short in construction period and low in cost. The invention further provides a construction method for the foundation pit supporting composite retaining wall.

Owner:刘小檀 +1

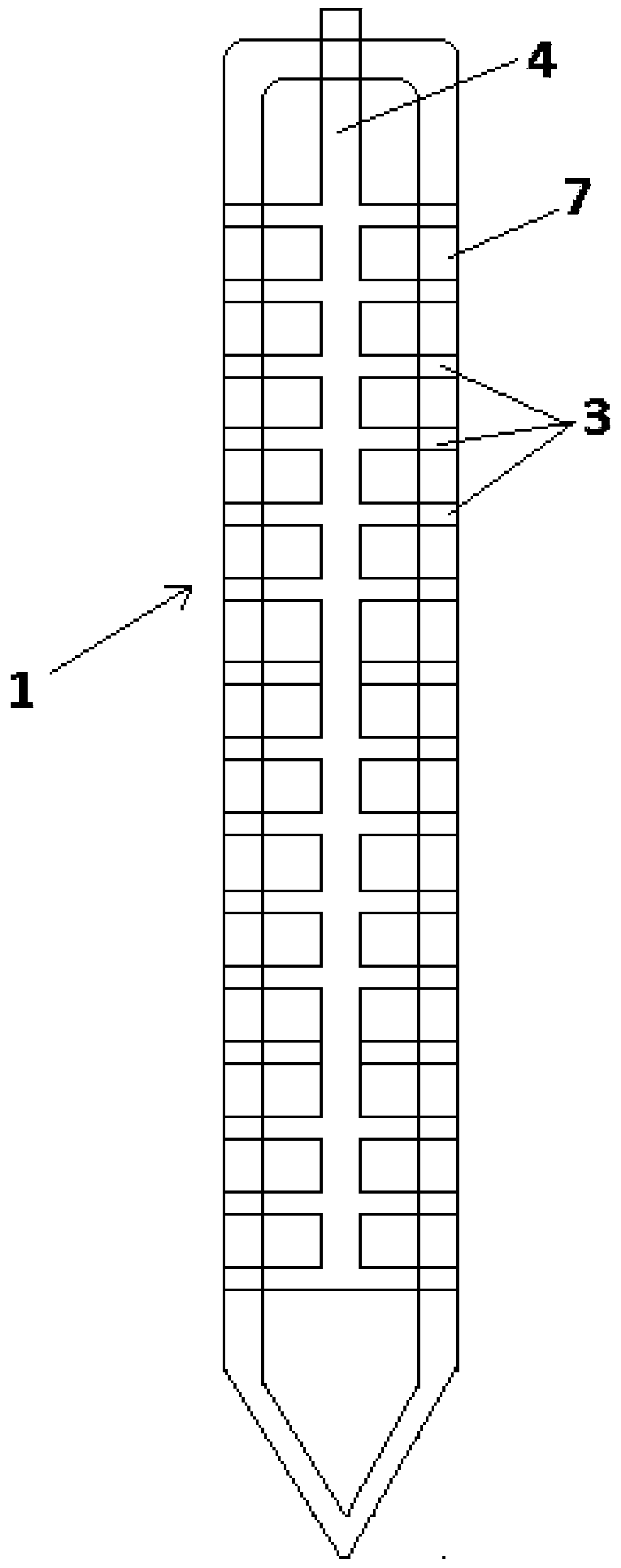

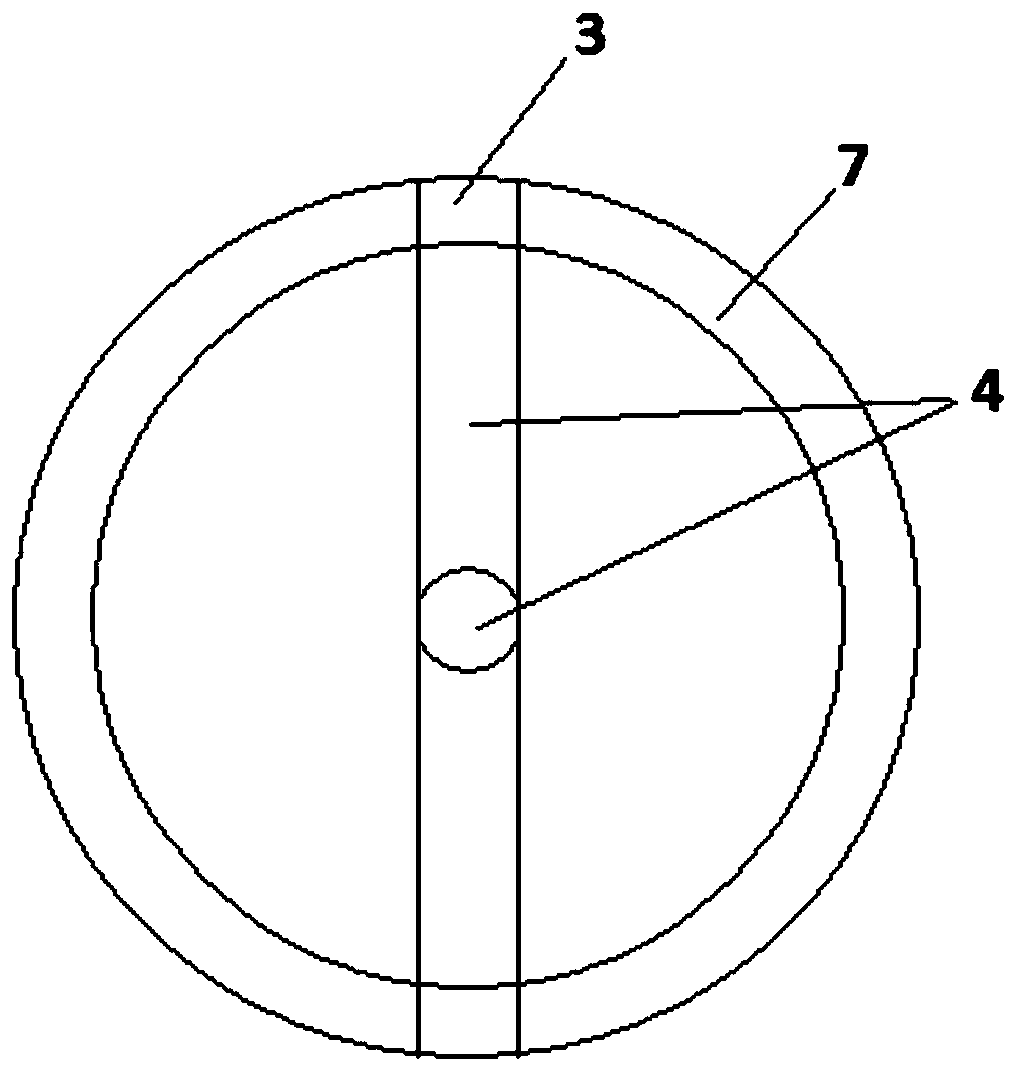

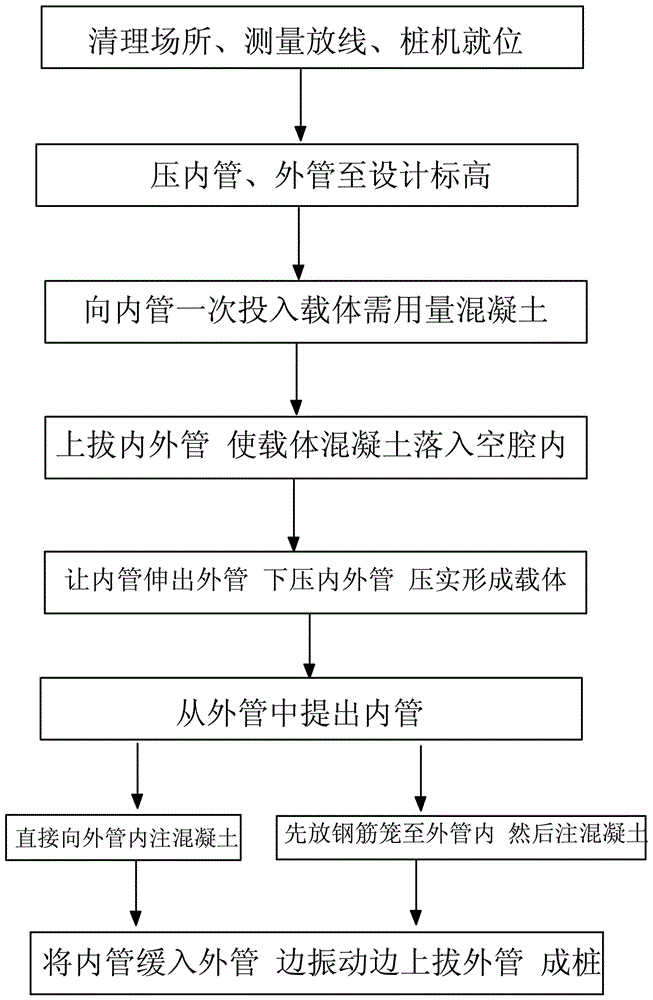

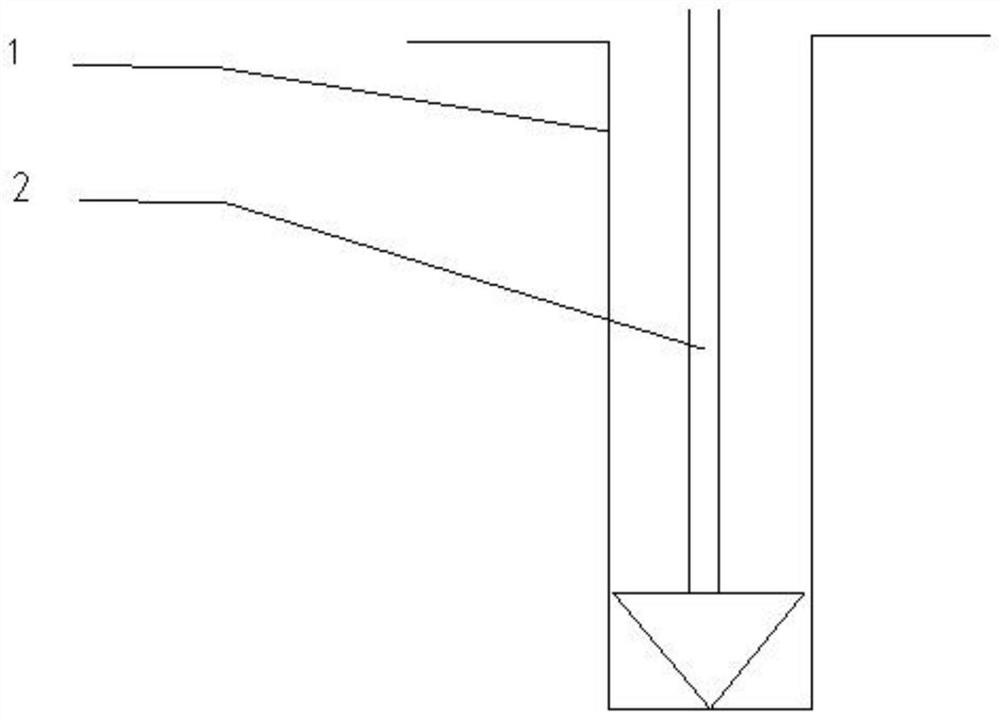

Double-pipe construction method for static pressure pipe-sinking carrier cast-in-place pile

InactiveCN105926594AImprove bearing capacityOvercome the defects of pile forming processBulkheads/pilesDouble tubeArchitectural engineering

The invention provides a double-pipe construction method for a static pressure pipe-sinking carrier cast-in-place pile. The carrier pile is manufactured through a static pile driver, an inner pipe and an outer pipe. Throwing of a carrier concrete material is completed at a time, the pile-forming period is shortened, energy is saved, and the environment is protected; and the pull resistance of the manufactured pile is improved remarkably. The double-pipe construction method includes the following steps that firstly, a site is cleaned, surveying and setting-out are conducted, and the pile driver is moved to a station; secondly, the inner pipe and the outer pipe are pressed to the designed elevation; thirdly, concrete required by a carrier is thrown into the inner pipe at a time; fourthly, the inner pipe and the outer pipe are up-pulled to the set height together, and a space formed when the inner pipe and the outer pipe are up-pulled can be filled with the carrier concrete automatically; fifthly, the inner pipe is lowered, the bottom end of the inner pipe extends out of the bottom end of the outer pipe, the inner pipe and the outer pipe are pressed downwards, the downward pressing force and the elevation reach the preset numerical value, and the expanded carrier is formed; sixthly, the inner pipe is lifted out of the outer pipe; seventhly, concrete is poured into the outer pipe, or a reinforcement cage is placed in the outer pipe firstly, and pile body concrete is poured; and eighthly, the inner pipe is put into the outer pipe, the outer pipe is up-pulled while vibrating, and the pile is formed.

Owner:朱龙

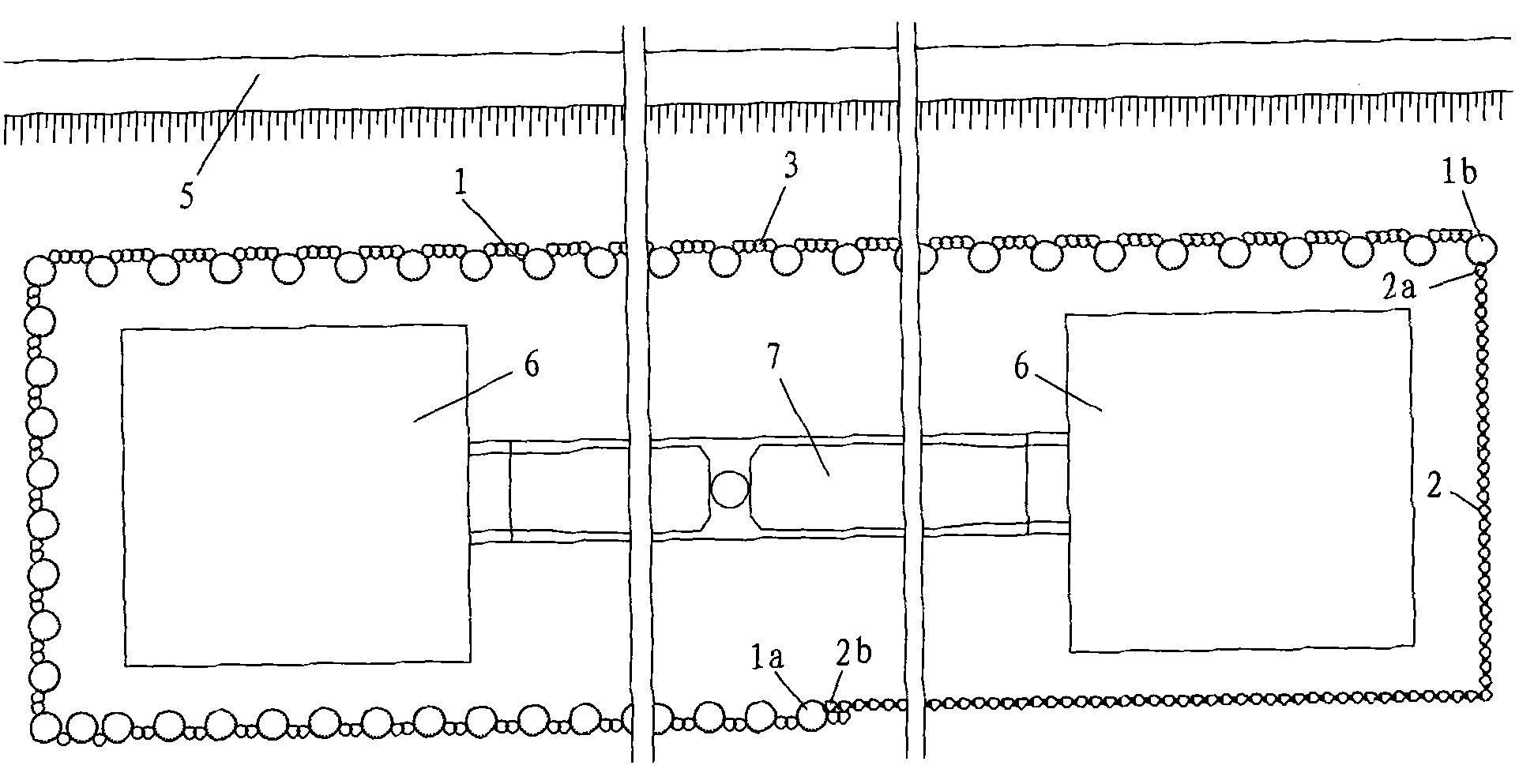

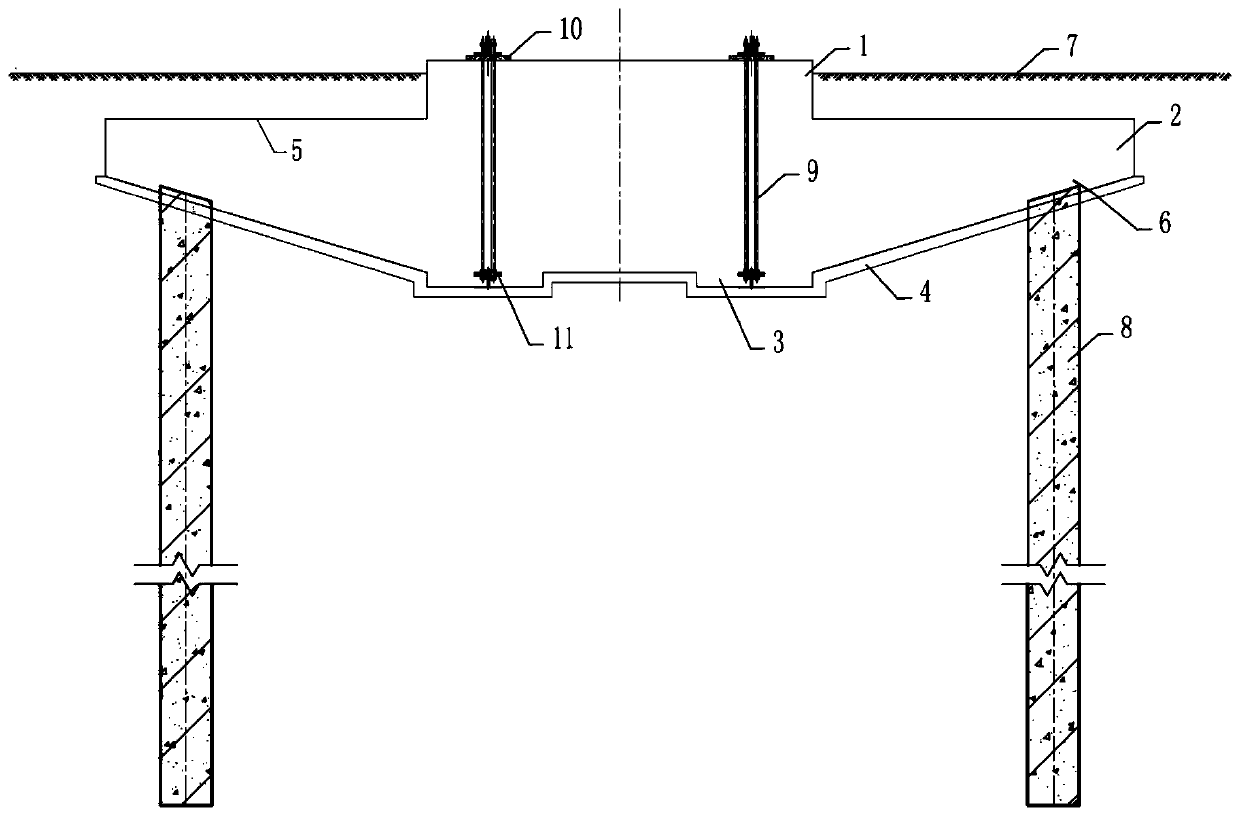

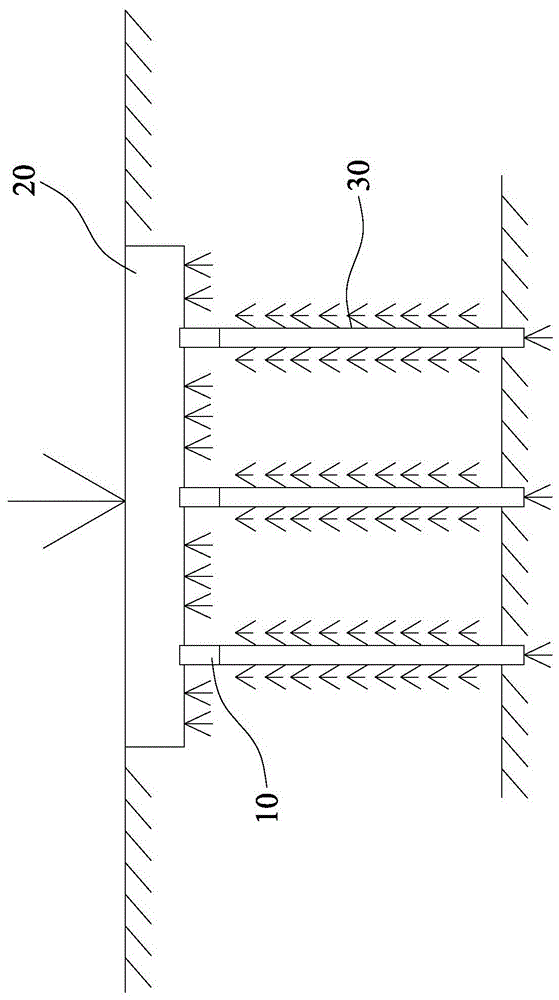

Horizontal bearing combined foundation based on piles and underground continuous wall and method

InactiveCN105756075AIncrease stiffnessReduce the number of pilesFoundation engineeringSlurry wallLoad bearing

The invention discloses a horizontal bearing combined foundation based on piles and an underground continuous wall and a method.The horizontal bearing combined foundation comprises the underground continuous wall and the multiple horizontal load-bearing piles arranged underground, a top plate is arranged at the top face of the underground continuous wall, the horizontal load-bearing piles are embedded into the bottom face of the underground continuous wall, and the combined foundation is used for bearing horizontal loads.The piles and the underground continuous wall are combined to serve as the foundation bearing horizontal loads, the advantage of high horizontal rigidity of the underground continuous wall is brought into play, and meanwhile embedding of the foundation is guaranteed through the piles on the lower portion.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

Fan bearing platform assembly improving pile uplift bearing capacity

PendingCN110607801AReduce thicknessReduce excavationWind motor supports/mountsFoundation engineeringCushionEngineering

The invention discloses a fan bearing platform assembly improving pile uplift bearing capacity. The fan bearing platform assembly comprises a bearing platform and foundation piles supporting the bearing platform; the bearing platform comprises a cylindrical upper platform column, a middle cylindrical middle platform column, a lower inverted circular truncated cone and an annular bottom convex platform which are concentrically connected in the axial direction; the diameter of the upper platform column is smaller than that of the cylindrical middle platform column, the large diameter of the upper portion of the lower inverted circular truncated cone is equal to the diameter of the cylindrical middle platform column, and the outer diameter of the bottom convex platform is equal to the small diameter of the lower portion of the lower inverted circular truncated cone; an anchor bolt cage connected with a fan tower barrel stretches into the bottom of the bearing platform; a lower anchor plate of the anchor bolt cage is located in the bottom convex platform, and an upper anchor plate of the anchor bolt cage is located above the upper platform column; the conical surface of the inverted circular truncated cone and the surface of the bottom convex platform are coated with cushion layers; and the bottom of the bearing platform is vertically provided with one or more circles of cylindrical foundation piles. By inverting a traditional bearing platform type structure, the thickness of a soil covering body is decreased, the excavation quantity and the backfill quantity of bearing platform soil are substantially reduced, the vertical pressure of the piles is reduced, the uplift force of the piles is increased, and the construction difficulty is lowered.

Owner:POWERCHINA BEIJING ENG

Drilling and high-pressure grouting construction method for uplift pile

ActiveCN104727305AReduce consumptionImprove pullout resistanceBulkheads/pilesSocial benefitsHigh pressure

The invention discloses a drilling and high-pressure grouting construction method for an uplift pile. The drilling and high-pressure grouting construction method includes the steps that step1, construction preparation is performed; step2, paying-off positioning is performed; step3, a drilling machine is in place; step4, drilling is performed; step5, casing running is performed; step6, drilling is continued to a designed elevation; step7, hole sealing grouting is performed; step8, concrete pouring is performed; step9, steel bars are inserted; step10, drilling tool and earthwork clearing is performed. The drilling and high-pressure grouting construction method has the advantages that in the drilling process, noise is low, vibration is small, the construction period is short, influences on surrounding traffic and social activities are small, and the construction method is a green construction method; while the uplift bearing capacity of a foundation is improved, the construction method saves a lot of resources and energy, and has remarkable social benefits.

Owner:ANHUI TONGJI CONSTR GRP

Foundation pit supporting composite retaining wall with water pumping and recharging function and construction method thereof

PendingCN109914427ASimple construction operationShort construction periodArtificial islandsExcavationsGroundwaterRetaining wall

The invention provides a foundation pit supporting composite retaining wall with water pumping and recharging functions. The foundation pit supporting composite retaining wall comprises a plurality ofpipe piles, connecting structures, a water pumping structure and a recharging structure. The plurality of pipe piles are arranged in the circumferential direction and are of hollow structures; the connecting structures are connected with the two adjacent pipe piles to form a circumferentially closed retaining wall; the water pumping structure is arranged on the pipe wall of at least one pipe pile, faces the inner side of the foundation pit, communicates with a soil body on the inner side of the foundation pit and the hollow structure, and is suitable for guiding underground water on the innerside of the foundation pit into the hollow structure of the pipe pile; the recharging structure is arranged on the pipe wall of the pipe pile provided with the water pumping structure, faces the outer side of the foundation pit, is located above the water pumping structure and communicates with the soil body and the hollow structure on the outer side of the foundation pit, is suitable for recharging the underground water in the hollow structure into the soil body on the outer side of the foundation pit. The invention further provides a construction method of the foundation pit supporting composite retaining wall.

Owner:刘小檀 +1

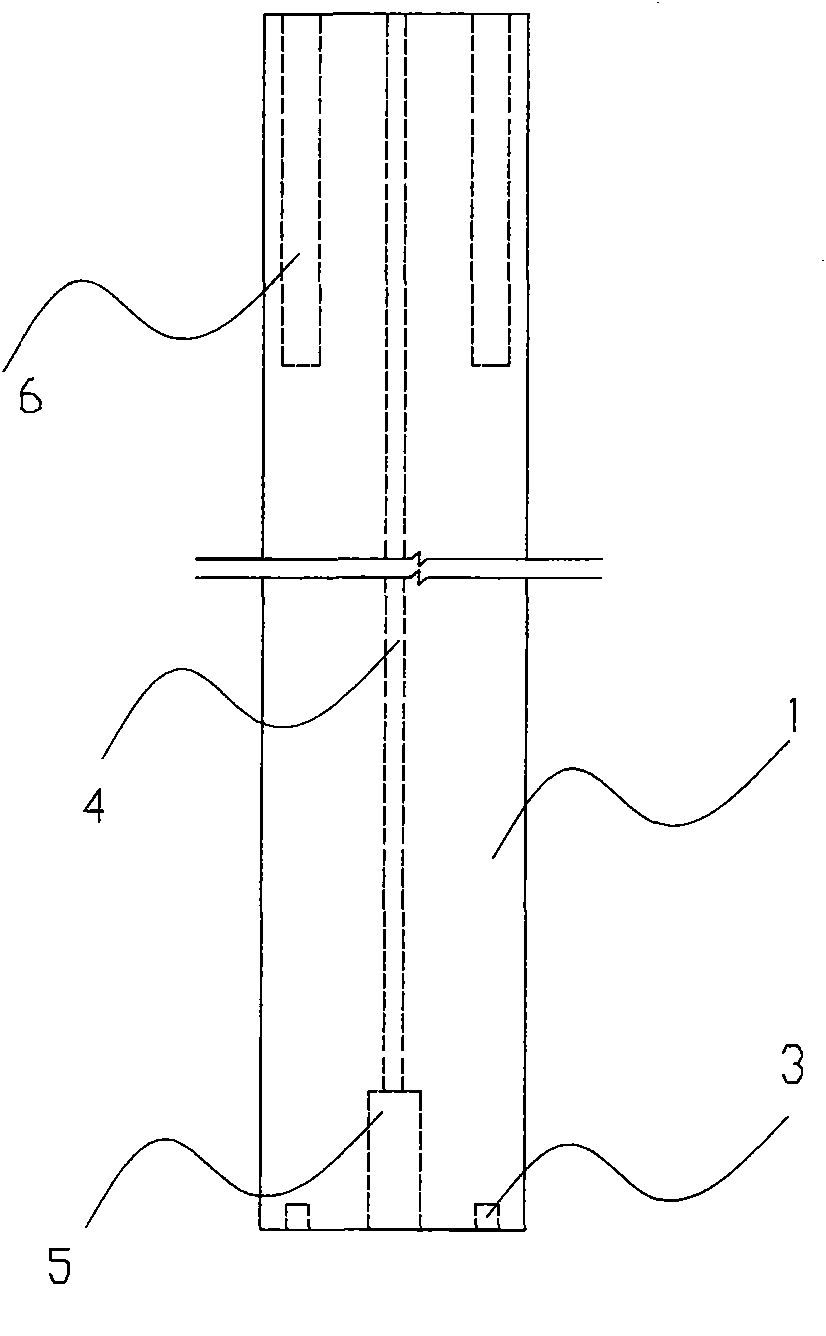

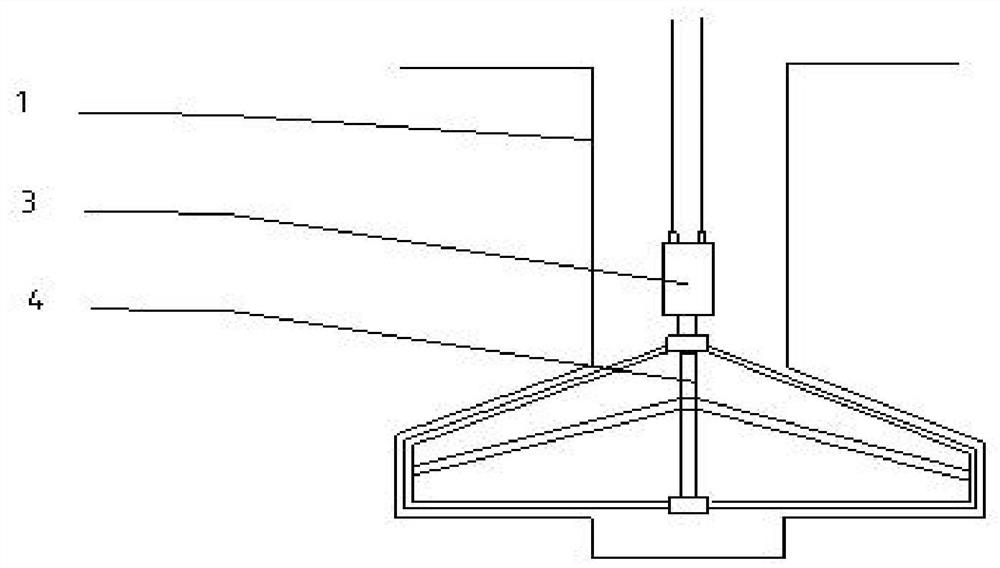

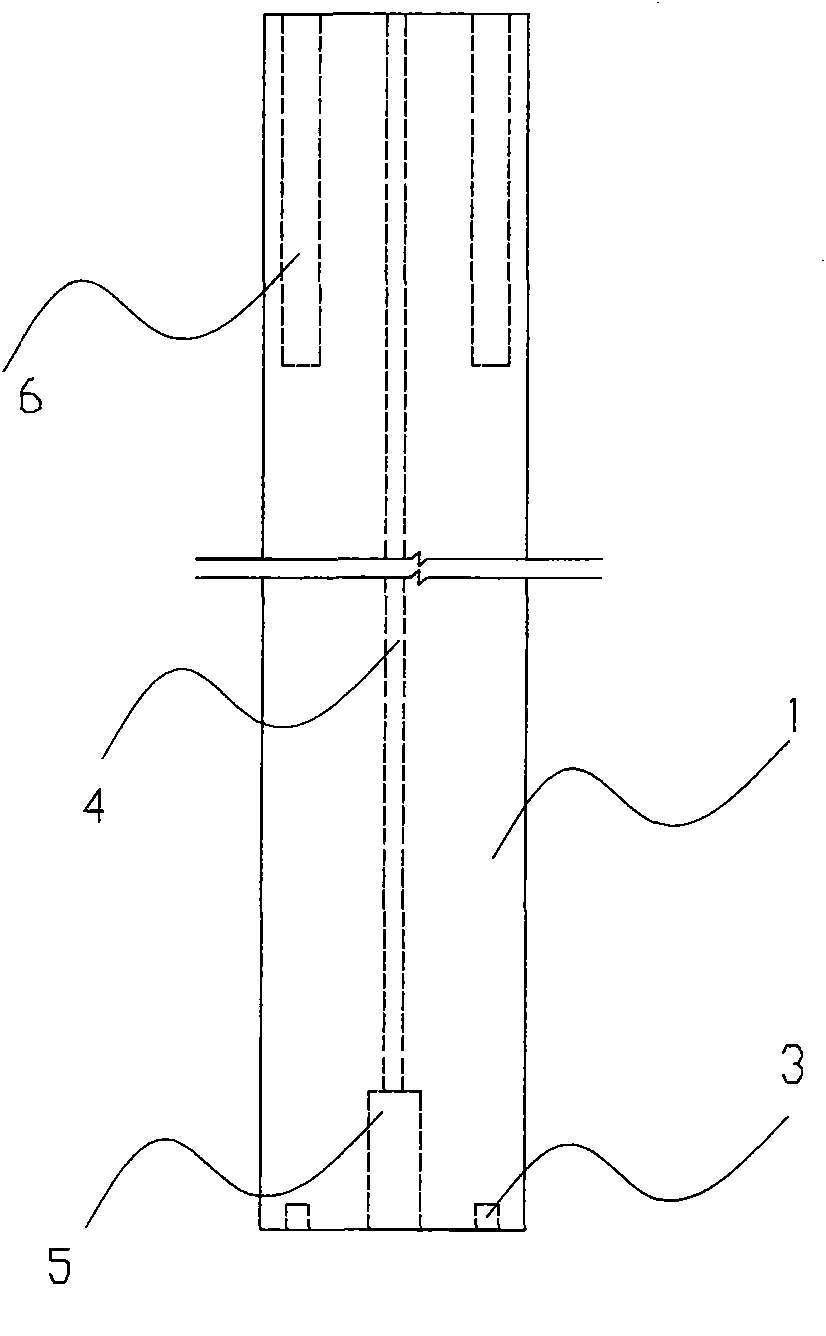

Tensile type pile soil deformation coordinator

ActiveCN106836263ALow costShorten the construction periodFoundation testingArchitectural engineeringBarrel Shaped

The invention discloses a tensile type pile soil deformation coordinator. The tensile type pile soil deformation coordinator comprises an outer barrel, a push rod, a ductile plate, a force transmission end plate and a force transmission pendant; the outer barrel is a barrel-shaped member, one end of the barrel-shaped member is opened, the force transmission pendent is buckled on an opened port of the outer barrel, the force transmission end plate is sleeved by the inner cavity of the outer barrel in a clearance manner, the ductile plate is sleeved by the inner cavity of the outer barrel, the two ends of the ductile plate are respectively connected onto the inner bottom surface of the force transmission pendant and the force transmission end plate, the push rod penetrates through a through hole at the middle part of the force transmission pendent and penetrates into the outer barrel, and a penetration end of the push rod is propped against the force transmission end plate. As the ductile plate is sleeved by the inner cavity of the outer barrel and the two ends of the ductile plate are respectively connected onto the inner bottom surface of the force transmission pendant and the force transmission end plate, the thickness and the width of the ductile plate (low yield point steel) are adjusted through calculation, so that the pressure-displacement curve of equipment at various tonnages meets the specific response spectrum, and the tensile type pile soil deformation coordinator has the advantage that the load on the soil is easy to control when a compound pile foundation is designed.

Owner:XTECH

High-bearing-capacity micro-settlement shearing resistant prestressed pipe pile and design and construction methods thereof

A high-bearing-capacity micro-settlement shearing resistant prestressed pipe pile is provided with a cylindrical prestressed reinforced concrete pile body and is characterized in that a grouting pipe is arranged in a pipe cavity or the pipe wall of the prestressed pipe pile, a pile large end formed by cement slurry poured in after pile forming is arranged at the end of the pipe pile, and a reinforcement cage is placed into the pipe cavity and concrete is poured when the material strength of the pile body is smaller than the sum of side resistance and end bearing capacity of the soil layer to form a reinforced concrete pile core. Compared with the originally designed punched and drilled pile, the engineering pile production price can be reduced by 50-70%, the construction period is shortened by 60-70%, mud pollution is avoided, the field is clean and civilized, and the post-construction settlement amount is small. Compared with the existing prestressed pipe pile, the single pile bearing capacity of the prestressed pipe pile is greatly improved, the number of the piles used in projects is reduced, production cost is reduced and the construction period is shortened.

Owner:邹宗煊

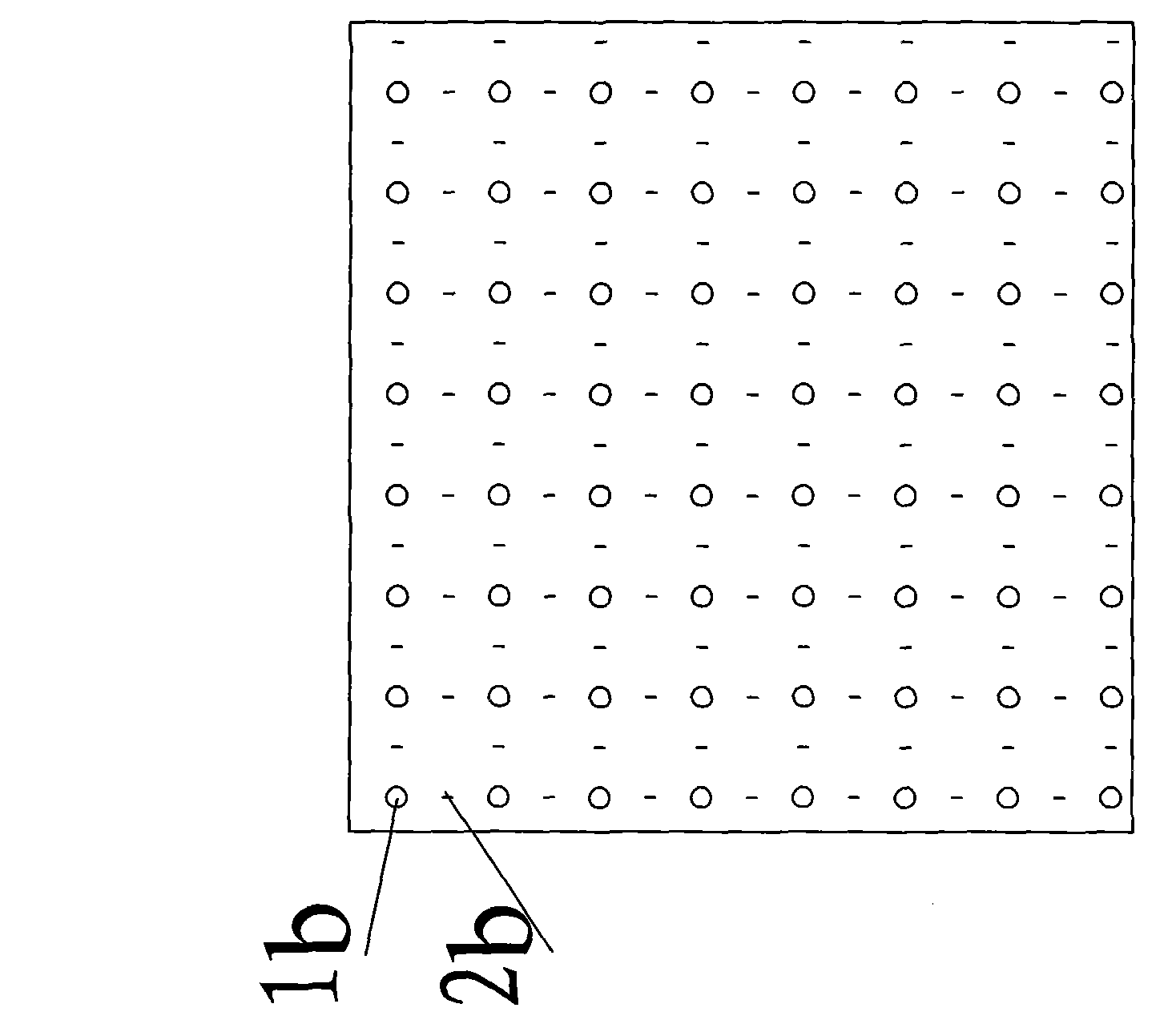

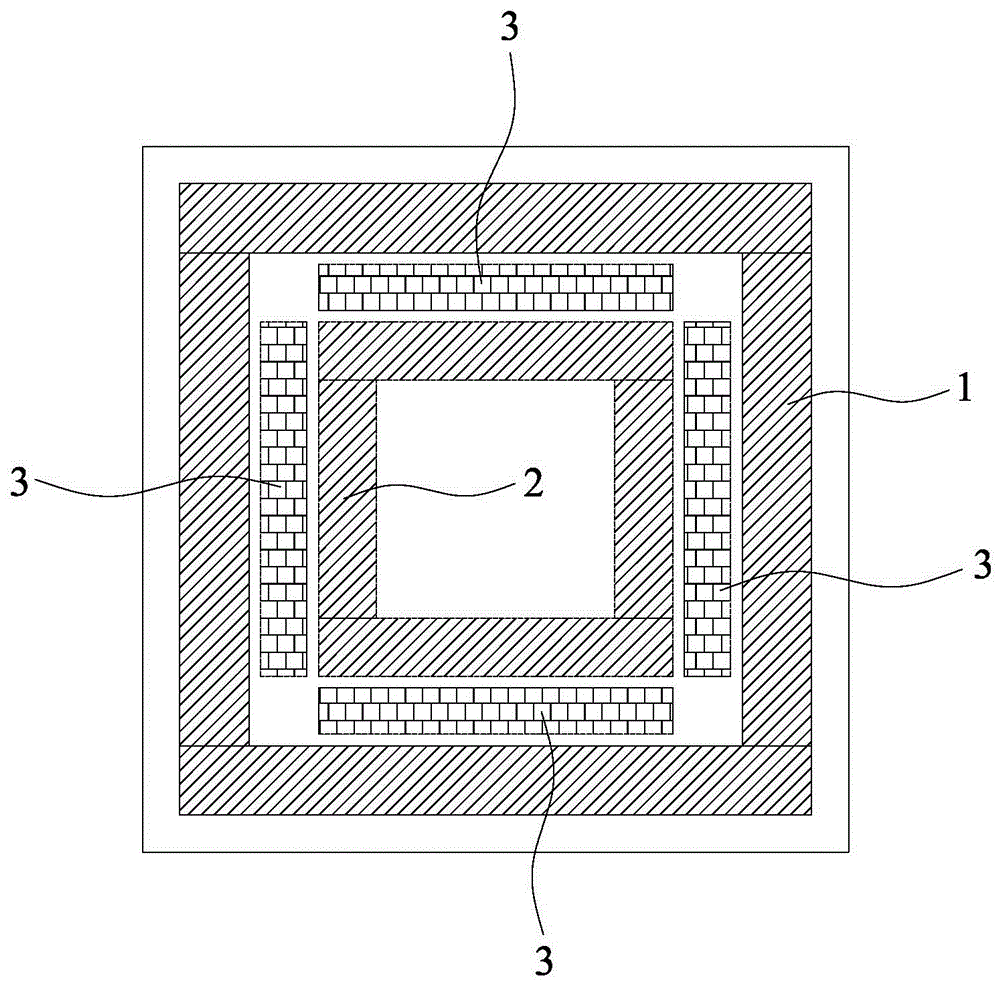

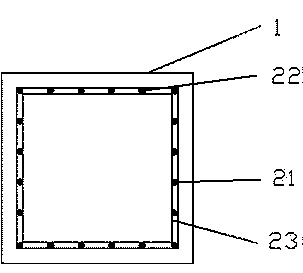

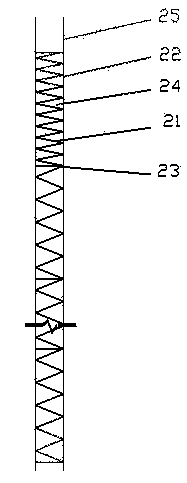

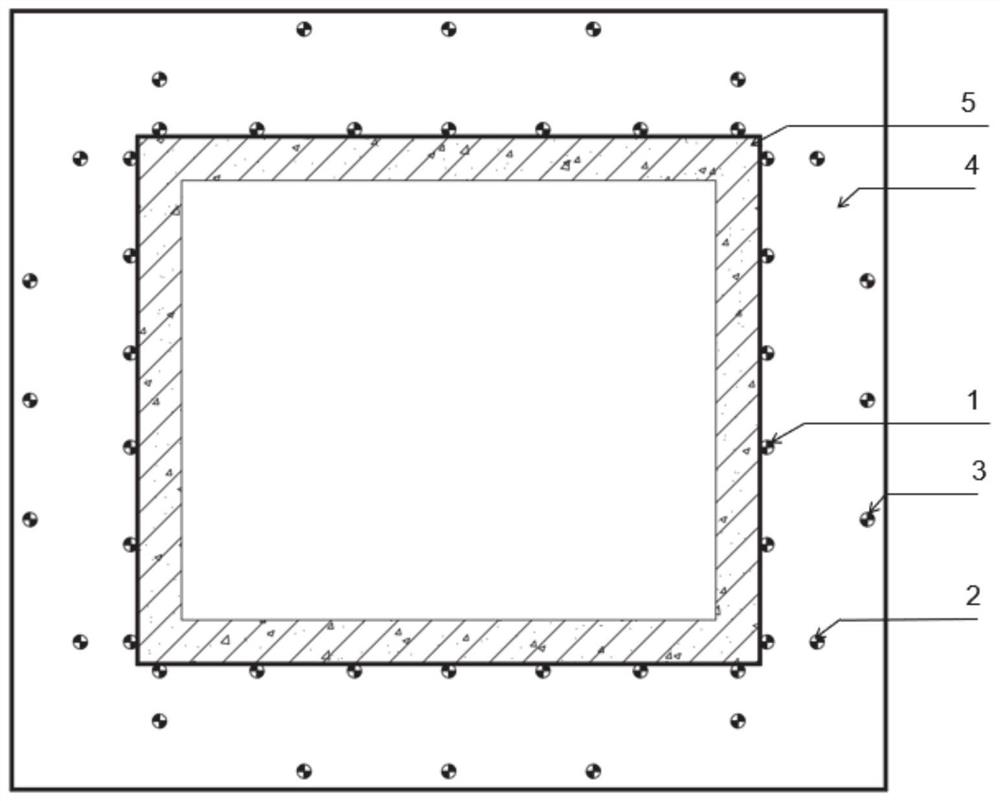

Multi-branch disk square bored pile

InactiveCN103953028AImprove the bearing capacity of single pileReduce the number of pilesBulkheads/pilesFoundation engineeringEngineering

The invention discloses a multi-branch disk square bored pile and belongs to the field of buildings. The multi-branch disk square bored pile comprises a pile body, a steel reinforcement cage and concrete branch disks, wherein the steel reinforcement cage is arranged in the pile body; the concrete branch disks are arranged on the pile body. Compared with a square bored pile with equal length and equal sectional area, the multi-branch disk square bored pile has the advantages that under the condition that only a small number of concrete materials are added, the bearing capacity of a single pile is improved to a larger extent, the number of piles is decreased, and the cost of pile foundation engineering is reduced.

Owner:JIANGSU HEZHENG ENERGY TECH

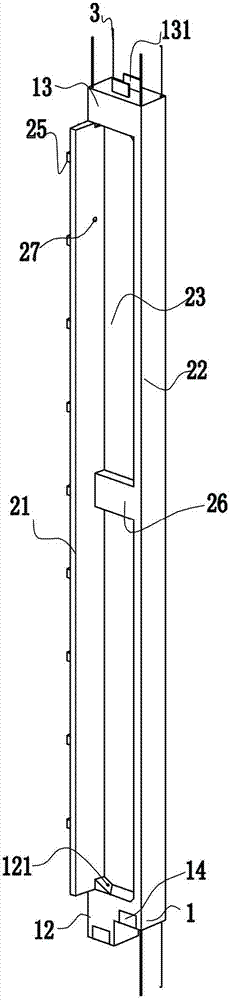

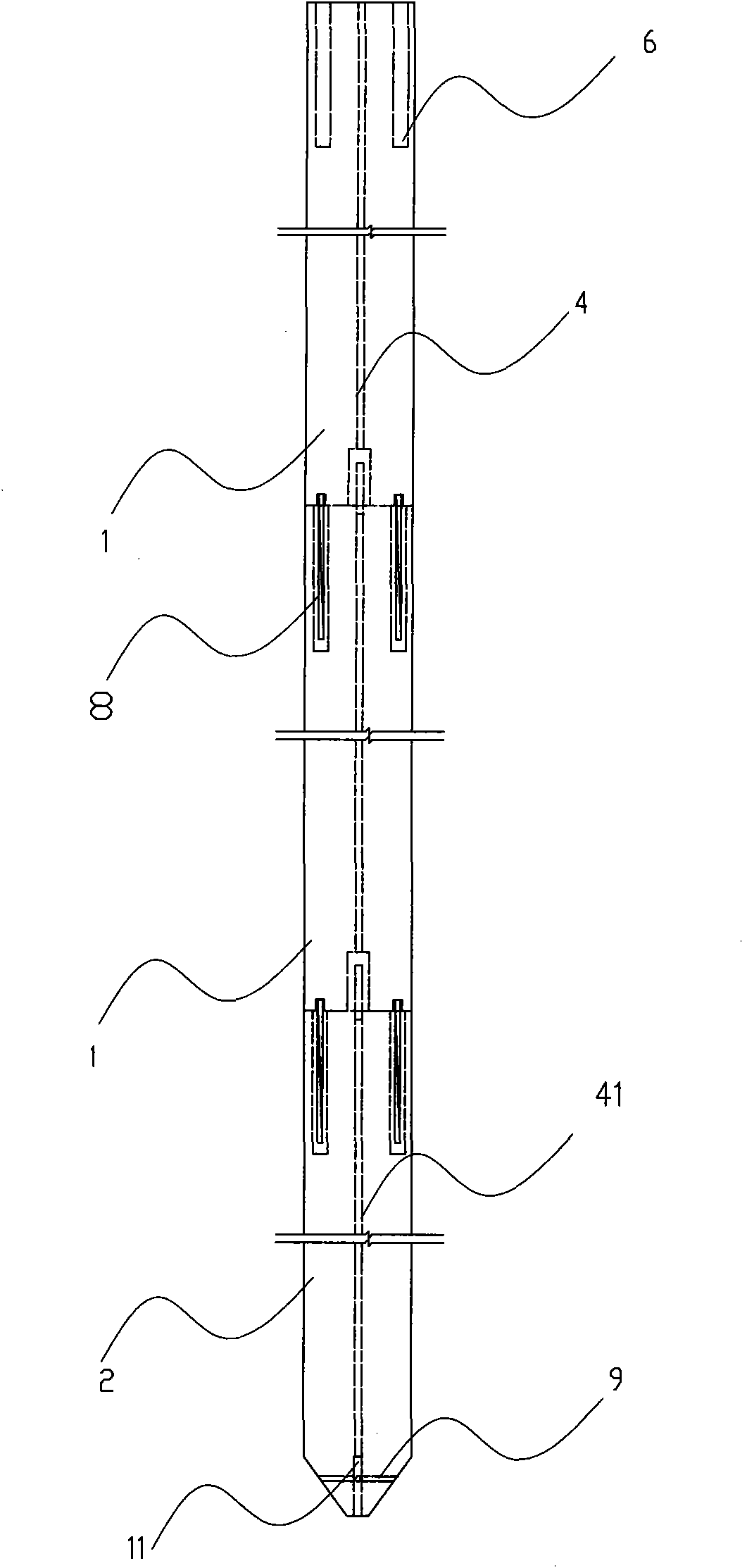

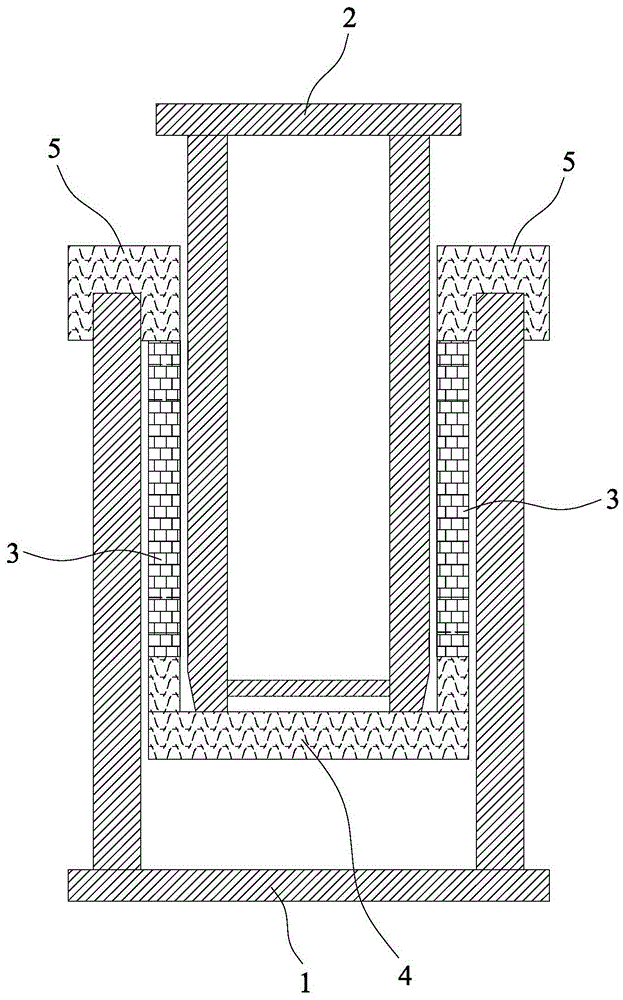

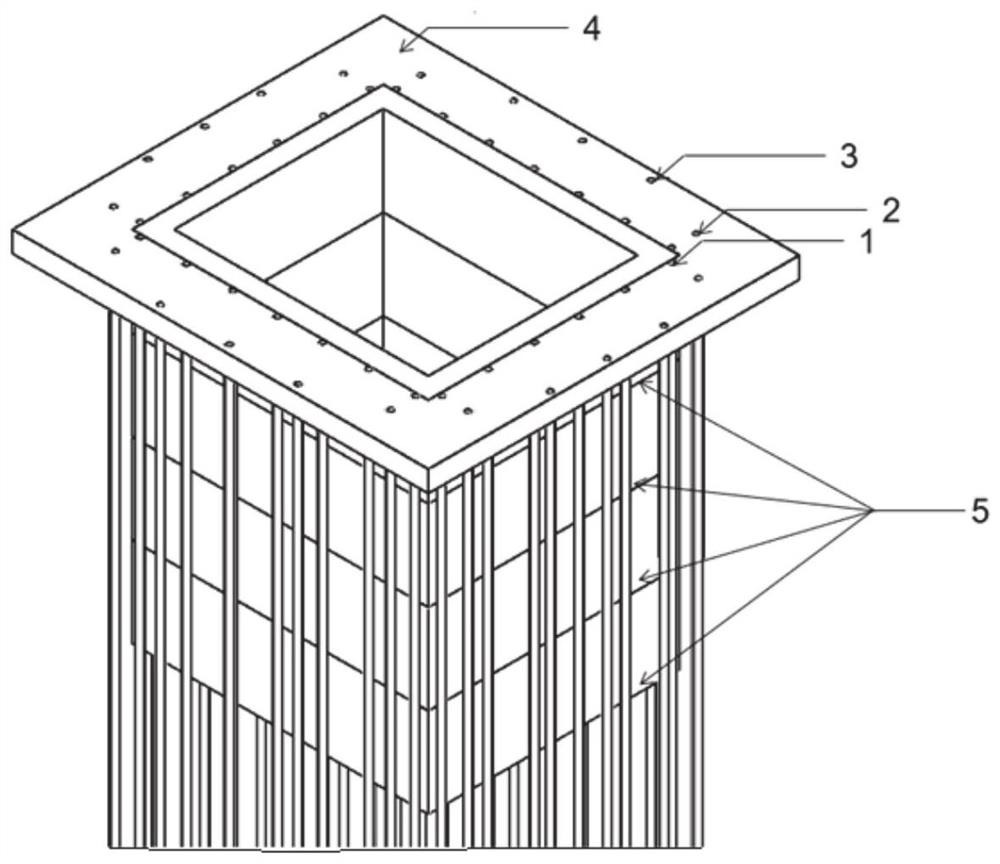

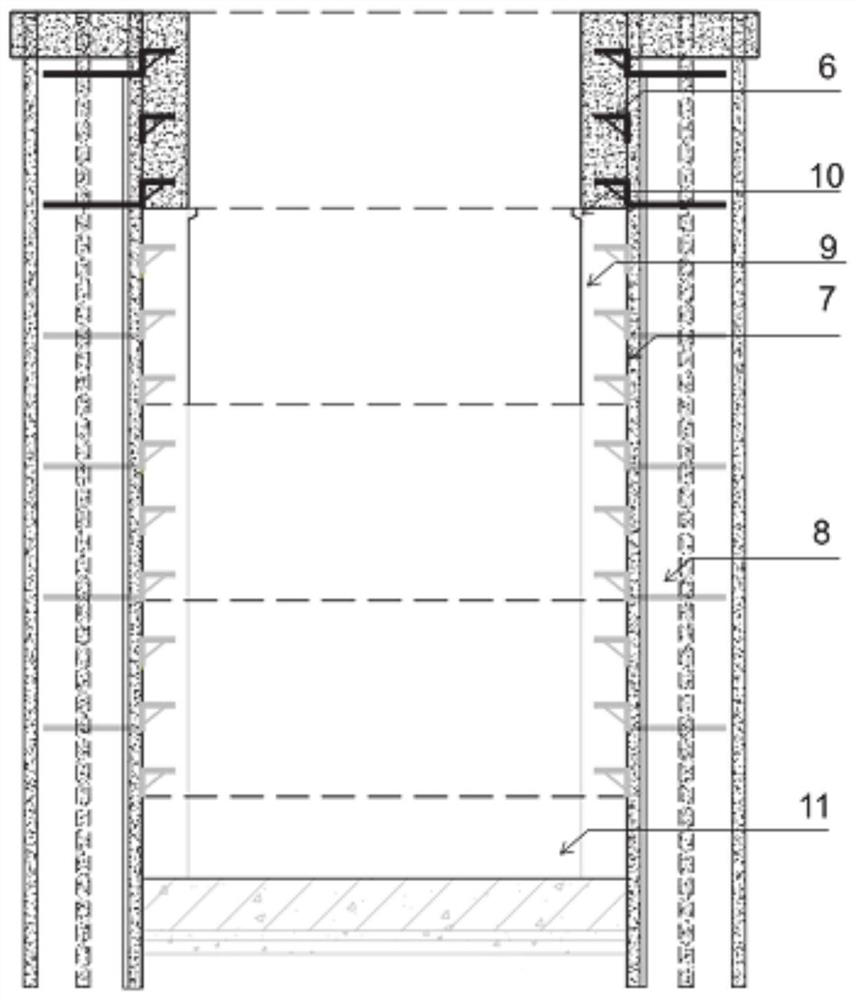

Suspended reverse wall working well supporting structure and construction method

ActiveCN113027463AImprove support strengthReduce settlementShaft liningArchitectural engineeringUltimate tensile strength

The invention discloses a suspended reverse wall working well supporting structure and a construction method, solves the problem of poor strength of a working well supporting structure in the prior art, and has the beneficial effects that the working well supporting structure is improved, and the construction is facilitated. The specific scheme is as follows: the suspended reverse wall working well supporting structure comprises a well wall; the well wall comprises multiple sections from top to bottom; every two adjacent sections of well walls are connected; the top of the well wall extends towards the peripheral side to be provided with a coping plate; the coping plate is connected with the well wall to form a suspended well wall; a plurality of rows of supporting piles are arranged at the outer side of the well wall in the width direction of the coping plate; the insides of the supporting piles are hollow; the coping plate is connected with the top of each supporting pile through pouring of the coping plate and concrete pouring in the supporting piles; and all the supporting piles and the coping plate are used as a composite suspension stress structure to suspend the well wall.

Owner:SHANDONG JIANZHU UNIV

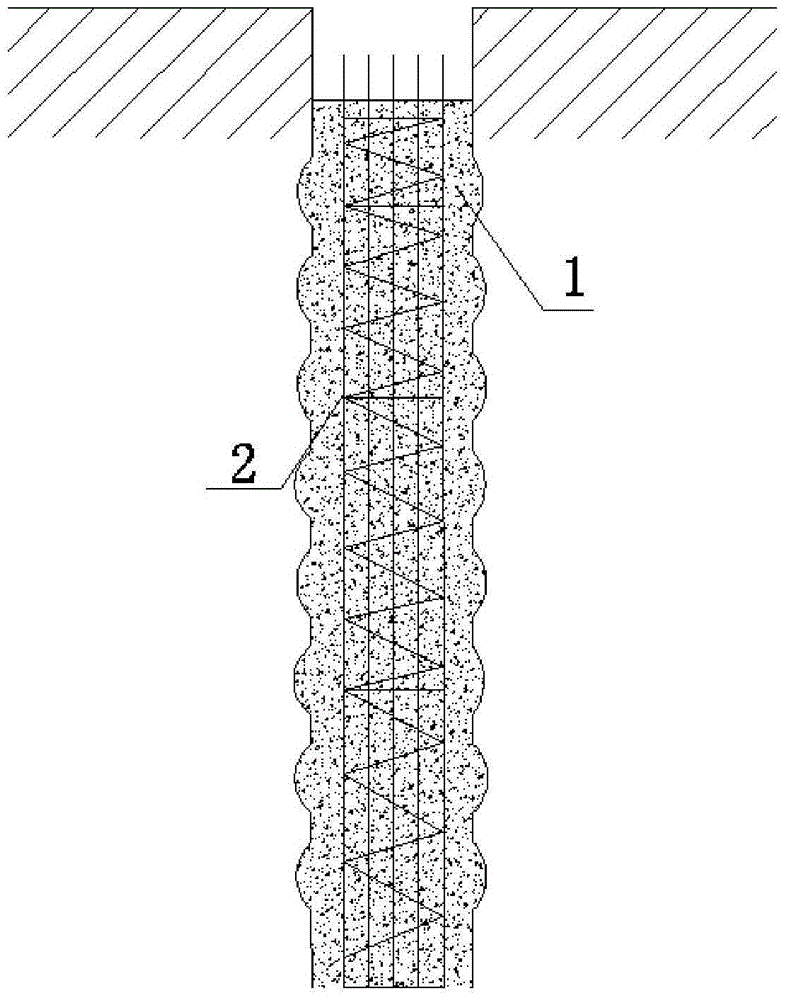

Construction method for extruding and expanding foundation in soft foundation area

InactiveCN113047271AShorten pile lengthShorten the construction periodBulkheads/pilesArchitectural engineeringRebar

The invention discloses a construction method for extruding and expanding a foundation in a soft foundation area, and belongs to the technical field of construction of extruding and expanding foundations in soft foundation areas. The construction method comprises the following steps that 1, according to the requirements of a design drawing, the size and depth of foundation drilling and drilling equipment used are determined; 2, measurement and positioning are conducted, the drilling position is determined, the drilling equipment is placed in place, foundation drilling is conducted till the depth is 200mm or above the design depth value and the remaining depth is 200mm, and construction continues after hole cleaning and measuring and setting; 3, after hole forming, a hydraulic hole expanding device is placed for correction, a hydraulic conveyor is used for hole expanding, the preset width and stress are achieved, and the extruding and expanding effect is formed; and 4, after extruding and expanding are conducted in place, the hydraulic hole expanding device is taken out, a foundation reinforcement cage is placed, foundation concrete is poured, and the extruding and expanding foundation is formed. According to the construction method, the foundation construction efficiency can be effectively improved, the construction period is shortened, and cost is saved; and meanwhile, the pile length is shortened, the pile diameter or the pile number is reduced, the manufacturing cost is low, and the settling amount is small.

Owner:CHINA MCC17 GRP

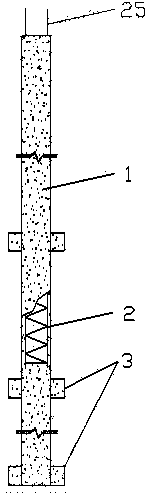

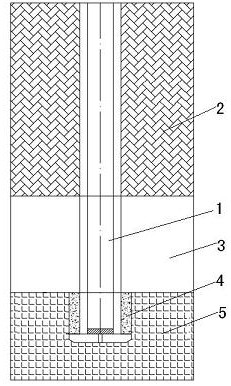

Post-planted steel tube concrete stiffened pile reinforcing and settling-preventing foundation strengthening method

InactiveCN106337432AReduce disturbanceReduce the number of pilesBulkheads/pilesEngineeringMachine tool

The invention discloses a post-planted steel tube concrete stiffened pile reinforcing and settling-preventing foundation strengthening method. The post-planted steel tube concrete stiffened pile reinforcing and settling-preventing foundation strengthening method includes the following steps that firstly, a pile planting part is determined; secondly, the whole process of the stress and deformation states of an existing foundation and a key part of an upper structure is monitored; thirdly, an existing foundation top face is dug on the existing foundation; fourthly, a pile planting hole is formed in the existing foundation top face through a machine tool; fifthly, a counterforce anchor bar is constructed in the pile planting hole; sixthly, a pile planting device is arranged in situ and is used for correcting the position of the hole; seventhly, the pile planting device is used for implanting a steel tube, and the steel tube is welded segment by segment till the steel tube is implanted to the designed preset depth; eighthly, the length of the steel tube is adjusted; and the steel tube is filled with micro-expansion concrete, and compact vibration is conducted; and tenthly, the implanted concrete stiffened pile is subjected to re-pressing and pile connecting. The post-planted steel tube concrete stiffened pile reinforcing and settling-preventing foundation strengthening method has the beneficial effects that the reinforcing construction difficulty of the existing foundation is lowered, the construction space limitation is overcome, fast control over settlement of the existing foundation is achieved, differential deformation is prevented from being developed continuously, reinforcing is achieved, and energy conservation and environment friendliness are achieved.

Owner:SOUTHWESTERN ARCHITECTURAL DESIGN INST

Core-grouted static pressure anchor rod pile

The invention relates to a core-grouted static pressure anchor rod pile forming device, which comprises a standard pile section and a bottom pile section, wherein a hard plastic pipe is embedded in the center of the cross section of the standard pile section; the bottom end of the hard plastic pipe is connected with a straight-through hollow chamber, and the four corners of the top end thereof are respectively provided with an anchor rod hole; the four corners of the bottom end of the standard pile section are respectively provided with a connecting hole; the connecting holes correspond to the axial positions of the anchor rod holes; a bottom hard plastic pipe is embedded in the center of the cross section of the bottom pile section; the bottom end of the bottom hard plastic pipe is in threaded connection with a hard plastic casing pipe; the four corners of the top surface of the bottom pile section are respectively provide with a bottom anchor rod hole; the bottom anchor rod holes correspond to the axial positions of the anchor rod holes; reinforcing steel bars the upper parts of which are provided with nuts are anchored into the bottom anchor rod holes; the nuts and the connecting holes are configured; a plurality of lower outlet pipes are communicated in the circumferential direction of the hard plastic casing pipe; and a plurality of upper outlet pipes are communicated in the circumferential direction of the straight-through hollow chamber. The invention has the advantages that firstly, the value of the pile bearing capacity can be increased, and thereby, the number of piles can be decreased so as to reduce construction cost, and the quality is reliable; secondly, the influence of compaction soil on adjacent buildings can be reduced so as to protect the surrounding construction environment.

Owner:孔超

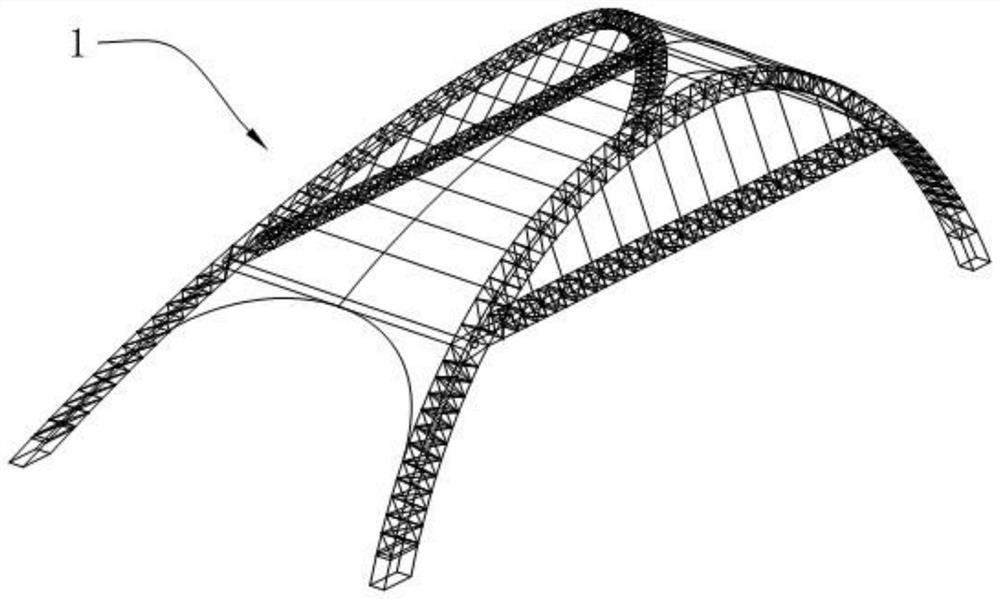

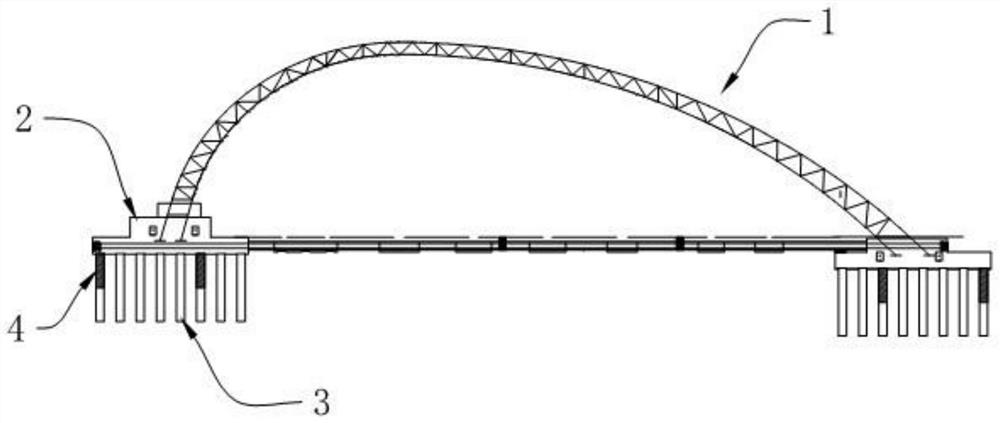

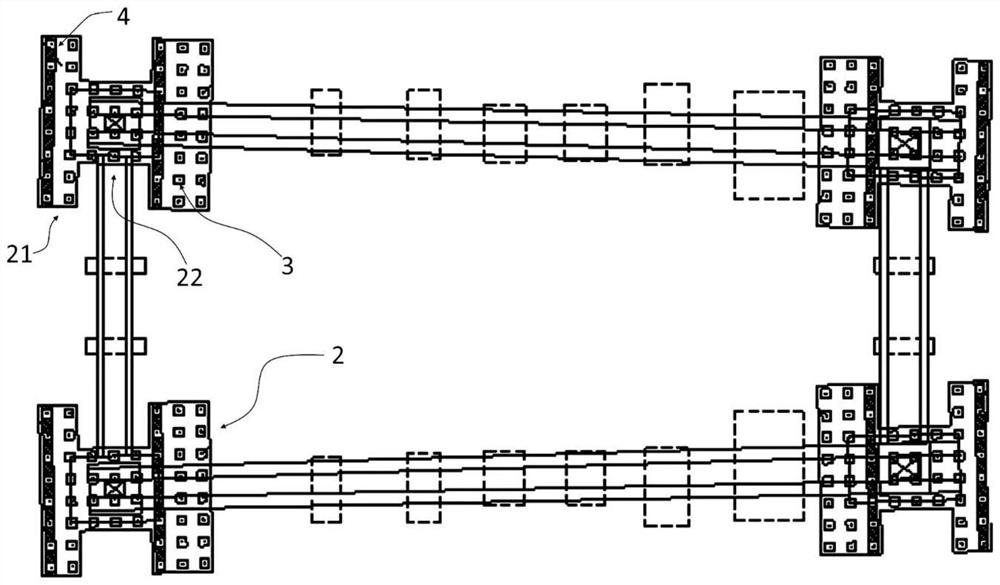

I-shaped bidirectional row pile foundation with prestressed pull rods and anti-push retaining walls

PendingCN113700022AAvoid destructionEffective resistance to horizontal loadsFoundation engineeringArch-type bridgeSlurry wallReinforced concrete

The invention provides an I-shaped bidirectional row pile foundation with prestressed pull rods and anti-push retaining walls. The I-shaped bidirectional row pile foundation comprises an I-shaped pile bearing platform, hole digging piles, an underground diaphragm wall and straining beams, the upper end face of a web plate of the I-shaped pile bearing platform is connected with arch feet and is parallel to the projection line direction of a main arch on the horizontal plane, flanges intersect with the projection line direction of the main arch on the horizontal plane, the hole digging piles are distributed on the lower end face of the I-shaped pile bearing platform at equal intervals, the hole digging piles and the I-shaped pile bearing platform form a row pile foundation, the underground diaphragm wall is arranged on the lower end face of the I-shaped pile bearing platform, the extending direction of the underground diaphragm wall is parallel to the flanges of the I-shaped pile bearing platform, and the underground diaphragm wall is located on the edge of the flange on the side, close to the tail end of the arch axis, of the I-shaped pile bearing platform. The straining beams are reinforced concrete prestressed straining beams, horizontal loads generated in the out-of-plane direction when the main arch inclines can be effectively resisted through the web structure of the I-shaped pile bearing platform, and meanwhile damage to a roadbed close to the arch feet is avoided.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

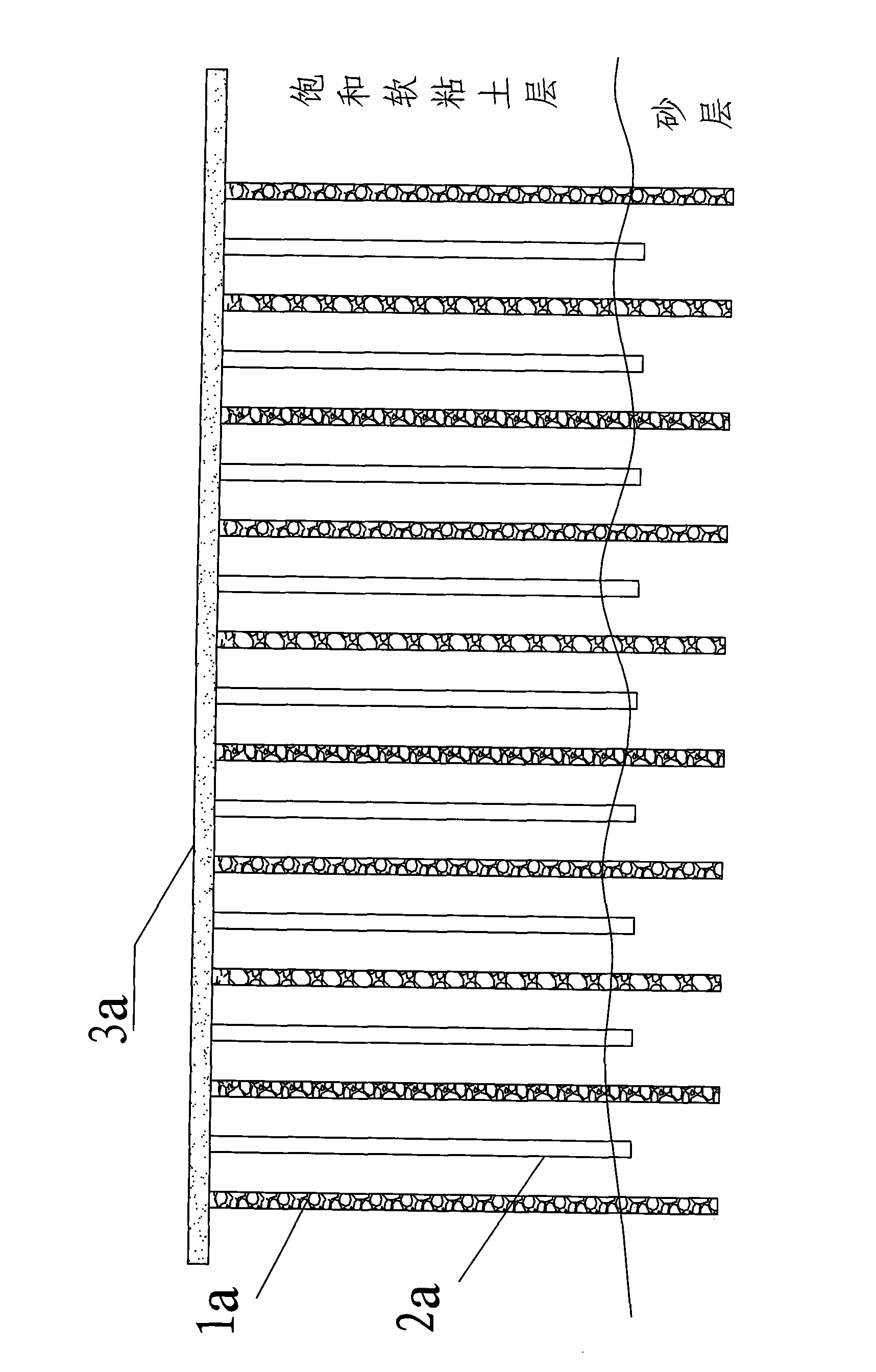

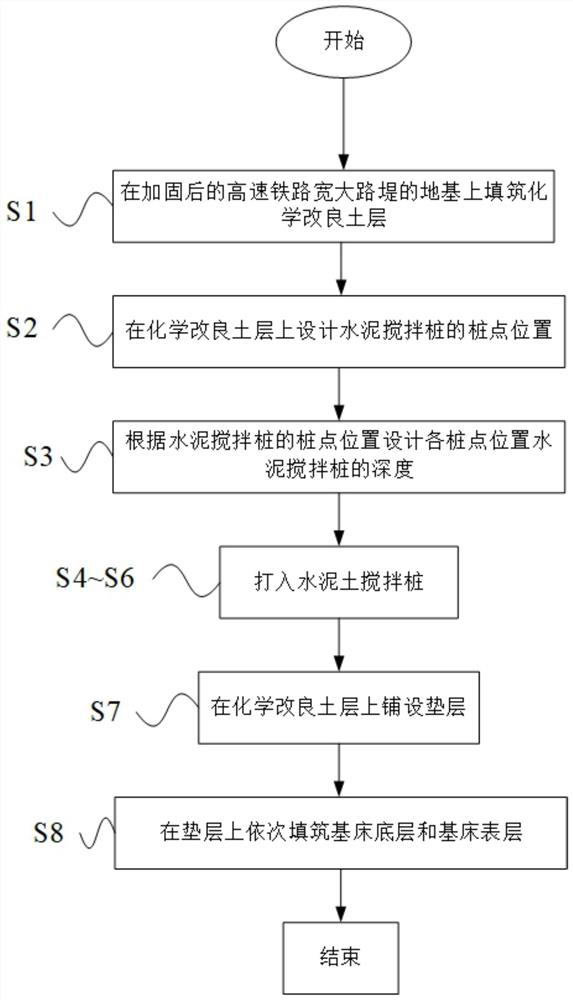

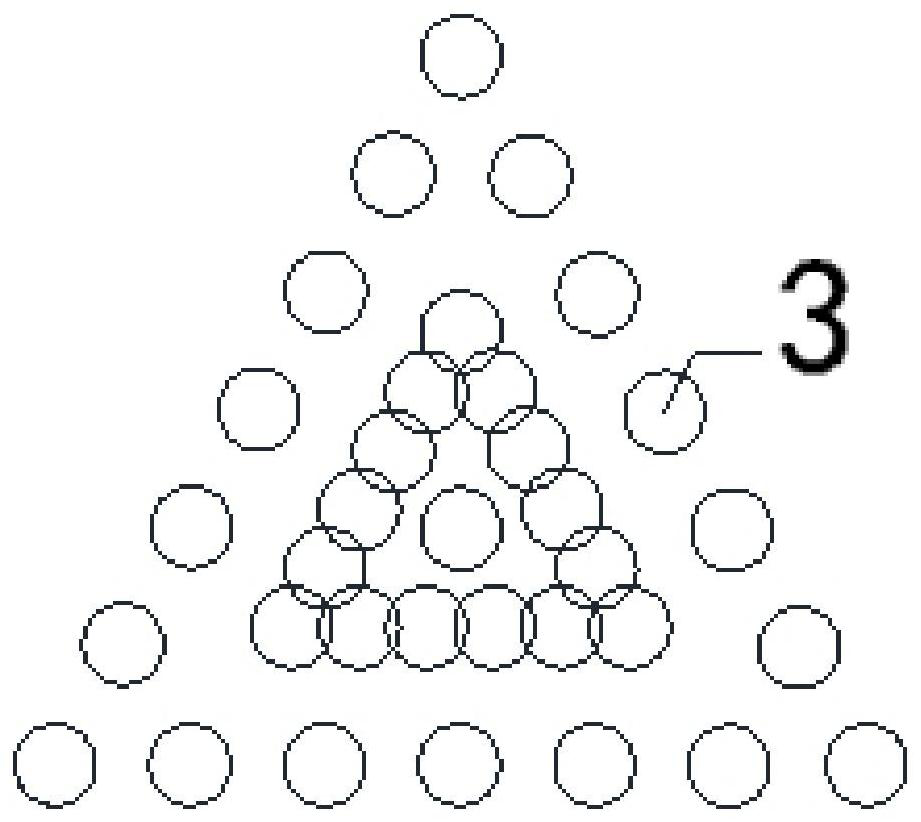

A Settlement Control Method of Wide Embankment of High-speed Railway Using Cement Mixing Pile

ActiveCN110952387BReduce economic costsAvoid exceeding the requirements of the "High-speed Railway Design Code"Railway tracksBulkheads/pilesSoil scienceRailway embankment

The invention relates to a high-speed railway wide and large embankment settlement control method adopting cement mixing piles. The reinforcing method comprises the following steps: a chemical improved soil layer is filled on the foundation of the reinforced high-speed railway embankment; pile point positions of cement mixing piles are designed on the chemical improvement soil layer, the depths of the cement mixing piles at all the pile point positions are designed according to the pile point positions of the cement mixing piles, the cement mixing piles are driven into all the pile point positions, a cushion layer is laid on the chemical improvement soil layer, and a foundation bed bottom layer and a foundation bed surface layer are sequentially filled on the cushion layer. Compared withthe prior art, chemical improved soil is used as embankment filler under a foundation bed layer; the cement mixing piles are used for reinforcing the chemically-improved soil layer, the depth and density of the cement mixing piles are reduced along with increase of the distance between the pile point positions and the reinforcing area under the main line, on the premise that the safety performanceof the embankment is guaranteed, the economic cost of the embankment is reduced, and the embankment settlement amount is prevented from exceeding the high-speed railway design specification requirement.

Owner:TONGJI UNIV

Construction method of long auger bored pressure grouting concrete uplift pile

ActiveCN104631438BIncrease construction costsReduce construction costsBulkheads/pilesDrilling machinesBuilding construction

The invention discloses a method for constructing a long auger bored cast-with-pressure concrete uplift pile. The method for constructing the long auger bored cast-with-pressure concrete uplift pile comprises the steps that the preparation for construction is made, paying-off for positioning is conducted, a drilling machine is prepared to work, a hole is formed by the drilling machine, drill lifting and fine aggregate concrete pouring are conducted at the same time, the hole is sealed and grouting is conducted, a steel reinforcement cage is inserted, and drilling tools and an earthwork are cleaned. The method for constructing the long auger bored cast-with-pressure concrete uplift pile has the advantages that concrete is pressed in a soil body and is located on the bottom and the side wall of the pile according to the specific grouting technique, the concrete and the soil body are glued into a whole, and in this way, the contact area between a pile body and the soil body is increased; compared with a traditional uplift pile, the uplift performance of the long auger bored cast-with-pressure concrete uplift pile is improved remarkably.

Owner:ANHUI TONGJI CONSTR GRP

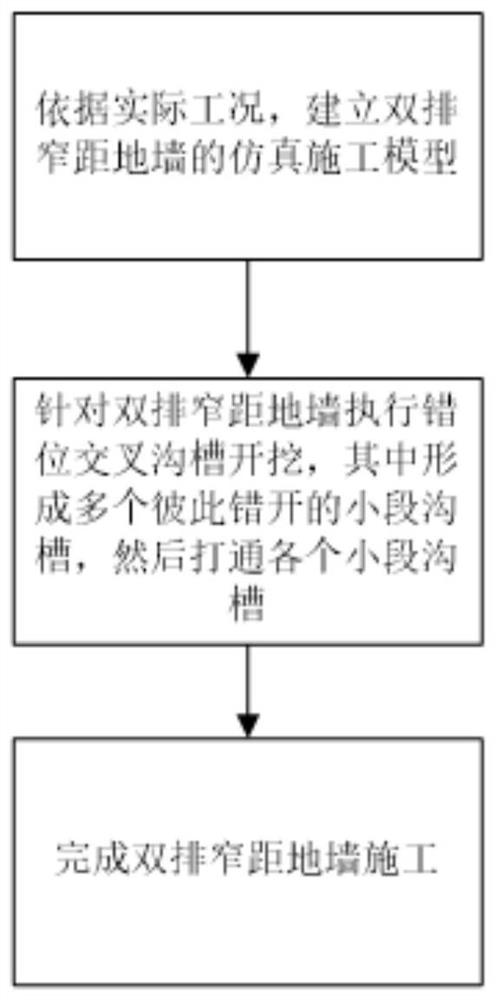

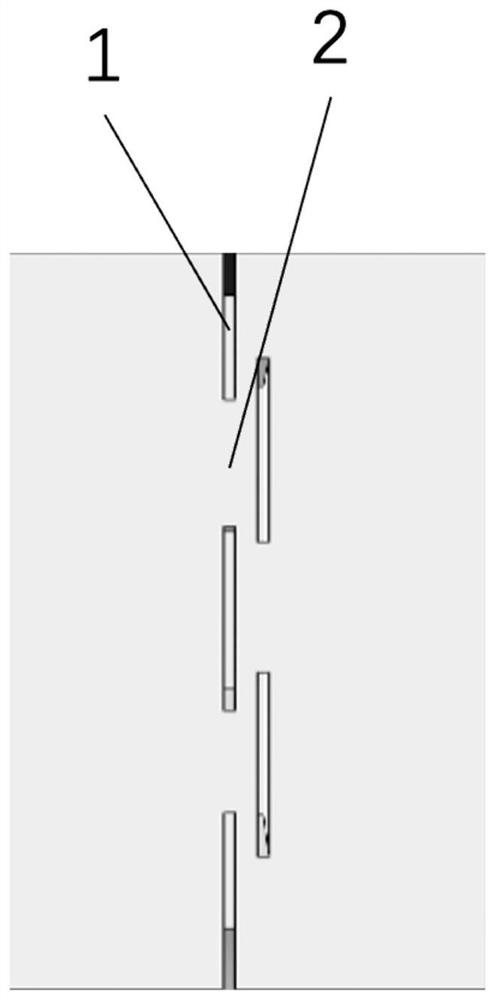

Staggered crossing grooving method suitable for double-row narrow-distance ground wall construction

The invention belongs to the related technical field of foundation pit construction, and discloses a staggered crossing grooving method suitable for double-row narrow-distance ground wall construction, which comprises the following steps: a simulation modeling analysis step; and a staggered and crossed excavation step. Wherein the operation design of performing staggered and crossed excavation on the double-row parallel grooves is as follows: firstly, the double-row parallel grooves are respectively divided into a plurality of mutually spaced small sections in advance along the extension direction, and the adjacent small sections of the double-row parallel grooves are staggered and overlapped to a certain extent; and then, the small sections of grooves which are staggered and overlapped with one another are excavated in sequence in a segmented mode, and then the remaining middle parts are excavated in sequence until the complete double-row parallel grooves are formed. By means of the method, disturbance to a thin-wall groove wall soil body is remarkably reduced, the groove stability is improved, collapse can be effectively controlled through the fluid-solid coupling effect, and meanwhile the method has the advantages of being convenient to control, high in safety, suitable for various complex construction environments and the like.

Owner:NO 1 ENG LIMITED OF CR20G

Method of vibration and extrusion for cast-in-place concrete in pile hole and its vibration rod device

InactiveCN100351470CLow powerReduce lossBuilding material handlingBulkheads/pilesSteel tubeBearing capacity

A method for pouring concrete into pile hole and compressing and its vibrator are disclosed; including the following steps: (1) according to the work mode of concrete pile to choose the type of vibrator, use shape steel or steel pipe as the structural force-passing element; when there is mud staying in the upper part, use steel pipe; (2) pour concrete into the pile hole; (3) insert the vibrator into the concrete to vibrate and stress. The method suits for CFG pile dry work pouring pile method, wet work circulative pouring method and digging-drilling method etc.

Owner:北京市机械施工集团有限公司

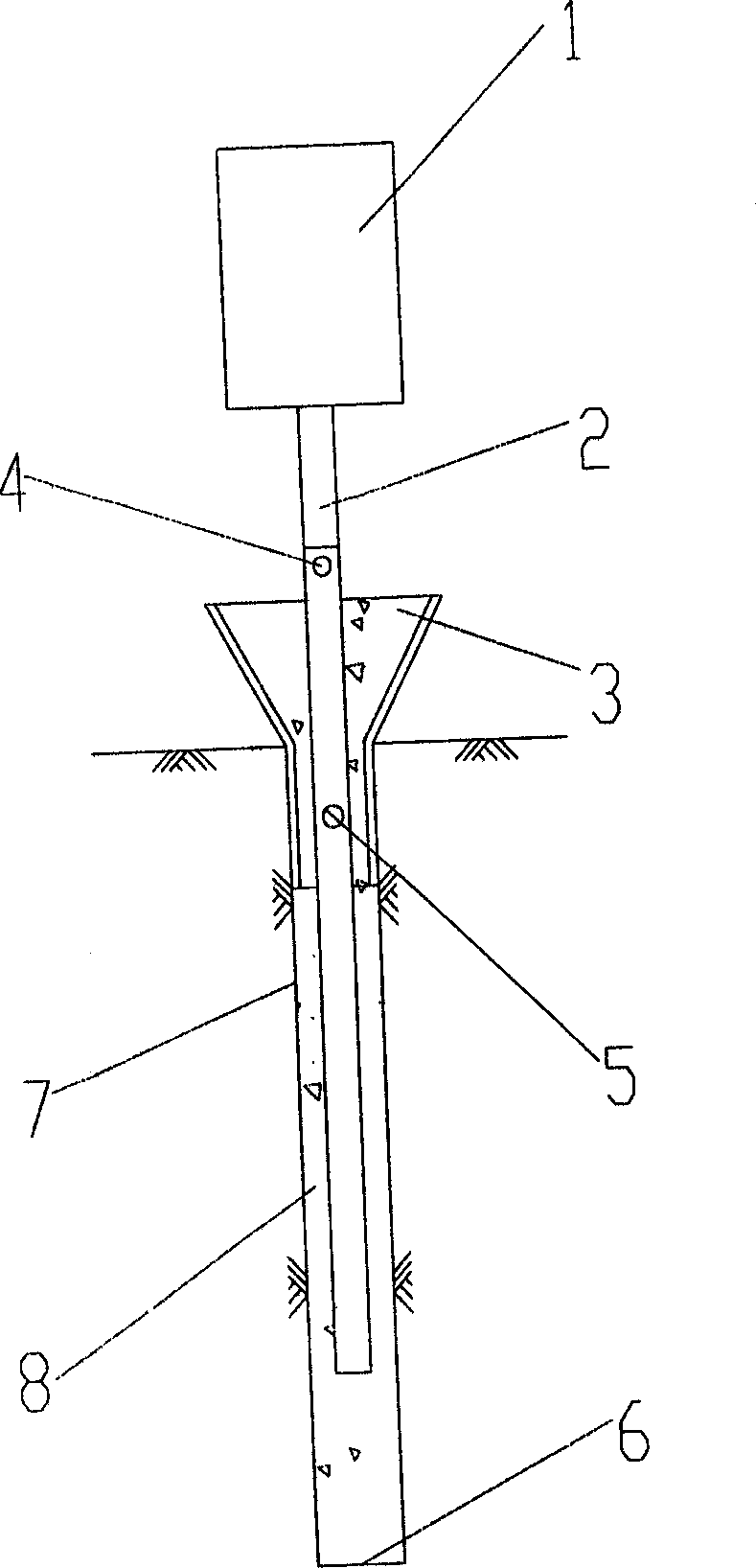

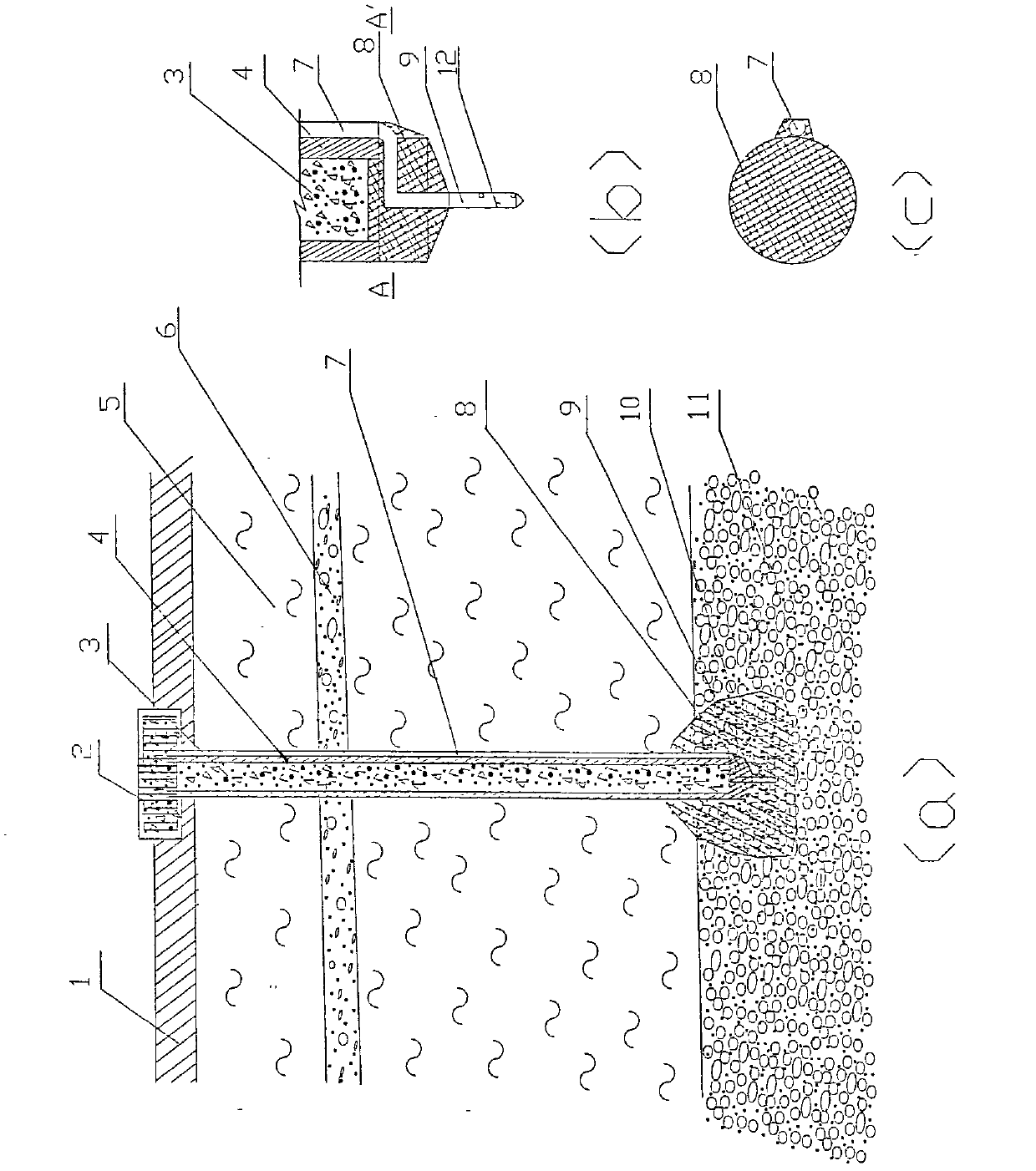

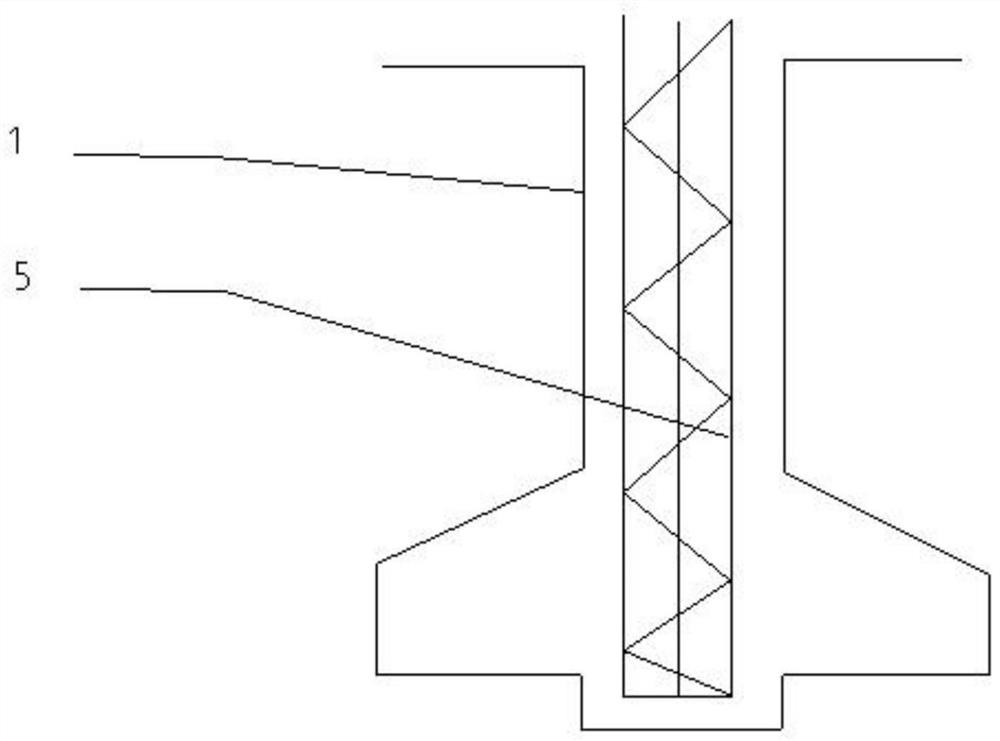

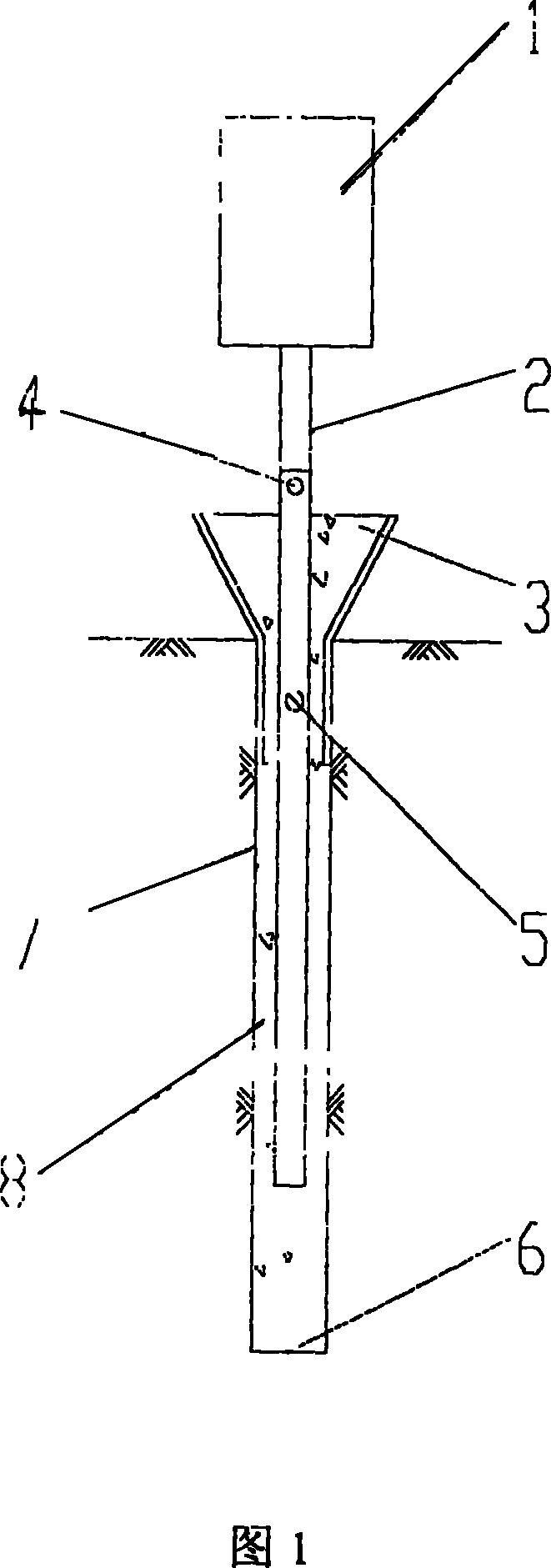

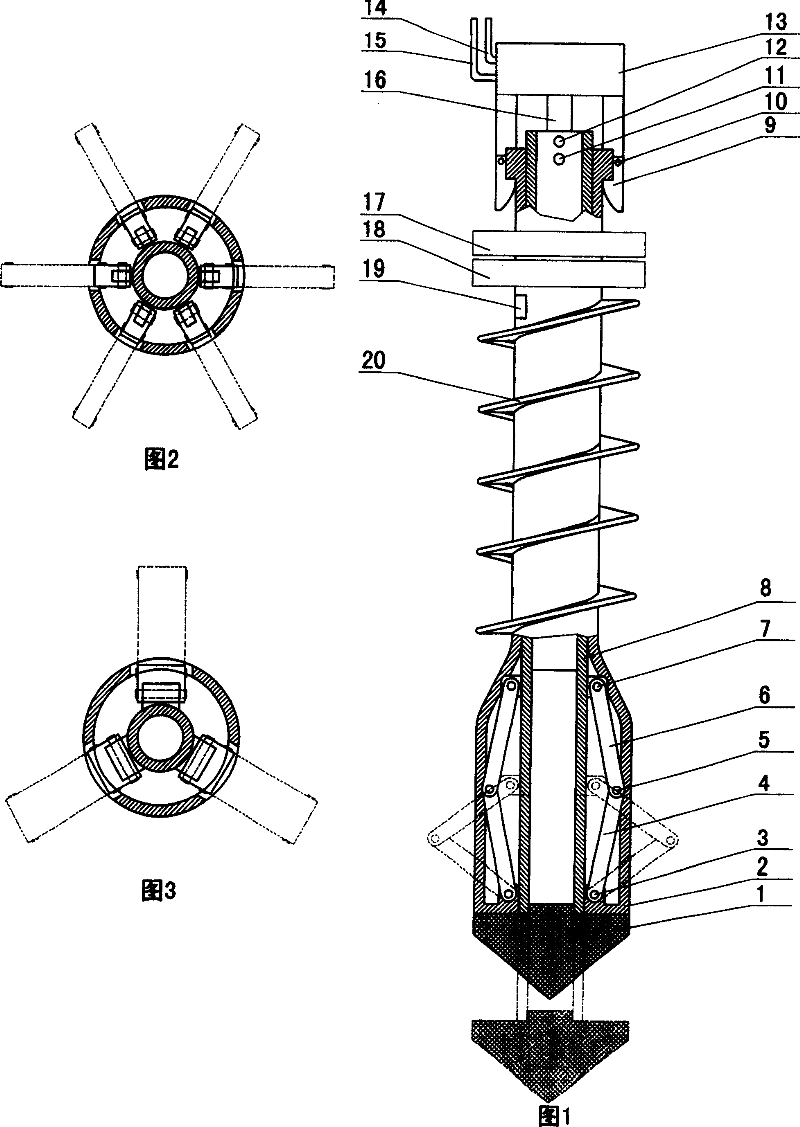

Device for knobby pushing and expanding spiral immersed tube stake and its engineering method

ActiveCN100357527CHigh strengthSolve the lack of carrying capacityBulkheads/pilesDrilling machines and methodsHydraulic motorHelical blade

The invention relates to a multi-section expansion screw pipe-deposition post, which is formed by inner pipe, outer pipe, upper and lower bow compression arms, axial pin, cylinder, hydraulic motor, vibrator and a cement head. First, entering said device into ground via vibration and rotation; lifting the steel cage into pipe; filling concrete; connecting the cylinder on the upper end of pipe to be expanded; vibration lifting the pipe to a preset height to be expanded; calling back it to be lifted and expanded again; calling it back and filling concrete and lifting the pipe from the hole to from several pipe-deposition post with multi-expanded head and multi-branch. The invention can fully utilize the bearing ability of soil, and the multi-section expanded head has strong strength of post, big distance between posts and less posts. Since the outer pipe with bigger outer diameter and the screw blades can discharge the soil, it can solve the soil-compression effect to confirm the operation quality with improved working efficiency, reduced cost and non-noise.

Owner:CHINA RAILWAY ECONOMIC & PLANNING RES INST +2

Foundation pit supporting composite retaining wall and construction method thereof

InactiveCN109914428AEasy to recycleRealize detachmentArtificial islandsExcavationsRetaining wallCost savings

The invention provides a foundation pit supporting composite retaining wall. The foundation pit supporting composite retaining wall comprises a plurality of tubular piles which are arranged in the circumferential direction and are of hollow structures, and a connecting structure connected with two adjacent tubular piles to form a circumferentially closed retaining wall, wherein the pipe wall of the lower portion of at least one tubular pile is provided with a water pumping structure which faces the inner side of a foundation pit and communicates with a soil body on the inner side of the foundation pit and the hollow structure, and the water pumping structure is suitable for guiding underground water located on the inner side of the foundation pit into the hollow structure of the tubular piles. By means of the structure, the overall construction operation is simple, the construction time is short, due to the fact that the connecting structure is arranged between adjacent two tubular piles serving as the main soil retaining part of the retaining wall, the number of pile bodies can be reduced, recycling is convenient, and cost saving is facilitated; and furthermore, due to the fact that the water pumping structure is arranged, the purpose of pumping underground water on the inner side of the foundation pit is achieved.

Owner:刘小檀 +1

Construction method for solving pile foundation over-filling and sediment in karst region

InactiveCN112459051AHigh pile strengthAvoid the increase of pile cost and construction periodBulkheads/pilesKarstGeotechnical engineering

The invention discloses a construction method for solving pile foundation over-filling and sediment in karst regions. The method comprises the following steps: a rotary pile drilling machine or a down-the-hole hammer is adopted to guide a hole, the diameter of the guide hole is 20-100mm larger than that of a tubular pile, and a proper amount of fine aggregate concrete is poured into the range of abearing stratum at the lower end part of the tubular pile. After the prestressed high-strength concrete pipe pile is conveyed to be close to the bottom of a hole, a hammering pile driver or a staticpressure machine is started, a gap between the pipe wall and the hole wall of the pipe pile is filled with fine aggregate concrete poured into the pile end in advance through extrusion, the pile end is stabilized, and the sediment problem is solved. The method well solves the difficult problems of pile foundation over-filling and pile bottom sediment in karst regions. Compared with a traditional cast-in-place pile, the cast-in-place pile has obvious advantages in the aspects of construction quality, construction period and engineering investment.

Owner:CHINA NERIN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com